Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Fiber laser welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

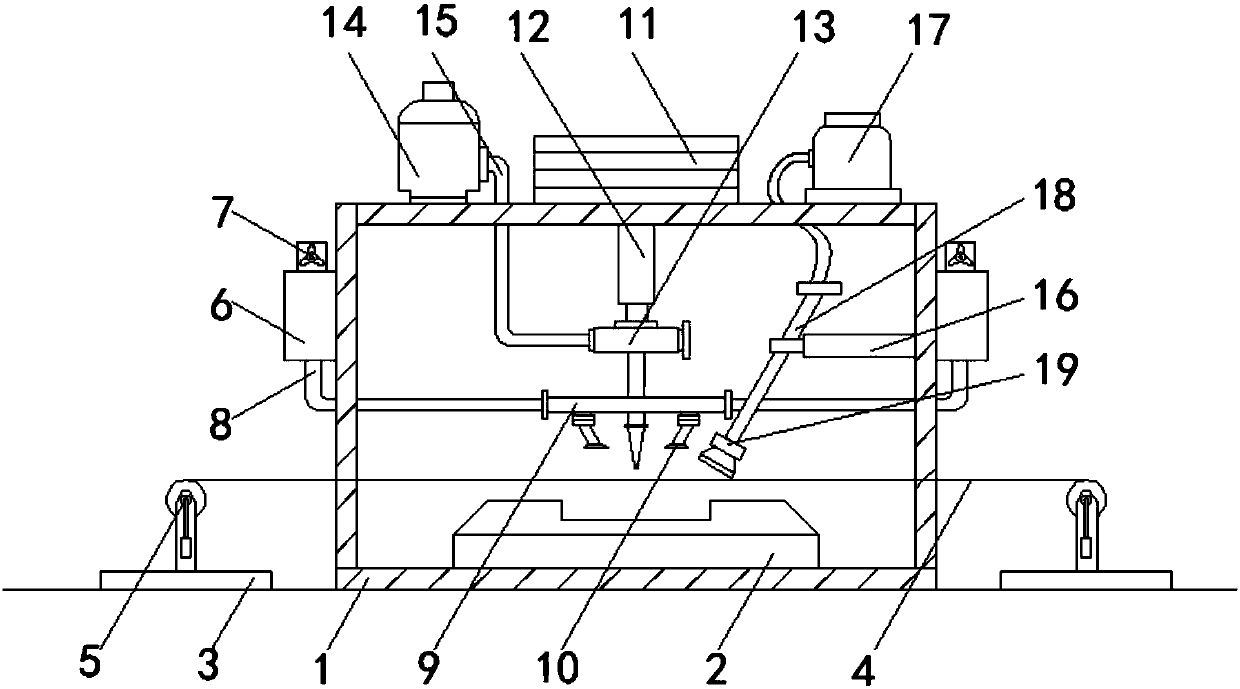

Dustless efficient optical fiber laser welding device

InactiveCN107695516AImprove dust removal effectImprove efficiencyLaser beam welding apparatusEngineeringMachining

The invention relates to the technical field of industries, and discloses a dustless efficient optical fiber laser welding device. The dustless efficient optical fiber laser welding device comprises amachining box. A ceramic table is fixedly arranged on the bottom wall in a cavity of the machining box. Alignment frames are fixedly arranged on the two sides of the machining box, and an optical fiber penetrating the machining box is fixedly arranged on the opposite sides of the two alignment frames. Shaking wheels are fixedly arranged on the front surfaces of the alignment frames. Dust boxes are fixedly arranged on the two sides of the machining box. The tops of the dust boxes communicate with exhaust fans. The bottom of each dust box communicates with a dust suction pipe with one end penetrating and extending into a machining box cavity. The end, away from the corresponding dust box, of each dust suction pipe communicates with an annular pipe, wherein the bottom of the annular pipe communicates with a dust suction pipe head. A hydraulic machine is fixedly arranged on the top of the machining box, and a telescopic rod with one end penetrating and extending into the machining box cavity is fixedly arranged at the bottom of the hydraulic machine. The dustless efficient optical fiber laser welding device is good in dust removing effect and good in using efficiency and is conveniently used by people.

Owner:扬州杰泰克电子有限公司

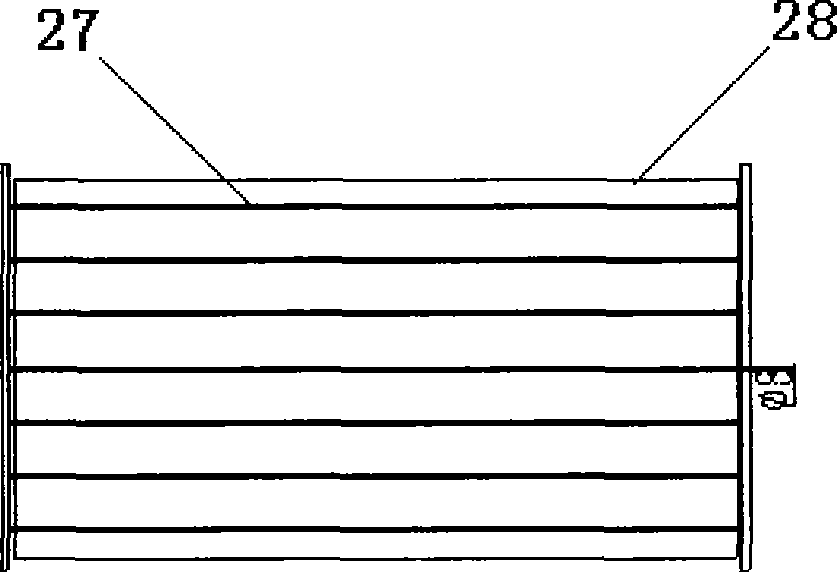

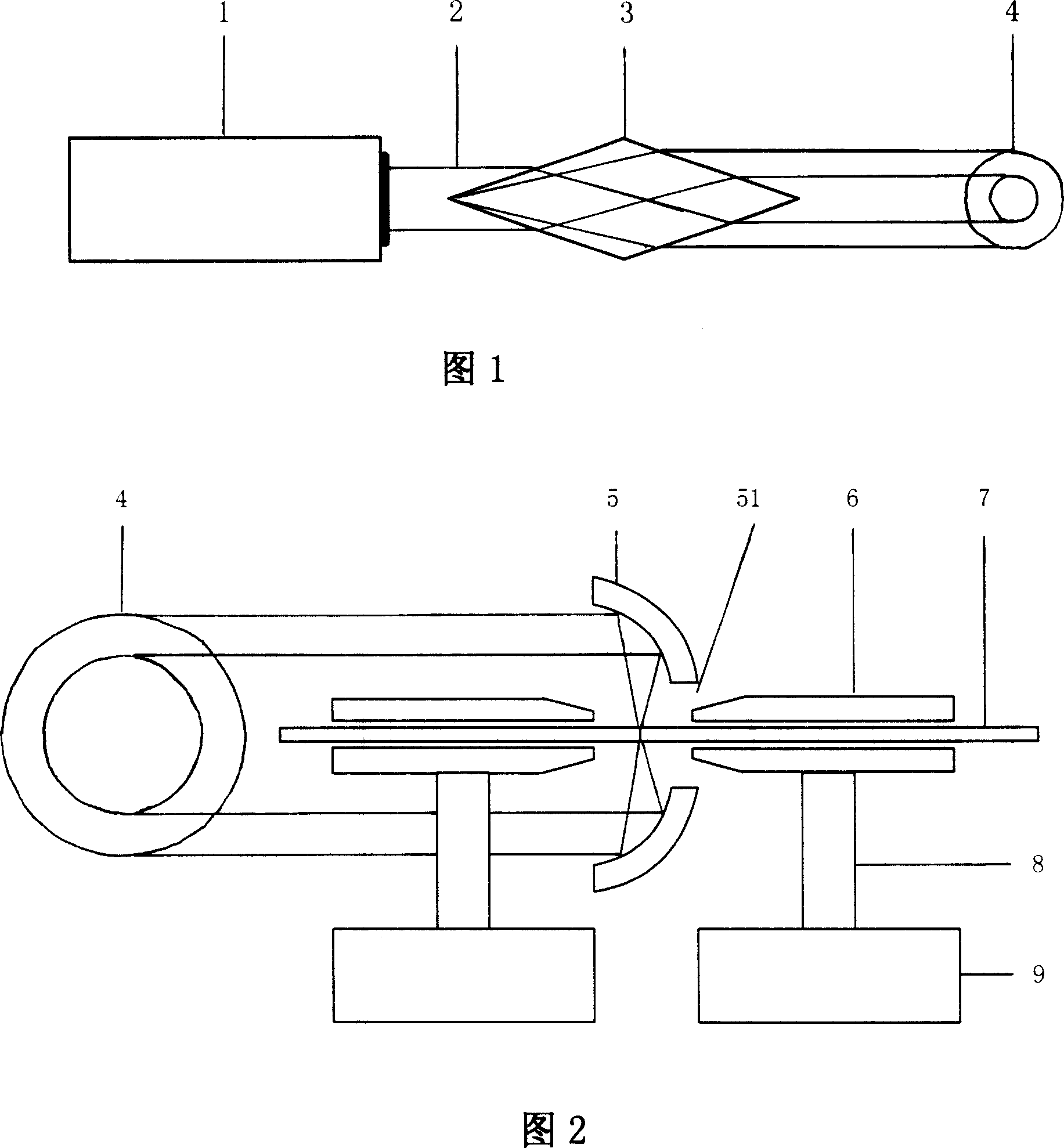

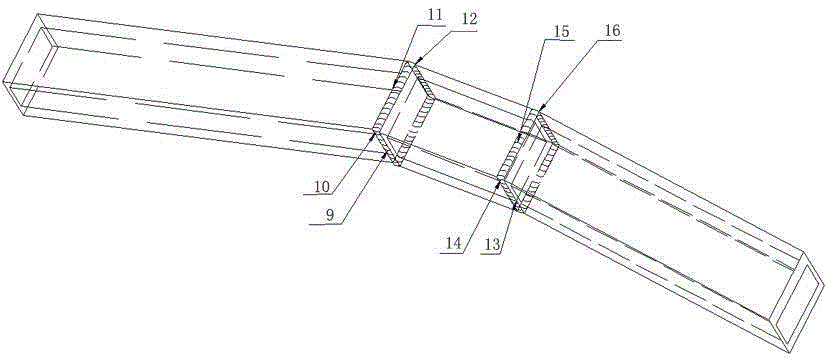

Double light path optical-fiber laser bonding machine for plate-type solar thermal absorber

InactiveCN101380695AQuality improvementFast welding speedLaser beam welding apparatusLaser bondingEngineering

The invention relates to a laser welding machine. The invention discloses a double-light path fiber laser welding machine used for a plate solar heat absorber which includes a laser, a fiber and a focusing system. The laser is connected with the focusing system by the fiber. The invention also includes a base device and a goal-post device; wherein, the goal-post device is arranged on the base device; the focusing device is arranged on the goal-post device for inducing the laser emitted by the laser between the goal-post device and the base device. Aiming at the position of a workpiece to be welded, the focusing system can move along the three directions of X, Y and Z; wherein, X and Y refer to a horizontal direction parallel to the ground; Z refers to a direction vertical to the ground. The welding machine solves the welding difficulty between a copper tube and an aluminum plate and changes the manufacturing technique flow of a solar heat absorber, thus leading the quality of the solar heat absorber to be greatly improved.

