Dielectric ceramic material, method for manufacturing same, and composite dielectric material

A technology of ceramic materials and manufacturing methods, applied in fixed capacitor dielectrics, chemical instruments and methods, titanium compounds, etc., can solve the problems of low dielectric constant of composite dielectrics, and achieve excellent filling, high dielectric constant, and excellent dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098]

[0099] 720 g of pure water was added to 130 g of barium chloride dihydrate and 130 g of oxalic acid dihydrate, and stirred at a temperature of 55° C. for 0.5 hours, and the obtained suspension was used as liquid A.

[0100] In addition, to TiO 2 560 g of pure water was added to 256 g of titanium tetrachloride aqueous solution converted into 15.3 mass %, and the solution which diluted was made B liquid.

[0101] Next, liquid B was added to liquid A at a reaction temperature of 55° C. over 30 minutes while stirring, and aging was performed for 0.5 hours while stirring was continued after the addition. After the aging, filter to recover the barium titanyl oxalate.

[0102] Next, the recovered barium titanyl oxalate was reslurried in pure water, and left to dry at 80° C. for 24 hours to obtain a powder of barium titanyl oxalate.

[0103]

[0104] 20 g of the obtained barium titanyl oxalate powder was put into an alumina crucible, the temperature was raised over 5 ho...

Embodiment 2

[0106]

[0107] The powder of barium titanyl oxalate was obtained in the same manner as in Example 1.

[0108]

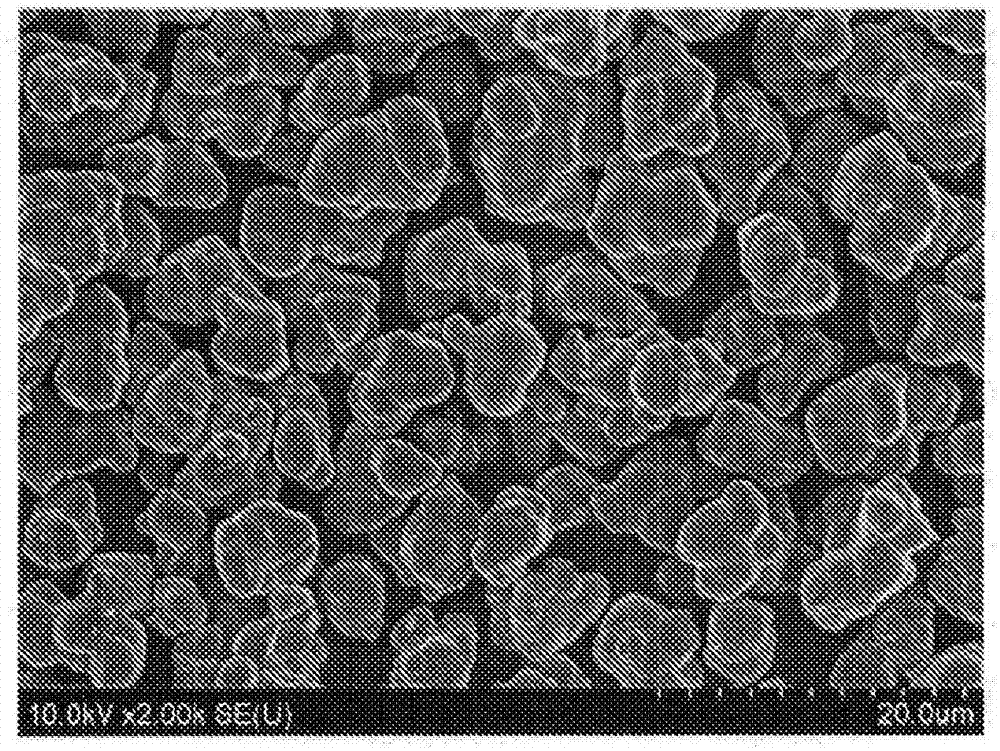

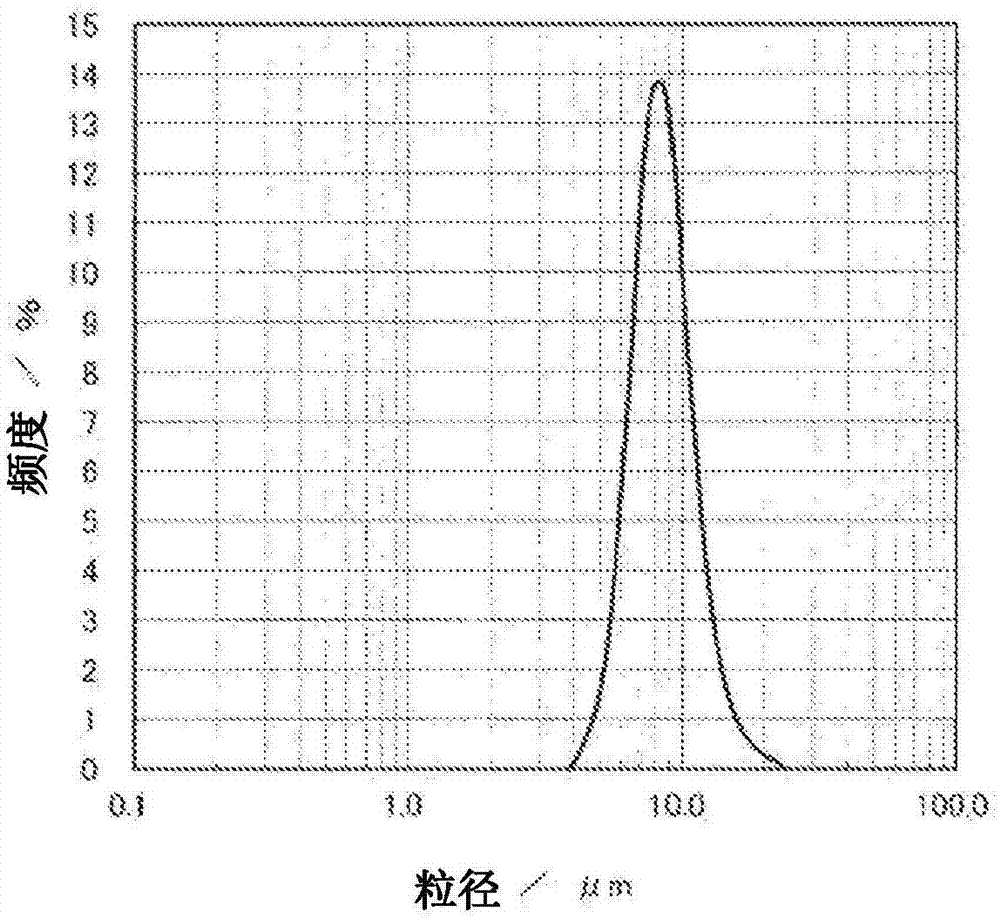

[0109] Barium titanate particles were obtained in the same manner as in Example 1 except that the firing temperature was set to 1200°C. Table 1 shows various physical properties of the obtained barium titanate particles. In addition, the SEM photograph of the obtained barium titanate particles is shown in figure 1 , the particle size distribution is shown in figure 2 .

Embodiment 3

[0111]

[0112] The powder of barium titanyl oxalate was obtained in the same manner as in Example 1.

[0113]

[0114] Barium titanate particles were obtained in the same manner as in Example 1 except that the firing temperature was set to 1250°C. Table 1 shows various physical properties of the obtained barium titanate particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com