High-efficiency drying equipment for graphene production and drying method

A drying equipment and high-efficiency technology, which is applied in drying, drying machines, lighting and heating equipment, etc., can solve the problems affecting the drying effect of draining effect, so as to improve the drying effect, increase contact, and speed up draining speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

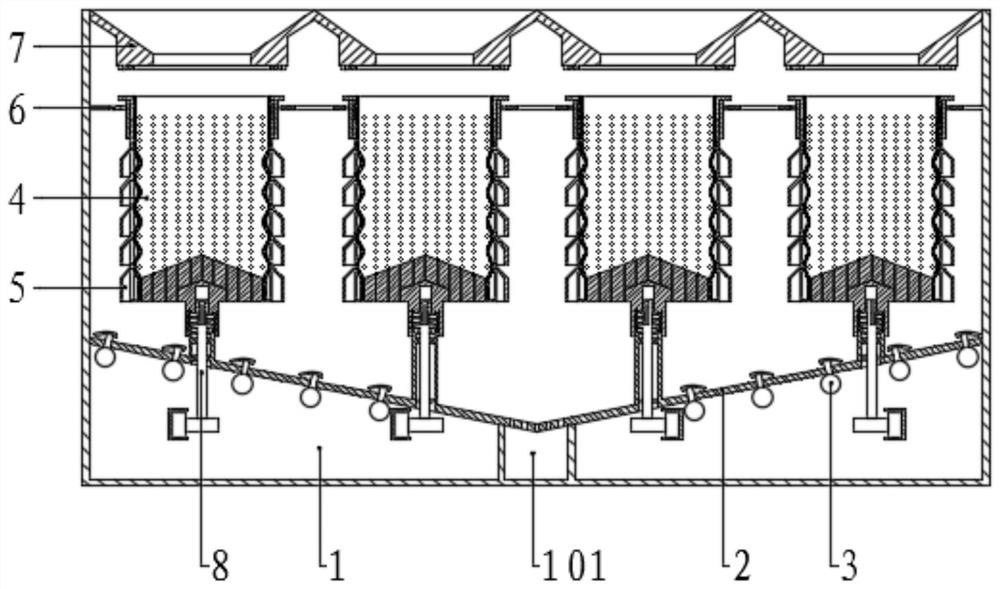

[0058] Please refer to the drawings, the present invention provides a technical solution: a highly efficient drying apparatus for graphene production, including a drying tank 1, and a feed plate 7, a feed plate 7, a feed A positioning plate 6 is provided below the plate 7, and the bottom portion of the drying box 1 is fixed, and a plurality of material placement mechanisms are uniformly provided between the conductive plate 2 and the positioning plate 6, and the conductive plate 2 is provided. There is a drying assembly, and the bottom of the dryer 1 is provided with a drive assembly, and the material placement mechanism corresponds to the drive assembly, and the two sides of the conductive plate 2 are symmetrically inclined, and the intermediate is higher than that of both sides, which is easy to dry after drying The material is concentrated in the middle of the conductive plate 2 for the lower material, and the central portion of the conductive plate 2 is uniformly provided with...

Embodiment 2

[0066] The structure of the present embodiment is substantially identical to the examples, and the feed plate 7 is evenly provided with a plurality of stroke feed grooves 701 along the rectangular array, and the feed groove 701 is provided with a feed. The mouth 702, and the bottom surface of the feed plate 7 has an annular third electromagnet 703 on the outer side of the pumping port 702, the third electromagnet 703 is electrically connected to the power source and switch, and the positioning plate 6 includes a plurality of positioning rings that are uniformly set. 601. The positioning ring 601 corresponds to the position of the feed cell 701, and the adjacent two positioning ring 601 are fixedly connected by the fixed lever 602, and the positioning ring 601 located outside is passed through the side of the fixed rod 602 and the side of the drying box 1. The wall fixing is connected, and the positioning ring 601 is rotated and connected to the positioning cartridge 603, and there...

