Simple optoacoustic detector for detecting high-corrosion gas

A technology for corrosive gases and detectors, applied in the field of simple photoacoustic detectors, can solve problems such as unusability and lack of chemical resistance, and achieve the effects of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

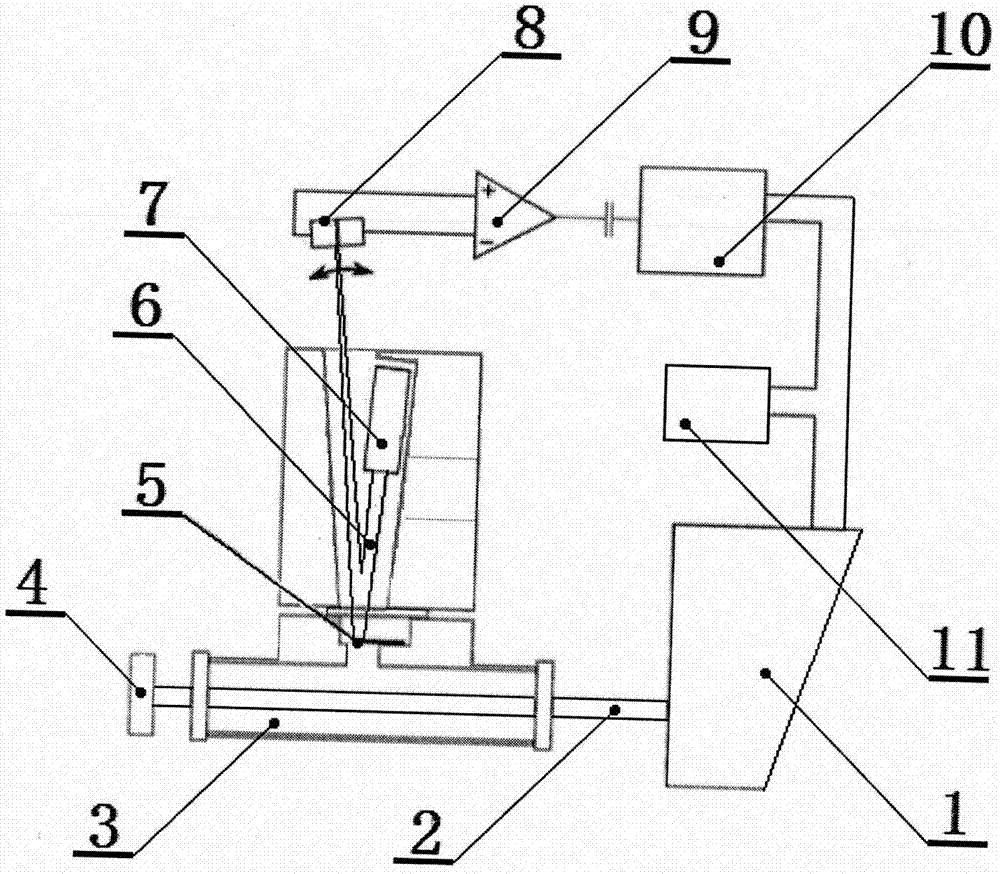

[0017] Such as figure 1 It is a structural schematic diagram of the present invention. The simple photoacoustic detector for detecting highly corrosive gases mainly includes an infrared laser 1, an infrared laser beam 2, a photoacoustic cell 3, an energy meter 4, a cantilever 5, and a probe laser beam 6. Probe laser 7, photodiode detector 8, differential amplifier circuit 9, digital-to-analog conversion circuit 10, computer 11, the cantilever 5 can vibrate, and the photodiode detector 8 is a single block composed of four silicon diodes Orthogonal photodiode units are formed, two adjacent photodiodes can detect the position of the probe laser beam 6, and the photodiode detector 8 is sequentially connected to the differential amplifier circuit 10, the digital-to-analog conversion circuit 11, the The infrared laser 1, the computer 12 is connected between the digital-to-analog conversion circuit 10 and the infrared laser 1, the energy meter 4 is located at the rear side of the pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com