Preparation method of graphene

A technology of graphene and rotation direction, applied in the direction of graphene, nano-carbon, etc., which can solve problems such as sticking to the inner wall of the first cylinder, affecting the efficient peeling and preparation of graphene, and clumping or agglomerating of graphene slurry , to achieve the effect of improving the effect and improving the effect of high-efficiency grinding and peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

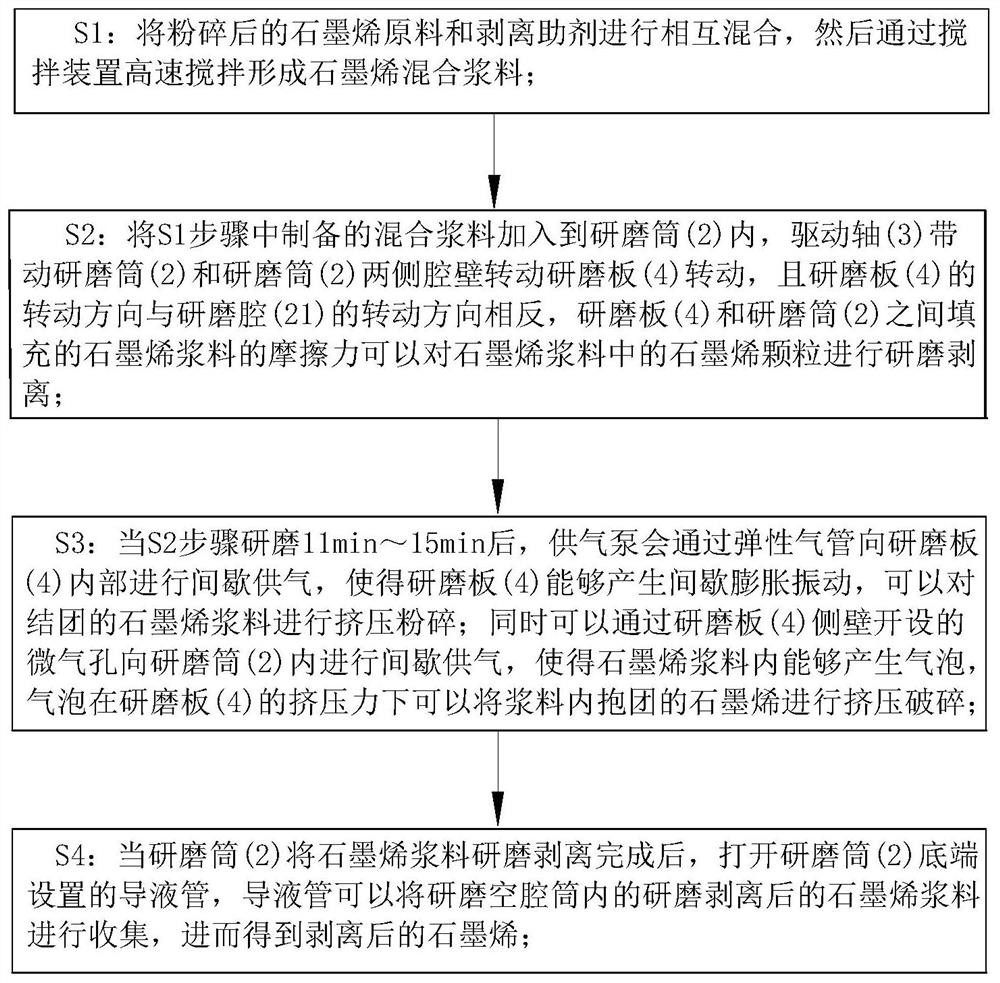

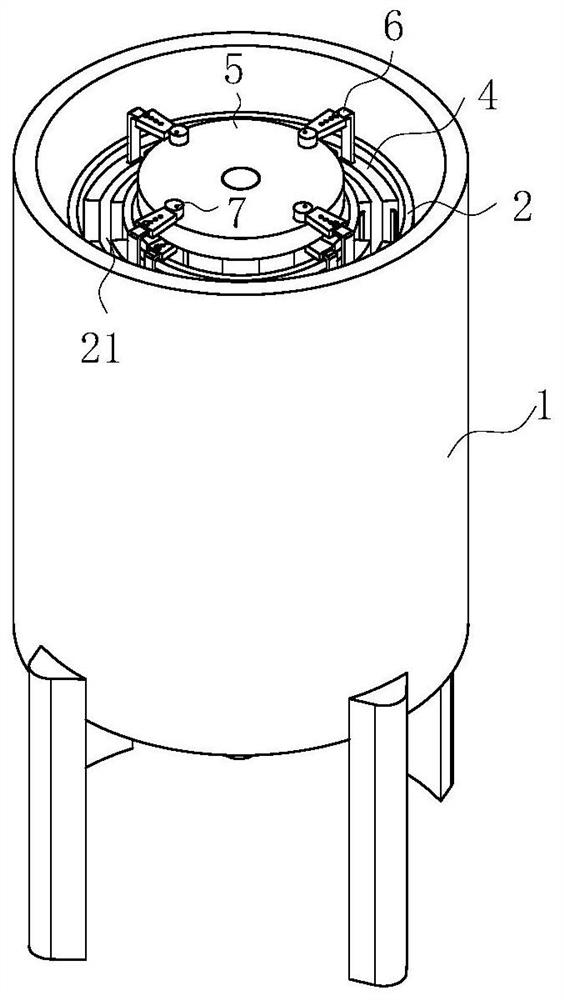

[0030] Such as Figure 1-Figure 6 Shown, a kind of graphene preparation method of the present invention, this method comprises the steps:

[0031] S1: Mix the pulverized graphene raw material and the exfoliation aid with each other, and then stir at high speed through a stirring device to form a graphene mixed slurry;

[0032] S2: Add the mixed slurry prepared in step S1 into the grinding cylinder 2, the drive shaft 3 drives the grinding cylinder 2 and the chamber walls on both sides of the grinding cylinder 2 to rotate the grinding plate 4, and the rotation direction of the grinding plate 4 is the same as that of the grinding chamber 21 The direction of rotation is opposite, and the friction force of the graphene slurry filled between the grinding plate 4 and the grinding cylinder 2 can grind and peel off the graphene particles in the graphene slurry;

