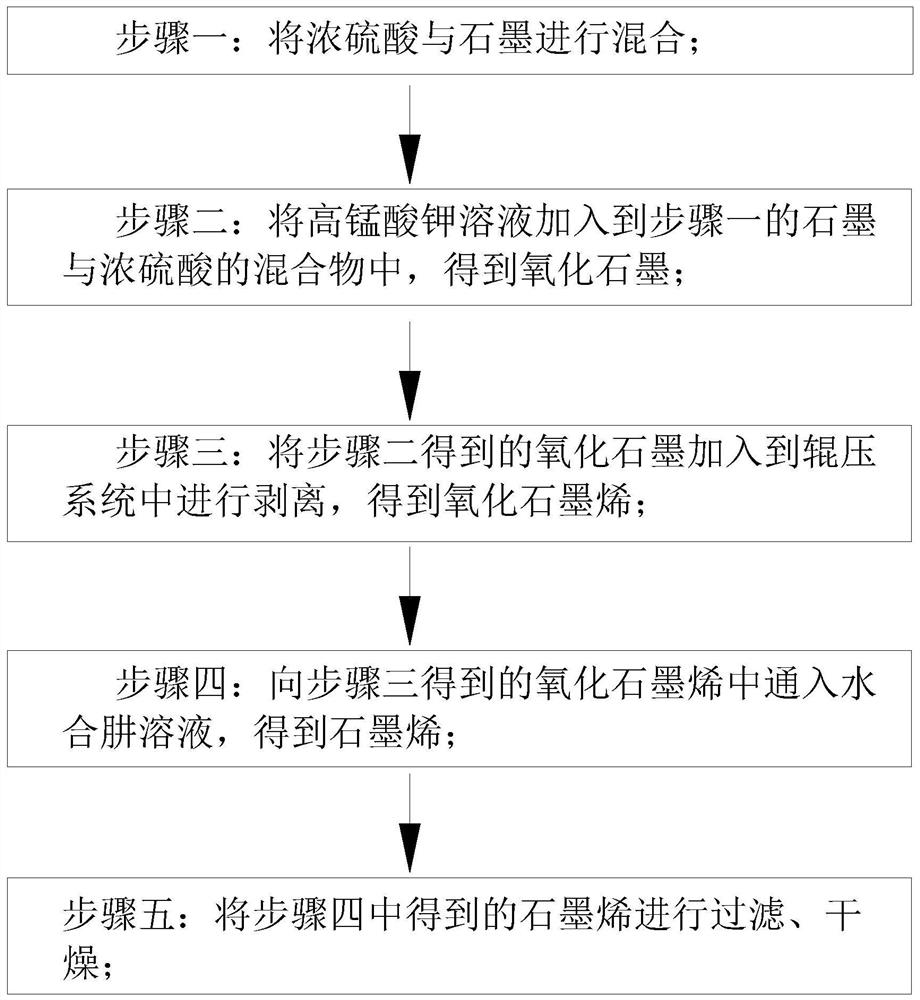

A kind of graphene rolling peeling method

A graphene, rolling technology, applied in the field of graphene roll peeling, can solve problems such as overgrinding, graphene structural defects, small crystal size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

