Graphene preparation method

A technology of graphene and graphite rods, which is applied in the field of graphene production and preparation, can solve problems such as crushing, uneven pressure applied to graphite, and structural defects of graphene, and achieve the effect of reducing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

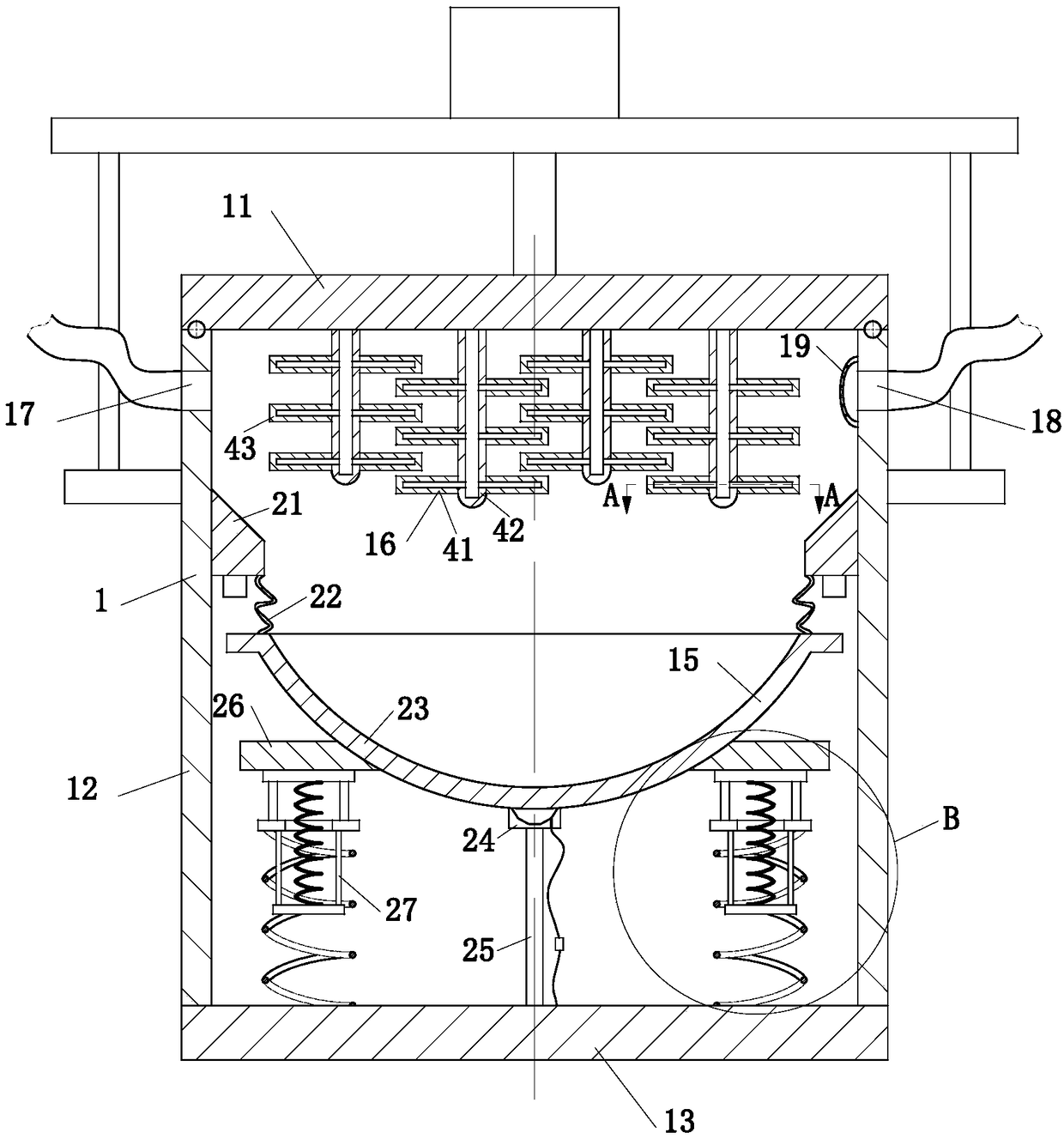

[0031] Such as Figure 1 to Figure 5 Shown, a kind of graphene production preparation method of the present invention, the method comprises the steps:

[0032] Step 1: soak the graphite rod in concentrated sulfuric acid for 5 minutes;

[0033] Step 2: adding the graphite rod soaked in step 1 to the potassium permanganate solution and soaking for 5 minutes to obtain a graphite oxide rod;

[0034] Step 3: crushing the graphite oxide rod in step 2 to obtain graphite oxide particles;

[0035] Step 4: adding the graphite oxide particles in step 3 to the graphene production equipment to obtain graphene;

