Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Diffraction scattering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

• Diffraction is a phenomenon observed only in waves, but scattering is a phenomenon observed in both waves and particles. • Diffraction is a property of propagation of waves, whereas scattering is a property of wave interactions. • Diffraction can be taken as evidence for the wave nature of light.

Composite particles and method for production thereof and use thereof

InactiveUS20060116279A1Improve photocatalytic activityImprove efficiencyPigmenting treatmentMaterial nanotechnologyFiberUltraviolet

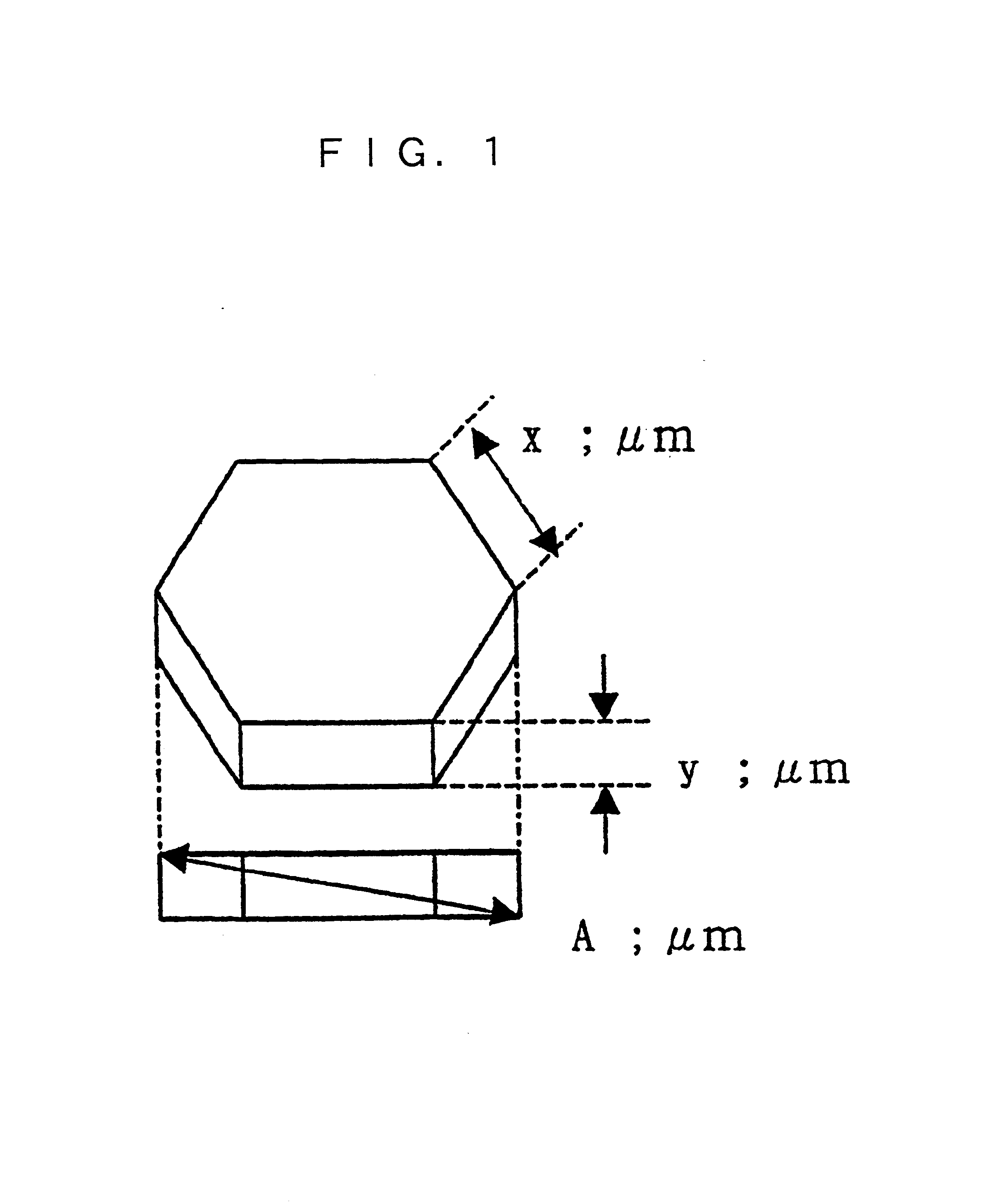

A composite particle comprised of a larger particle and, supported thereon, smaller particles wherein the smaller particles are photocatalyst-containing fine particles with an average particle diameter of 0.005-0.5 μm as calculated from a BET specific surface area, and the larger particle has an average particle diameter of 2-200 μm as measured by the laser diffraction-scattering particle size measuring method. The smaller particle is preferably a composite particle of titanium dioxide with an inorganic compound exhibiting no catalytic activity, such as silica, or a particle containing a Brφonsted acid salt, especially on the surface thereof; and an advantageous method for producing the above composite particles wherein the above larger particles and smaller particles are dry mixed by a ball-mill or mixed by rotation of blades or by shaking, with an energy constant controlled within a specific range. A composition comprising an organic polymer and the above composite particles can give a shaped article, such as fiber, film or a molding, exhibiting ultraviolet ray-screening function.

Owner:SHOWA DENKO KK

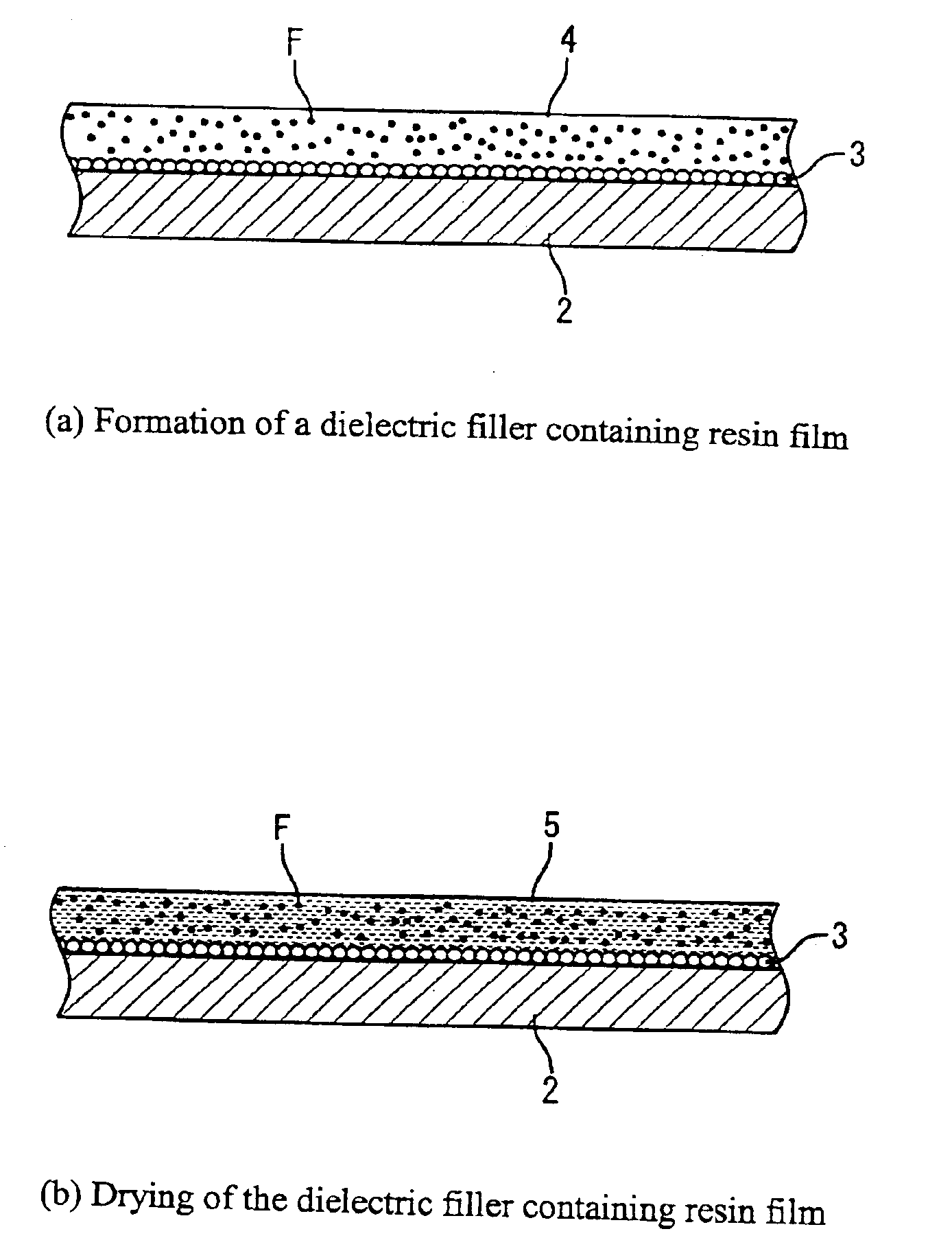

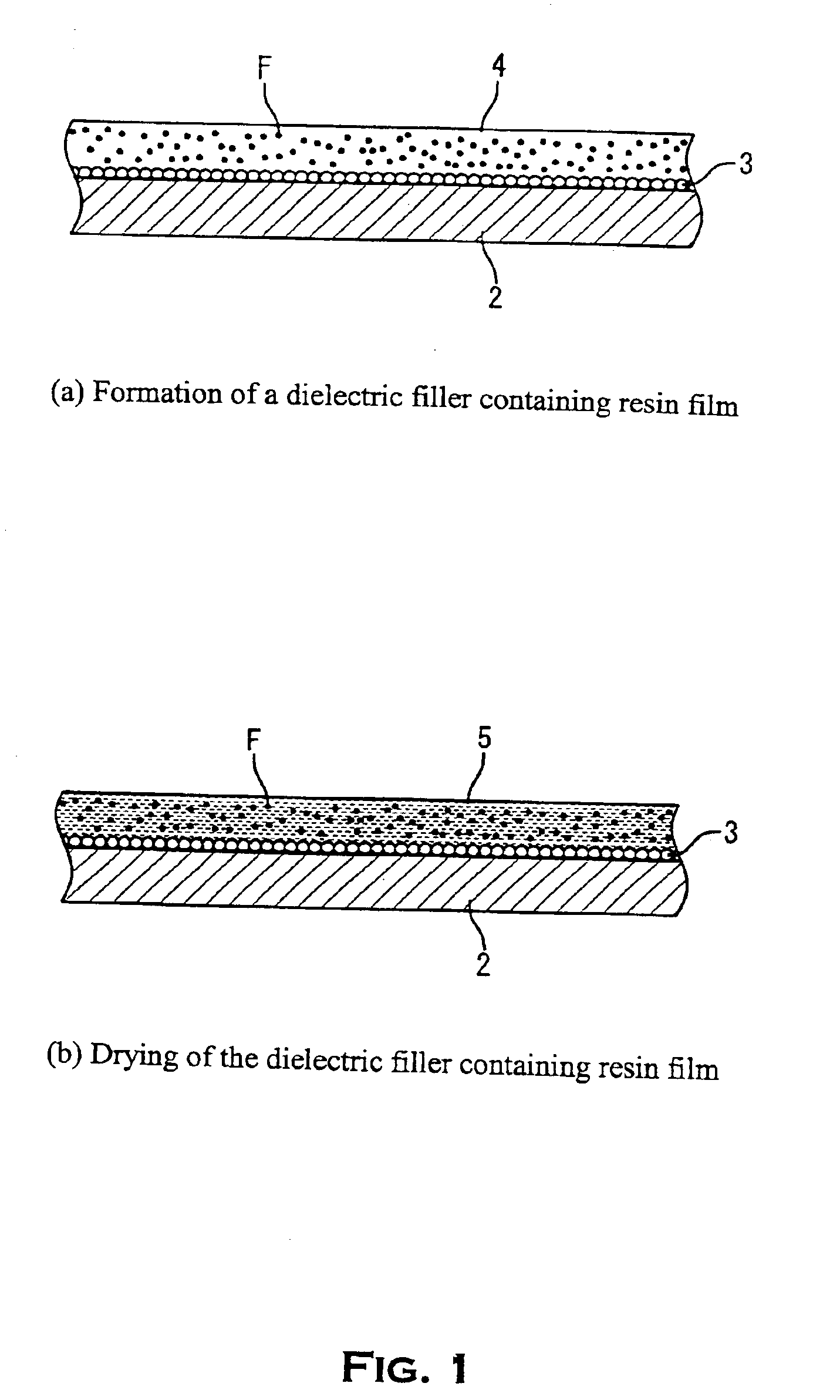

Method of forming polymide coating containing dielectric filler on surface of metallic material process for producing copper clad laminate for formation of capacitor layer for printed wiring board and copper clad laminate obtained by the process

InactiveUS20050161149A1Avoid damageIncrease flexibilityInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsMetallic materialsMaterials science

A method of forming a dielectric layer containing dielectric filler, which is excellent in film thickness uniformity, from a polyimide electrodeposition liquid containing dielectric filler. In particular, a method of forming a polyimide coating container dielectric filler on a surface of metallic material according to the electrodeposition coating technique, characterized in that as the dielectric filler, use is made of dielectric powder of perovskite structure in approximately spherical form which has an average particle diameter (D1A) of 0.05 to 1.0 μm and a weight cumulative particle diameter (D50), measured in accordance with the laser diffraction scattering type particle size distribution measuring method, of 0.1 to 2.0 μm and further exhibits an aggregation degree, in terms of D50 / D1a wherein D50 and D1a represent a weight cumulative particle diameter and an average particle diameter obtained by image analysis, respectively, of 4.5 or less.

Owner:MITSUI MINING & SMELTING CO LTD

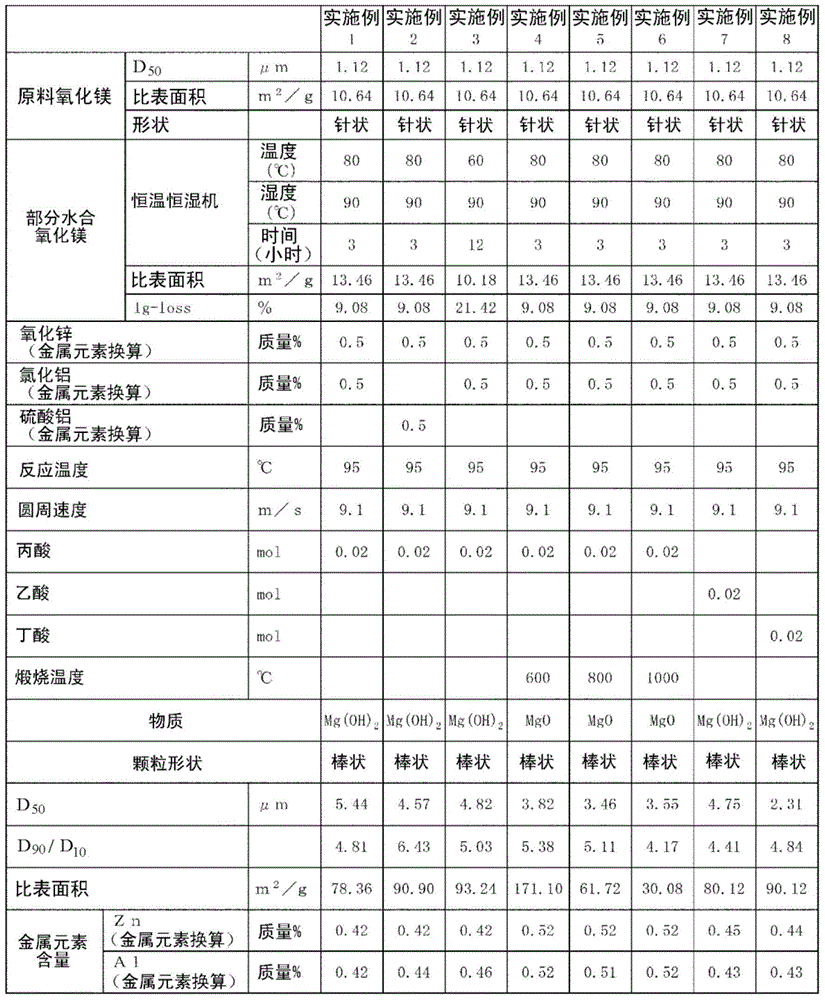

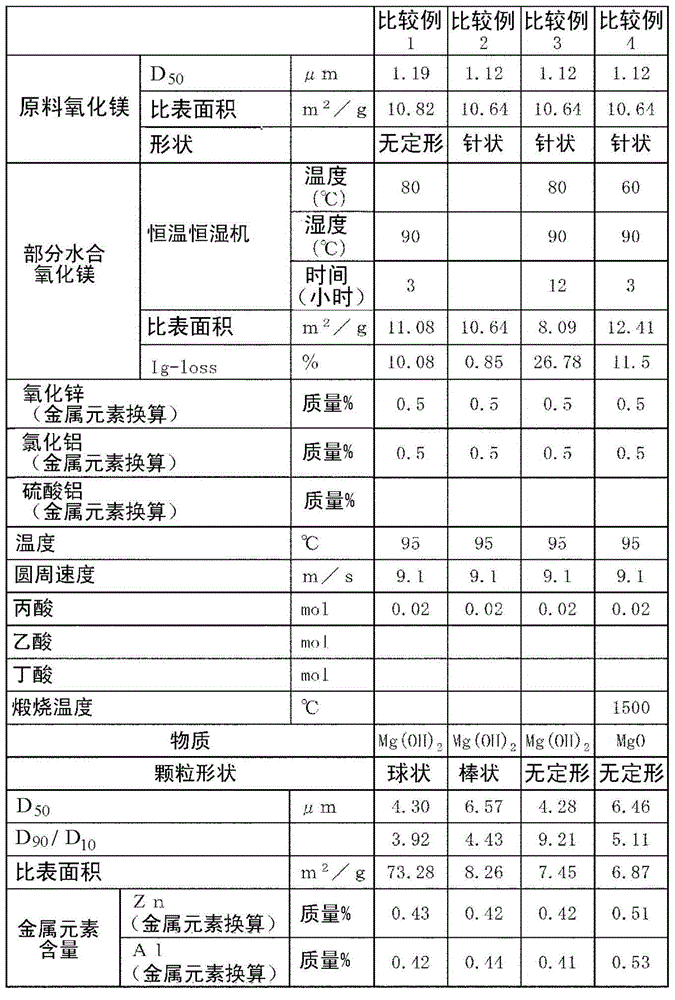

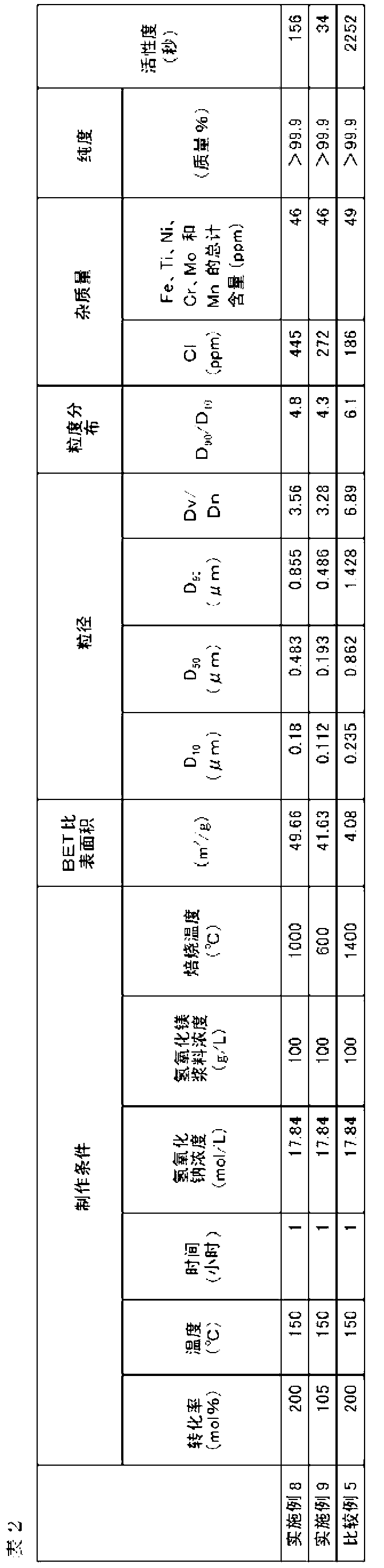

Magnesium hydroxide particles, process for producing the same, and resin composition containing the particles

InactiveUS6676920B1Maintain good propertiesOxide/hydroxide preparationSilicaShell moldingSingle crystal

Owner:KYOWA CHEM IND

Silver-coated copper powder, and method for producing same

InactiveUS20150262729A1Reduce the required powerDrawback can be obviatedMetal-working apparatusNon-conductive material with dispersed conductive materialMicroscopic imageCopper

