Graphene production and manufacturing system

A manufacturing system and graphene technology, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems that affect the scope of graphene production, no crushing device, backlog of graphite particles, etc., to improve efficiency and production. Efficiency, fine graphite particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

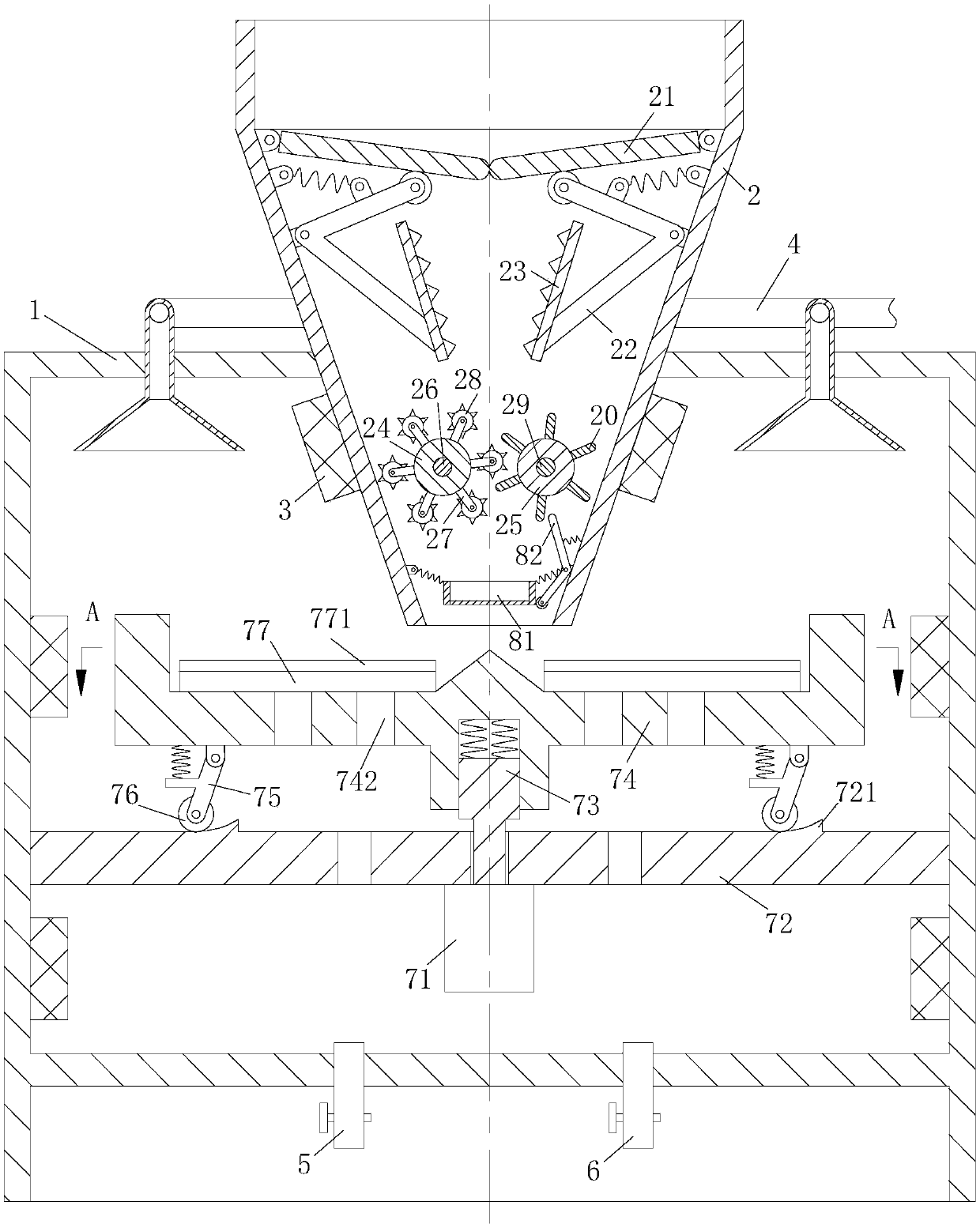

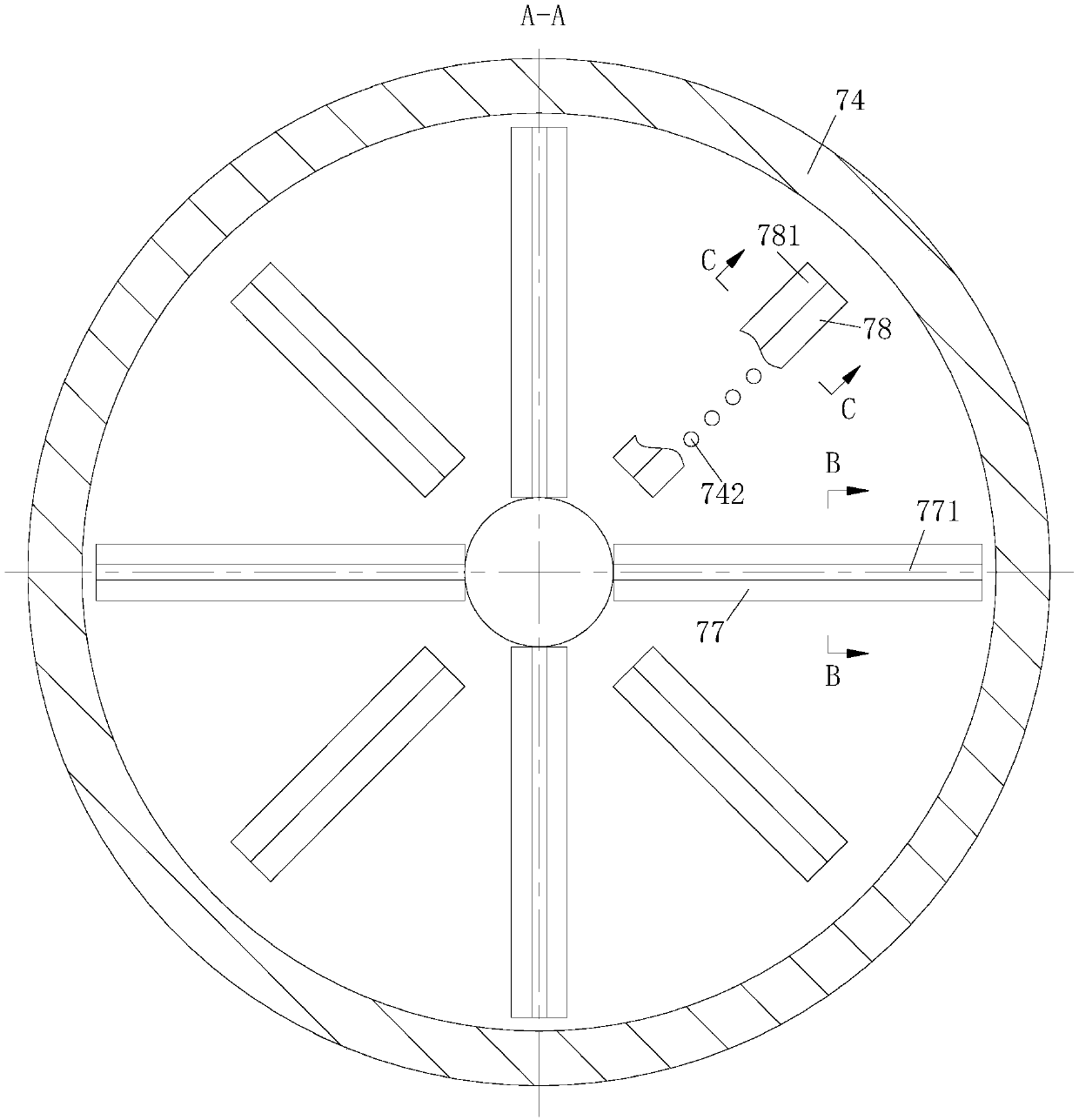

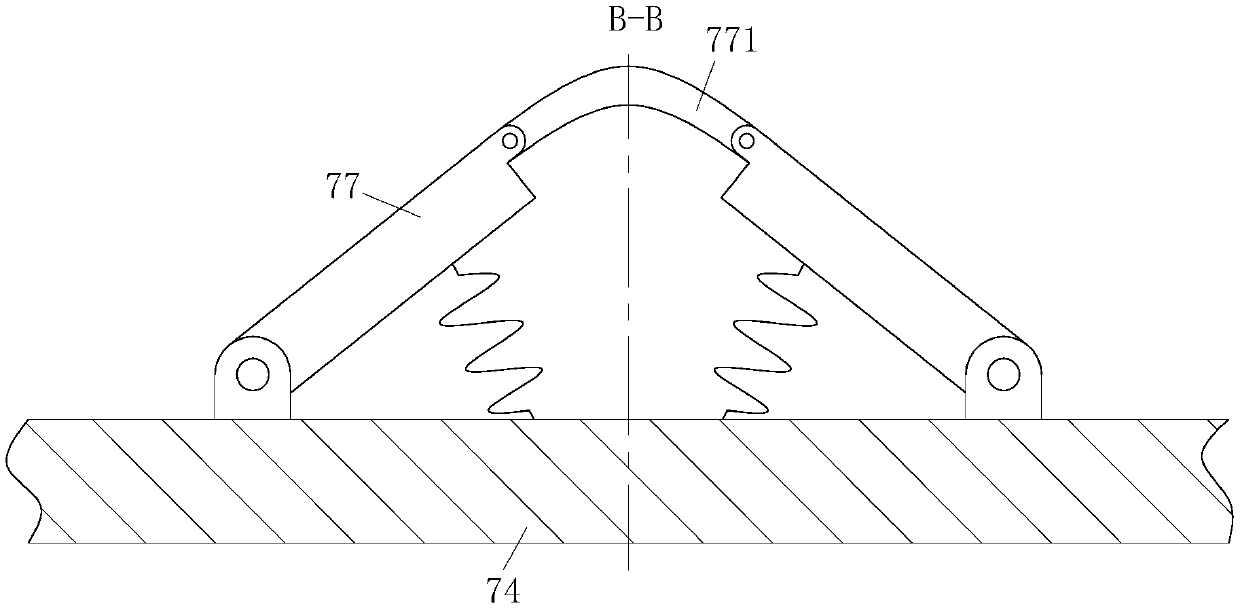

[0024] Such as Figure 1 to Figure 4 As shown, a kind of graphene production and manufacturing system of the present invention comprises microwave cavity 1, feed hopper 2, microwave generator 3, finished product conveying pipe 4, compressed air inlet valve 5, inert gas inlet valve 6 , the top of the microwave cavity 1 is provided with a feed hopper 2; the feed hopper 2 is a square cone, the middle part of the outer wall of the feed hopper 2 is fixedly connected to the top plate of the microwave cavity 1, and the outer wall of the middle part of the feed hopper 2 is fixedly connected A group of microwave generators 3; the finished product delivery pipe 4 is arranged on both sides of the feed hopper 2, and the finished product delivery pipe 4 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com