Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Binary optics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

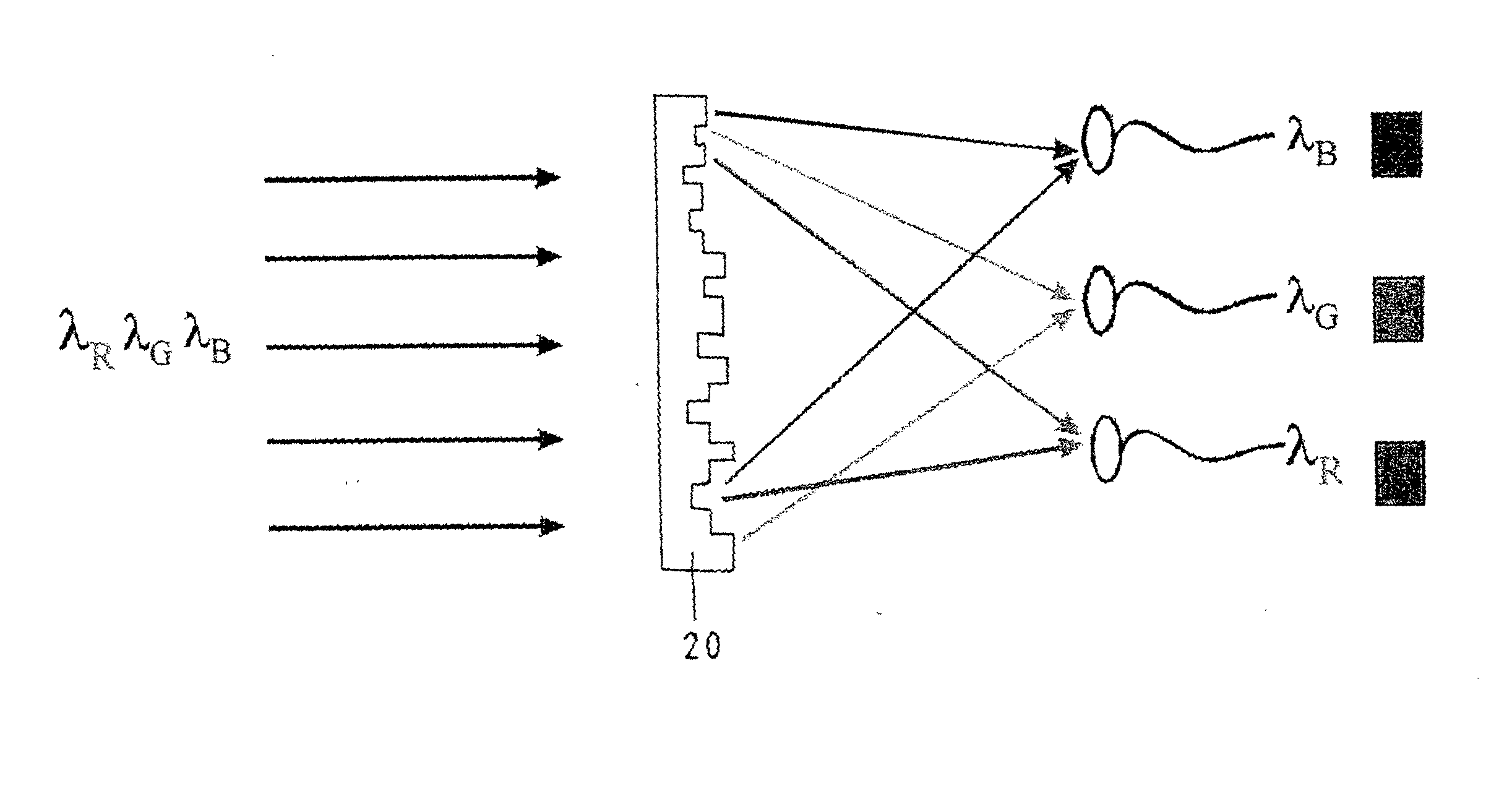

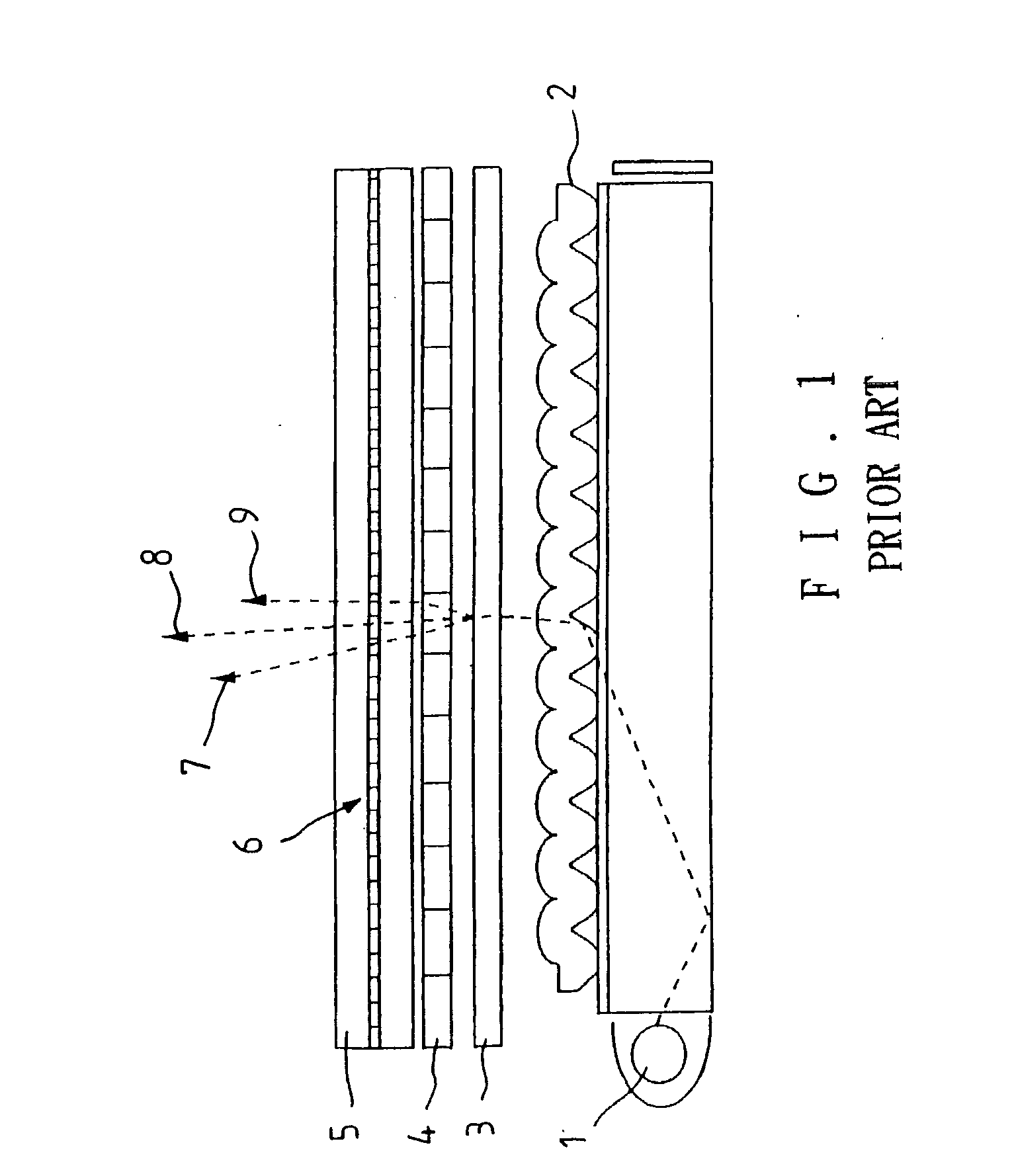

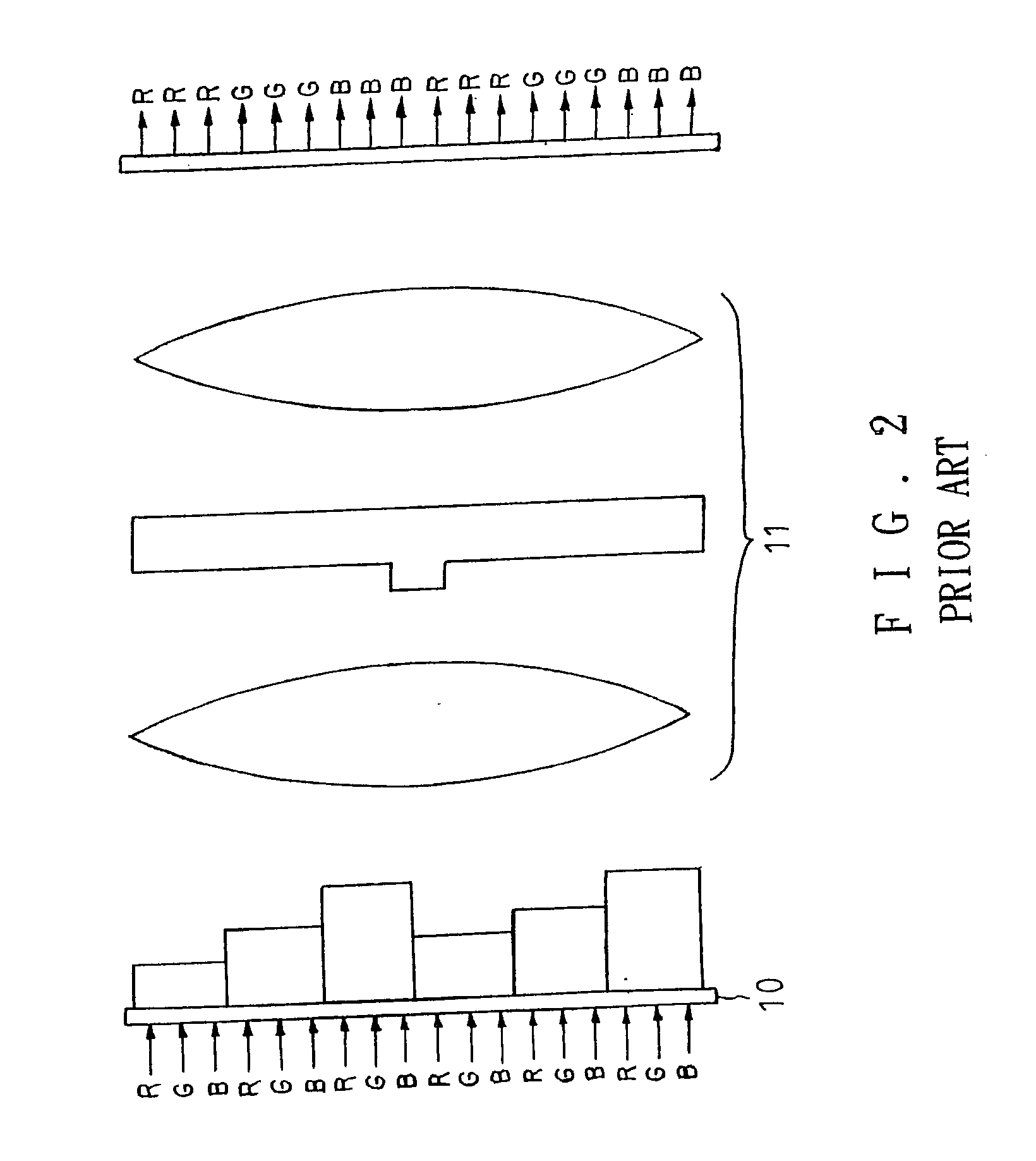

Differactive micro-structure color wavelength division device

InactiveUS20050062928A1Enhance optical operational efficiencyHigh aspect ratioPicture reproducers using projection devicesDiffraction gratingsColor imageSurface phase

A diffractive micro-structure color wavelength division device makes use of diffraction theory, binary optics theory, and operation of phase iteration algorithm to its complex two-dimensional surface phase micro-structure. The color wavelength division device has a multi-wavelength modulation function and is capable of wavelength division and focus, thereby resulting in structural simplification and enhancement of light utilized efficiency of a color image system.