Owner:武汉楚天激光(集团)股份有限公司

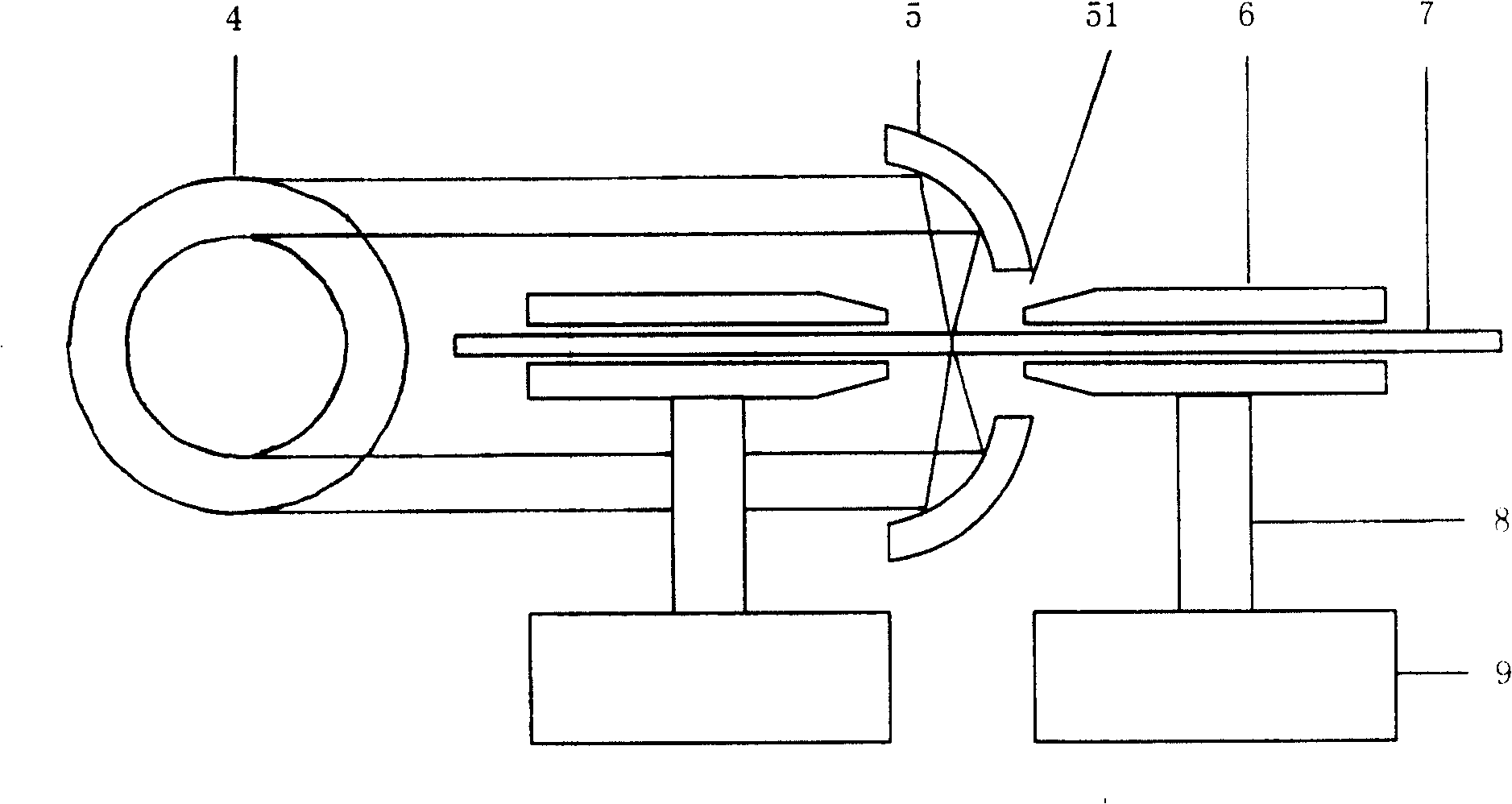

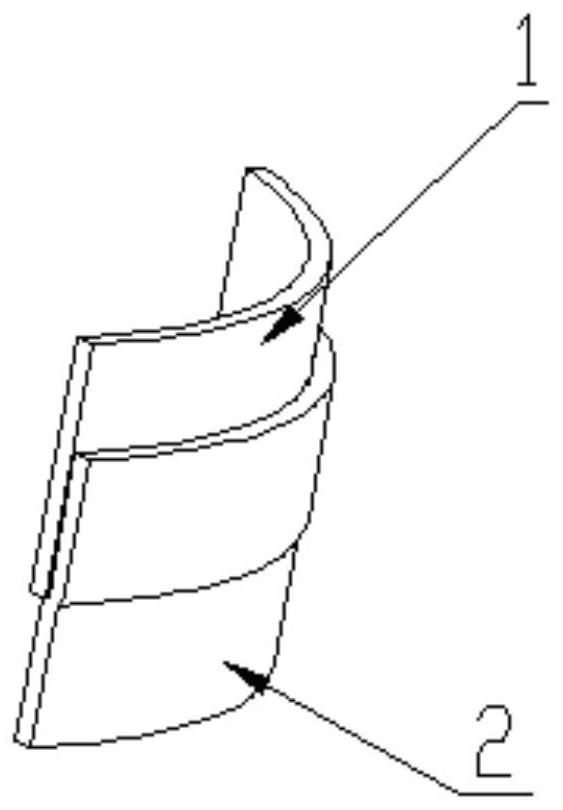

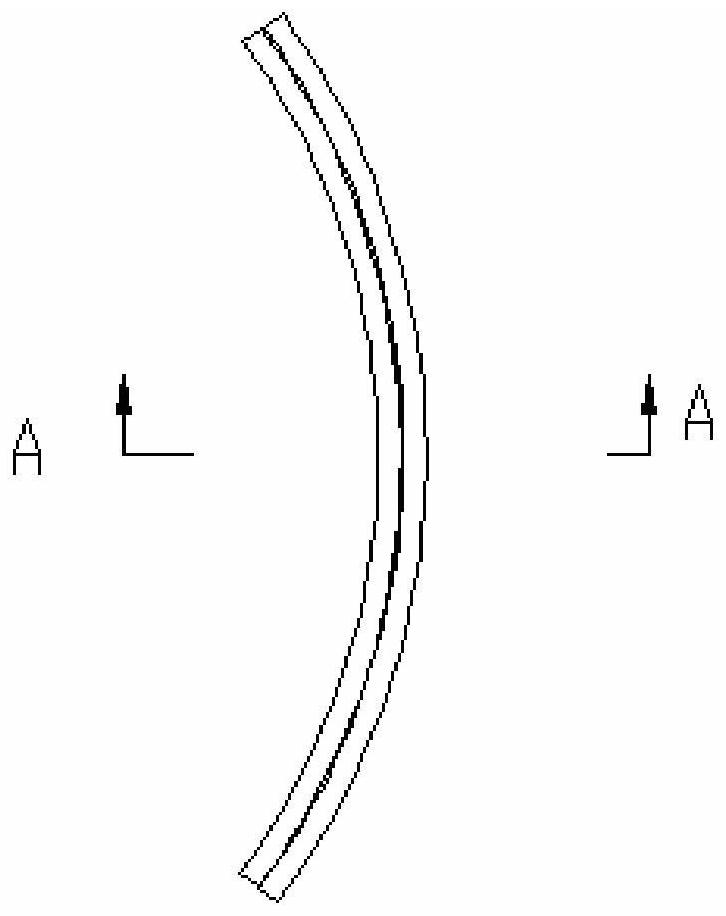

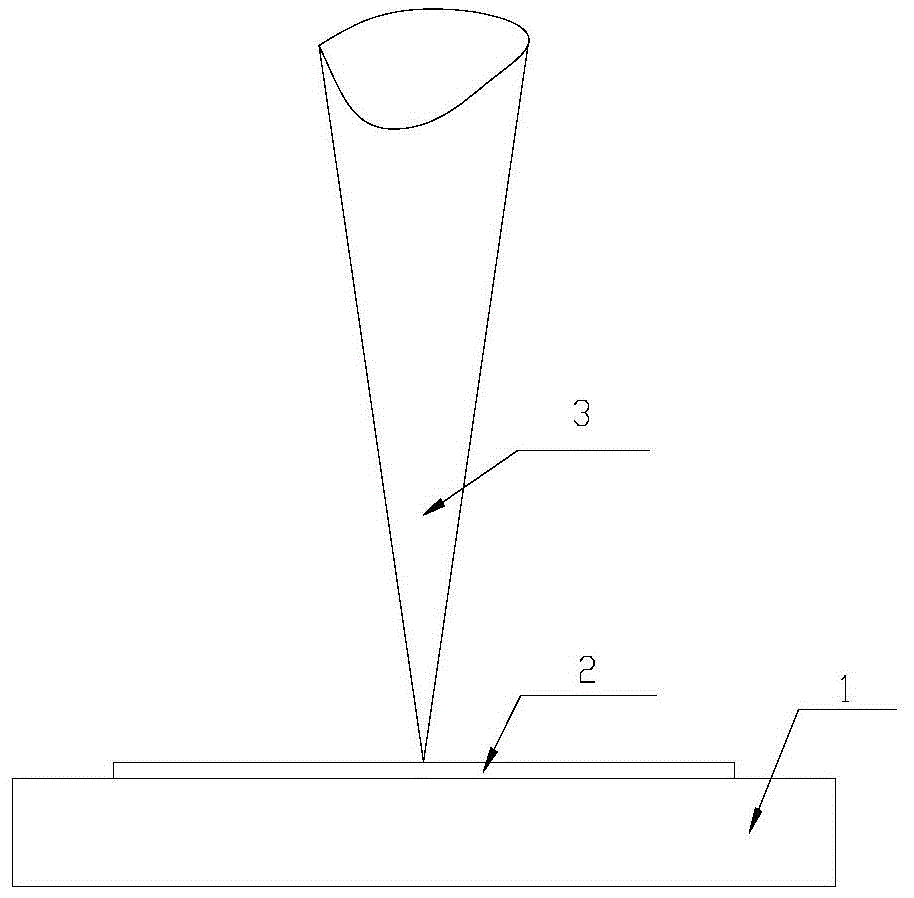

Thick core optical fibre laser welder and welding method

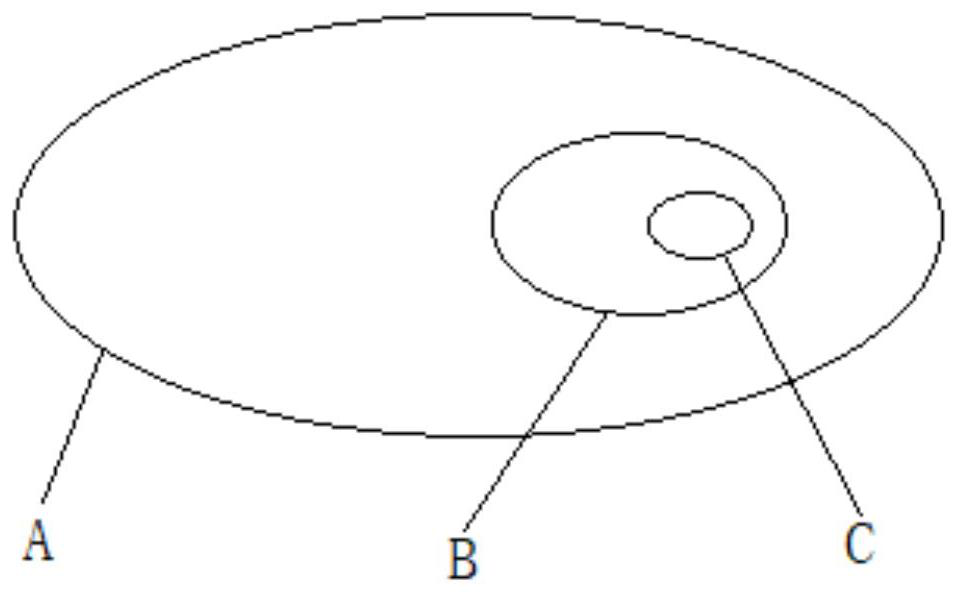

InactiveCN101013183AHeating power can be controlled preciselyHeating evenlyLaser detailsCoupling light guidesFocal positionOptoelectronics

It is a coarse fiber laser welding device and welding method for coarse fiber welding, using a small 100-watt CO2 laser as light source, and using an oral-shaped lens to form the laser beam of the laser to the ring beam, and bowl-shape mirror respecting this ring laser beam to the focus in the center of the bowl-shape mirror, and the welding fiber is placed on the position of focus. There is a hole in the center of the bowl-shape mirror, and the fiber passing through this hole, making the fiber welding part locating in the center of the bowl-shape mirror focus, and after the ring laser focusing, it can uniform irradiate on the welding position around the fiber. Control power and power output time of CO2 laser, to weld different diameter fibers. The invention solves the welding problem of the coarse fiber, making the fiber welding point uniform and smooth.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

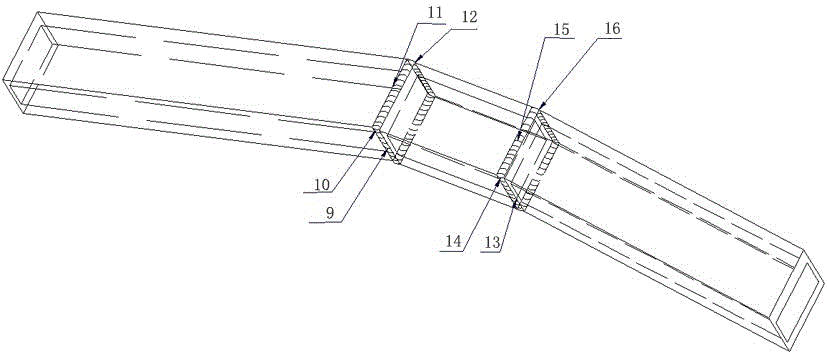

Optical fiber laser welding method of liquid crystal display support

ActiveCN105328340ALow defective rate of laser weldingIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesFillet weldLiquid-crystal display

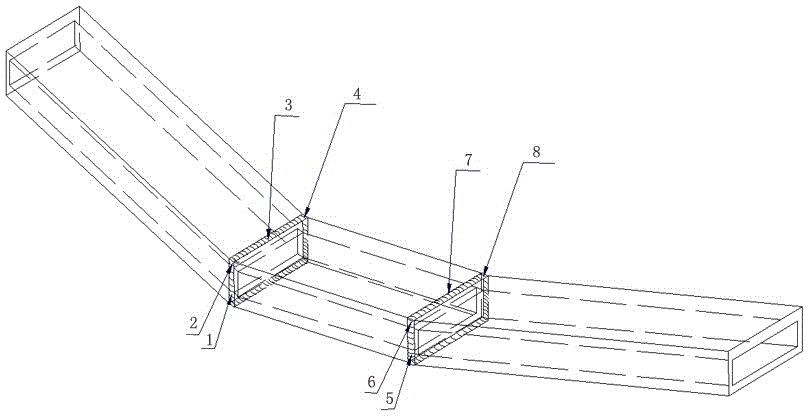

The invention relates to a welding forming method of a liquid crystal display support, in particular to a method for welding the liquid crystal display support by means of advanced optical fiber laser. The method comprises the following steps that three sections of square tubes forming the support are placed on an automatic clamp and are in butt joint; and an optical fiber laser welding head is adjusted to reach the preset position, welding of a weld joint on the front face of the support is performed at first, the automatic clamp is driven to rotate by 180 degrees after welding is completed, and then welding of a weld joint on the back face of the support is performed. According to the technological parameters, optical fiber laser is continuous wave, the wavelength is 1064 nm, the laser power needed when a vertical weld joint and a flat weld joint are welded is 500-1000 W, the welding speed is 15-25 mm s<-1>, the laser power needed when a fillet weld joint is welded is 500-900 W, and the welding speed is 15-25 mm s<-1>. The method has the beneficial effects that compared with traditional welding methods, the laser welding defective rate of the liquid crystal display support is quite low, the automatic laser welding quantity production of the display support is achieved, the welding quality is ensured, the enterprise production efficiency is improved, and meanwhile the production cost of a single workpiece is lowered.

Owner:YANGJIANG KNIFESCISSOR HARDWARE RES INSTITUTION OF IND TECH

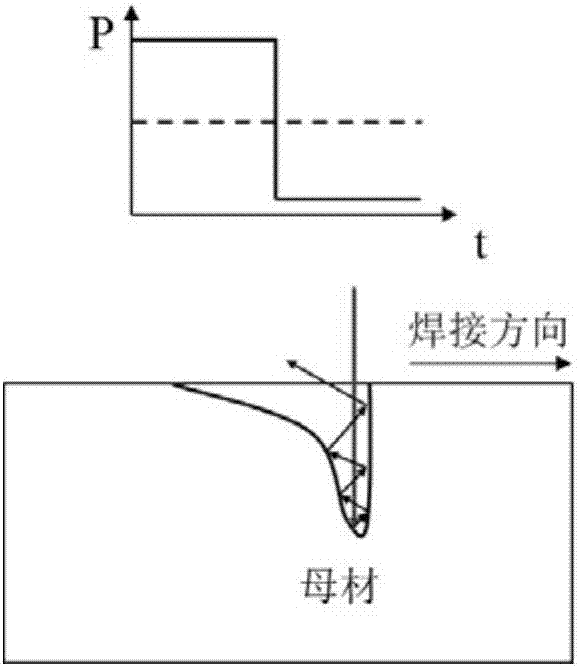

Method for improving fiber laser welding heat efficiency of red copper based on power modulation

InactiveCN107363401AHigh thermal efficiencyImprove transfer efficiencyLaser beam welding apparatusPower modulationEngineering

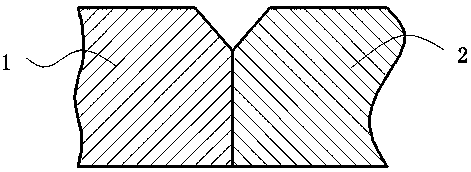

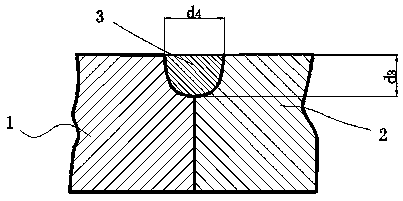

The invention discloses a method for improving the thermal efficiency of copper optical fiber laser welding based on power modulation, which comprises the following steps: providing an I-shaped groove between two pre-butted coppers, and then performing pretreatment on the surface of the I-shaped groove , and then complete the laser welding of two pre-butted coppers based on laser power modulation, wherein the waveform modulation method is used to realize the laser power modulation, which can effectively improve the thermal efficiency of copper fiber laser welding.

Owner:XI AN JIAOTONG UNIV

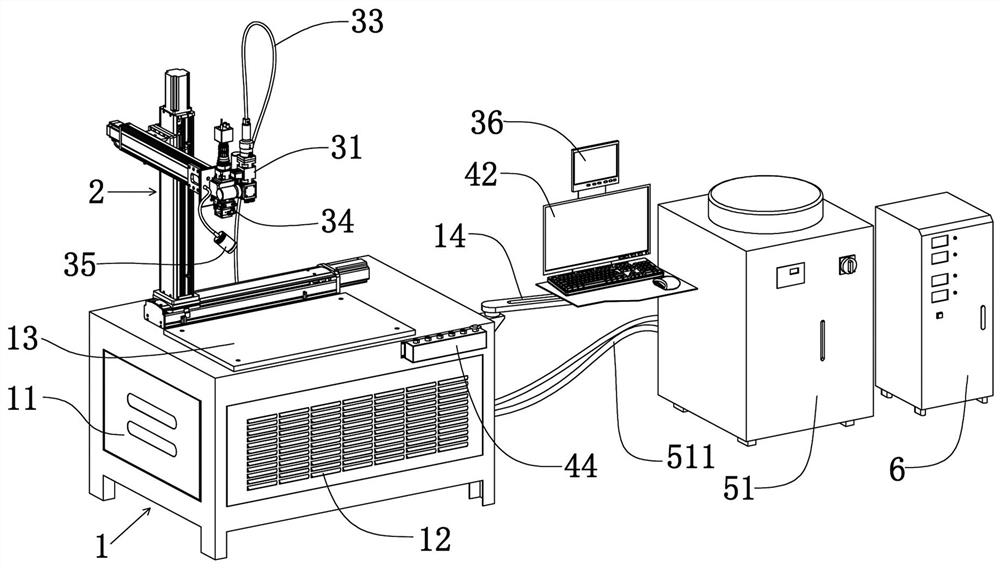

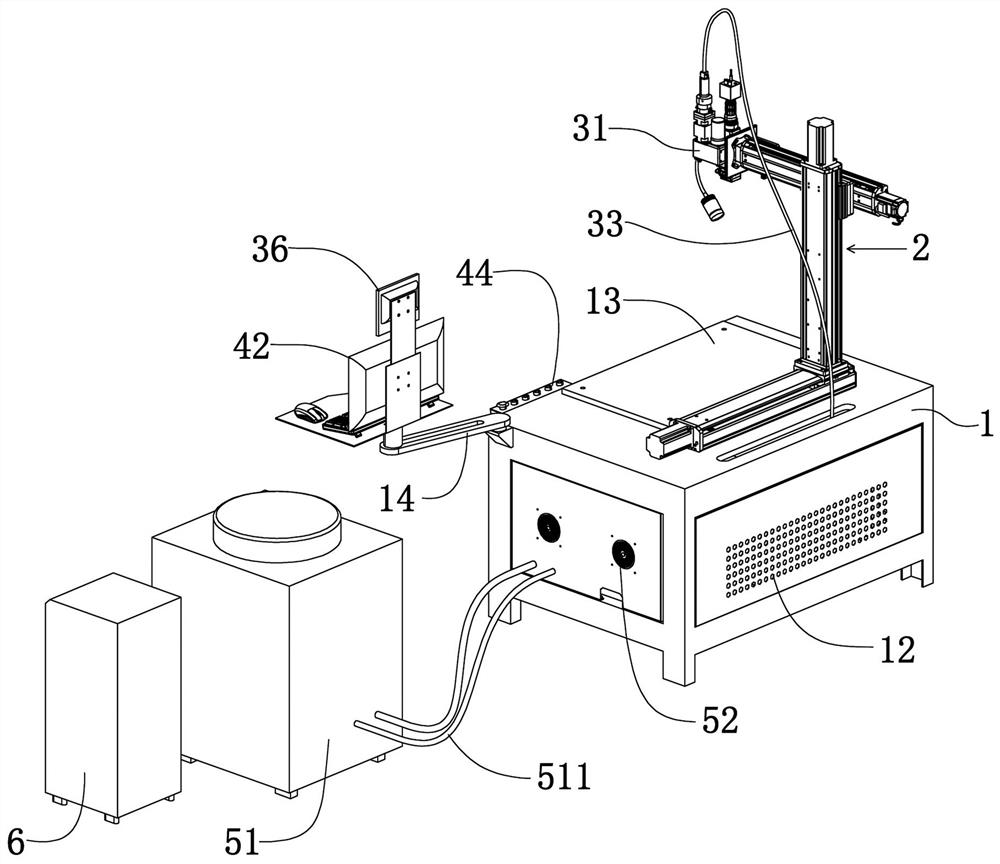

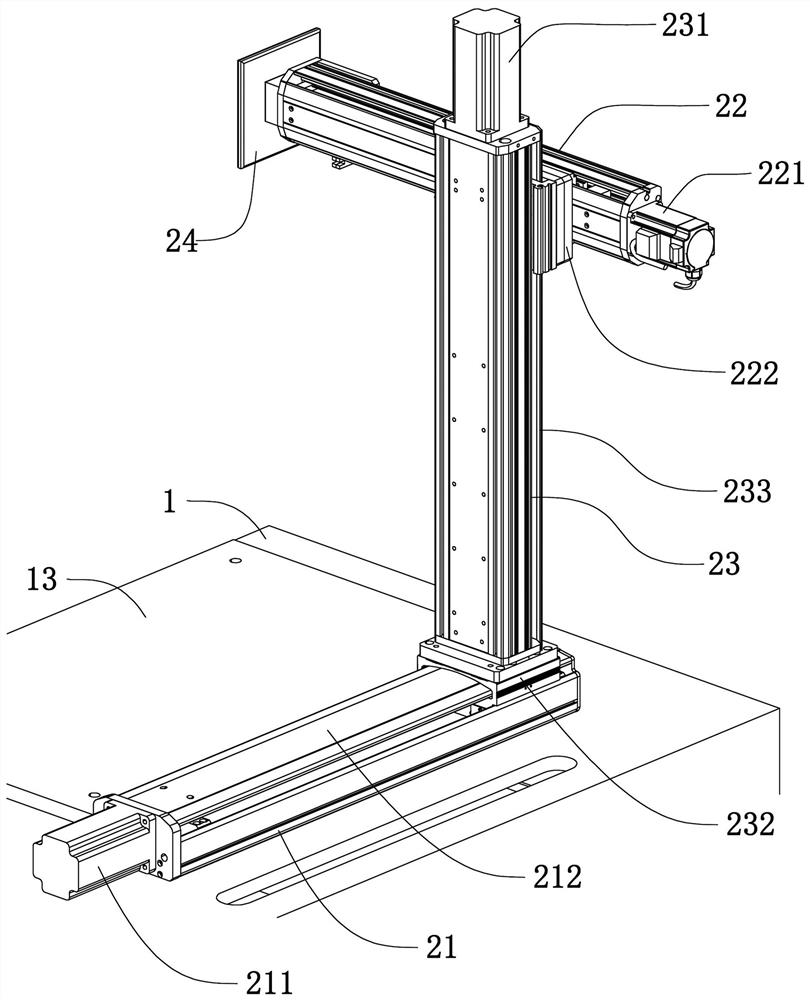

Four-axis optical fiber laser welding device

PendingCN111958114APrevent oxidationRealize automatic weldingLaser beam welding apparatusRotational axisControl system

