Multi-stage treatment device for industrial wastewater

A technology for treatment device and industrial wastewater, applied in water/sewage multi-stage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of inability to add fixed chemicals, small wastewater contact area, and inability to filter solid waste And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

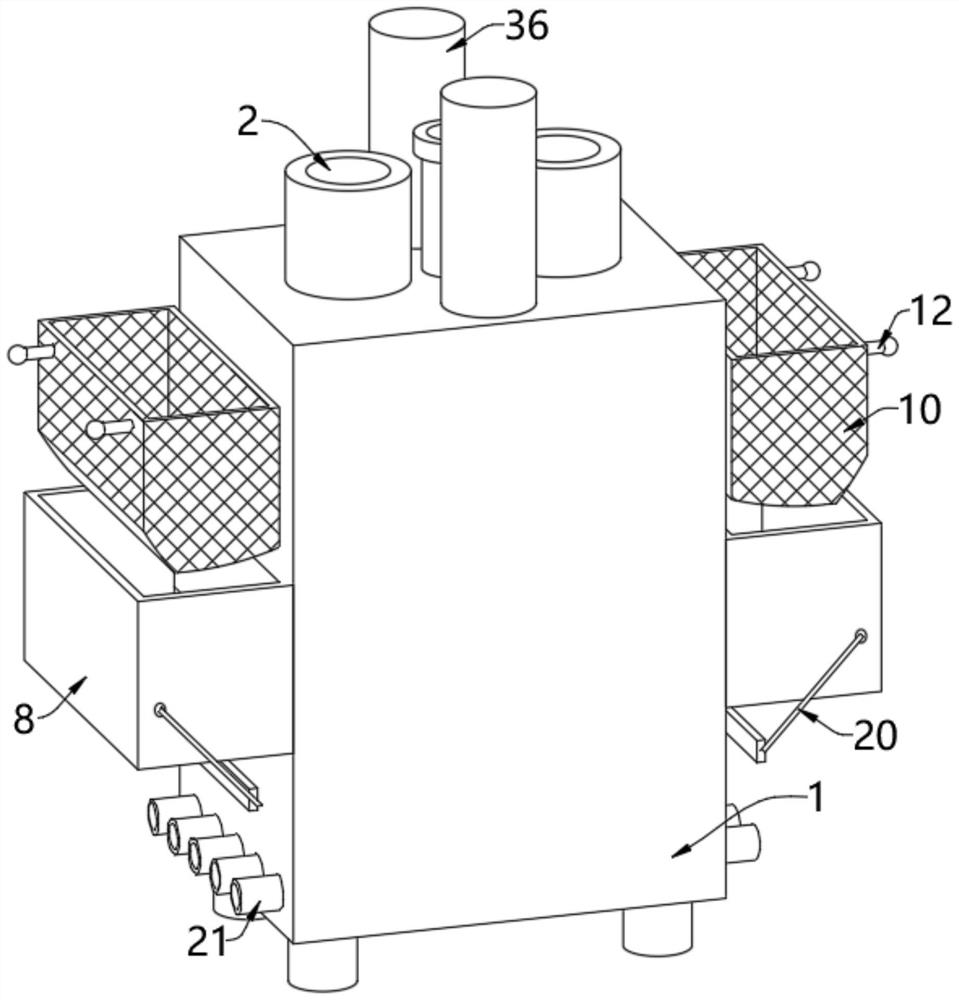

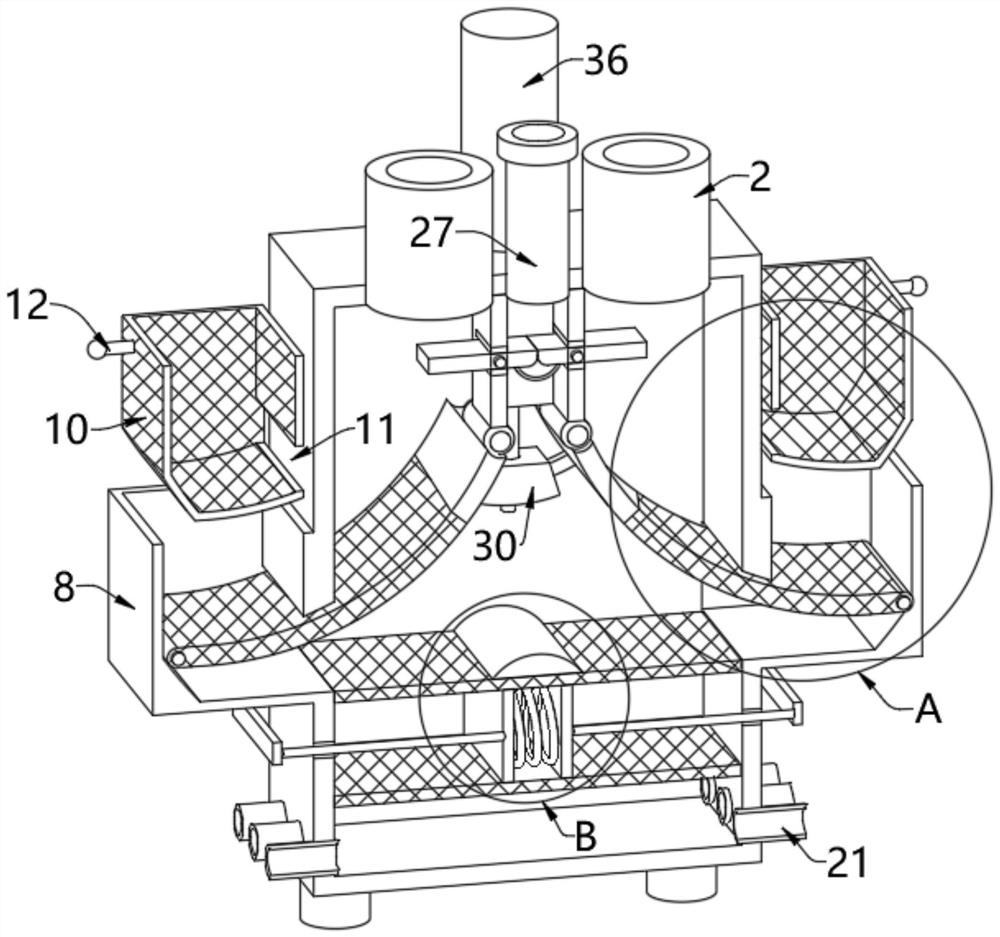

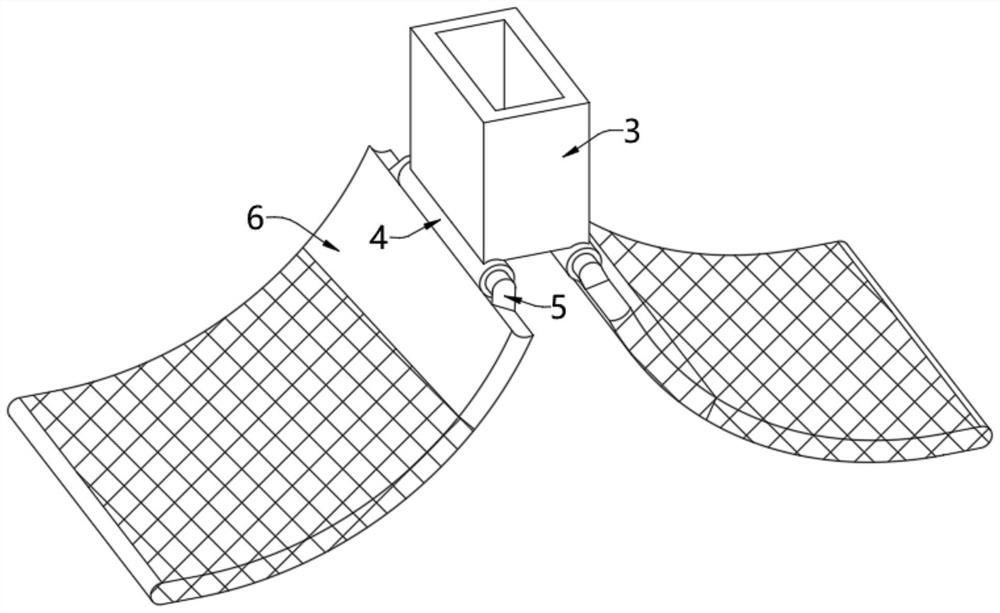

[0055] See Figure 1 - Figure 5 A multi-stage processing apparatus for industrial wastewater, including the processing box 1, both sides of the top of the treatment box 1, fixedly mounted in the water pipe 2, and the industrial wastewater is entered into the treatment tank 1, and the treatment box 1 The middle portion of the top wall is fixedly mounted having a square cylinder 3, and both sides of the bottom portion of the square tube 3 are provided with a shaft sleeve 4, and the inner rotation of the shaft sleeve 4 is rotated, and the end of the two rotating shafts 5 is fixed by the connecting column. Size filter 6;

[0056] The outer wall of the rotating shaft 5 fixes the tablet 45, and the tablets 45 are active on the inner wall of the movable tank 46, and the movable groove 46 is opened on the inner wall of the shaft sleeve 4, and the outer wall of the tablet 45 and the inner side wall of the movable tank 46 It is also fixed to be connected to the support spring 47, when the cu...

Embodiment 2

[0064] See Image 6 and Figure 7 On the basis of the first embodiment, the inner wall of the treatment tank 1 is further secured to mounting the upper barrier mesh 13 and the lower barrier mesh 14, the mounting position of the upper barrier mesh 13 and the lower barrier mesh 14 is located below the side box 8;