Owner:IND TECH RES INST

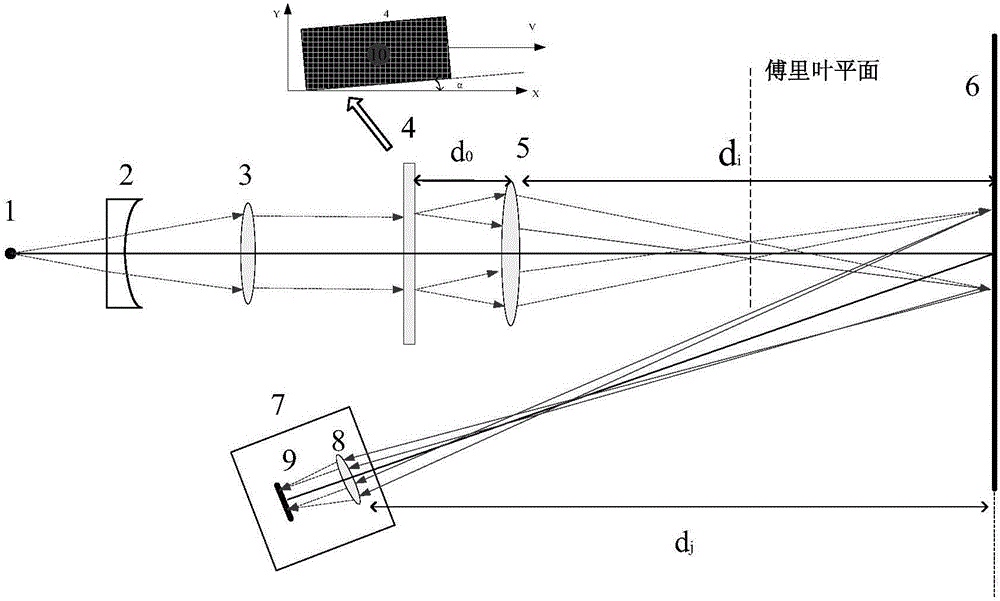

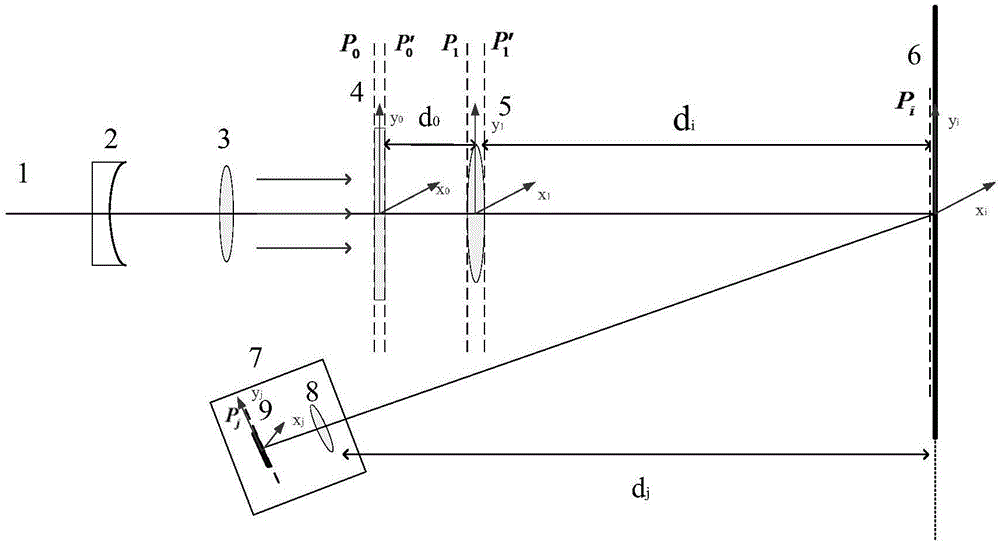

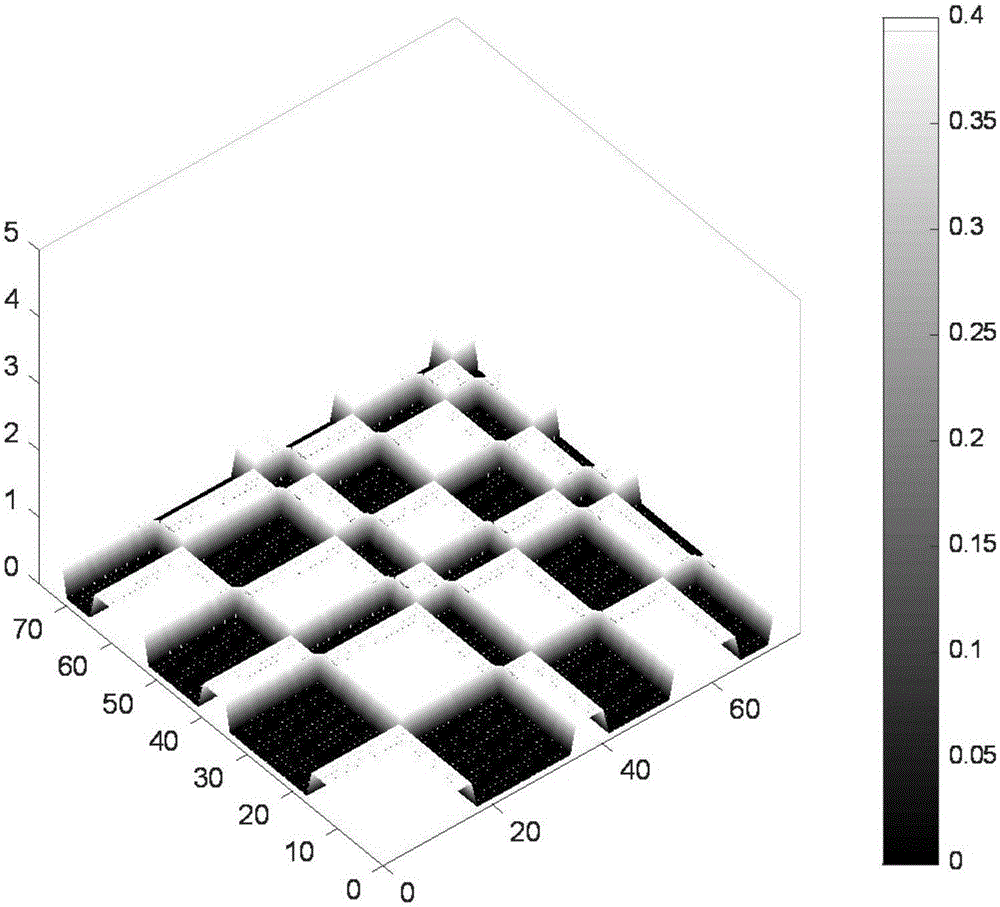

Optical diffraction element-based laser speckle suppressing method

ActiveCN106896520ASimple structureEasy to makeProjectorsOptical elementsOptical diffractionOptoelectronics

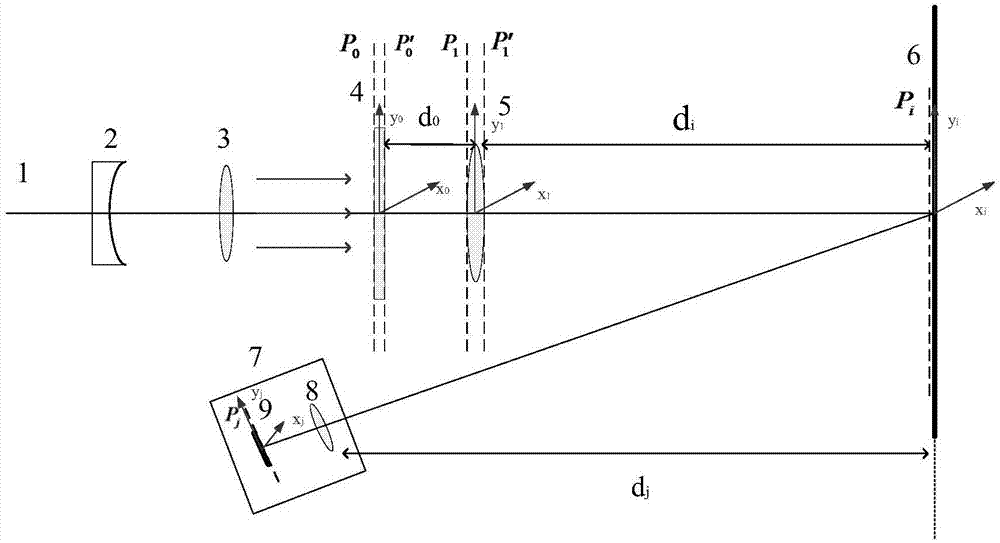

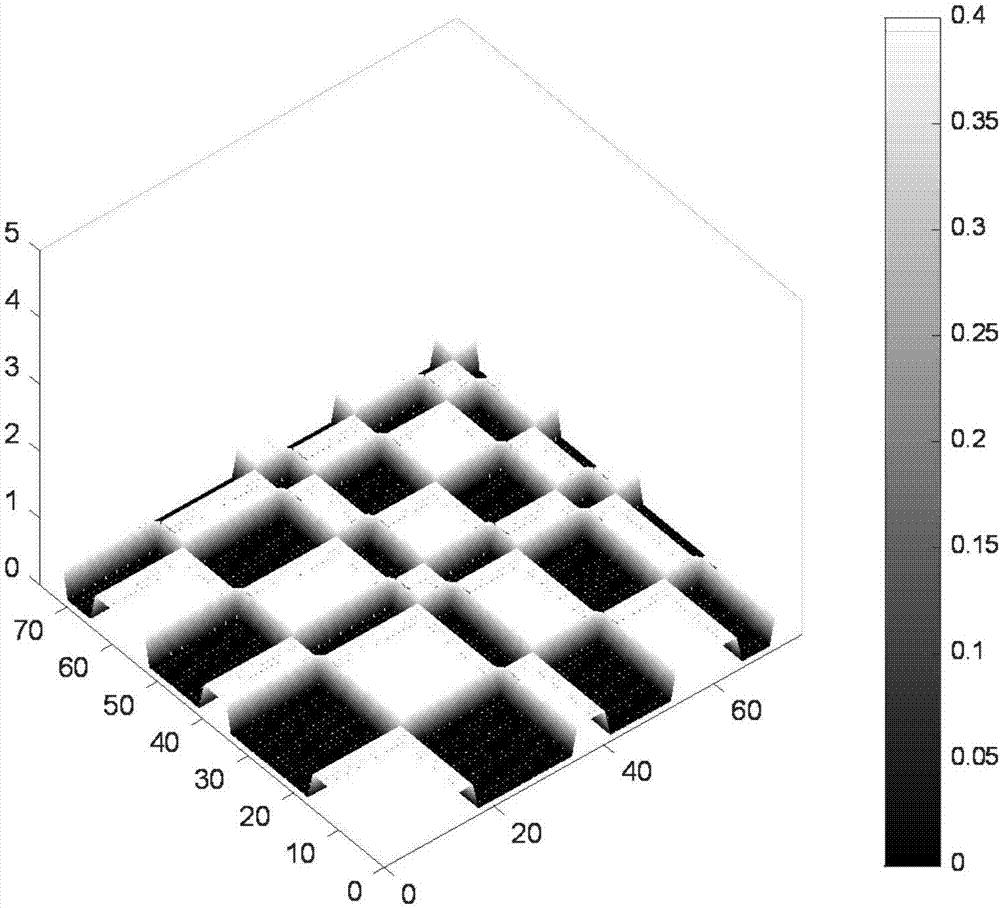

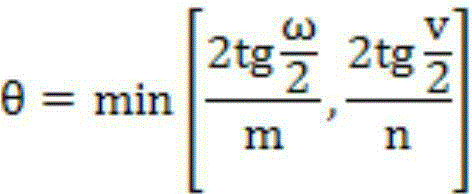

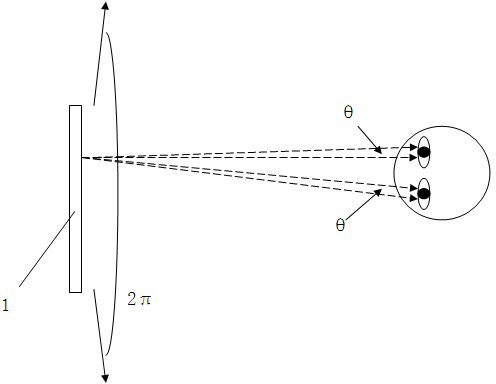

The invention relates to an optical diffraction element-based laser speckle suppressing method. According to the implementation system of the method, a laser beam emitted by a laser is subjected to beam expansion, shaping and calibration by a modulation lens assembly; and the normal incidence of the processed laser beam into the plane of a binary optical diffractive element is realized; the binary optical diffractive element can be mounted on a horizontal guide rail in a horizontally movable manner, an included angle being formed between the binary optical diffractive element and a horizontal plane; the movement velocity and the included angle of the binary optical diffractive element are calculated according to the theoretical derivation of a mathematical model; and the binary optical diffraction element is controlled to move according to the set movement velocity and the included angle. The optical diffraction element-based laser speckle suppressing method provided by the invention has the advantages of good speckle suppression effect, simple structure, easiness in realization, good system versatility, good robustness and low cost.

Owner:ZHEJIANG UNIV OF TECH

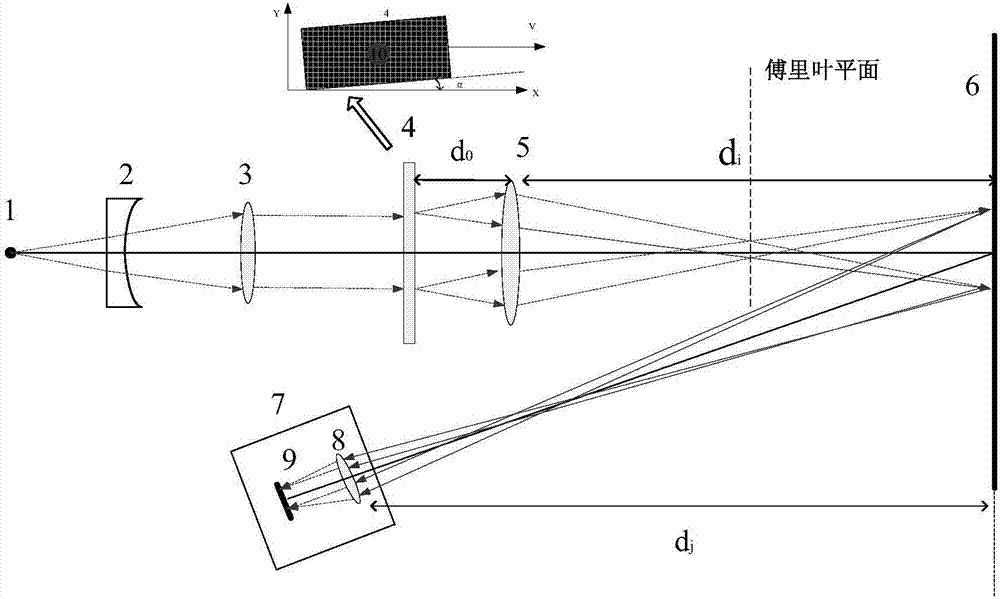

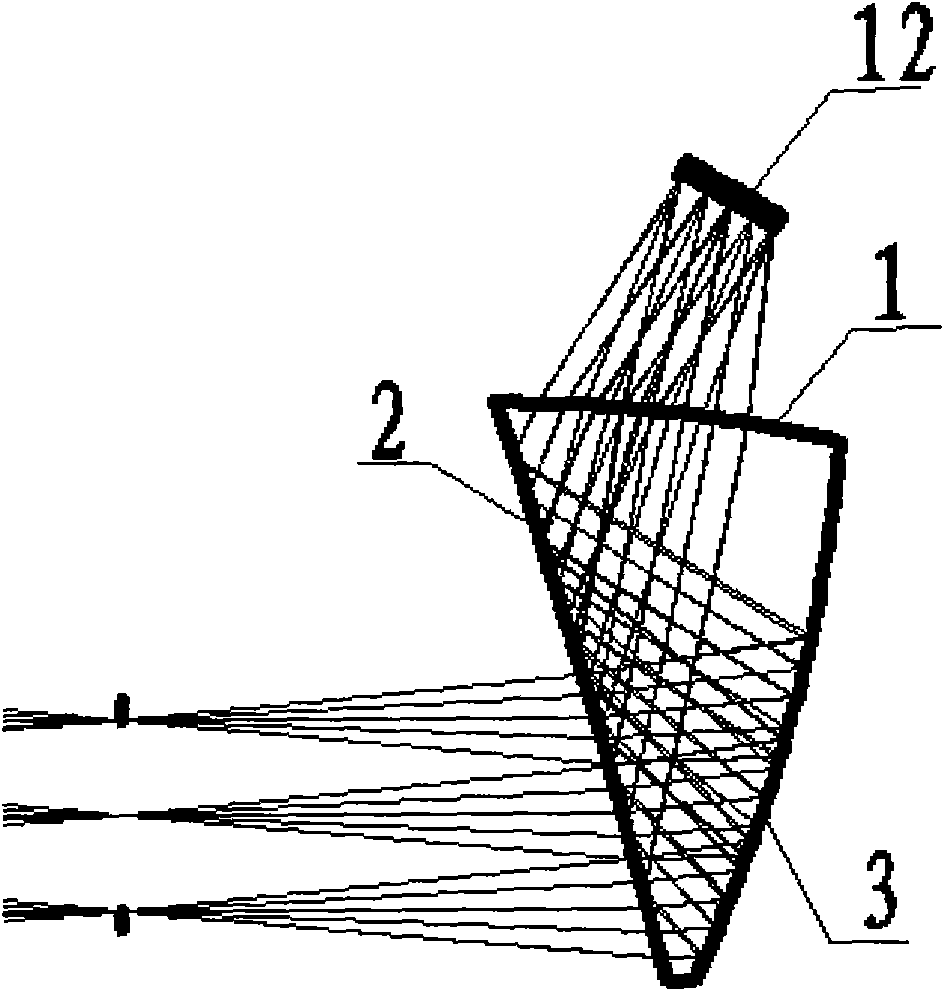

Hartmann wavefront sensor based on micro-prism array for pulse light beam quality detection