[0033] S3: After step S2 is ground for 11-15 minutes, the air supply pump will intermittently supply air to the inside of t...

Embodiment approach

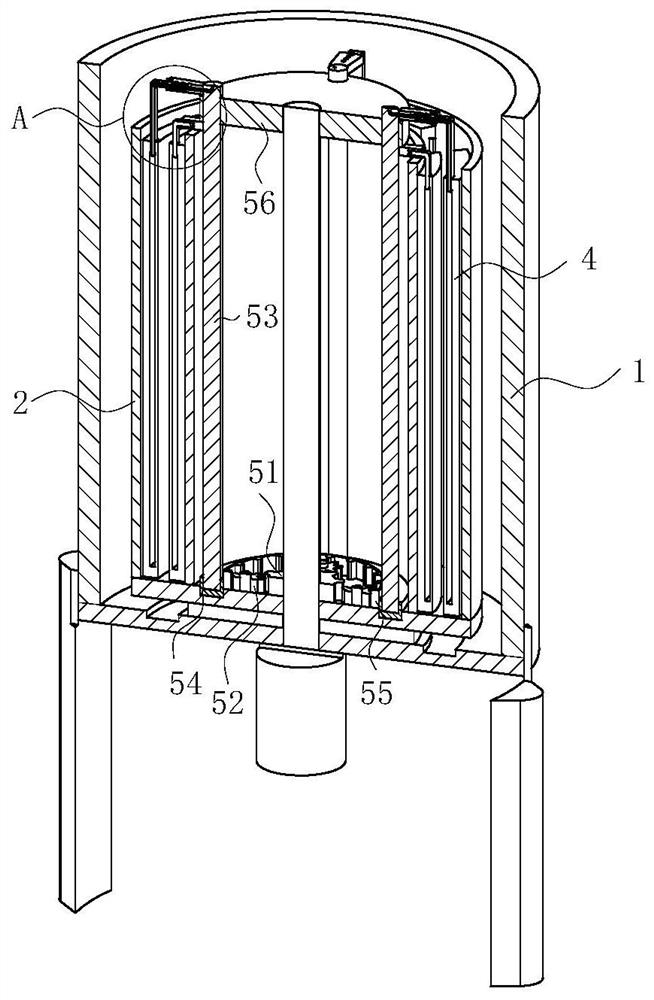

[0036] As an embodiment of the present invention, the grinding drive mechanism 5 includes a driving gear 51, a planetary gear 52, a rotating rod 53, a rotating ring 54, an internal gear disc 55, a support disc 56 and an L-shaped connecting rod 6; Gear 51 is fixed to the bottom end of drive shaft 3, and driving gear 51 is positioned at in grinding cylinder 2; meshing; a plurality of the rotating rods 53 are fixedly connected to the rotating ring 54, and the rotating ring 54 is mounted on the bottom end of the grinding cylinder 2; the inner ring wall of the rotating ring 54 is provided with an internal gear plate 55, and The inner gear disc 55 meshes with a plurality of planetary gears 52; the top ends of the plurality of rotating rods 53 are symmetrically provided with L-shaped connecting rods 6, and the plurality of L-shaped connecting rods 6 are respectively connected to a plurality of grinding plates 4; A plurality of said rotating rods 53 are all connected to the support di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com