Graphene production technology

A production process, graphene technology, applied in the field of graphene production process, can solve the problems affecting the efficiency of graphene grinding and stripping, affecting the quality of graphene production, etc., to achieve the effect of improving efficiency and quality, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

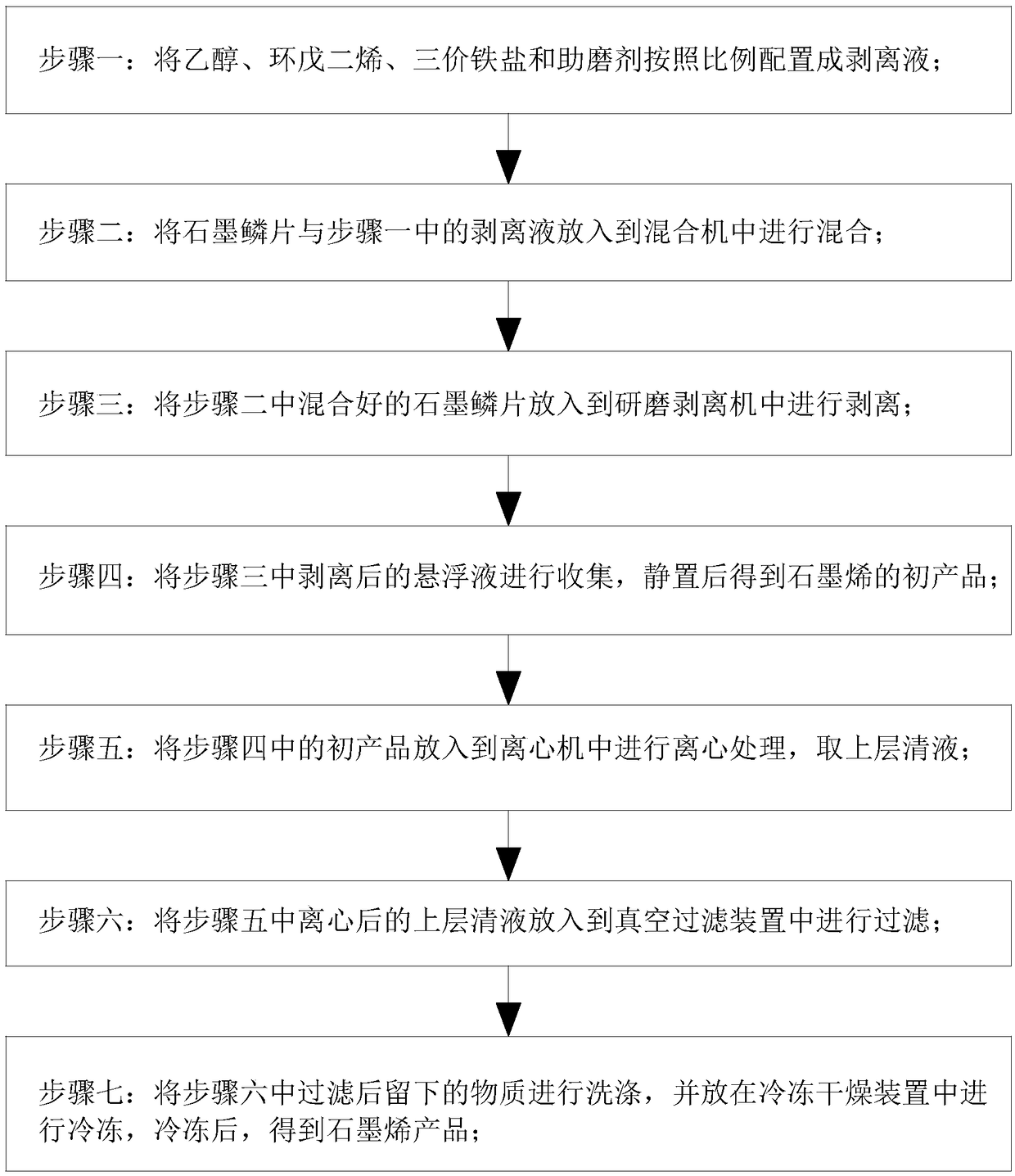

Method used

Image

Examples

Embodiment approach

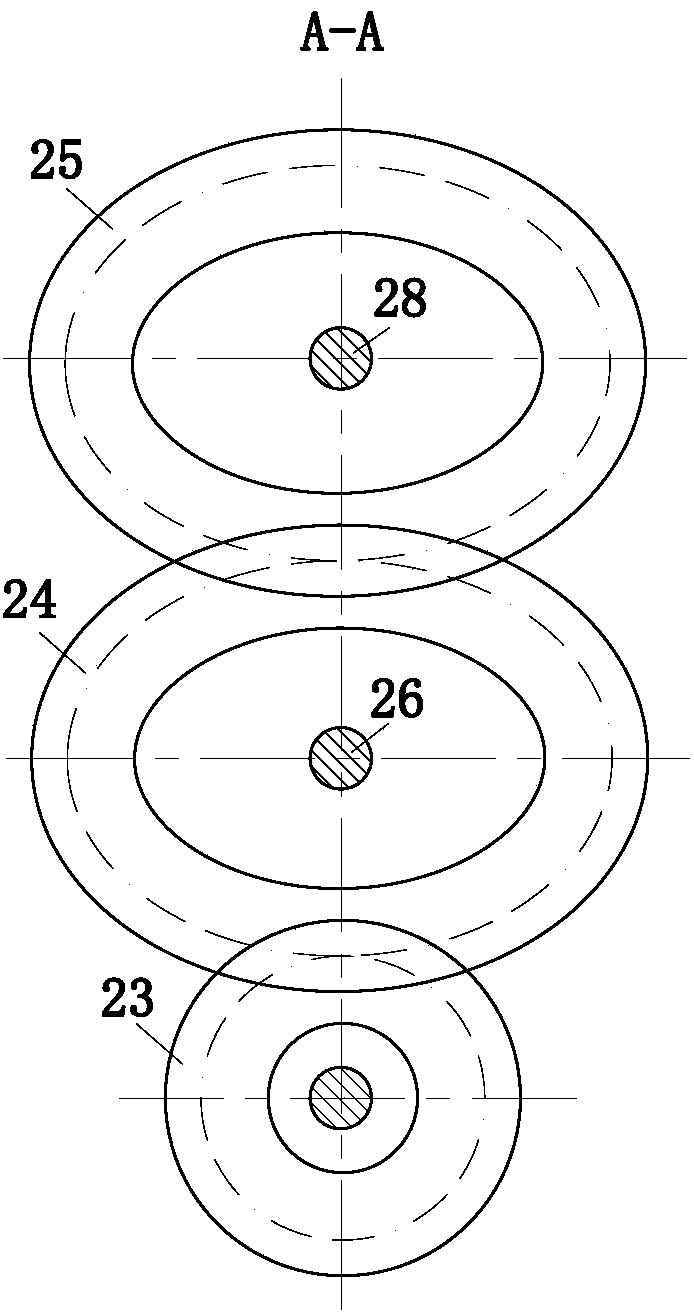

[0044] As an embodiment of the present invention, the second rod 28 is composed of the third rod 281 and the fourth rod 282; the end of the fourth rod 282 is fixedly connected with the second oval gear 25; the third rod 281 The end is fixedly connected with the upper grinding disc 36, the third rod 281 is located below the blocking plate 4, and a buckle 283 is fixedly installed in the third rod 281; the buckle 283 is used to clamp the third rod 281 and the fourth rod 282 Together, a spring is connected between the third rod 281 and the fourth rod 282 . During work, when the third rod 281 is not blocked by the blocking plate 4, the third rod 281 and the fourth rod 282 are under the action of the buckle 283, and the third rod 281 and the fourth rod 282 are stuck together without separation. When No. 1 elliptical gear 24 and No. 2 elliptical gear 25 rotate from the nearest meshing point to the farthest meshing point, No. 2 lever 28 slowly approaches the blocking plate 4. When No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com