InactiveCN1607379AAccuracy impactBeam aperture split implementationPhotometryLensEtchingPhase grating

A pulse light beam quality test Hartmann wavefront sensor includes a data collection device capable of receiving and sending synchronous pulse signals, a micro-prism array, a Fourier lens and a photoelectric detector, characterizing that said sensor is composed of a micro-prism array in a variable period two-dimension saw-tooth phase grating structure, a Fourier lens close to it and the photoelectric detector, among which, the micro-prism array has a ring layout structure with a symmetrical single etching center and a double sided grating structure with double-sided etching which can either apply the micro-optical technology or binary optical technology.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

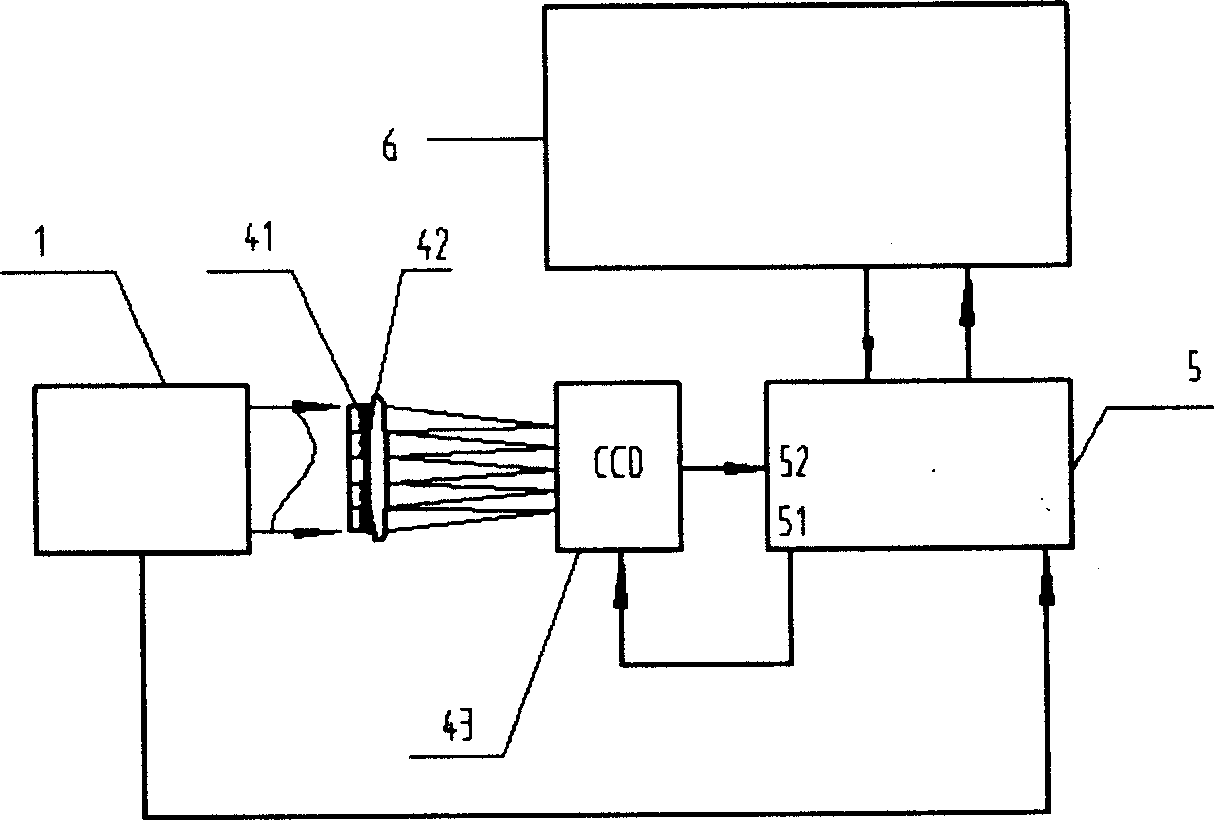

Realization system for laser speckle restraining based on optical diffraction element

ActiveCN106842607ASimple structureEasy to makeProjectorsOptical elementsOptical diffractionOptical Module

A realization system for laser speckle restraining based on an optical diffraction element comprises an optical module and an electrical control module, the optical module comprises a modulation lens component, the binary optical diffraction element and a focusing objective lens. The modulation lens component, the binary optical diffraction element and the focusing objective lens are located in the same optical axis, laser beams emitted by a laser device are expanded, shaped and calibrated through the modulation lens component and carry out normal incidence on the plane of the binary optical diffraction element, the binary optical diffraction element can be horizontally and movably installed on a horizontal guide rail, and an included angle is formed between the binary optical diffraction element and the horizontal plane; the electrical control module is used for controlling the binary optical diffraction element to move at set movement speed and by the included angle. The realization system for laser speckle restraining based on the optical diffraction element is good in speckle restraining effect, simple in structure, easy in realization, good in generality and robustness and low in cost.

