Vibration test simulator for levitation sensor of high-speed maglev train

A suspension sensor, maglev train technology, applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve the problems of output signal interference, neglect reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

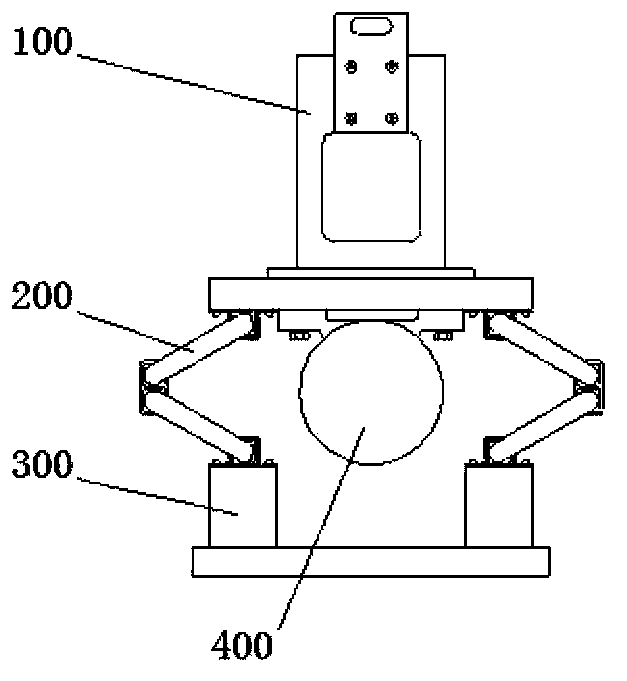

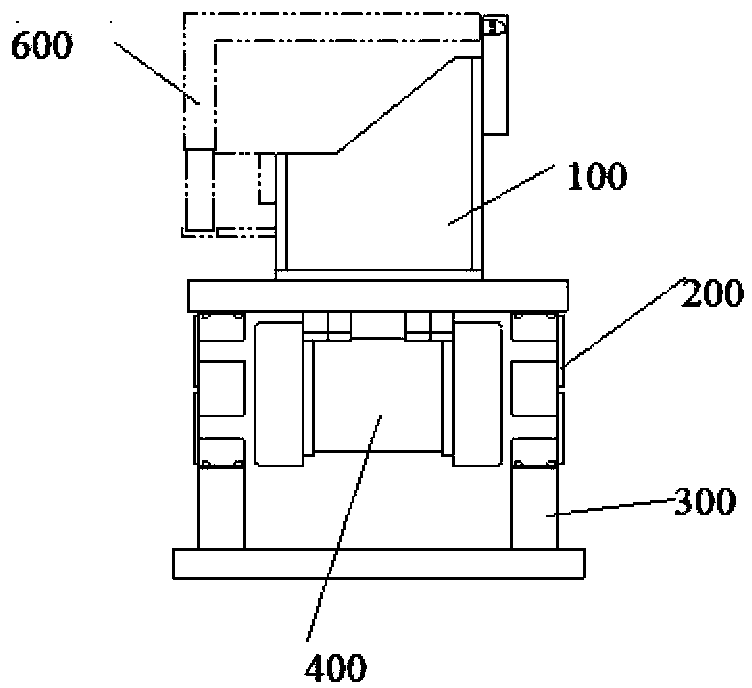

[0014] combine figure 1 and figure 2 It can be seen that,

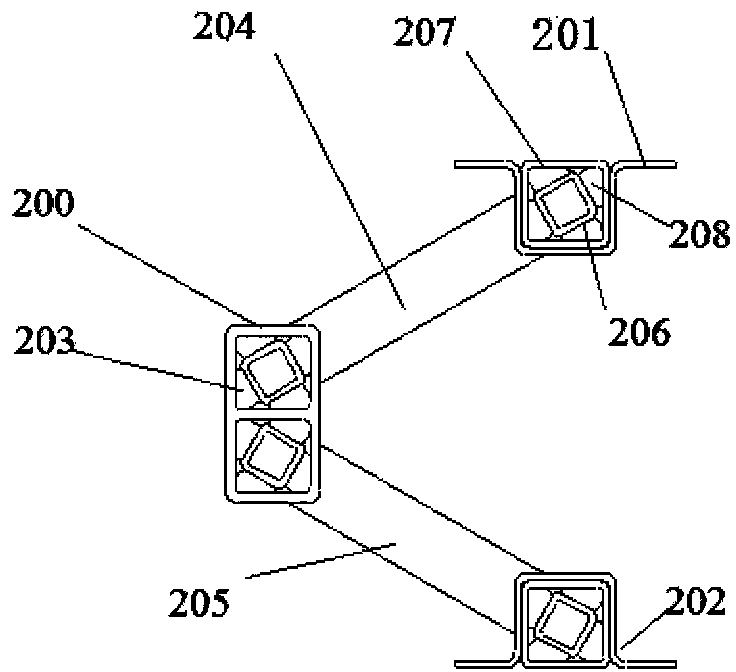

[0015] The high-speed maglev train suspension sensor vibration test simulation device is mainly composed of a sensor mount 100, a shock absorber 200, a base 300 and a vibration motor 400; the upper part of the sensor mount is used to install the suspension sensor under test, and the lower part of the sensor mount is provided with a vibration motor ; A shock absorbing device is arranged between the sensor mounting seat and the base, and the shock absorbing devices are respectively located at the four corners of the sensor mounting seat. combine image 3 and Figure 4 , each shock absorbing device has two independent square bushing joints 201 and 202 at both ends, which are respectively connected with the sensor mounting seat and the base 300, and a parallel square bushing joint 203 in the middle and a square bushing joint supported on the square bushing. The supporting rods 204 and 205 in between are formed. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com