Method of forming polymide coating containing dielectric filler on surface of metallic material process for producing copper clad laminate for formation of capacitor layer for printed wiring board and copper clad laminate obtained by the process

a technology of dielectric filler and metallic material, which is applied in the direction of electrophoretic coating, insulating substrate metal adhesion improvement, and semiconductor/solid-state device details, etc., can solve the problems of easy decomposition and unstable of polyamide acid, and achieve the effect of preventing any damage and high strength and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

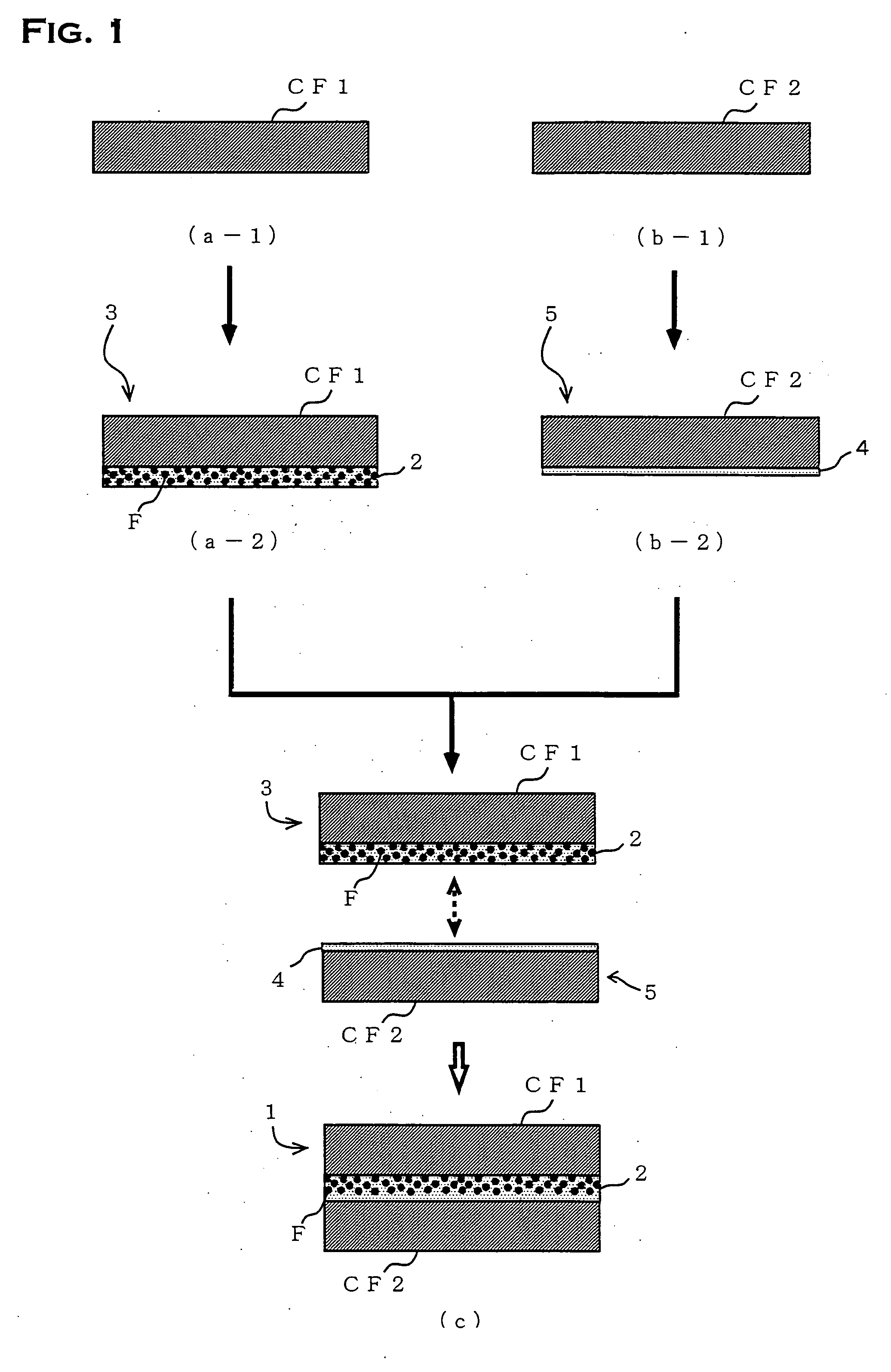

[0054] In the present example, a copper clad laminate 1 for forming a capacitor layer for use in a printed wiring board was manufactured based on a production flow shown in FIG. 1. In the example, a very low profile (VLP) with a nominal thickness of 35 μm was employed as a first copper foil CF1.

[0055] In advance of forming a dielectric filler-containing polyimide coating 2 on a surface of the first copper foil CF1, an acid pickling treatment and electrolytic degreasing treatment were conducted for cleaning the surface of the first copper foil CF1 in a step of (a-1) in FIG. 1. The acid pickling treatment was carried out with the first copper foil CF1 immersed for 1 minute in a sulphuric acid solution having a liquid temperature of 25° C. and concentration of 1M, and then the first copper foil CF1 was rinsed with water.

