Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Diode detectors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

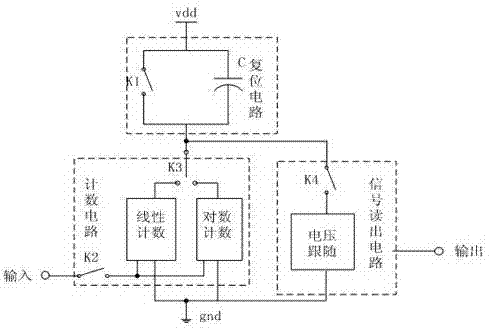

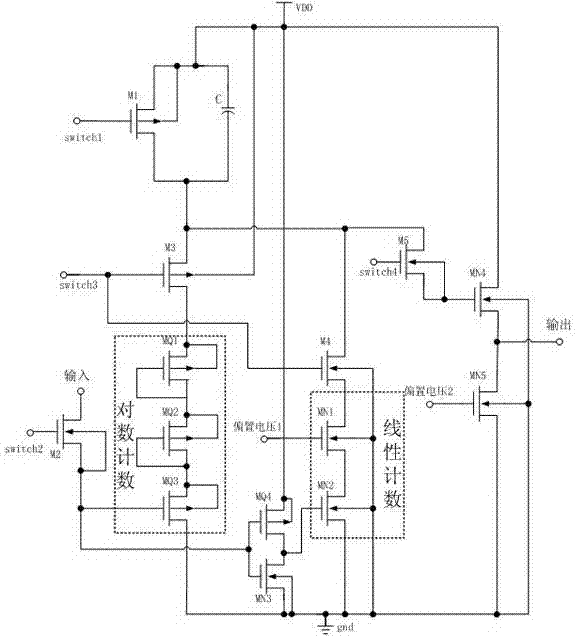

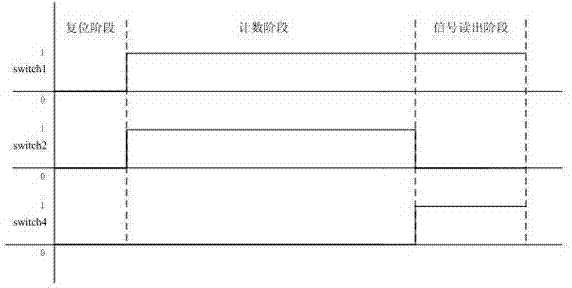

Analog signal reading method for single photon avalanche diode detector

InactiveCN103207024AHighly integratedIncreased readout dynamic rangeInstrumentsCapacitanceOvervoltage

The invention provides an analog signal reading method in terms of a single photon avalanche diode (SPAD) detector. The analog signal reading method comprises three successive processes of resetting, counting and signal reading. During the resetting, a capacitor is firstly charged to the power source voltage. During the counting after the resetting, a counting circuit counts for once every time an avalanche pulse signal generated by the SPAD detector is input, and charges on the capacitor are discharged for once. During a period of counting, the voltage changing value on the capacitor is proportional to changing of the quantity of photons detected by the SPAD detector during the time, and the number of the photons detected by the SPAD can be calculated. The signal reading stage can be entered after counting is finished, and the voltage value on the capacitor can be read through a voltage follower. Additionally, counting and reading of the analog signals can be performed for twice before and after exposure of the detector, and influence of dark counting can be eliminated by subtracting the analog signals read in two times to obtain accurate photon counting.

Owner:NANJING UNIV OF POSTS & TELECOMM

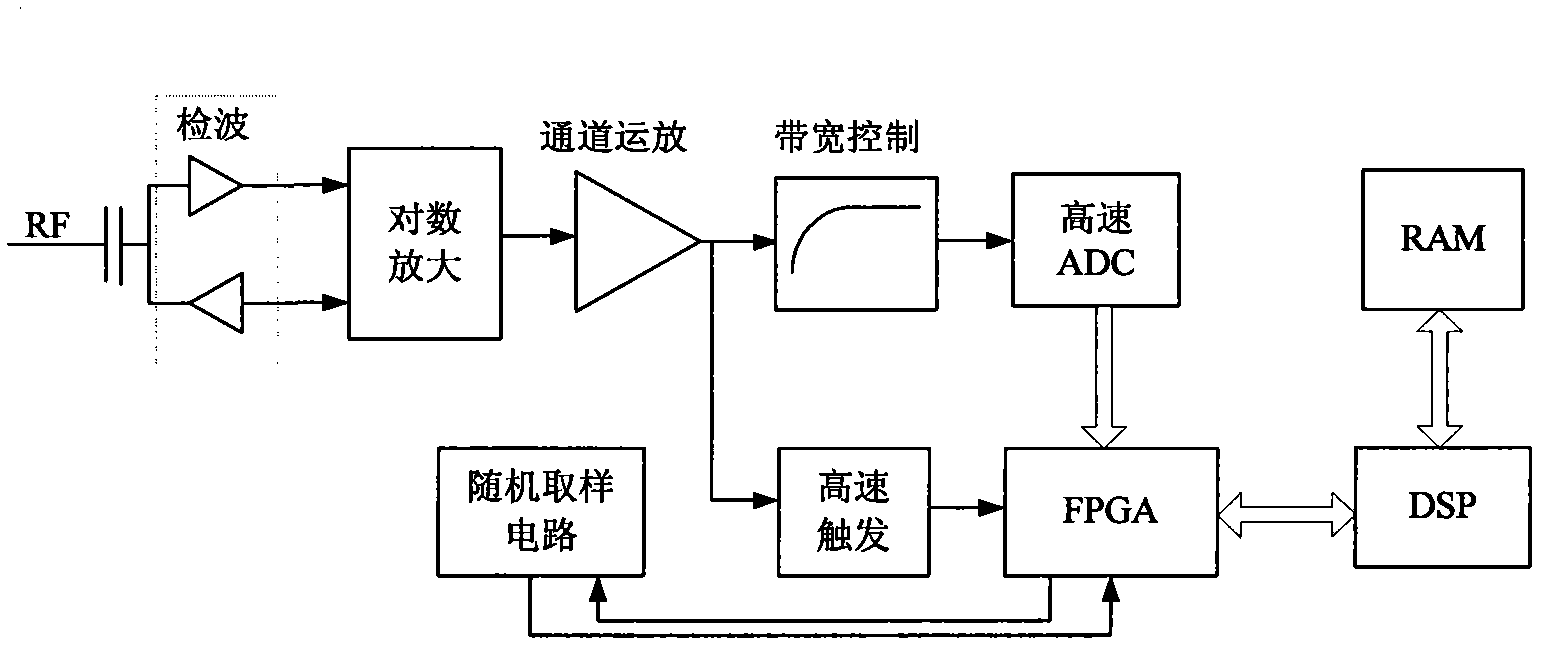

Method for accurately measuring narrow pulse modulation parameter

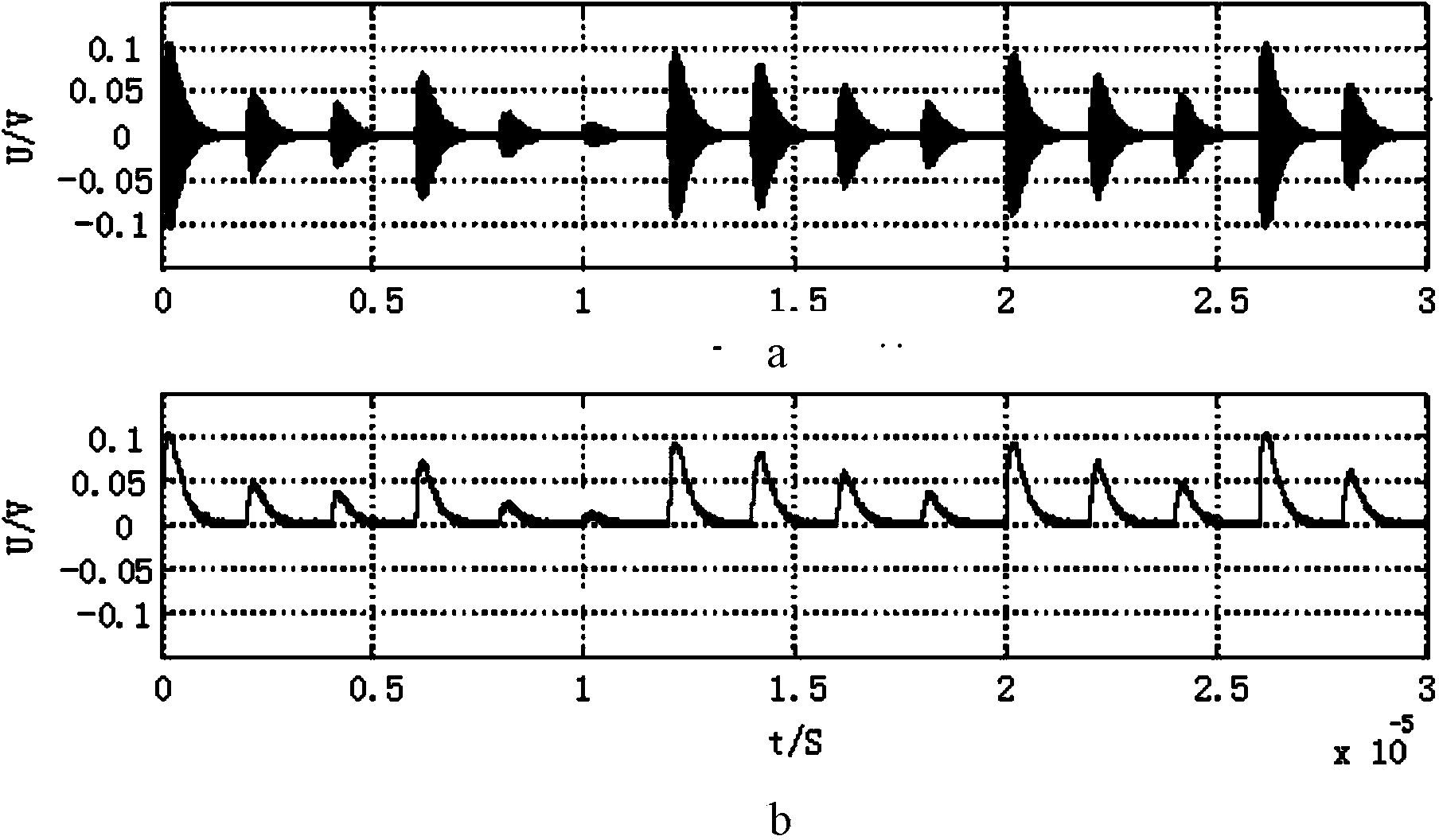

InactiveCN102508045AModulation depth measurementsTransmission monitoringAnalog-to-digital converterField-programmable gate array

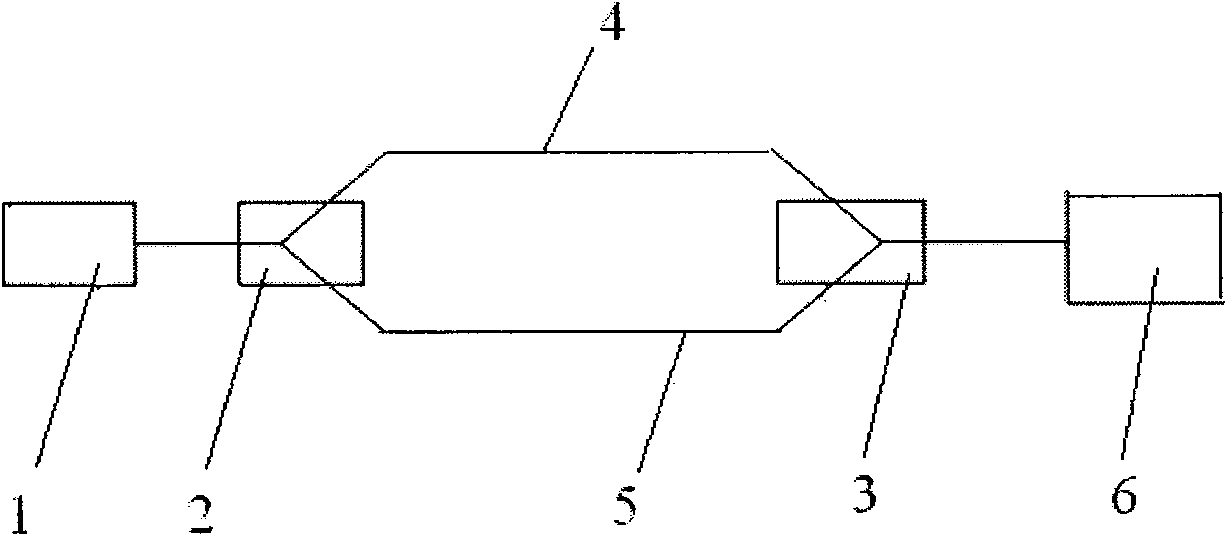

The invention relates to a method for accurately measuring a narrow pulse modulation parameter. According to the method, a narrow pulse modulation signal RF passes through a double-diode detector, a logarithmic amplifier and a channel operational amplifier unit in sequence and is divided into two paths of signals, one path of signal is fed into a high-speed analog-to-digital converter (ADC) module for analog-to-digital (A / D) conversion by a bandwidth control unit, the other path of signal is fed into a high-speed trigger circuit, the high-speed ADC module triggers A / D conversion according to a pulse signal generated by the high-speed trigger circuit, and effective ADC data is acquired, fed into a field programmable gate array (FPGA) and stored in the FPGA according to a trigger signal generated by the high-speed trigger circuit; and a digital signal processor (DSP) unit reads the effective ADC data from the FPGA, processes the data and stores an operation result in a high capacity random access memory (RAM). By the method for accurately measuring the narrow pulse modulation parameter, the narrow pulse modulation parameter with the minimal pulse width of 30ns and the dynamic range of -27 to +20dBm can be measured, and both the time parameter and the amplitude parameter of the narrow pulse modulation signal can be measured.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

Manufacturing method of flat-type avalanche diode detector used for detecting single photon

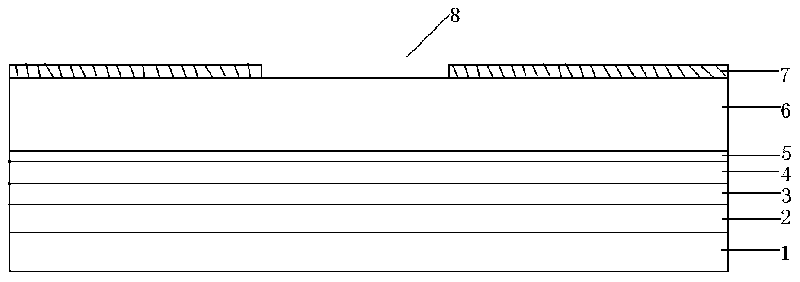

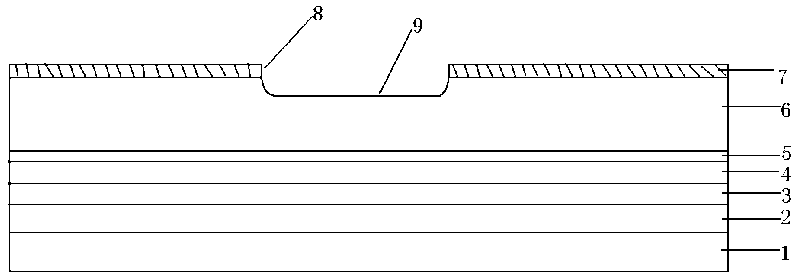

The invention relates to a manufacturing method of a flat-type avalanche diode detector used for detecting a single photon. The manufacturing method comprises the following steps: sequentially growing an InP buffer layer, an InGaAs absorbing layer, an InGaAsP gradient layer, an N-type InP charge layer and an InP cap layer on an N-type InP substrate; growing an SiO2 protective layer on the InP caplayer; photoengraving a round window at the middle of the SiO2 protective layer; eroding the InP cap layer in the round window through wet-method erosion, thereby forming a round hole; carving a protection ring window on the SiO2 protective layer around the round window; removing surplus SiO2 protective layer by utilizing an HF (hydrogen fluoride) solution in the protection ring window through a diffusion process; regrowing the InP cap layer an SiO2 layer, and caving an electrode window at the periphery of the round hole; forming a top ring electrode on the electrode window through an electron beam evaporation and desquamation process, and preparing a metal electrode at the periphery and one side of the ring electrode; and forming a back electrode at the back of the N-type InP substrate through electron beam evaporation, and preparing a SiNx antireflection layer at the surface of the InP cap layer in the round hole, thereby finishing the manufacture of the avalanche diode detector.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

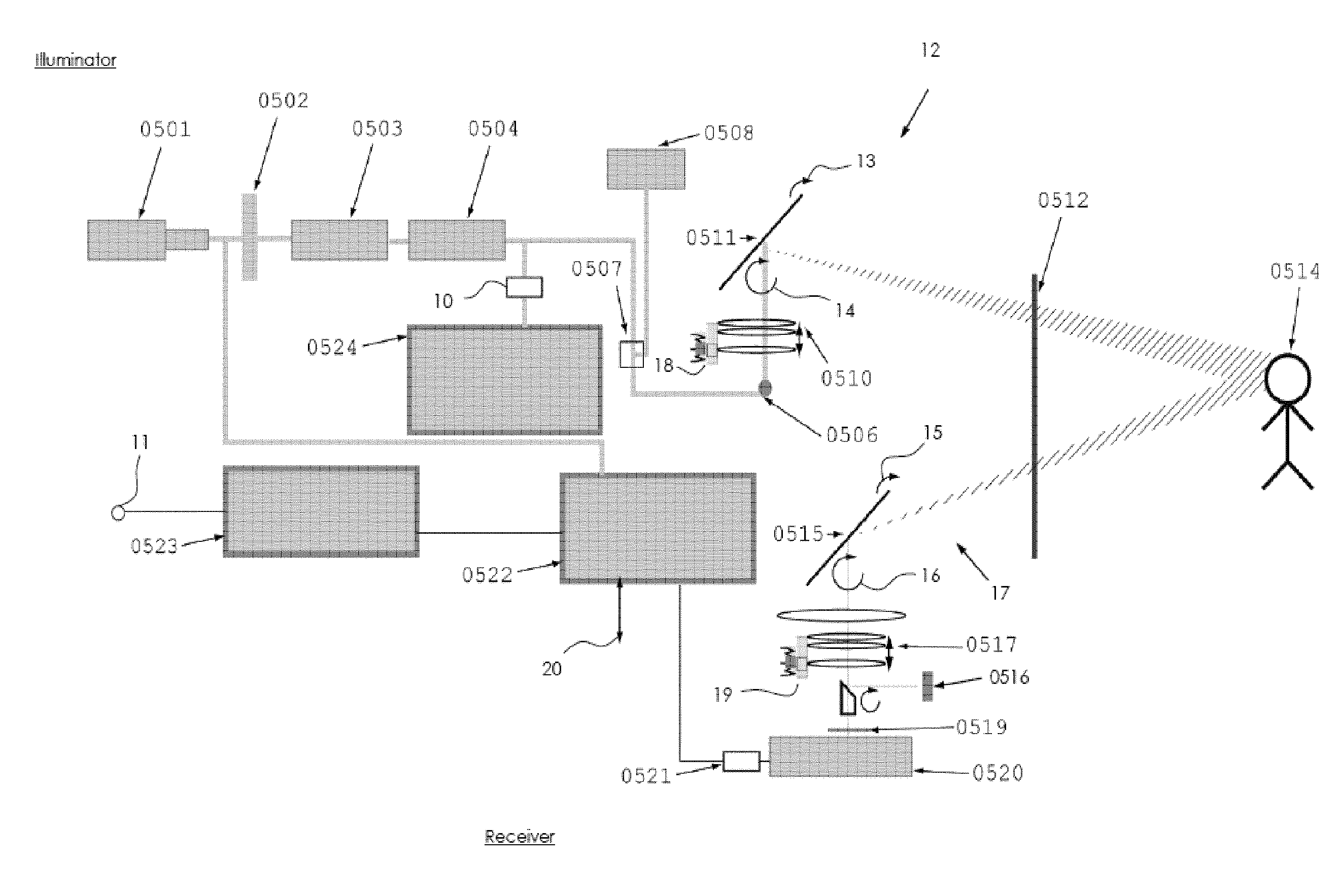

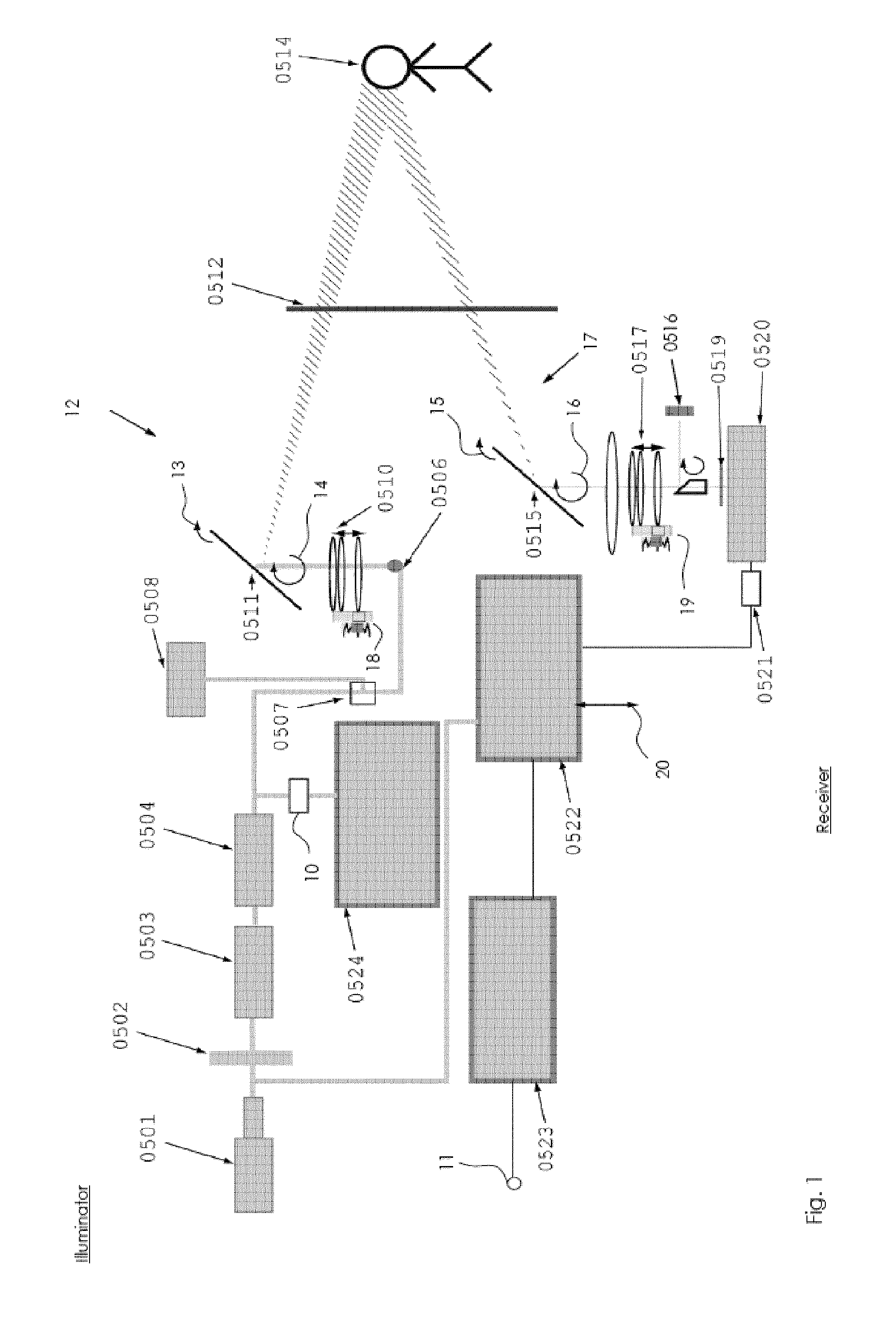

2D/3D real-time imager and corresponding imaging methods

ActiveUS9392259B2Increase speedIncrease distanceColor television detailsElectromagnetic wave reradiationSingle-photon avalanche diodeDetector array

The present invention relates generally to methods and devices of generating an electrical representation of at least one object in a scene in the real word. The detail real-time imager for the representation of a scene of a real world comprises:—at least an illuminator (0501-0511) of said scene providing at least a series of ultra-short power laser pulses with time-related positions; and—a receiver (0515-0523) of a SPAD Single Photon Avalanche Diode detector array according to the method of the invention and associated to at least said series of ultra-short power laser pulses of said illuminator.