Embodiment 3

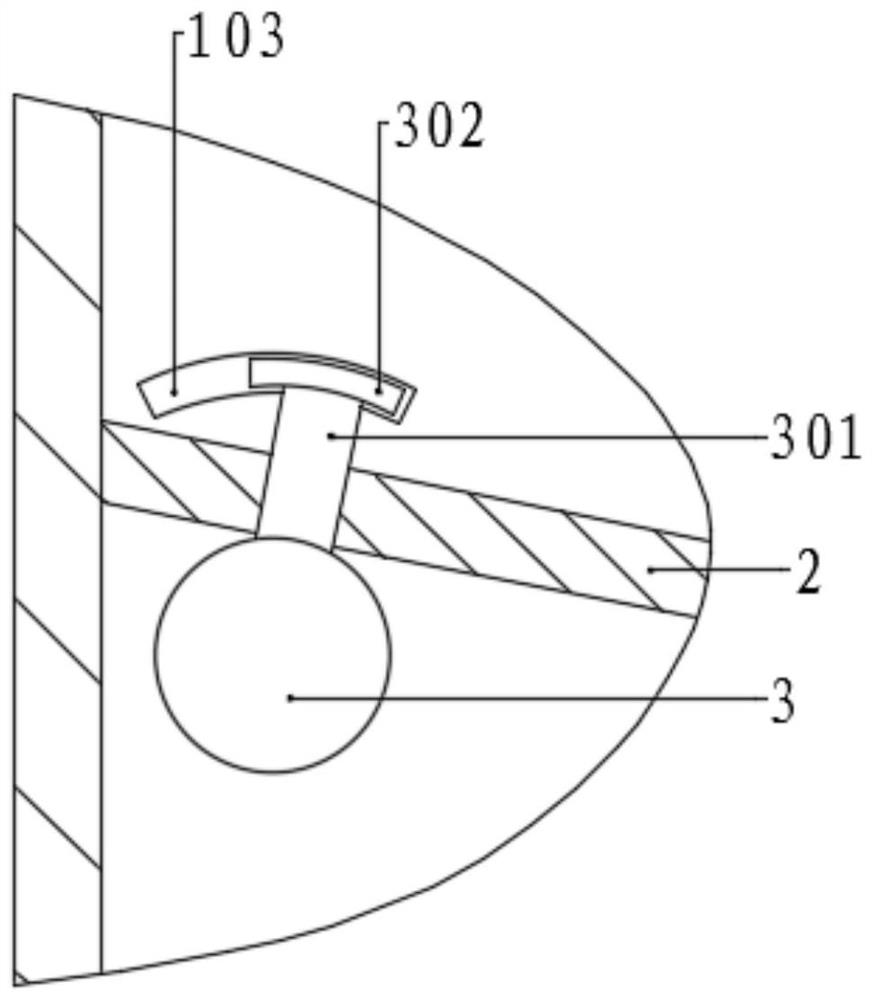

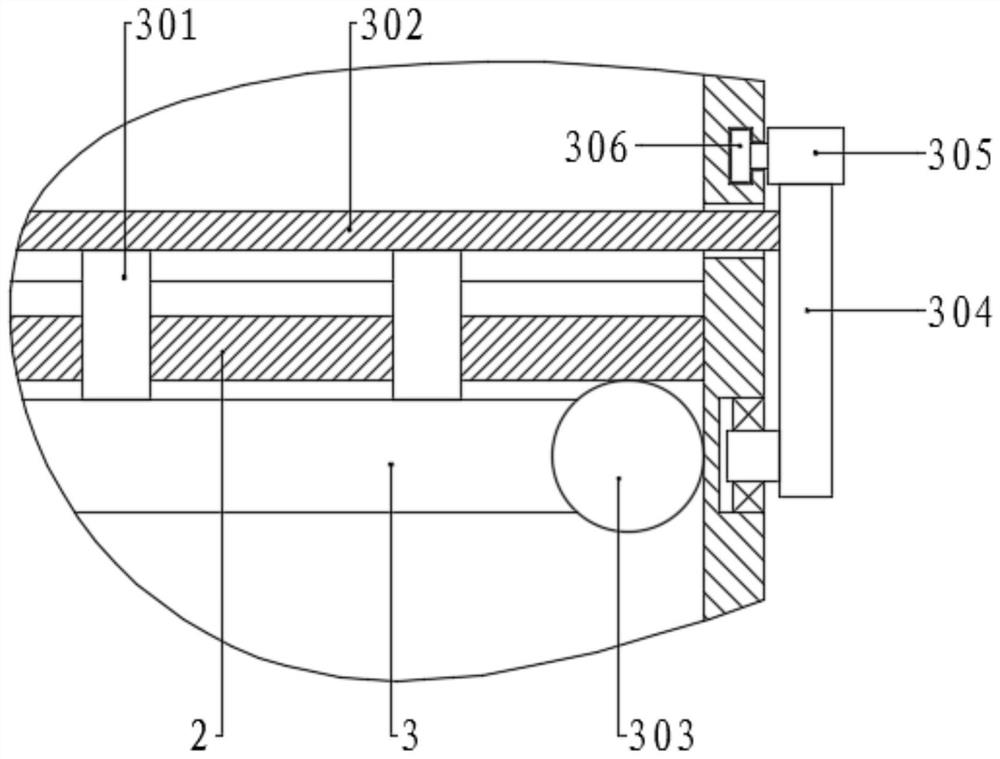

[0079] The structure of the present embodiment is substantially identical to the second embodiment, and the distinction is that the top end of the exhaust pipe 301 is set to a curved shape, and a curved seal is provided with a top of the outlet pipe 301 on the same dry tube 3. The plate 302, and the bottom curve surface of the sealing plate 302 slides to the top arc surface of the outlet tube 301, and there is a curved groove 103 on both sides of the drying box 1, and both ends of the sealing plate 302 are slidably connected to the arc. The groove 103, and one end projects out of the drying tank 1, and fixes the center of the sector plate 304, the center sealing plate 302 of the sector plate 304, and the arc-shaped top surface of the sector plate 304 is uniformly fixed in the arc direction. A plurality of sector plates 304 located on the same side are in the same first rack 305 by the tooth teeth, and the first rack 305 is the same as the tilt angle of the corresponding side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com