[0056] Subsequently, an alkaline degreasing aqueous solution containing 20 g / L of sodium carbonate and 5 g / L of trisodium phosphate was employed to degrease for 1 min...

example 2

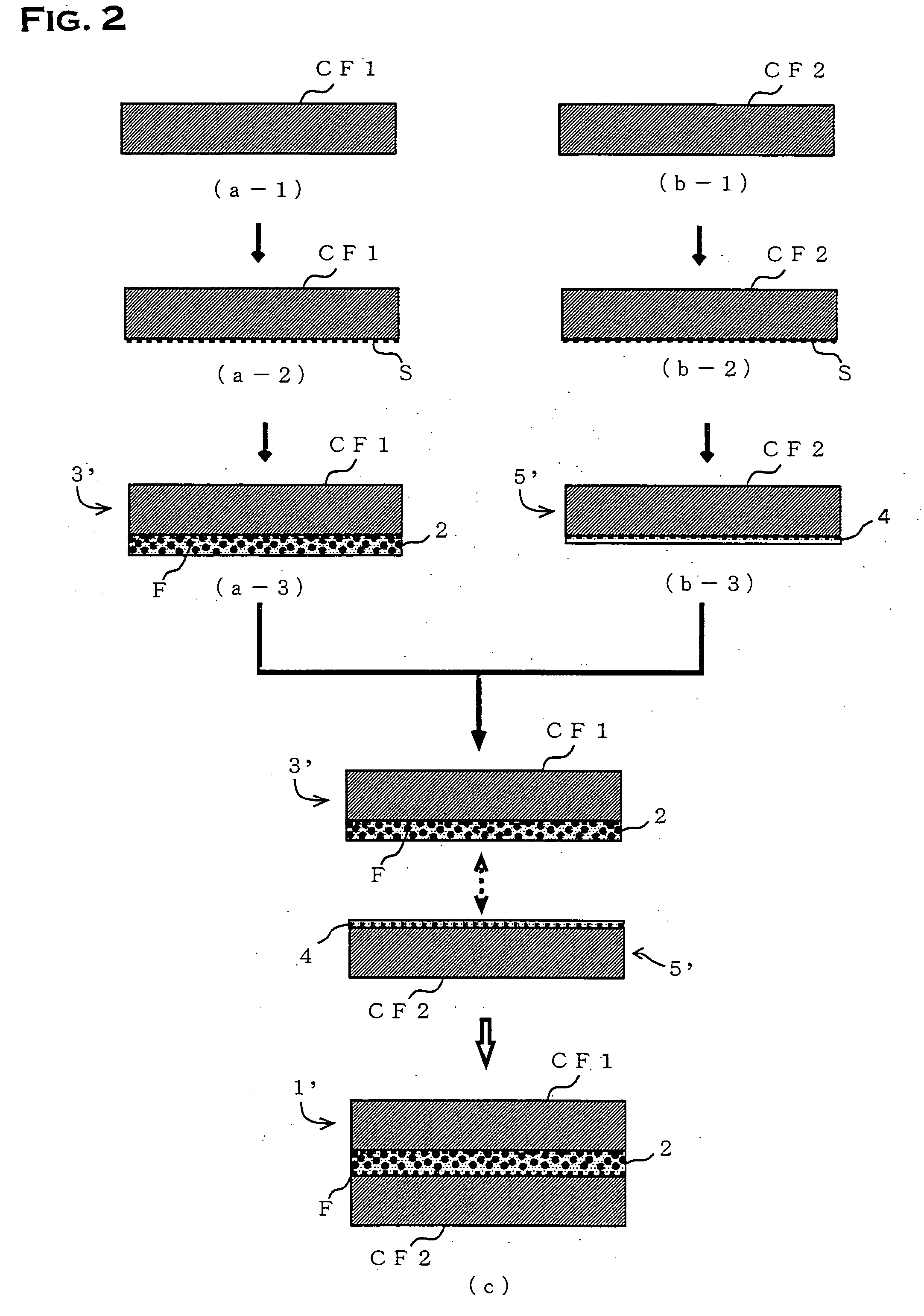

[0066] The present example describes manufacture of a copper clad laminate 1′ for forming a capacitor layer for use in a printed wiring board based on a production flow shown in FIG. 2. In the present example, a very low profile (VLP) with a nominal thickness of 35 μm was employed as a first copper foil CF1, as in the case of Example 1.

[0067] The steps carried out at the stage in FIG. 2(a-1) which include acid pickling and degreasing treatments are the same as those done in Example 1. On completion of a degreasing treatment, a nickel metallic seed layer S as shown in FIG. 2(a-2) was provided, and then a dielectric filler-containing polyimide coating 2 was formed on the surface of the first copper foil CF1 as shown in FIG. 2(a-3) to prepare a copper foil 3 with a dielectric filler-containing polyimide coating. As to formation steps for a dielectric filler-containing polyimide coating 2 after provision of a metallic seed layer S are the same as done in Example 1.

[0068] Therefore, on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size DIA | aaaaa | aaaaa |

| particle size DIA | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com