Owner:FASTREE3D

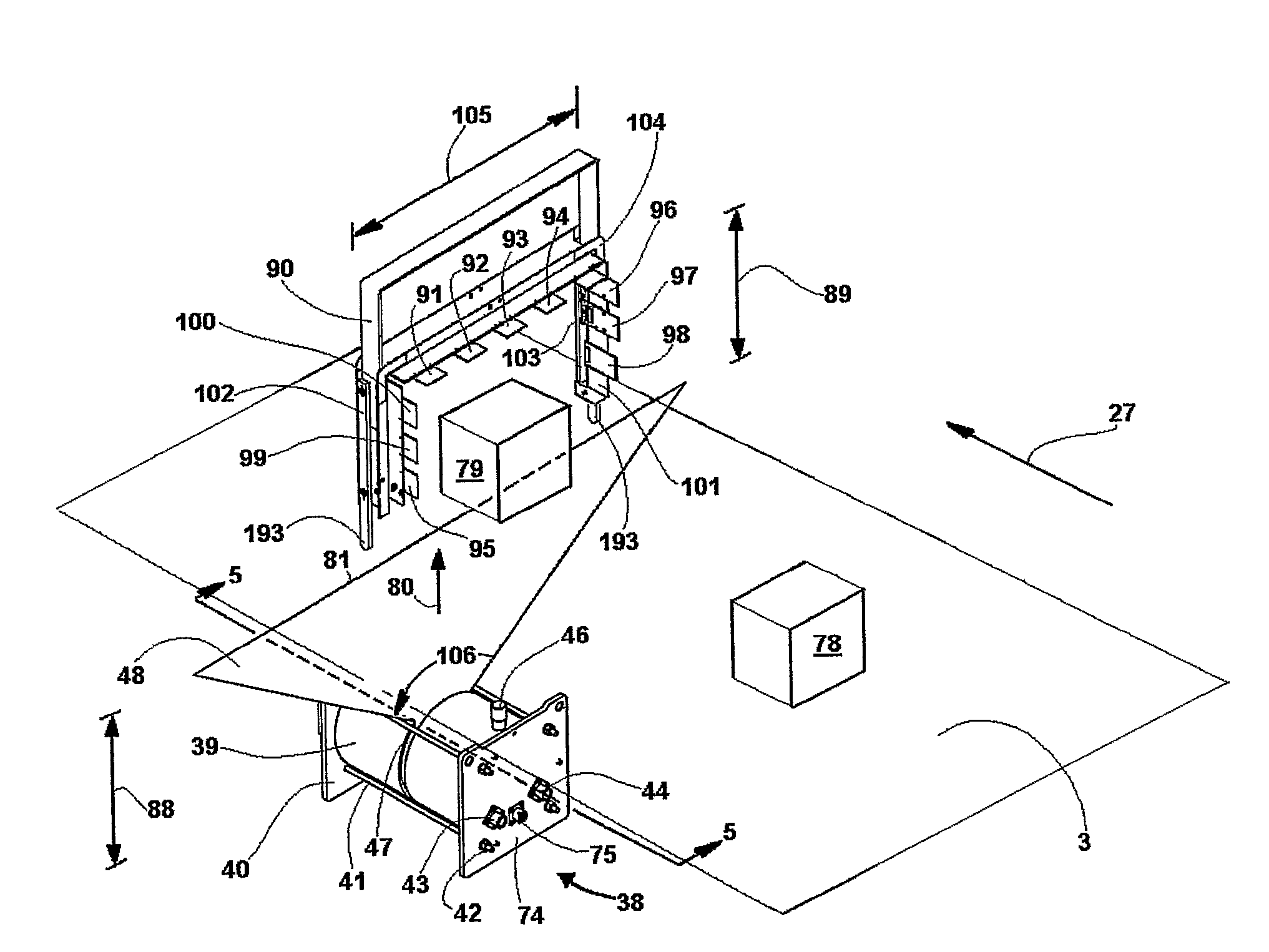

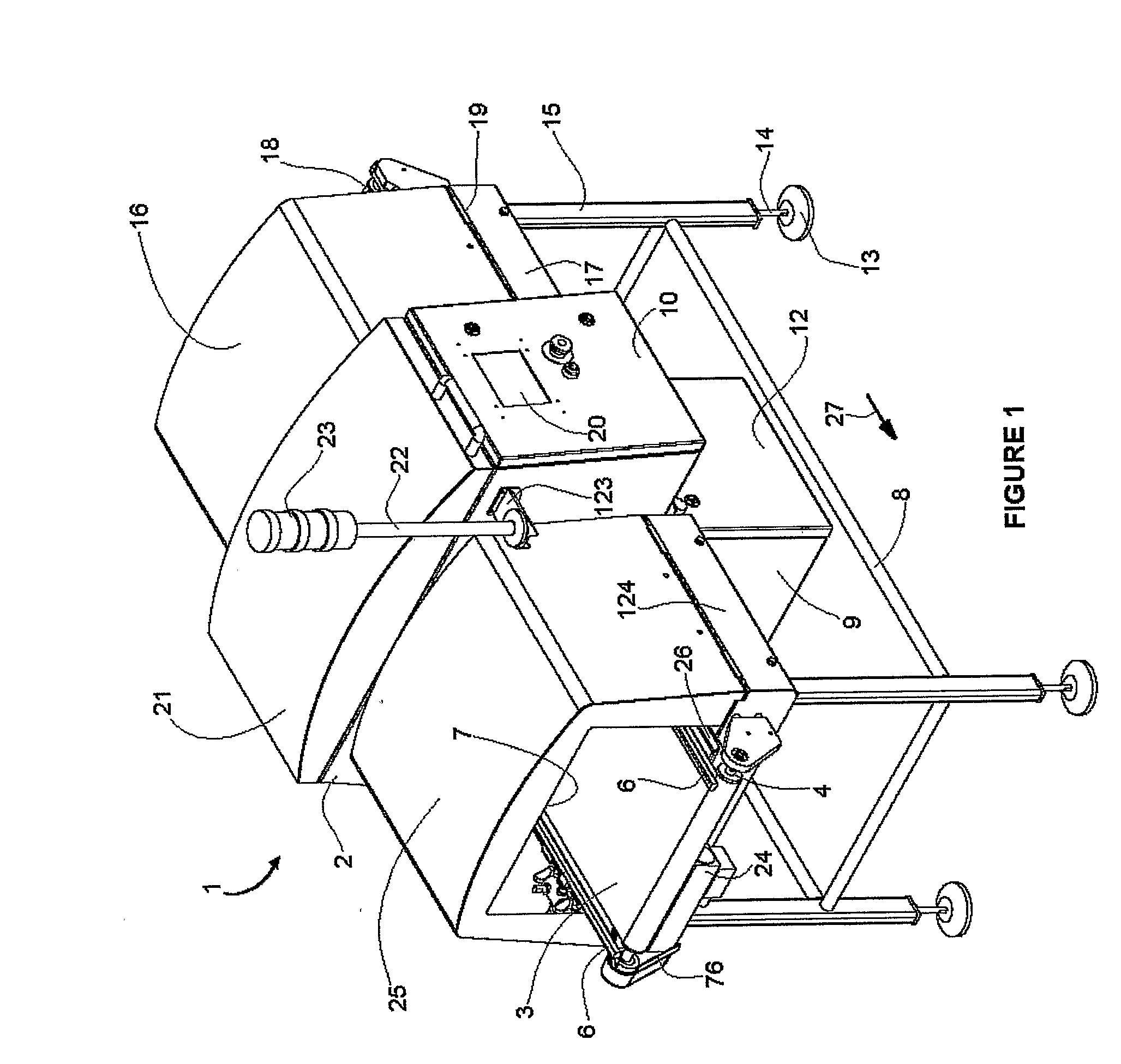

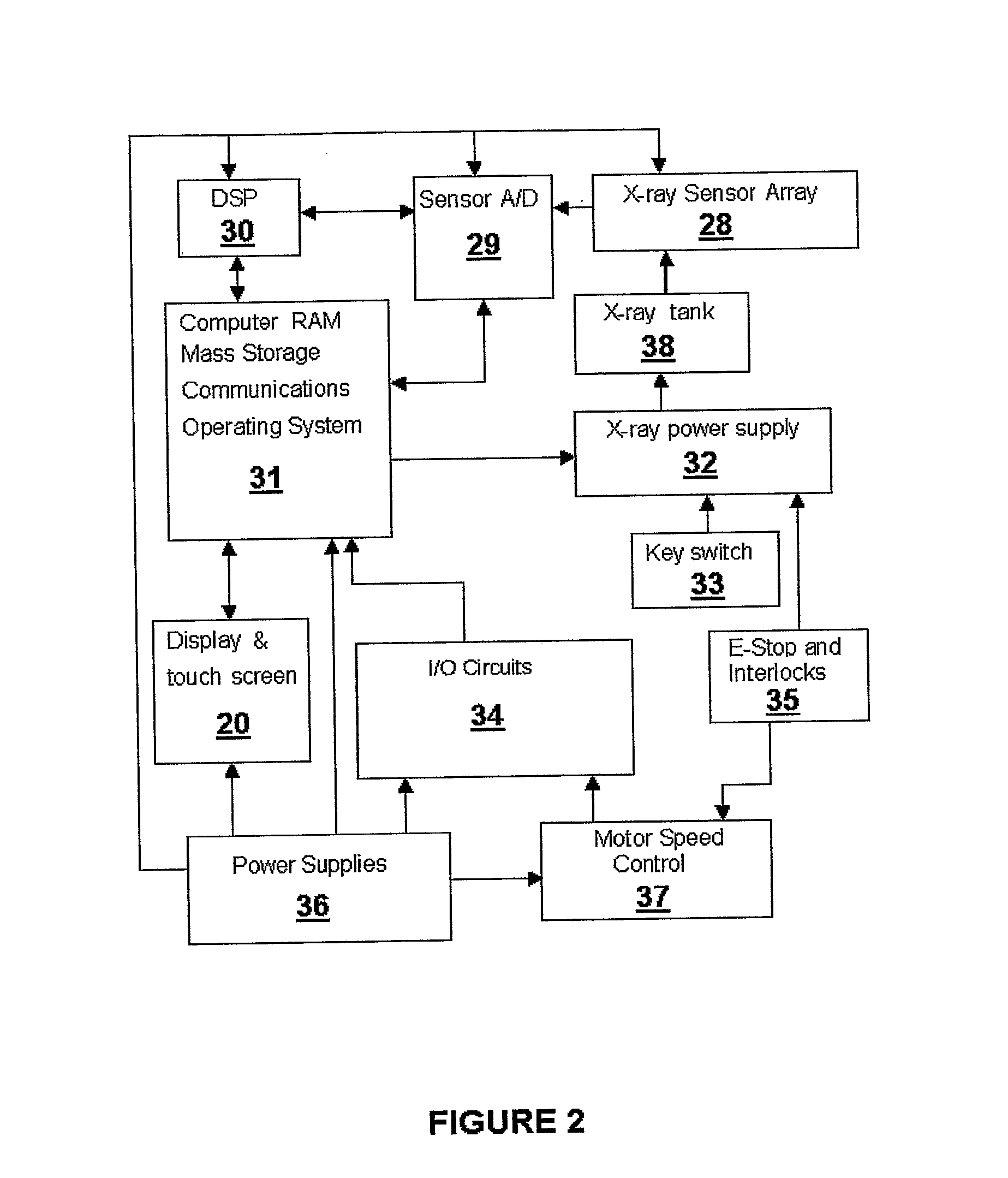

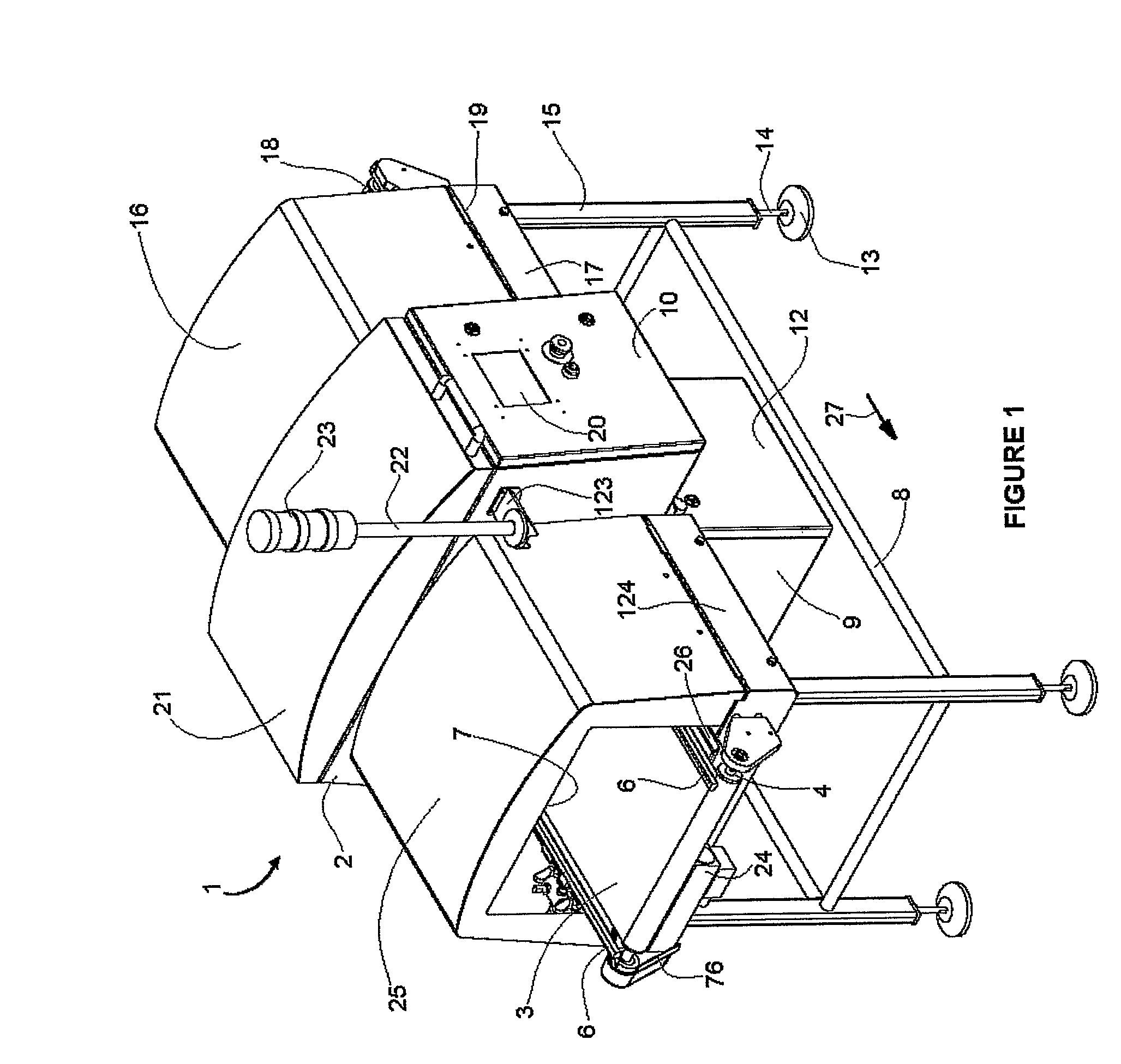

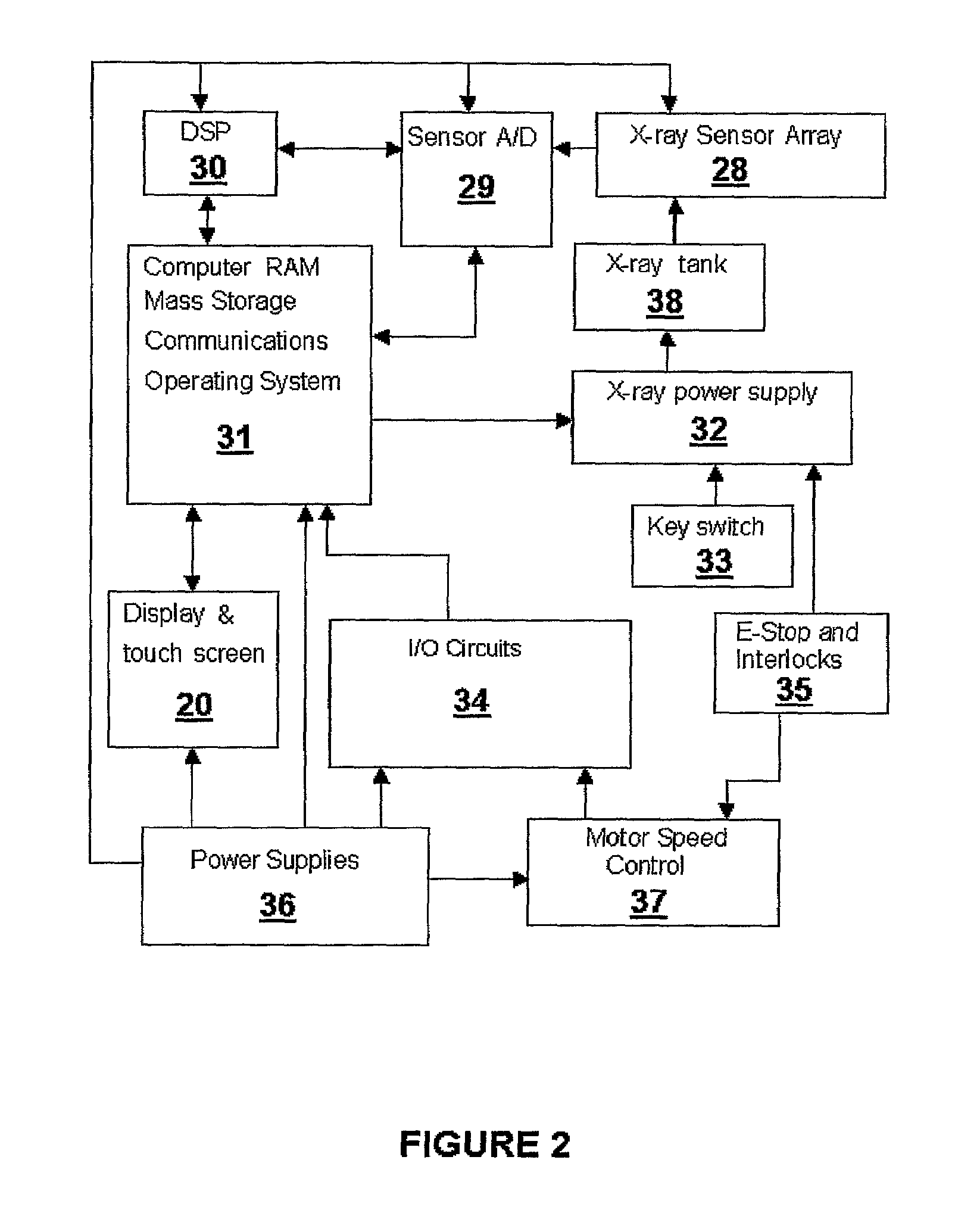

Contaminant Detector For Food Inspection

InactiveUS20080118026A1Low costLow production costRadiation/particle handlingX-ray tube electrodesX-rayDetector array

A contaminant detection machine (1) including a conveyor (3) which causes an object under inspection (79) to pass through a plane (48) of emitted x-ray radiation. The plane is generated by an x-ray tube (55) that emits a lateral beam, thereby permitting the distance (88) between the x-ray tube and the object under inspection to be reduced. A photo diode arch mounting assembly (104) is placed above the object under inspection and is mated to a collimator assembly (125) that also serves as the mounting bracket for the x-ray generation assembly (38), thereby preserving optical alignment between the photo diode detector array (28) and the emitted x-ray plane (48). The detector array (28) scans the object under inspection (79) so as to produce a continuous series of discrete lines, each line being analyzed by an image processing unit (116) to determine the presence or absence of a contaminant. The conveyor (3) passes over a pair of slider bed surfaces (155, 156) which are mounted in a hinged manner such that the leading edge (168) of one surface (156) is parallel to and spaced apart from the trailing edge (172) of the other surface (155), thereby creating a gap that is coplanar with the collimation slot (129) and the emitted x-ray plane (48). Each bed surface (155, 156) is rigidly constrained within open ended mounting brackets (159, 160, 161 and 162) yet can be removed by hand without the use of tools. Similarly, the conveyor (3) is supported by a roller assembly (182) that includes a tracking block (142) and pivot pin (143) which permits the roller assembly to be mounted to and removed from flip up mounts (151, 152) by hand and without the need of tools. Graphical user interfaces (249, 260, 261, 266, 275, 282 and 288) permit a user to operate the machine (1) by means of a liquid crystal display touch screen (20).

Owner:THERMO FISHER SCIENTIFIC INC

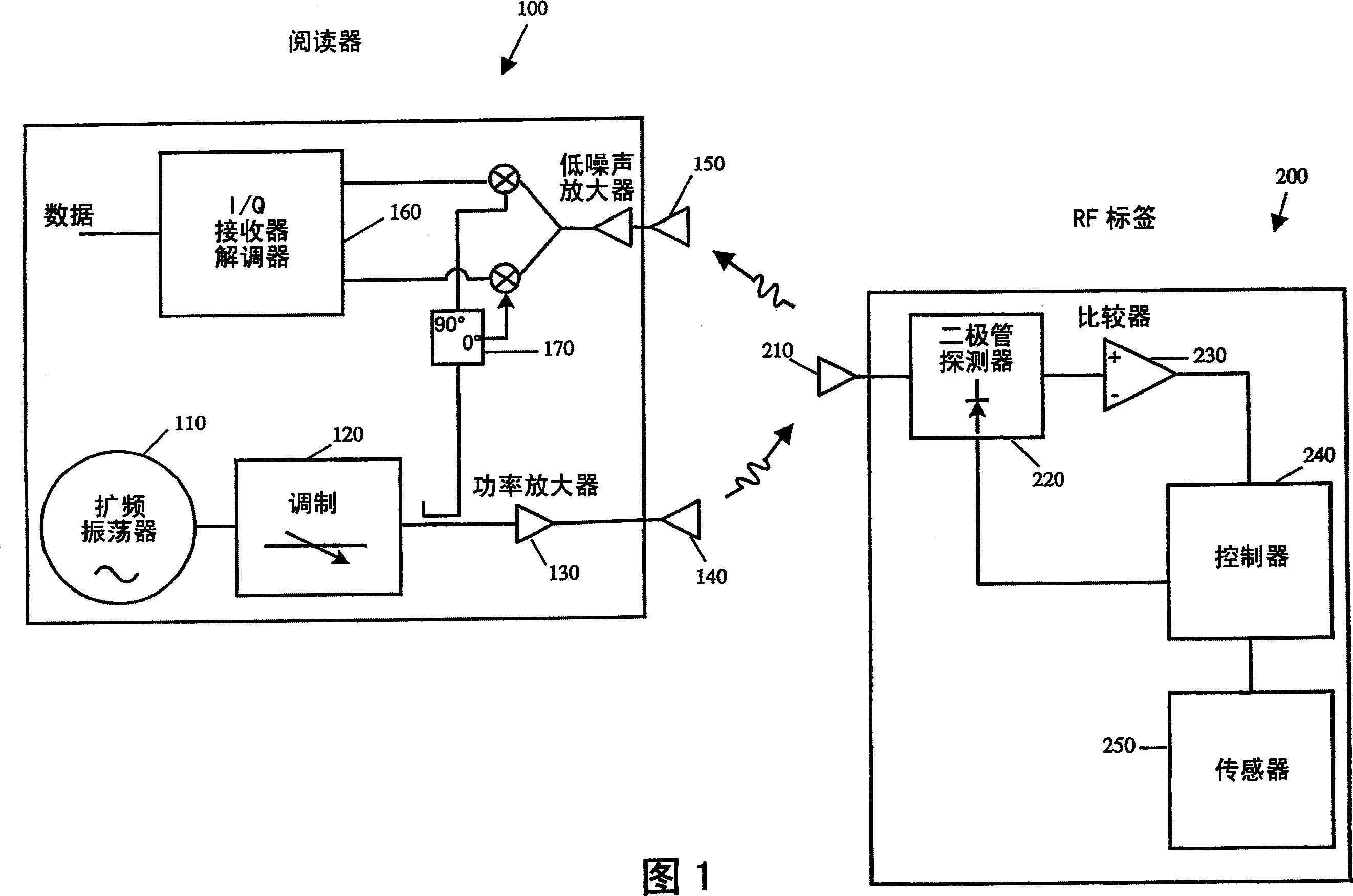

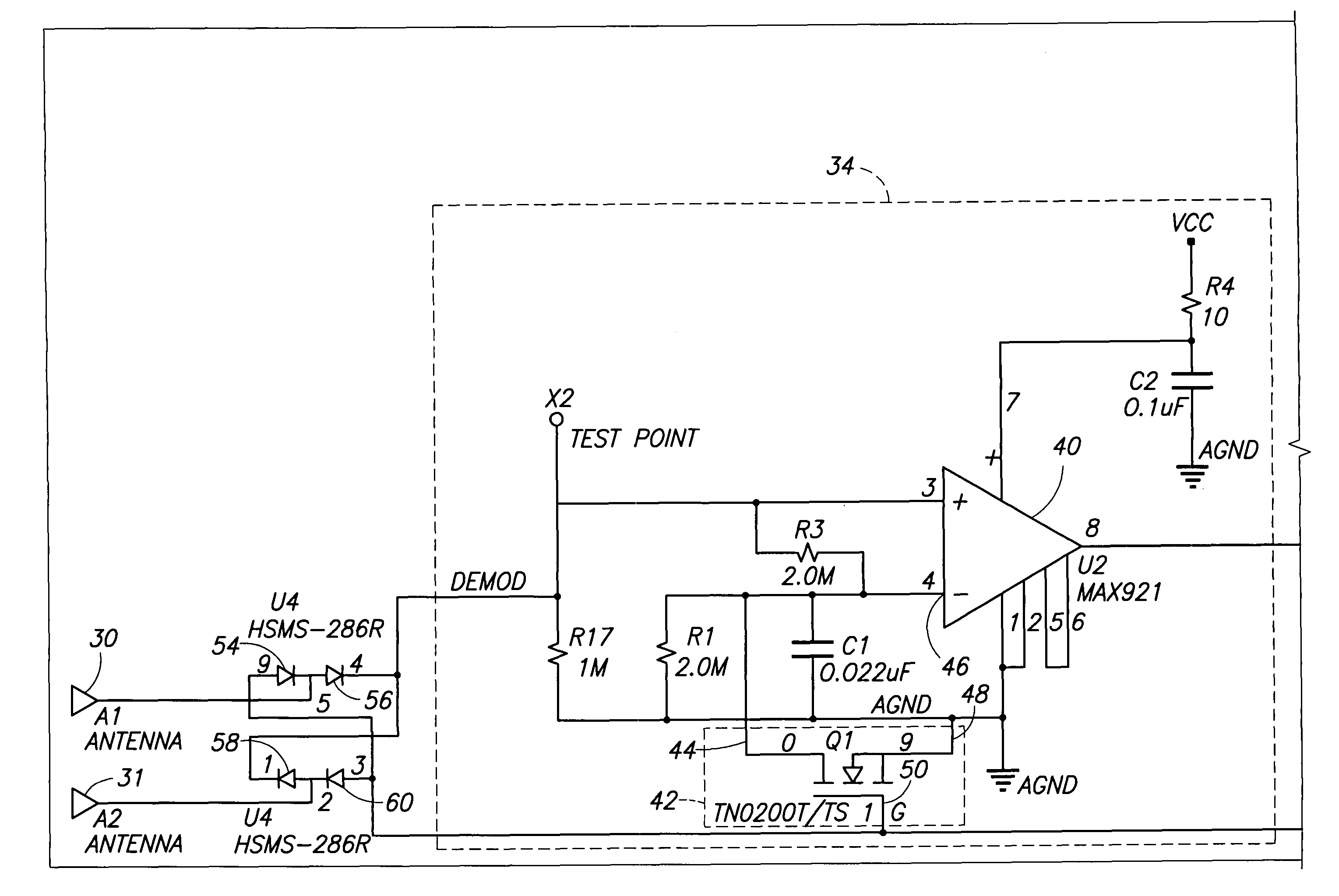

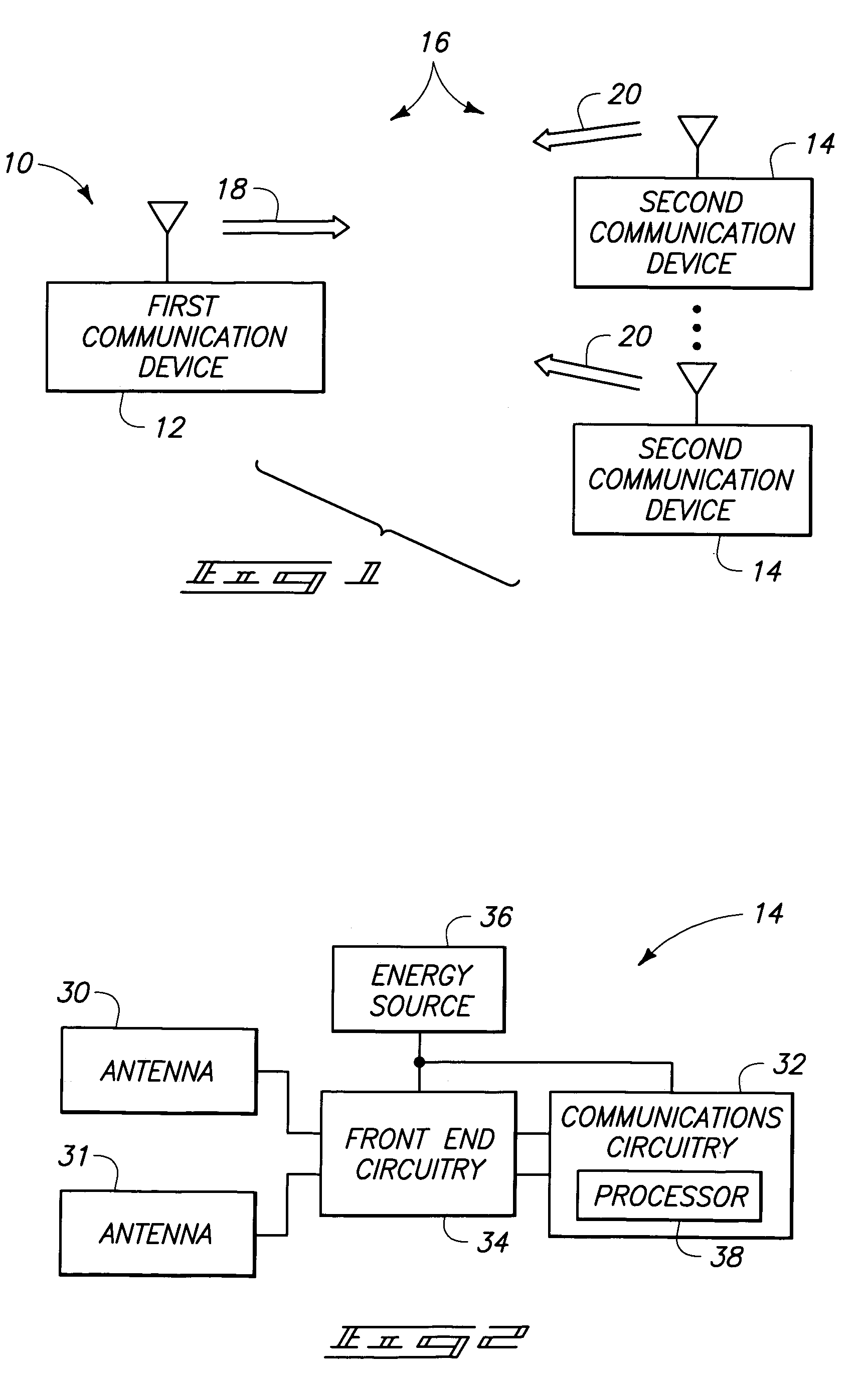

Tire pressure monitoring system

InactiveCN1553867AImproperly inflatedReduce the chance of accidentsTyre measurementsAtmospheric pressureElectronic component

This invention relates to systems and methods for monitoring tire pressure using radio frequency identification (RFID). The RFID systems of the present invention include a reader and a RF tag in communication with a pressure sensor. The reader of the present invention comprises an oscillator, modulator, transmitting antenna, receiving antenna and demodulator. The RF tag comprises an antenna, diode detector, comparator, controller and pressure sensor interface. The RF tag further comprises a battery which powers the electronic components of the tag. In embodiments of the present invention, the oscillator generates a signal that is fed to the modulator for encoding information. The modulated signal is then broadcast via the antenna to the RF tag. An antenna on the RF tag received the signal where the comparator and controller interpret the information sent by the reader, receive a pressure reading from the pressure sensor and transmit an encoded signal back to the reader via modulation of reflected energy. The reader in turn receives this reflected energy and demodulates the signal to retrieve the encoded information including the pressure reading.