Owner:ZHEJIANG UNIV OF TECH

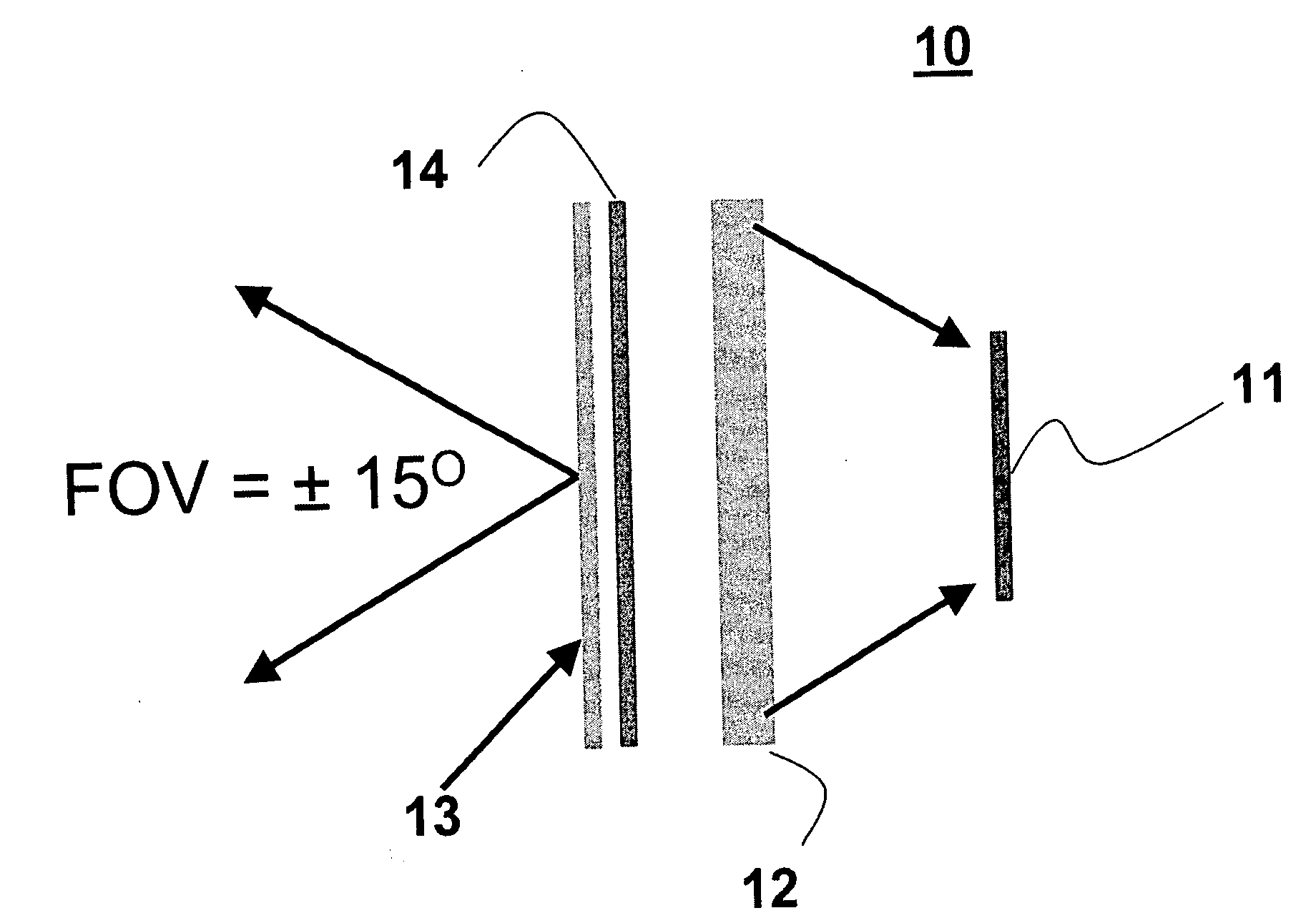

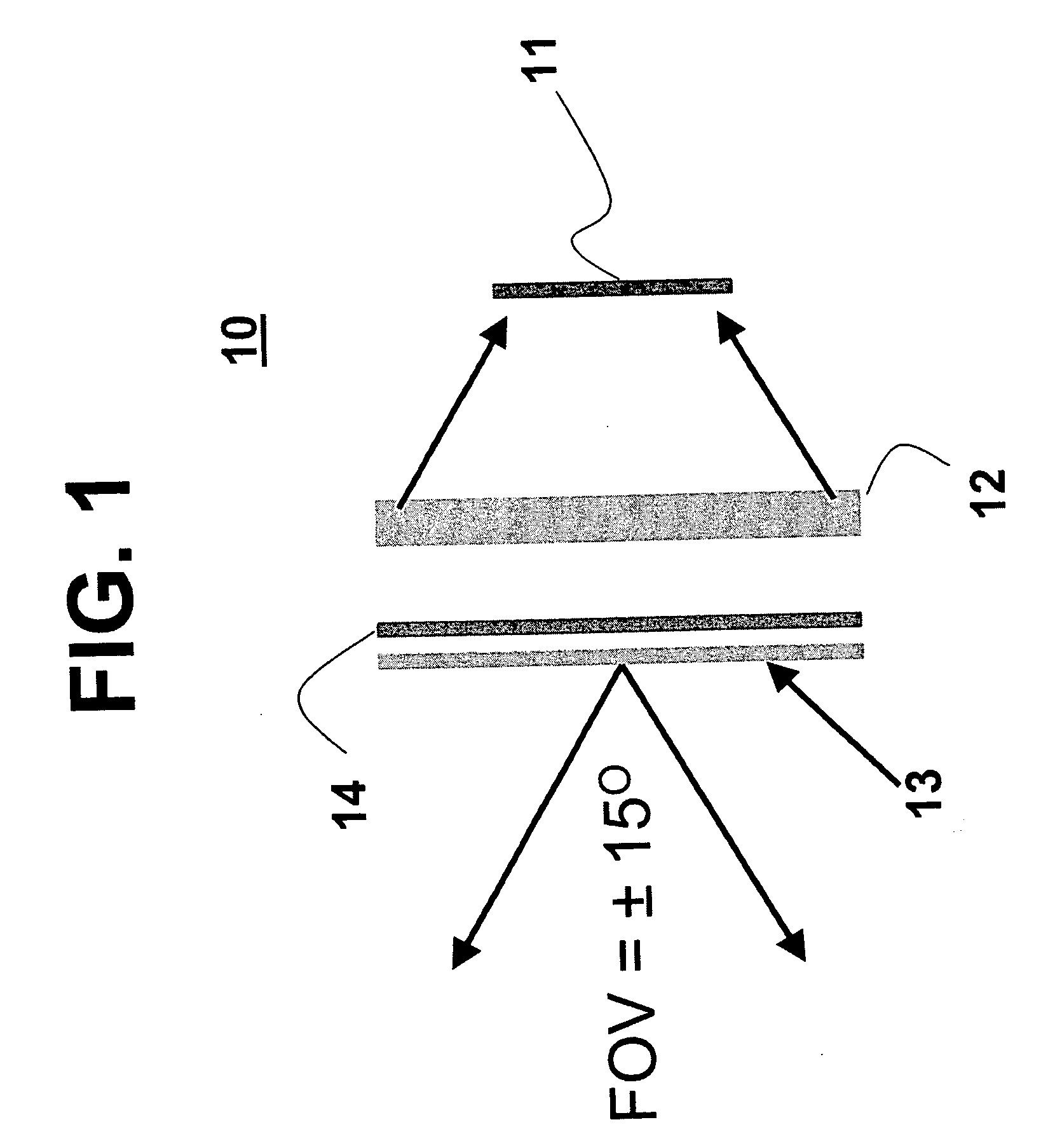

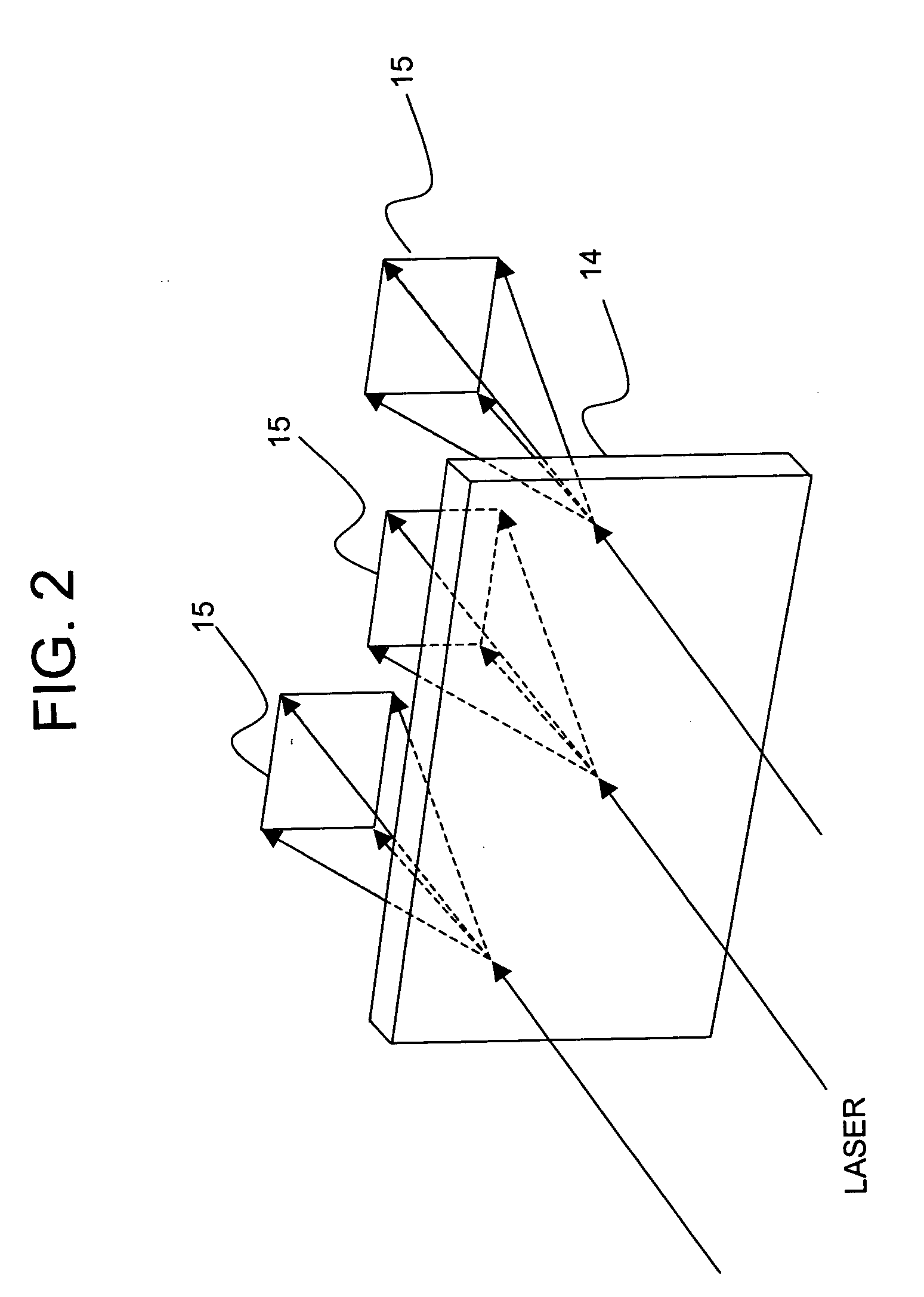

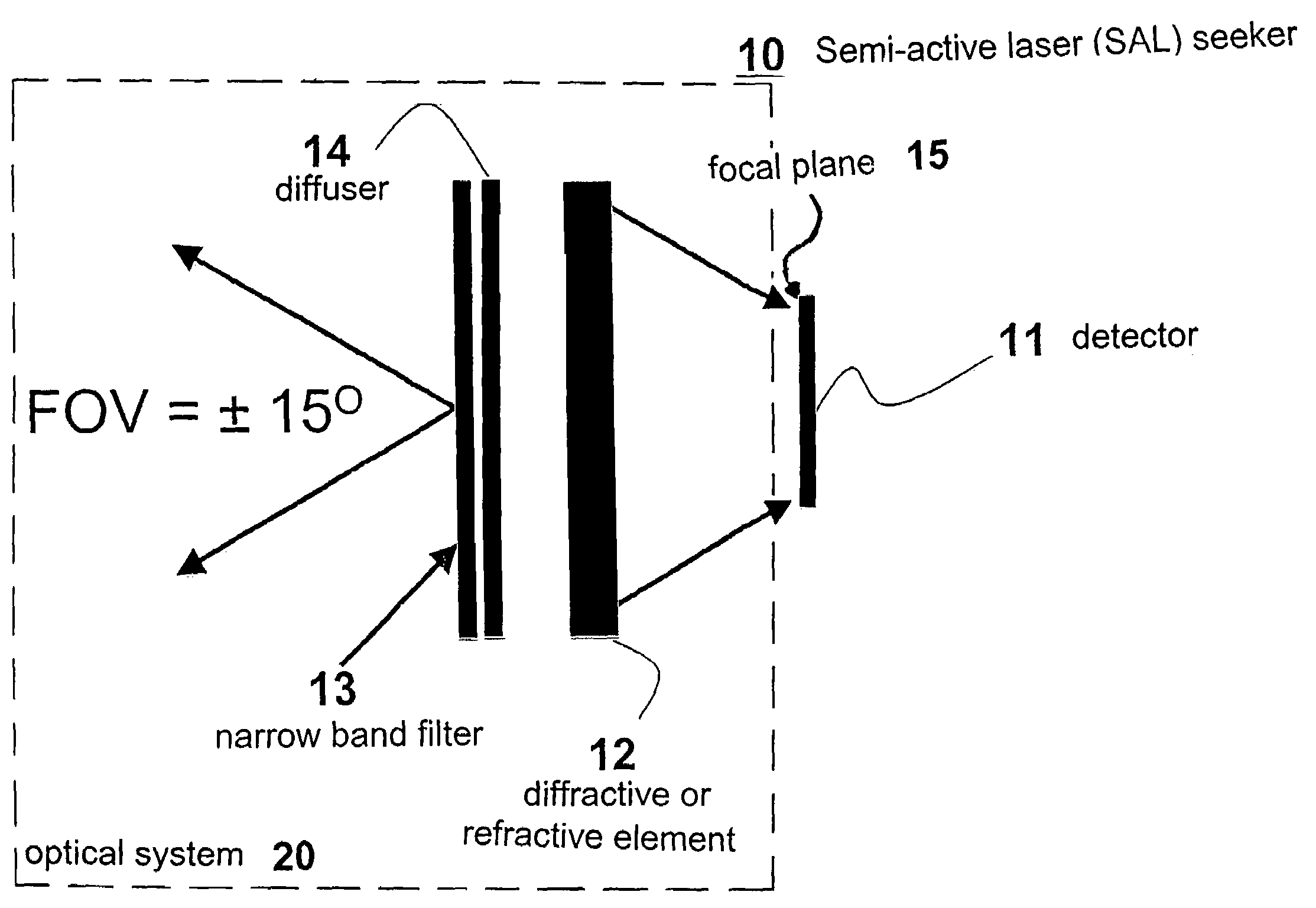

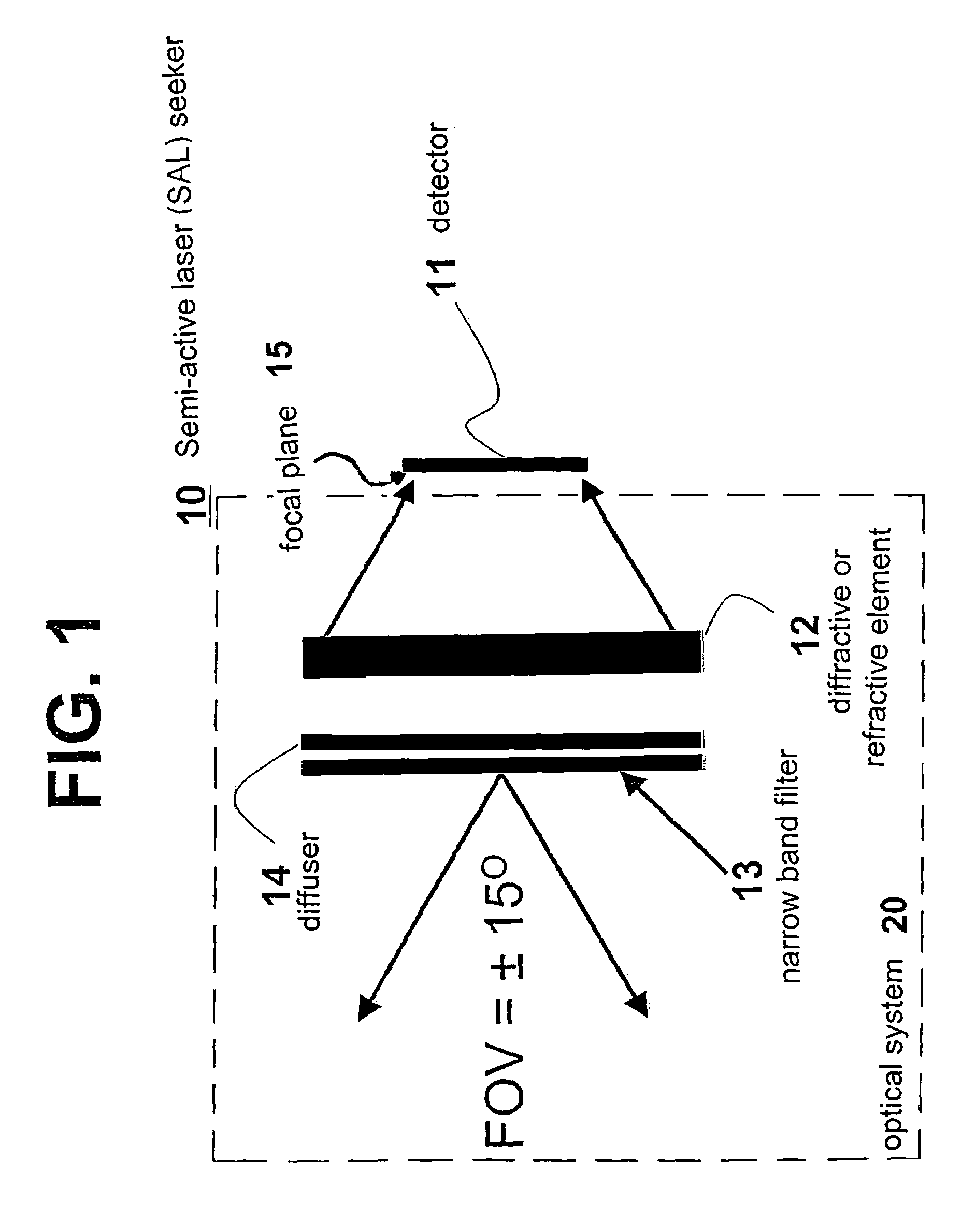

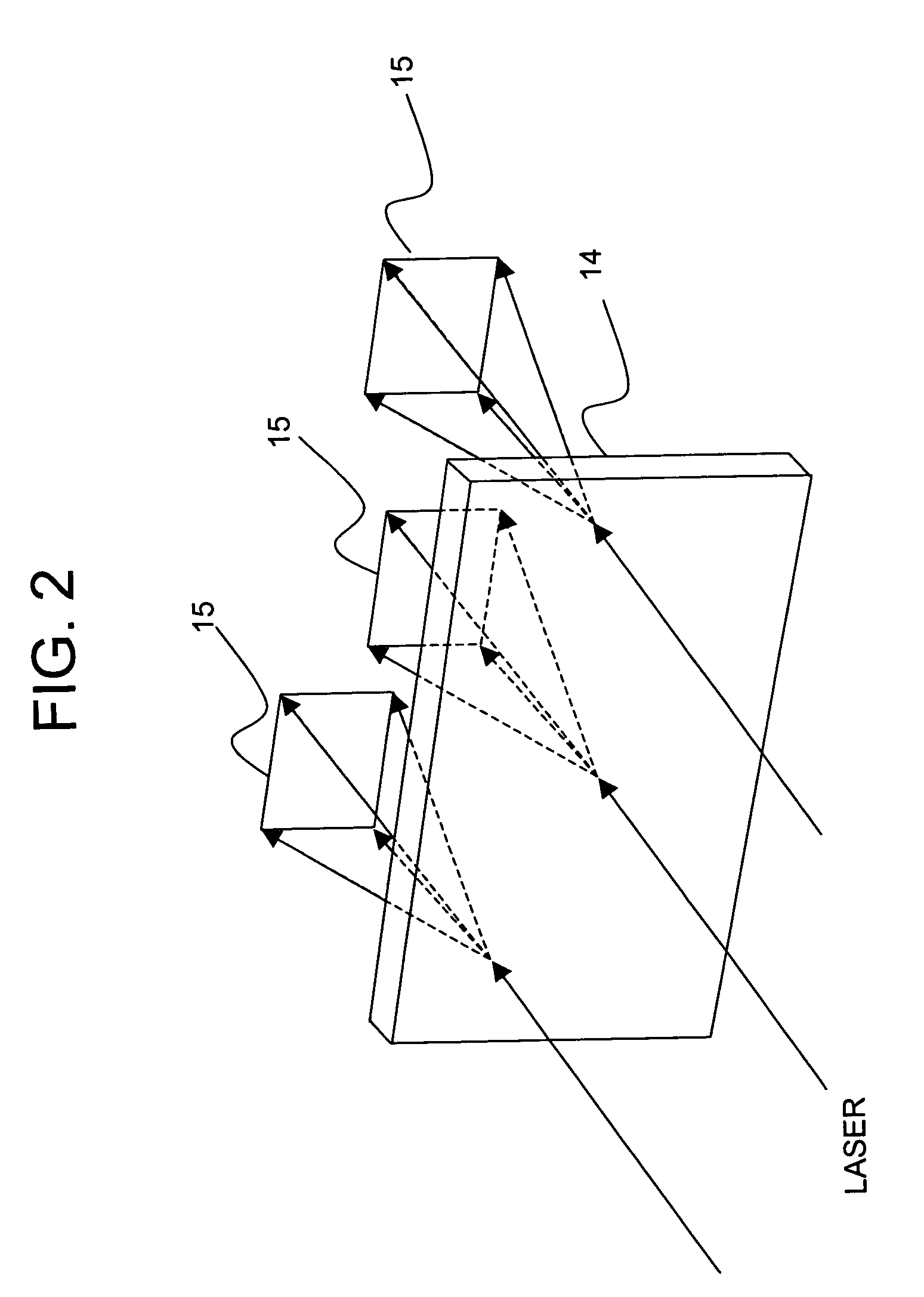

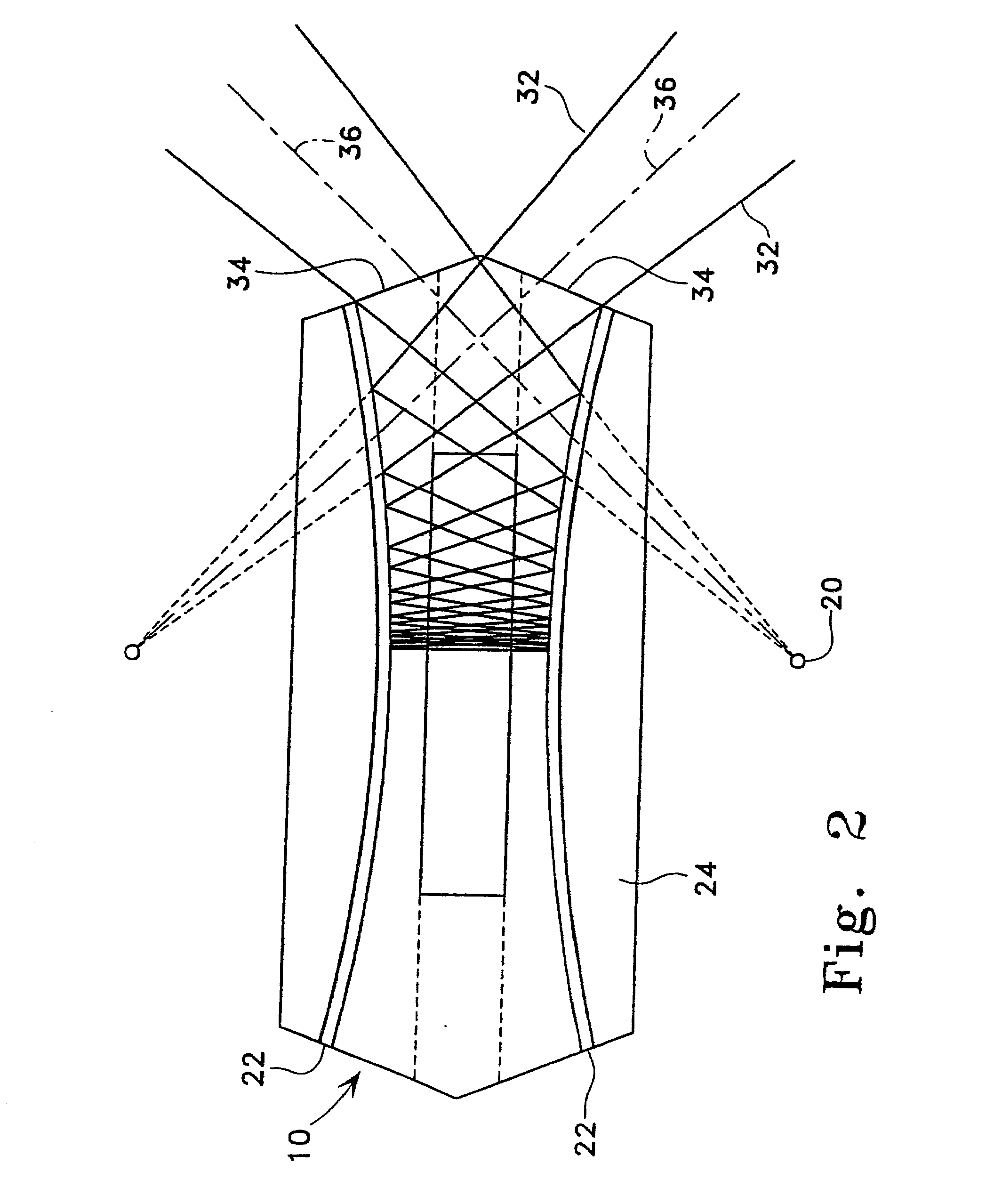

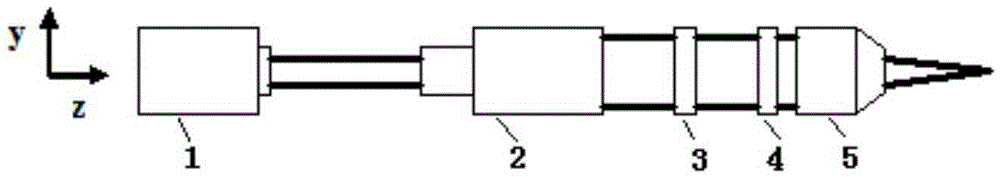

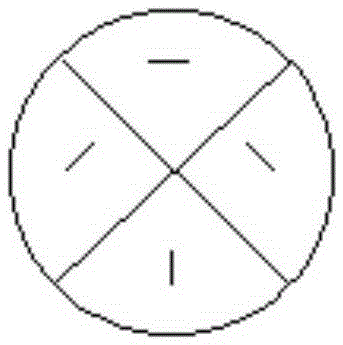

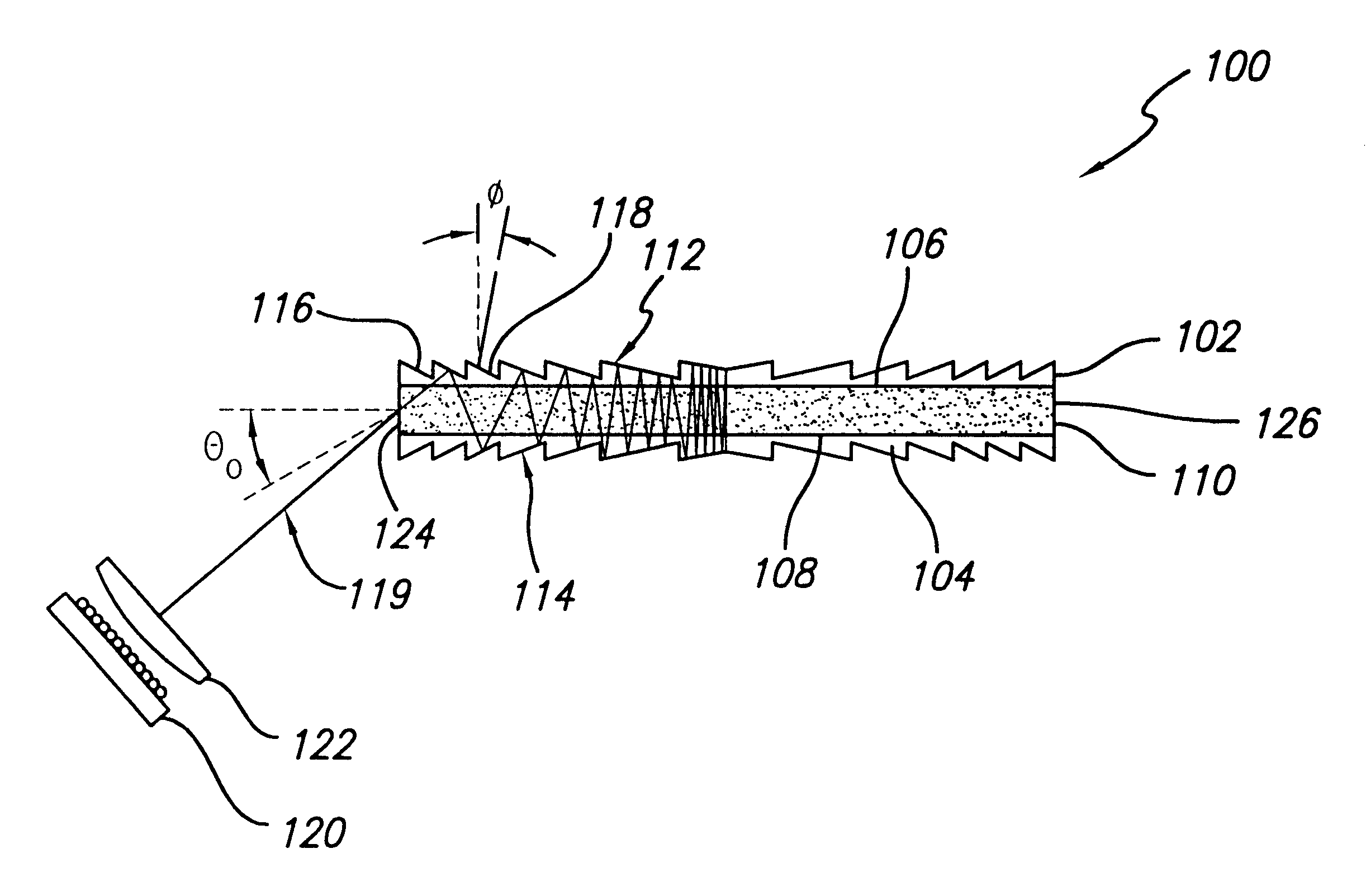

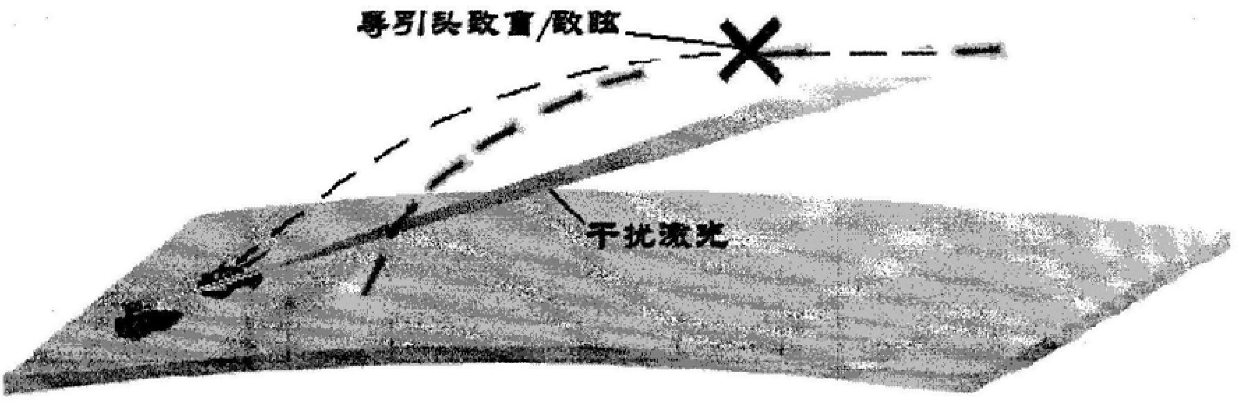

Binary optics SAL seeker (BOSS)

ActiveUS20070187546A1Maintain compatibilityLarge and compact designDirection controllersSelf-propelled projectilesOptical energySilicon

The present invention relates to a strap down SAL seeker that includes an optical system having an engineered diffuser for transforming a laser spot into a uniform distribution of optical energy with a predetermined shape. The predetermined shape is preferably a square “top hat” or uniform scatter pattern. The SAL seeker further includes a silicon quad detector, having a focal plane defined by at least two axes. The detector is operatively associated with the engineered diffuser, and it generates signals indicative of the position of the optical energy with respect to the focal plane of the detector.

Owner:LOCKHEED MARTIN CORP

Binary optics SAL seeker (BOSS)