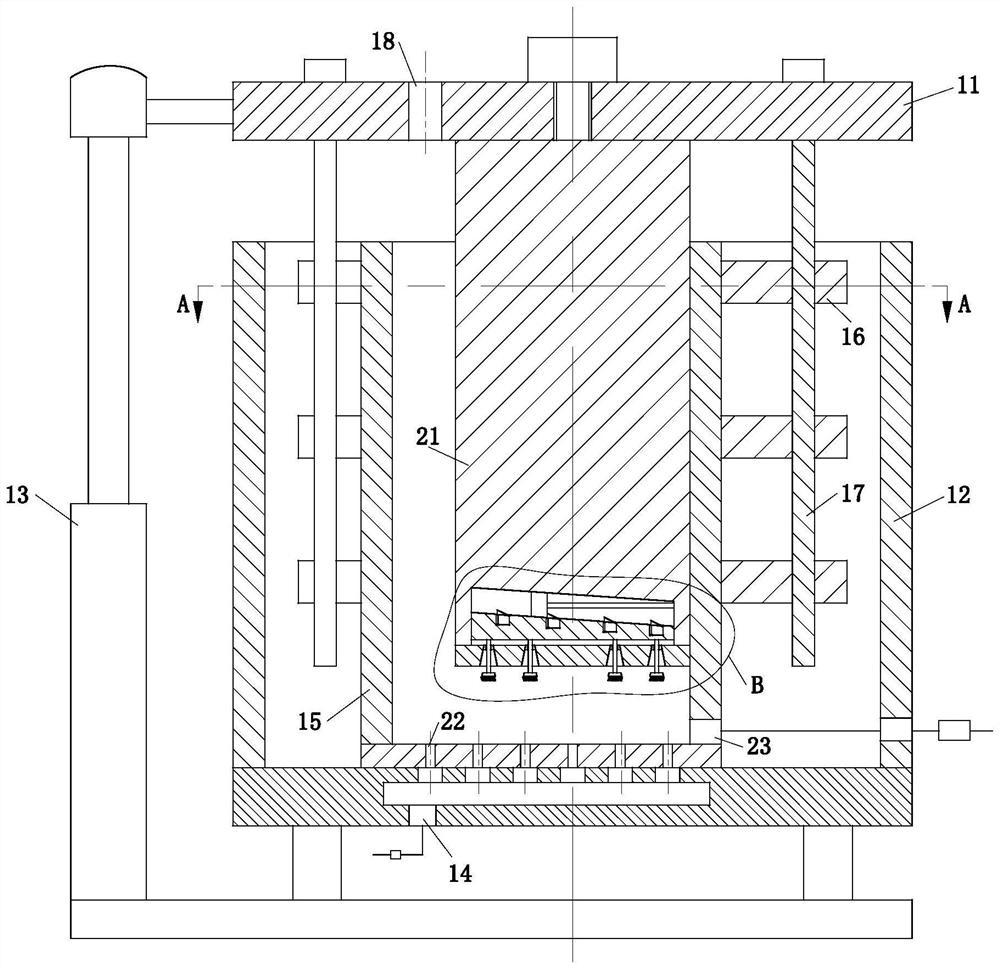

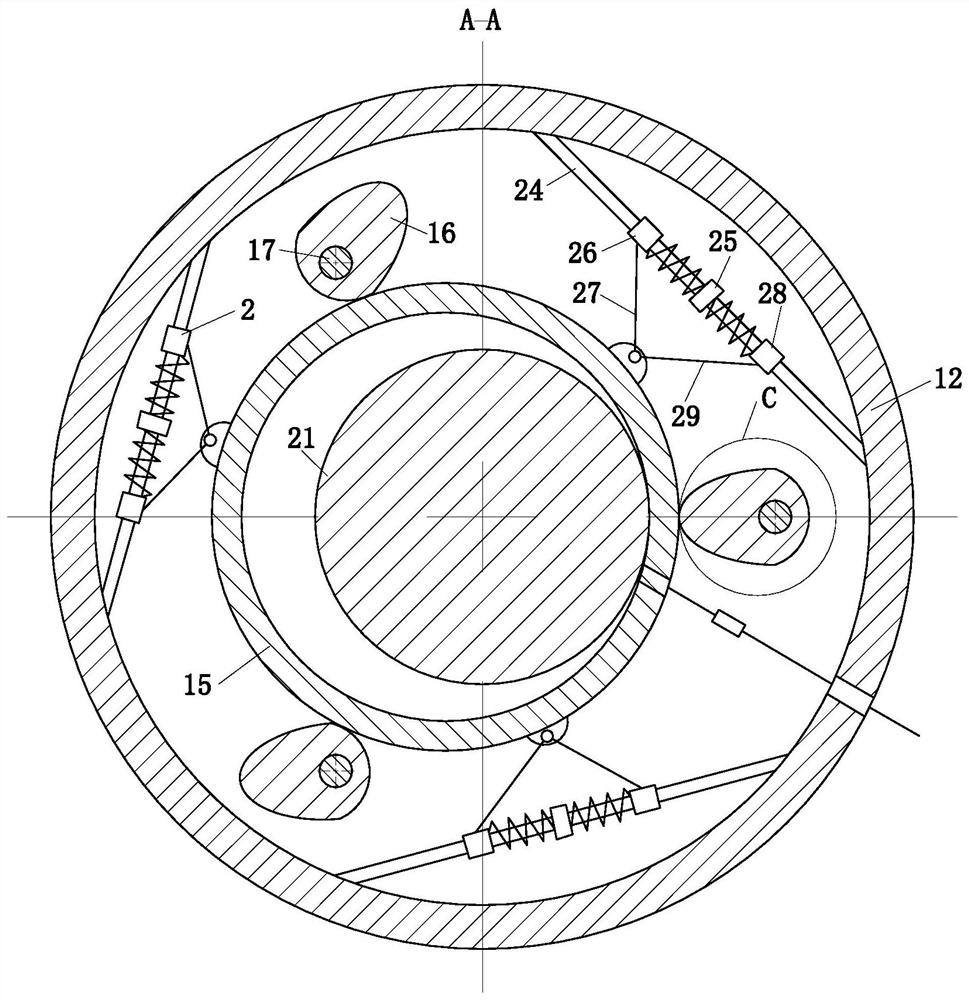

[0039] As an embodiment of the present invention, the No. 1 limit mechanism 2 includes a sliding rod 24, a fixed block 25, a No. 1 sliding block 26, a No. 1 connecting rod 27, a No. 2 sliding block 28 and a No. 2 connecting rod 29, The middle position of described slide bar 24 is fixedly installed with fixed block 25, and slide bar 24 is slidably installed No. 1 sliding block 26 and No. 2 sliding block 28; One side of described fixed block 25 is connected with No. 1 sliding block 26 by spring , the other side of the fixed block 25 is connected with the No. 2 sliding block 28 by a spring; the No. 1 sliding block 26 is hinged with the mounting block through the No. 1 connecting rod 27, and the No. 2 sliding block 28 is connected with the mounting block through the No. 2 connecting rod 29 Hinged; three sets of No. 1 limit mechanism 2 are used to limit the extrusion cylinder 15 to prevent the extrusion cylinder 15 from disengaging from the three cam groups 16; if the extrusion cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com