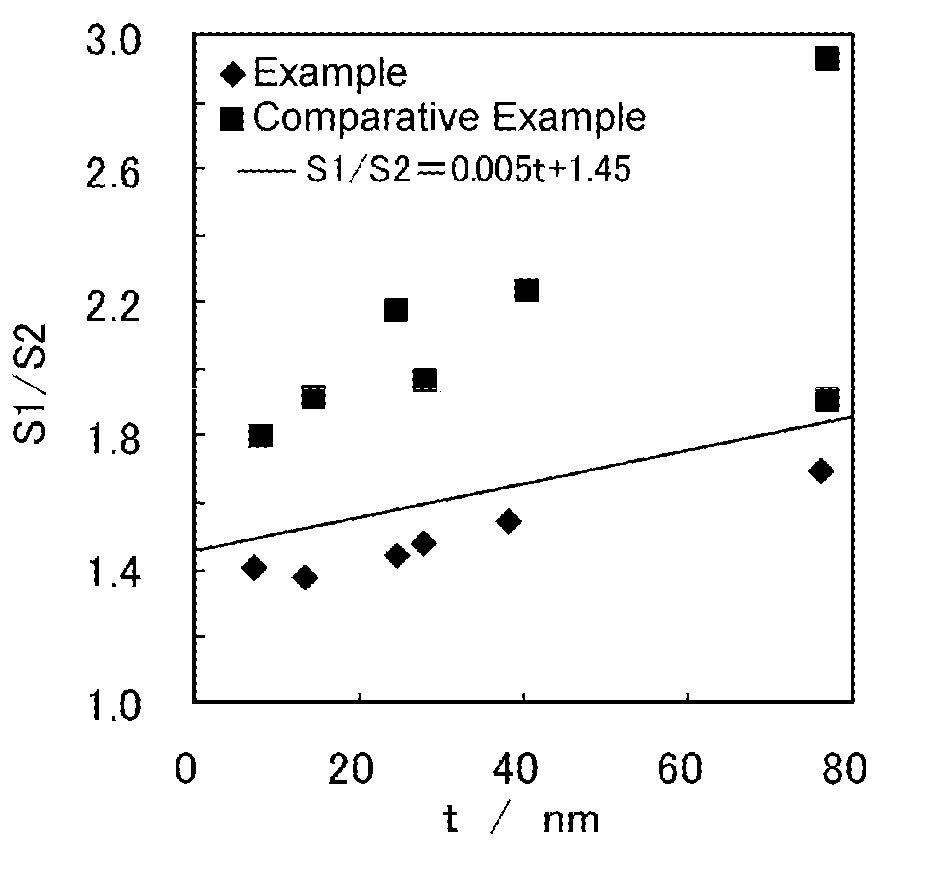

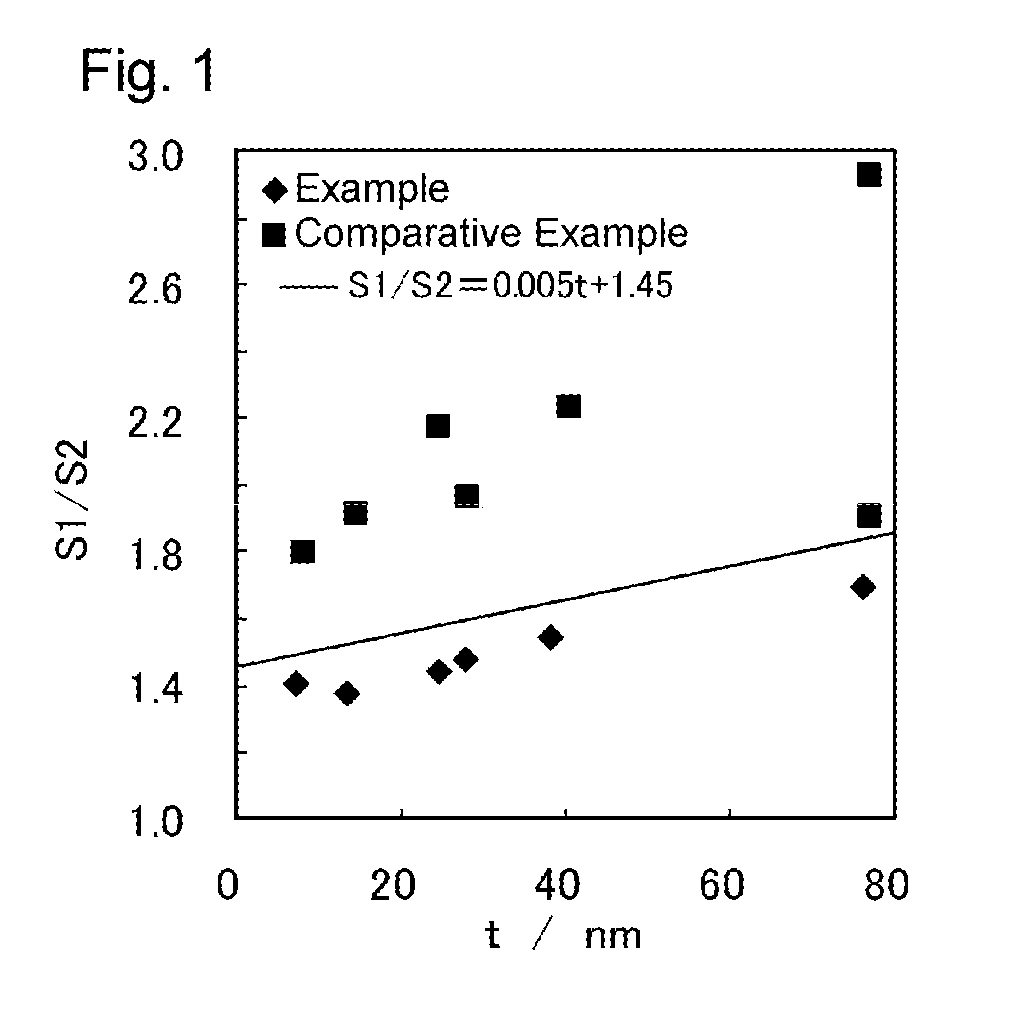

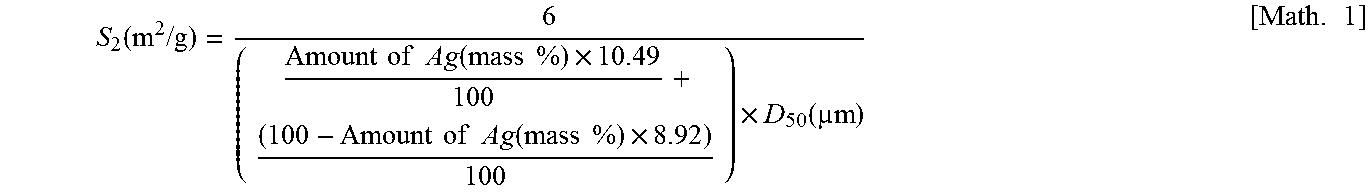

A silver-coated copper powder includes copper core particles and a silver coat layer located on the surface of the core particles. When S1 is a BET specific surface area (m2 / g) of the silver-coated copper powder; S2 is a specific surface area (m2 / g) calculated from a particle diameter D50 obtained by the analysis of a microscopic image of the silver-coated copper powder; and t is a thickness of the silver coat layer, the silver-coated copper powder satisfies Expression: (S1 / S2)≦0.005×t+1.45. The silver-coated copper powder has a volume cumulative particle diameter D50L at a cumulative volume of 50 vol % as measured by laser diffraction-scattering method of 0.01 to 100 μm.

Owner:MITSUI MINING & SMELTING CO LTD

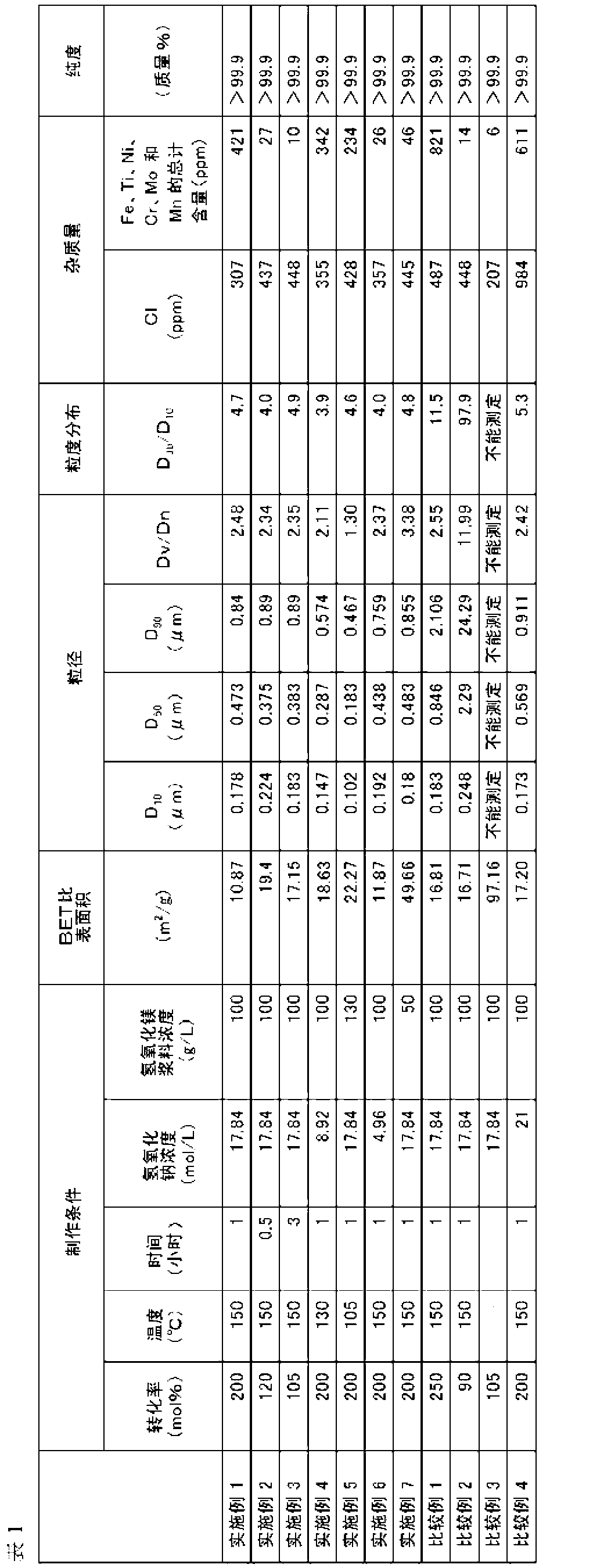

Method for producing lithium composite metal oxide, lithium composite metal oxide, and nonaqueous electrolyte secondary battery

ActiveUS20120244413A1Improved secondary battery characteristicCobalt compoundsNon-aqueous electrolyte accumulator electrodesPhosphateTungstate

The present invention provides a method of producing a lithium mixed metal oxide, a lithium mixed metal oxide and a nonaqueous electrolyte secondary battery. The method includes a step of calcining a mixture of one or more compounds of M wherein M is one or more elements selected from the group consisting of nickel, cobalt and manganese, and a lithium compound, in the presence of one or more inactive fluxes selected from the group consisting of a fluoride of A, a chloride of A, a carbonate of A, a sulfate of A, a nitrate of A, a phosphate of A, a hydroxide of A, a molybdate of A and a tungstate of A, wherein A is one or more elements selected from the group consisting of Na, K, Rb, Cs, Ca, Mg, Sr and Ba. The lithium mixed metal oxide contains nickel, cobalt and manganese, has a BET specific surface area of from 3 m2 / g to 15 m2 / g, and has an average particle diameter within a range of 0.1 μm or more to less than 1 μm, the diameter determined by a laser diffraction scattering method.

Owner:SUMITOMO CHEM CO LTD

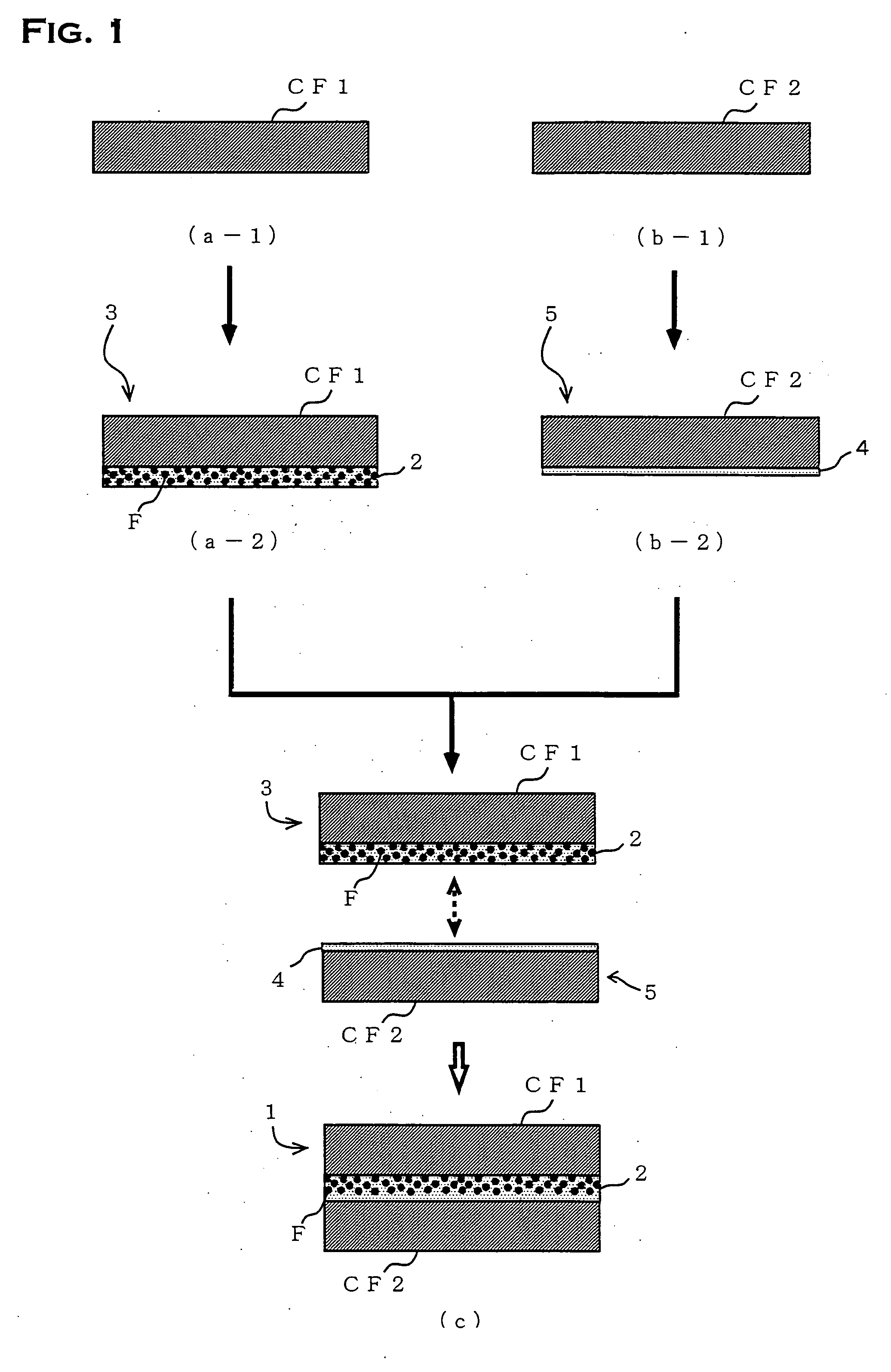

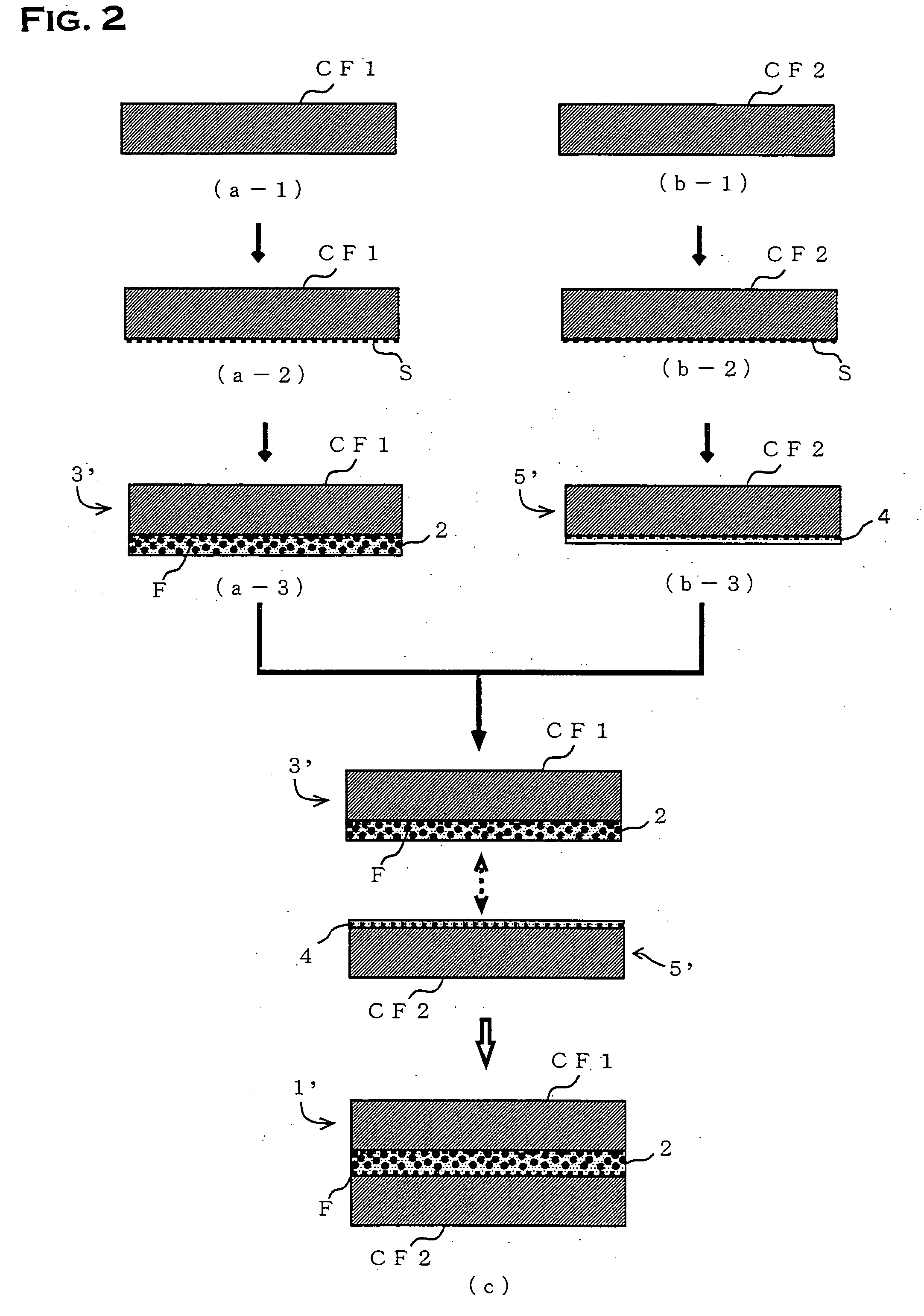

Dielectric filler containing resin for use in formation of built-in capacitor layer of printed wiring board and double-sided copper clad laminate with dielectric layer formed using the same dielectric filler containing resin, and production method of double-sided copper clad laminate

InactiveUS6905757B2Liquid surface applicatorsSemiconductor/solid-state device detailsEpoxyCapacitance

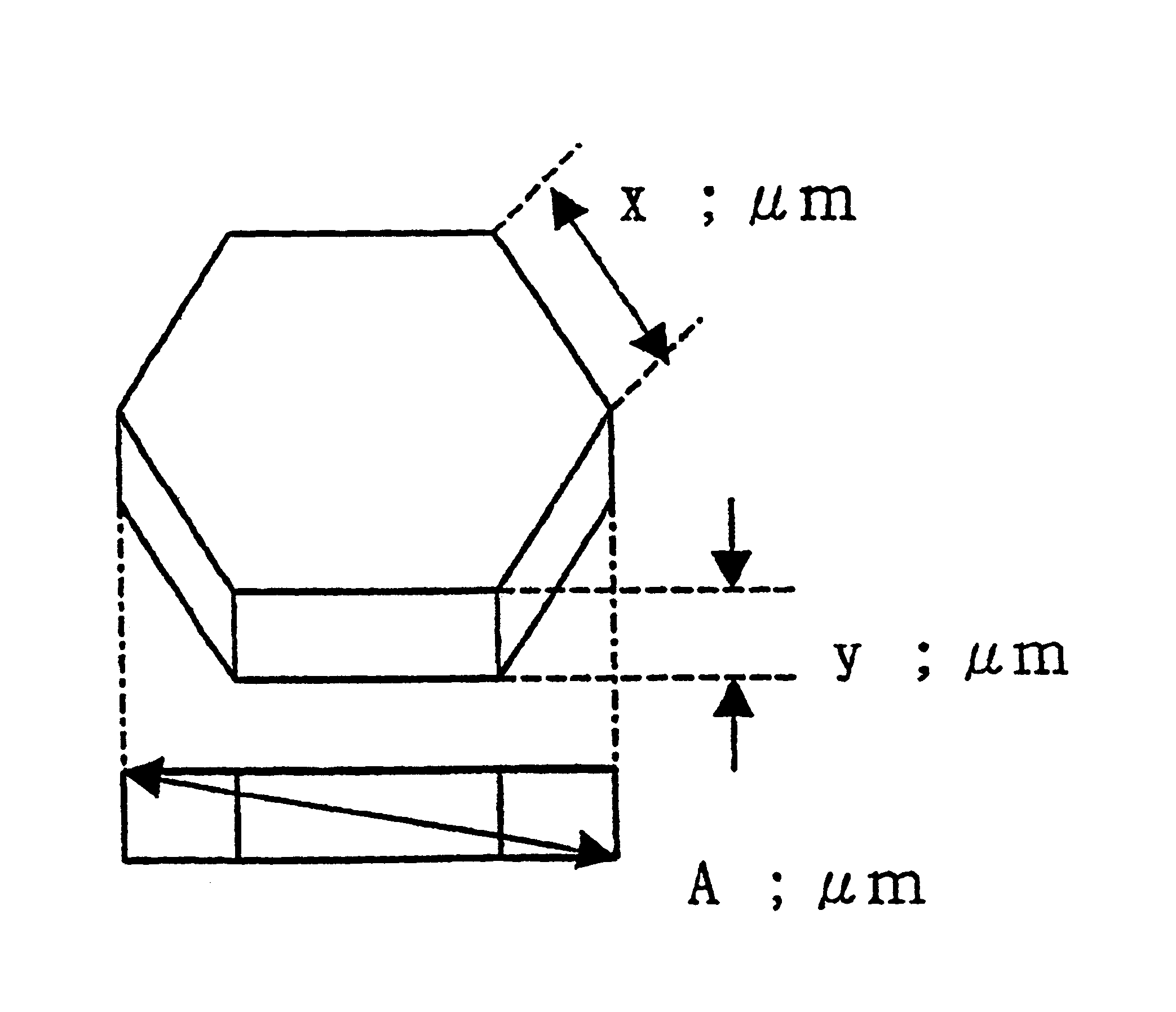

An object is to provide a dielectric layer of a double-sided copper clad laminate, for use in formation of a built-in capacitor layer, which can be formed in an optional thickness without using a skeletal material and is provided with a high strength. For the purpose of achieving the object, “a dielectric filler containing resin for use in formation of the built-in capacitor layer of a printed wiring board obtained by mixing a binder resin comprising 20 to 80 parts by weight of epoxy resin (inclusive of a curing agent), 20 to 80 parts by weight of a solvent soluble aromatic polyamide resin polymer, and a curing accelerator added in an appropriate amount according to need; and a dielectric filler which is a nearly spherical dielectric powder having perovskite structure which is 0.1 to 1.0 μm in the average particle size DIA, 0.2 to 2.0 μm in the weight cumulative particle size D50 based on the laser diffraction scattering particle size distribution measurement method, and 4.5 or less in the coagulation degree represented by D50 / DIA where the weight cumulative particle size D50 and the average particle size DIA obtained by the image analysis”; and the like are used.

Owner:MITSUI MINING & SMELTING CO LTD

Positive electrode for lithium secondary cell and lithium secondary cell using the same

InactiveUS20090263718A1Improve liquidityViscosity can be suppressedSecondary cellsNon-aqueous electrolyte accumulator electrodesLithiumMetal

A positive electrode for a lithium secondary cell is provided that is excellent in dispersibility and adhesion of the conductive agent and provides a lithium secondary cell excellent in performance. The positive electrode for a lithium secondary cell contains a positive electrode active substance represented by the following formula (I), a conductive agent and a binder, and the conductive agent has an average particle diameter of from 3 to 20 μm measured by a laser diffraction scattering method:LixMPO4 (I)wherein M represents a metallic atom containing at least one member selected from the group consisting of Co, Ni, Fe, Mn, Cu, Mg, Zn, Ti, Al, Si, B and Mo; and 0<x<2.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