Owner:LOCKHEED MARTIN CORP

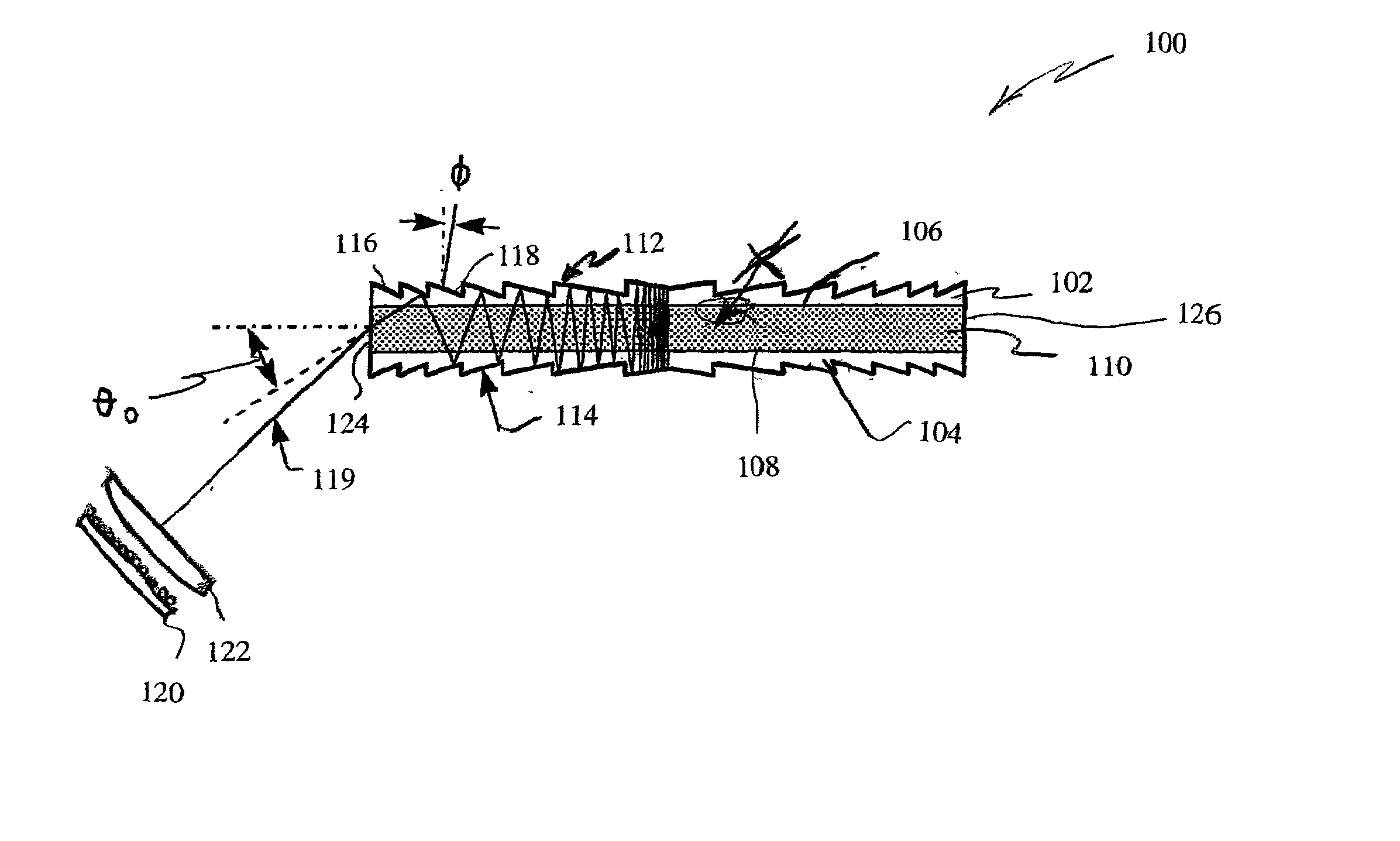

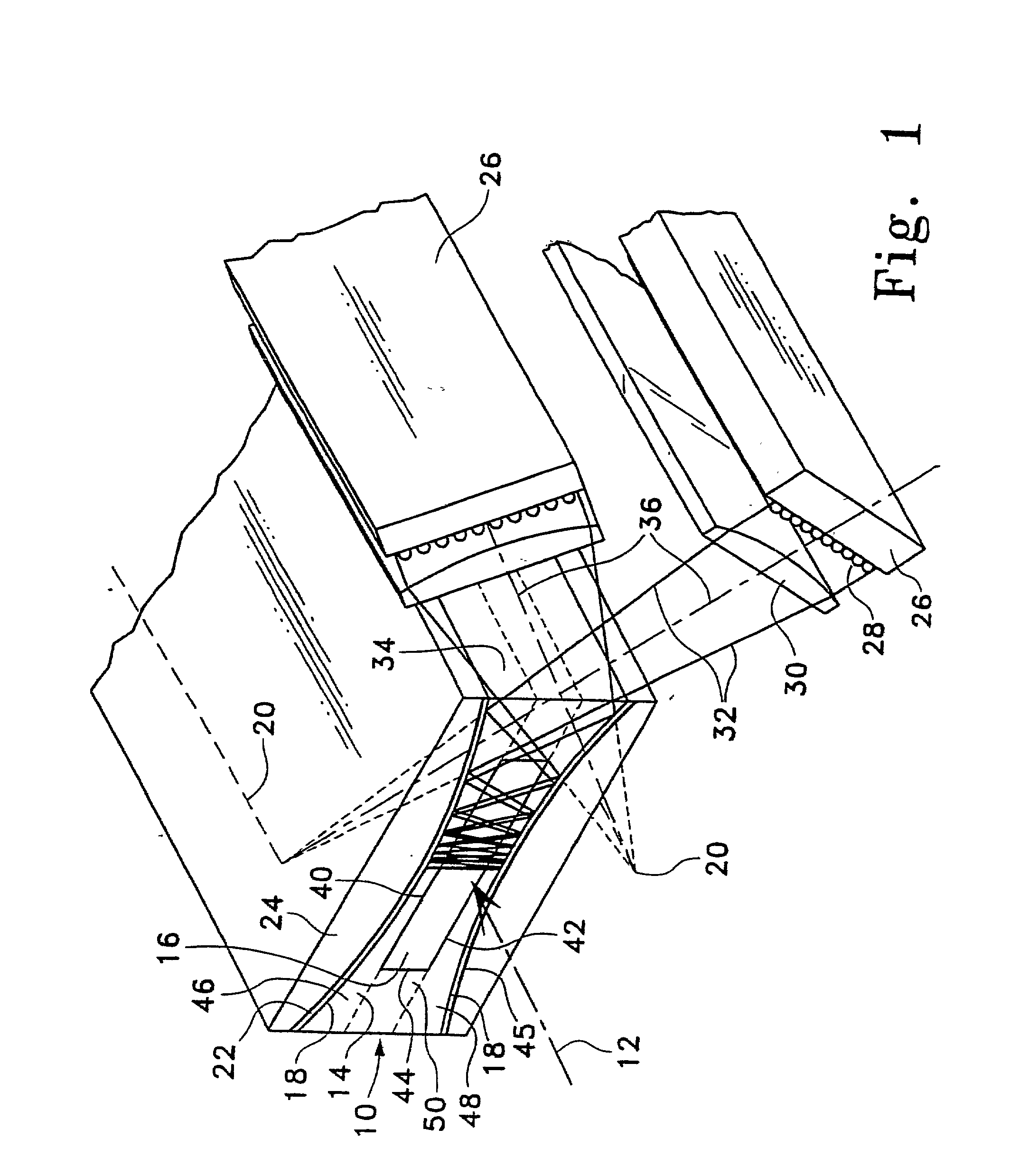

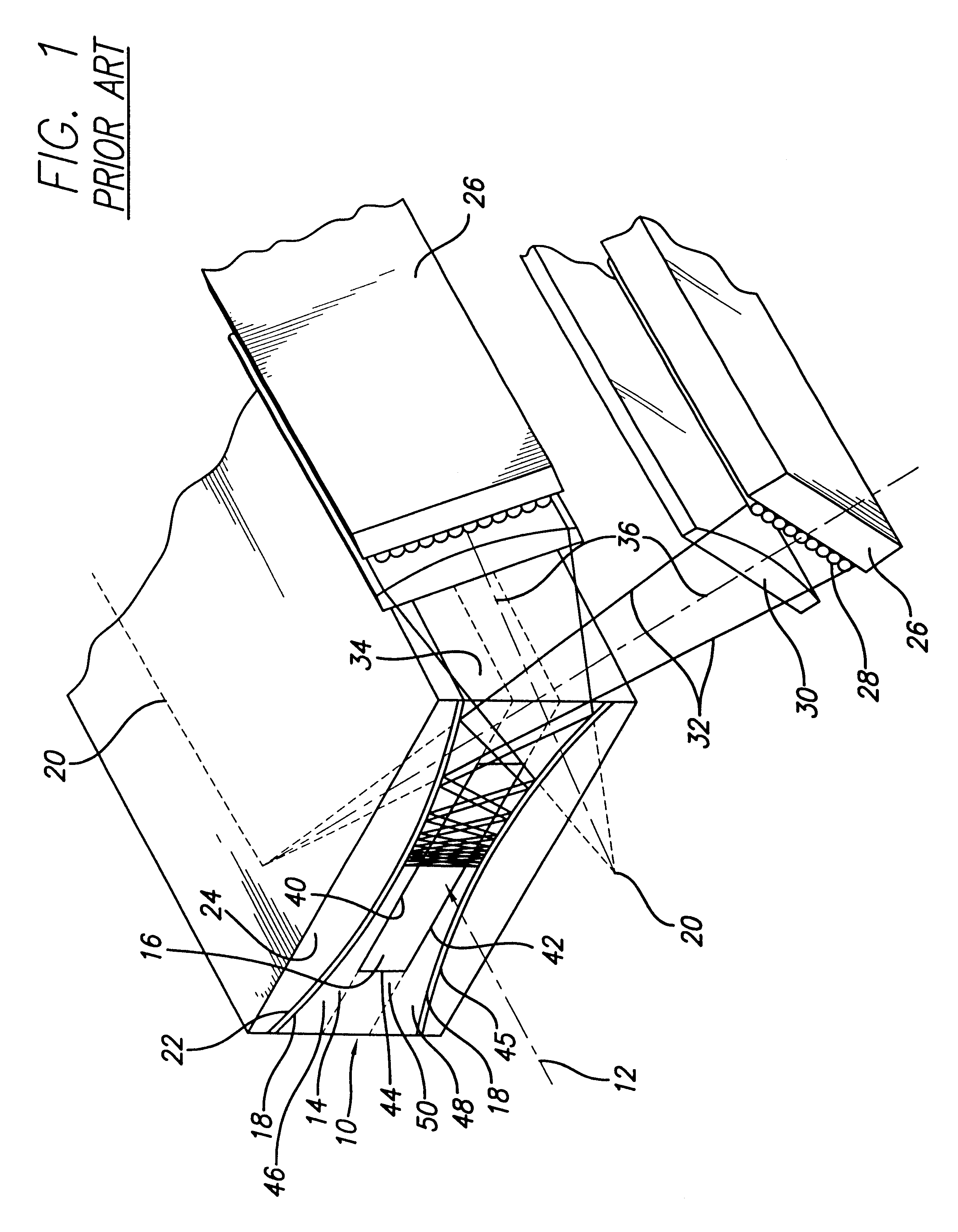

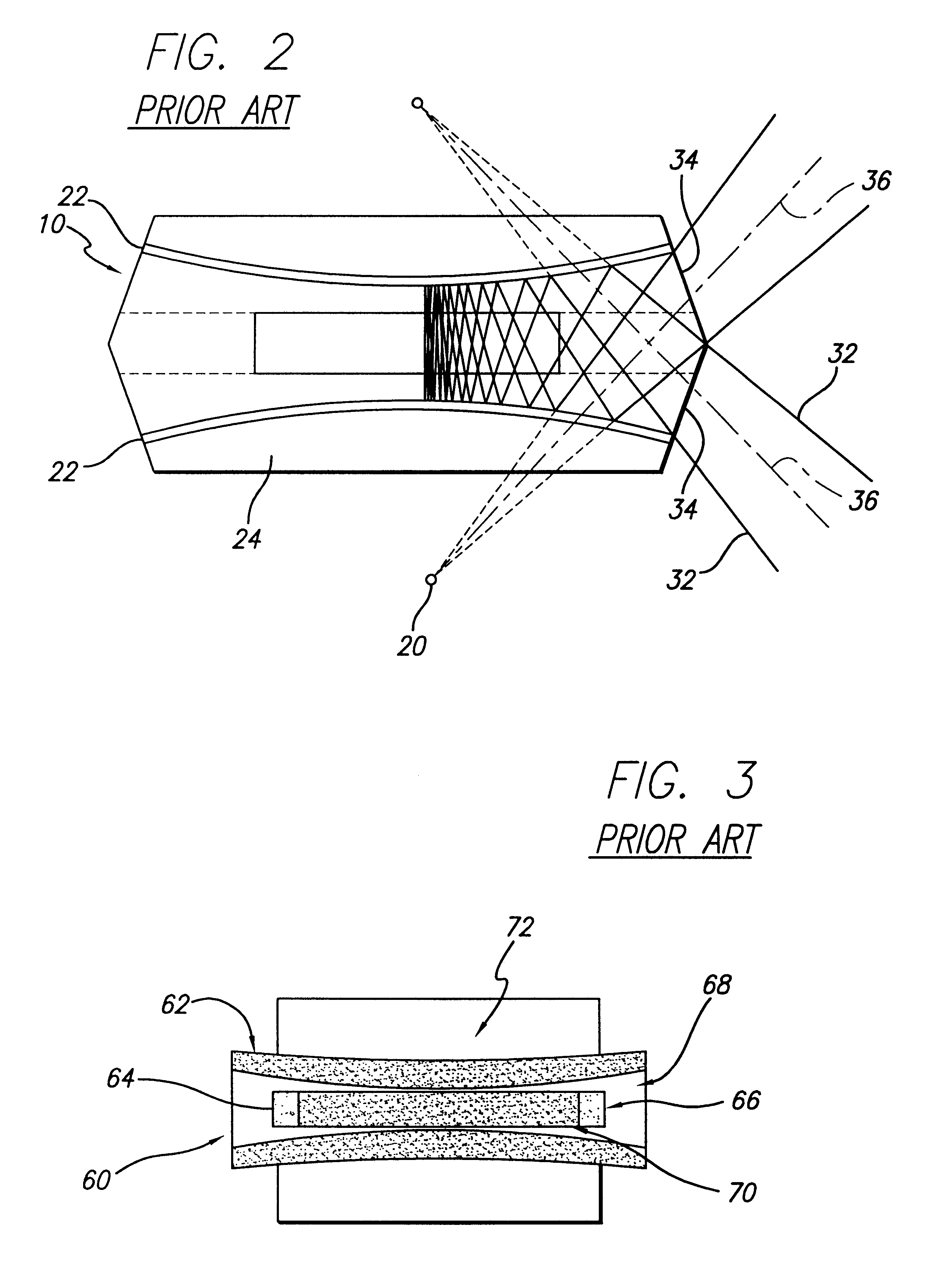

System and method for pumping a slab laser

InactiveUS20030031226A1Active medium shape and constructionLaser cooling arrangementsPosition dependentActive medium

A concentrator including a volume of at least partially transmissive material and a plurality of facets disposed at at least one surface thereof. Each of the facets is disposed at a position dependent angle relative to the surface effective to cause an internal reflection of energy applied to the layer whereby the density of the applied energy varies as a function of position. In the illustrative implementation, the volume is an active medium, i.e., a slab. The slab has substantially parallel, planar upper and lower surfaces and first and second edges therebetween. A plurality of cladding layers are disposed on the upper and lower surfaces of the slab. The facets are provided in the cladding layers on the upper and lower surfaces of the slab and angled as a function of distance relative to the first or the second edge. The facets provide a Fresnel reflecting surface or a binary optic surface.

Owner:RAYTHEON CO

Optical system of reflective helmet-mounted display based on antigas mask

The invention discloses an optical system of a reflective helmet-mounted display based on an antigas mask. The optical system is characterized by comprising a hypertorus toroidal reflector and a relay system, wherein the reflector is provided with a hypertorus toroidal surface; and light rays are emitted from a micro display screen, pass through the relay system and the reflector in sequence, and finally enter human eye pupils. The optical system has the advantages as follows: the size of the system is small and the weight of the system is light; as the inclination angles of a mechanical shaft of the reflector and main light ray of a zero view field are zero and the reflection surface is plated with a narrow-band high-reflection film, dual-channel displaying can be achieved; and as the dual-channel displaying is adopted, the whole helmet-mounted display hardly blocks the view field, and the human eyes do not need to deflect when watching, so that the comfortableness is improved.