[0065] The active slide 15 and the second sliding plate 16 are disposed between the upper barrier web 13 and the lower barrier web 14, and the linkage device is disposed between the two curved filter 6 and the first slide 15 and the second slide plate 16. When the two curved filter 6 is swung, drive two curved filter 6 to be away from each other;

[0066] The linkage includes a first spring 17, a tie rod 18, a pull plate 19, and a connecting rope 20, and the first spring plate 15 is connected between the first spring 17, in this embodiment, the elastic force of the first spring 17 is smaller than The elastic force of the support spring 47, one side of the first slide 15 and...

Embodiment 3

[0071] See Figure 8 Based on the first embodiment, the center of the treatment box 1 is fixed at the top of the treatment box 1, and the dosing tube 27 is attached to the addition of a solid agent, and the bottom portion of the dosing tube 27 and the square cylinder 3 are penetrated. The three sides of the inner wall are opened, and the inner wall of the swing groove is rotated on the inner wall of the swing groove is provided with the movable shaft 23, and the outer wall of the movable shaft 23 is fixedly mounted.

[0072]Both the bottom of the two branch plates 24 are formed with an arcuate surface 25, and a resilient repellent network 26 is also fixed between the bottom of the two branch plates 24;

[0073] An elastic feeding pad 22 is also provided between the inner wall of the swing groove and the branch plate 24, which can ensure the seal between the branch plate 24 and the square tube 3, preventing solid medication, and can also provide a certain elastic force, The branch p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com