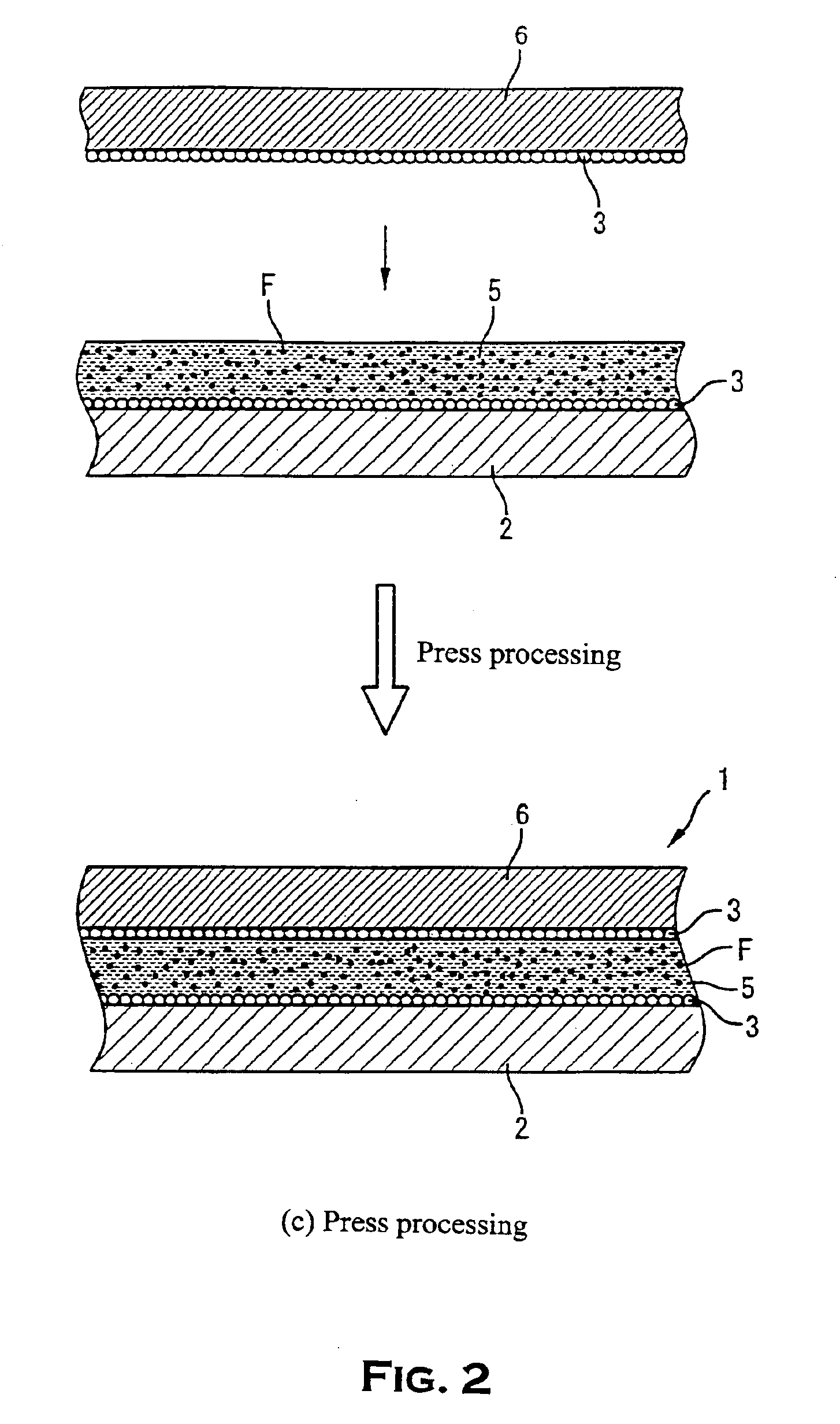

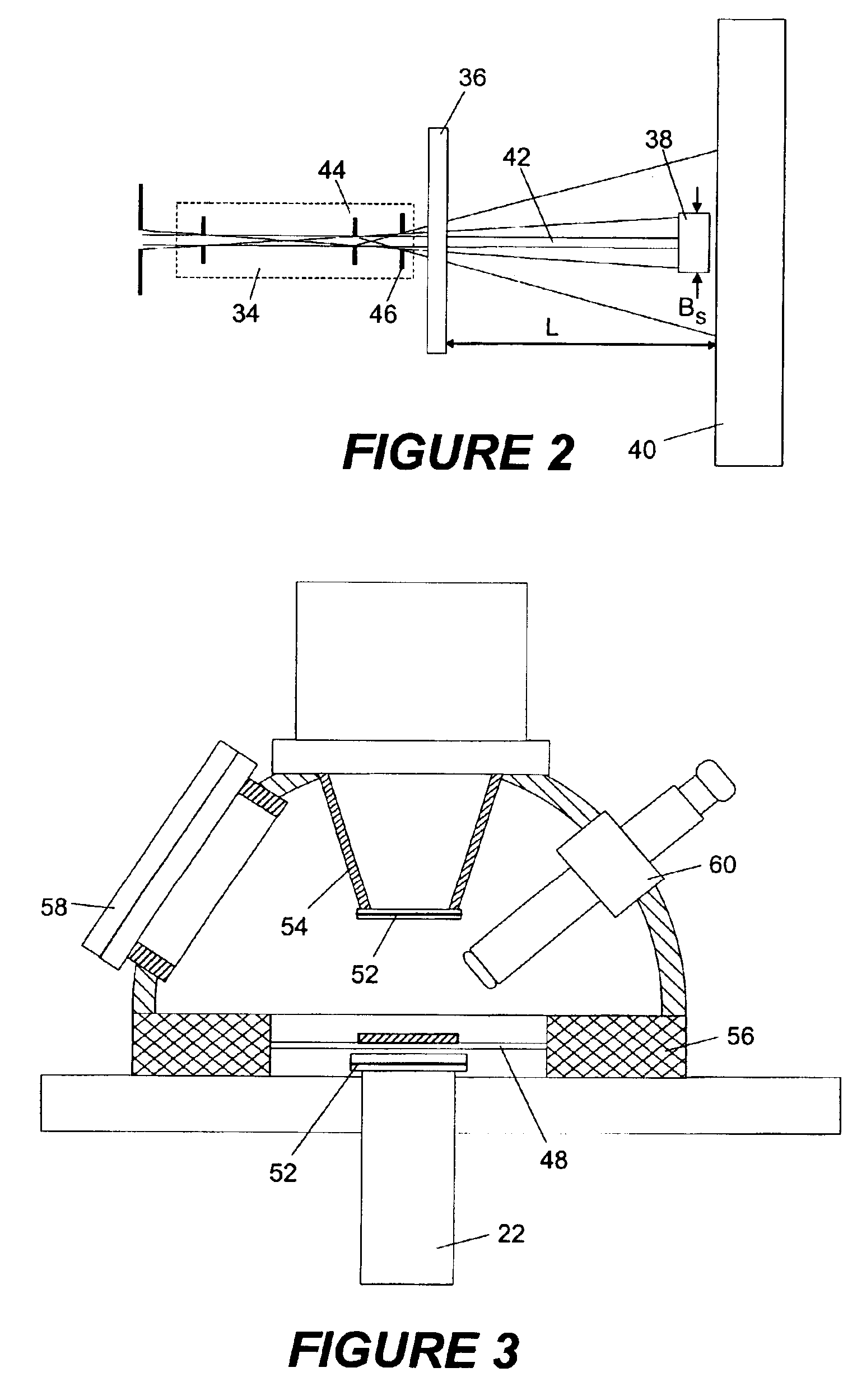

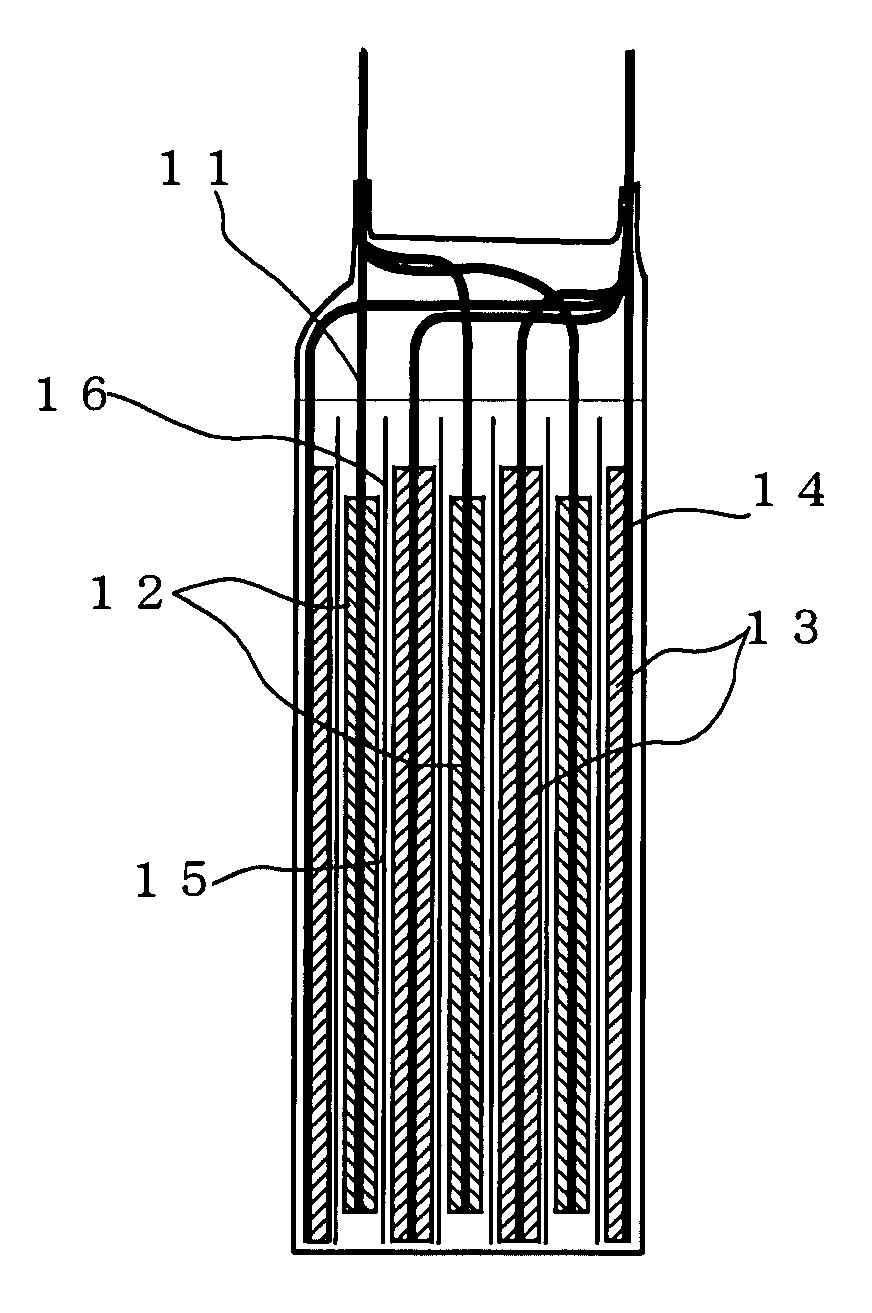

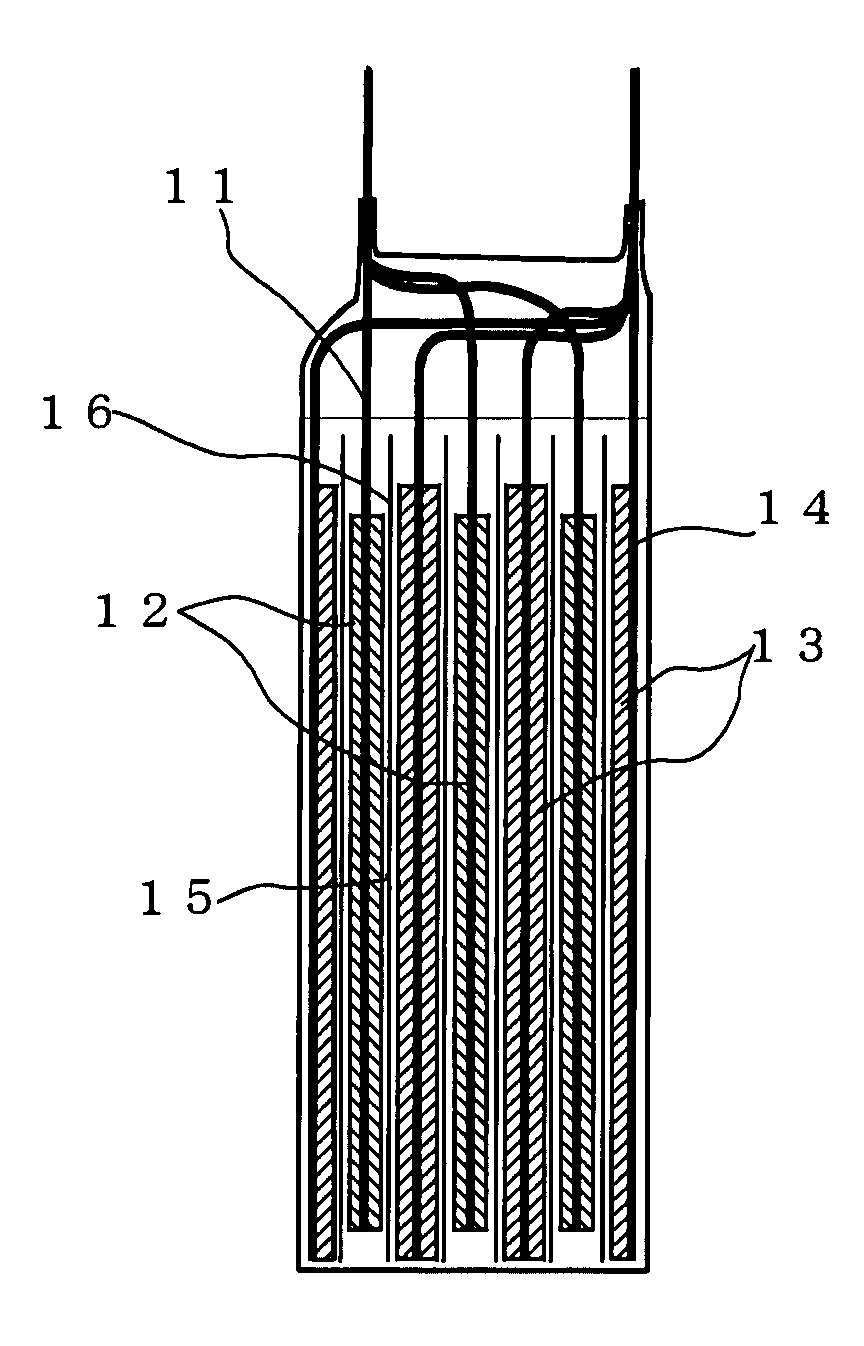

Vertical small angle x-ray scattering system

InactiveUS6956928B2Distance minimizationUsing wave/particle radiation meansMaterial analysis using radiation diffractionSmall-angle X-ray scatteringX-ray

A small angle x-ray diffraction scattering system has a vertical orientation, allowing for simplified analysis of liquid samples. The system may function in a beam-up or a beam-down configuration. An x-ray source provides an initial x-ray beam that is directed vertically along a primary beampath to a sample located on a sample support. The small angle scattered x-ray energy travels through a secondary beampath to a detector. The primary and secondary beampaths may be evacuated and separated from a sample chamber by fluid seals. Beam conditioning optics and a collimator may be used in the primary beampath, and a beamstop used in the secondary beampath. The sample chamber may have a microscope or camera, which may be movable, for observing the sample, and a translation stage for moving the sample in at least two dimensions.

Owner:BRUKER AXS

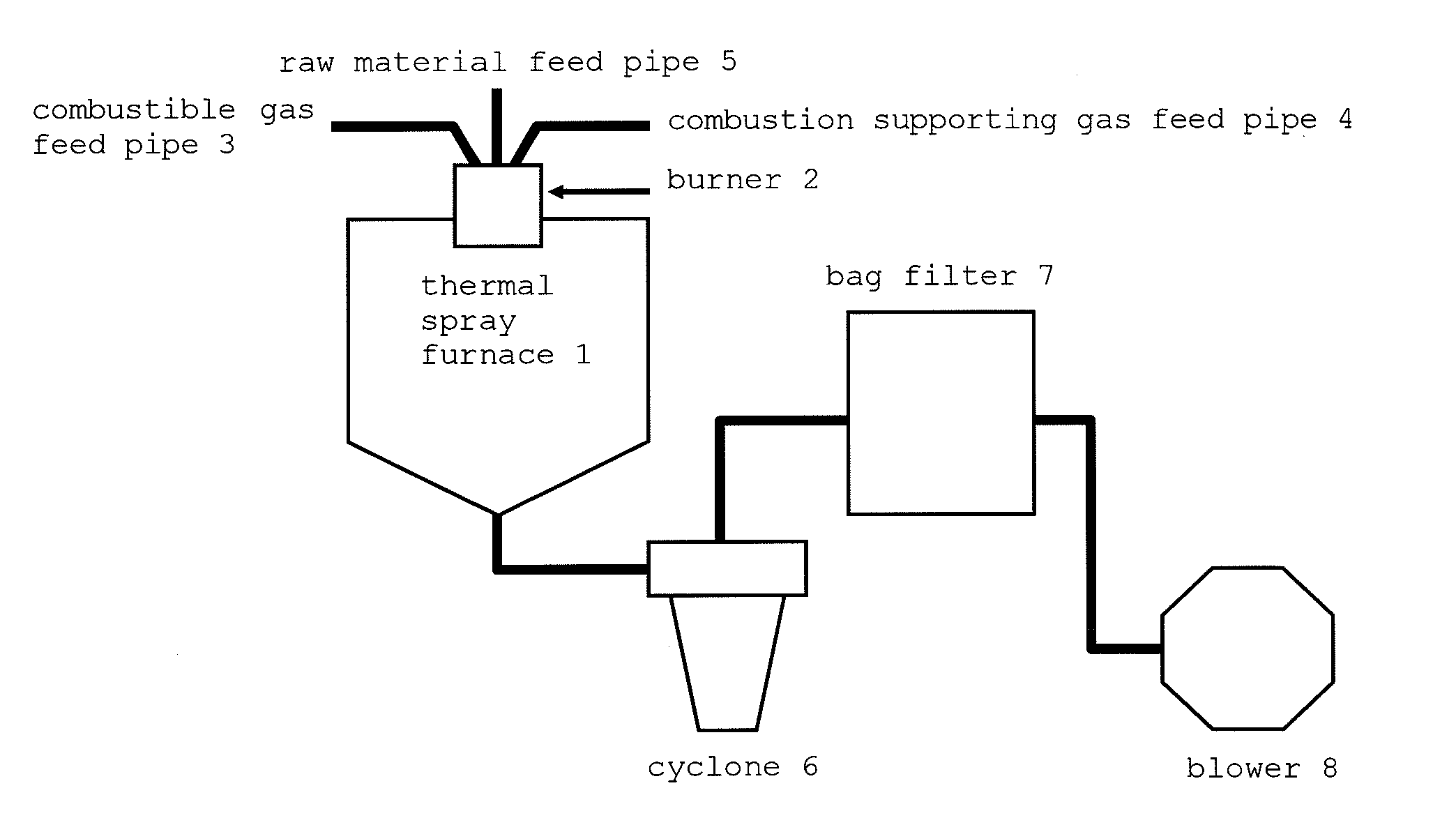

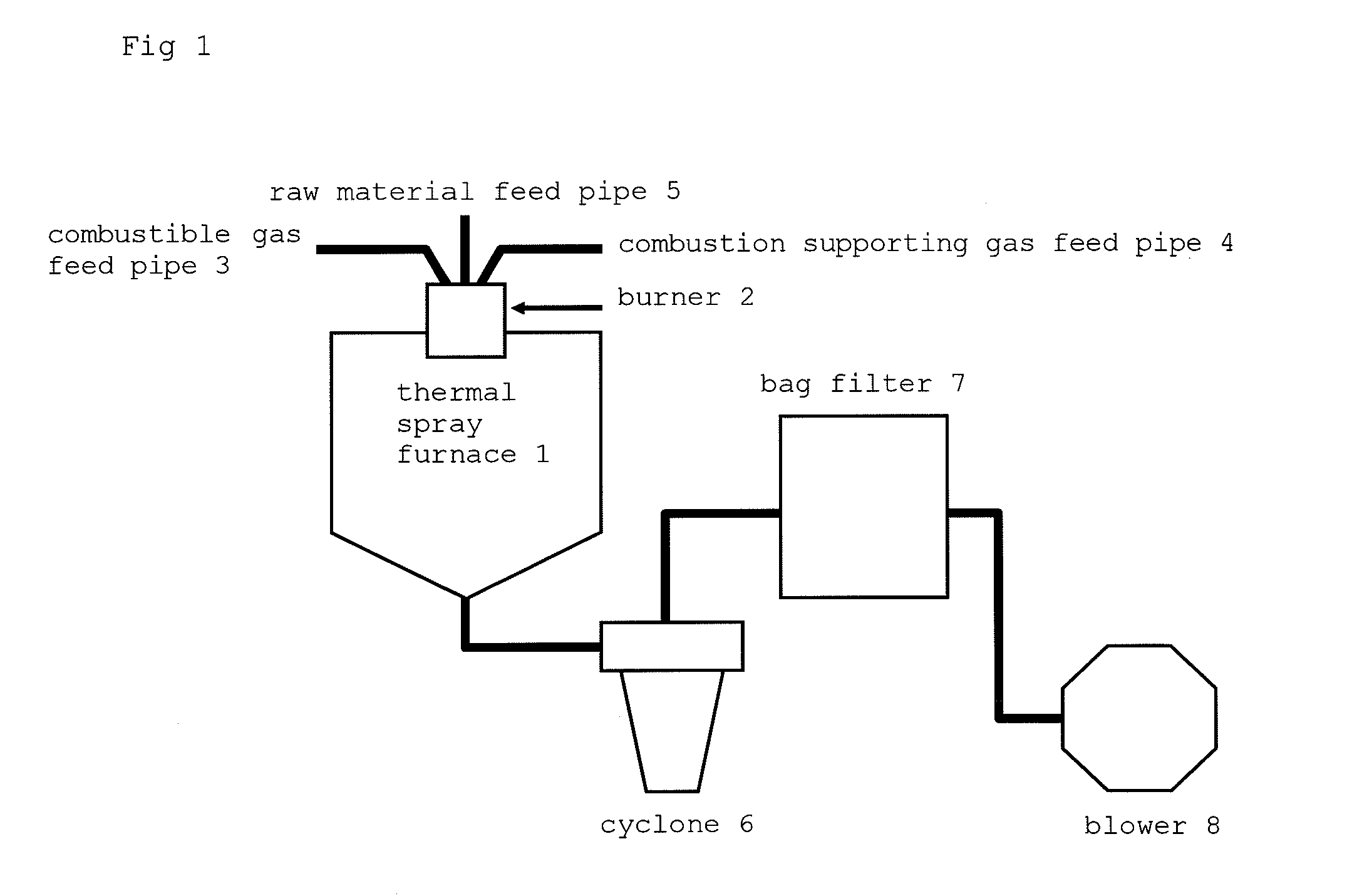

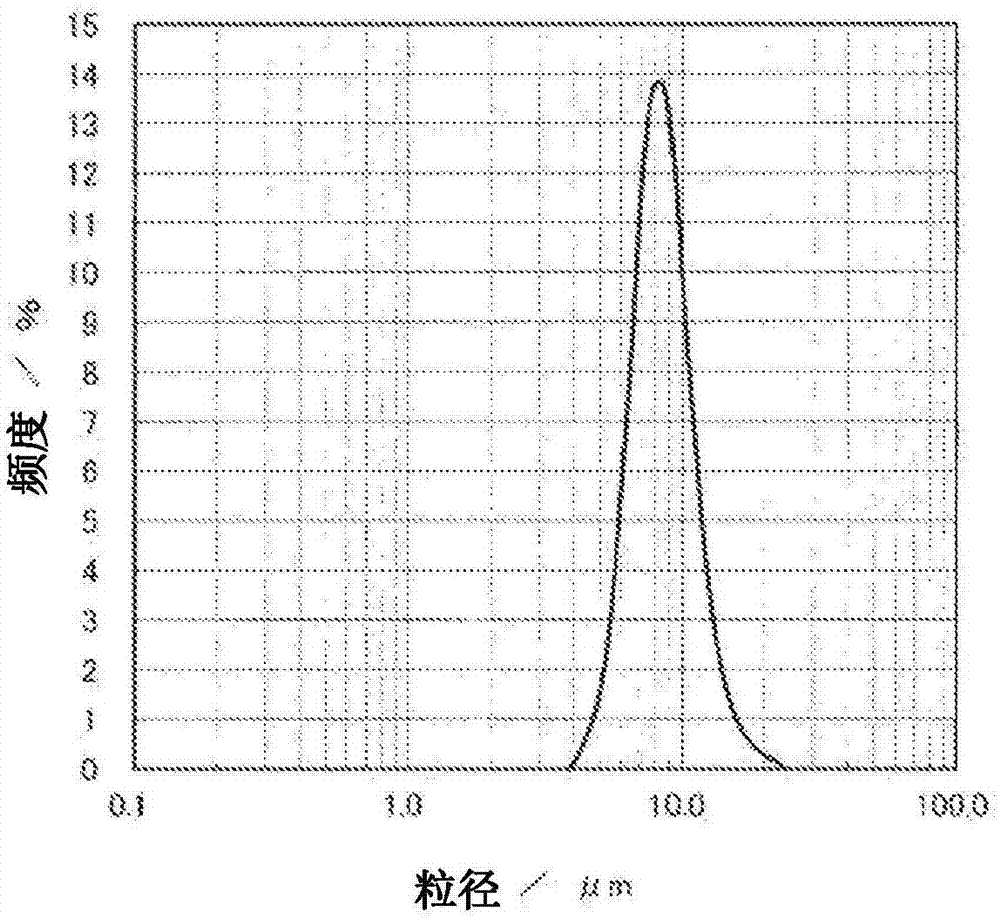

Method for producing spherical alumina powder

ActiveUS20110256051A1Small specific surface areaLow alpha dosePigmenting treatmentGranulation by powder suspensionNitrogenSpherical form

A production method comprising the steps of: spraying an aluminum hydroxide powder having a specific surface area measured by a nitrogen adsorption method of 0.3 m2 / g or more and 3 m2 / g or less; a ratio of an average particle diameter D50, which is a particle diameter at which 50% by weight of particles from the finest particle side are accumulated in a particle diameter distribution measured by a laser diffraction scattering method, to a sphere conversion particle diameter Dbet calculated from a specific surface area, of 10 or less; and the average particle diameter D50 of 2 μm or more and 100 μm or less, into flames, and then collecting it in the form of a powder to give a spherical alumina powder having a small specific surface area and a low uranium content, and capable of providing high thermal conductivity to resin compositions.