Owner:斯特姆科有限公司

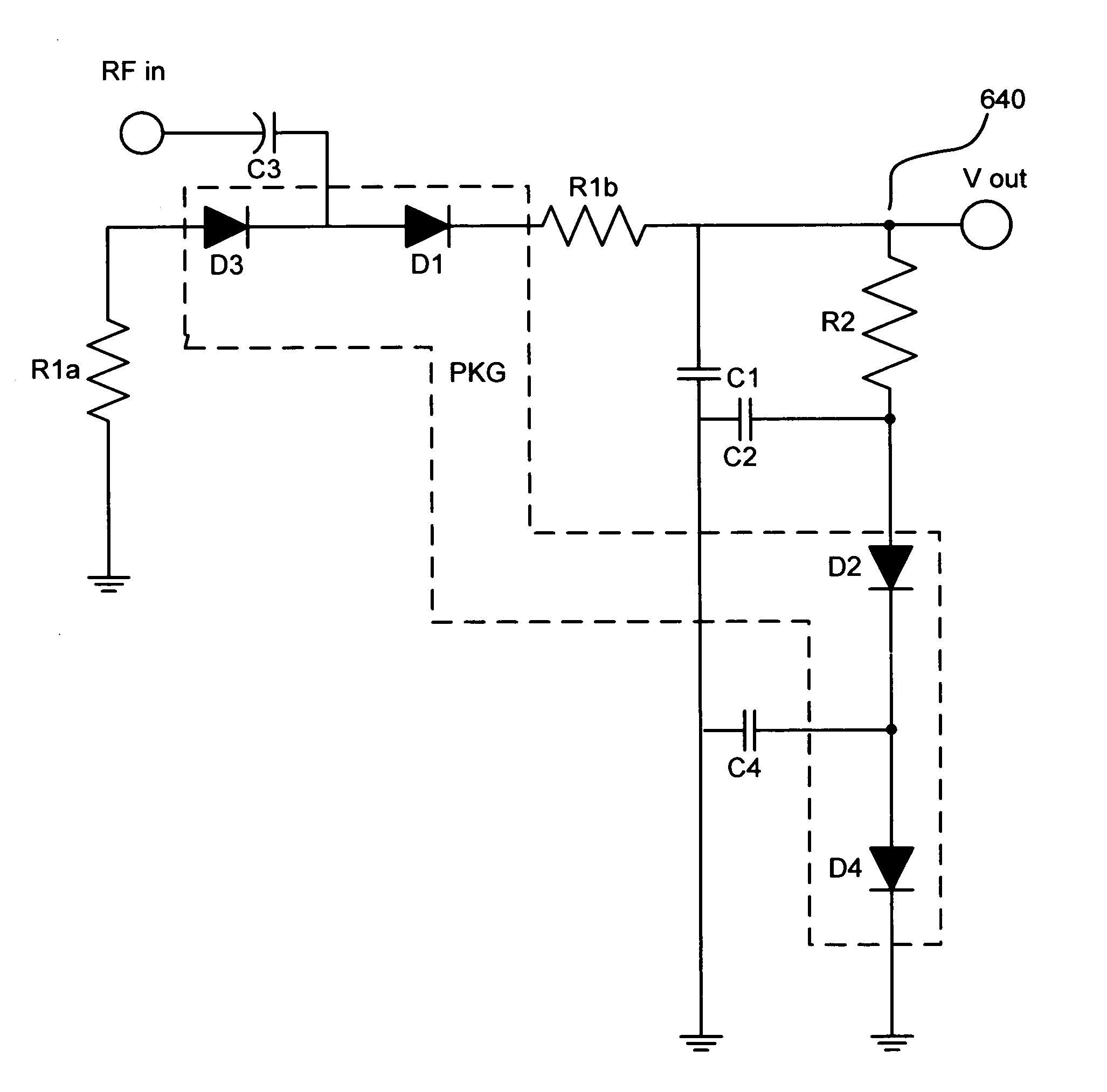

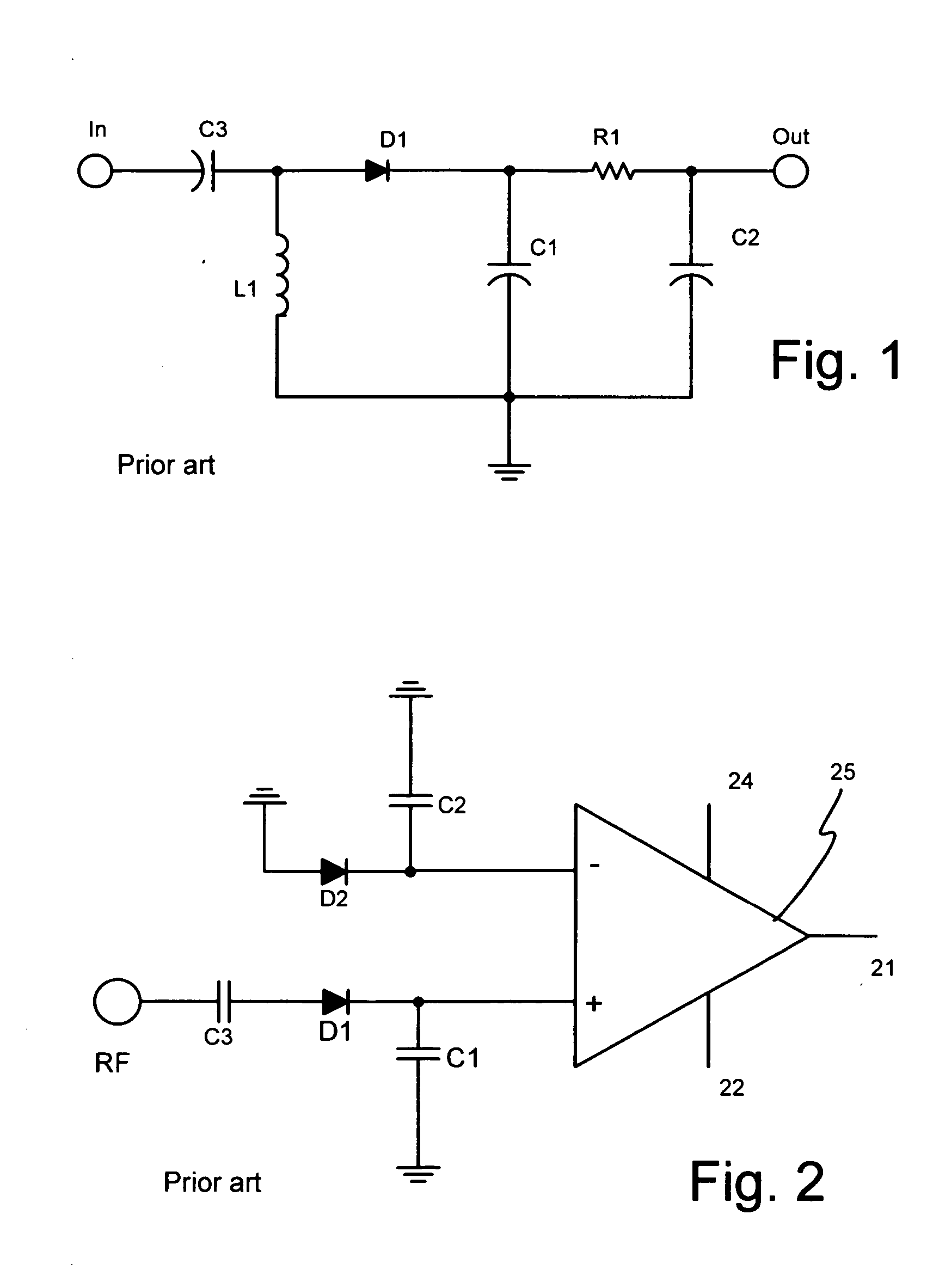

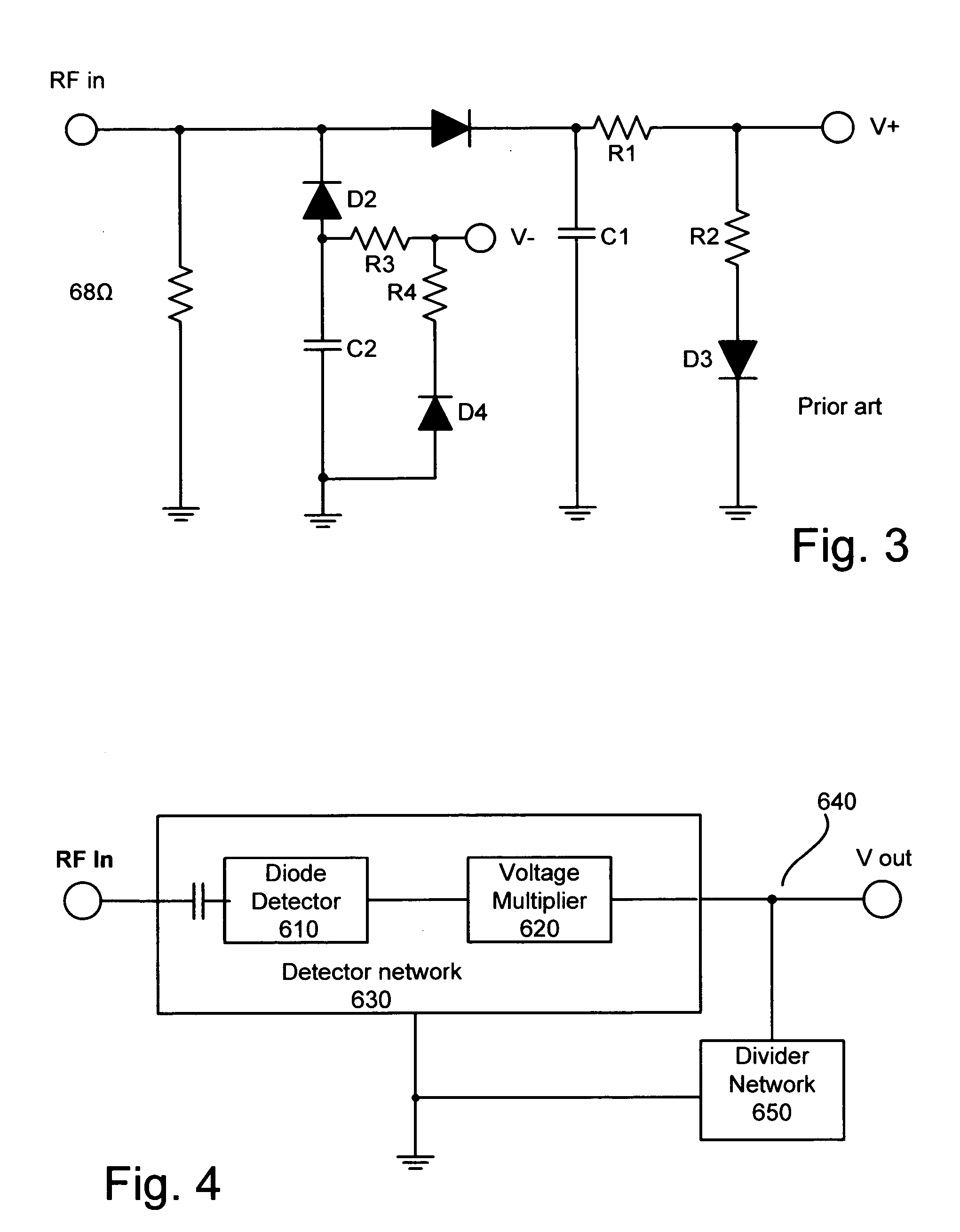

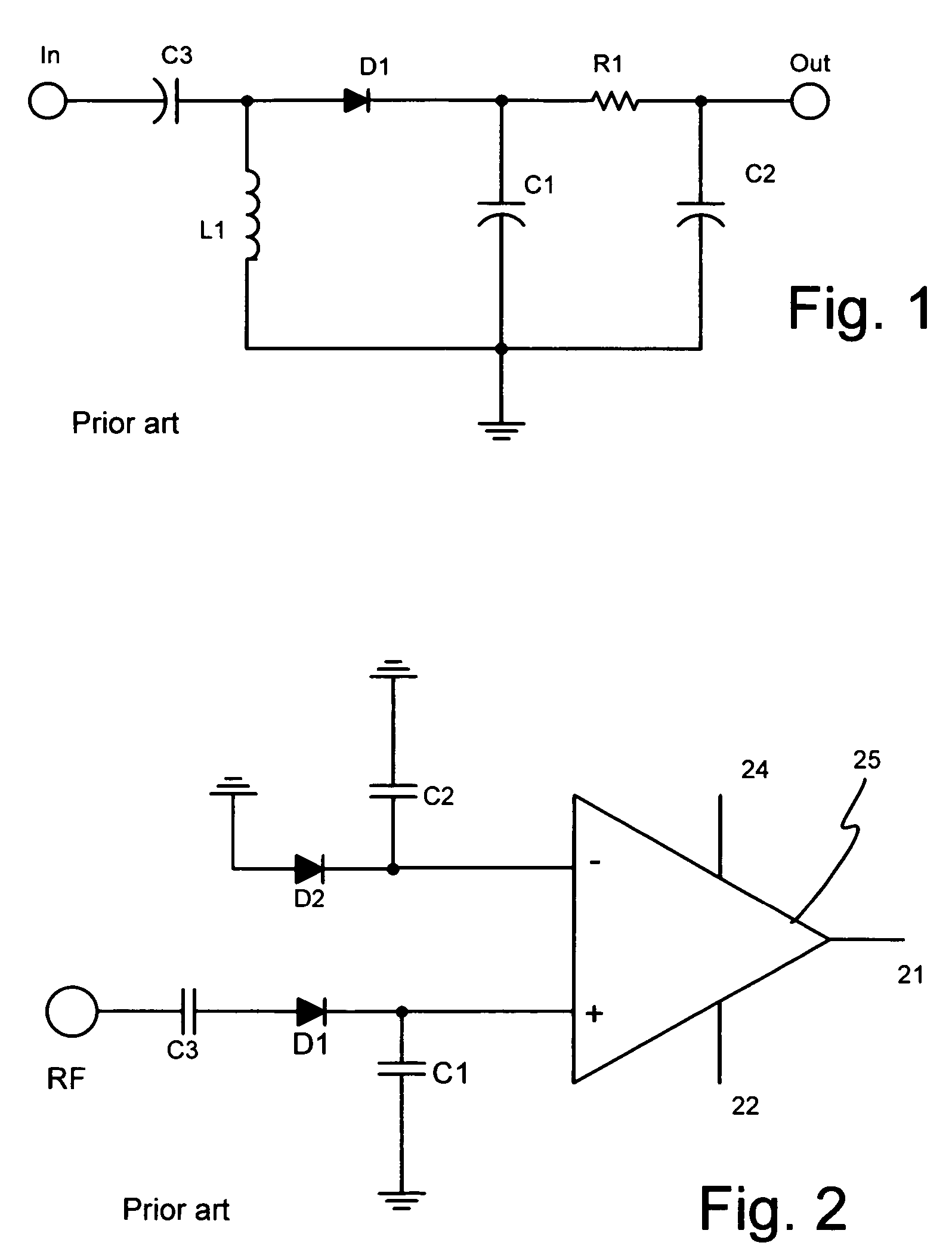

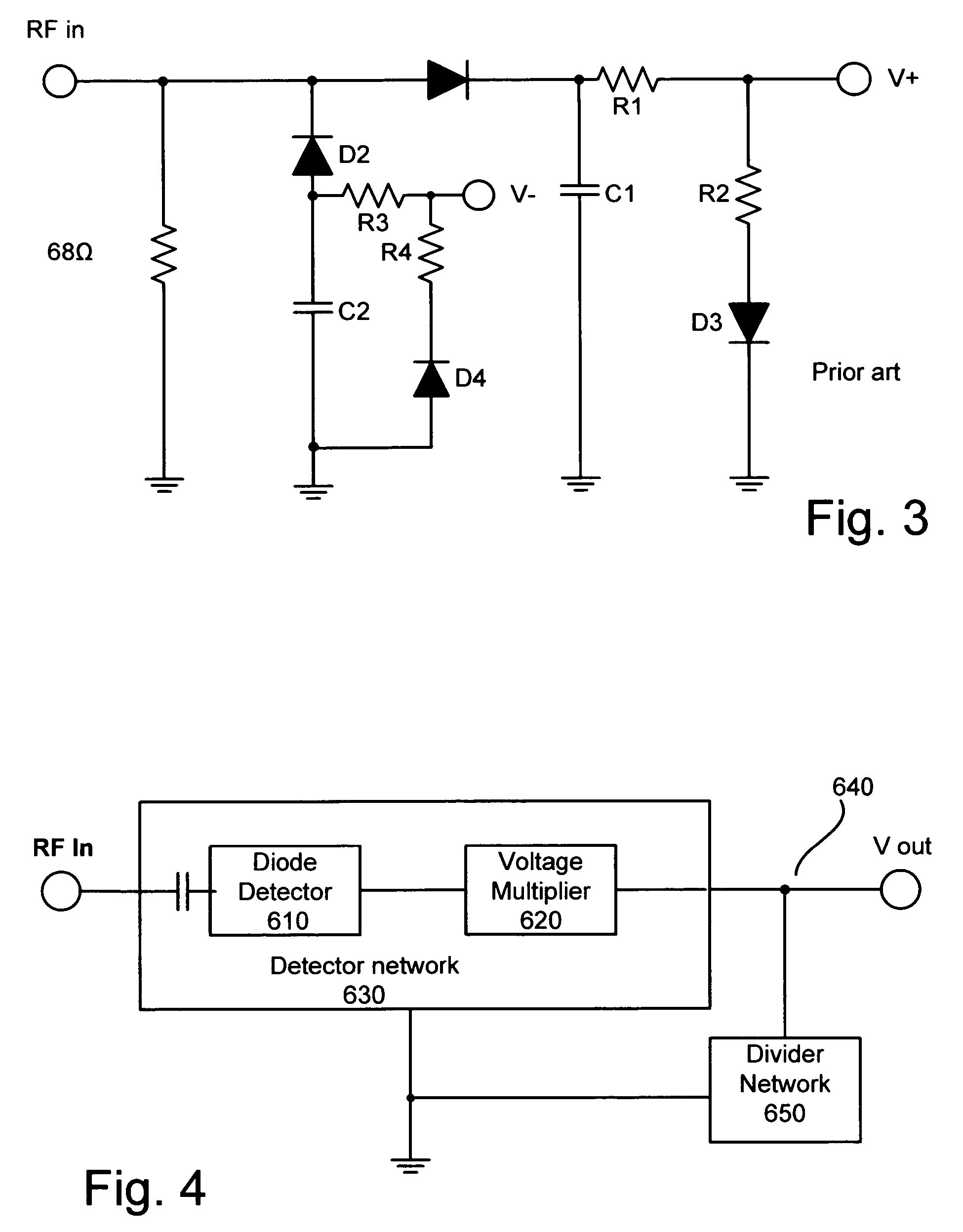

Temperature compensated, high efficiency, controlled input impedance diode detector

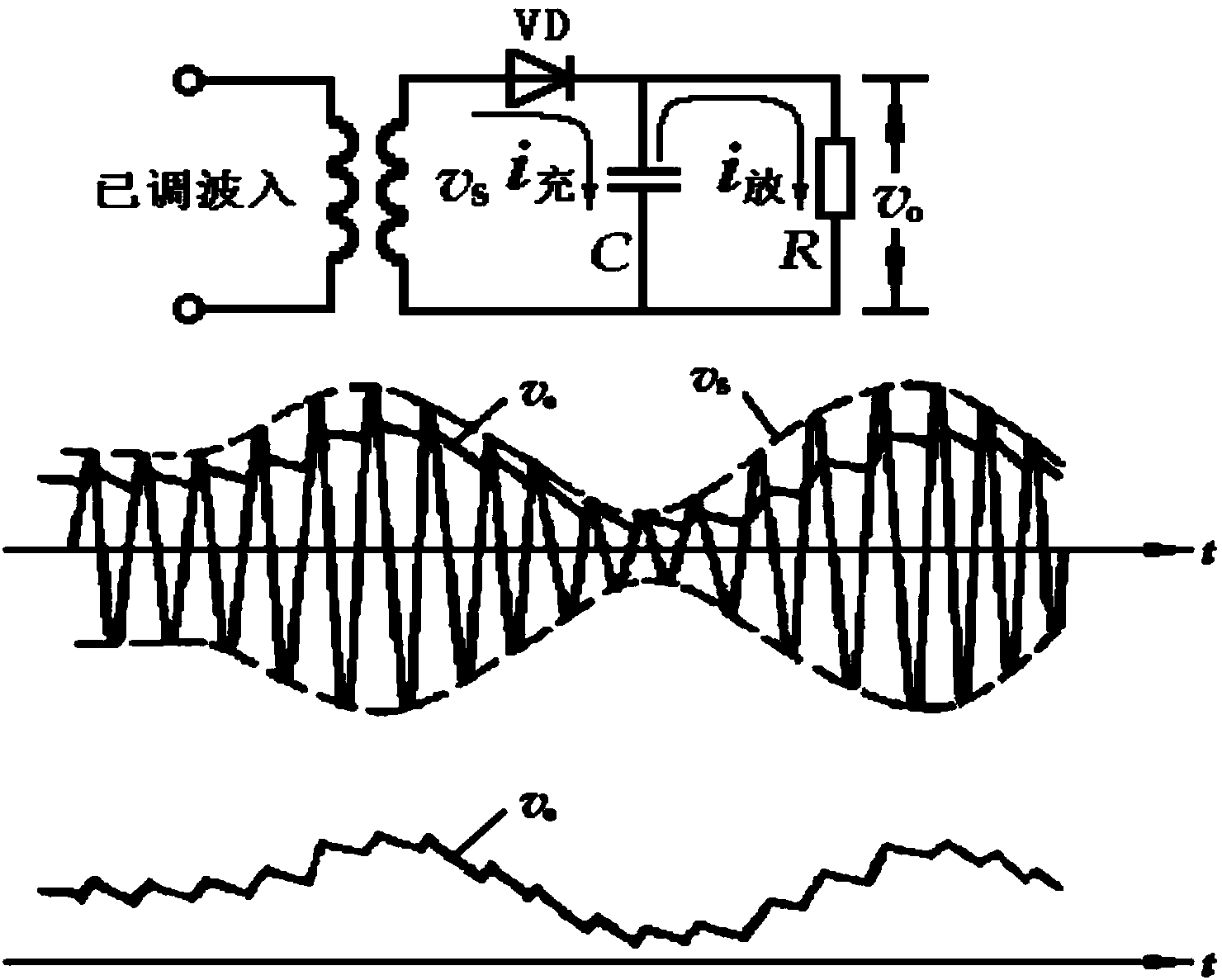

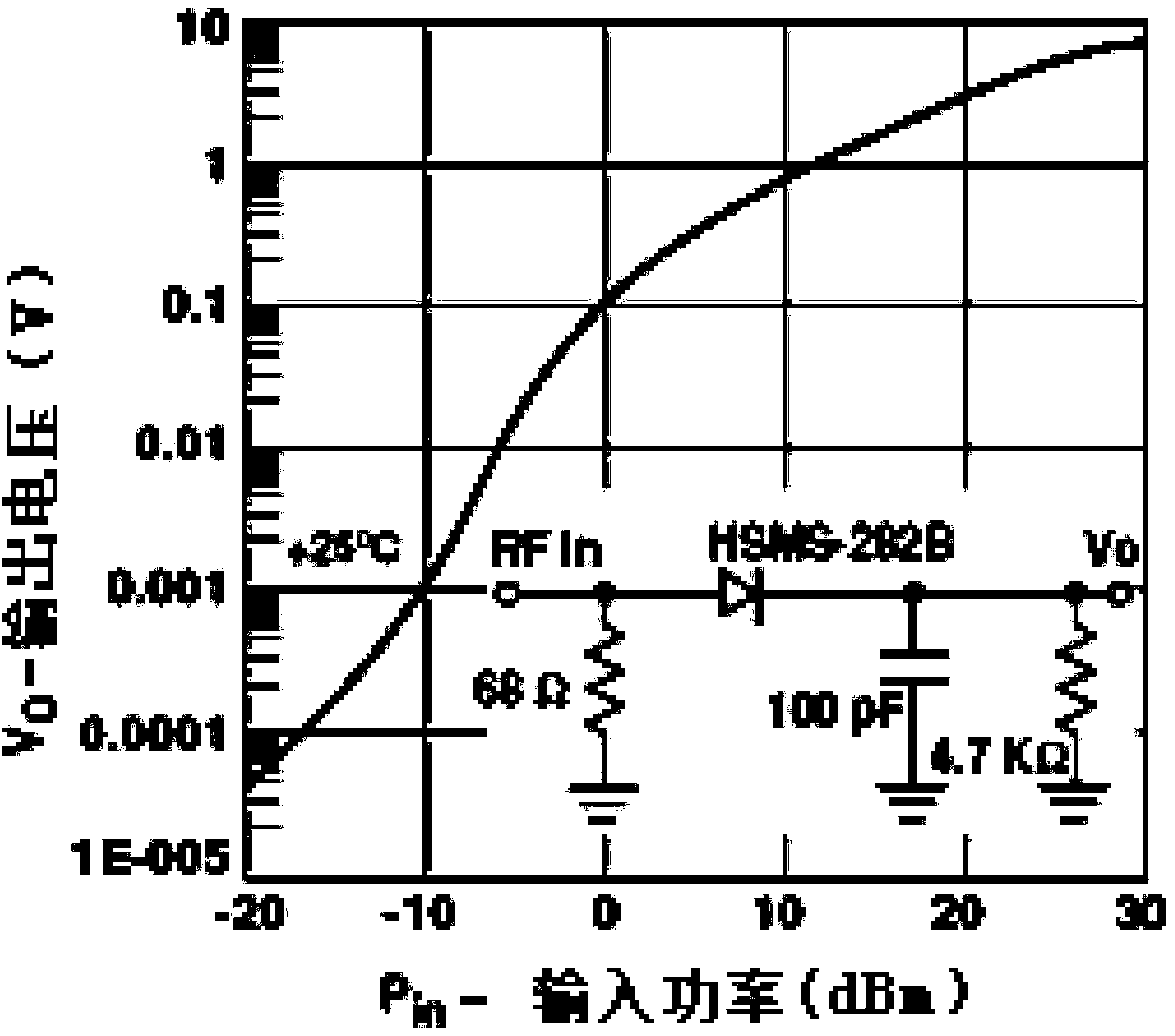

InactiveUS20050057302A1Pulse automatic controlAmplitude demodulation by non-linear two-pole elementsVoltage converterInput impedance

A diode detector comprising a detector network adapted to detect and multiply the detected voltage coupled to a divider network that comprise diodes in equal number to the number of diodes in the detector network, provides a passive detector applicable to any application requiring a small, efficient, high output, inexpensive temperature compensated detector for use as demodulator or as power to voltage converter. Integrating a portion of the divider network in the detector / multiplier network allows control over the minimum input impedance of the detector.