Owner:中航华东光电有限公司

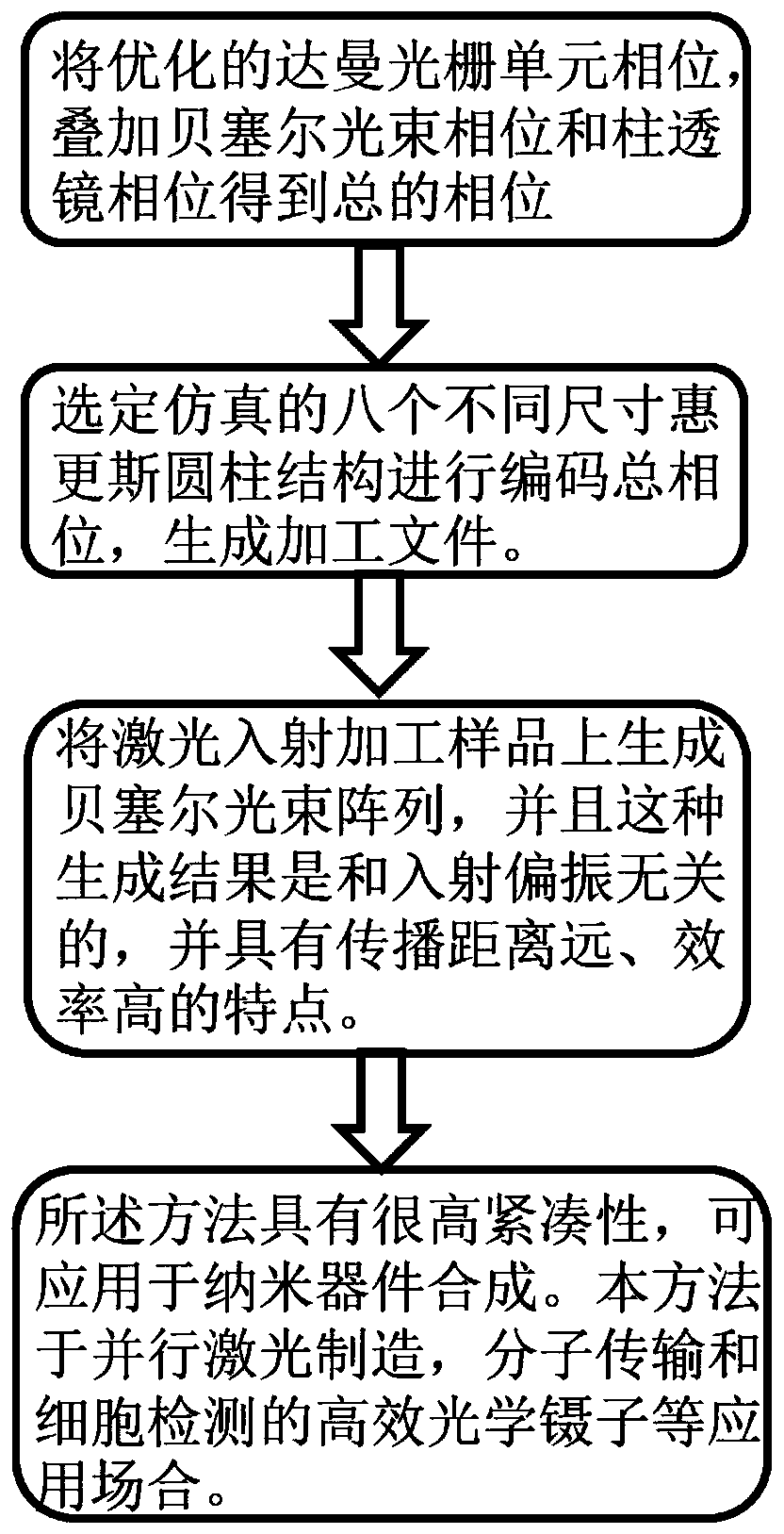

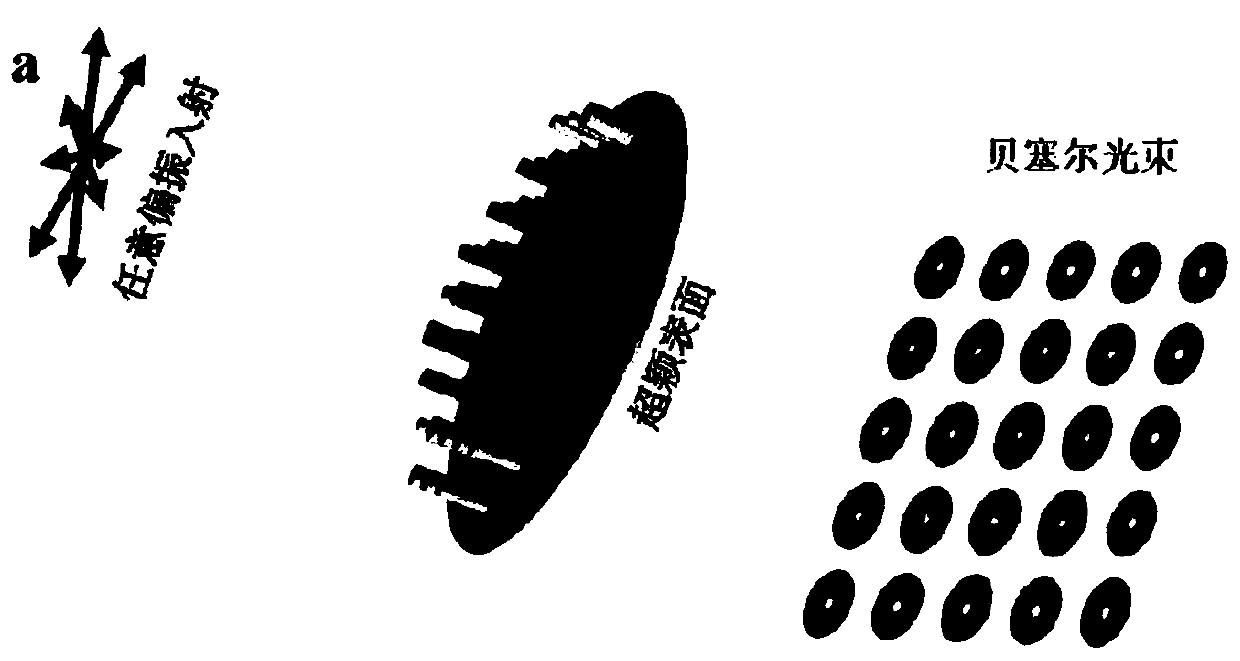

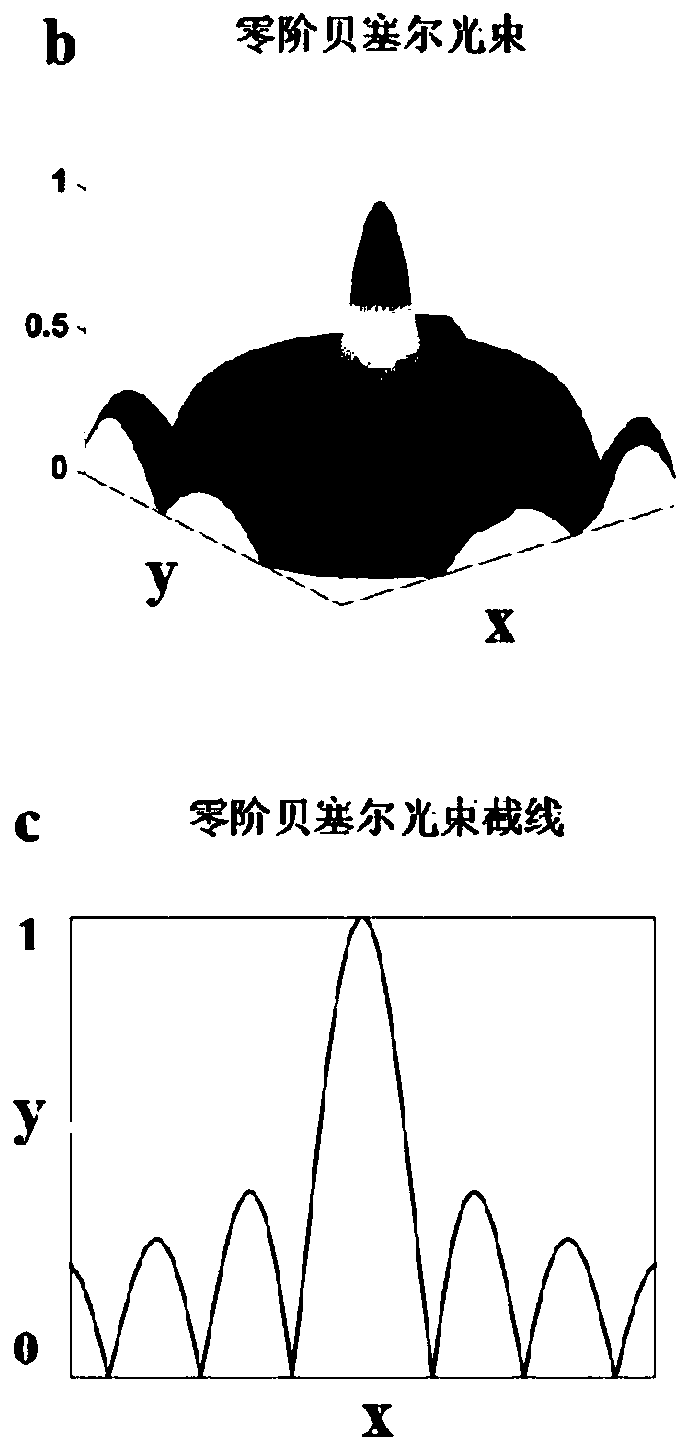

Method for generating Bessel beam array based on Huygens' meta-surface

ActiveCN110361864APolarization insensitiveImprove compactnessOptical elementsCircular discMicro nano

The invention relates to a method for generating a Bessel beam array based on a Huygens' meta-surface, belonging to the technical fields of micro nano optics and binary optics applications. The methodcomprises the following steps: the phase of a Daman grating unit is optimized through a genetic algorithm to realize a uniform-power beam splitting function; the phases of Bessel beams are superimposed to obtain a total phase; a meta-surface is encoded according to the optimized total phase; the phases and amplitudes of outgoing beams are adjusted arbitrarily through the meta-surface by changingthe radius of a disk nanopillar unit; and the phase change of the transmitted light can cover the range from 0 to 2*Pi and the transmittance can be kept over 70% by changing the radius of the nanopillar unit, and a processing file of a corresponding medium meta-surface is generated. A Bessel beam array will be generated in the transmission direction when a sample is irradiated by laser, and the generation result is independent of the incident polarization. The method has the characteristics of long propagation distance and high efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

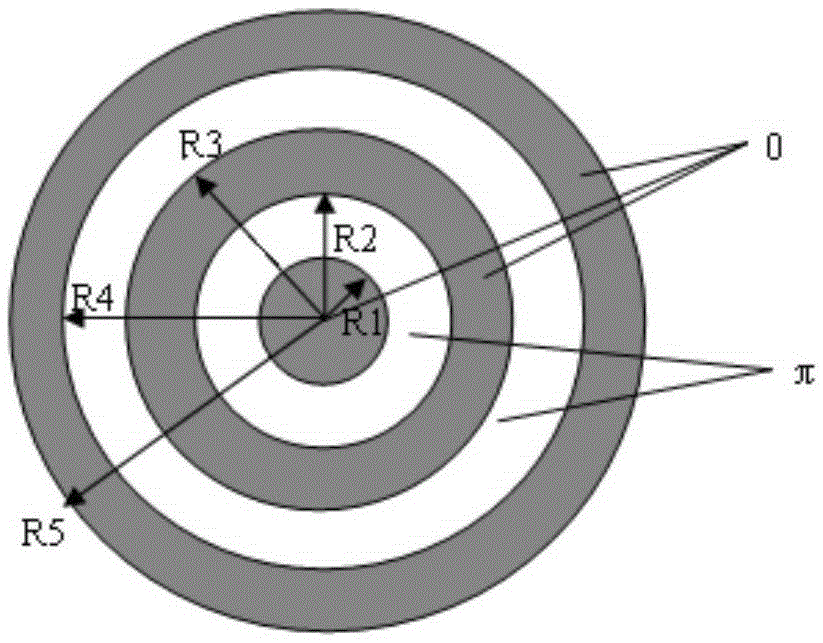

Generation method of super-resolution optics pipeline

The present invention relates to a generation method of a super-resolution optics pipeline. The generation method of the super-resolution optics pipeline comprises: a laser emits a laser beam of linear polarization, and the laser beam is vertically irradiated to a polarization converter or a vortex phase plate along a direction of an optical axis after collimation and beam expanding through a collimation and beam expander so as to convert to an angular polarized light or a vortex light; a binary optics device is designed, five annular grooves with 0 / [Pi] alternation are engraved on a glass substrate, so that the phase of a light beam having a sizing ring belt which is zero is invariant and the phase delay of a light beam having a sizing ring belt which is a [Pi] is [Pi] after the angular polarized light or the vortex light vertically irradiate into the binary optics device; the angular polarized light or the vortex light are focused by passing through a microobjective with high numerical aperture after the modulation of the binary optics device, the destructive interference of the modulated light beams is performed at the focus, and a super-resolution optics pipeline is obtained. On the basis of the phase adjustment of the binary optics device provided by the invention, and a super-resolution optics pipeline with dark focused faculas at the focus of the microobjective and is taken as a de-excitation light source, so that the three-dimensional super-resolution imaging is realized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

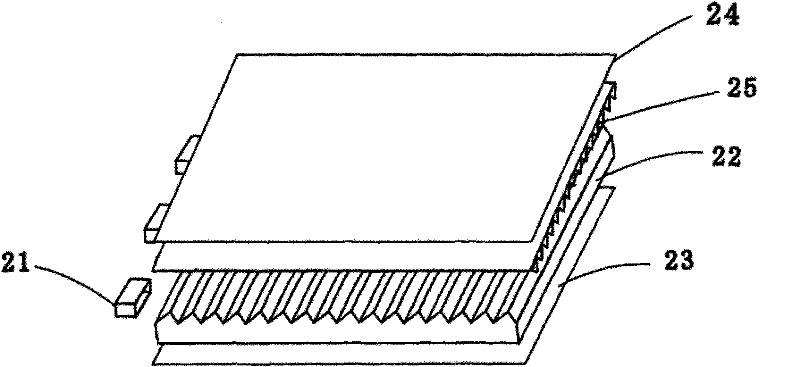

Integrated micro-optics backlight module

InactiveCN102537762AImprove coupling efficiencyRealize the structureMechanical apparatusLight guides for lighting systemsLight guideRadiance

The invention provides an integrated micro-optics backlight module, which comprises an integrated micro-optics light-guiding plate and at least one light source. The light-guiding plate comprises a light incidence surface, a light emitting surface, a bottom surface opposite to the light emitting surface and three side faces, wherein the three side faces are connected with the light emitting surface and the bottom surface, a micro-optics light condensing structure designed by utilizing micro-optics and binary optic iterative algorithm is arranged on the light emitting surface, and a micro-optics reflection structure matched with the micro-optics light condensing structure on the light emitting surface is arranged on the bottom surface. The micro-optics reflection structure on the bottom surface can reflect and diffract light beams, and the micro-optics light condensing structure on the light emitting surface is matched with the micro-optics reflection structure on the bottom surface so that the light beams can be concentrated in an ideal view field to be emitted, and radiance and uniformity of emitted light are improved. The integrated micro-optics backlight module does not use a flat surface reflective sheet, a diffusing sheet and a double-layer crossed-prism lens in a typical backlight module but exceeds a typical multiple-layer structure in effect, the backlight module is highly integrated, utility rate of luminous energy is improved, and cost is reduced.

Owner:徐平 +1

System and method for pumping a slab laser

InactiveUS6567452B2Active medium materialActive medium shape and constructionPosition dependentActive medium

A concentrator including a volume of at least partially transmissive material and a plurality of facets disposed at at least one surface thereof. Each of the facets is disposed at a position dependent angle relative to the surface effective to cause an internal reflection of energy applied to the layer whereby the density of the applied energy varies as a function of position. In the illustrative implementation, the volume is an active medium, i.e., a slab. The slab has substantially parallel, planar upper and lower surfaces and first and second edges therebetween. A plurality of cladding layers are disposed on the upper and lower surfaces of the slab. The facets are provided in the cladding layers on the upper and lower surfaces of the slab and angled as a function of distance relative to the first or the second edge. The facets provide a Fresnel reflecting surface or a binary optic surface.

