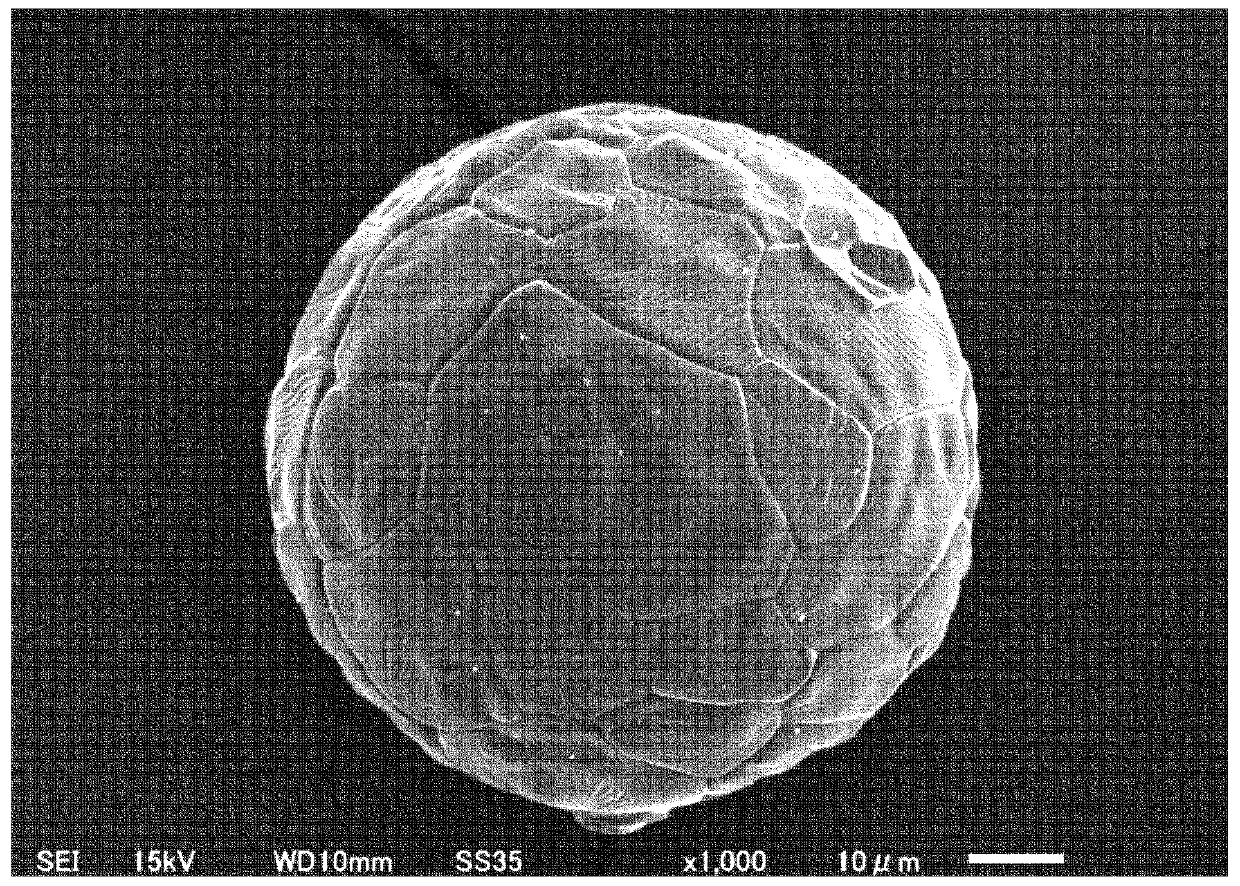

Spherical magnesium oxide and production method therefor

一种氧化镁、球状的技术,应用在氧化镁、氢氧化镁、化学仪器和方法等方向,能够解决填充性颗粒表面平滑性和耐湿性存在问题、氧化镁球形度不高等问题,达到填充性优异、导热性填料优异、球形度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Anhydrous magnesium chloride (MgCl 2 ) was dissolved in ion-exchanged water to prepare an aqueous magnesium chloride solution of about 3.5 mol / l. MgCl 2 Solution and 25% NaOH solution are pumped to the reactor with quantitative pumping respectively, and the continuous reaction is carried out, so that the MgCl 2 The reaction rate was 90 mol%.

[0067] Thereafter, boric acid (manufactured by Kanto Chemical Co., Ltd., reagent special grade) was added to the reaction liquid so that the boron content in the finally obtained spherical magnesium oxide became 650 ppm, and iron (II) oxide (manufactured by Hayashi Junyaku Kogyo Co., Ltd.) was added to make the iron content It becomes 350ppm. Thereafter, it was filtered, washed with water, and dried to obtain magnesium hydroxide. The obtained magnesium hydroxide was calcined at 900° C. for 1 hour to obtain magnesium oxide particles. An organic solvent was added to the magnesium oxide particles so as to have a concentration of...

Embodiment 2

[0069] Spherical magnesia was obtained by the same production method as in Example 1, except that boric acid was added to the reaction solution so that the boron content in the spherical magnesia became 900 ppm, and iron (II) oxide was added so that the iron content became 350 ppm. The physical properties thereof were evaluated in the same manner as in Example 1.

Embodiment 3

[0071] Spherical magnesia was obtained by the same production method as in Example 1, except that boric acid was added to the reaction solution so that the boron content in the spherical magnesia became 1000 ppm, and iron (II) oxide was added so that the iron content became 350 ppm. The physical properties thereof were evaluated in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com