The invention provides a four-axis optical fiber laser welding device and belongs to the technical field of welding equipment. The four-axis optical fiber laser welding device comprises a machine table, a welding mechanism, a locating mechanism, a cooling mechanism, a power supply mechanism and a control mechanism. The locating mechanism comprises an X-axis device horizontally and fixedly connected with the top surface of the machine table, a Z-axis device perpendicularly connected with the top surface of the X-axis device, a Y-axis device perpendicularly connected with the side face of the Z-axis device and a C-axis rotary shaft connected with one end of the Y-axis device. The welding mechanism comprises a laser welding head arranged on the C-axis rotary shaft, a laser generator arrangedinside the machine table and a gas shielding device. A control system comprises an industrial personal computer arranged inside the machine table, a displayer, a keyboard and a mouse, wherein the displayer, the keyboard and the mouse are arranged beside the machine table and matched with the industrial personal computer for use. The four-axis optical fiber laser welding device can realize automatic welding, substantially reduces the manual workload and the requirement for the special technical skills, reduces human errors and the manpower requirement and improves the production efficiency andproduct quality.

Owner:张斌

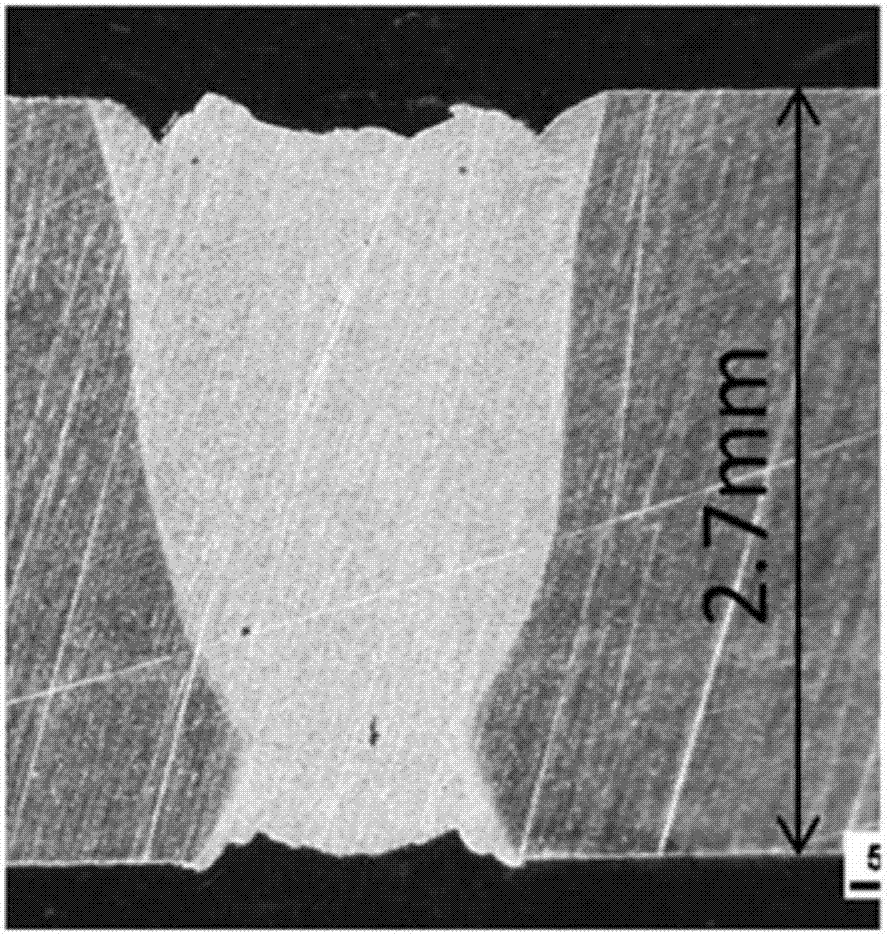

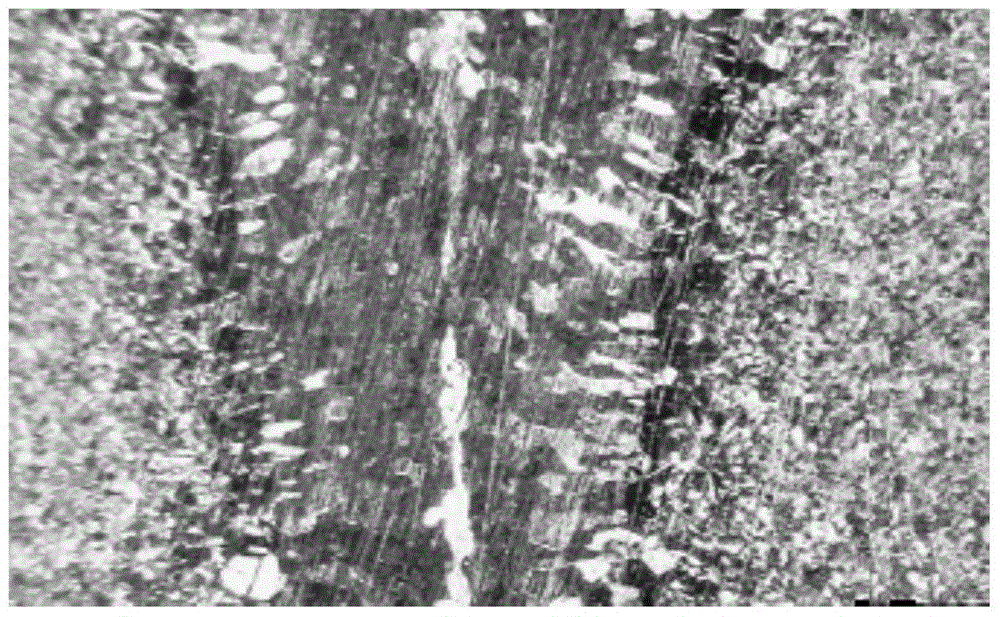

Method for improving weld penetration of optical fiber laser welding

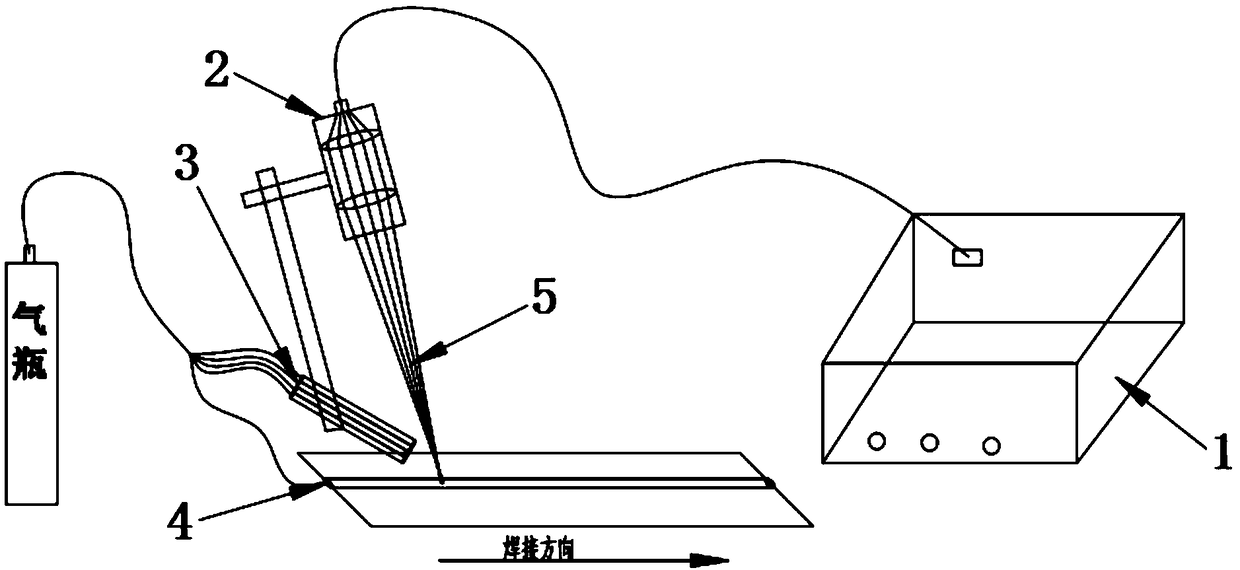

ActiveCN103612011AIncrease weld penetrationImprove welding efficiencyLaser beam welding apparatusGas compositionShielding gas

The invention discloses a method for improving weld penetration of optical fiber laser welding. In the optical fiber laser welding process, the weld penetration is realized through changing gas composition, namely, the mixed gas of inert gas and active gas is used as protection gas. The mixed gas comprises He-O2 mixed gas, wherein the proportion of O2 is 5%-20%, Ar-O2 mixed gas, wherein the proportion of O2 is 5%-20%, He-CO2 mixed gas, wherein the proportion of CO2 is 10%-50%, and Ar-CO2 mixed gas, wherein the proportion of CO2 is 10%-50%. The method has the advantages of increasing the depth of small laser holes and improving the weld penetration through adjusting the content of active gas in the protection gas.