Owner:VECTRON INT INC

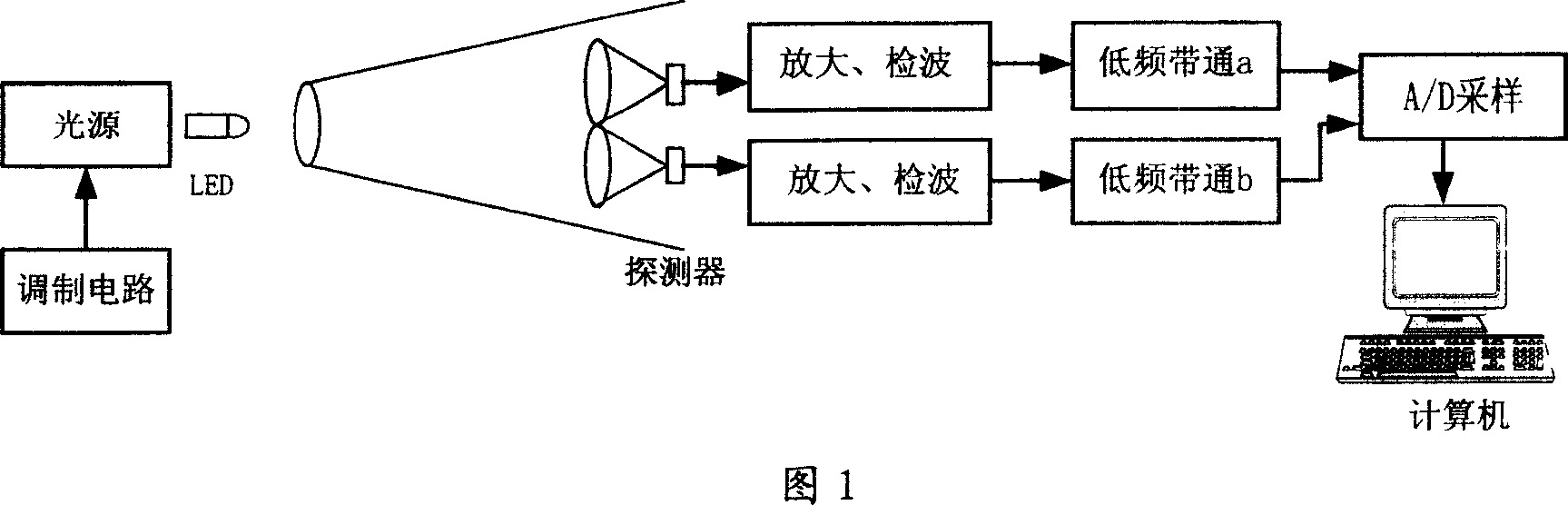

Optical method and device for measuring concentration of granules in certain velocity of flow

InactiveCN1959373AEasy maintenanceLow costMaterial analysis by optical meansParticle suspension analysisTime delaysLow frequency band

A device used for measuring concentration of optical velocity particle consists of LED and modulation circuit. It is featured as setting photoelectric diode detector in front of LED, amplifying signals by said detector then sending them to two low frequency band-pass filters, sending signals outputted by filters to computer through A / D conversion, calculating cross-correlation of two signals and their flow velocity by computer then calculating concentration of particle after signal is passed through two filters and is converted by A / D conversion.

Owner:刘文清 +8

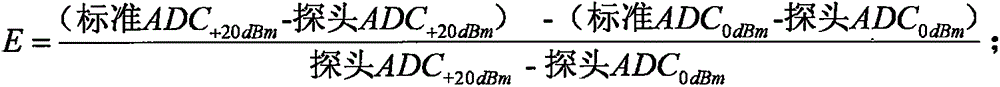

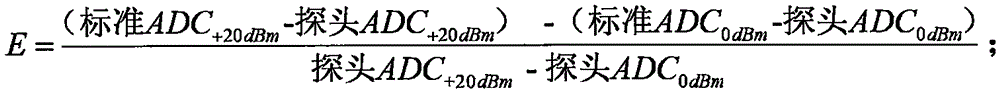

Internal calibration circuit of microwave power probe and calibration method

ActiveCN105259528AAchieve accurate calibrationGuaranteed accuracyElectrical measurementsAudio power amplifierControl signal

The invention provides an internal calibration circuit of a microwave power probe. The internal calibration circuit of the microwave power probe includes a microwave power sensor, a multi-core cable and a host power measurement channel; after microwave signals are inputted, a diode detector pair enabling +detection and -detection performs detection, so that +detection voltage and -detection voltage which are opposite to each other and have the same amplitude are outputted; a precise input operational amplifier performs 1:1 reverse amplification on output voltage of a D / A converter; various kinds of compensation data of the probe are stored in an EEPROM; an interface extender controls port output states through an IIC bus and is used for controlling the switching selection of high-speed switches and operating control signals of the D / A converter; and a linear differential amplifier enhances the transmission capability of the signals and transmits the signals to a power meter host through a cable. Compared with a method in which a calibration source plate is arranged inside a host, with the circuit and method of the invention adopted, 2000 yuan to 3000 yuan is expected to be saved, and calibration time is short, and calibration can be completed in one minute.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

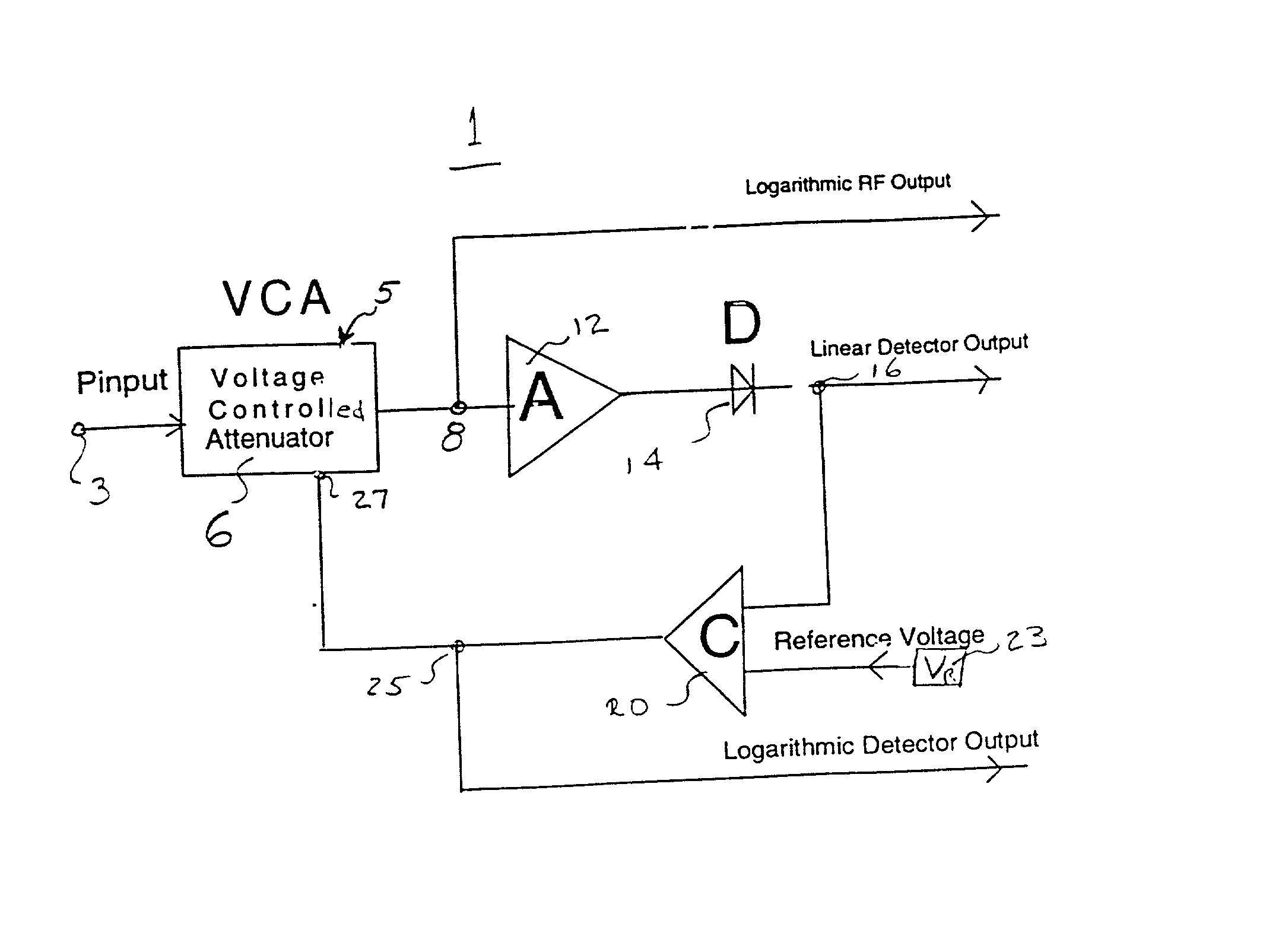

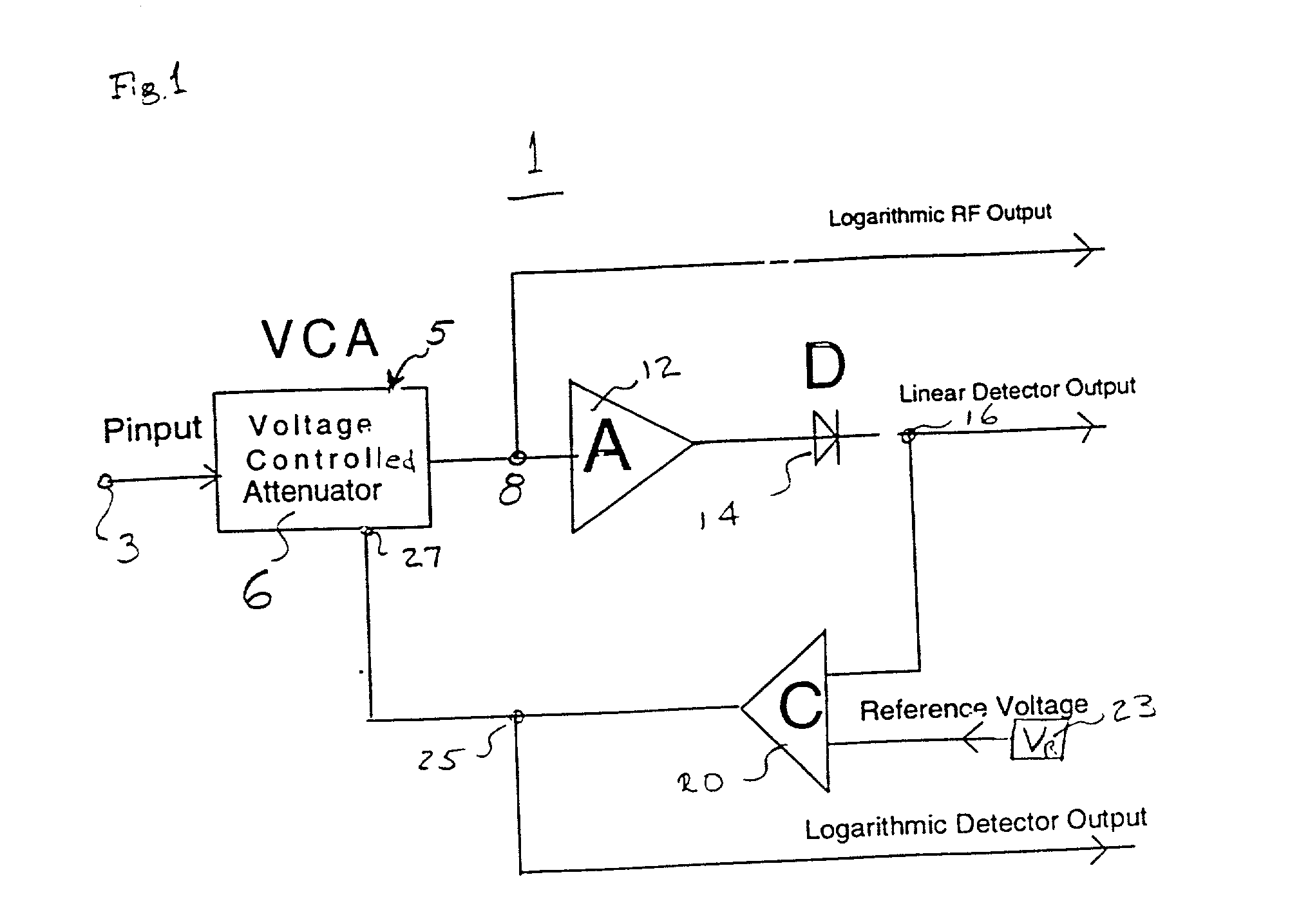

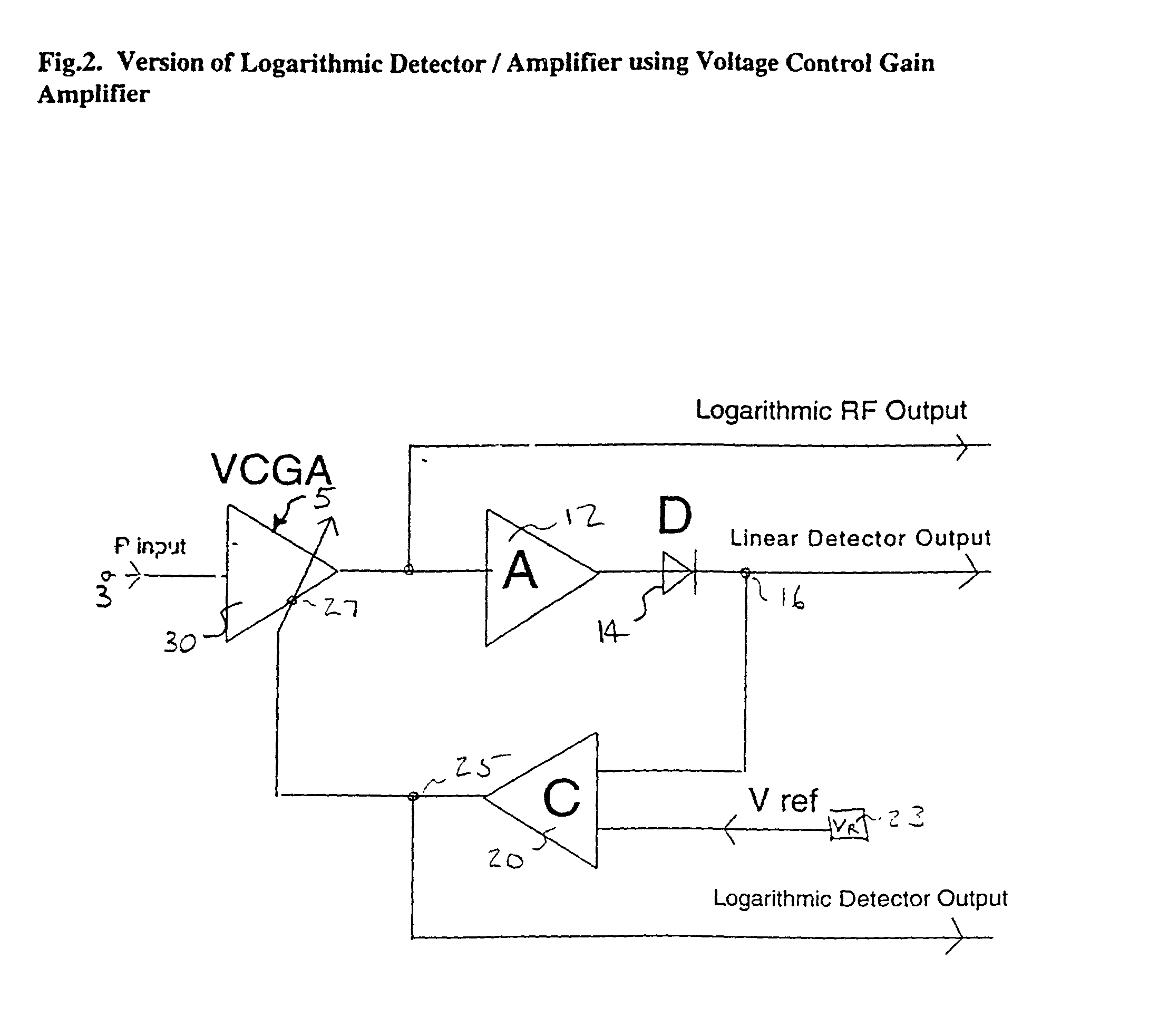

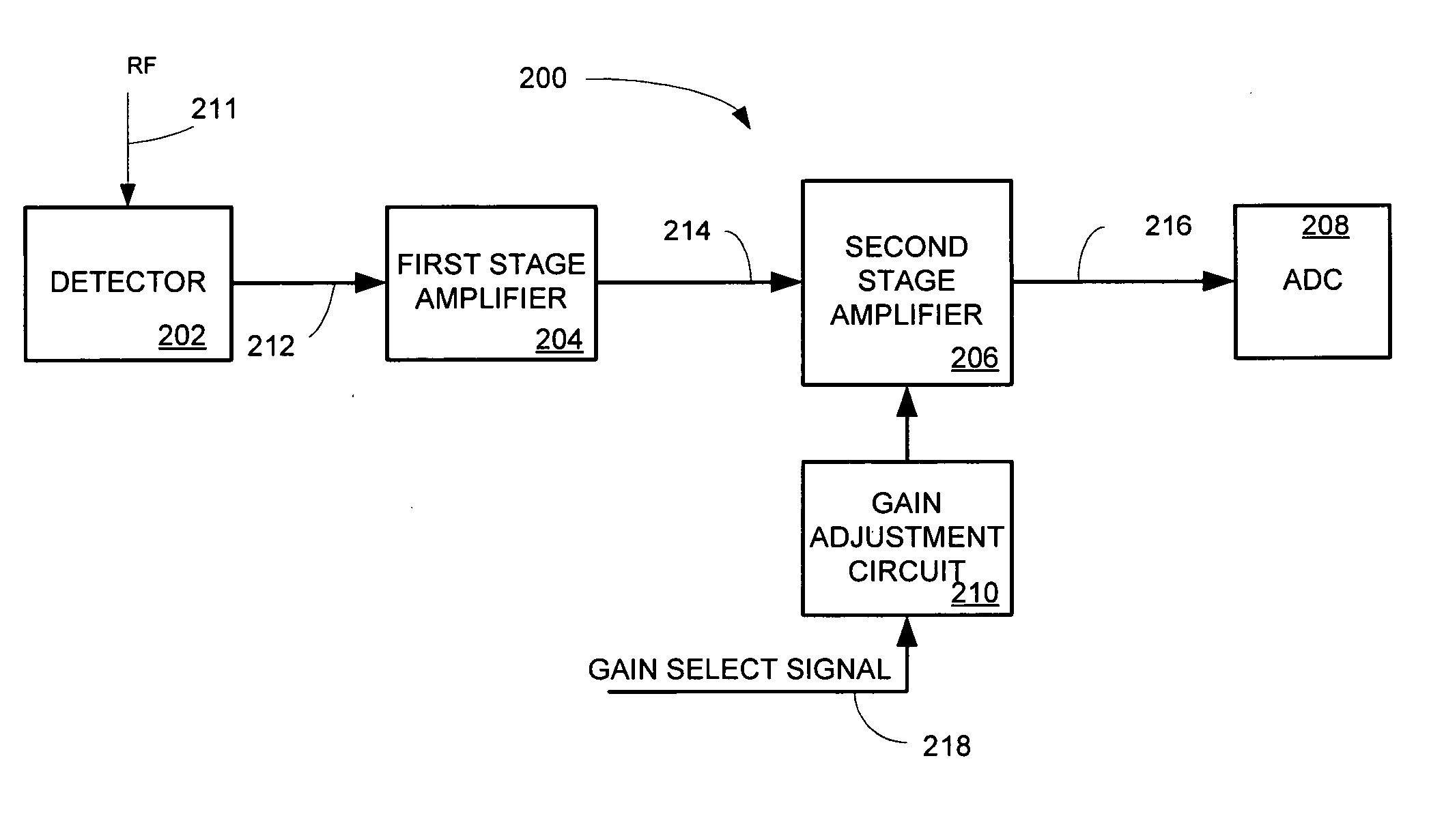

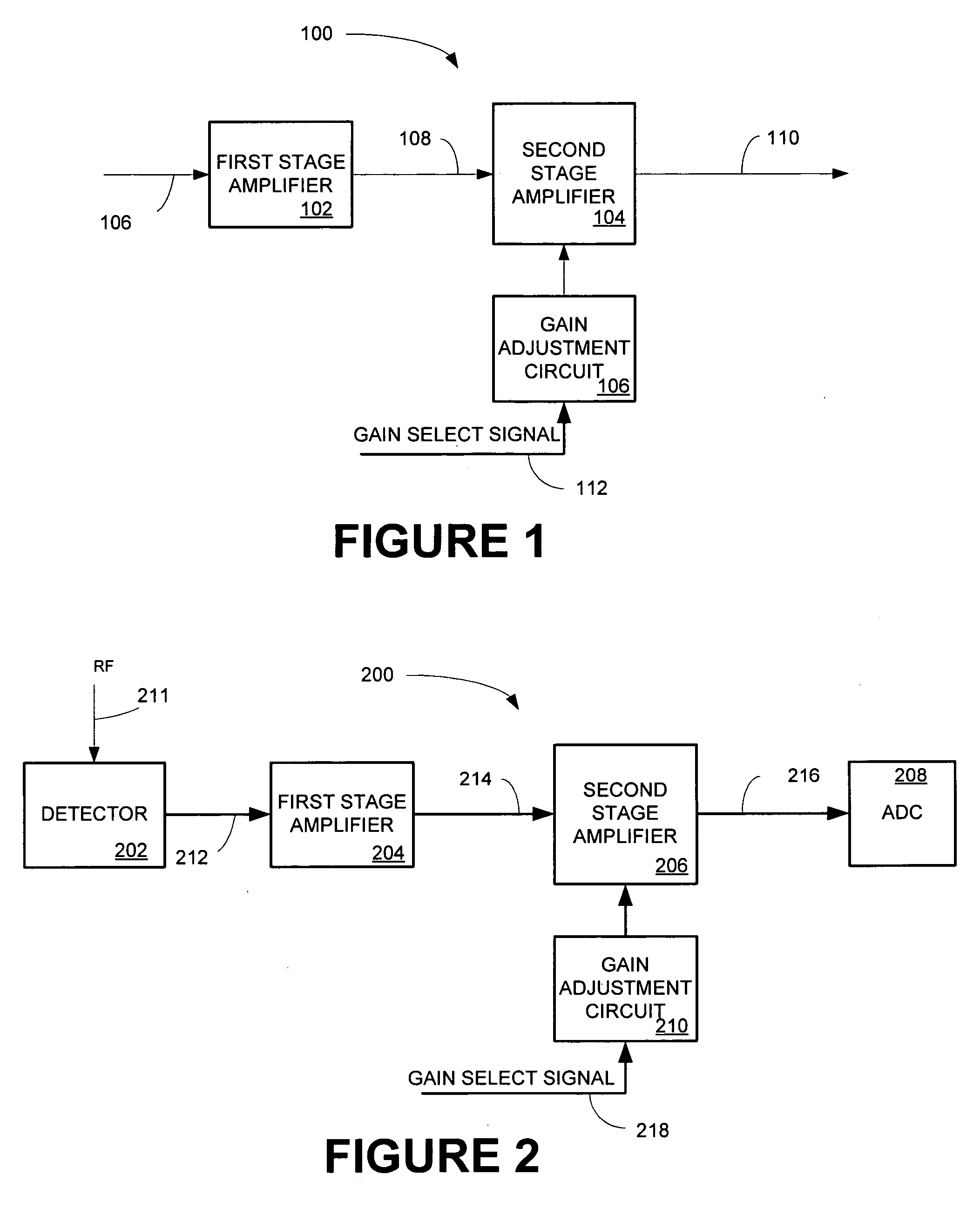

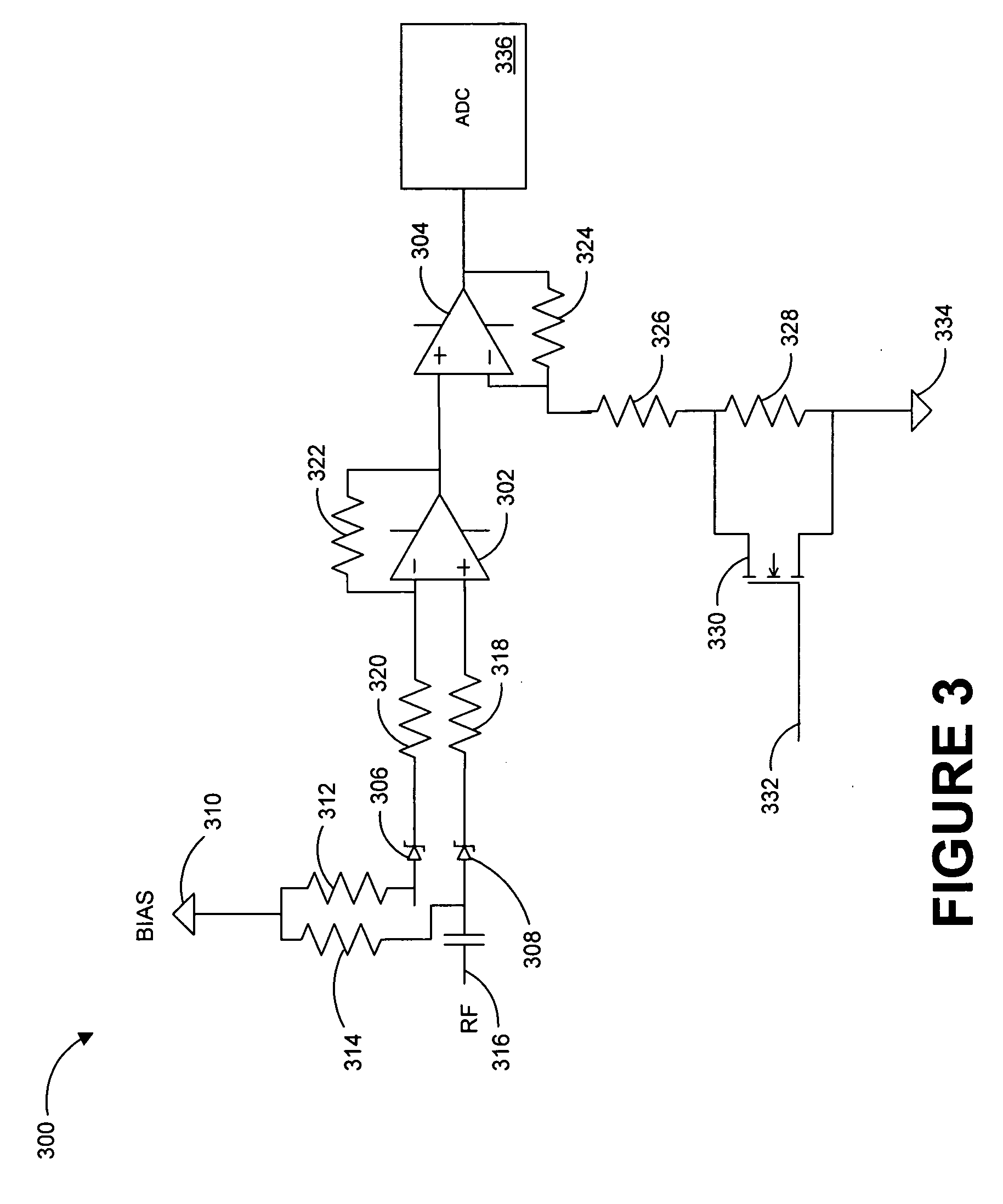

Extended range power detector and amplifier and method

InactiveUS20030006839A1Simplified and reliable adjustmentGain controlMulti-tester circuitsUltrasound attenuationVariable-gain amplifier