Owner:NIPPON STEEL CHEMICAL CO LTD +1

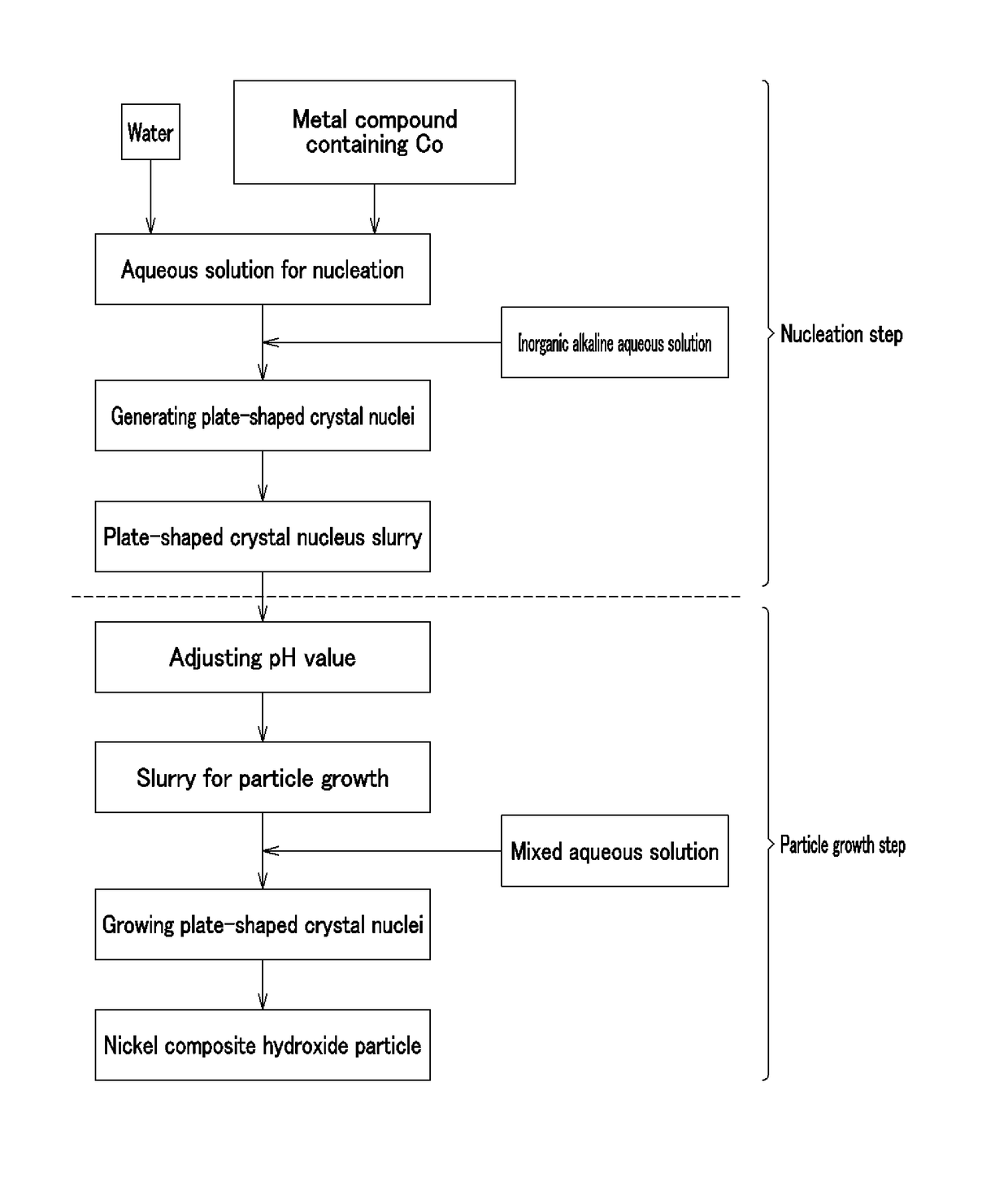

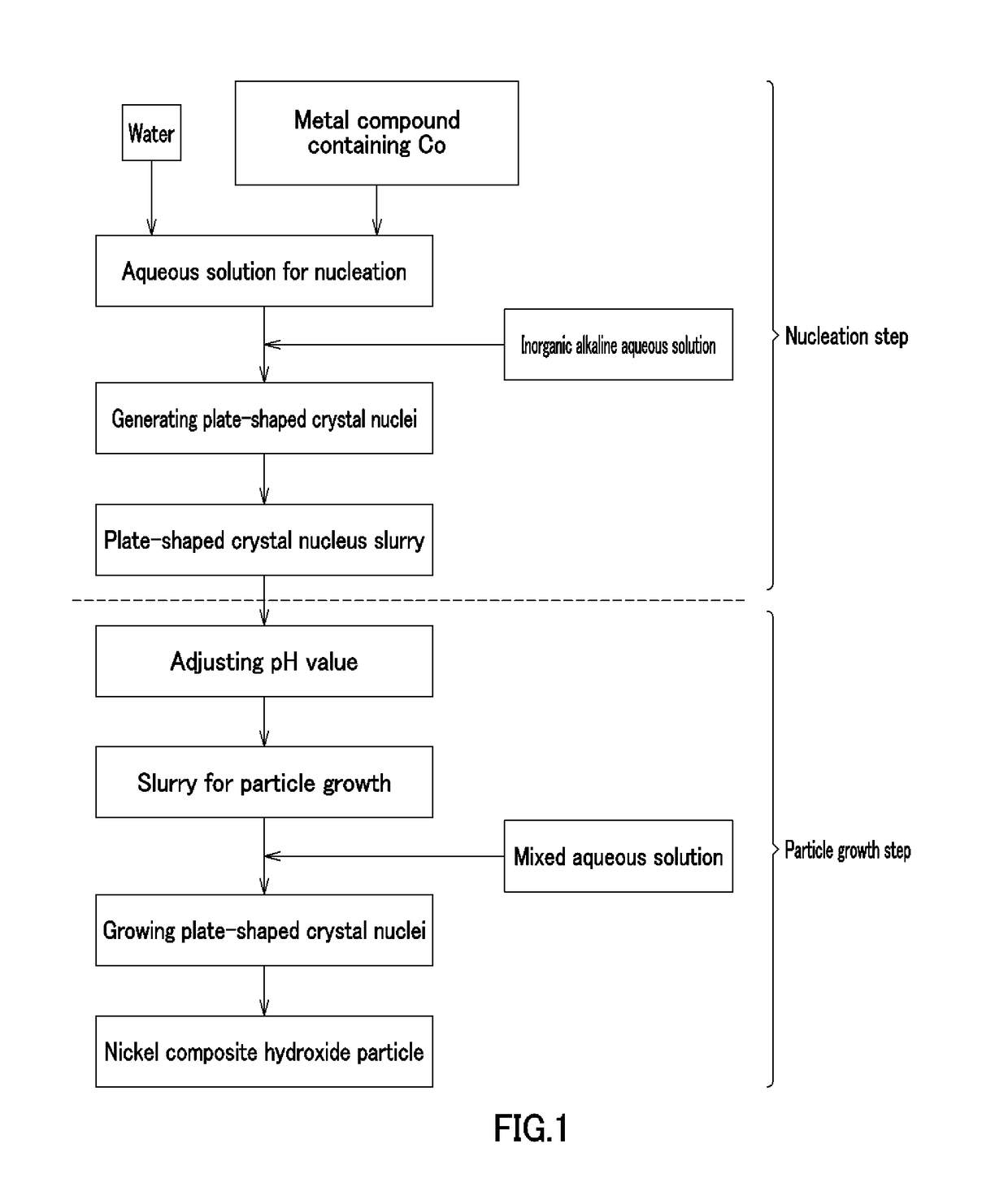

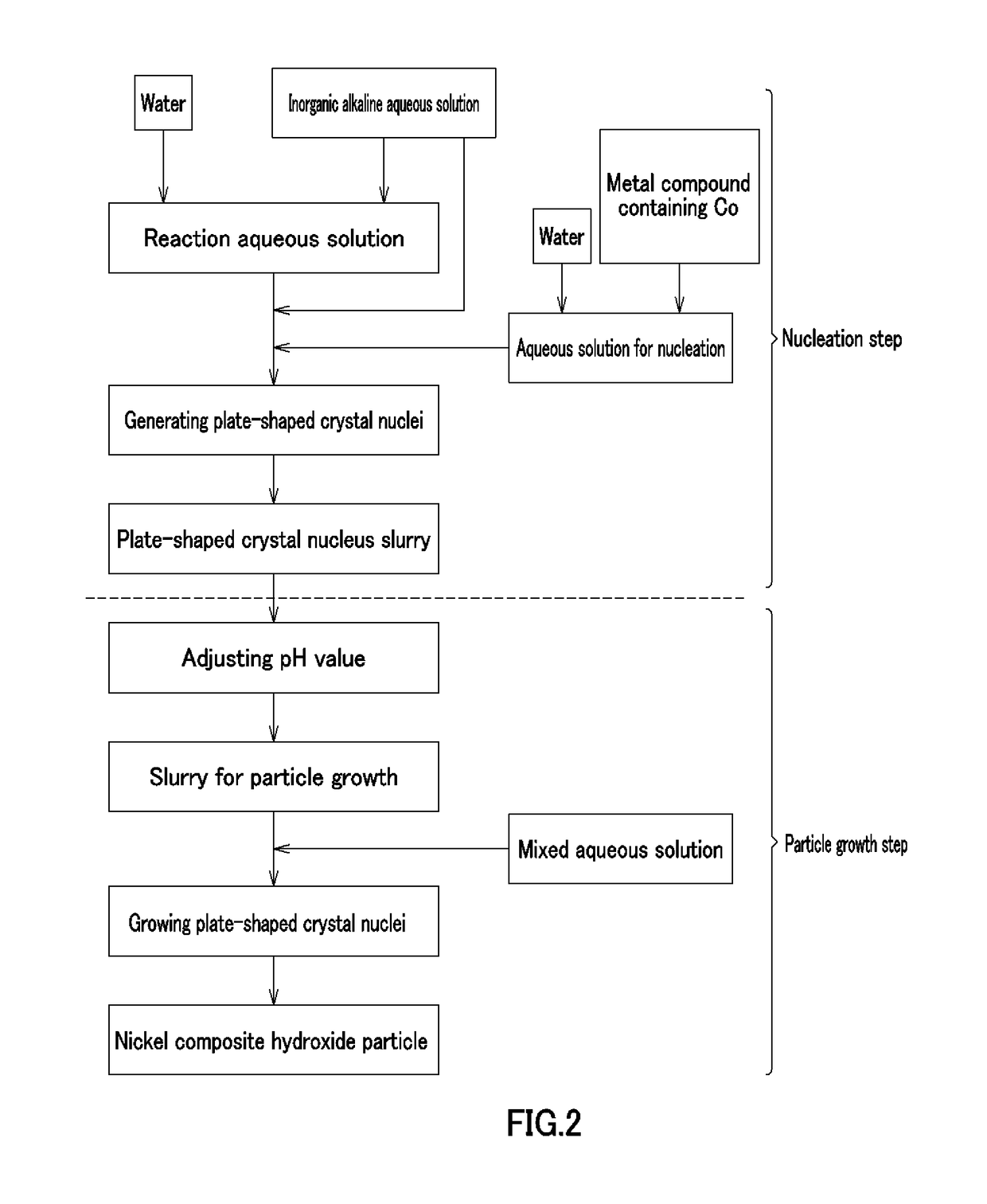

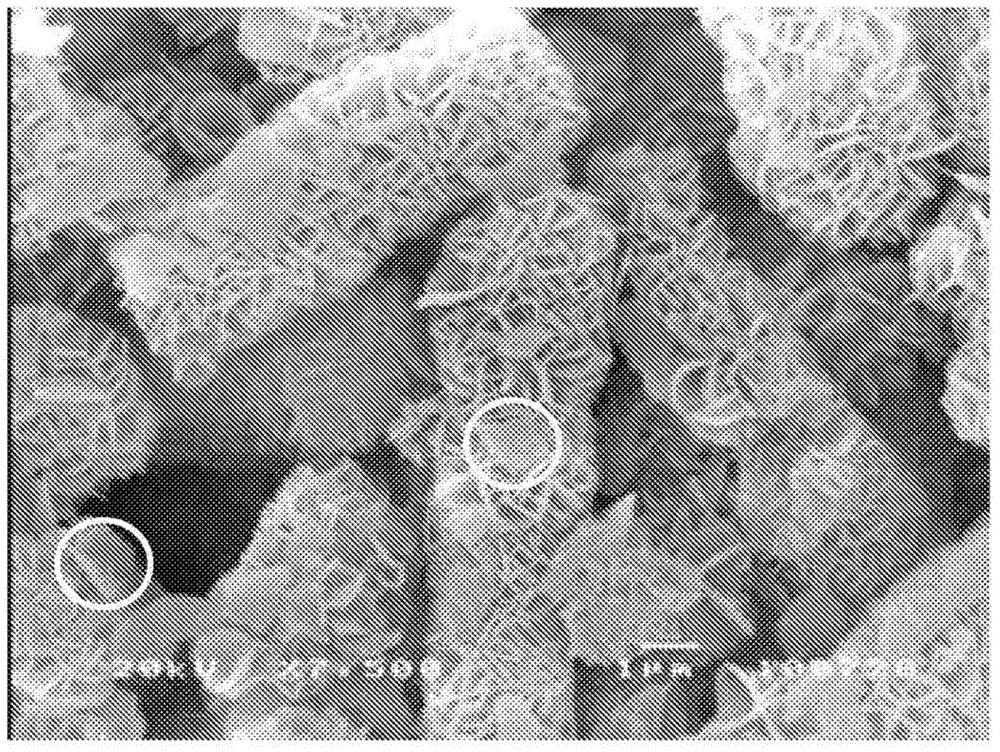

Nickel composite hydroxide and process for producing same, positive electrode active material and process for producing same, and non-aqueous electrolyte secondary battery

ActiveUS20170271653A1Improve durability and output characteristicReduce capacityElectrode manufacturing processesPositive electrodesVolume averagePlanar projection

A positive electrode active material for a non-aqueous electrolyte secondary battery achieves high output characteristics and battery capacity, and allows a high electrode density to be achieved in the case of using the material for a positive electrode of a battery; and a non-aqueous electrolyte secondary battery uses the positive electrode active material, thereby achieving a high output with a high capacity. Prepared is a nickel composite hydroxide including plate-shaped secondary particles aggregated with overlaps between plate surfaces of multiple plate-shaped primary particles, where shapes projected from directions perpendicular to the plate surfaces of the plate-shaped primary particles are any plane projection shape of spherical, elliptical, oblong, and massive shapes, and the secondary particles have an aspect ratio of 3 to 20, and a volume average particle size (Mv) of 4 μm to 20 μm measured by a laser diffraction scattering method.

Owner:SUMITOMO METAL MINING CO LTD

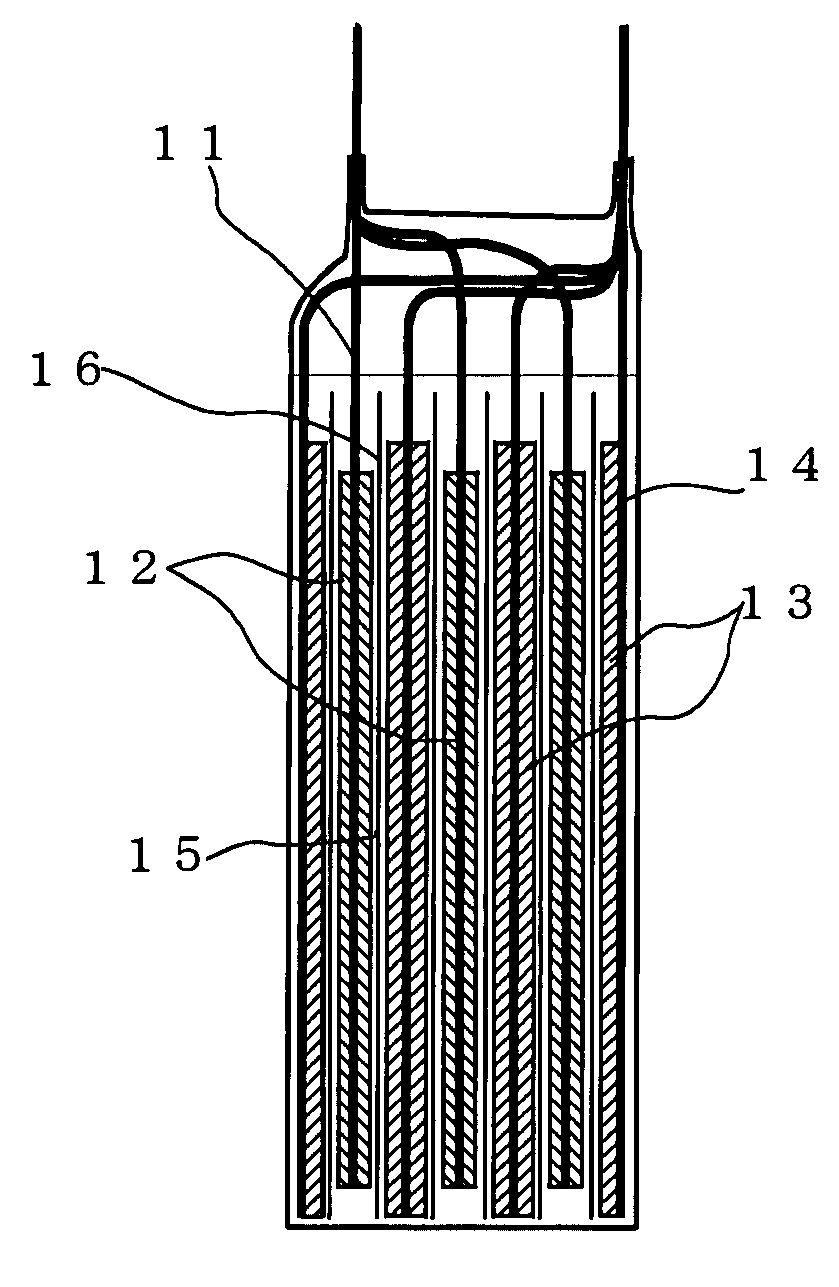

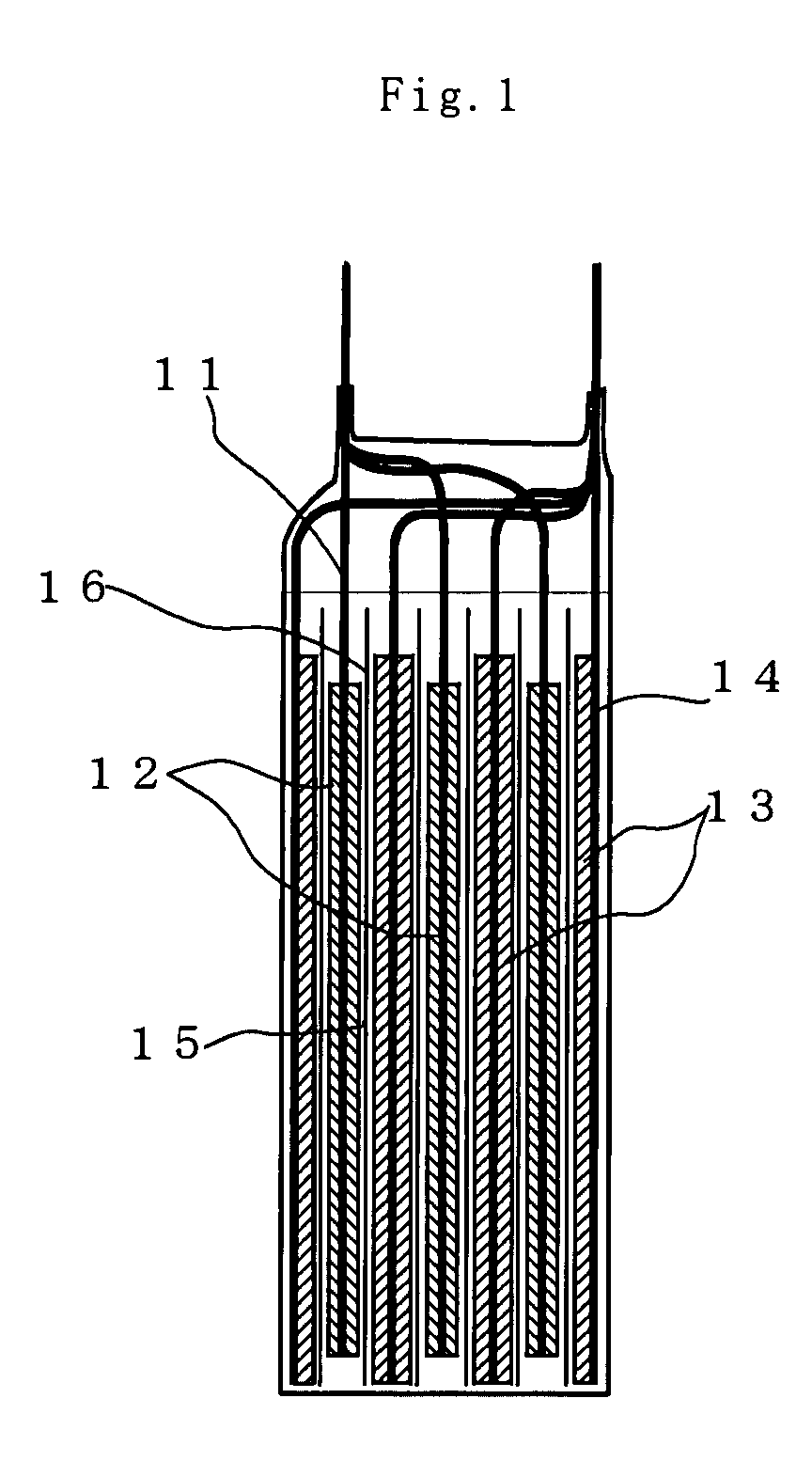

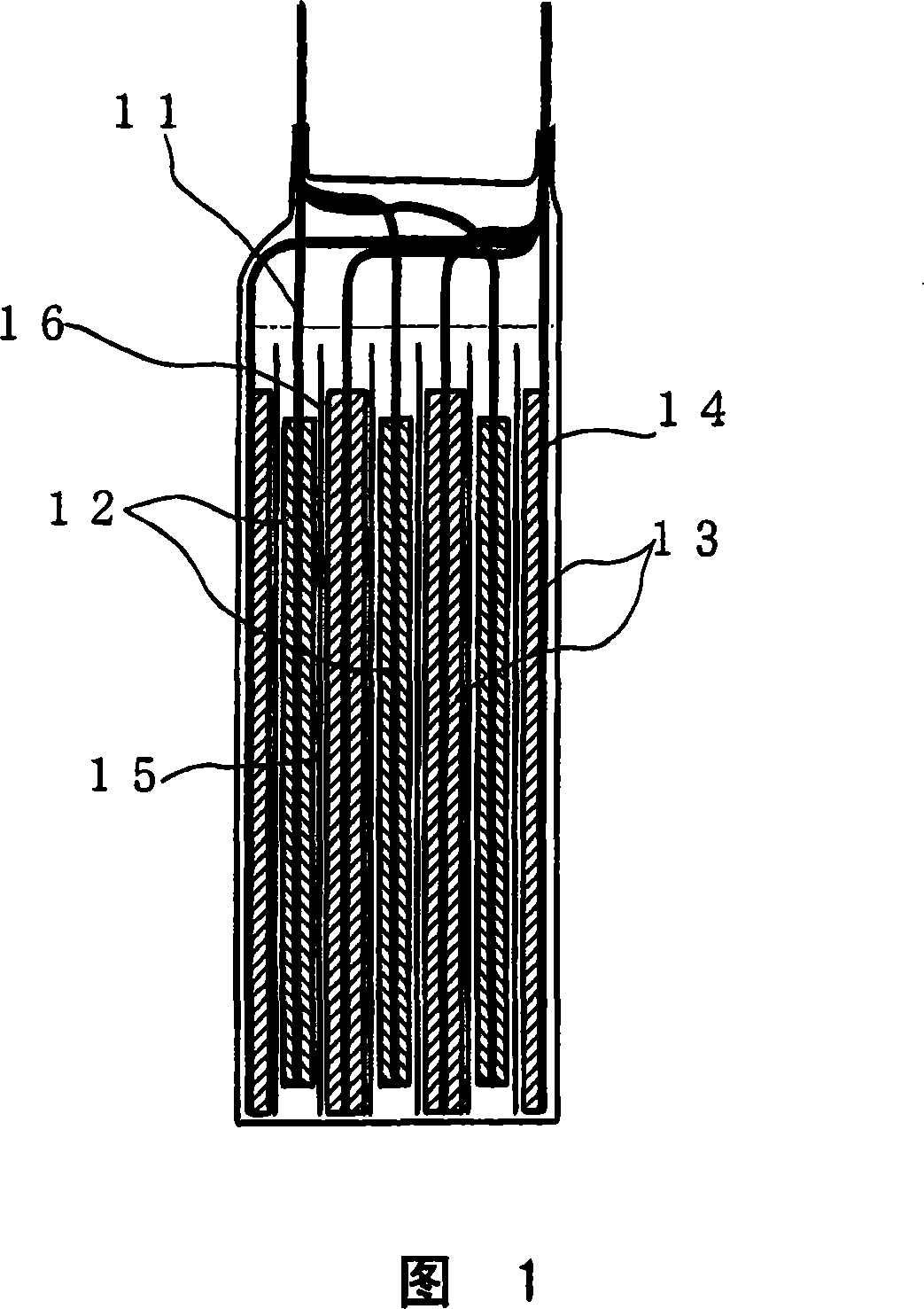

Lithium ion secondary battery

ActiveUS20070248885A1Increase energy densityReduce weightNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsLithiumElectrolysis

The invention provides a lithium ion secondary battery comprising a positive electrode, a negative electrode and an electrolysis solution containing an aprotic solvent having an electrolyte dissolved in it, wherein the negative electrodes uses an amorphous carbon material as a negative electrode active material. The amorphous carbon material has (A) an average particle diameter (median size of 7 μm to 20 μm inclusive as measured by a laser diffraction scattering method and (B) a particle size distribution as measured by a laser diffraction scattering method, in which distribution the ratio of particles of less than 3 μm in diameter is 1% by mass to 10% mass inclusive, and is free of an electrical conducting material.