Owner:CENT IRON & STEEL RES INST

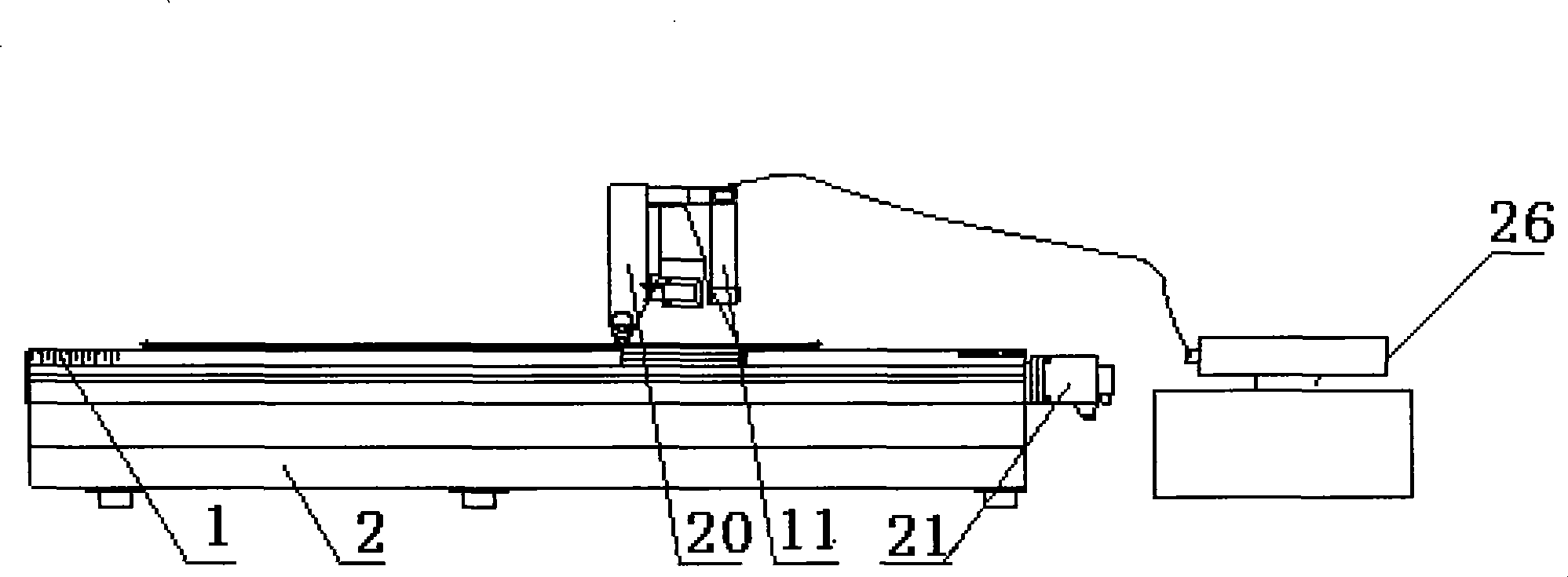

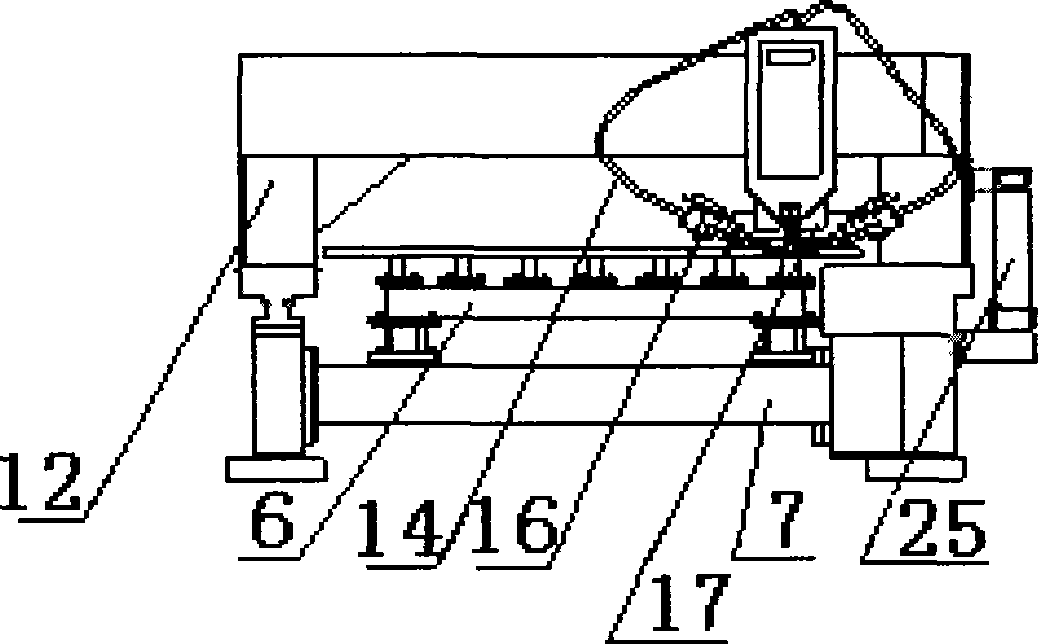

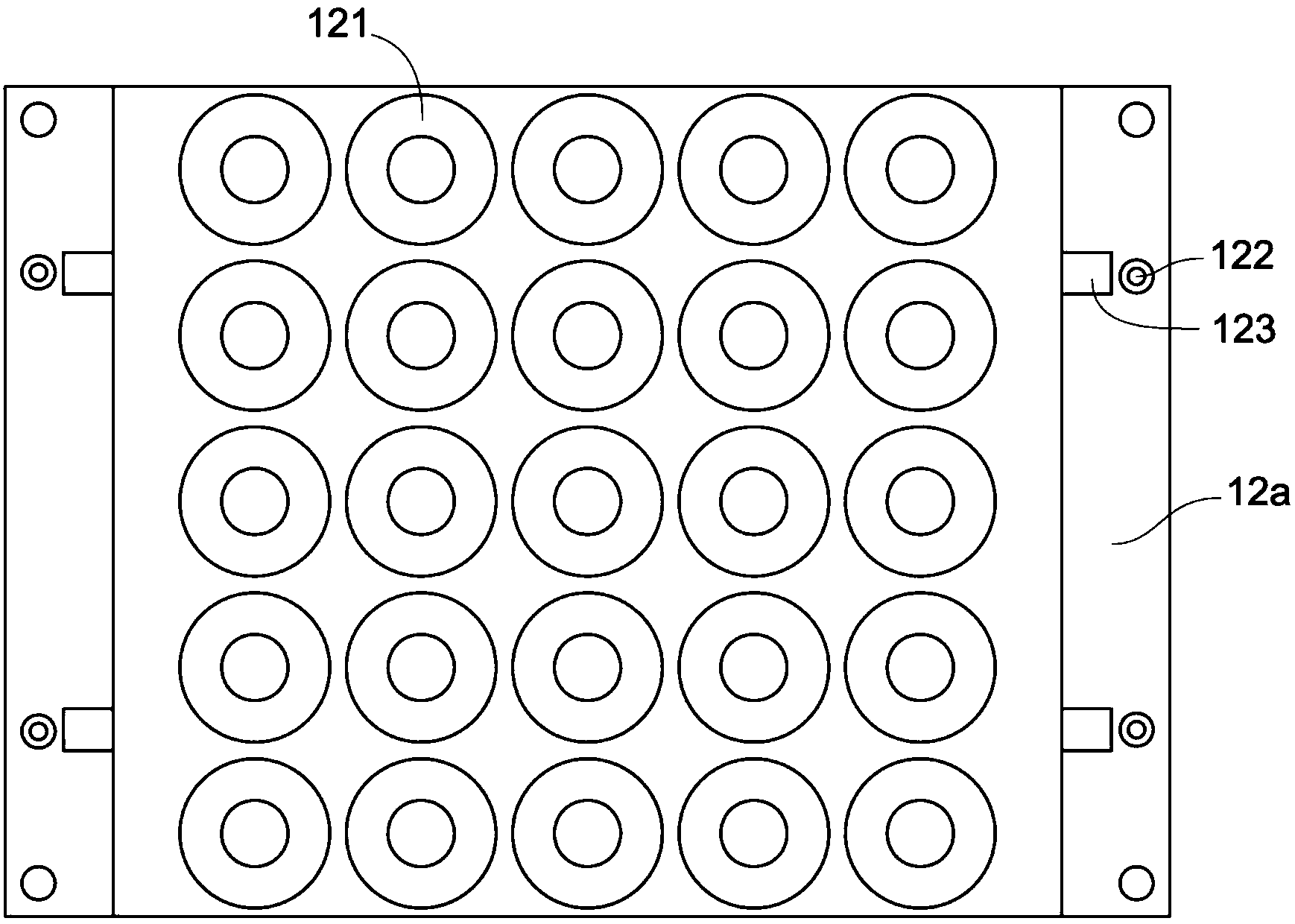

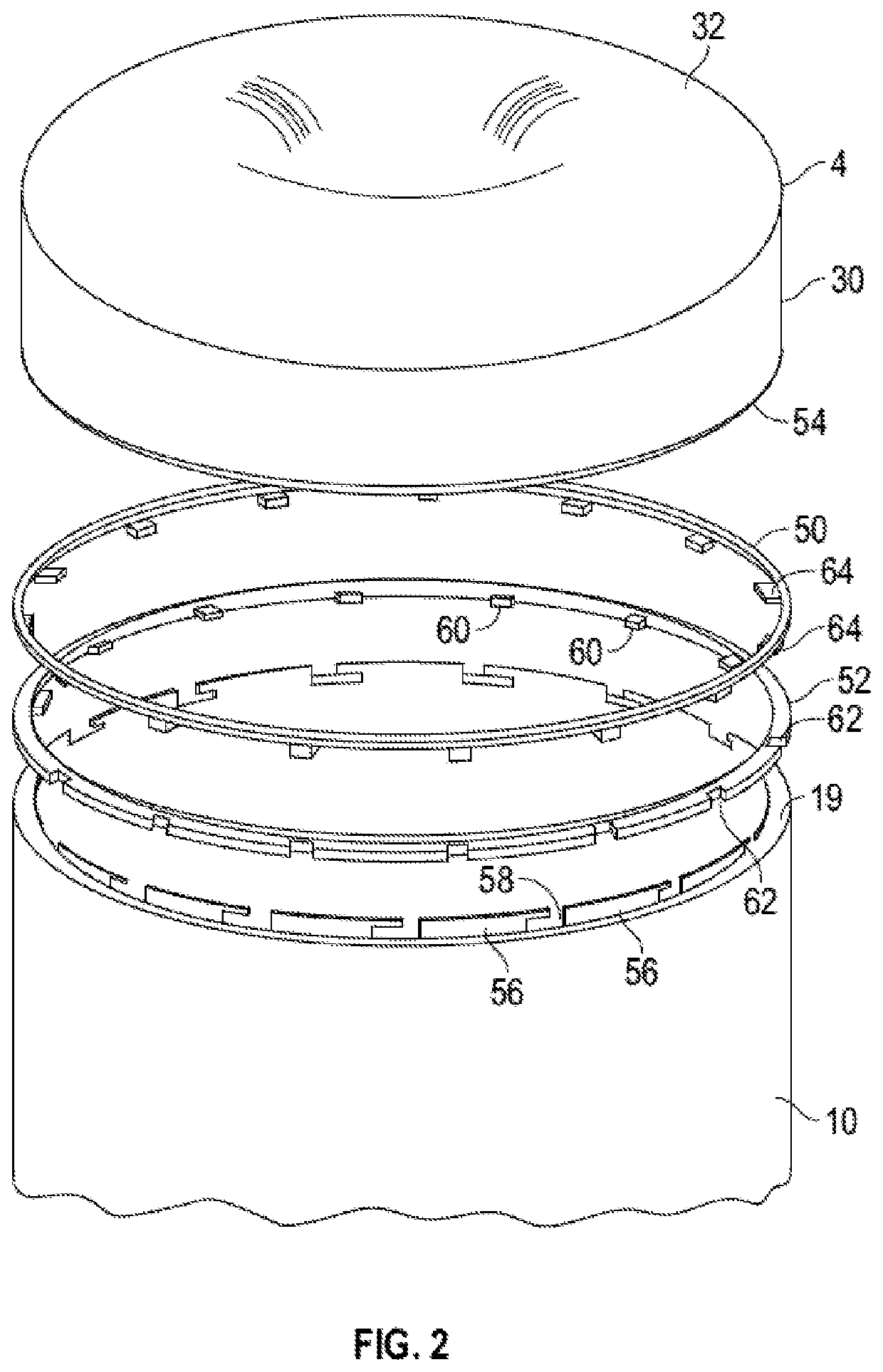

Pressing welding device and process for high-power optical fiber laser welding speed changer gear

InactiveCN104384731AImprove processing efficiencyReduce investmentWelding/cutting auxillary devicesAuxillary welding devicesLaserWelding process

The invention discloses a pressing welding device and process for a high-power optical fiber laser welding speed changer gear. A laser welding mechanism, a pressing mechanism, a carrying mechanism and a feeding and discharging station are arranged on a work table, a welding station is arranged under the laser welding structure, a pressing station is arranged under the pressing mechanism, the pressing welding device also comprises a gear clamp, the gear clamp comprises an upper layer gear ring clamp plate and a lower layer gear tray, a plurality of gear ring accommodating holes through which gear rings can pass are formed in the upper layer gear ring clamp plate, a gear ring support sheet mechanism for supporting the gear rings is arranged in the gear ring accommodating holes, a plurality of gear struts are arranged in the lower layer gear tray, the positions of the gear struts correspond to the positions of the gear ring accommodating holes, and a plurality of clamp plate positioning posts used for realizing the combination positioning with the upper layer gear ring clamp plate are also arranged on the lower layer gear tray. The pressing welding device and the pressing welding process have the advantages that the one-step pressing of a plurality of groups of gears and gear rings can be realized, the pressing and welding connection is good, and the processing efficiency of the speed changer gear is high.

Owner:CHONGQING LEIBAO LASER INTELLIGENT ROBOT MFG

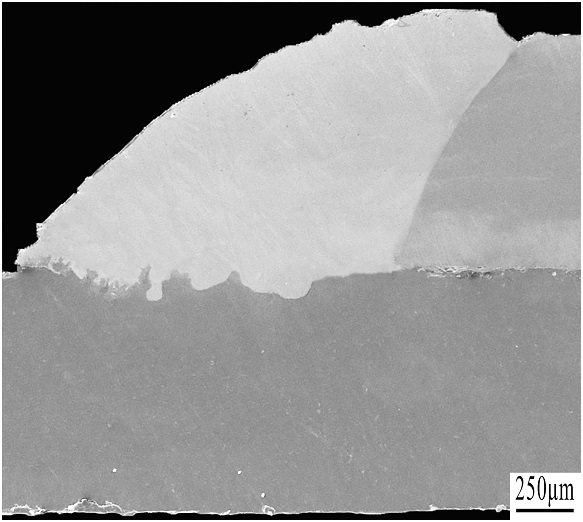

Method for high-speed optical fiber laser welding for pure titanium plate with thickness of 1mm

InactiveCN108655567APrevent splashImprove welding qualityWelding/soldering/cutting articlesMetal working apparatusFour jointedFiber laser welding

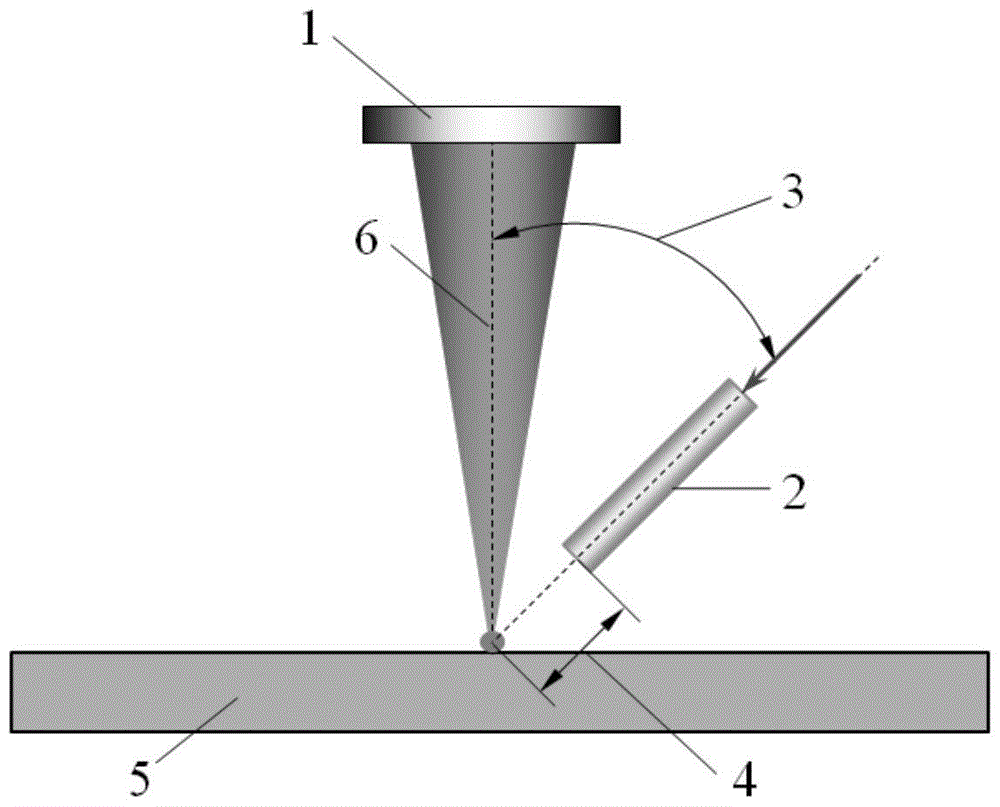

The invention relates to a method for high-speed optical fiber laser welding for a pure titanium plate with a thickness of 1mm. The method is carried out according to the following steps: (1) a laserbeam is focused onto the surface of the pure titanium plate with the thickness of 1mm through an optical system in a welding head, and the pure titanium plate absorbs laser and then is melted to formwelding joints; (2) the welding head is connected with argon gas provided by a joint-row protection gas pipe and a back surface protection gas chamber to protect the welding joints formed after melting; (3) the welding head is moved to weld the pure titanium plate; and (4) the diameters of the transmission optical fibers of the laser beam output by a laser device are 100[mu]m, the welding head forms an angle of 60-75 degrees with the horizontal direction, the focused spots of the laser beam output by the welding head are located at a +9mm position on the surface of the pure titanium plate withthe thickness of 1mm, the welding head is paraxially connected with the four-joint-row protection gas pipe to protect the welding joint in the front surface, the back surface protection gas chamber protects the welding joint in the back surface, until the whole welding process is concluded, so that welding with a speed of 9m / min, for the pure titanium plate with the thickness of 1mm, is realized,and the welding front surface and back surface are spatter-free after welding. The method disclosed by the invention is capable of effectively avoiding the spatter generated in the welding process; and meanwhile, the protective gas effectively prevents the welding joints from being oxidized, so that the welding quality and the product stability are guaranteed, the rejection rate is lowered, and the welding speed for the pure titanium plate with the thickness of 1mm is increased.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

Optical fiber laser welding method for double-layer tabs and bar sheet

PendingCN113118624AReliable weldingWelding/soldering/cutting articlesLaser beam welding apparatusBi layerCell fabrication

The invention belongs to the technical field of battery manufacturing, and particularly relates to an optical fiber laser welding method for double-layer tabs and a bar sheet. The method comprises the steps that (S1) the copper bar sheet, the copper tab and the aluminum tab are placed in sequence from bottom to top, the copper bar sheet, the copper tab and the aluminum tab are clamped through a clamp, and predetermined welding positions are arranged on the copper bar sheet, the copper tab and the aluminum tab; and (S2) a laser beam is emitted to the welding positions through a welding head of an optical fiber laser, the laser beam is a continuous wave, and the wavelength is 1064nm. The welding is conducted for the first time, the laser power ranges from 1500w to 1800w, and the welding speed ranges from 120mm / s to 150mm / s; and then the welding is conducted for the second time, the laser power ranges from 1000w to 1200w, and the welding speed ranges from 150mm / s to 180mm / s. Protective gas is conveyed to the welding positions in the welding process. According to the method, the reliable welding among the copper bar sheet, the copper tab and the aluminum tab can be realized.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

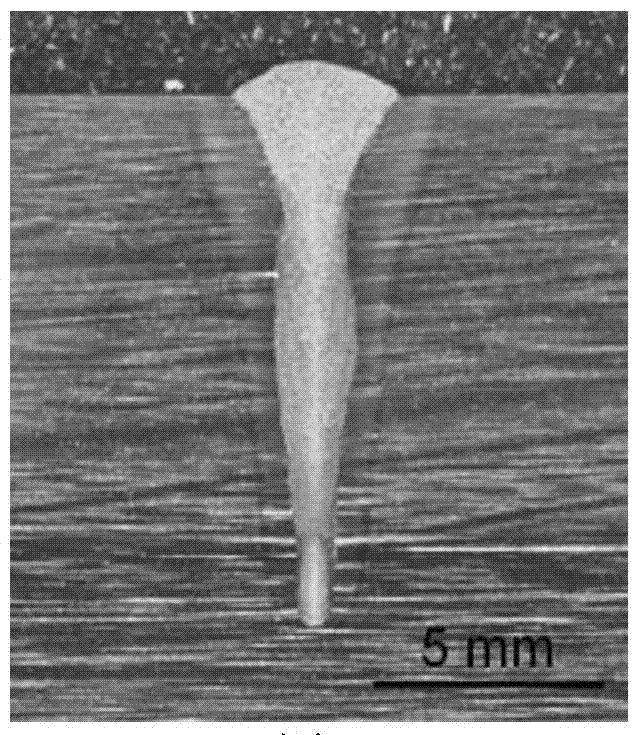

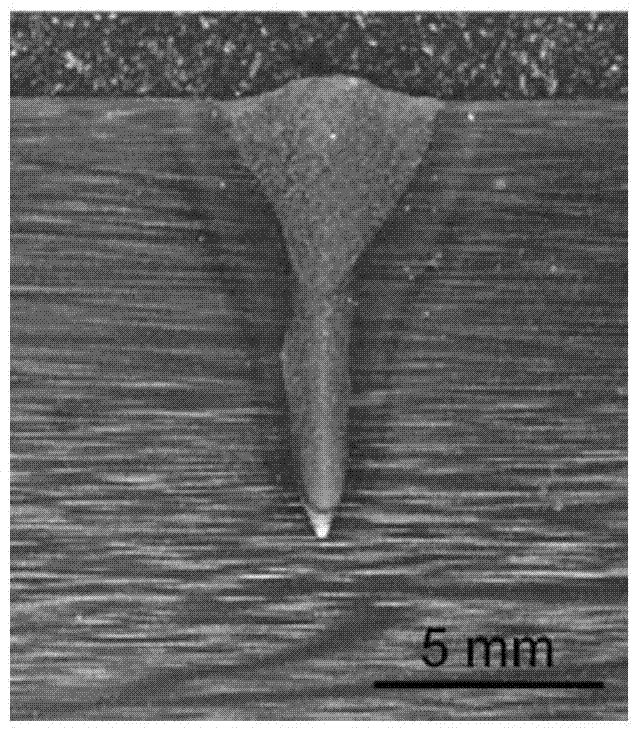

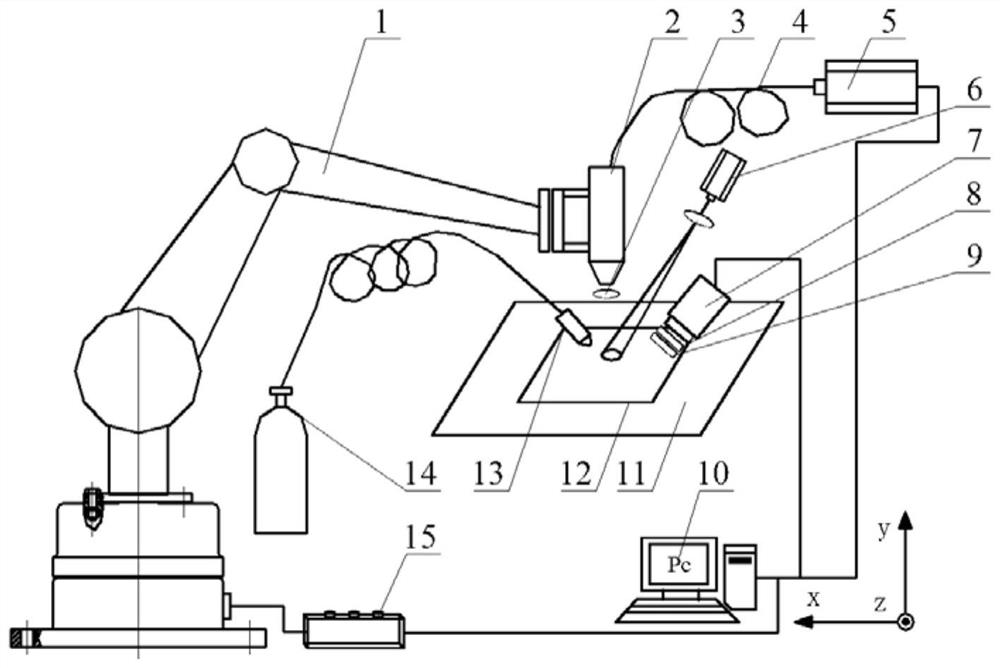

Online detection method for laser deep penetration welding defects and detection device

PendingCN112025090AEasy to separateAccurate separationLaser beam welding apparatusEngineeringWelding defect

The invention relates to an online detection method for laser deep penetration welding defects. In the welding process, an imaging system is used for extracting and storing shape contour images of small holes and penetrating holes in a molten pool formed in the welding process in real time, and on the basis of a pre-trained relation model between contour features of the images of the small holes and the penetrating holes and the fusion welding defects, on-line detection of the optical fiber laser welding quality is achieved. Establishment of a relation model between the contour features of theimages of the small holes and the penetrating holes and the welding quality is based on detection of a large amount of sample data, and training of feature data of the small holes and the penetratingholes is carried out by using a hidden Markov process. The invention further relates to a detection device applied to the online detection method. According to the online detection method and device,online defect detection and quality analysis in the optical fiber laser welding process are achieved, various defects possibly influencing the welding quality can be found conveniently in the weldingprocess, and the time and cost of later manual detection or X-ray detection are reduced.