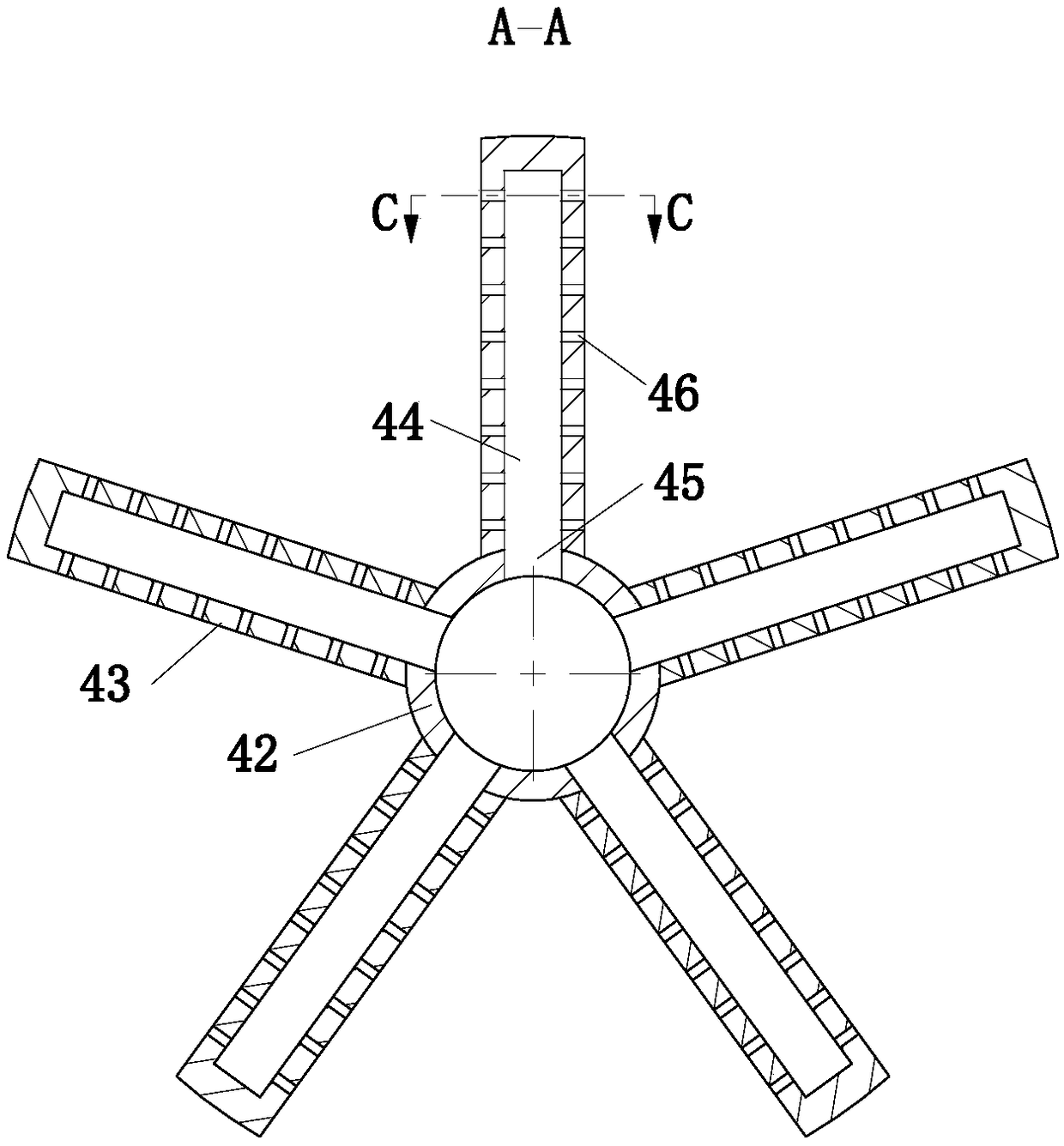

[0036] The graphene production equipment that adopts in this method comprises purification module and closed warehouse 1, and closed warehouse 1 is made up of upper base plate 11, side plate 12 and lower base plate 13; Described purification module is not the innovation of the present invention, is not described here Do go into details; also include a shaker module 15 and a crus...

Embodiment approach

[0041] As an embodiment of the present invention, the elastic member 27 includes an adjustment device 31 and a No. 1 spring 32; the adjustment device 31 includes a No. 1 disc 33, a No. 2 disc 34, a No. 3 disc 35 and a No. 2 Spring 36; the lower surface of the No. 1 circular plate 33 is connected with the upper surface of the No. 2 circular plate 34 through the No. 1 sliding telescopic rod 37; the lower surface of the No. 2 circular plate 34 is connected with the No. The upper surface of disc 35 is connected, and the center of No. 2 disc 34 is provided with circular opening 38; The upper end of described No. 2 spring 36 is installed on the lower surface of No. 1 disc 33, and the lower end of No. 2 spring 36 passes through the circle. Shaped opening 38 is installed on the upper surface of No. 3 disc 35; The diameter of No. 1 spring 32 is positioned at the outer layer of No. 3 disc 35, and No. 1 spring 32 is positioned at the inner layer of No. 2 disc 34; The second circular plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com