Owner:IBM CORP

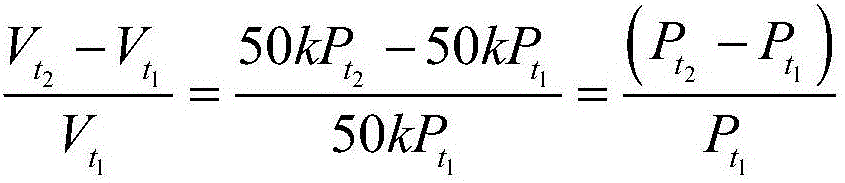

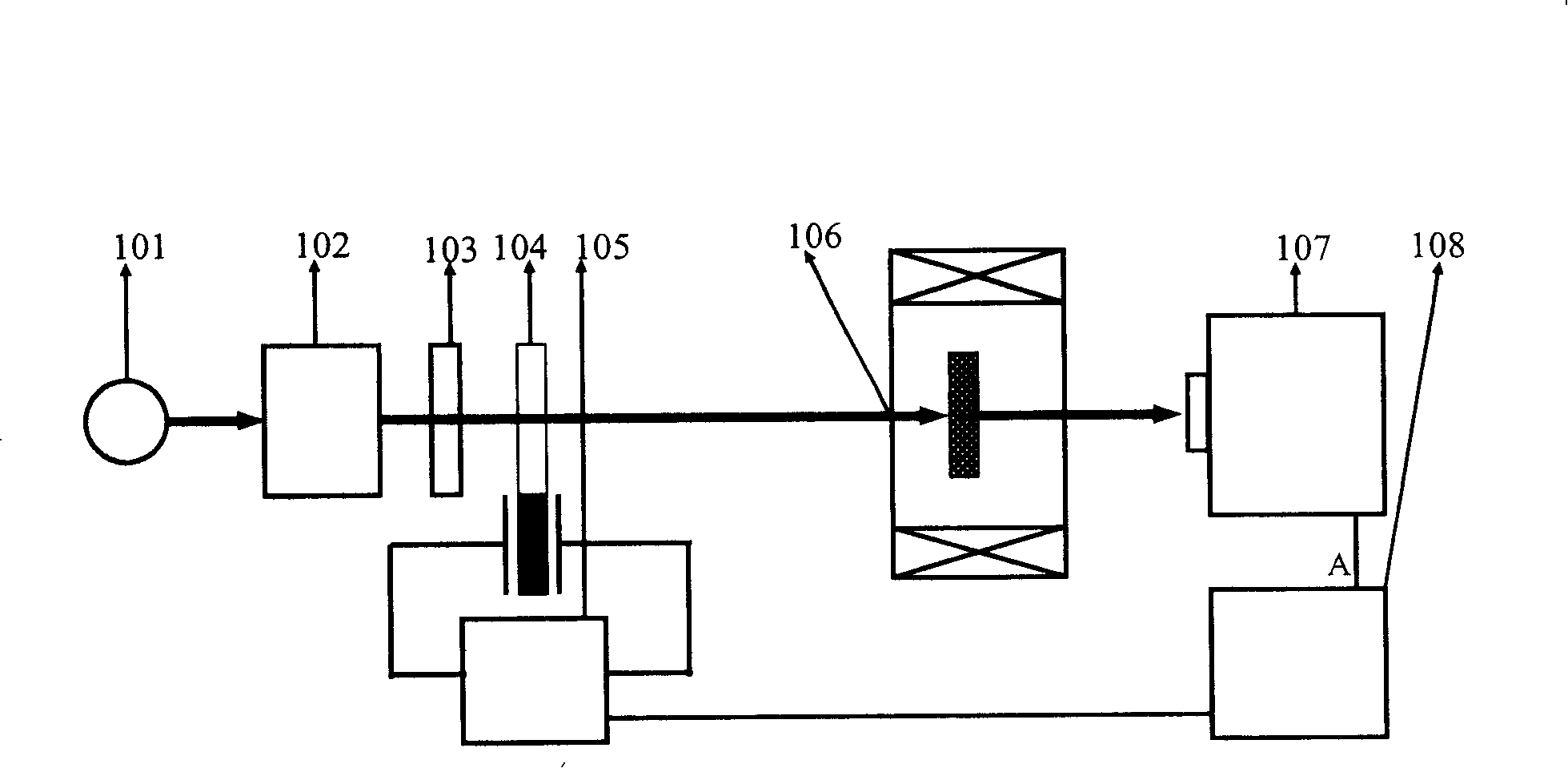

System and method for testing power stability of highly stable radiofrequency signal

ActiveCN105929222ARealize proportional conversion outputReduced by temperature changes, etc.Transmitters monitoringElectric devicesTest powerMicrowave power meter

The invention discloses a system and method for testing power stability of a highly stable radiofrequency signal. The system includes a directional coupler, an attenuator set, a microwave power meter, an upper computer, a high precision digital universal meter and a diode detector. The directional coupler is successively in serial connection to the attenuator set and the microwave power. The upper computer conducts system application measurement and control respectively on the microwave power meter and the high precision digital universal meter. A coupling end of the directional coupler is connected to the diode detector. The diode detector is in connection to the high precision digital universal meter and is a gallium arsenide diode detector. According to the invention, the system and the method have the following benefits: through the testing of stability of demodulation voltage, the evaluation object in testing the power stability of the radiofrequency signal is synchronously acquired in a non-distortion manner, and a constant temperature chamber and a gallium arsenide device are configured to reduce the influence on the demodulation voltage by temperature changes to the minimum with the proviso that the power of the input radiofrequency signal stays unchanged.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

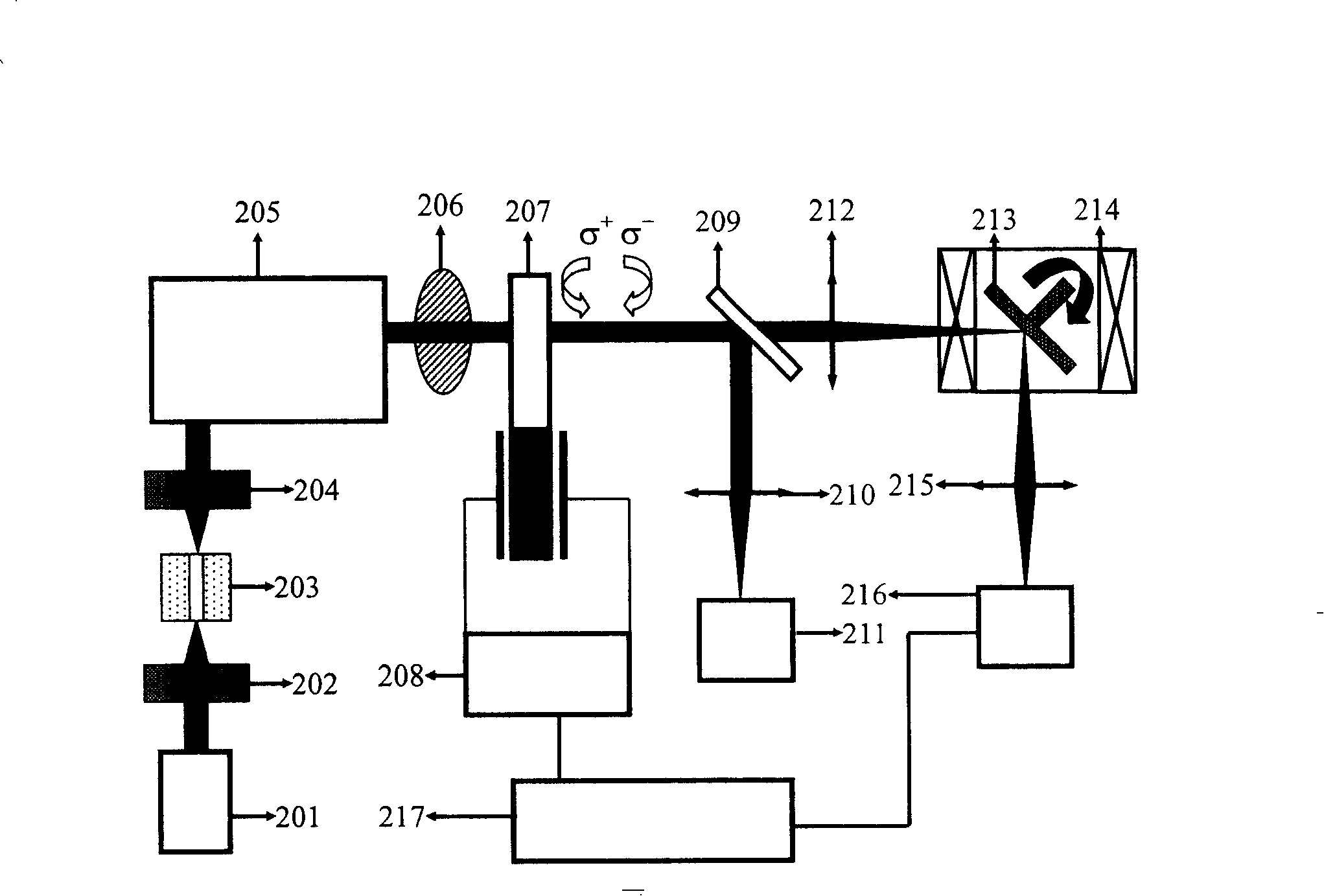

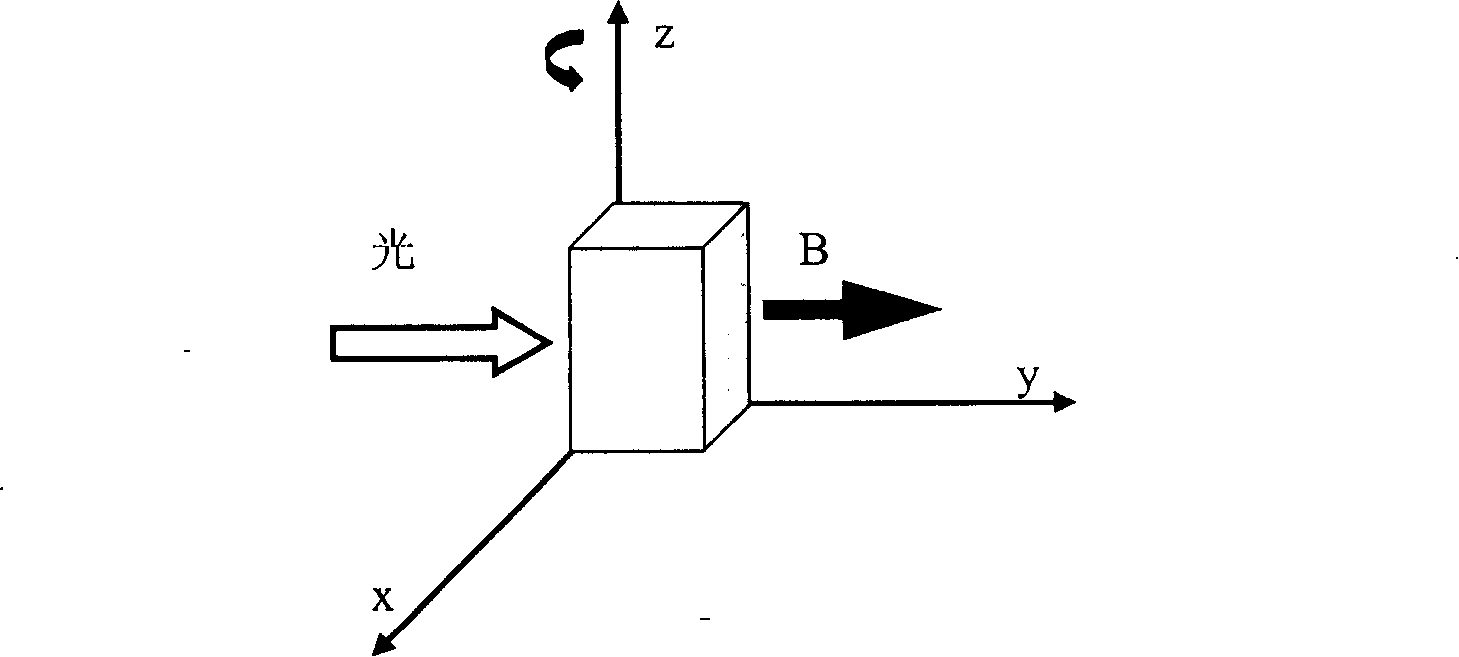

Magneto-optic circular polarization dichroism measuring system capable of adjusting measuring geometry

InactiveCN101196559AGood collimationNo lossMagnetic property measurementsTesting optical propertiesFrequency spectrumLantern

A measuring system for measuring the dichroism of the magneto-optical circular polarization with adjustable measuring geometry is provided, whose structure is that: a femtosecond laser excites the white light of the ultra-continuous spectrum, and divides the light by a monochrometer, which forms a monochromatic light whose wavelength can be adjustable. The monochromatic light can polarize through a purified Glan-Taylor prism with the extinction coefficient of 10 <5>; a lantern fly modulator, whose optical axis is 45degree angled with the optical axis of the Glan-Taylor prism to make the light become the circularly polarized light with the alternative variation of the sinistrality and the dextrorotation; a sample, which is put on the center of the cryogenic magnet; The circularly polarized light focuses on the sample, and the reflex reflected from the sample is focuses on the first LED detector; a phase-locking amplifier, whose reference signal is provided by the lantern fly modulator used for testing the difference of light intensity between the sinistrality and the dextrorotation of the circularly polarized light. The invention can not only test the frequency spectrum of the dichroism of the magneto-optical circular polarization of the materials, magnetic density and temperature dependence, but also can test the magnetocrystalline anisotropy of the magnetic semiconductor.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

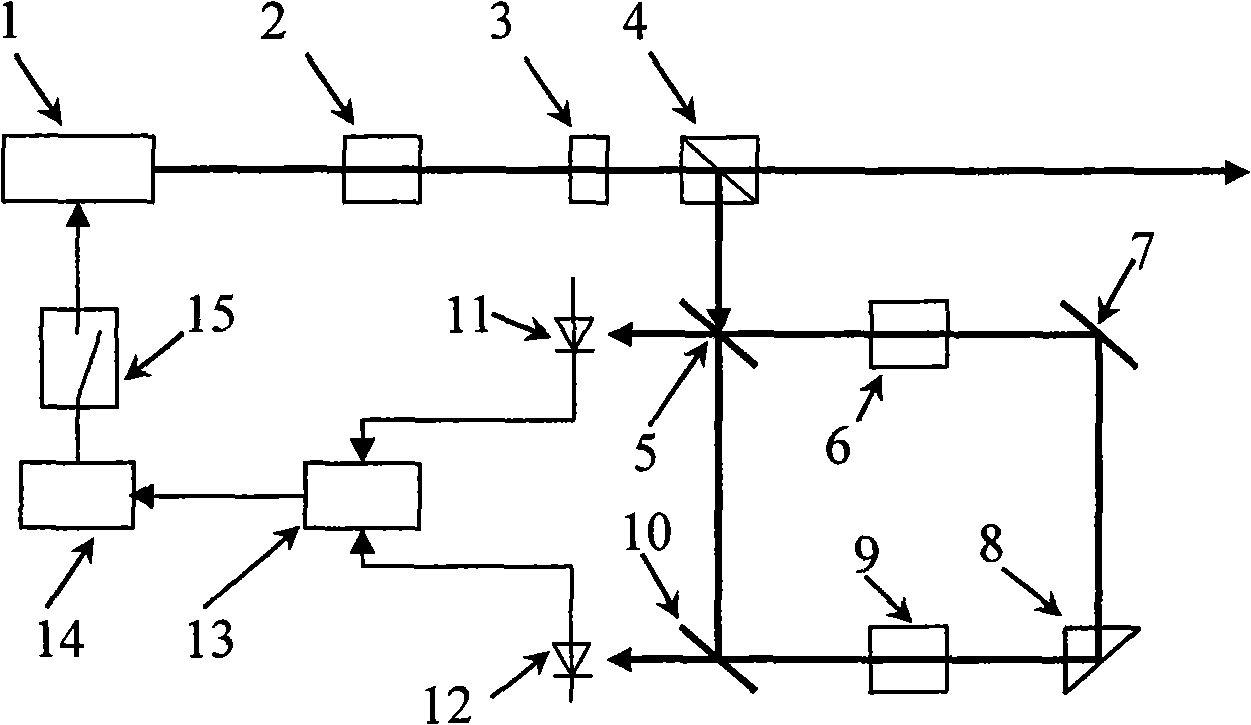

Coherent phase detecting method based on Mach-Zehnder interferometer

InactiveCN101957238AEasy to operateLow costOptical measurementsPhase differenceMach–Zehnder interferometer

The invention discloses a coherent phase detecting method based on a Mach-Zehnder interferometer, belonging to the technical field of optical quantity detection. Lasers emitted by a laser source (1) are divided into two paths through a first optical fiber coupler (2) and then are respectively transmitted by a first optical fiber interference arm (4) and a second optical fiber interference arm (5); the first optical fiber interference arm (4) and the second optical fiber interference arm (5) are putted into the same constant-temperature control system; two paths of lasers are combined into one path in a primary phase difference detection process, and the photocurrent intensity Io of the combined laser is detected by using a photoelectric diode detector; the intensities I1, I2 of photocurrents output from the two optical fiber interference arms are respectively detected; and the primary phase difference of the two optical fiber interference arms is calculated by using a formula. The invention has the advantages of simple operation and low cost because of no use of a phase shifter of a piezoelectric crystal and the like; a computer is not used to assist calculation, and the measurement precision is superior to 0.04 and better precision can be obtained under larger laser drive current.

Owner:JILIN UNIV

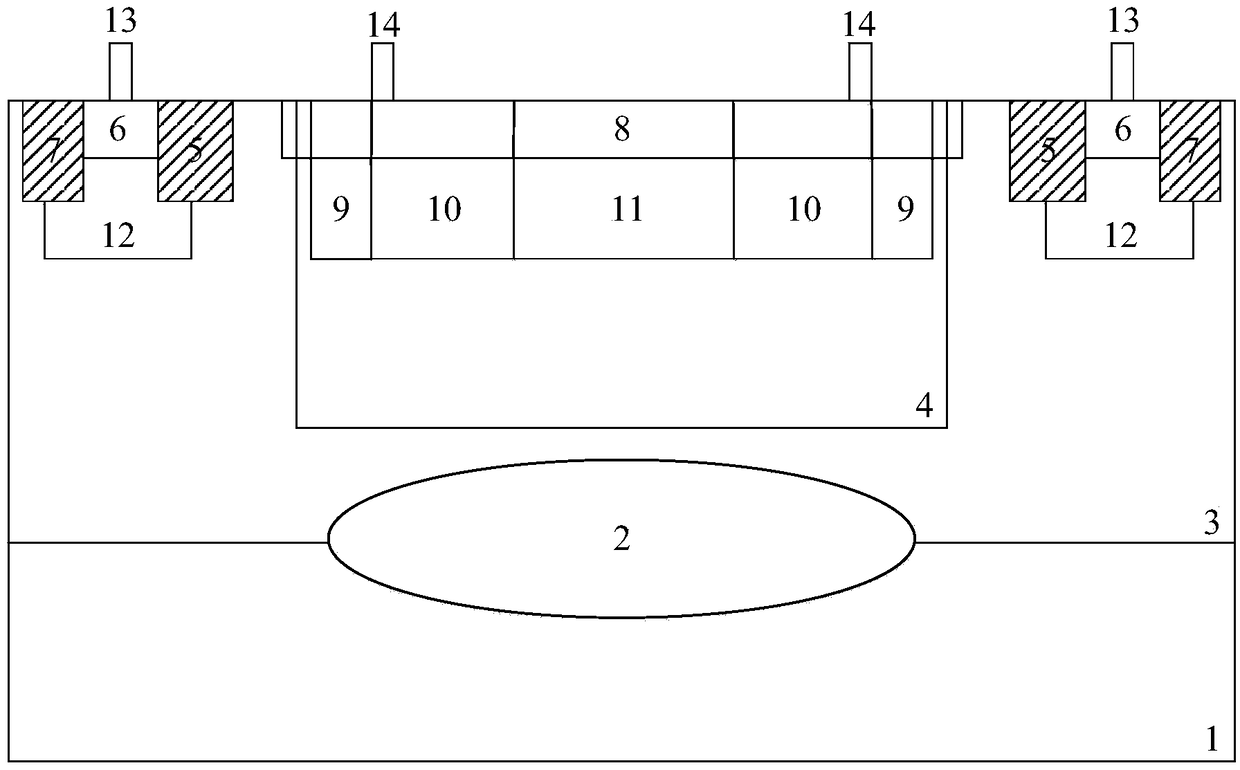

Optical topology imaging system and method on basis of digital phase locking detection technology

InactiveCN102599888ALow priceQualitative measurement imaging stability is goodDiagnostic recording/measuringSensorsData acquisitionInfrared wavelength

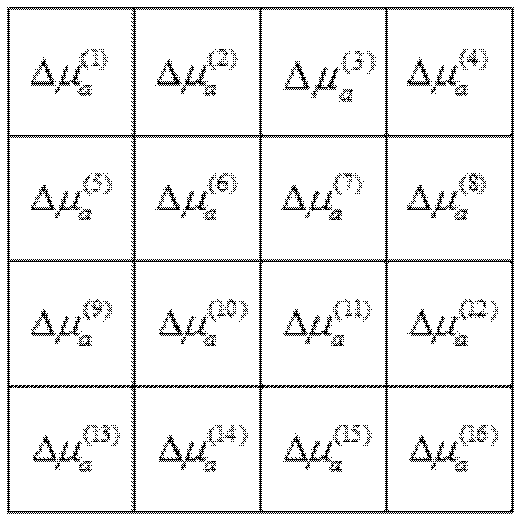

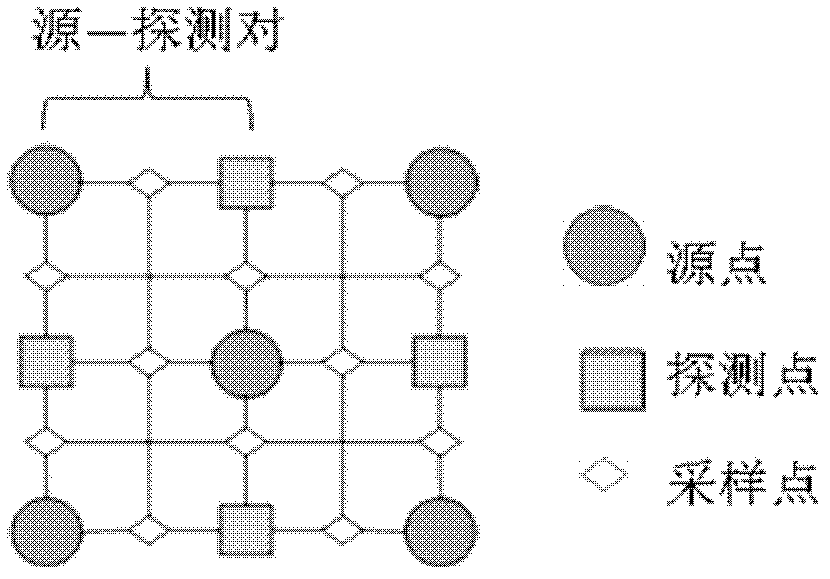

The invention belongs to the field of near-infrared optical tissue imaging, and relates to an optical topology imaging system on the basis of digital phase locking detection technology. The optical topology imaging system comprises a light source, a detection portion, a data acquisition portion and a computer, the light source comprises at least two laser devices capable of generating laser with different near-infrared wavelengths, a multichannel direct digital synthetic sine signal modulator, a single-mode optical fiber and wavelength division multiplexer and a light switch; and the detection portion comprises a plurality of source optical fibers, a plurality of detection optical fibers, source and detection optical fiber distribution patches, four silicon photoelectric diode detectors and a multichannel program control filter amplifier, each source and detection optical fiber distribution patch comprises five source points and four detection points, wherein the five source points of each source and detection optical fiber distribution patch are respectively distributed at the four vertexes and the center of a square, and the four detection points of each source and detection optical fiber distribution patch are distributed at the midpoints of four sides of the corresponding square. The invention also provides a tissue imaging method realized by the aid of the optical topology imaging system. The imaging system is cheap in price, stability of observational measurement imaging is fine, and the measurement area and the accuracy of the system can be improved.

Owner:TIANJIN UNIV

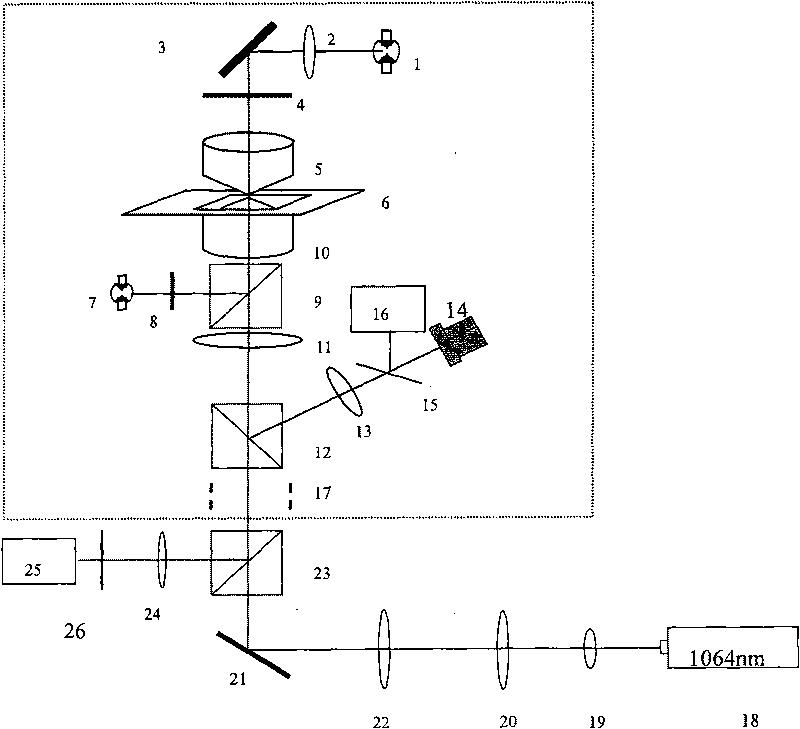

Modulation-free frequency stabilizer of external cavity semiconductor laser

ActiveCN101526714AImprove stabilityGood anti-interferenceLaser optical resonator constructionPhotometry using electric radiation detectorsProportional integral differentialFrequency stabilization

A modulation-free frequency stabilizer of an external cavity semiconductor laser consists of a single frequency narrow-linewidth external-cavity semiconductor laser, a Faraday isolator, a first half-wave plate, a polarization beam splitter, a Sagnac ring, a differential detection circuit consisting of two photoelectric diode detectors, a subtraction circuit, a proportional-integral-differential processing circuit and a switch. The modulation-free frequency stabilizer has the advantages of simple structure, good frequency stabilization effect, low cost and the like.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