Owner:NEC ENERGY DEVICES LTD

Antacid and laxative tablets

An antacid and laxative tablet comprising magnesium oxide particles as an effective component, wherein(i) the magnesium oxide particles contained in the tablet have an average secondary particle diameter measured by a laser diffraction scattering method of 0.5 to 10 μm,(ii) the content of magnesium oxide particles in the tablet is 88 wt % or more,(iii) the tablet does not become blackish and has substantially no tableting spot, and(iv) the disintegration time is 10 sec or less.The antacid and laxative tablet of the present invention has a high content of magnesium oxide particles, a short disintegration time, does not become blackish, has no tablet trouble and no tableting spot and is suitably administered orally.

Owner:KYOWA CHEM IND

Rod-like magnesium hydroxide particle and rod-like magnesium oxide particle each having high specific surface area, and methods respectively for producing said particles

Provided are: a magnesium hydroxide particle and a magnesium oxide particle, each of which has a high specific surface area; and methods respectively for producing the particles. A magnesium hydroxide particle and a magnesium oxide particle, each of which has a rod-like shape formed by the aggregation of scale-like primary particles, also has a volume cumulative 50% particle diameter (D50) of 1.0 to 10.0 μm as measured by a laser diffraction scattering particle size distribution measurement method, and also has a specific surface area of 10 m2 / g or more.

Owner:TATEHO CHEM IND CO

Polishing composition

ActiveUS9505951B2High rateSuppression of surface defectsOther chemical processesSemiconductor/solid-state device manufacturingMaterials scienceMetal

[Problem] Provided is a polishing composition that can sufficiently maintain a high polishing rate for a barrier layer and an insulating film and suppress the occurrence of a surface defect such as erosion or fang.[Solution] Provided is a polishing composition which is used in the application to polish a polishing object having a barrier layer, a metal wiring layer and an insulating film, the polishing composition including abrasive grains, an oxidant, a metal corrosion inhibitor, a pH adjusting agent and water, in which an aspect ratio of abrasive grains is 1.22 or less and a ratio D90 / D10 of a diameter D90 of particles when a cumulative particle weight from the fine particle side reaches 90% of the total particle weight to a diameter D10 of particles when the cumulative particle weight from the fine particle side reaches 10% of the total particle weight of the entire particles is 1.5 or more in a particle size distribution of the abrasive grains determined by a laser diffraction scattering method.

Owner:FUJIMI INCORPORATED

Lithium ion secondary battery

ActiveCN101060182AIncrease capacityNon-aqueous electrolyte accumulatorsNegative electrodesLithiumElectrolysis

The invention provides a lithium ion secondary battery comprising a positive electrode, a negative electrode and an electrolysis solution containing an aprotic solvent having an electrolyte dissolved in it, wherein the negative electrodes uses an amorphous carbon material as a negative electrode active material. The amorphous carbon material has (A) an average particle diameter (median size of 7 mum to 20 mum inclusive as measured by a laser diffraction scattering method and (B) a particle size distribution as measured by a laser diffraction scattering method, in which distribution the ratio of particles of less than 3 mum in diameter is 1% by mass to 10% mass inclusive, and is free of an electrical conducting material.

Owner:ENVISION AESC ENERGY DEVICES LTD

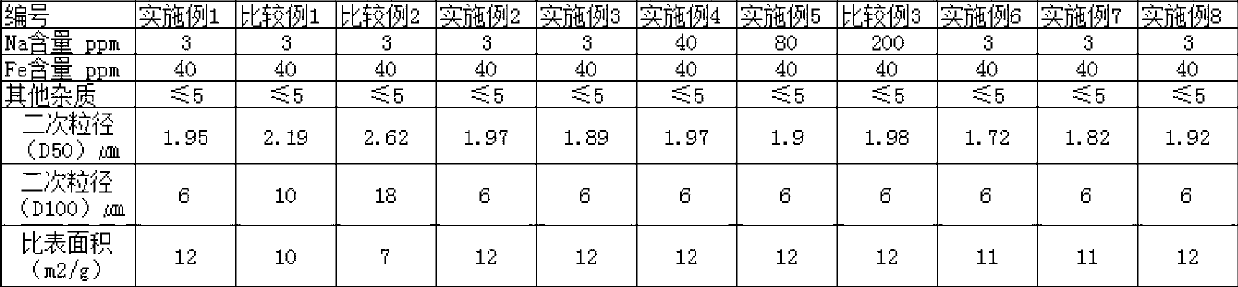

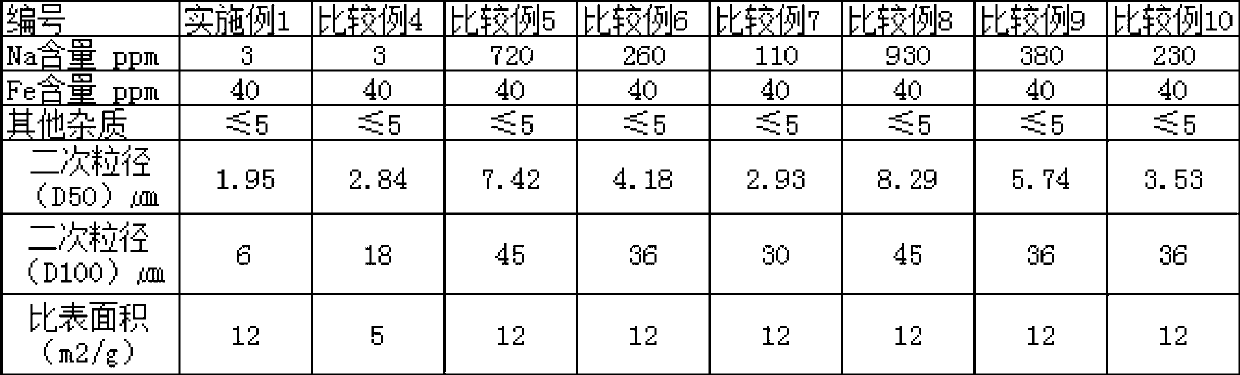

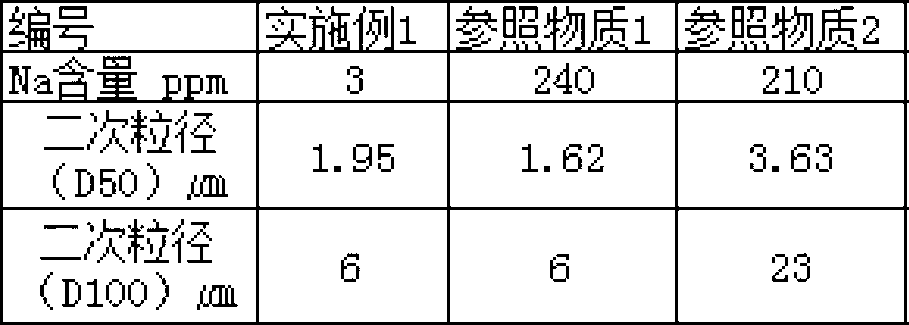

Hydrotalcite having sodium content limited to ultra-low volume, method for preparing same, and synthetic resin composition containing same

ActiveCN103108907AReduce manufacturing costUniform and small secondary particle sizeMaterial nanotechnologyHydrotalciteManganeseHydrotalcite

Disclosed is hydrotalcite having properties and sodium content limited to ultra-low volume, a method for preparing same, and a synthetic resin composition hydrotalcite containing same. (1) In the general formula [M(II)y M(II)z]1-x(Al)x(OH)2(CO3)2- (x) / n mH2O, M(II) represents Mg2+, Zn2+, Ca2+, Li2+, which are divalent metal ions, M(III) represents Al3+, which is a trivalent metal ion, A represents an anion (CO3 2-), and x, y, z, and m represent the values that satisfy the following conditions: 0.2=x<0.4, y+z=1, 0.7=y=1, 0=z=0.3, 0=m<1; (2) The hydrotalcite particles have an average secondary particle diameter of 0.5~2? when measured using laser diffraction scattering method. (3) The sodium content in the hydrotalcite particles is less than 80 weight ppm.; (4) The hydrotalcite particles contain iron compound and manganese compound at a total volume of less than 0.005 weight% when converted into metals (Fe+Mn). (5) When measured using BET method, the hydrotalcite particles have a specific surface area of 5~40 ? / g, or more desirably 5~20 ? / g.

Owner:丹石产业株式会社

Magnesium hydroxide microparticles, magnexium oxide microparticles, and method for producing each

InactiveCN103140446AHigh puritySmall and uniform particle sizeMagnesiaMagnesium hydroxideMicroparticleMaterials science

Highly pure magnesium hydroxide microparticles and highly pure magnesium oxide microparticles that are even and have a small particle size are provided. Regarding the magnesium hydroxide microparticles, the BET specific surface area is at least 5 m2 / g, the volume-based cumulative 50% particle diameter (D50) resulting from laser diffraction scattering measurement of the particle size distribution is 0.1-0.5 [mu]m, the ratio D90 / D10 between the volume-based cumulative 90% particle diameter (D90) and the volume-based cumulative 10% particle diameter (D10) resulting from laser diffraction scattering measurement of the particle size distribution is no greater than 10, and the purity is at least 99.5 mass%. Regarding the magnesium oxide microparticles, the BET specific surface area is at least 5 m2 / g, the volume-based cumulative 50% particle diameter (D50) resulting from laser diffraction scattering measurement of the particle size distribution is 0.1-0.5 [mu]m, the ratio D90 / D10 between the volume-based cumulative 90% particle diameter (D90) and the volume-based cumulative 10% particle diameter (D10) resulting from laser diffraction scattering measurement of the particle size distribution is no greater than 10, and the purity is at least 99.5 mass%.

Owner:TATEHO CHEM IND CO

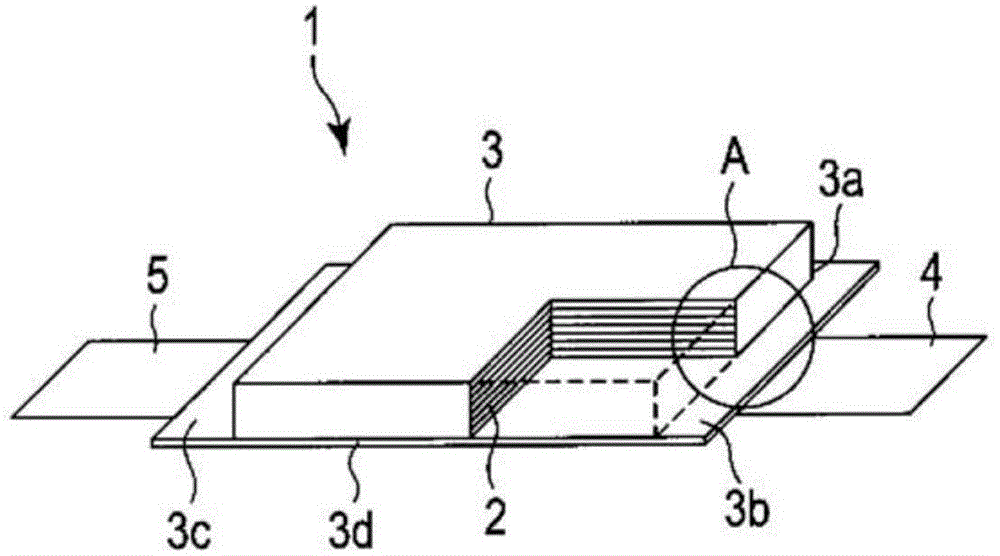

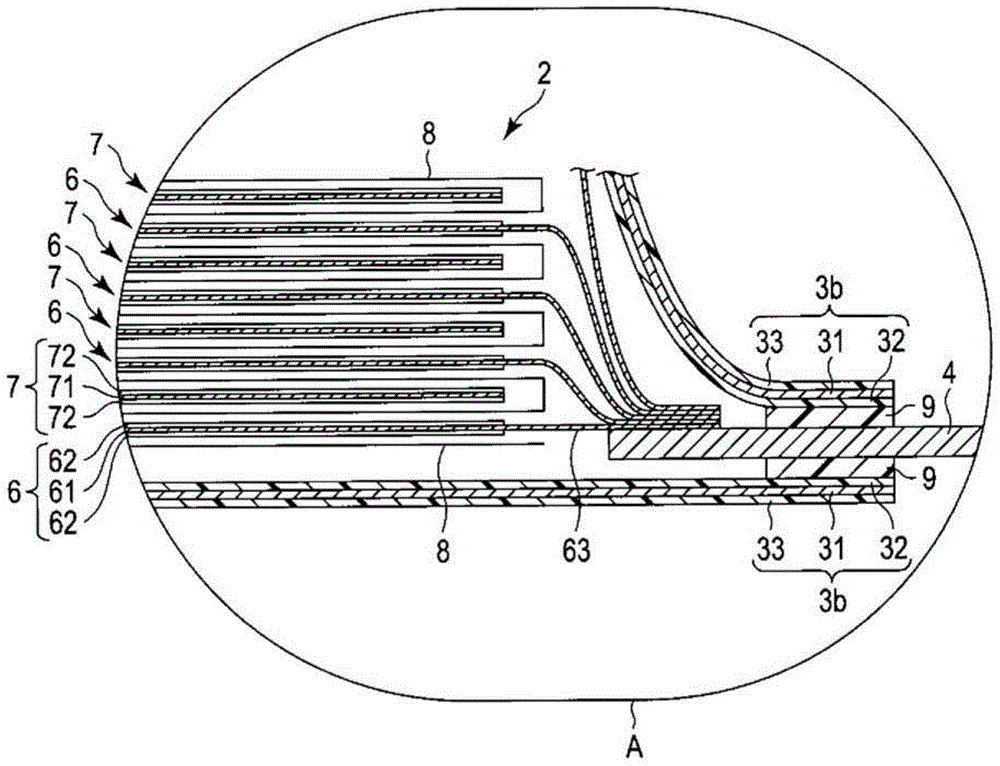

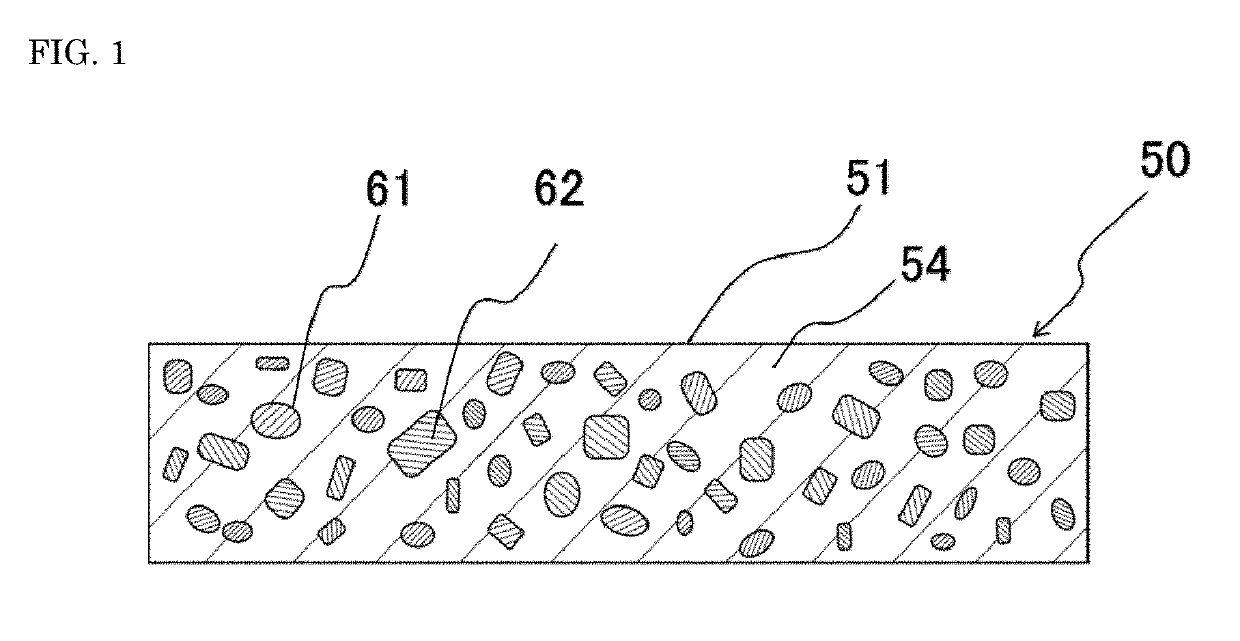

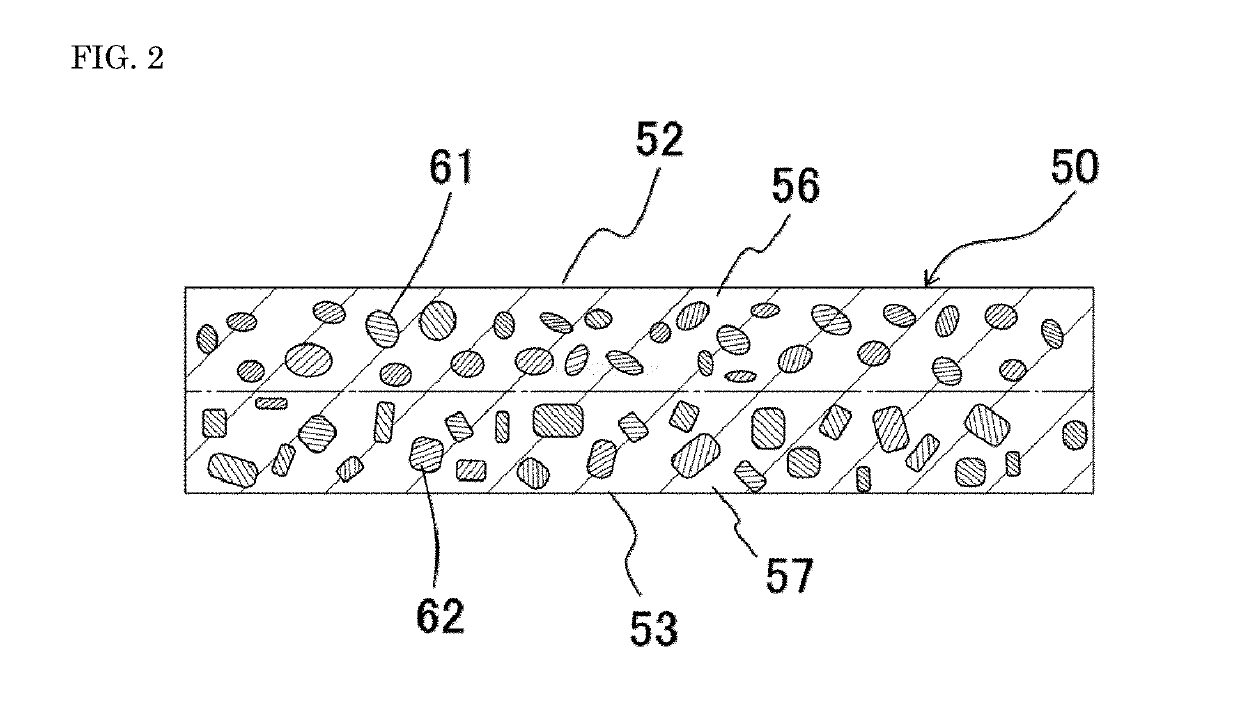

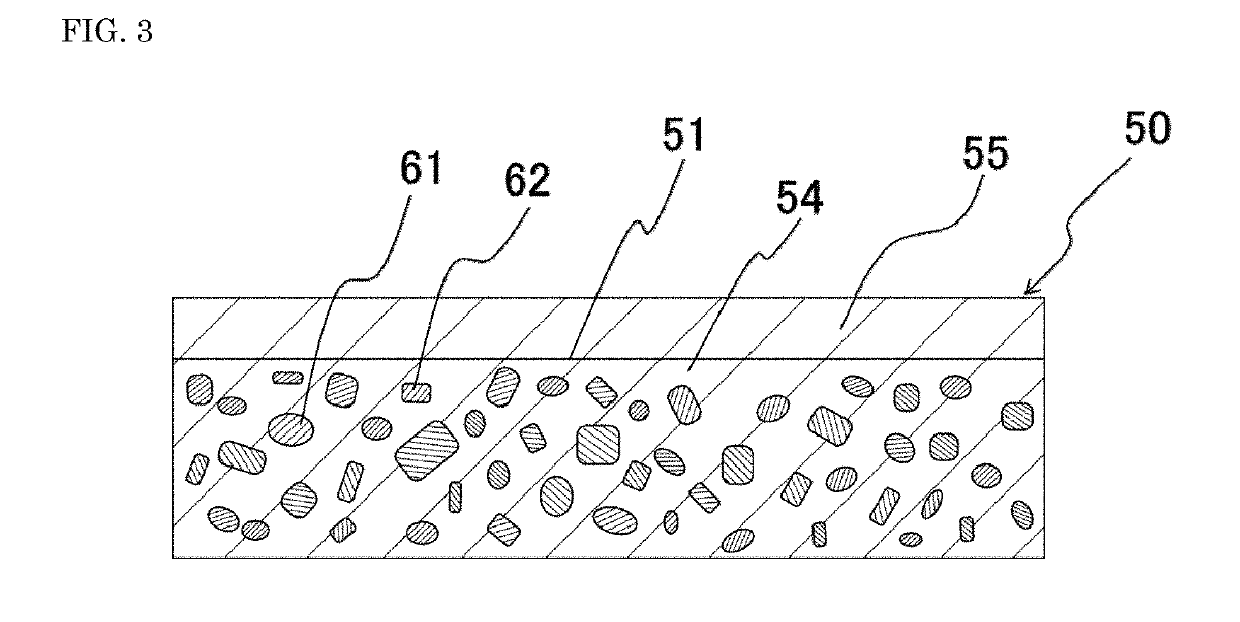

Nonaqueous electrolyte battery

ActiveCN104466094ANon-aqueous electrolyte accumulator electrodesVehicular energy storageCharge dischargeEngineering

Embodiments of the invention provide a nonaqueous electrolyte battery with good charge-discharge cycle performance. Embodiments provide a nonaqueous electrolyte battery (1) including a positive electrode (6), a negative electrode (7), and a nonaqueous electrolyte. The positive electrode (6) includes a positive electrode current collector (61) and a positive electrode active material-containing layer (62) formed on the positive electrode current collector (61). The positive electrode active material-containing layer (62) includes at least one lithium-nickel composite oxide and a conductive agent. The positive electrode active material-containing layer (62) has, in a particle size distribution obtained by a laser diffraction scattering method, an average particle diameter d50 within a range of 1 [mu]m to 5.5 [mu]m, a maximum particle diameter within a range of 10 [mu]m to 100 [mu]m, a particle diameter d10, with a cumulative frequency of 10% from the small particle size side, within a range of 0.5 [mu]m to 3 [mu]m, and X, represented by X = (d50 - d10 ) / d50, within a range of 0.5 to less than 1.