Owner:SHANGHAI INST OF LASER TECH

Laser welding equipment for power battery anti-explosion valve

PendingCN107931839ARealize flexible light guideUniform weldingLaser beam welding apparatusPower batteryLight guide

The invention discloses laser welding equipment for a power battery anti-explosion valve. The laser welding equipment comprises an optical fiber laser welding head (1), a welding fixture (2) and a welding bench (3), wherein a positioning groove (2b) is formed in a movable block (2a) of the welding fixture (2), and a vacuum nozzle (2c) is arranged in the positioning groove (2b); the optical fiber laser welding head (1) comprises a composite lens focused coupling system and an optical fiber output focusing system, the composite lens focused coupling system is composed of a composite lens group,and the optical fiber output focusing system is composed of a collimating lens group and a focusing lens group. According to the laser welding equipment, an optical fiber transmission system can be optimally designed, so that the power density of high-power pulse solid laser meets the laser welding requirement after optical fiber transmission, flexible light guide of a pulse solid laser welding machine is realized, fine control over laser is realized, welding seams of the power battery anti-explosion valve are uniform, and bad phenomena of false welding, weld penetration, weld misalignment andthe like do not occur.

Owner:何琼

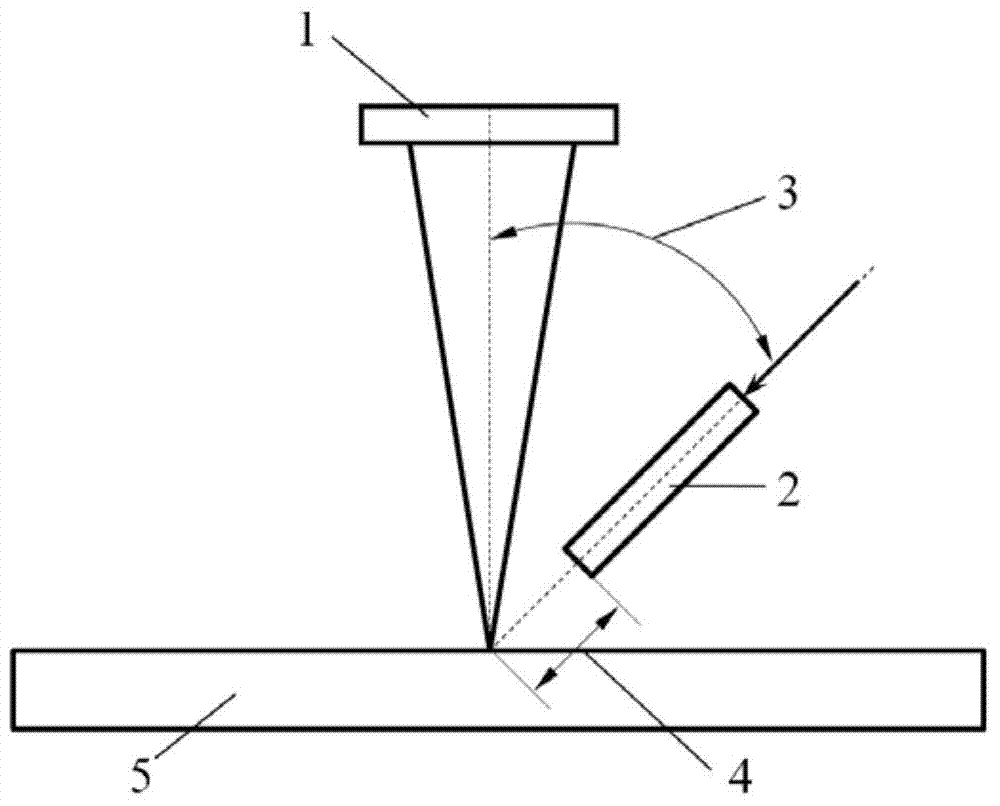

Laser welding method for dissimilar materials of titanium alloy and aluminum alloy

PendingCN113857669AImprove bindingGood macroscopic appearanceWelding/soldering/cutting articlesLaser beam welding apparatusHigh entropy alloysLap joint

The invention relates to a laser welding method for dissimilar materials of a titanium alloy and an aluminum alloy, and belongs to the technical field of laser welding and high-entropy alloys. Firstly, a workpiece to be welded is cleaned, then the workpiece to be welded is placed on a clamp, clamping force is applied through the welding clamp, the incident angle of lasers is adjusted to be 40 degrees-45 degrees, base metal is in lap joint, a titanium plate is arranged at the upper portion, and an aluminum plate is arranged at the lower portion; and the assembled workpiece is placed in a fiber laser welding chamber, prepared high-entropy alloy powder is preset at a lap joint, after welding parameters are adjusted, a laser beam is aligned with the center of a welding seam, laser welding is conducted on the workpiece to be welded, the high-entropy alloy powder is firstly melted in the welding process, due to the fact that the laser beam completely irradiates the high-entropy alloy powder, reflection of the base metal to the lasers is avoided, the base metal is melted through heat convection and heat conduction by means of heat transmitted by a molten pool, the melting amount of the base metal is reduced, and natural cooling is achieved. The energy utilization rate is increased, and the laser weldability of the TC4 titanium alloy / 6082 aluminum alloy dissimilar materials is greatly improved.

Owner:JILIN UNIV

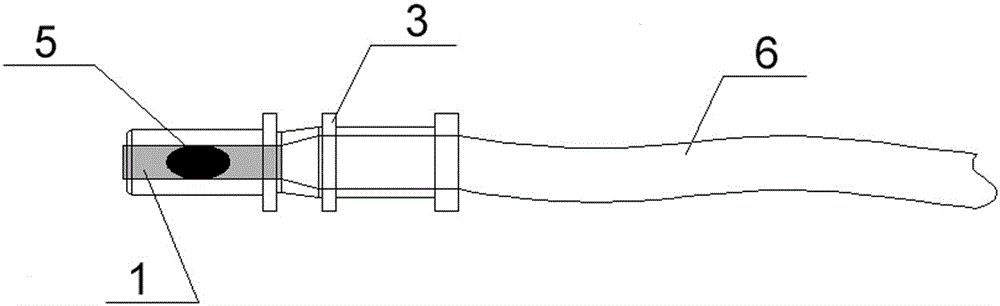

Plastic optical fiber laser-welding technique and application thereof

InactiveCN105817763AReduce degradationReduce debrisLaser beam welding apparatusPlastic optical fiberSemiconductor

The invention provides a plastic optical fiber laser-welding technique. The plastic optical fiber laser-welding technique is characterized in that a plastic ferrule is welded to an inner jacket of a plastic optical fiber through a semiconductor laser-welding technique. Through laser welding, precise, firm and sealed weld joints can be formed, the resin degradation quantity is small, and few chips are generated; through the non-contact property of laser, no pollution is generated; and the vibrating stress and thermal stress generated by laser welding are smaller than the vibrating stress and thermal stress generated by other connection ways, and the aging speed of the interior of the optical fiber can be effectively decreased.

Owner:CHANGZHOU HUASHENG FUTAO PHOTOELECTRIC SCI ANDTECH CO LTD

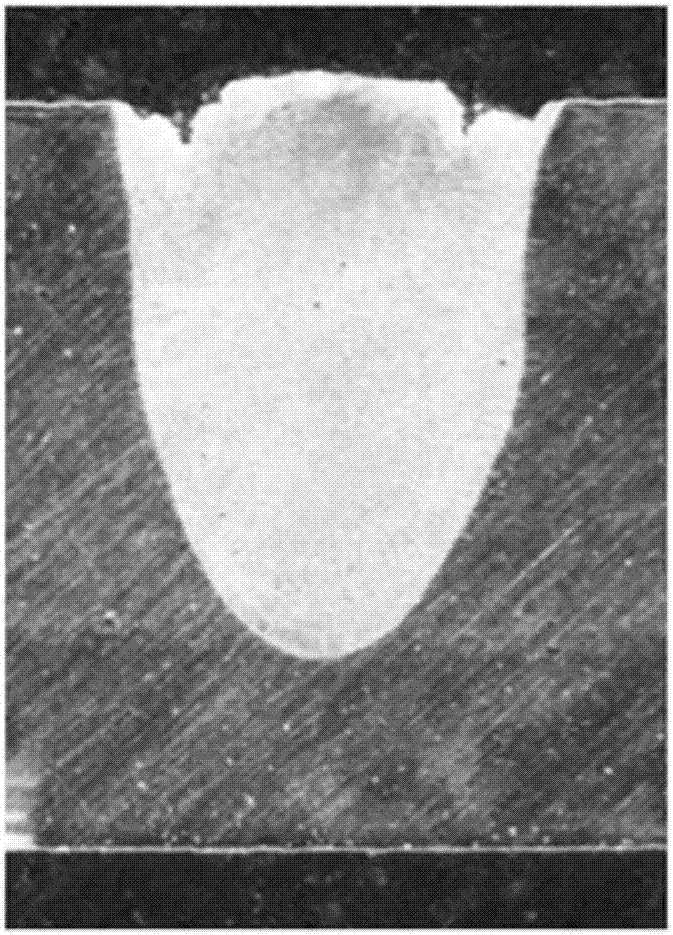

Plate welding method

ActiveCN109500497AImprove stabilityAvoid local evaporationArc welding apparatusLaser beam welding apparatusRare-earth elementEngineering

The invention relates to a laser plate welding method. The method is characterized by comprising the following steps that S1, a first parent material and a second parent material are machined to formbutt-joint end surfaces and groove surfaces, and impurities on the upper surfaces, the lower surfaces, the butt-joint end surfaces and the groove surfaces of the first parent material and the second parent material are removed; S2, the first parent material and the second parent material are accurately connected and clamped in a butt-joint manner; S3, welding rods added with rare earth elements are provided; S4, a manual consumable-electrode metal-inert gas welding (MIG) method is adopted, and butt-joint grooves of the first parent material and the second parent material are welded; and S5, high-power optical fiber laser beams formed by laser welding head focusing irradiate on the surfaces of MIG welding seams, and then penetration welding of the first parent material and the second parentmaterial is achieved. According to the method, a welding seam layer which is rich in rare earth elements is loaded in the upper portion of small-hole welding plates, and the surface tension of the front wall of each small hole is effectively improved in the laser welding process, so that a smooth small hole wall form is obtained, the stability of the optical fiber laser welding process is improved, and the defects of splashing, root leakage and the like are avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A Fiber Laser Welding Method for Reducing Welding Spatter

ActiveCN105345258BImprove stabilityDegree of reductionWelding/soldering/cutting articlesMetal working apparatusPeak valueLaser

The invention belongs to the technical field of laser welding, and particularly relates to an optical fiber laser welding method for reducing welding spatter. The method adopts triangular-wave pulses to modulate laser power, wherein pulse peak-value power is 5-10kW; basic-value power is 2-4kW; pulse frequency is 15-125Hz; and triangular-wave pulse rising time is 3-7ms. According to the optical fiber laser welding method, by modulating the laser power, laser keyhole stability is improved and welding spatter is reduced.

Owner:CENT IRON & STEEL RES INST

Fiber laser welding method for liquid crystal display bracket

ActiveCN105328340BLow defective rate of laser weldingIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesFillet weldLiquid-crystal display

The invention relates to a welding forming method of a liquid crystal display support, in particular to a method for welding the liquid crystal display support by means of advanced optical fiber laser. The method comprises the following steps that three sections of square tubes forming the support are placed on an automatic clamp and are in butt joint; and an optical fiber laser welding head is adjusted to reach the preset position, welding of a weld joint on the front face of the support is performed at first, the automatic clamp is driven to rotate by 180 degrees after welding is completed, and then welding of a weld joint on the back face of the support is performed. According to the technological parameters, optical fiber laser is continuous wave, the wavelength is 1064 nm, the laser power needed when a vertical weld joint and a flat weld joint are welded is 500-1000 W, the welding speed is 15-25 mm s<-1>, the laser power needed when a fillet weld joint is welded is 500-900 W, and the welding speed is 15-25 mm s<-1>. The method has the beneficial effects that compared with traditional welding methods, the laser welding defective rate of the liquid crystal display support is quite low, the automatic laser welding quantity production of the display support is achieved, the welding quality is ensured, the enterprise production efficiency is improved, and meanwhile the production cost of a single workpiece is lowered.