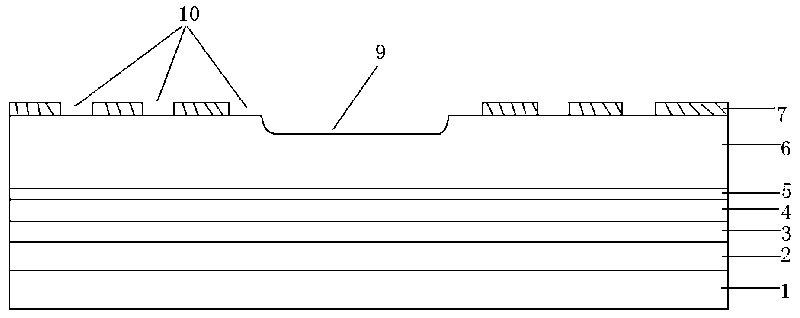

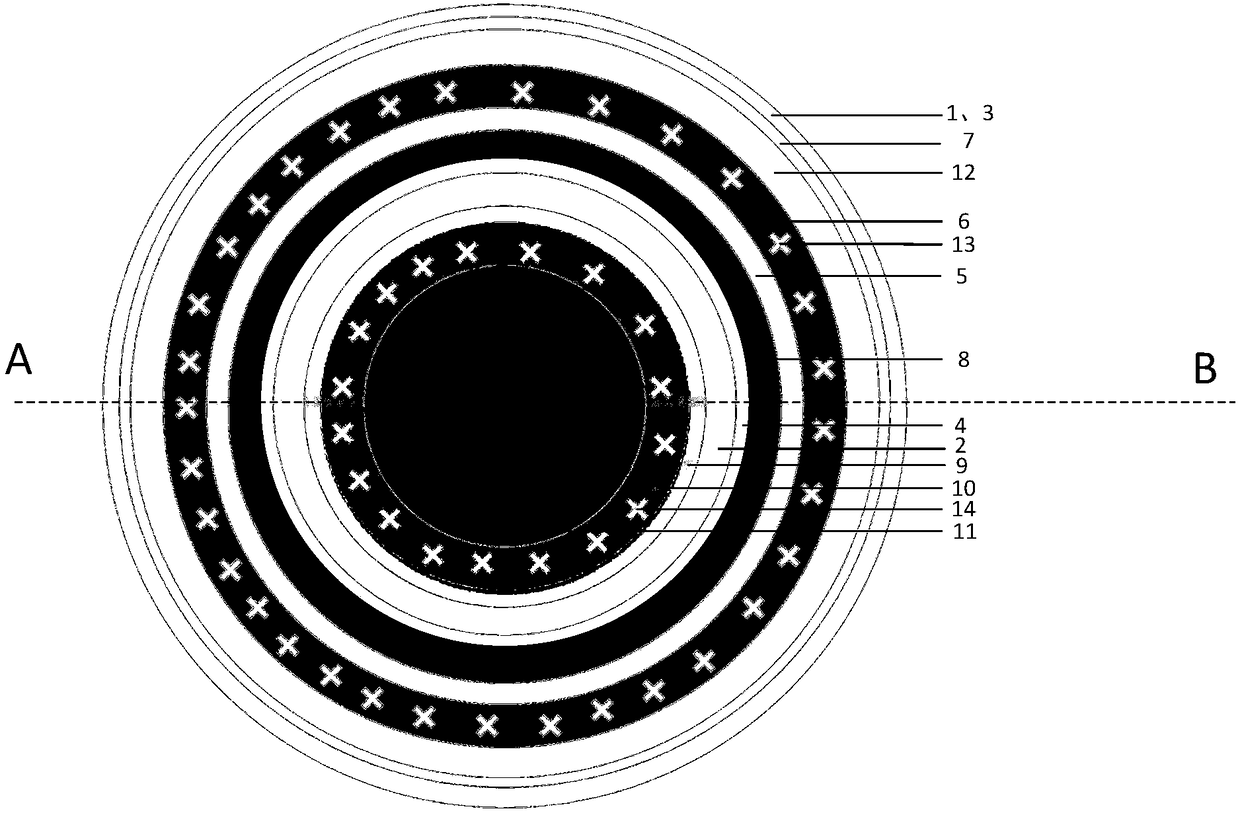

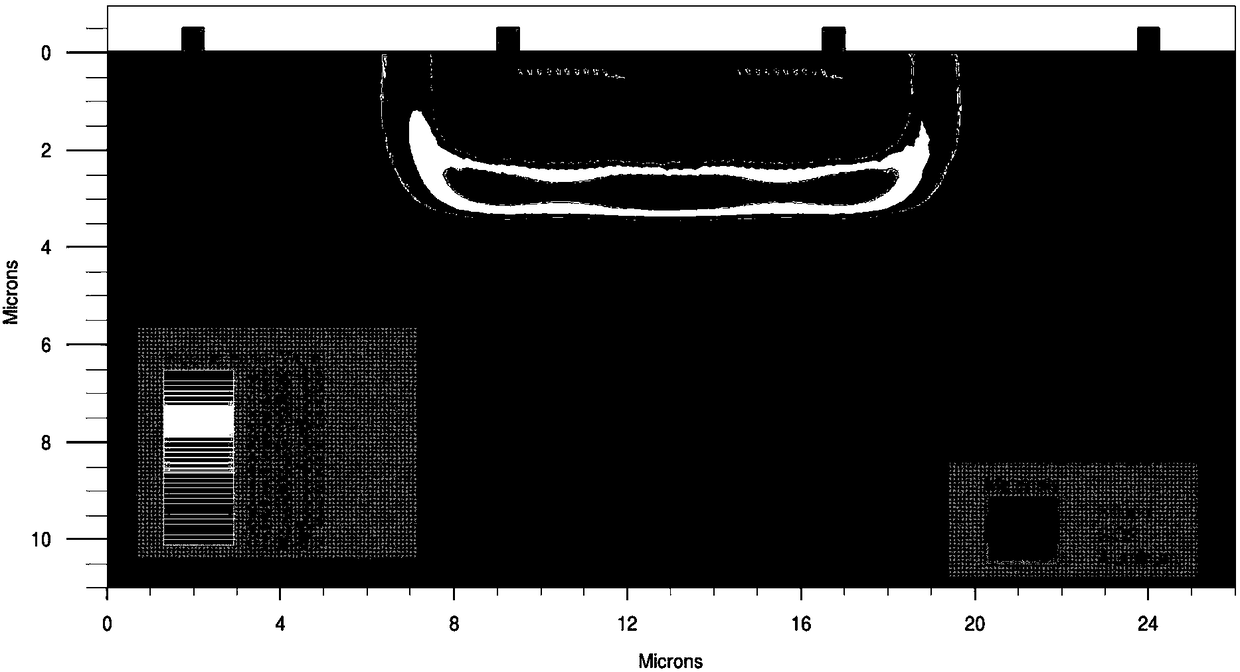

CMOS single photon avalanche diode detector of near-infrared wide spectrum and manufacturing method thereof

ActiveCN108511467AImplement detectionEnhanced electric fieldFinal product manufactureSolid-state devicesCMOSSingle-photon avalanche diode

The present invention discloses a CMOS single photon avalanche diode detector of a near-infrared wide spectrum. The detector comprises a cylindrical P-type substrate, a P epitaxial region, a deep N well region, a center N well region, an N+ region and an annular first P well region, a side N well region, a second P well region and a P+ region which are coaxially arranged. The SPAD (single photon avalanche diode) detector forms a deep main avalanche region between the deep N well region and the P- epitaxial region to detect near-infrared shortwave photons; and the deep N well is internally provided with two shallow secondary avalanche ring regions capable of detecting the shortwave photons so as to achieve detection of wide spectrum photons from blue light to the near-infrared shortwaves. The CMOS single photon avalanche diode detector can be manufactured by employing a standard CMOS technology, and is high integration, low in power loss and high in capacity of resisting disturbance.

Owner:武汉光迹融微科技有限公司

Contaminant detector for food inspection

InactiveUS7450686B2Low costFree of ChargeRadiation/particle handlingX-ray tube electrodesDetector arrayImage manipulation

Owner:THERMO FISHER SCIENTIFIC INC

System and method for increasing accuracy of transmitter power detection over a larger range of output power levels

ActiveUS20070080748A1Increase temperatureHigh gain or low gainNegative-feedback-circuit arrangementsGain controlAudio power amplifierLow gain

A system and method for increasing accuracy of transmitter power detection over a larger range of output power levels wherein a diode detector is followed by a series cascade of 2 op amps. The first op amp functions as a differential / buffer amplifier, which improves temperature performance. The second op amp has two selectable gain factors. The output of the second op amp is routed to the ADC. A single control can is connected to a controllable switching device that configures the second op amp for high gain or low gain.

Owner:CISCO TECH INC

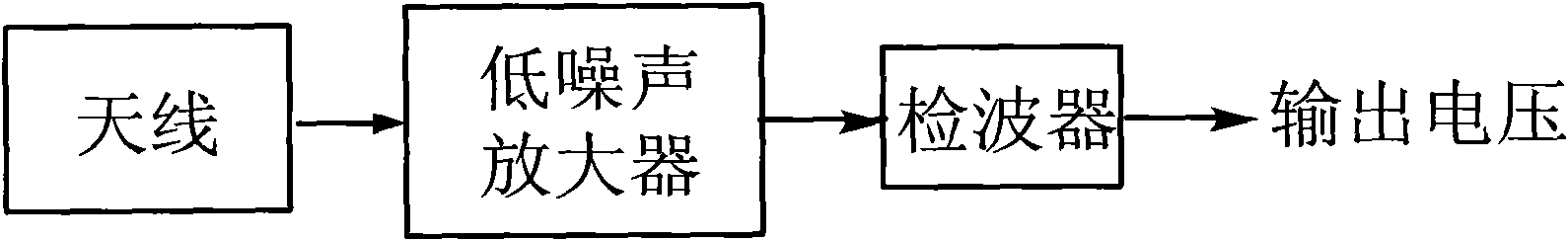

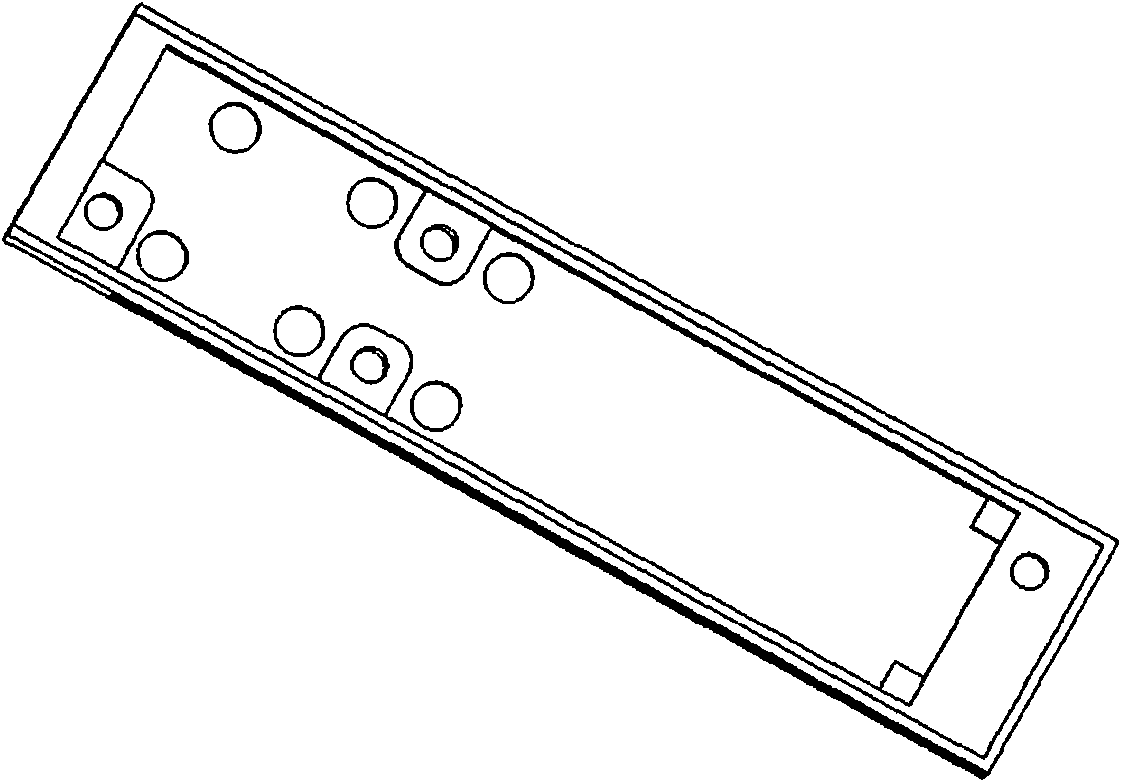

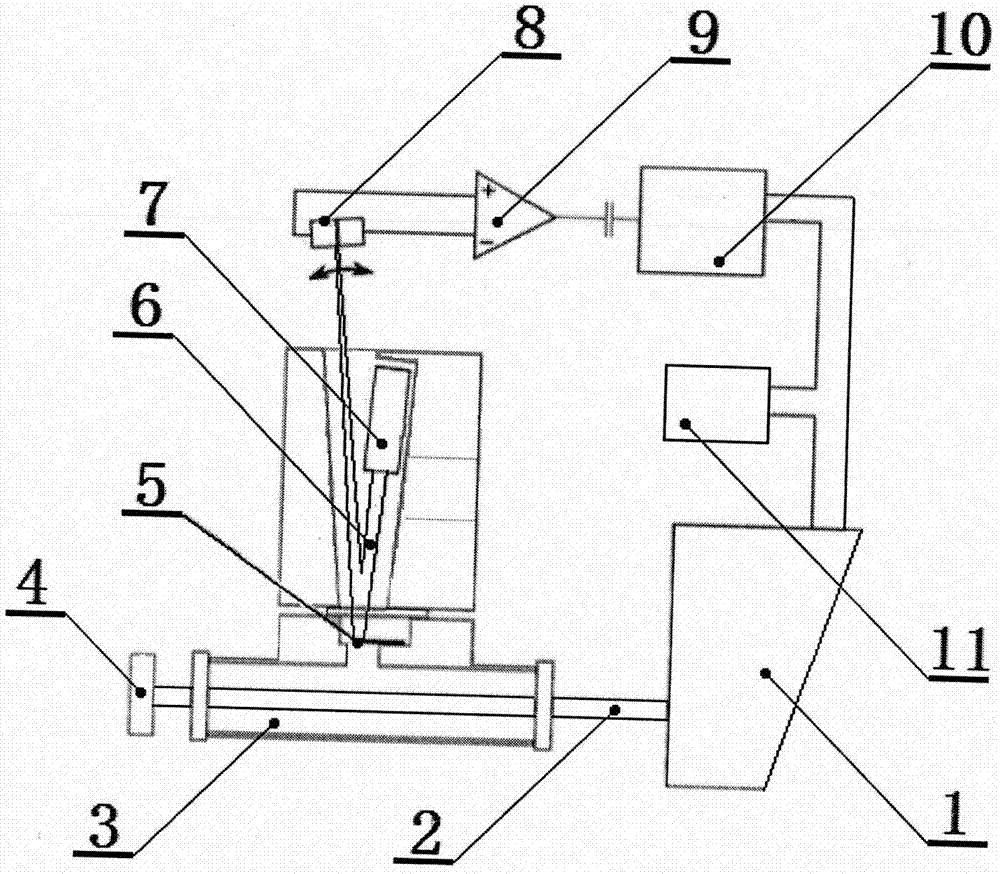

Integrated high-sensitivity millimeter wave receiver for millimeter wave array imaging system

ActiveCN101776750ASuitable for needsMeet needsWave based measurement systemsHigh volume manufacturingLarge size

The invention provides an integrated high-sensitivity millimeter wave receiver for a millimeter wave array imaging system, which comprises a plate body with a hole body, an integrated RF circuit fixed on one side of the plate body, a power supply circuit fixed on the other side of the plate body, and two packaging cover bodies; the integrated RF circuit further comprises a plane micro strip slot antenna used to receive millimeter wave, a low-noise amplifier used to amplify the accessed millimeter wave, and a mixed and integrated diode detector used to convert the amplified millimeter wave into low-frequency voltage signals which are in direct proportion to the power; the power supply circuit is connected with the integrated RF circuit through the hole body, and is used to supply power to the RF circuit; and the two packaging cover bodies are used to clamp the plate body for packaging. The compact structure can effectively overcome large size, poor stability and other defects, greatly reduces the size and the weight of the millimeter wave receiver, improves the performance, the quality and the reliability of the complete machine, and is applicable to mass production, so as to meet the needs of the array millimeter wave imaging system.

Owner:杭州芯影科技有限公司

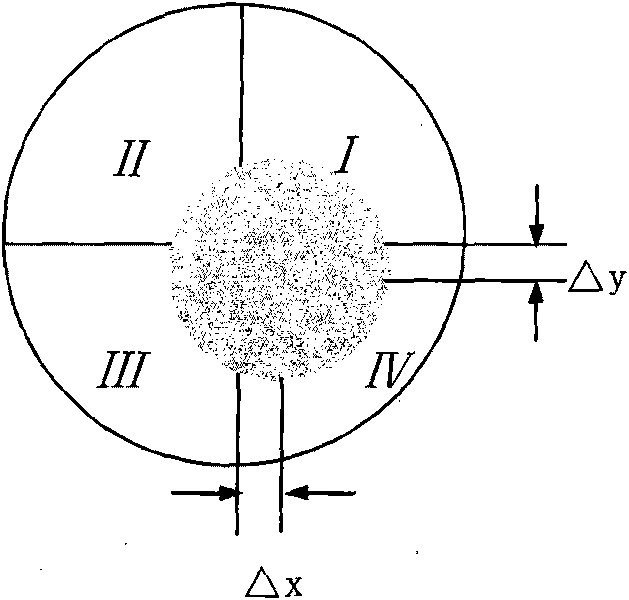

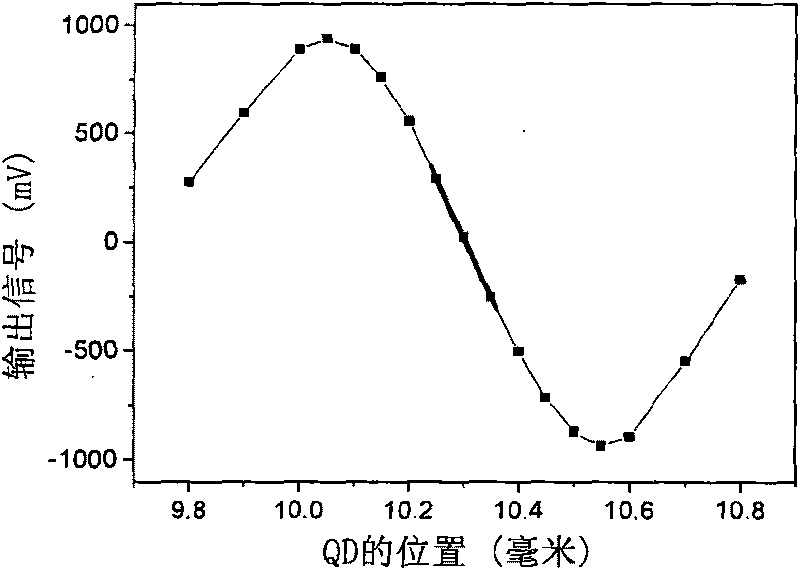

Method for demarcating four-quadrant detector in real time

InactiveCN101738164AAccurate acquisitionEasy to operateUsing optical meansFour quadrantsOptical measurements

The invention provides an optical measuring system. The system comprises a four-quadrant photodiode detector, a detected-object image generating device and a stepping motor which is provided with a glass slide and can drive the glass slide to vibrate, wherein the stepping motor is arranged between the four-quadrant photodiode detector and the detected-object image generating device and enables light rays radiated from the detected-object image generating device to the four-quadrant photodiode detector to straightly penetrate through the glass slide on the stepping motor. Based on the relationship between the distance of the light rays shifted by the glass slide and the output signals of the four-quadrant photodiode detector, the invention directly demarcates the switching coefficient between the output voltage of the four-quadrant photodiode and the displacement of the image of the detected object without making any regulation to the original light path system, thereby achieving the advantages of simple and convenient operation and real-time and accurate acquisition of experimental parameters.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

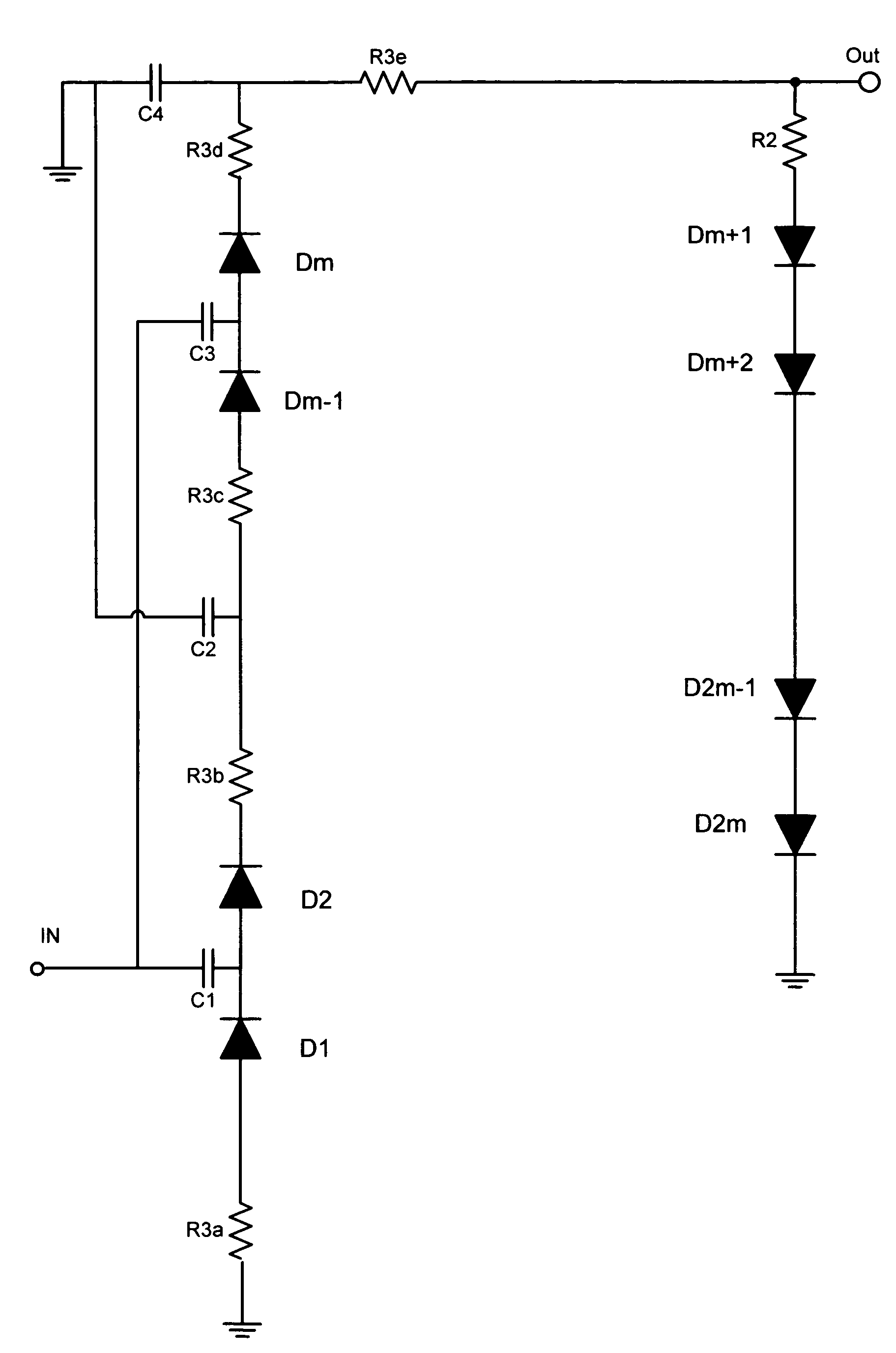

Partial-discharge ultrahigh-frequency-signal detection conditioning circuit

ActiveCN104035012AAmplitude demodulation by non-linear two-pole elementsAmplitude demodulation detailsCapacitanceAudio power amplifier

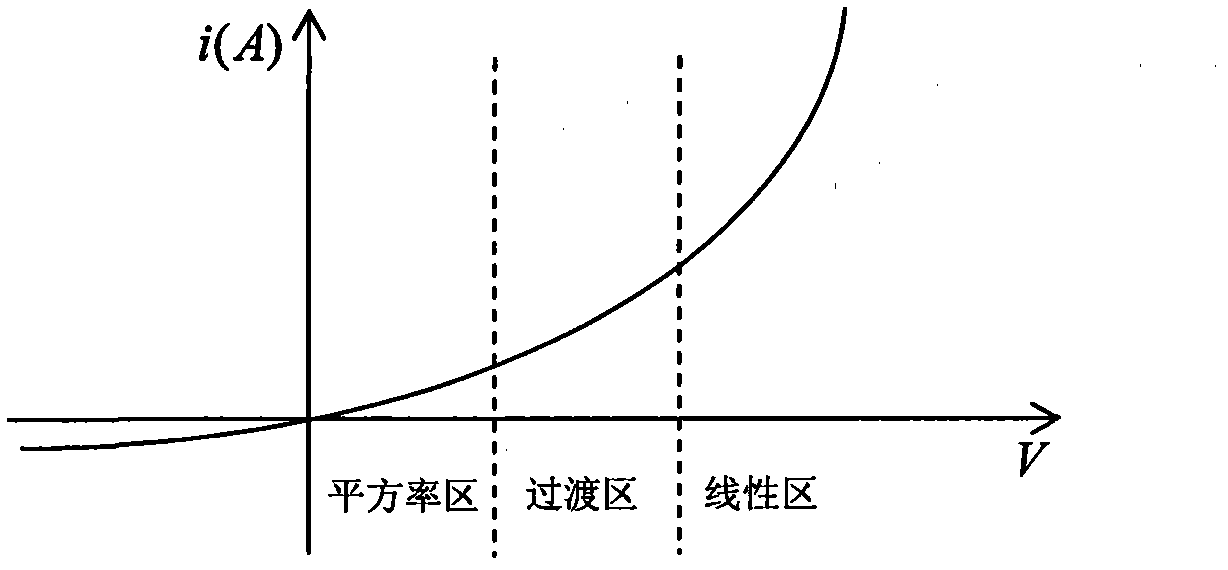

Disclosed is a partial-discharge ultrahigh-frequency-signal detection conditioning circuit which includes an input capacitor C0, a first capacitor C1, a second capacitor C2, a third capacitor C3, a first resistor R1, a second resistor R2, a third resistor R2, a forth resistor R4, a fifth resistor R5, a first diode D1, a second diode D2, a negative bias voltage UB and an amplifier A1. The partial-discharge ultrahigh-frequency-signal detection conditioning circuit improves defects of poor small-signal sensitivity, serious nonlinearity, low response speed and sensitivity to temperature and the like of a basic diode detector circuit through application of DC negative voltage bias and design of a balance-type topological structure on the basis of the basic diode detector circuit so that balance-type negative bias voltage diode detection is finally designed and realized.

Owner:STATE GRID CORP OF CHINA +1

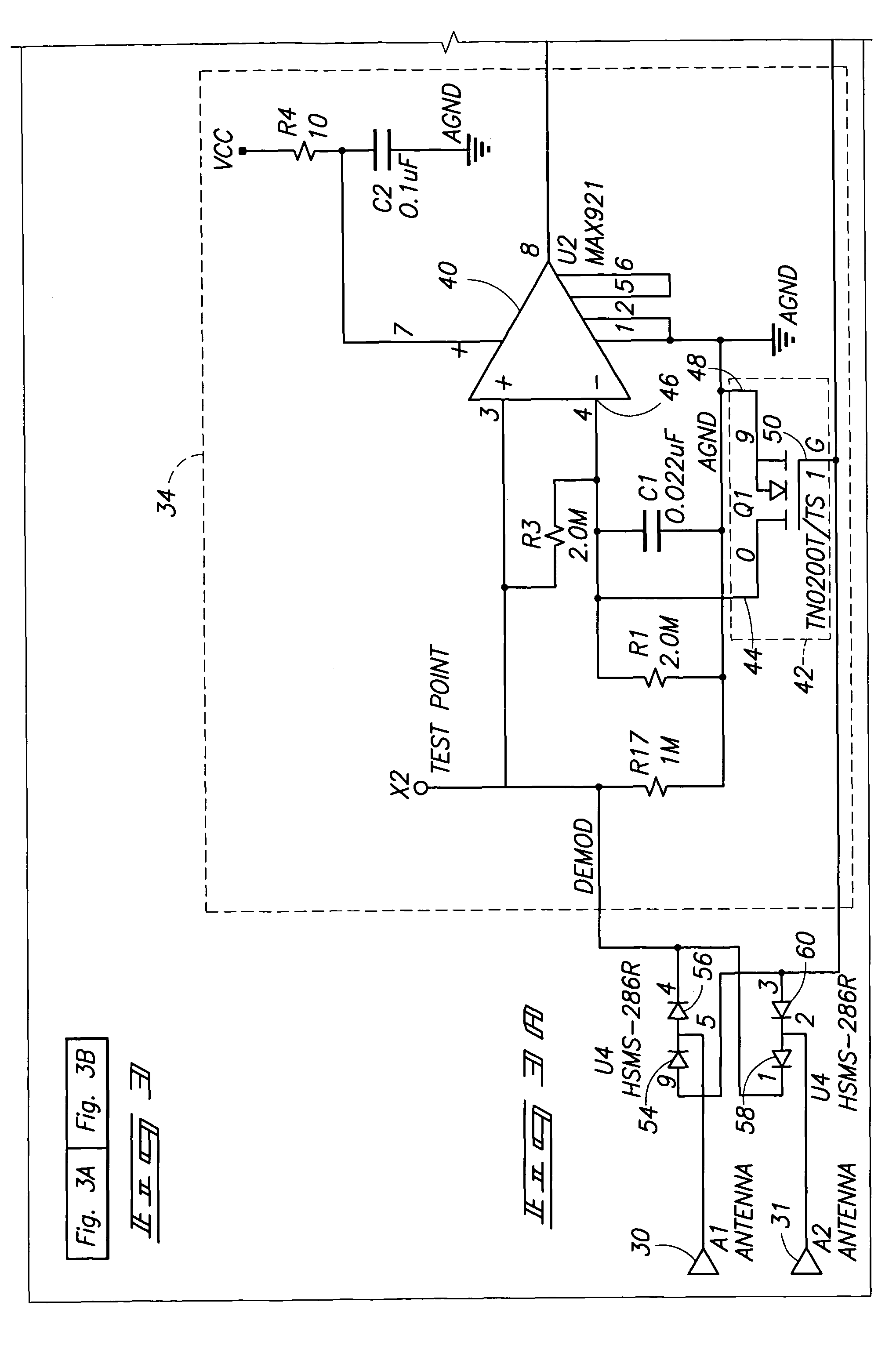

RFID tag modification for full depth backscatter modulation

InactiveUS7760073B2Increase changeReduced change in impedanceSubscribers indirect connectionRecord carriers used with machinesControl signalContinuous wave

A modulated backscatter radio frequency identification device includes a diode detector configured to selectively modulate a reply signal onto an incoming continuous wave; communications circuitry configured to provide a modulation control signal to the diode detector, the diode detector being configured to modulate the reply signal in response to be modulation control signal; and circuitry configured to increase impedance change at the diode detector which would otherwise not occur because the diode detector rectifies the incoming continuous wave while modulating the reply signal, whereby reducing the rectified signal increases modulation depth by removing the reverse bias effects on impedance changes. Methods of improving depth of modulation in a modulated backscatter radio frequency identification device are also provided.