Owner:KK TOSHIBA

Polishing composition

ActiveUS20150315418A1High rateSuppression of surface defectsOther chemical processesSemiconductor/solid-state device manufacturingMetalMaterials science

[Problem] Provided is a polishing composition that can sufficiently maintain a high polishing rate for a barrier layer and an insulating film and suppress the occurrence of a surface defect such as erosion or fang.[Solution] Provided is a polishing composition which is used in the application to polish a polishing object having a barrier layer, a metal wiring layer and an insulating film, the polishing composition including abrasive grains, an oxidant, a metal corrosion inhibitor, a pH adjusting agent and water, in which an aspect ratio of abrasive grains is 1.22 or less and a ratio D90 / D10 of a diameter D90 of particles when a cumulative particle weight from the fine particle side reaches 90% of the total particle weight to a diameter D10 of particles when the cumulative particle weight from the fine particle side reaches 10% of the total particle weight of the entire particles is 1.5 or more in a particle size distribution of the abrasive grains determined by a laser diffraction scattering method.

Owner:FUJIMI INCORPORATED

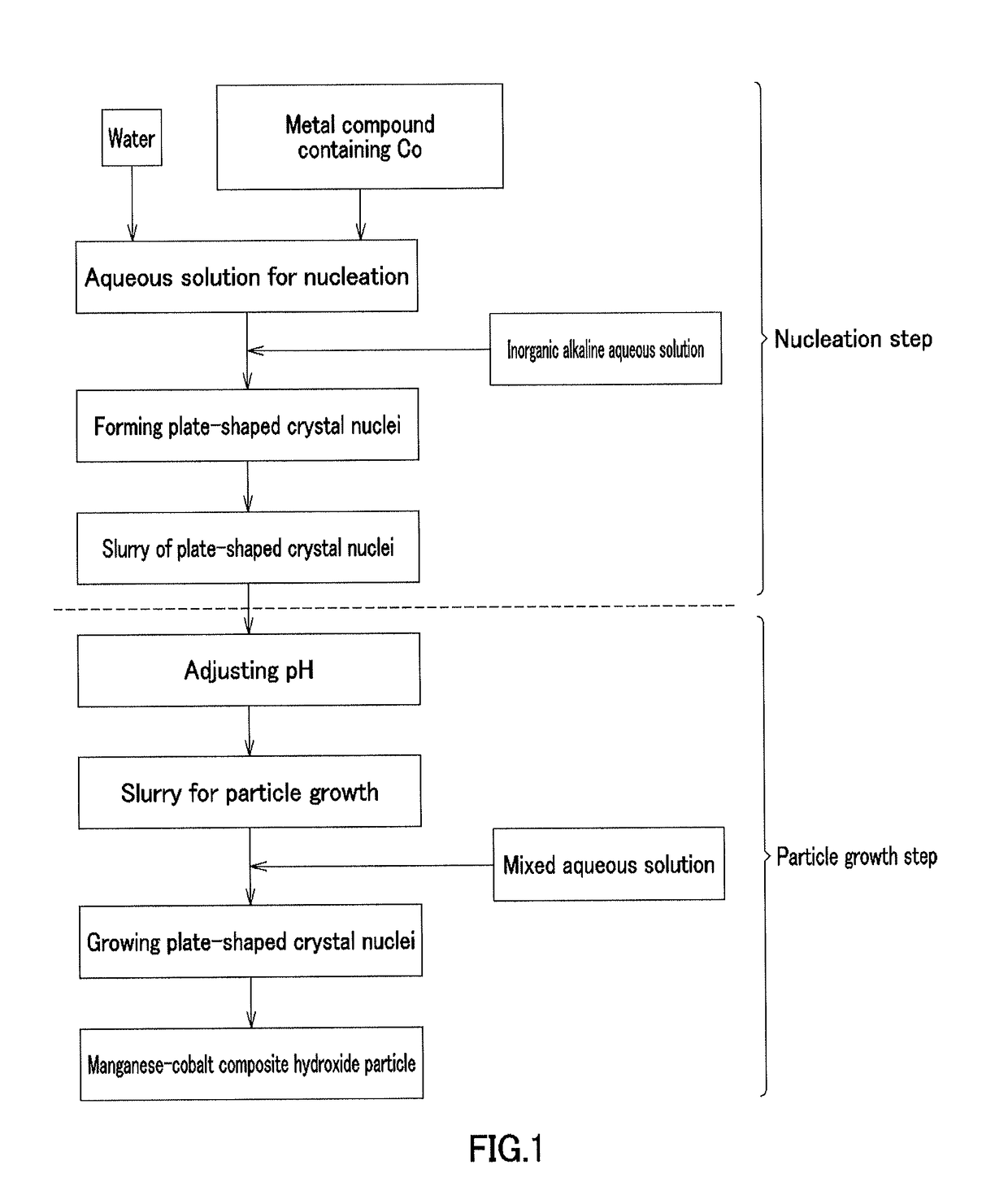

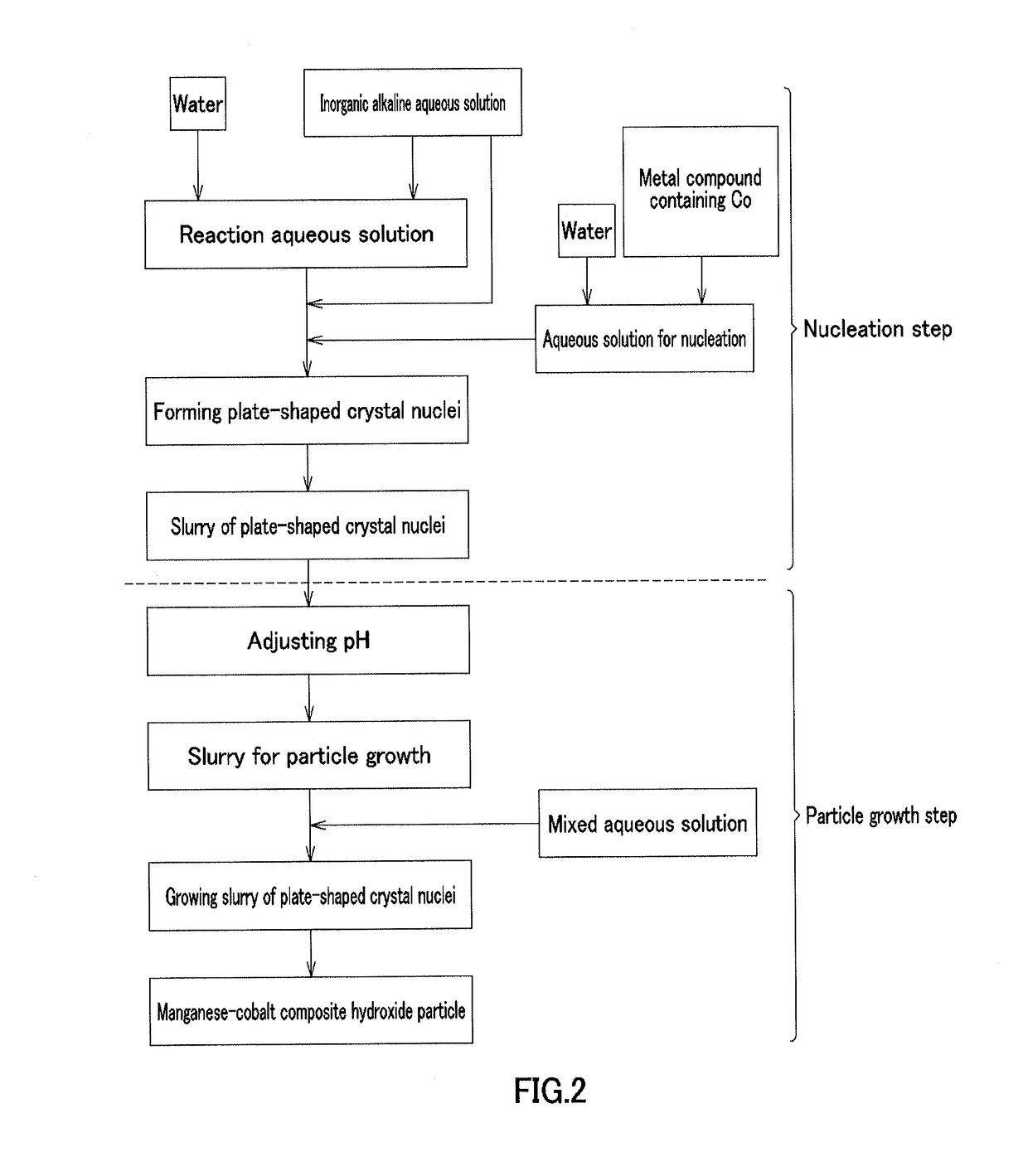

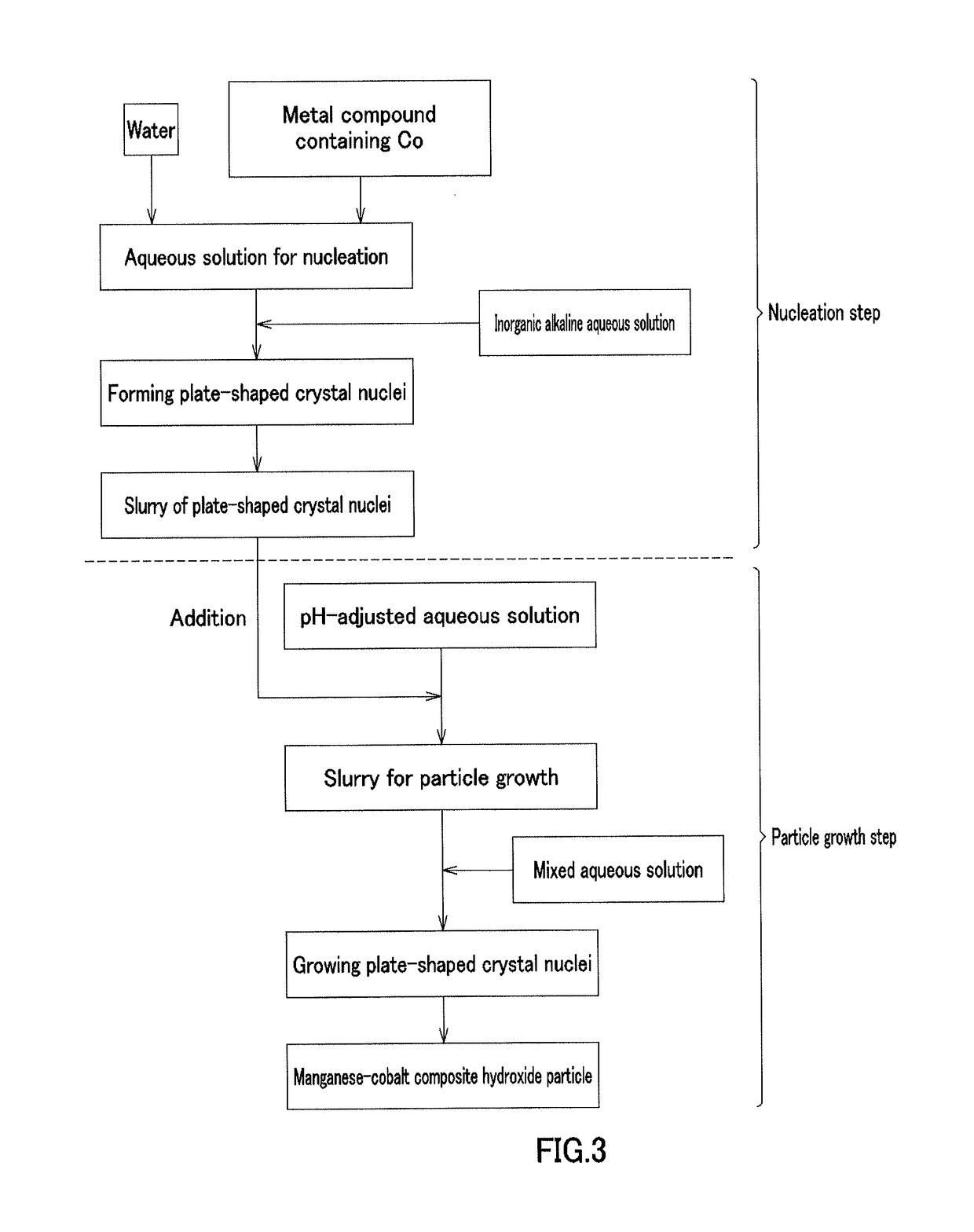

Manganese-cobalt composite hydroxide and process for producing same, positive electrode active material and process for producing same, and non-aqueous electrolyte secondary battery

ActiveUS20170155144A1Increase electrode densityIncrease battery capacityElectrode thermal treatmentPositive electrodesManganeseEngineering

A positive electrode active material for non-aqueous electrolyte secondary batteries that can achieve a high output characteristic and a high battery capacity when used in a positive electrode of a battery and that can achieve a high electrode density, and a non-aqueous electrolyte secondary battery that uses such a positive electrode active material and can achieve a high capacity and a high output. A lithium-manganese-cobalt composite oxide includes plate-shaped secondary particles each obtained by aggregation of a plurality of plate-shaped primary particles caused by overlapping of plate surfaces of the plate-shaped primary particles, wherein a shape of the primary particles is any one of a spherical, elliptical, oval, or a planar projected shape of a block-shaped object, and the secondary particles have an aspect ratio of 3 to 20 and a volume-average particle size (Mv) of 4 μm to 20 μm as measured by a laser diffraction scattering process.

Owner:SUMITOMO METAL MINING CO LTD

Ceramic powder and applications thereof

ActiveUS20110257300A1Good molding effectIncrease resistanceSilicaSemiconductor/solid-state device detailsMetallurgyHeat resistance

The present invention provides ceramic powder capable of being incorporated into rubber or a resin for the preparation of a composition, which shows excellent heat resistance and flame retardancy and which is used, for instance, as a semiconductor-sealing material. The ceramic powder has a multi-peak frequency distribution pattern having at least two peaks as a particle size distribution as determined using a laser diffraction-scattering type particle size-analyzer, wherein the maximum particle size for the first peak ranges from 40 to 80 μm and that for the second peak ranges from 3 to 8 μm and wherein the rate of the particles having a particle size of not less than 20 μm and less than 40 μm is not more than 20% by mass (inclusive of 0% by mass).

Owner:DENKA CO LTD

Binder for glass chopped strand mats

InactiveUS7998565B2Uniform strengthIncrease flexibilityAbsorbent padsBaby linensGlass fiberPolyester resin

A glass chopped strand mat binder according to the invention can be supplied in an amount smaller than a conventional binder amount and can form a glass chopped strand mat having desired uniform strength. The invention is a glass chopped strand mat binder that includes a polyester resin powder (A) having a volume average particle diameter DV of 100 to 250 μm, containing at most 20% by weight of particles with a volume based particle diameter of at least 300 μm, and having a coefficient CV of variation of volume based particle diameter distribution of 0.1 to 30% as measured by the laser diffraction scattering method.

Owner:SANYO CHEM IND LTD

Ethylene-Based Polymer Microparticles, Functional Group-Containing Ethylene-Based Polymer Microparticles,and Catalyst Carriers for Manufacture Thereof

ActiveUS20080044655A1Small particle sizeHigh degree of sphericitySynthetic resin layered productsCellulosic plastic layered productsPolymer scienceMicroparticle

Ethylene-based copolymer microparticles and functional group-containing ethylene-based copolymer microparticles that have particle diameter smaller than that of conventional polyethylene fine-particles, no inter-particle agglomeration, very narrow particle size distribution, and high sphericity are provided, in which requirements (A) to (E): (A) The intrinsic viscosity [η] measured in decalin at 135° C. is in the range of 0.1 to 50 dl / g, (B) at least 95 wt % or more of particles pass through a mesh screen with an opening of 37 μm, (C) the median diameter (d50) measured by laser diffraction scattering is 3 μm≦d50≦25 μm, (D) the circularity coefficient is 0.85 or more, and (E) the variation coefficient of particle diameter (Cv) is 20% or less. Non-agglomerated spherical magnesium-containing microparticles used as magnesium-containing carrier component for olefin-polymerization catalysts that can manufacture the above microparticles are also provided.

Owner:MITSUI CHEM INC

Negative electrode active material for nonaqueous electrolyte secondary batteries