Owner:YANGJIANG KNIFESCISSOR HARDWARE RES INSTITUTION OF IND TECH

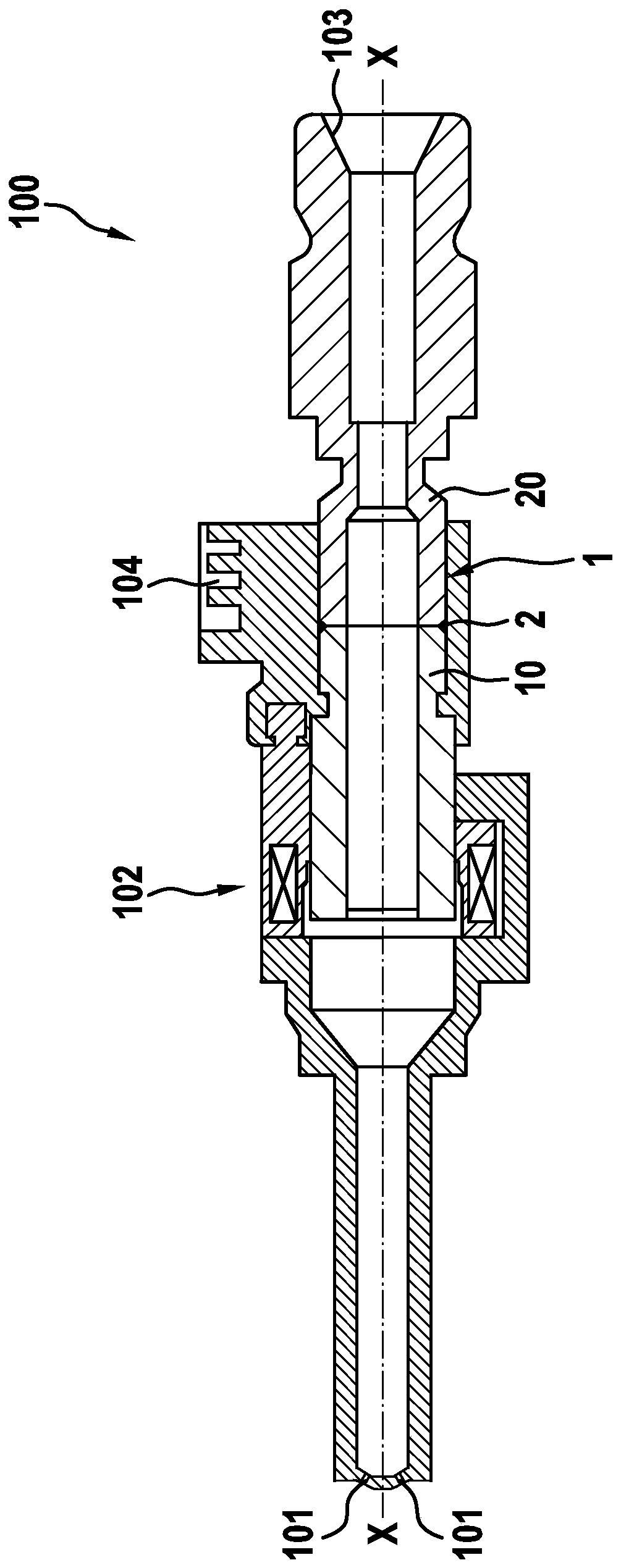

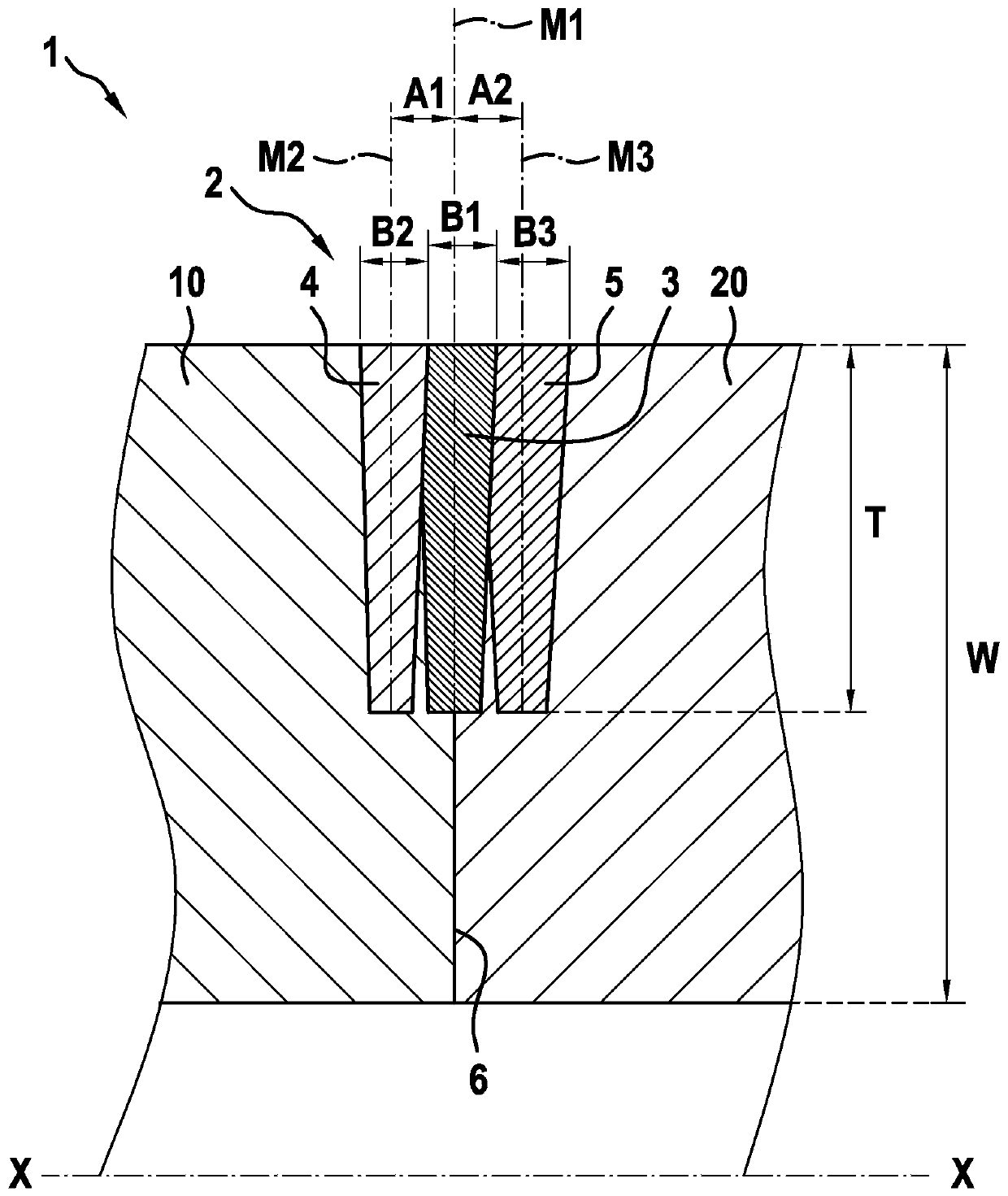

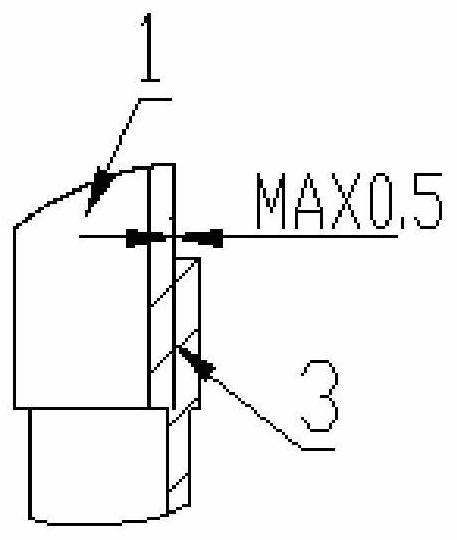

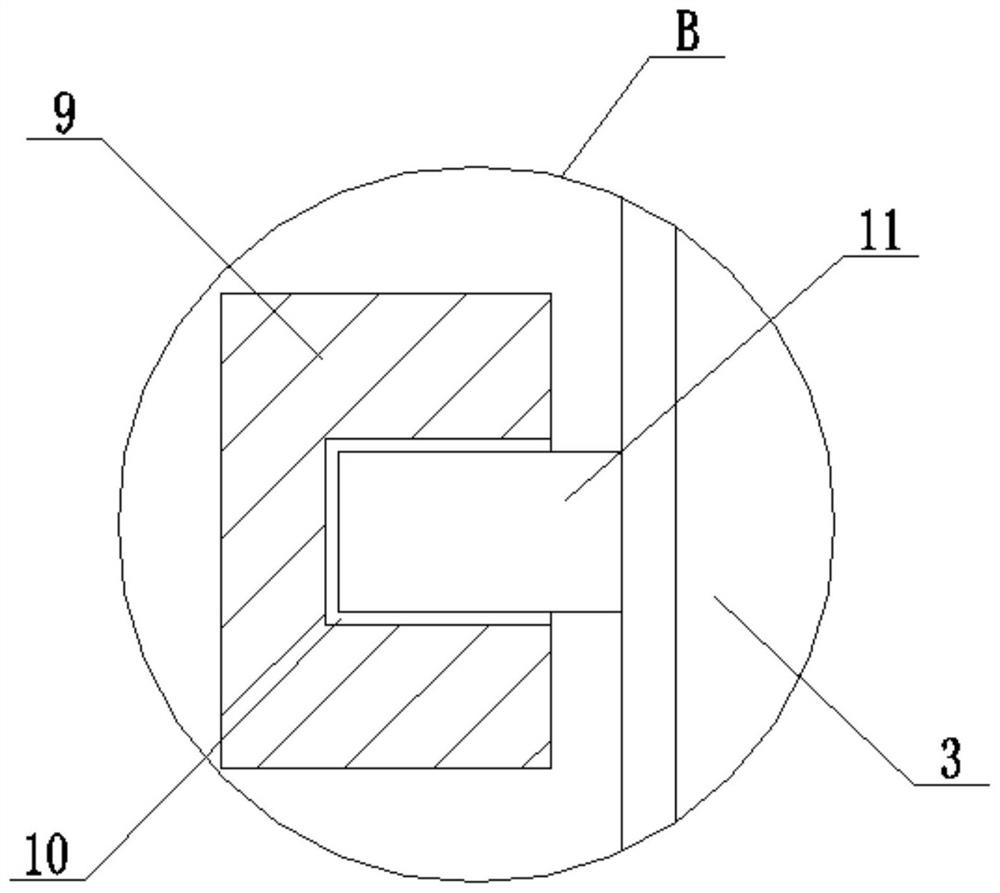

Component assembly with fiber laser welded joint and method for this

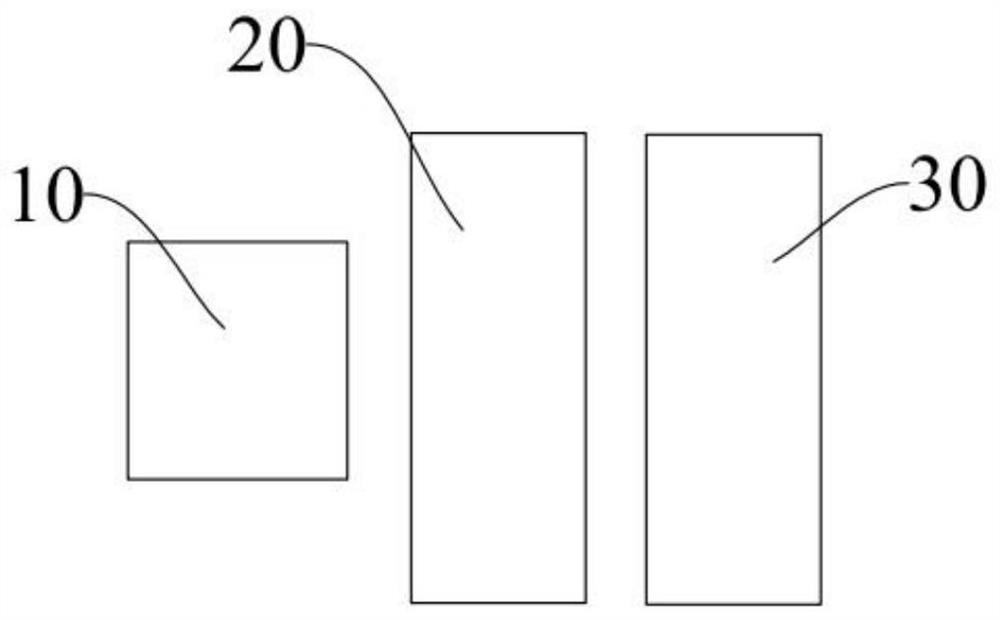

PendingCN110280901AHigh strengthAvoid Weld FailureWelding/cutting auxillary devicesCombustion enginesWeld seamEngineering

The invention relates to a component assembly, comprising a first component (10), a second component (20), and an optical fiber laser welding connection (2) disposed between the first component (10) and the second component (20), which can connect the first component to the second component at a bonding gap (6). The optical fiber laser welding connection (2) at least includes a first welding seam (3) and a second welding seam (4), which are arranged in parallel in a manner of mutually contacting. The invention also relates to a method for manufacturing the optical fiber laser welding connection.

Owner:ROBERT BOSCH GMBH

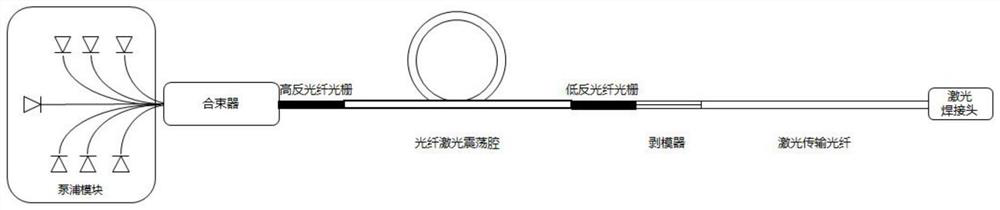

High-power optical fiber laser welding machine

ActiveCN102513693BAvoid nonlinear effectsSolve the thermal effectExcitation process/apparatusLaser beam welding apparatusDouble-clad fiberEngineering

The invention relates to the technical field of welding equipment, and particularly relates to a high-power optical fiber laser welding machine. The purpose of the high-power optical fiber laser welding machine is to reduce the heating effect of a coupling node, increase the output power, and definitely segment the coupling number and the best coupling distance in the optical fiber laser welding process. The high-power optical fiber laser welding machine is characterized in that the laser welding machine comprises a coupled doubly-clad optical fiber, a mechanical arm and a pure optical-fiber coupled optical fiber laser, and the pure optical-fiber coupled optical fiber laser is obtained through a segmented encouraging mode. The segmented encouraging mode determines the segmented coupling number according to the output power of a total laser, welding loss, optical fiber loss of an outsourcing layer and single-segment incentive semiconductor power. The light-light conversion rate and the output power are increased, and the heating effect and nonlinear effect and mode worsening caused by strong laser single points are avoided. The high-power optical fiber laser welding machine is suitable for cooling of a pumping source, and the service life is prolonged.

Owner:杭州奥克光电设备有限公司

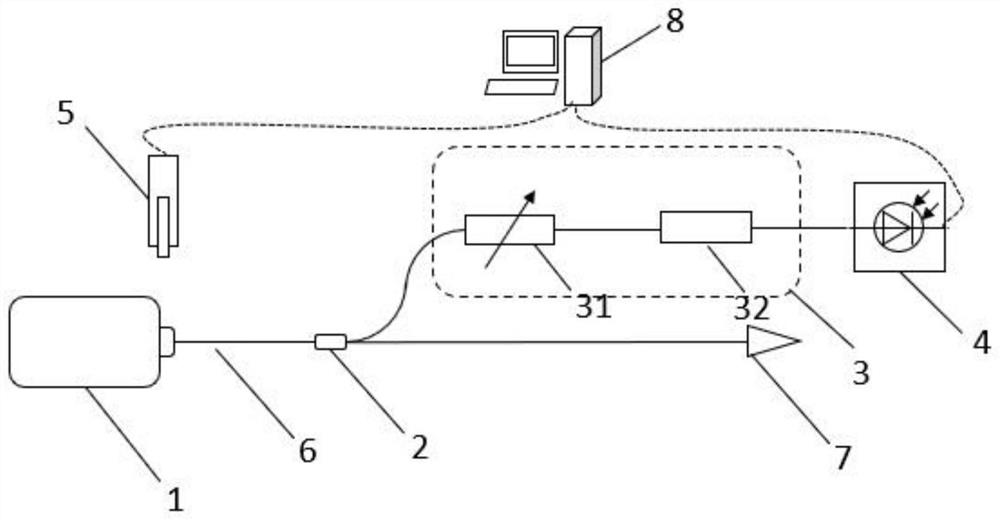

Optical fiber laser welding machine online monitoring system, application and optical fiber laser welding machine

PendingCN114682940AJudging the working statusAccurately judge the laser output qualityLaser beam welding apparatusEngineeringMechanical engineering

The invention discloses an optical fiber laser welding machine online monitoring system, application and an optical fiber laser welding machine. The system comprises an optical splitter, a detection light path and a photoelectric detector, the optical splitter is connected with a laser transmission optical fiber of the optical fiber laser welding machine or is arranged in a welding head light path, and is used for sampling output laser and inputting detection light obtained by sampling into a detection light path; the detection light path at least comprises a filter for selecting a detection wave band; the filter is used for selecting an optical signal of a Raman optical band; and the photoelectric detector is connected with the output of the detection light path and is used for detecting the optical power of the detection wave band output by the detection light path. The system is applied to online monitoring of the high-power continuous laser welding machine, optical power signals of Raman optical bands are monitored in real time, full-band output spectrum analysis is replaced, and laser output quality can be accurately judged while real-time response and online monitoring are achieved, so that the working state of the laser welding machine is judged.