Owner:BATTELLE MEMORIAL INST

Avalanche photo diode detector systems

ActiveCN104049193AReduce power consumptionIncreased power consumptionGain controlPhotometry electrical circuitsPower flowOptical power

An avalanche photo diode detector including an avalanche photo diode, an adjustable voltage source, a current mirror coupled to the voltage source output of the adjustable voltage source and having a current measurement output, and a processor coupled to the adjustable voltage source and the current mirror. The processor implements a process of obtaining a signal current measurement from the current mirror, computing an estimate of an input optical power level from the signal current measurement and adjusting the output of the adjustable voltage source based upon on the estimate of the input optical power level.

Owner:MAXIM INTEGRATED PROD INC

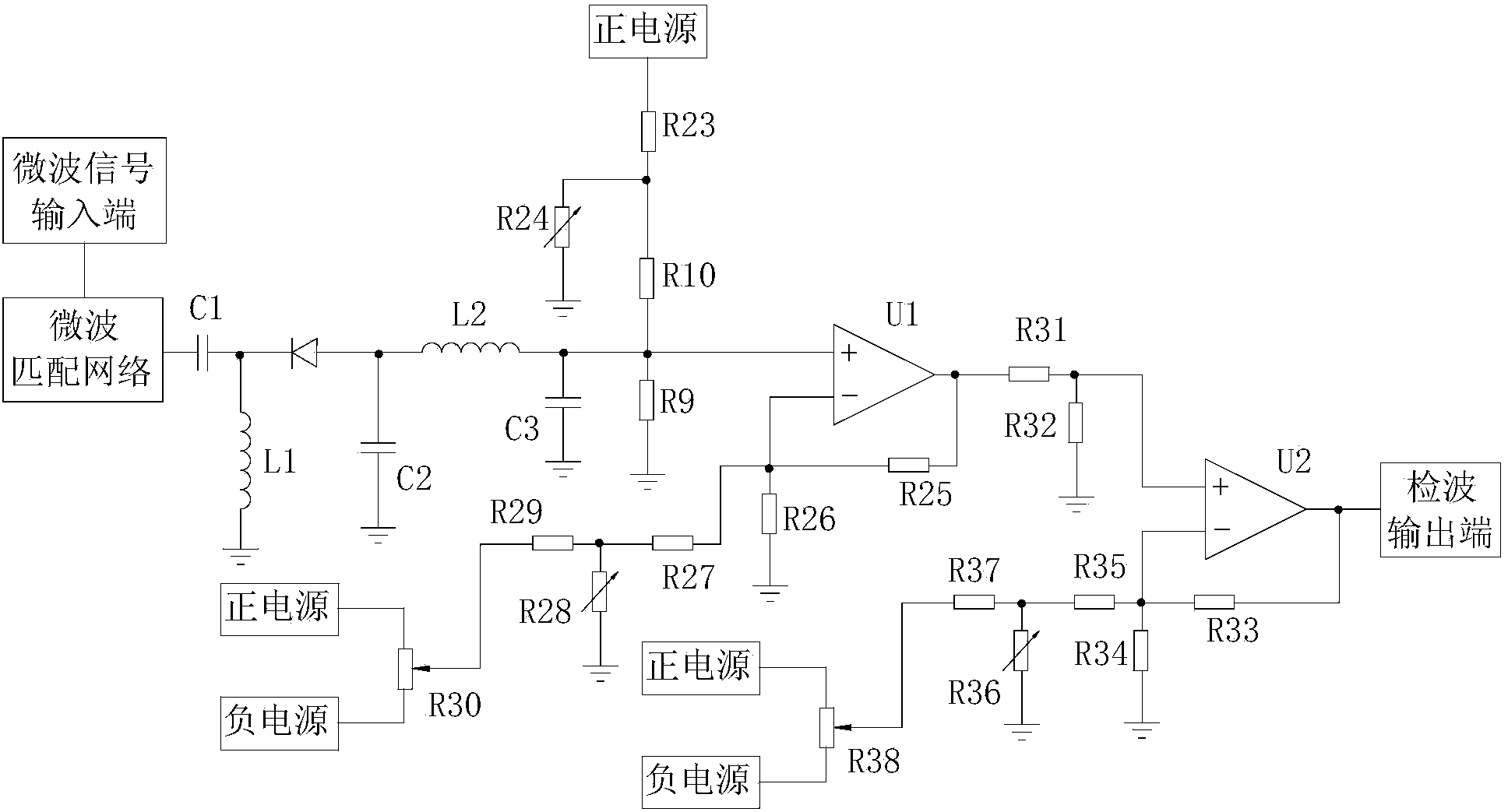

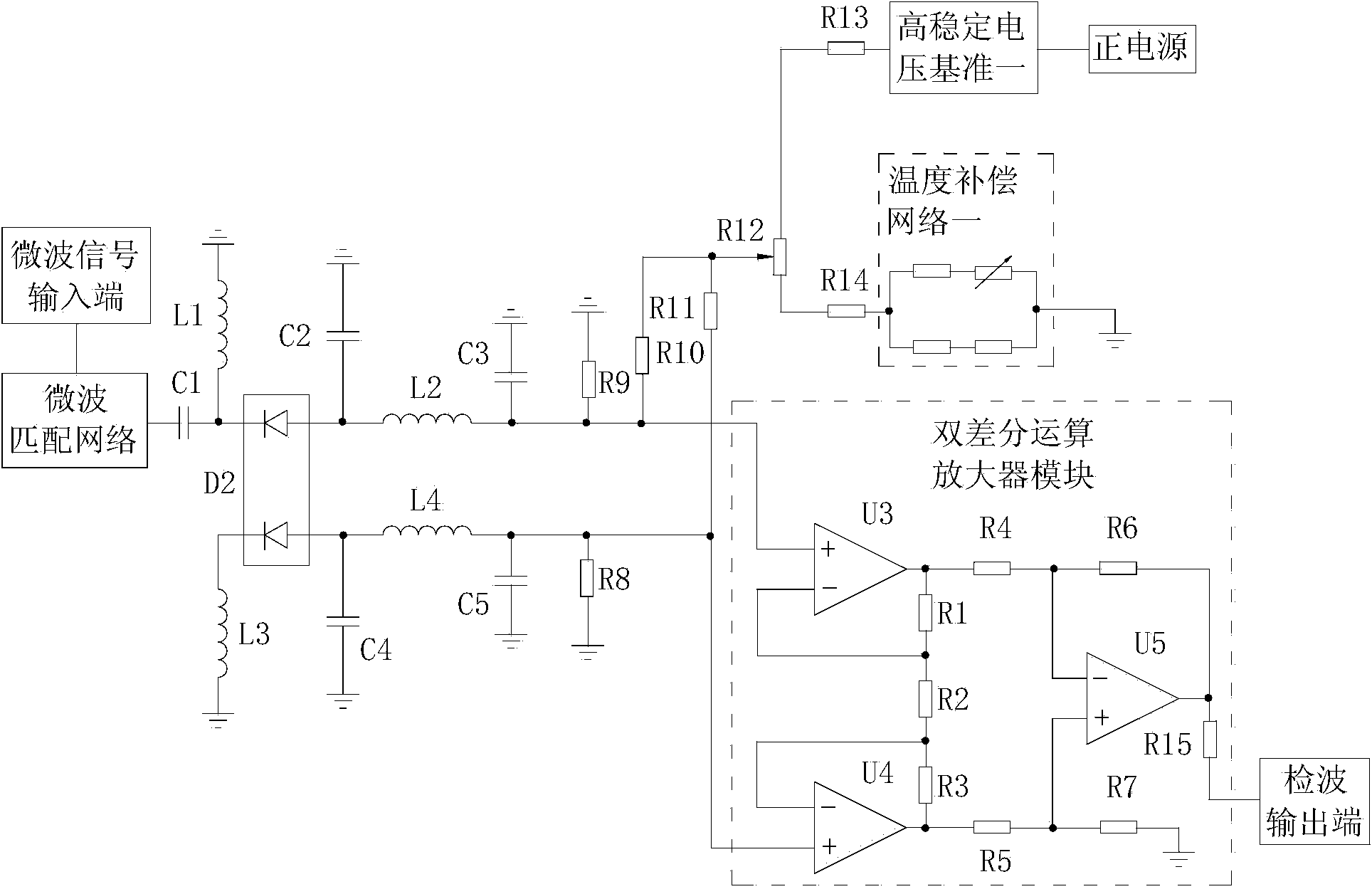

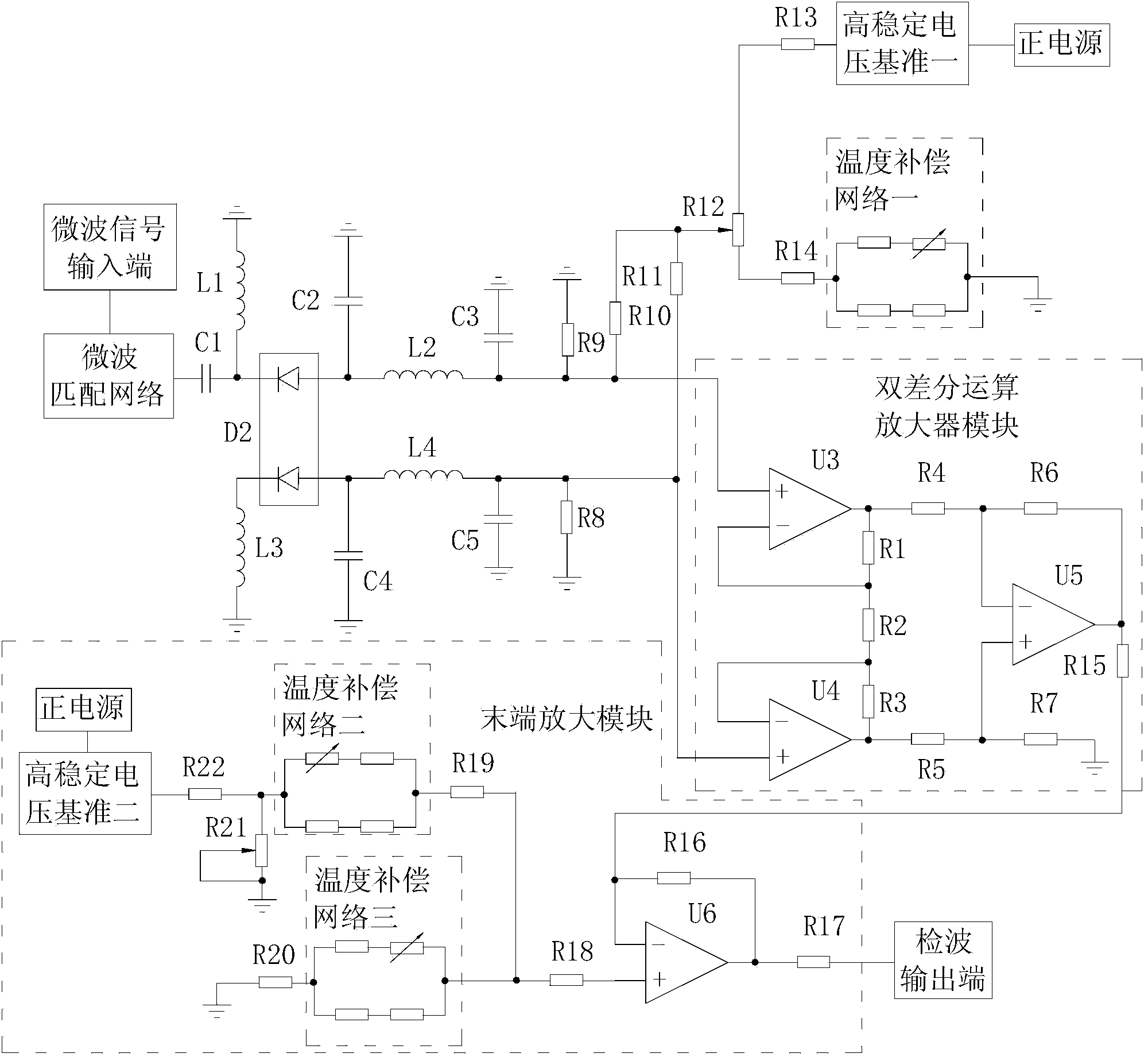

Microwave temperature compensation detector

ActiveCN104076859AReduce driftEasy to debugElectric variable regulationMicrowave technologyOperational amplifier

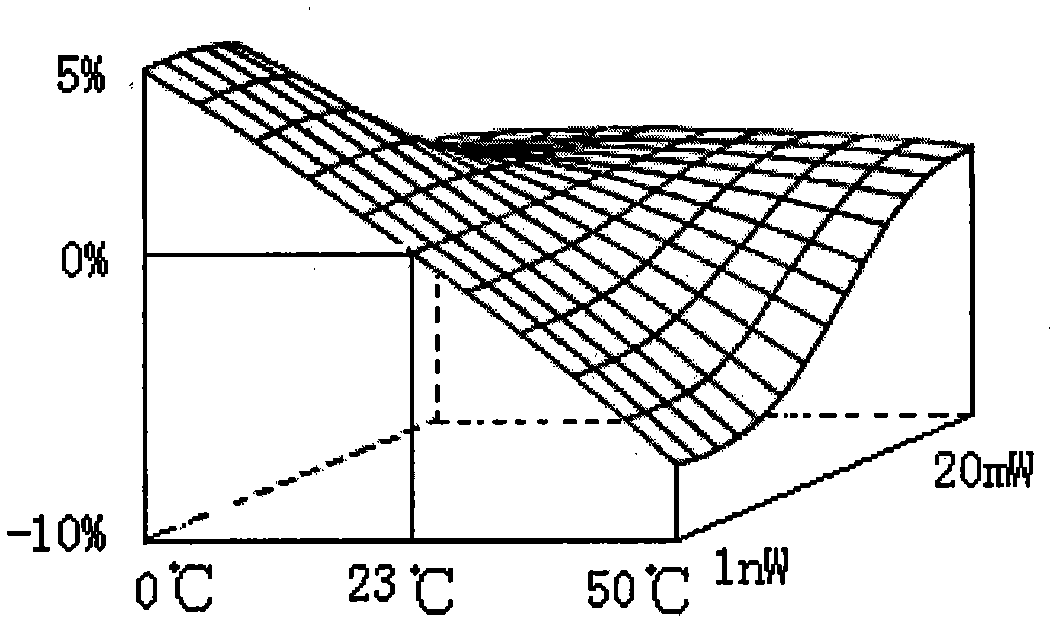

The invention relates to the microwave technology and discloses a microwave temperature compensation detector. The microwave temperature compensation detector solves the problems that an existing diode detector is low in precision under different environment temperatures, is large in direct current drift of detection signal output and needs to repeatedly debug a compensation dosage. The difference between the microwave temperature compensation detector and the prior art is that the microwave temperature compensation detector uses a double-PN-junction detector diode instead of a detector diode, uses a temperature compensation network instead of a temperature compensation resistor and uses a double-differential operational amplifier module. The microwave temperature compensation detector has beneficial effects of small detector voltage temperature drift and small direct current temperature drift of output.

Owner:CHENGDU SINE SCI & TECH

Simple optoacoustic detector for detecting high-corrosion gas

PendingCN107024432ASimple structureLow costMaterial analysis by optical meansInfrared laser beamDifferential amplifier

The invention relates to the field of optoacoustic detection, and provides a simple optoacoustic detector for detecting high-corrosion gas. The simple optoacoustic detector comprises an infrared laser, an infrared laser beam, an optoacoustic pool, an energy meter, a cantilever, a probe laser beam, a probe laser, a photodiode detector, a differential amplification circuit, a digital-to-analogue conversion circuit and a computer, wherein the photodiode diode detector is sequentially connected with the differential amplification circuit, the digital-to-analogue conversion circuit and the infrared laser; the cantilever is made of mica materials and is positioned in the optoacoustic pool; the distance from the photodiode detector to the surface of the cantilever is about 10cm; the infrared laser beam can enter the optoacoustic pool; the energy meter is positioned at the back side of the optoacoustic pool; the energy of each laser pulse can be measured; the optoacoustic signal can be normalized; the probe laser beam can be directly irradiated onto the surface of the cantilever and can be reflected to the photodiode detector; the signal distinguished regulation can be realized through inclining the photodiode.