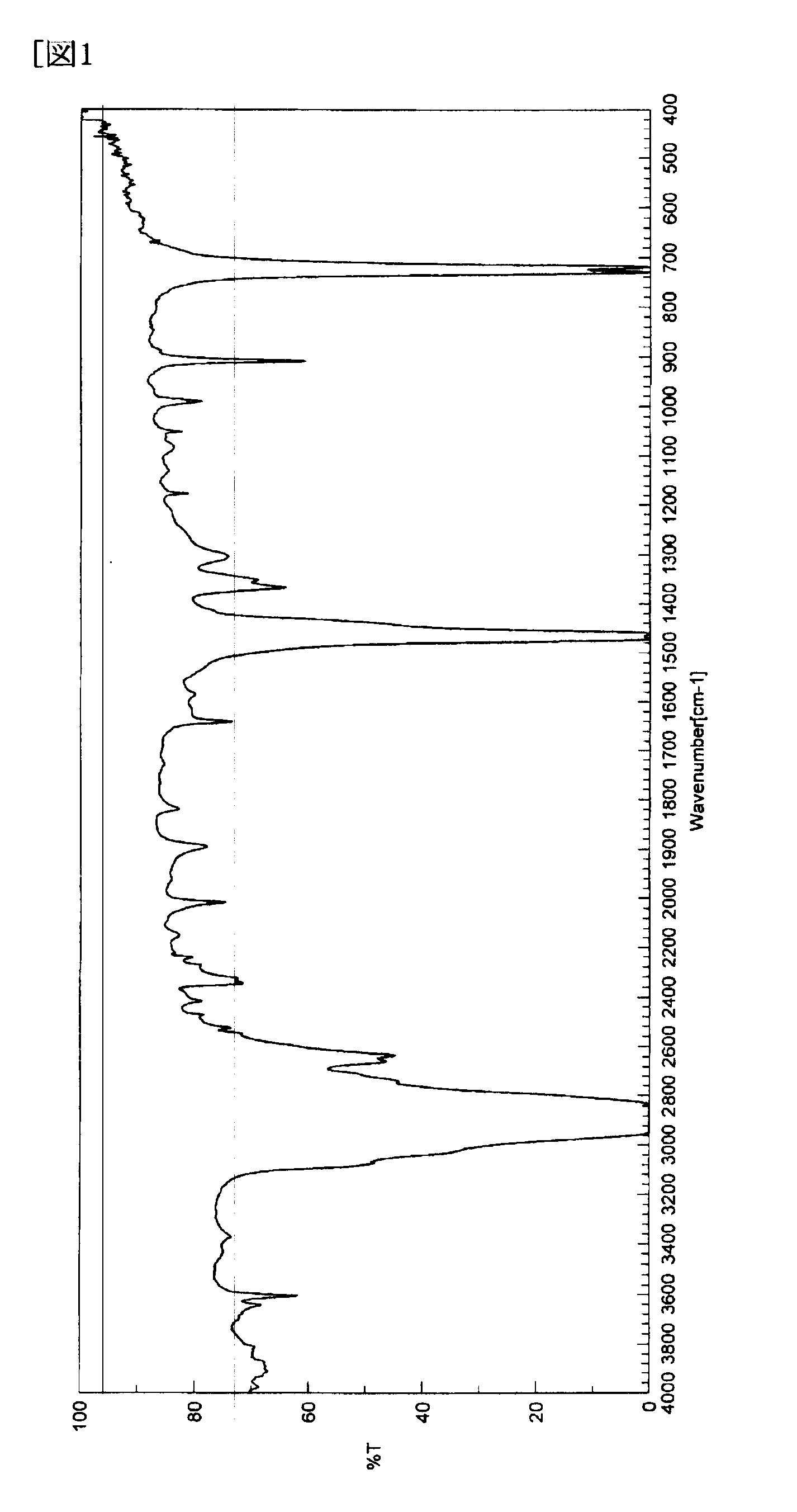

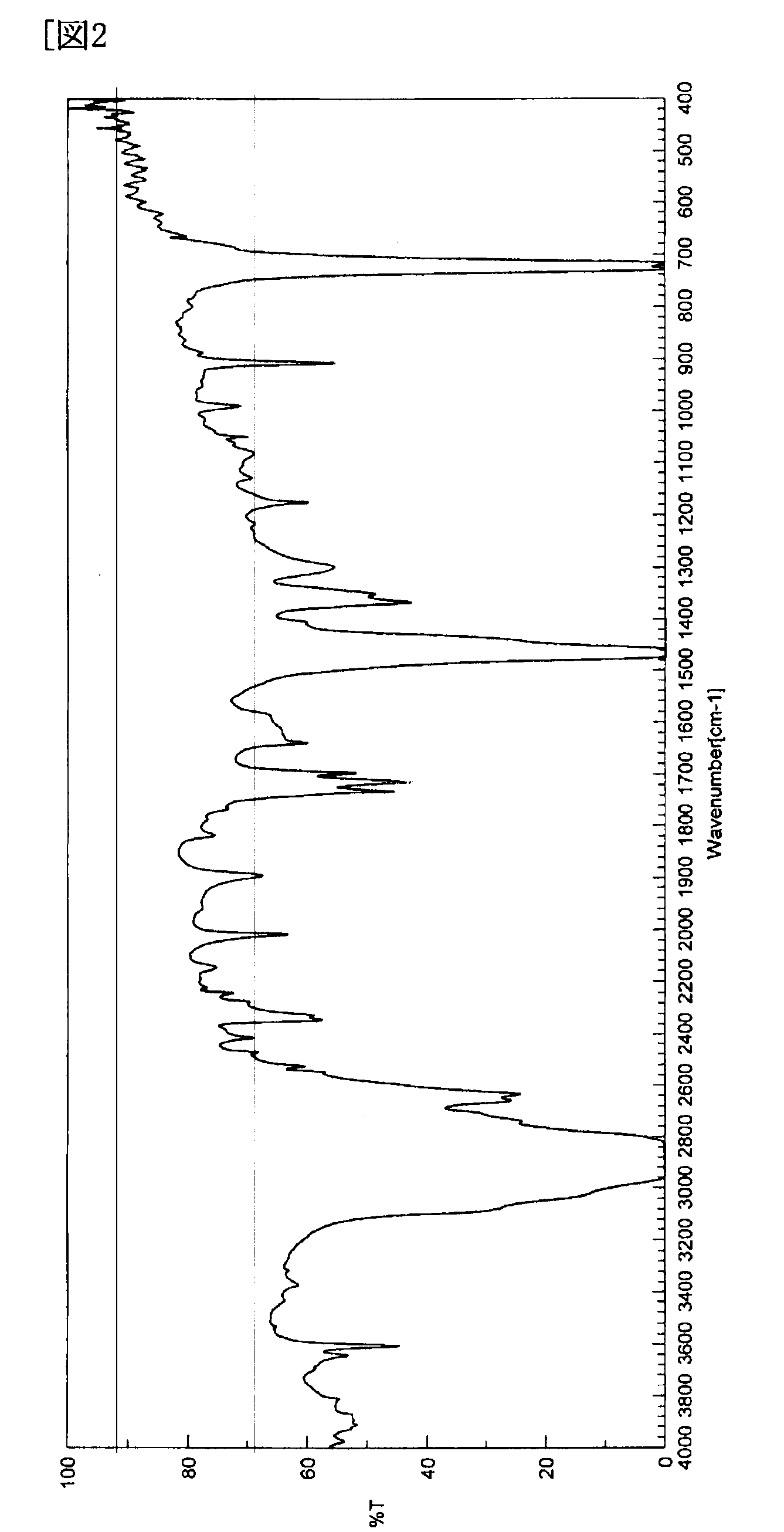

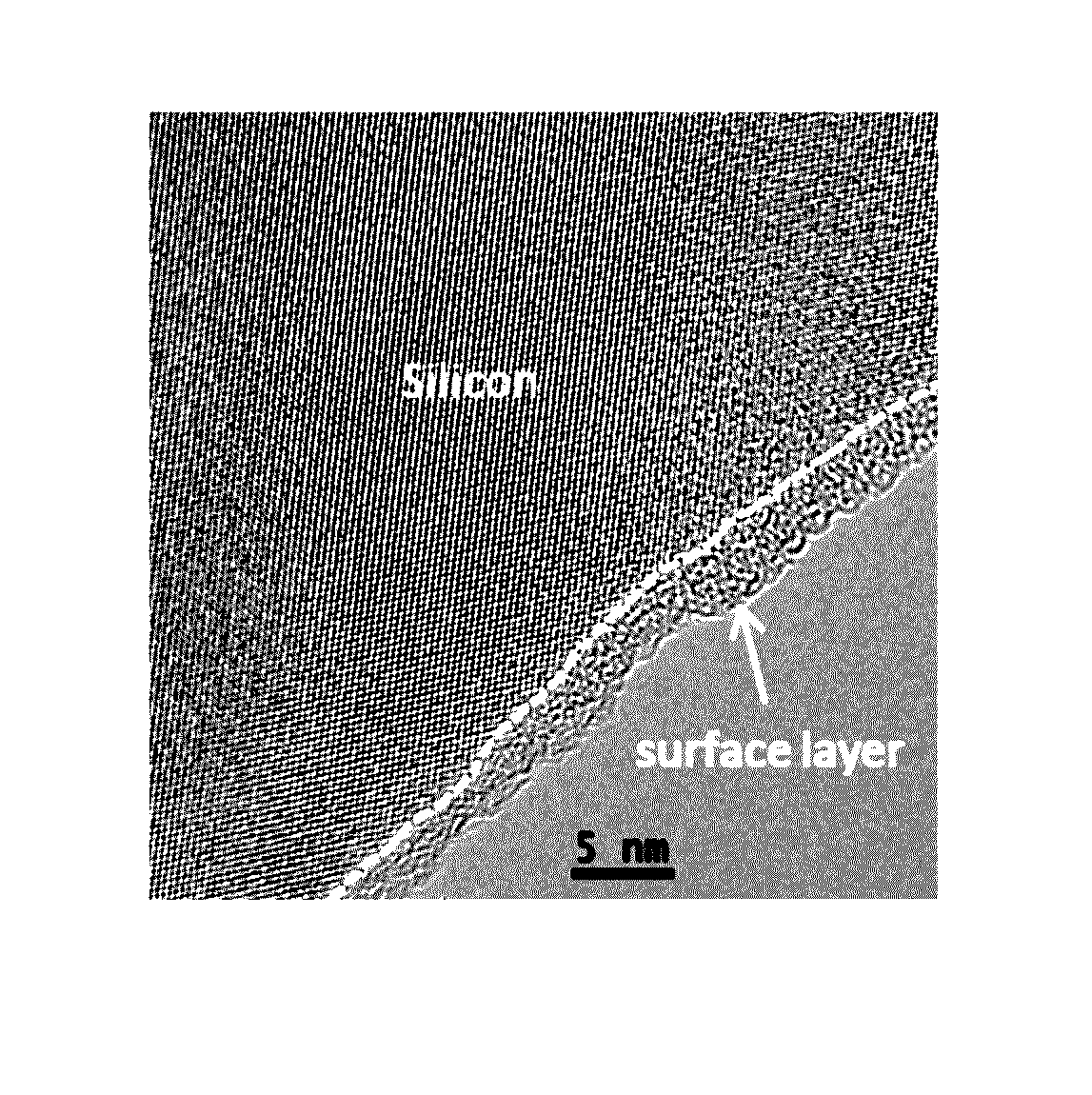

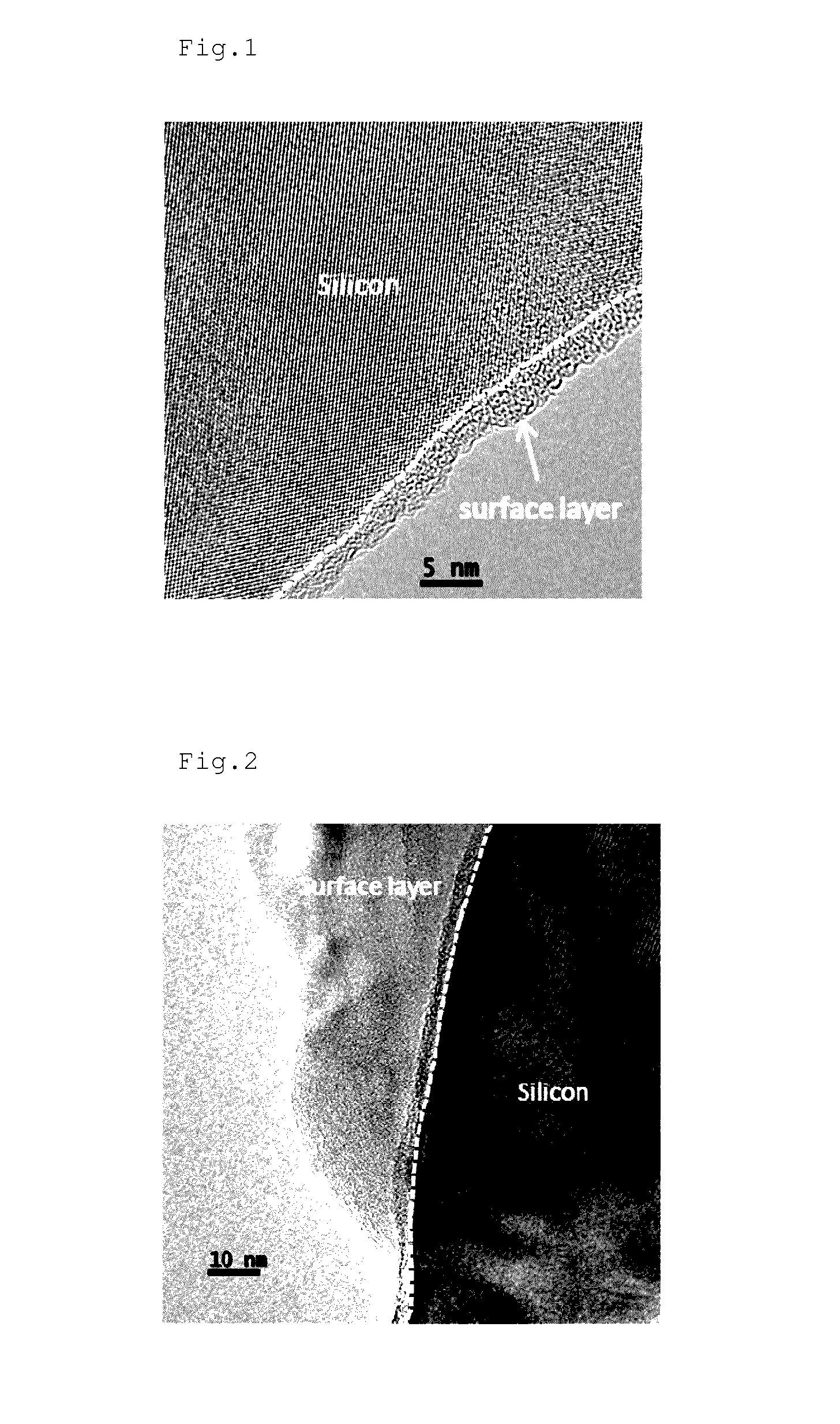

ActiveUS9478800B2Good dispersionSmallFinal product manufactureNegative electrodesSurface layerOxygen

In order to propose a new negative electrode for nonaqueous electrolyte secondary batteries having excellent dispersibility even with a negative electrode active material having a relatively small particle size, there is proposed a negative electrode active material for nonaqueous electrolyte secondary batteries, the negative electrode active material containing silicon and having negative electrode active material particles that have a D50 based on a volume-based particle size distribution obtainable by measurement by a laser diffraction scattering type particle size distribution analysis method, of 0.1 μm to 5.0 μm, and include a surface layer containing oxygen, silicon and carbon on the entire surface or a portion of the active material surface.

Owner:MITSUI MINING & SMELTING CO LTD

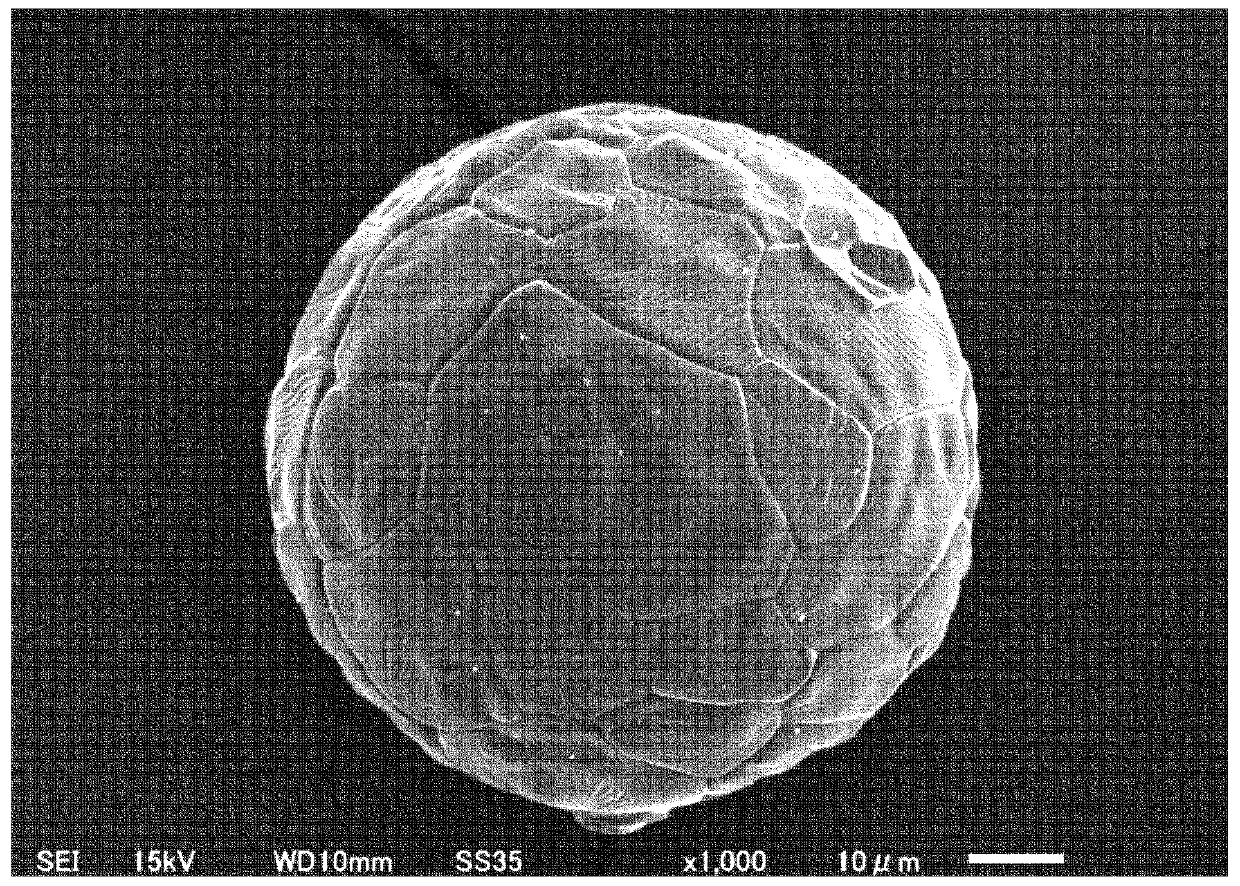

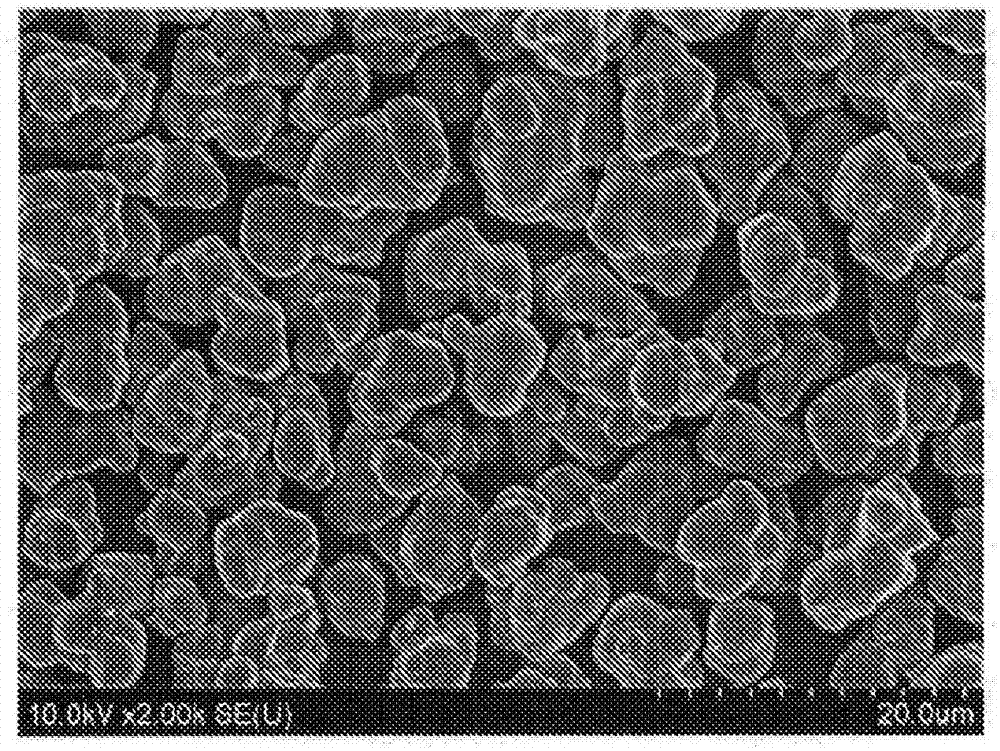

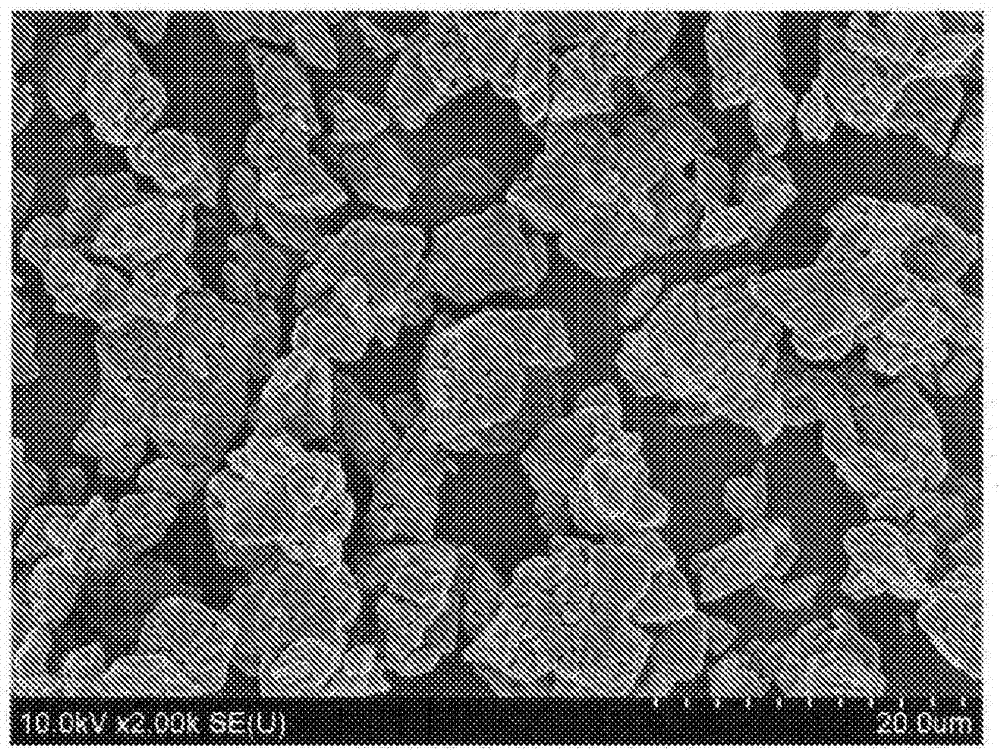

Spherical magnesium oxide and production method therefor

ActiveCN110167882AHigh sphericityFlat surfaceHeat-exchange elementsMagnesiaSem micrographsMoisture resistance

