Graphene heating film detection and sorting automation device

An automatic device and technology of olefin heating film, applied in sorting and other directions, can solve the problems of low sorting efficiency and high work intensity, and achieve the effects of reducing labor intensity, improving work efficiency, and saving detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

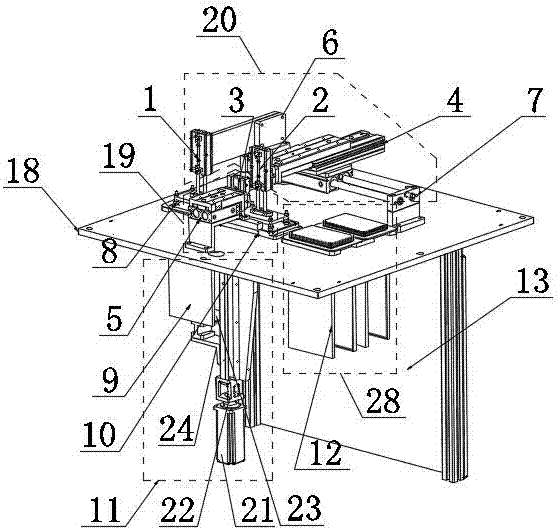

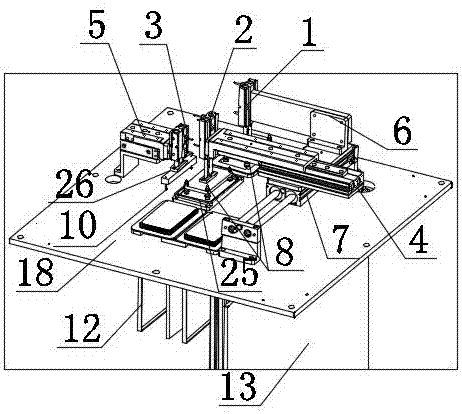

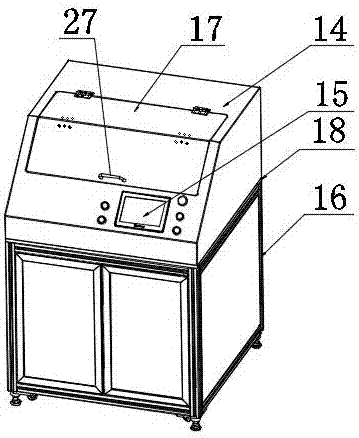

[0021] Such as Figure 1-4 It is a structural schematic diagram of the present invention, a graphene heating film detection and sorting automatic device, the box structure composed of aluminum profile frame 16 of the device is connected with sheet metal shell 14 by bolts, and the upper part of the aluminum profile frame 16 is connected by bolts The table top 18 is fixed, and the loading module 11 , the detection module 19 , the sorting module 20 and the unloading module 28 are fixed on the table top 18 by bolts.

[0022] This graphene heating film detection and sorting automatic device fixes the table panel 18 on the aluminum profile frame 16 through bolts, and installs the loading module 11, the detection module 19, and the sorting module 20 on the table panel. And the unloading module 28, the feeding module 11 transports the heating film to be detected to the control area of the sorting module 20, the sorting module 20 has two functions, the first can transfer the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com