Owner:武汉镧芯光电技术有限公司

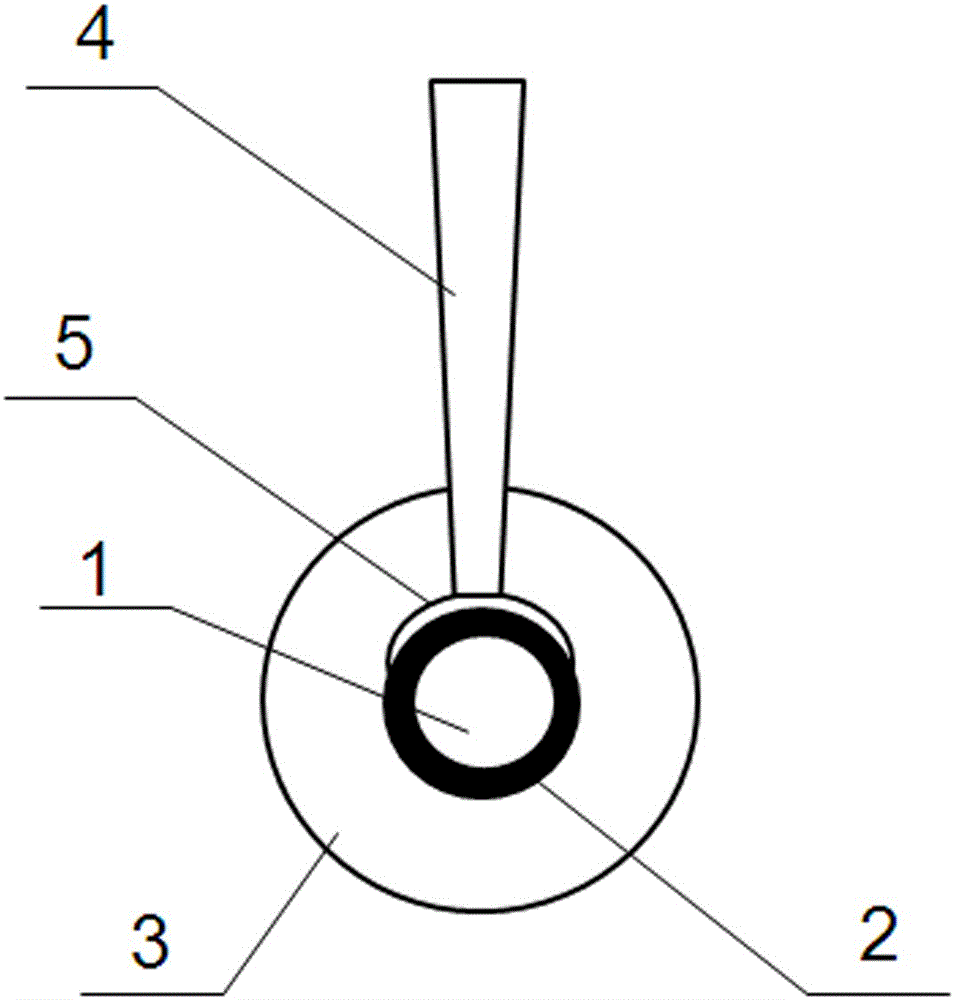

Thick core optical fibre laser welder and welding method

InactiveCN100451702CHeating power can be controlled preciselyHeating evenlyLaser detailsCoupling light guidesFocal positionOptoelectronics

It is a coarse fiber laser welding device and welding method for coarse fiber welding, using a small 100-watt CO2 laser as light source, and using an oral-shaped lens to form the laser beam of the laser to the ring beam, and bowl-shape mirror respecting this ring laser beam to the focus in the center of the bowl-shape mirror, and the welding fiber is placed on the position of focus. There is a hole in the center of the bowl-shape mirror, and the fiber passing through this hole, making the fiber welding part locating in the center of the bowl-shape mirror focus, and after the ring laser focusing, it can uniform irradiate on the welding position around the fiber. Control power and power output time of CO2 laser, to weld different diameter fibers. The invention solves the welding problem of the coarse fiber, making the fiber welding point uniform and smooth.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Laser-welded compressor shell body and welding method thereof

PendingCN111687532AStrong toughnessImprove toughnessPositive displacement pump componentsPositive-displacement liquid enginesThermal deformationEngineering

The invention discloses a laser-welded compressor shell body. The laser-welded compressor shell body comprises a lower shell body (2) and an upper cover (1) matched with the lower shell body, and theshape of the connection section of the upper cover (1) and the lower shell body (2) is elliptical; the upper cover (1) and the lower shell body (2) are matched by a spigot; and the maximum clearance of the spigot matching is 0.5 mm. The invention further discloses a laser welding method of the compressor shell body. According to the technical scheme, the continuous laser welding is achieved, the welding efficiency is high, and the welding strength is higher than base metal cold rolled steel or hot rolled steel; the welding joint strength is high; the appearance is neat and beautiful; and fiberlaser welding is based on the fusion of a self shell plate to for a molten pool connection, a welding wire is eliminated, the thermal deformation area is small, thus the damage of laser heat conduction to a pump body enclosed in the shell body is greatly reduced, the product cost is lowered, and the appearance quality and reliability of the product are improved.

Owner:WUHU ABAUR MECHANICAL & ELECTRICAL

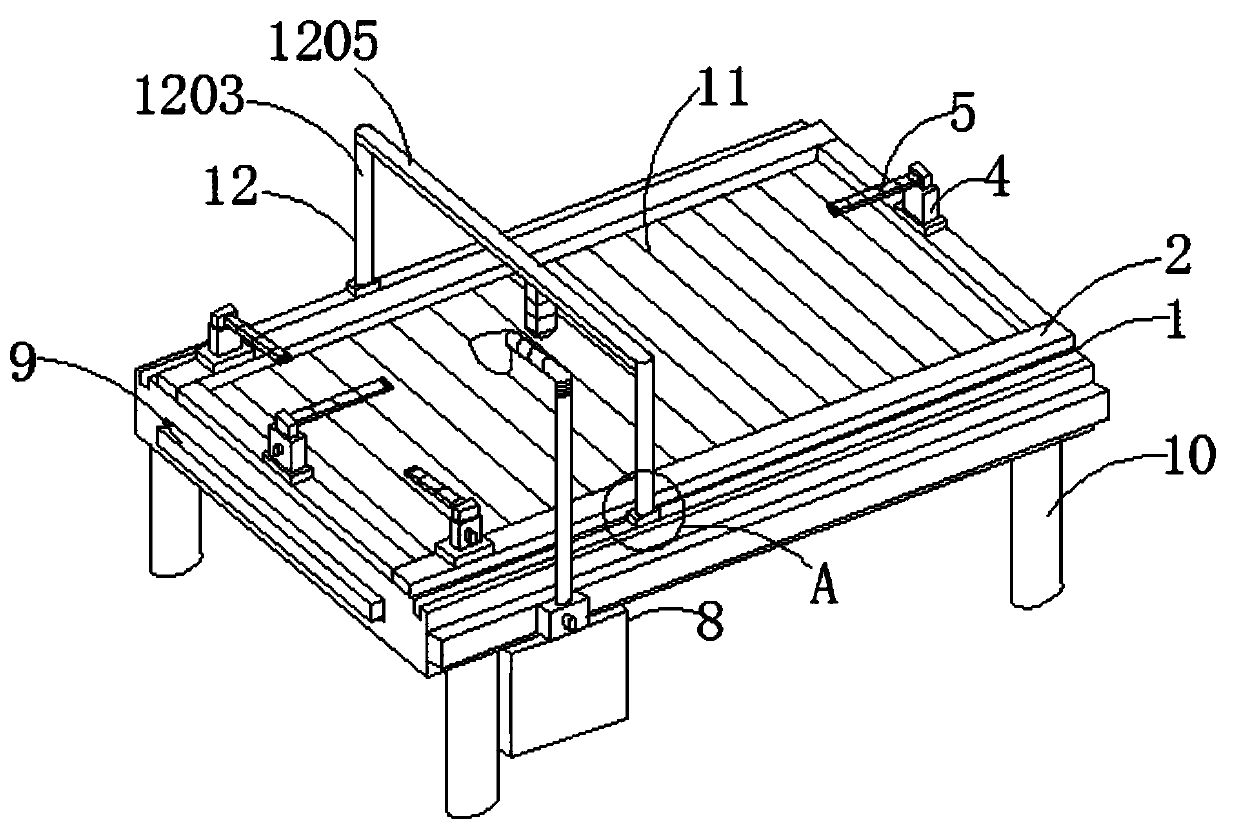

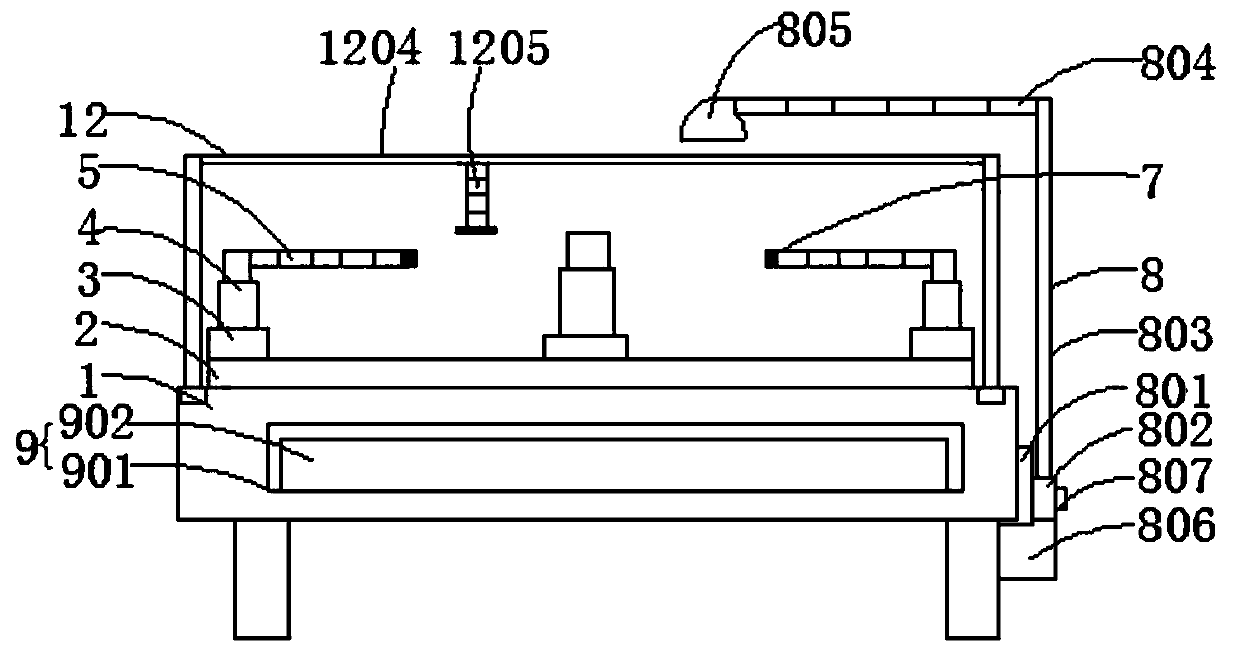

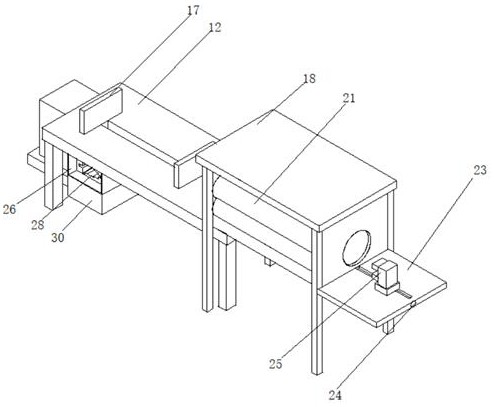

Multi-station intelligent fiber laser welding machine work platform

PendingCN110076454ASimple structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesSlagMarine engineering

The invention provides a multi-station intelligent fiber laser welding machine work platform and relates to the technical field of welding equipment. The multi-station intelligent fiber laser weldingmachine work platform comprises a work platform body. Four rails are arranged on the periphery of the upper end of the work platform body. Sliding blocks are installed on the rails, and supporting plates are vertically installed at the upper ends of the sliding blocks. Telescopic rods are horizontally arranged on the sides, facing the work platform body, of the supporting plates, and control switches used for controlling the length of the telescopic rods are installed on the side walls of the supporting plates. A smoke absorbing device is arranged on one side of the work platform body, and a welding slag collecting device is arranged in the work platform body. By means of the multi-station intelligent fiber laser welding machine work platform, due to cooperation of the rails and the sliding blocks, the length of the telescopic rods is adjusted so that a welded part can be tightly fixed through the four telescopic rods, the smoke absorbing device can absorb and treat the smoke generatedby welding in time, and the welding slag collecting device can conduct unified collecting and treatment on welding slag. The whole device is simple in structure and convenient to operate, it is ensured that welding is conducted accurately and efficiently, and practicability is high.

Owner:XUZHOU COLLEGE OF INDAL TECH

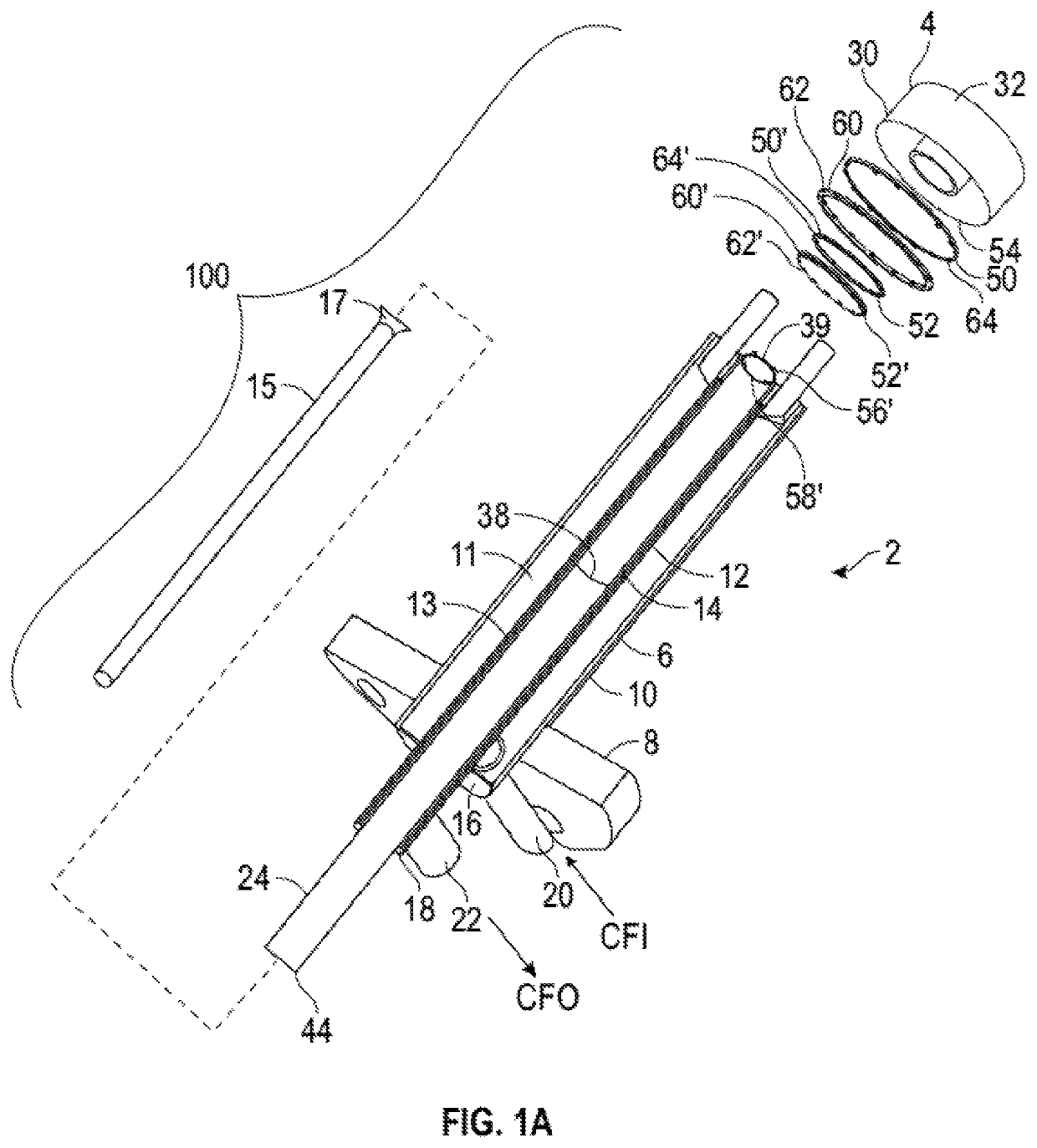

Combustion burner

Submerged combustion burners having a burner body and a burner tip connected thereto. The burner body has an external conduit and first and second internal conduits substantially concentric therewith, forming first and second annuli for passing a cooling fluid therethrough. The burner includes a generally central flow passage for a combustible mixture, the flow passage partially defined by an inner wall of the burner tip. The burner tip has an outer wall and crown connecting the inner and outer walls. The inner and outer walls and crown comprise materials having greater corrosion and / or fatigue resistance than the burner external conduit. The burner tip is connected to the burner body by inner and outer connections, at least one of which includes members interference fit to the burner tip and burner body, the members welded, soldered, or brazed together, in certain instances by fiber laser welding.

Owner:JOHNS MANVILLE CORP

Automatic laser welding system for metal straps for power battery pole lugs

PendingCN112917009AGood welding performanceNo poresLaser beam welding apparatusPower batteryButt welding

The invention relates to the technical field of laser welding, and discloses an automatic laser welding system for metal straps for power battery pole lugs. The automatic laser welding system for the metal straps for the power battery pole lugs comprises an equipment host; metal strap pressing devices are symmetrically connected to a welding station of the equipment host; a material strap optical fiber laser welding machine is arranged on one side of the equipment host; a welding gun is connected to the material strap optical fiber laser welding machine through a cable; and the welding gun is arranged between the two metal strap pressing devices and connected with the equipment host through a moving mechanism. According to the automatic laser welding system for the metal straps for the power battery pole lugs, multifunctional automatic welding such as spot welding, butt welding, stitch welding and sealing welding of the material strips can be achieved, the welding effect is good, welding seams are smooth, no air hole exists, the positioning precision is high, the welding gun can evenly and fully weld the connecting position of the two metal material strips, and the welding requirement is met.

Owner:三铃金属制品(东莞)有限公司

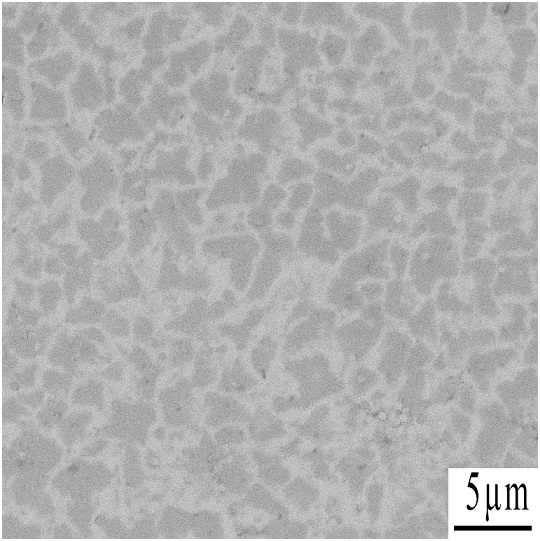

A method of fiber laser welding thick copper plate

ActiveCN104646825BEvenly dispersedImprove cleanlinessRadiation-absorbing paintsWelding/soldering/cutting articlesParticulatesWater based

The invention is suitable for the field of a laser welding process, and provides a method for welding a thick copper plate by a fiber laser. The method comprises the following steps of spraying a welding line of the thick copper plate with a light absorbing coating layer, and welding the welding line, which is sprayed with the light absorbing coating layer, of the thick copper plate by focused laser emitted from the fiber laser, wherein the coating of the light absorbing coating layer comprises light absorbing coating and water-based resin; the light absorbing coating consists of the following components in mass percent: 50-60 percent of ZnO submicron particulates, 20-25 percent of Al2O3 submicron particulates, 20-25 percent of TiO2 submicron particulates; the mass percent sum of all the components is 100 percent. By preinstalling a layer of self-developed light absorbing coating on the surface of the thick copper plate, the energy utilization rate when the thick copper plate is welded by the fiber laser is greatly increased, the welding penetration is increased, and the welding efficiency is increased; ceramic clinker of which the proportion is less than that of copper alloy covers the surface of a weld pool, and therefore the weld pool can be effectively prevented from being oxidized; without welding shield gas, the higher welding line quality can also be obtained.