Owner:TATEHO CHEM IND CO

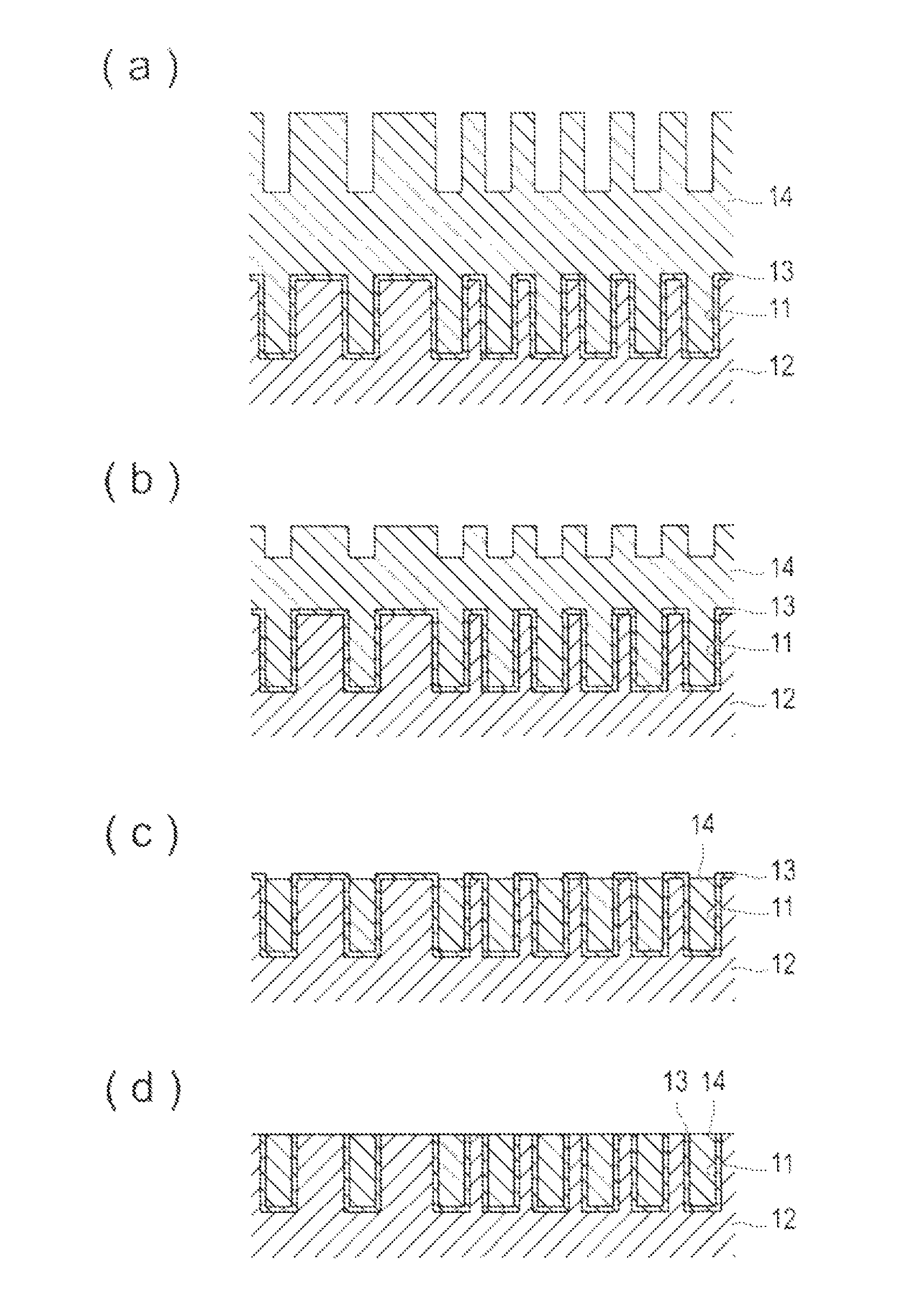

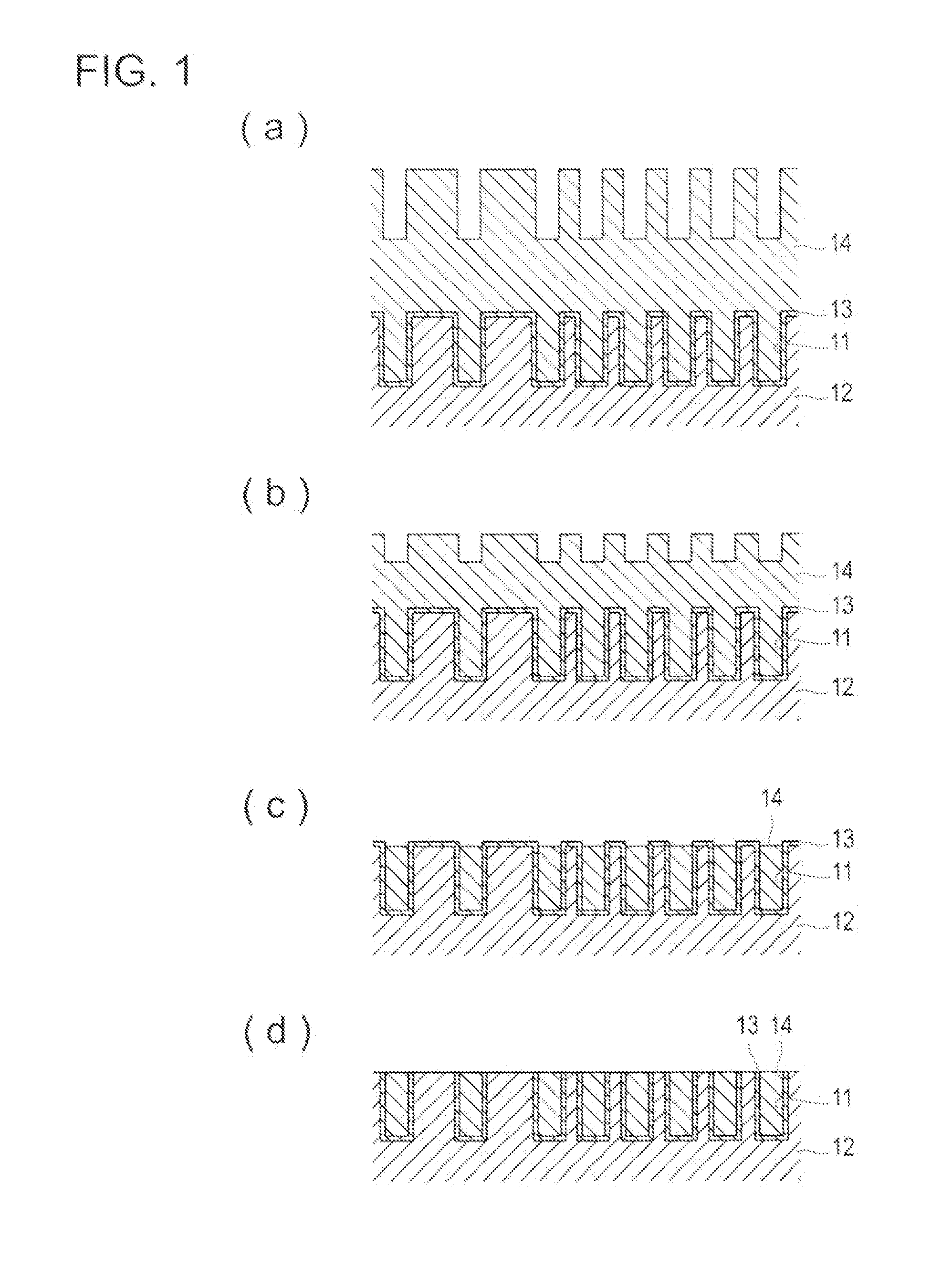

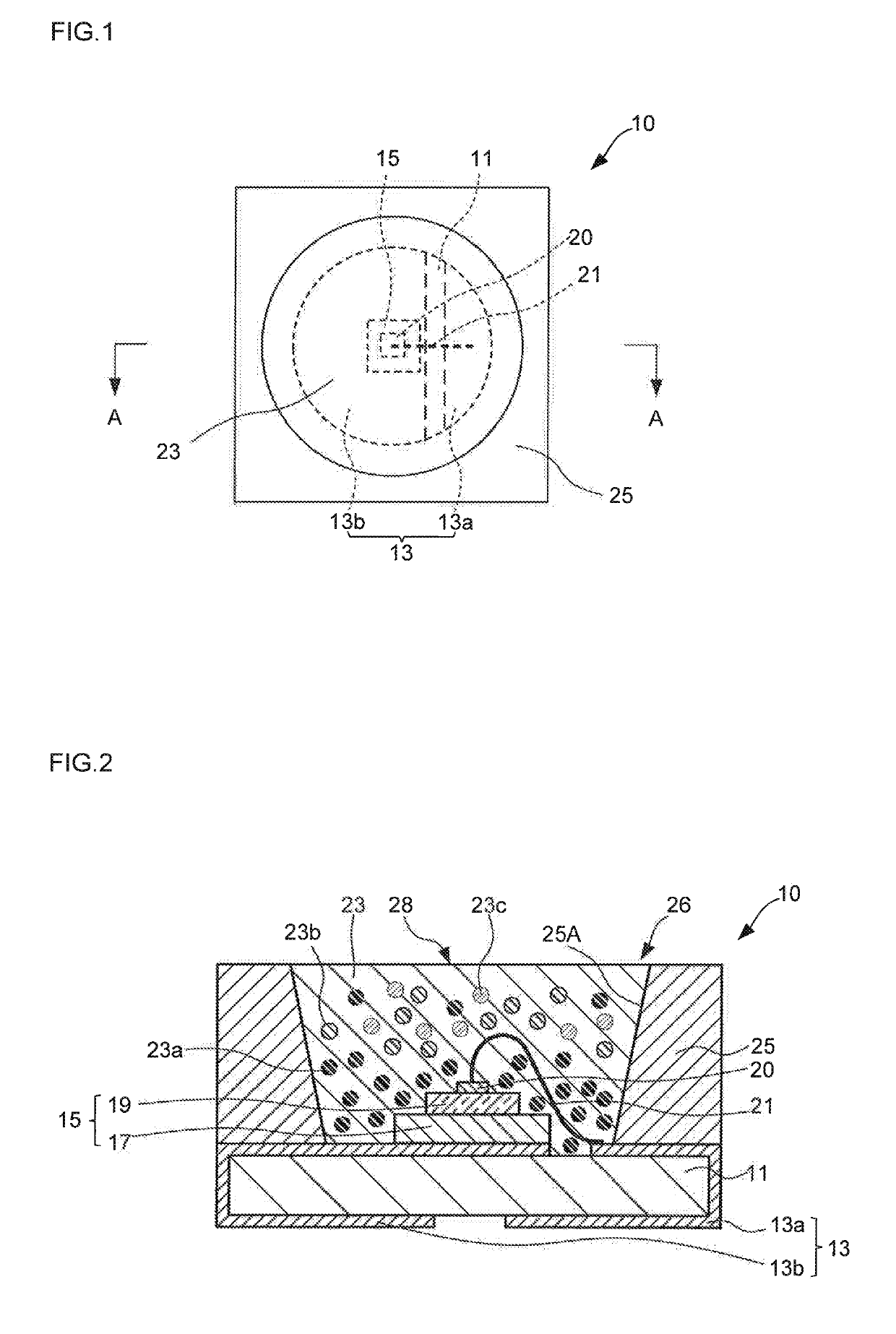

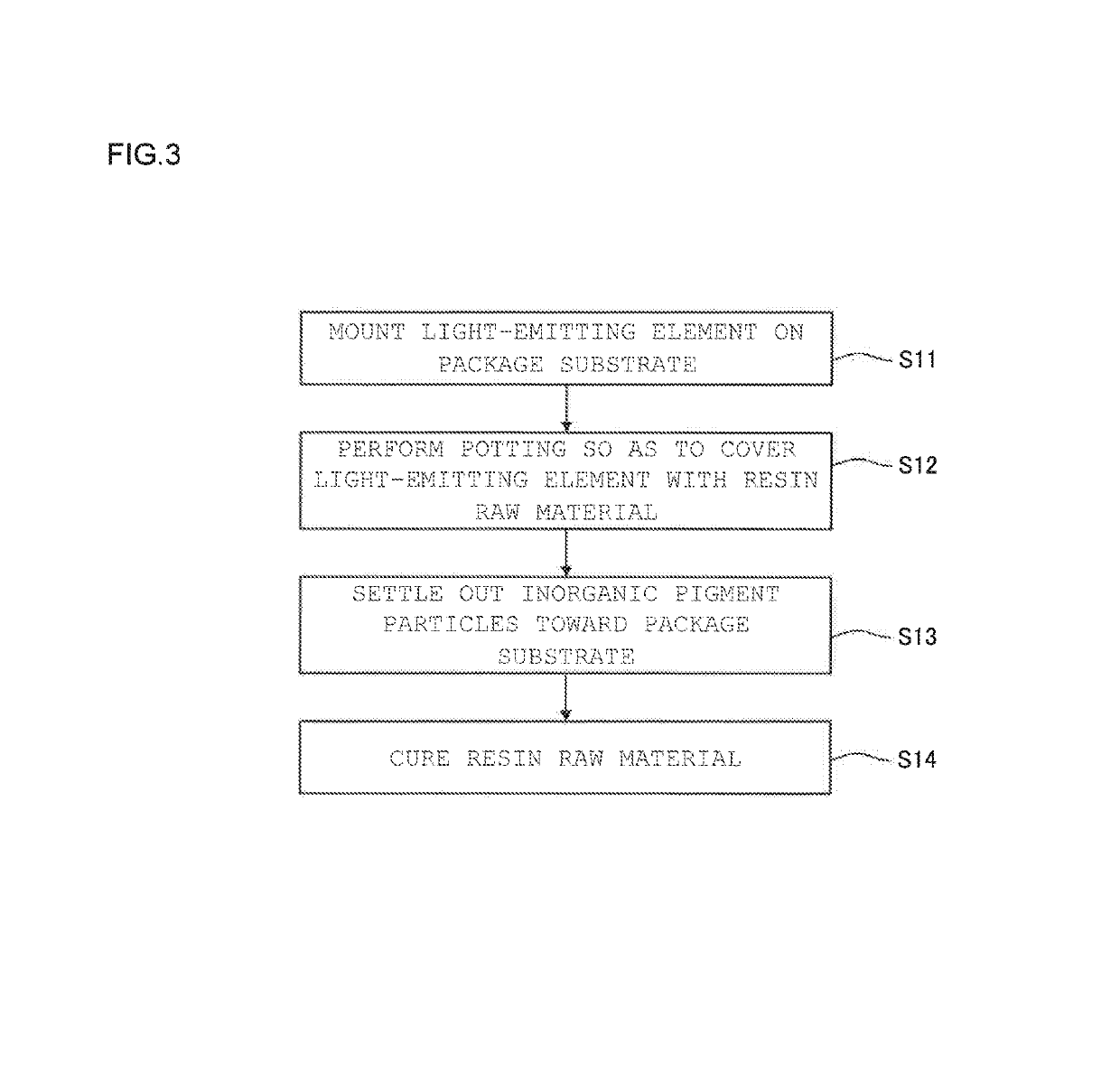

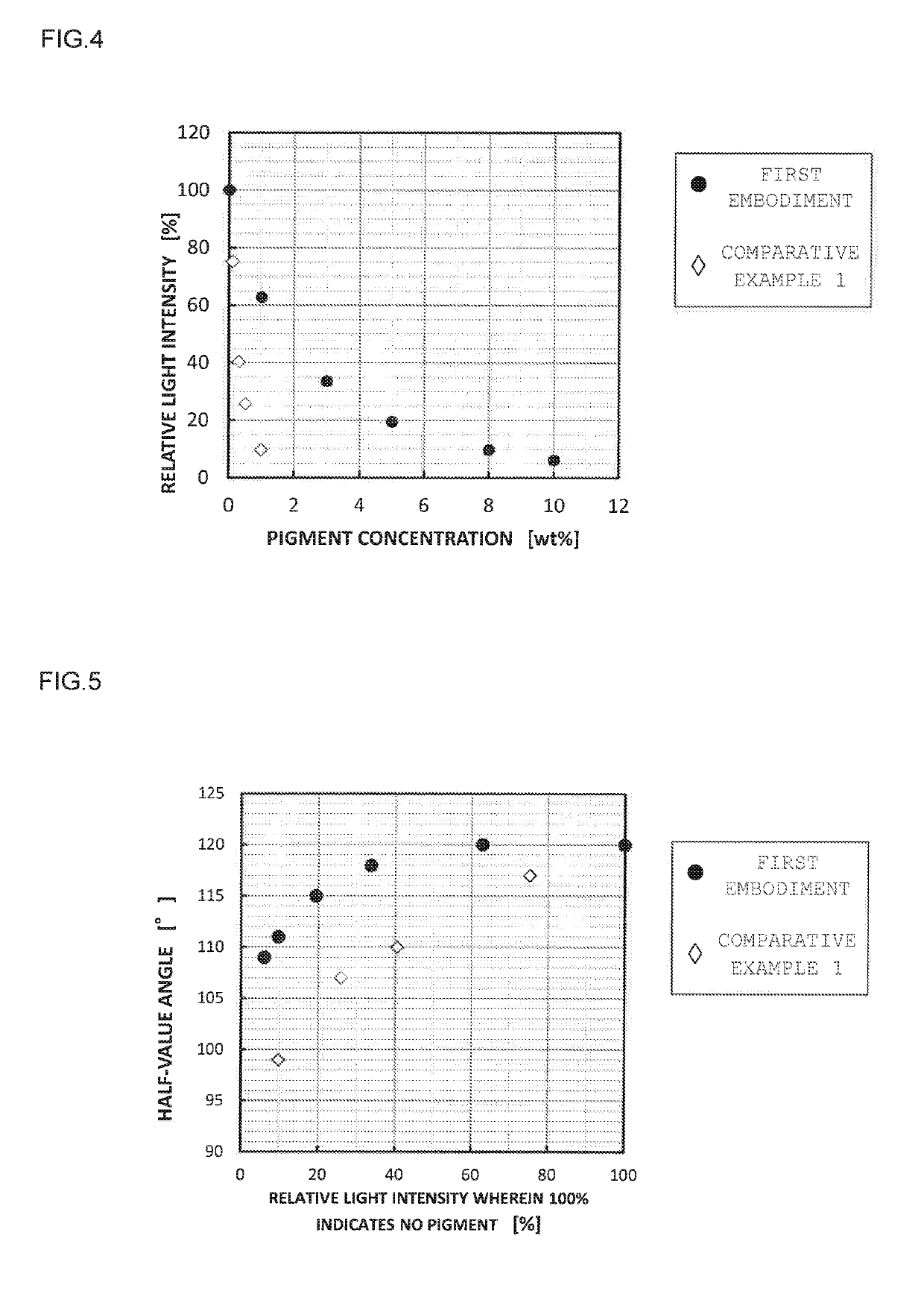

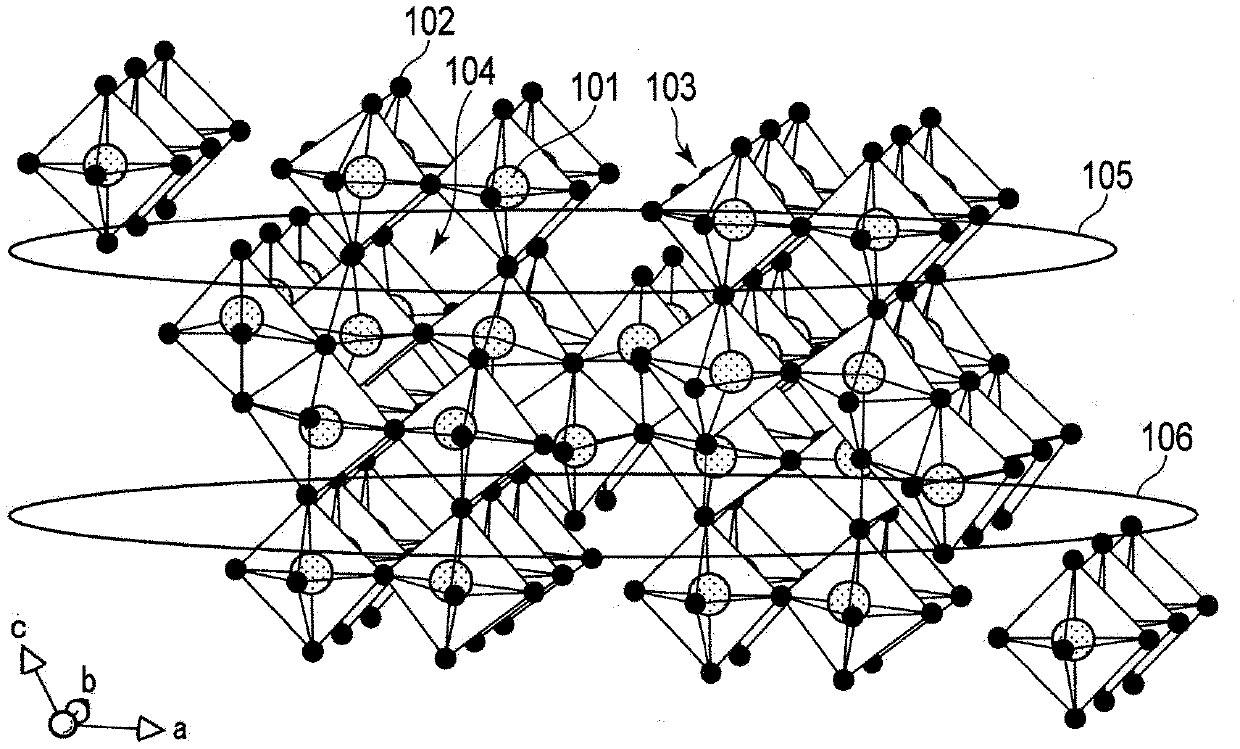

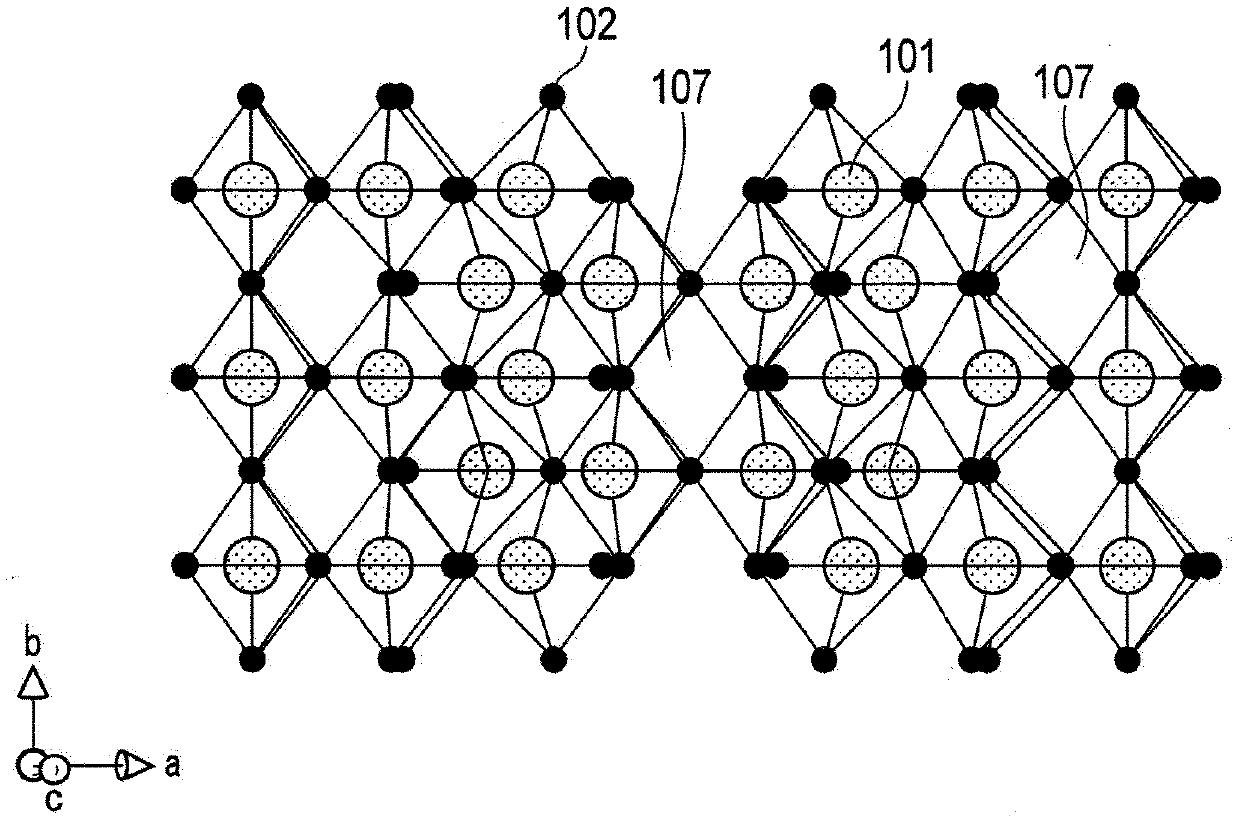

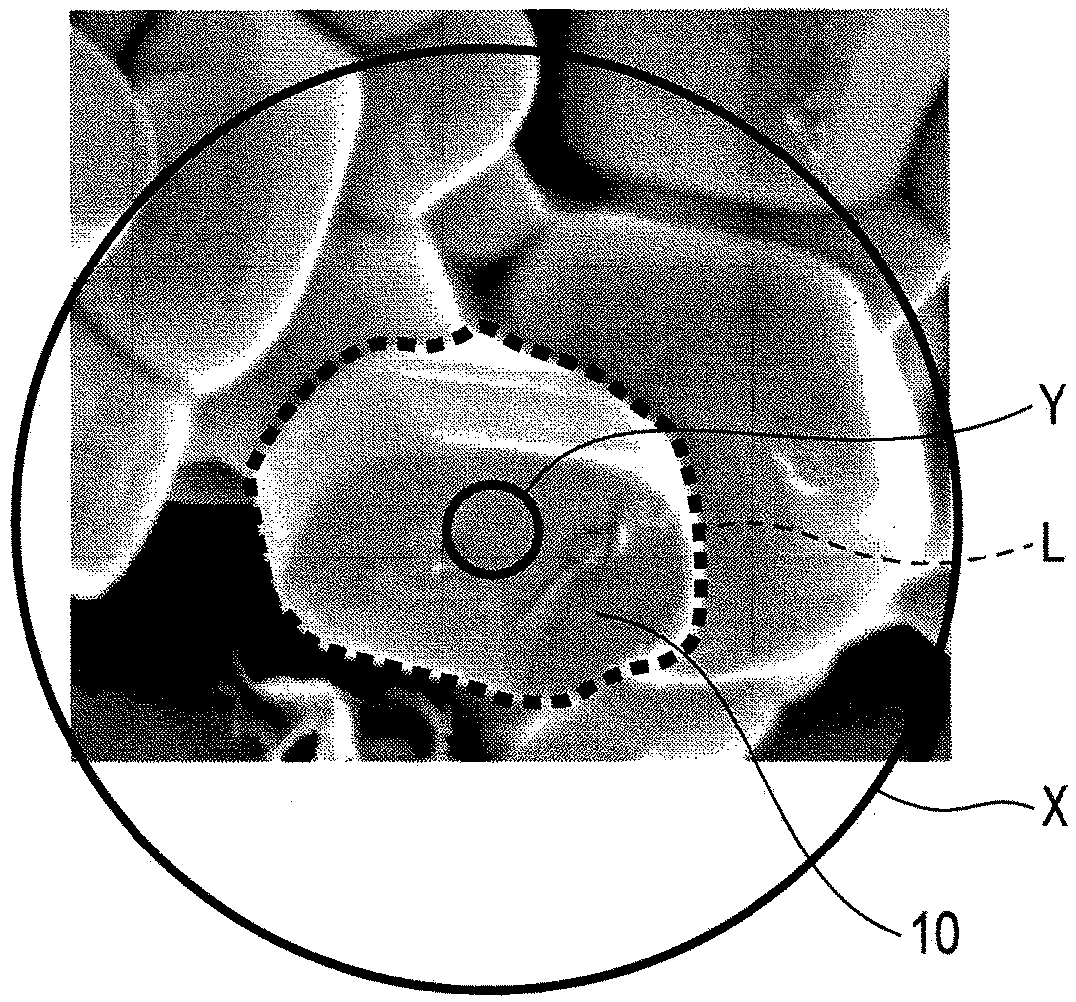

Semiconductor light-emitting device and method for producing the same

Provided are a semiconductor light-emitting device capable of easily adjusting the light intensity of output light and a method for producing such a semiconductor light-emitting device. The semiconductor light-emitting device includes: a substrate; a light-emitting element mounted on the substrate; and a seal layer provided on the substrate so as to cover the light-emitting element. The seal layer contains resin and inorganic pigment particles. The inorganic particles have an average particle size of 1 □m or larger and 50 □m or smaller in a volumetric basis particle size distribution by a laser diffraction scattering particle size distribution measurement method. The inorganic particles distributed at a concentration becoming thicker in a direction toward said substrate.

Owner:STANLEY ELECTRIC CO LTD

Electrode, secondary battery, battery pack, and vehicle

ActiveCN110299534AIncrease energy densityImprove life characteristicsNegative electrodesCells structural combinationHigh energyEngineering

The invention provides an electrode capable of realizing a secondary battery capable of displaying high energy density, excellent rapid charging and discharging performance and long service life, thesecondary battery provided with the electrode, a battery pack provided with the secondary battery, and a vehicle equipped with the battery pack. According to one approach, the electrode is provided. The electrode includes an active material-containing layer which contains an active material. The active material includes a plurality of primary particles containing a niobium-titanium composite oxide. For each of 100 primary particles among the plurality of primary particles, a concavo-convex shape coefficient FU is calculated according to formula (1), and the average value of the calculated concavo-convex shape coefficients FU is 0.70 or more. In formula (1), l represents the outer circumference of a projected cross-section of each primary particle, and a represents the cross-sectional areaof the projected cross-section of each primary particle. The 100 primary particles have a particle diameter that is 0.2-4 times the value of the average particle diameter determined from a particle size distribution diagram of the plurality of primary particles obtained by a laser diffraction scattering method.

Owner:KK TOSHIBA +1

Wavelength converting member and light emitting device

ActiveUS20190305193A1Improve production yieldLuminescent compositionsSemiconductor devicesFluorescenceVolume average

A wavelength converting member comprising a first wavelength converting layer containing: a first fluorescent material having a light emission peak wavelength in a range of 620 nm or more and 660 nm or less; a second fluorescent material having a light emission peak wavelength in a range of 510 nm or more and 560 nm or less; and a resin, wherein the average particle diameter, as measured according to a Fisher Sub-Sieve Sizer method, of the first fluorescent material is in a range of 2 μm or more and 30 μm or less, wherein the second fluorescent material comprises a β-SiAlON fluorescent material, the circularity of the β-SiAlON fluorescent material is 0.7 or more, and the volume average particle diameter, as measured according to a laser diffraction scattering particle size distribution measuring method, of the β-SiAlON fluorescent material is in a range of 2 μm or more and 30 μm or less, and wherein the thickness of the first wavelength converting layer is in a range of 50 μm or more and 200 μm or less.

Owner:NICHIA CORP

Lithium ion secondary battery

ActiveUS8435672B2Reduced service lifeIncrease energy densityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsLithiumElectrolysis

The invention provides a lithium ion secondary battery comprising a positive electrode, a negative electrode and an electrolysis solution containing an aprotic solvent having an electrolyte dissolved in it, wherein the negative electrodes uses an amorphous carbon material as a negative electrode active material. The amorphous carbon material has (A) an average particle diameter (median size) of 7 μm to 20 μm inclusive as measured by a laser diffraction scattering method and (B) a particle size distribution as measured by a laser diffraction scattering method, in which distribution the ratio of particles of less than 3 μm in diameter is 1% by mass to 10% mass inclusive, and is free of an electrical conducting material.

Owner:ENVISION AESC ENERGY DEVICES LTD

Dielectric ceramic material, method for manufacturing same, and composite dielectric material

ActiveCN107531575AHigh dielectric constantEasy to fillAlkaline earth titanatesFixed capacitor dielectricDielectricElectricity

Provided is a dielectric ceramic material which is characterized in that: the dielectric ceramic material comprises perovskite (ABO3) composite oxide particles; the value of ((D90-D10) / D50) is 1.2 orless, where D10 is the particle size at which an accumulated value in a volume frequency particle size distribution measurement by a laser diffraction scattering method is 10%, D50 is the particle size at which the accumulated value therein is 50%, and D90 is the particle size at which the accumulated value therein is 90%; the average particle size D50 is 3 to 15 [mu]m; and the relationship between the theoretical specific surface area (m2 / g) calculated by the average particle size D50 and the BET specific surface area (m2 / g) measured by the BET method is 0.5<=((BET specific surface area-theoretical specific surface area) / theoretical specific surface area)<=9.0.

Owner:NIPPON CHECMICAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com