Owner:JINHUA VOCATIONAL TECH COLLEGE

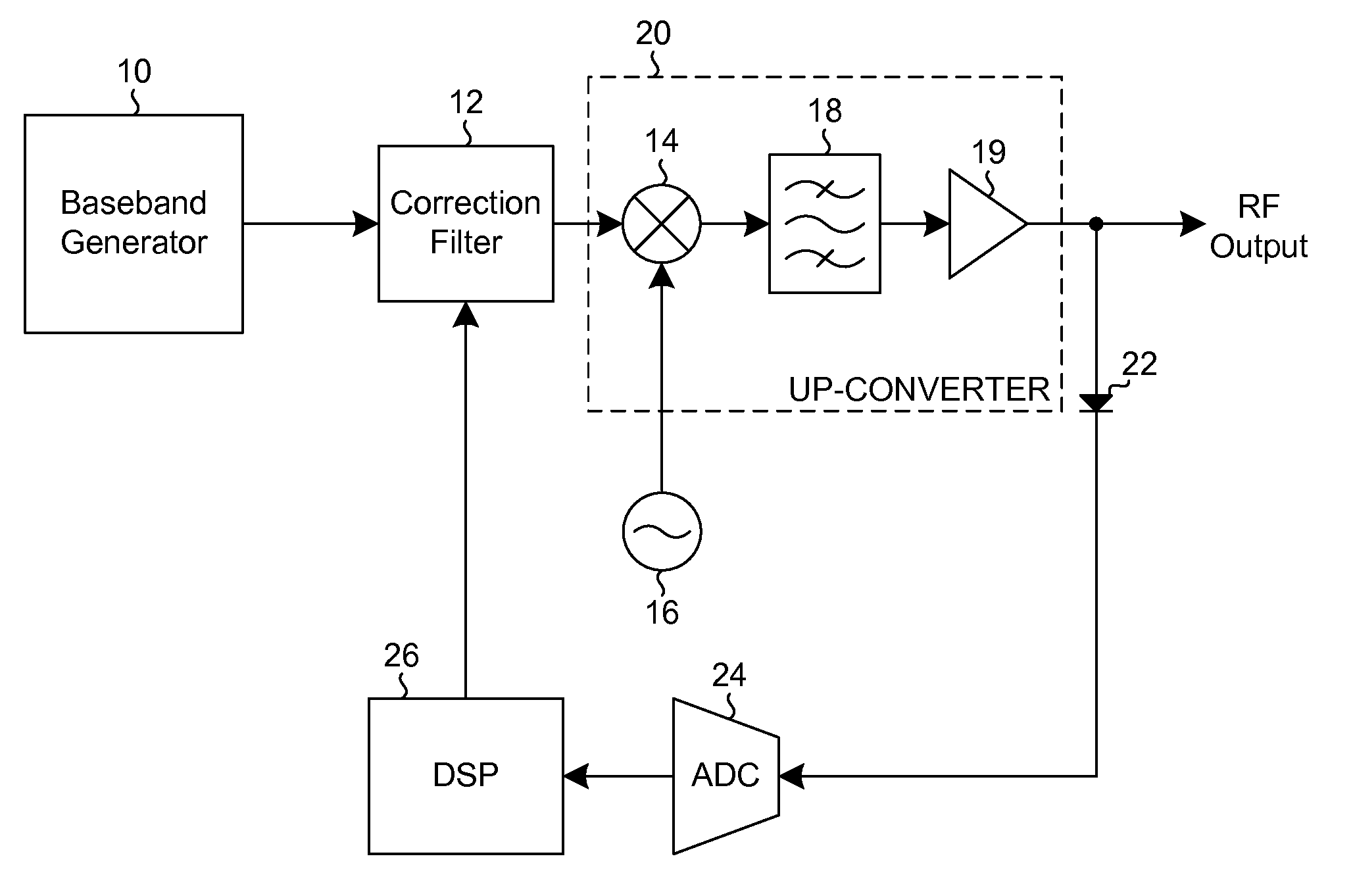

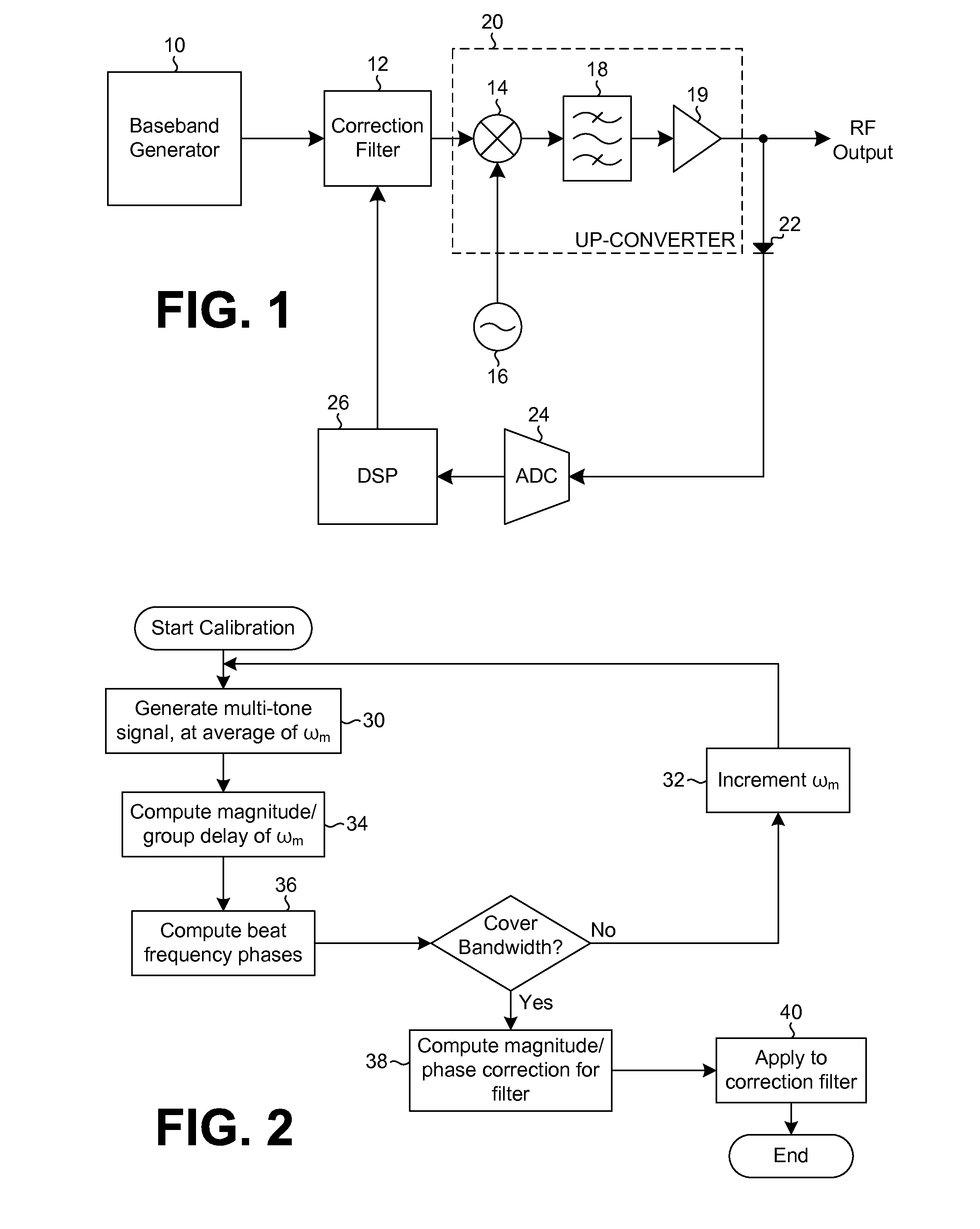

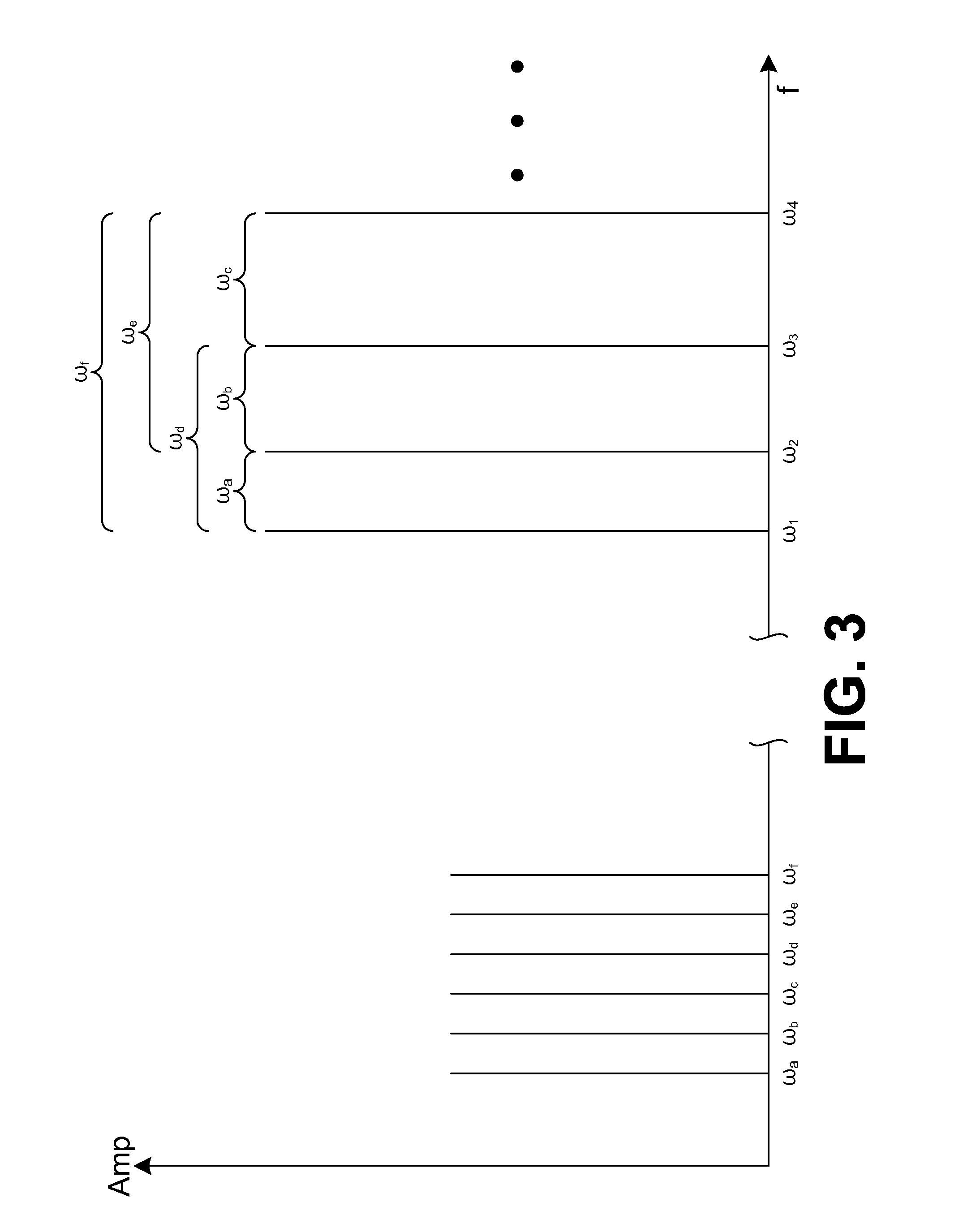

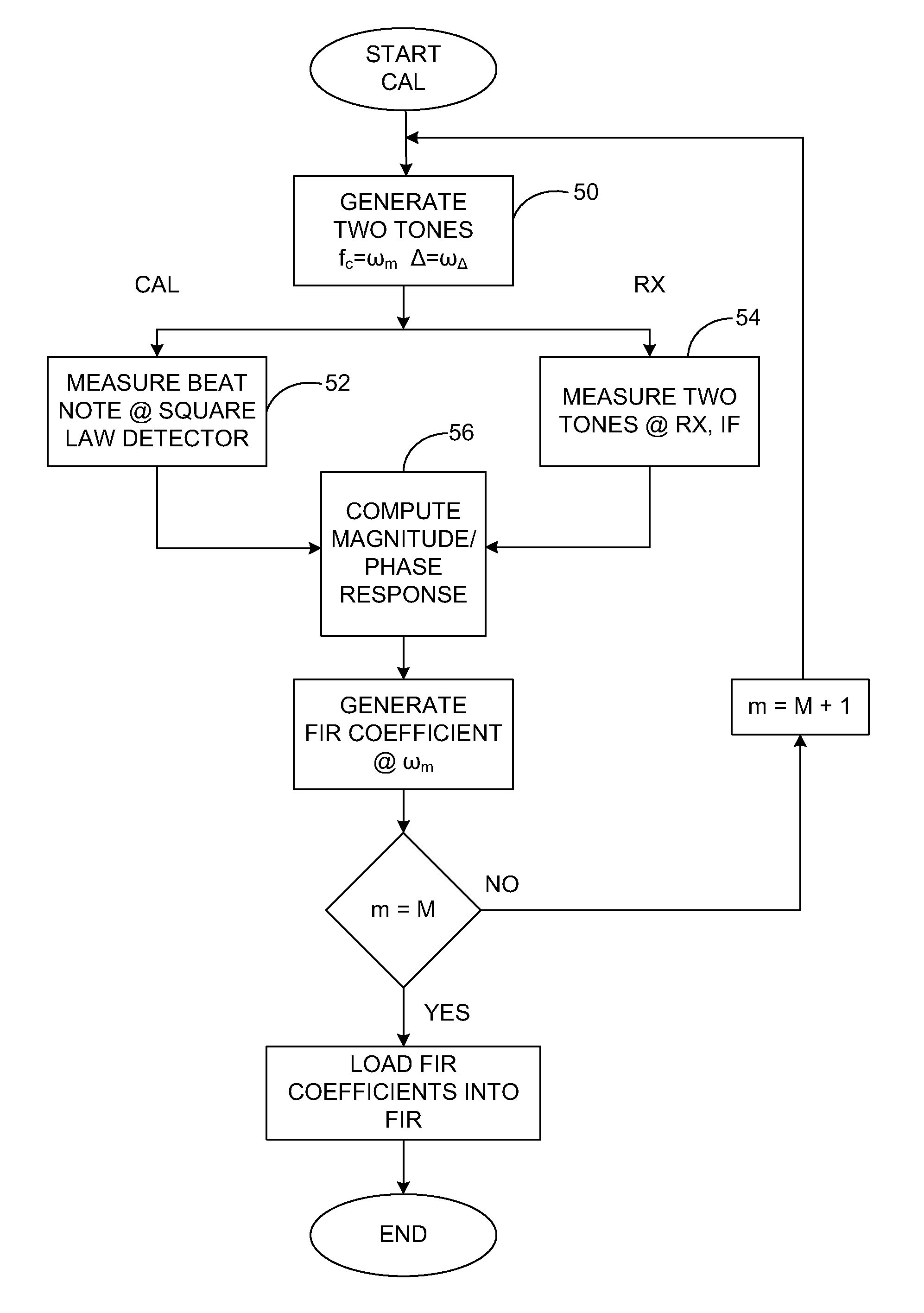

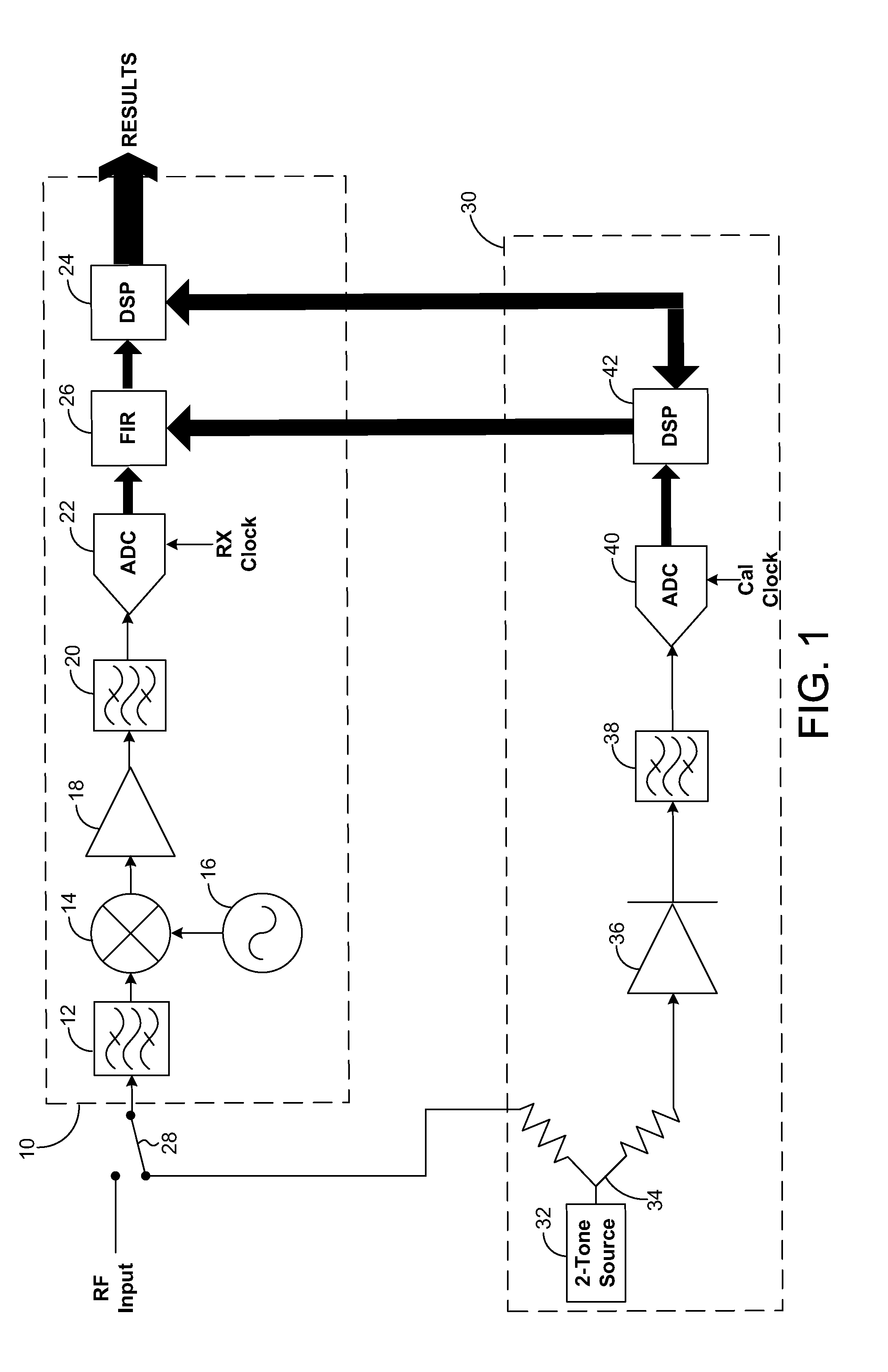

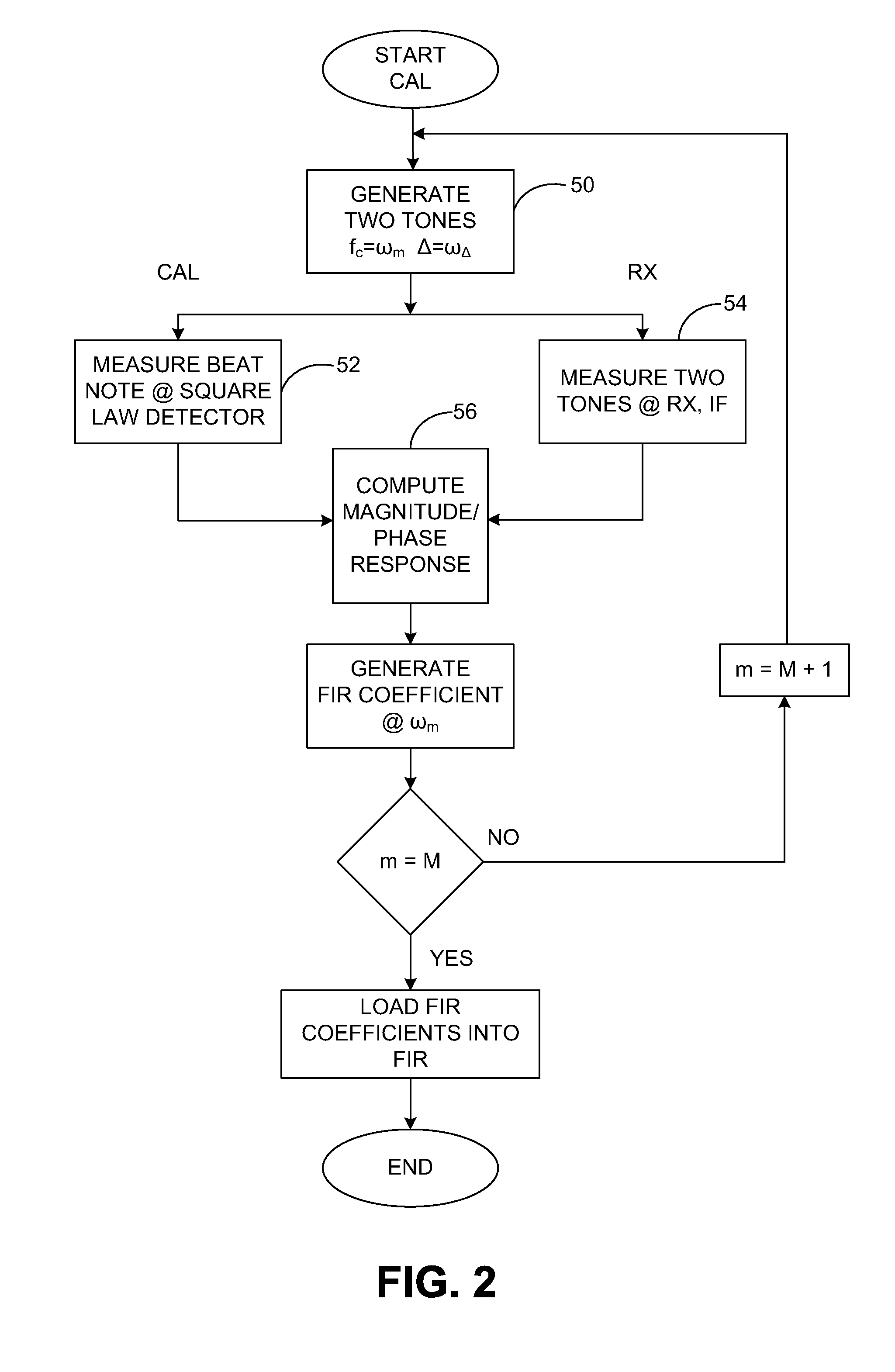

Amplitude flatness and phase linearity calibration for RF sources

An amplitude flatness and phase linearity calibration method for an RF source across a wide frequency bandwidth uses a simple square law diode detector and at least a pair of equal amplitude frequency tones. A baseband generator for the RF source generates the tones, which are applied in series to a correction filter and an up-converter to produce an output RF signal. The tones are stepped across a specified frequency bandwidth, and at each average frequency for the tones a magnitude and group delay is measured as well as a phase for the beat frequency between the tones. The resulting measurements are used to calibrate filter coefficients for the correction filter to assure amplitude flatness and phase linearity across the specified frequency bandwidth.

Owner:TEKTRONIX INC

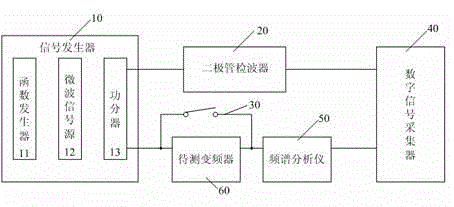

Absolute delay measurement method for frequency converter

The invention discloses an absolute delay measurement method for a frequency converter. The method comprises the following steps: (1) calibration measurement: generating two paths of signals through a signal generator, inputting one path of signal into a first channel of a digital signal acquiring device through a diode detector, inputting the other path of signal into a second channel of the digital signal acquiring device through a spectrum analyzer, and computing a pulse time difference T1 between the first channel and the second channel; (2) delay measurement: generating two paths of signals through the signal generator, inputting one path of signal into the first channel of the digital signal acquiring device through the diode detector, inputting the other path of signal into the second channel of the digital signal acquiring device after the signal passes through the frequency converter to be measured and the spectrum analyzer, and computing a pulse time difference T2 between the first channel and the second channel; and (3) computation of the absolute delay of the frequency converter, wherein the absolute delay value of the frequency converter is computed according to a formula deltaT=T2-T1. According to the absolute delay measurement method for the frequency converter disclosed by the invention, reference to standard comparison is not required, and the measuring accuracy is high.

Owner:SHANGHAI PRECISION METROLOGY & TEST RES INST

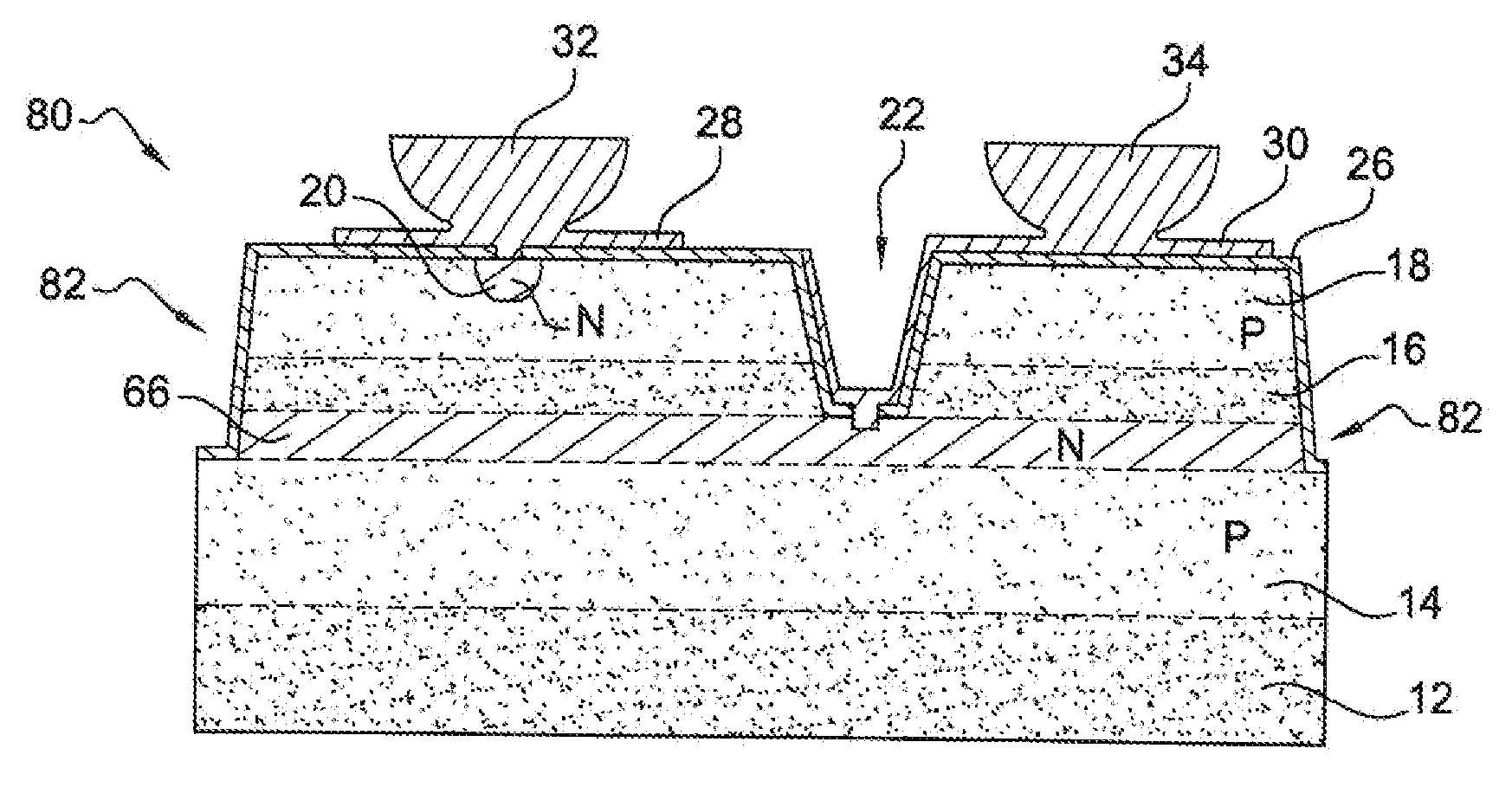

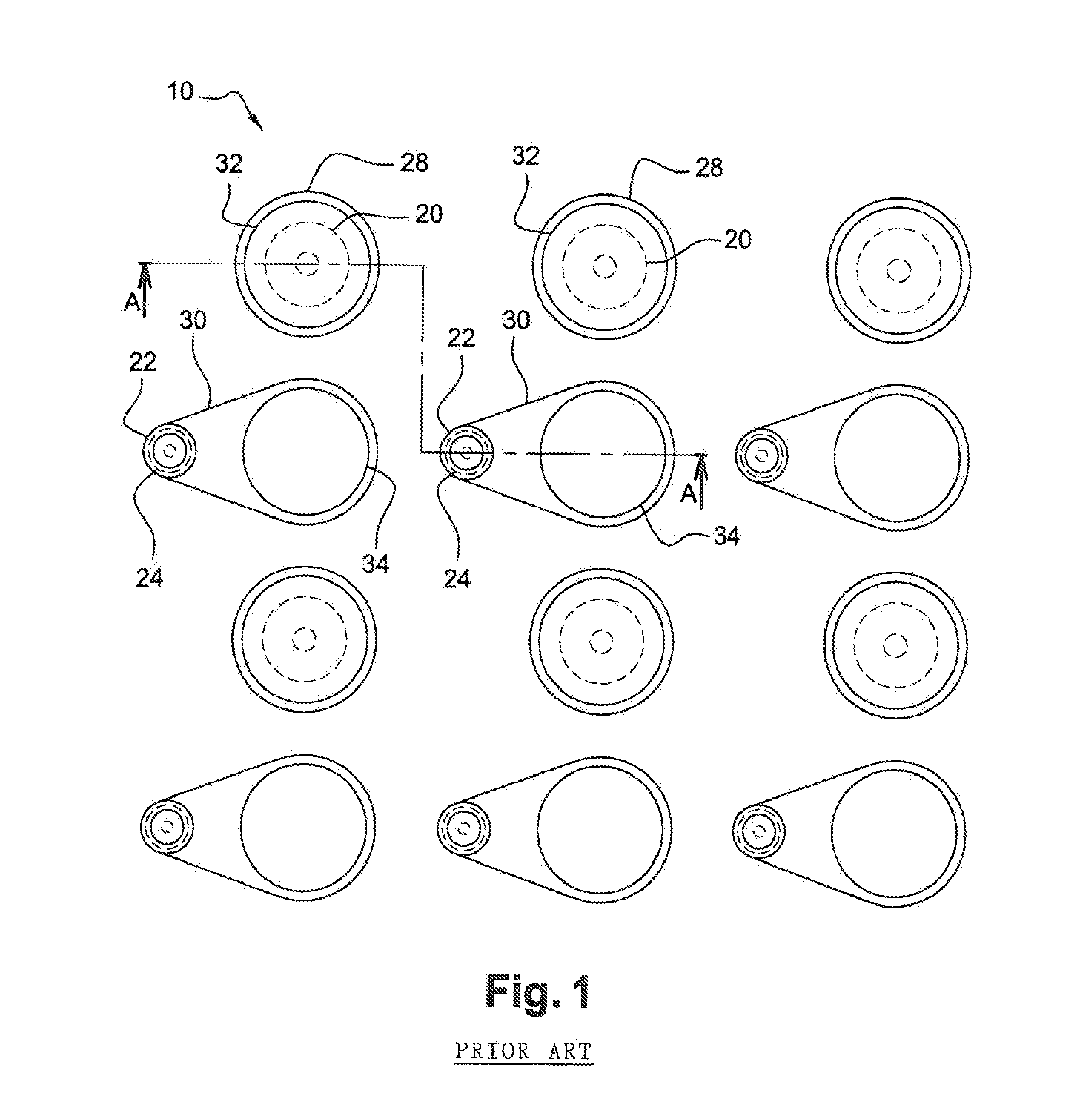

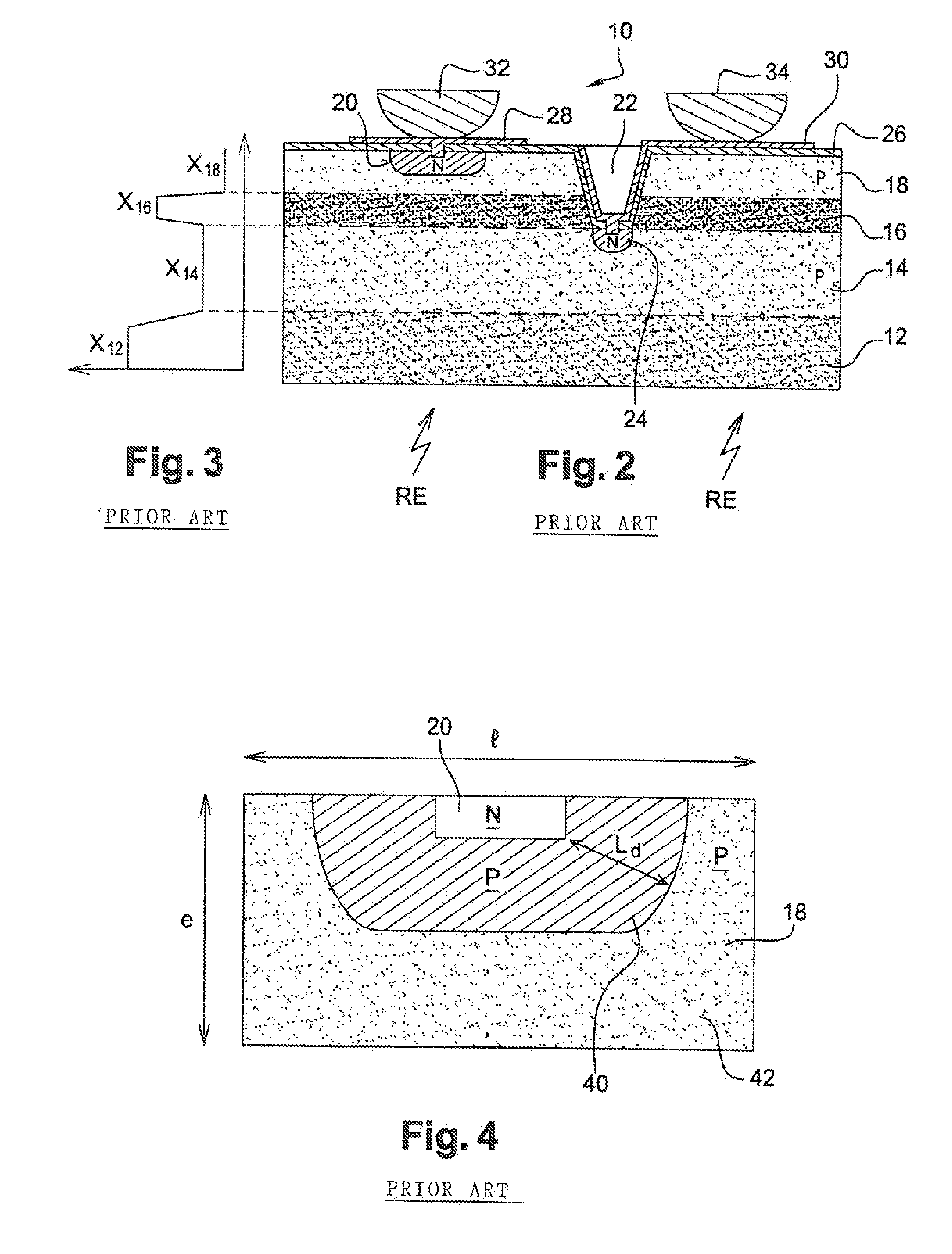

Multilayer bispectral photodiode detector

ActiveUS20120068295A1Easy to manufactureGood temporalSolid-state devicesSemiconductor/solid-state device manufacturingInter layerSemiconductor package

This bispectral detector comprises a plurality of unitary elements for detecting a first and a second electromagnetic radiation range, consisting of a stack of upper and lower semiconductor layers of a first conductivity type which are separated by an intermediate layer that forms a potential barrier between the upper and lower layers; and for each unitary detection element, two upper and lower semiconductor zones of a second conductivity type opposite to the first conductivity type, are arranged respectively so that they are in contact with the upper faces of the upper and lower layers so as to form PN junctions, the semiconductor zone being positioned, at least partially, in the bottom of an opening that passes through the upper and intermediate layers. The upper face of at least one of the upper and lower layers is entirely covered in a semiconductor layer of the second conductivity type. Cuts are made around each unitary detection element from the upper face of the stack and at least through the thickness of each semiconductor layer of the second conductivity type, entirely covering one or other of the upper and lower semiconductor layers of the first conductivity type, so as to form semiconductor zones of the second conductivity type.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Temperature compensated, high efficiency, controlled input impedance diode detector

A diode detector comprising a detector network adapted to detect and multiply the detected voltage coupled to a divider network that comprise diodes in equal number to the number of diodes in the detector network, provides a passive detector applicable to any application requiring a small, efficient, high output, inexpensive temperature compensated detector for use as demodulator or as power to voltage converter. Integrating a portion of the divider network in the detector / multiplier network allows control over the minimum input impedance of the detector.

Owner:VECTRON INT INC

Magnitude and phase response calibration of receivers

An integrated calibrator provides for magnitude and phase response calibration of RF receivers to produce amplitude flatness and phase linearity across the frequency range of the RF receiver by using a simple square law diode detector and a frequency-stepped two-tone source. A two-tone source generator provides two sinusoidal signals separated by a specified frequency delta about a center frequency. The center frequency is stepped across the bandwidth of the RF receiver. At each center frequency the two sinusoidal signals are input to the RF receiver and to the diode detector. The two sinusoidal signals are processed by both the receiver path and the calibrator path, and the results are used by the calibrator to generate coefficients for a correction filter in the receiver path at each of the stepped center frequencies.

Owner:TEKTRONIX INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com