Owner:WUHAN HGLASER ENG CO LTD

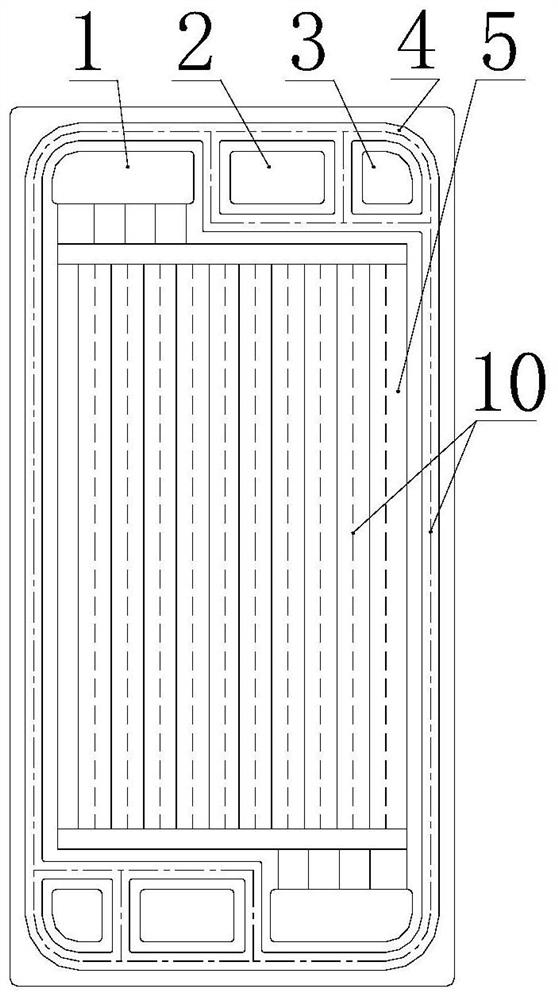

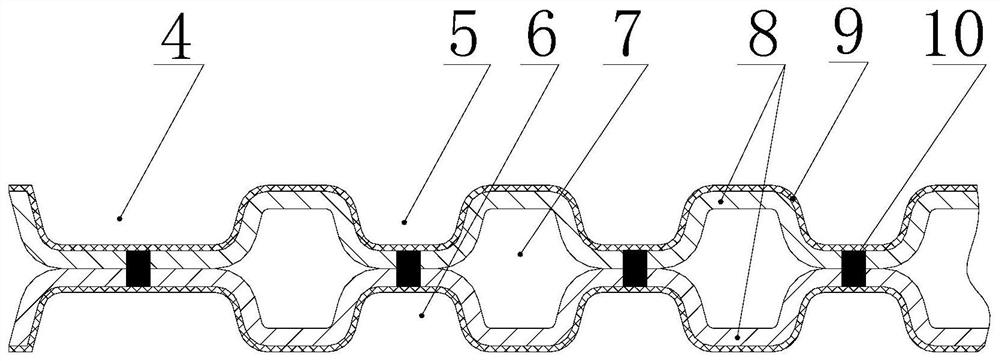

A kind of preparation method of metal graphite composite bipolar plate of proton exchange membrane fuel cell

ActiveCN108963294BLower resistanceIncreasing the thicknessFinal product manufactureCollectors/separatorsPhysical chemistryProton exchange membrane fuel cell

A method for preparing a metal-graphite composite bipolar plate for a proton exchange membrane fuel cell, comprising making the metal bipolar plate, treating flexible graphite paper, and adhering the flexible graphite paper on the surface of the bipolar plate. The making of the metal bipolar plate includes: molding a stainless steel sheet The hydrogen unipolar plate and the oxygen unipolar plate, the unipolar plates have a corrugated flow field structure, and are welded together by fiber laser to form a bipolar plate; the treatment of flexible graphite paper and the adhesion of flexible graphite paper on the surface of the bipolar plate include: Graphite paper is vacuum-impregnated in resin, and the impregnated flexible graphite paper is pressed on the front and back surfaces of the bipolar plate, and the resin is cured in the furnace to obtain the finished metal-graphite composite bipolar plate. The beneficial effects of the invention are: simple process, low cost; small bipolar plate resistance; corrosion resistance and long service life.

Owner:大连一元氢能源科技有限公司

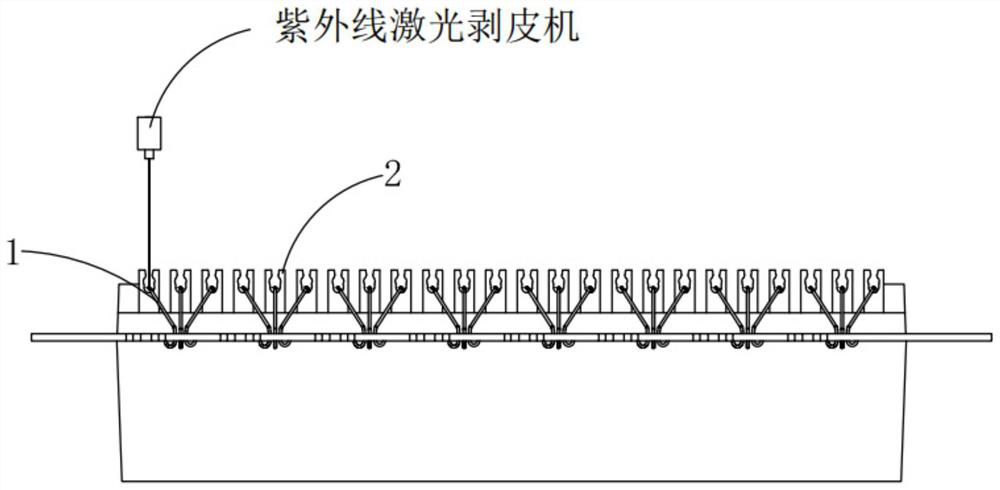

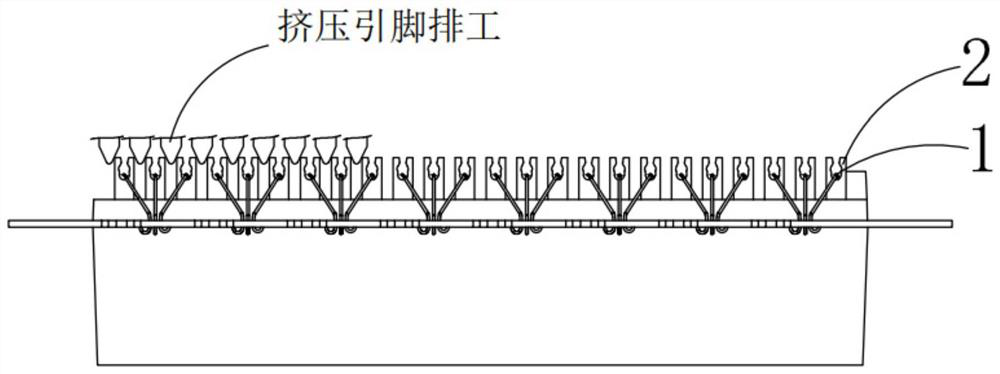

Production process of novel network transformer

PendingCN113571319AFix stability issuesSolve efficiency problemsLine/current collector detailsInductances/transformers/magnets manufactureUltraviolet laser lightMechanical engineering

The invention relates to a production process of a novel network transformer, which comprises a part assembly process, an ultraviolet laser peeling and depainting process and an optical fiber laser welding process, wherein the part assembly process comprises a process of connecting a wire in a coil with a pin on a transformer shell, the ultraviolet laser peeling and depainting process comprises a process of feeding a part subjected to the assembly process into an ultraviolet laser peeling machine to peel and depaint a wire, and the optical fiber laser welding process comprises a process of closing up, clamping and fixing the peeled and depainted wire, then welding and taking out a product after welding is completed. According to the production process of the novel network transformer, the full automation rate and the yield of production are improved, and the problems that the production stability of the network transformer is poor, the production efficiency is low, the rejection rate is high, and the product quality is easily affected are solved.

Owner:东莞市全方位自动化设备有限公司

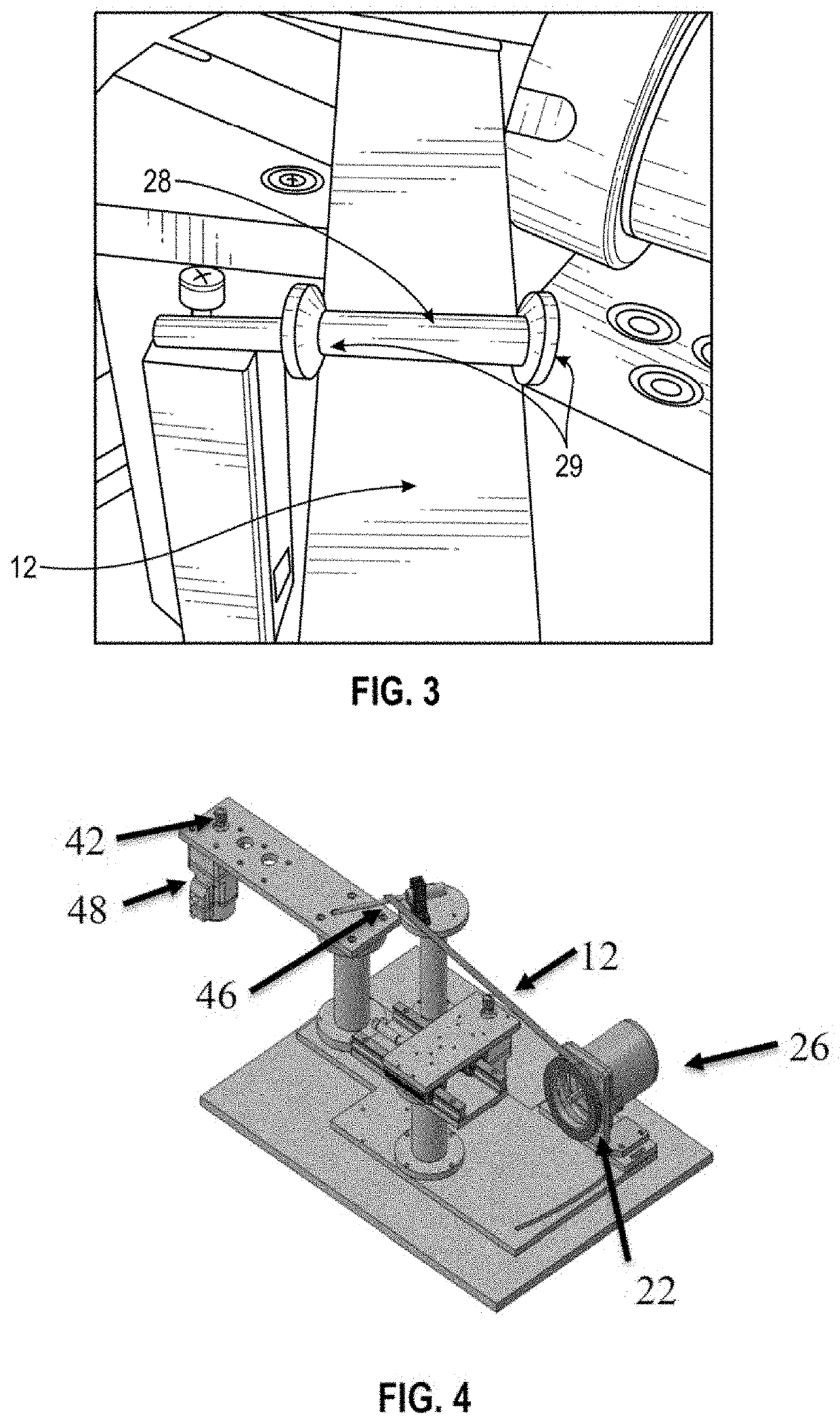

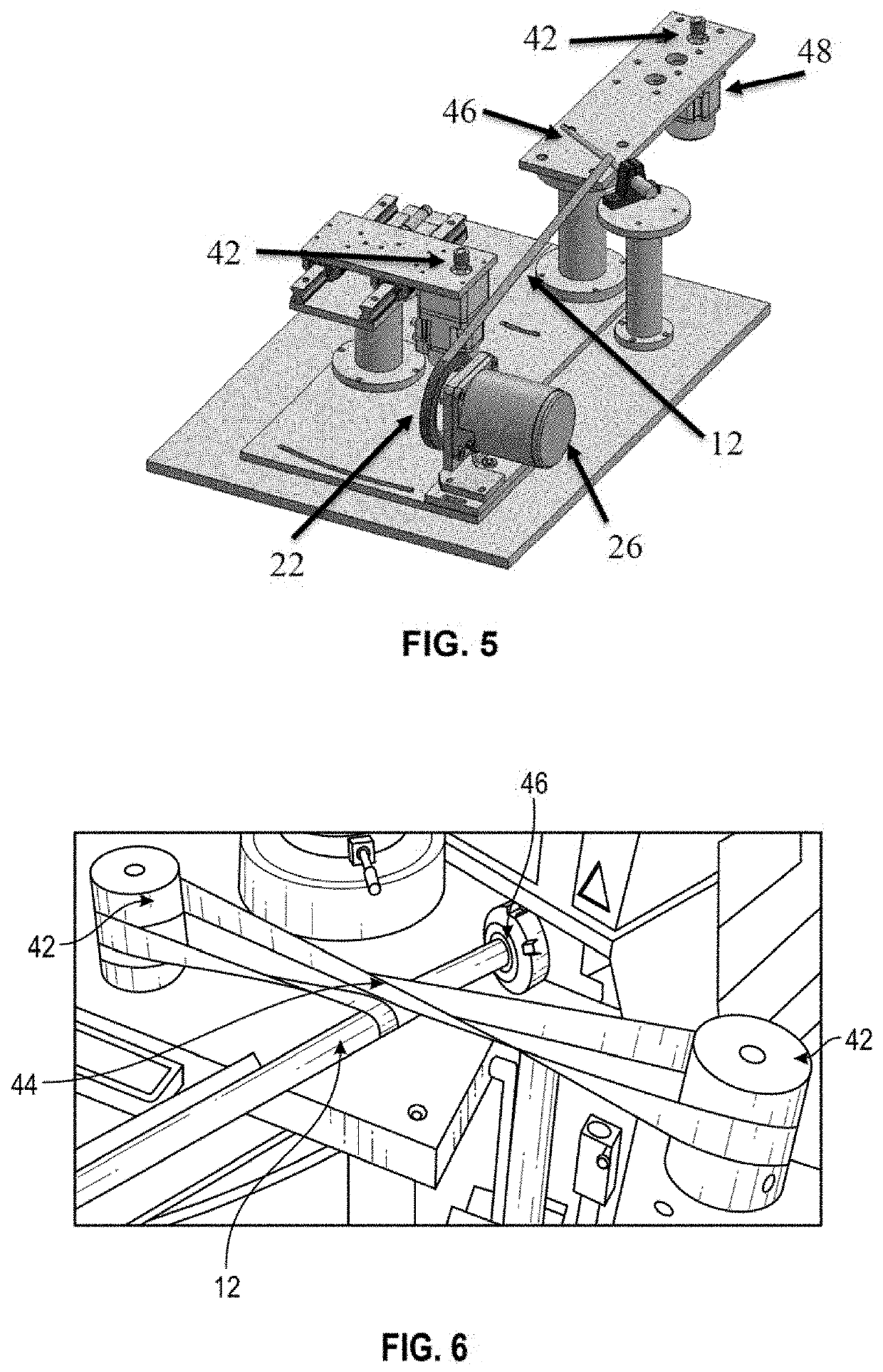

Method of manufacturing boron coated straws for neutron detection through spiral winding and welding

ActiveUS10974300B2Minimizes operator interventionWelding/soldering/cutting articlesMetal working apparatusEngineeringBorium

Owner:PROPORTIONAL TECH

A fiber laser welding device

ActiveCN112276357BAvoid exposure to bright lightReduce harmWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSafety goggles

The invention discloses an optical fiber laser welding device, which relates to the field of laser welding and includes a welding machine. A connecting ring is connected to the outer side of the welding machine, and a spring rotating shaft is connected to the outer side of the connecting ring, and the outer side of the connecting ring passes through the spring rotating shaft. A connecting block is rotatably connected, and goggles are arranged inside the connecting block, a clamping block is connected to one side of the connecting block, and a moving block is connected to the outside of the clamping block. The present invention realizes that when the welding machine is operated to weld the workpiece, The push block can be pushed, and the goggles will pop open under the action of the spring shaft, and the operator can watch the welding through the pop-up goggles during welding, thus preventing the operator's eyes from directly contacting the bright light generated by welding , thereby reducing the damage to the operator's eyes.

Owner:GUILIN UNIV OF AEROSPACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com