Owner:RAYTHEON CO

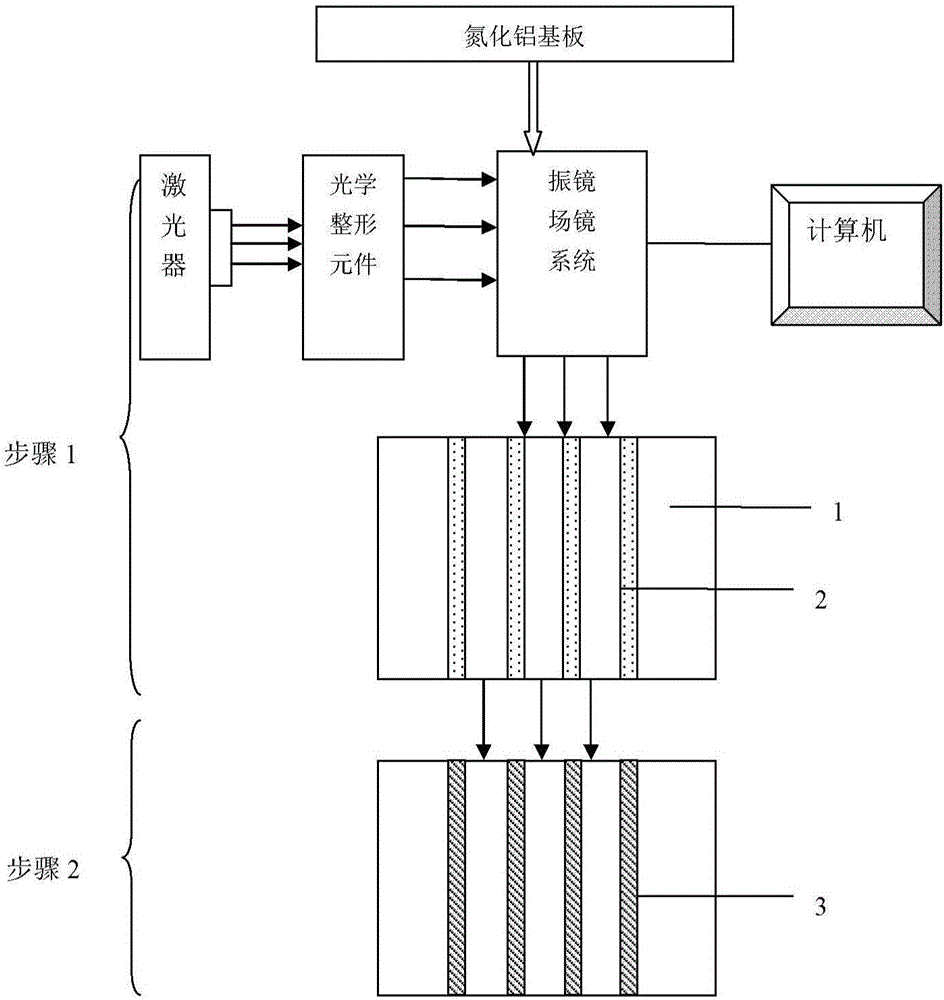

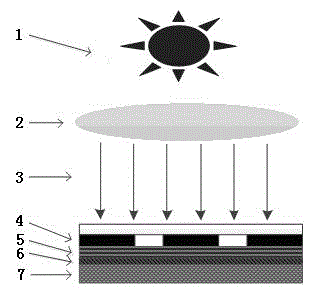

Method for metalizing aluminide substrate through laser light and aluminide substrate

InactiveCN106312300AUniform thicknessEvenly distributedWelding/soldering/cutting articlesLaser beam welding apparatusChemical platingMetallic aluminum

The invention discloses a method for metalizing an aluminide substrate through laser light and the corresponding aluminide substrate. Phase modulation is conducted on the laser light through an optical shaping element based on binary optics, so that flat-topped light is obtained, and the flat-topped light is irradiated onto the aluminide substrate in a focused mode through a galvanometer field lens system. Metallic aluminum is separated from aluminide through ultrahigh temperature generated by the laser light, so that an aluminum wire in a specific shape and of a specific size and distribution form on the aluminide surface is obtained; and then the conductive aluminum surface is metalized through an electroplating method or a chemical plating method. The area which is not subjected to laser light treatment is not metalized, the aluminum wire is directly formed on the aluminide substrate in the way that a computer is used for controlling galvanometer scanning, and accordingly patterning of a metal electrode is achieved. Compared with a traditional aluminide substrate metalizing method, the method for metalizing the aluminide substrate through laser light and the corresponding aluminide substrate have the advantages that the technique is simpler, the cost is lower, and patterning of the metal electrode can be achieved directly; and in addition, by using the optic shaping element, distribution of laser energy is made uniform, and the obtained metal thickness is also uniform.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

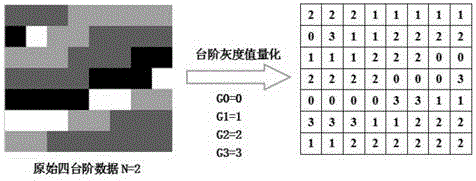

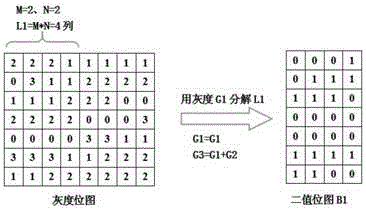

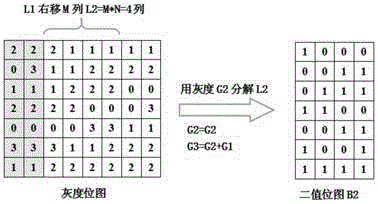

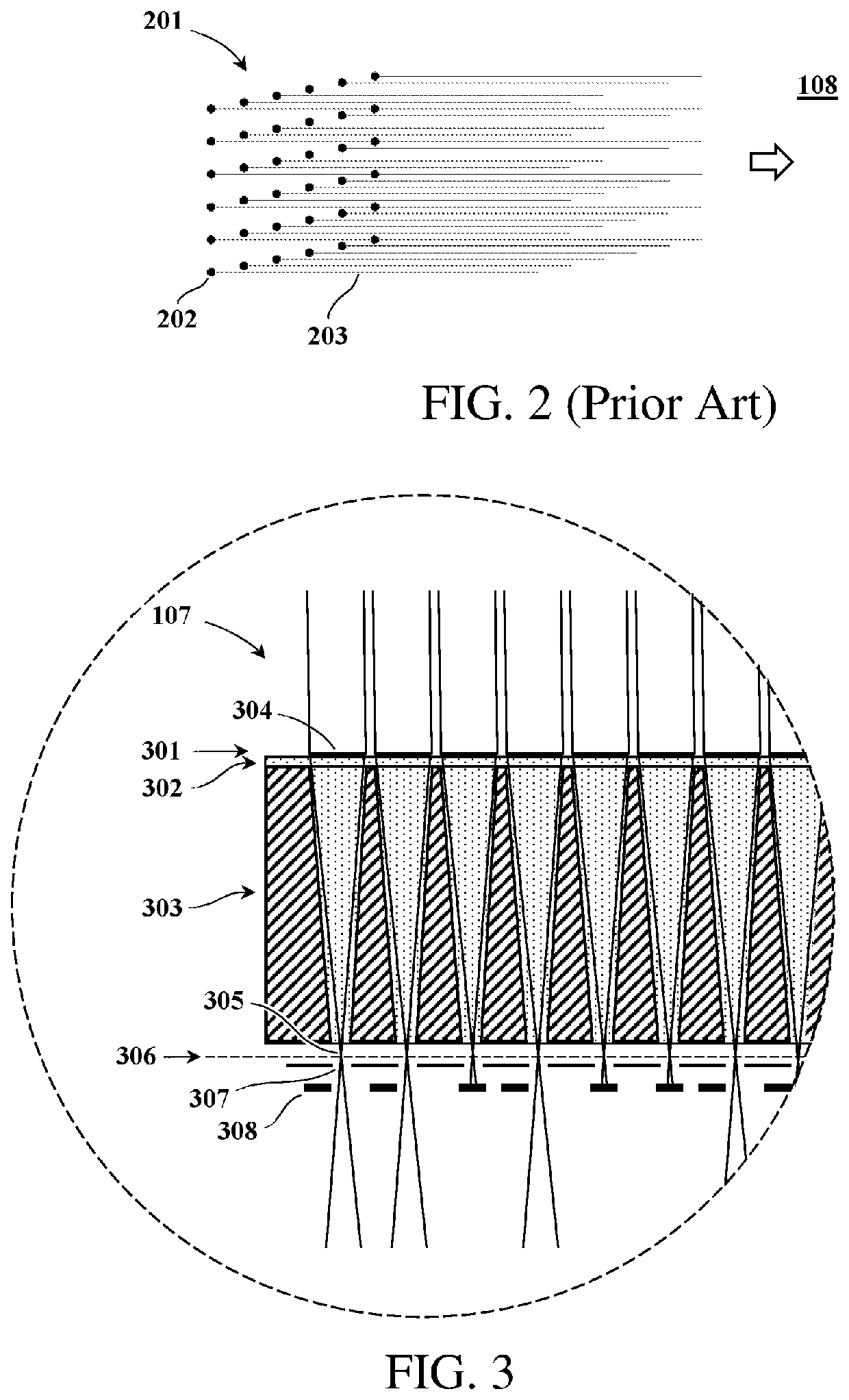

Laser direct writing method based on large-area multi-step binary optical element

ActiveCN104570619APrecise Control of Exposure MeteringImprove lithography efficiencyDiffraction gratingsPhotomechanical exposure apparatusData fileComputer science

The invention discloses a laser direct writing method based on large-area multi-step binary optical element, which comprises the following steps: processing a 2N-order step data document into a gray BMP image with gray values starting from G0=0 to G2<N>-1=2<N>-1, decomposing the gray BMP image according to exposure metering accumulation formula P=P1+P2+....Pn, Pn=2<n-1>*P1 (n<=N), expressing the exposure metering of all the 2<N>step exposure through separately or accumulatively combination, to realize the covering of the exposure metering of all the steps by maximally overlapping N exposures (P=P1+P2+....Pn) at the position area in the Y stepping direction. The exposure metering of each step is decomposed into X and Y two-dimension unit meterings which are superposed. By adopting the mode of scanning the synchronous pulse triggering exposure, on one hand, the exposure metering is accurately controlled, on the other hand, the photoetching efficiency is improved, all the data are written only once in an entirely digital manner, alignment nesting is not required, and the error probability brought in the middle links can be reduced.

Owner:SVG TECH GRP CO LTD

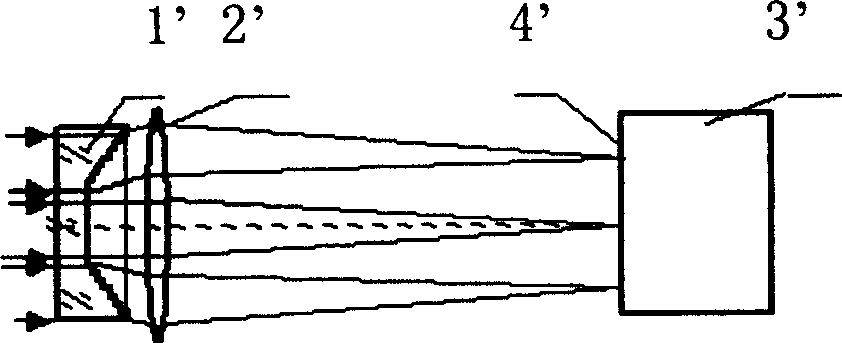

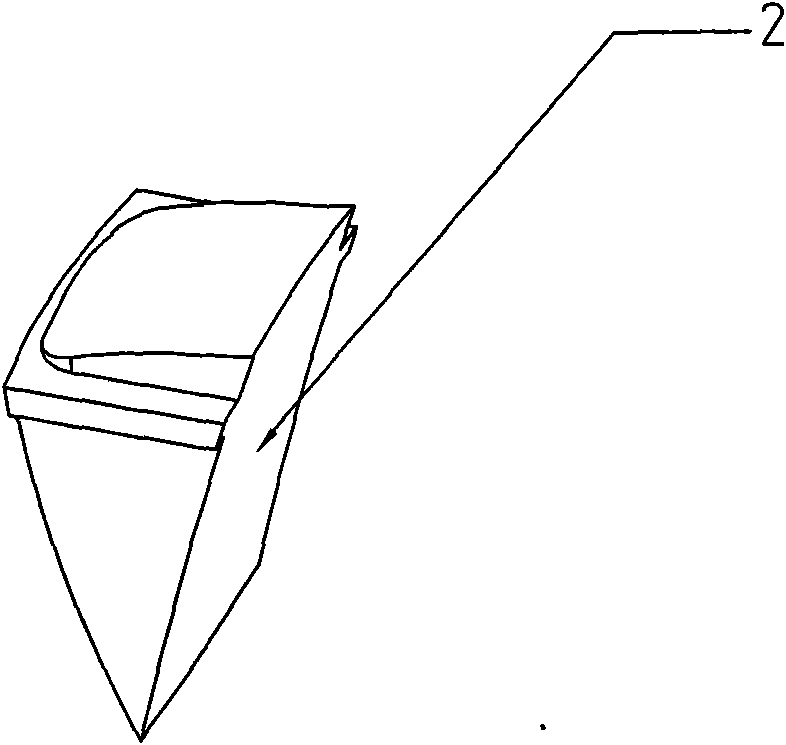

Binary optical system of anti-gas mask helmet displayer

The invention discloses a binary optical system of an anti-gas mask helmet displayer. The binary optical system consists of a binary optical holographic plane reflecting mirror and a relay system, wherein the reflecting mirror has a holographic plane, and light is emitted from a miniature display screen, sequentially passes through the relay system and the reflecting mirror and finally enters human eye pupils. In addition, a dip angle formed by a mechanical axis of the reflecting mirror and a primary ray of a zero view field is zero. The binary optical system of the anti-gas mask helmet displayer has the advantages that the system is small in volume and light in weight, double-path displaying can be achieved due to the facts that the dip angle formed by the mechanical axis of the reflecting mirror and the primary ray of the zero view field is zero and the reflecting mirror has the holographic plane, the blocking influence of the whole helmet displayer on view field is very small due to the fact that a double-path displaying mode is adopted, human eyes do not need to perform angle deflection in viewing, and the comfort is improved.

Owner:中航华东光电有限公司

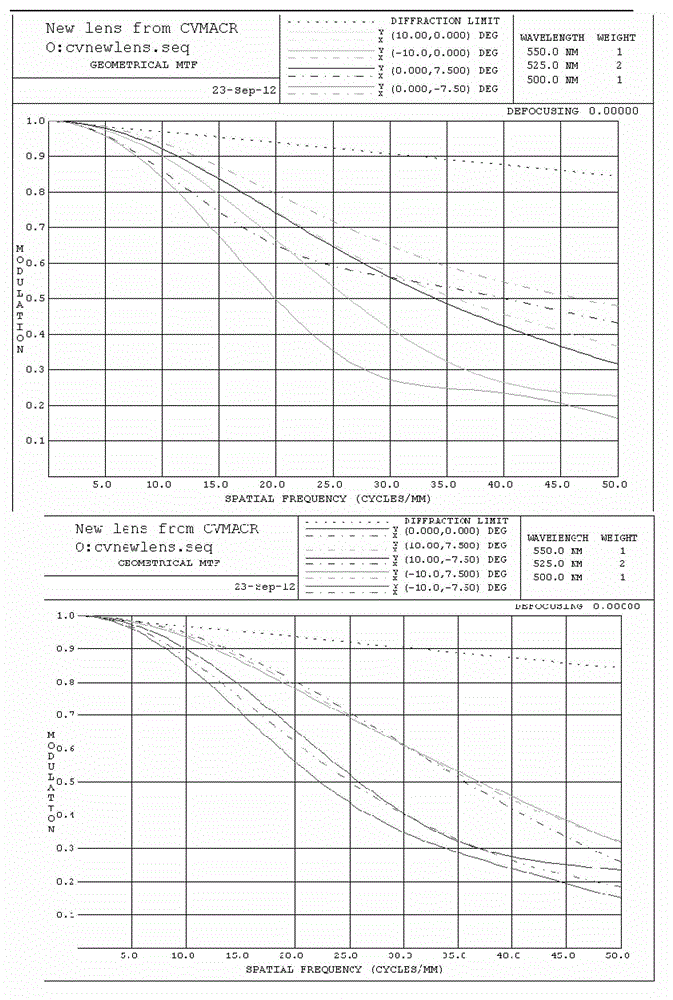

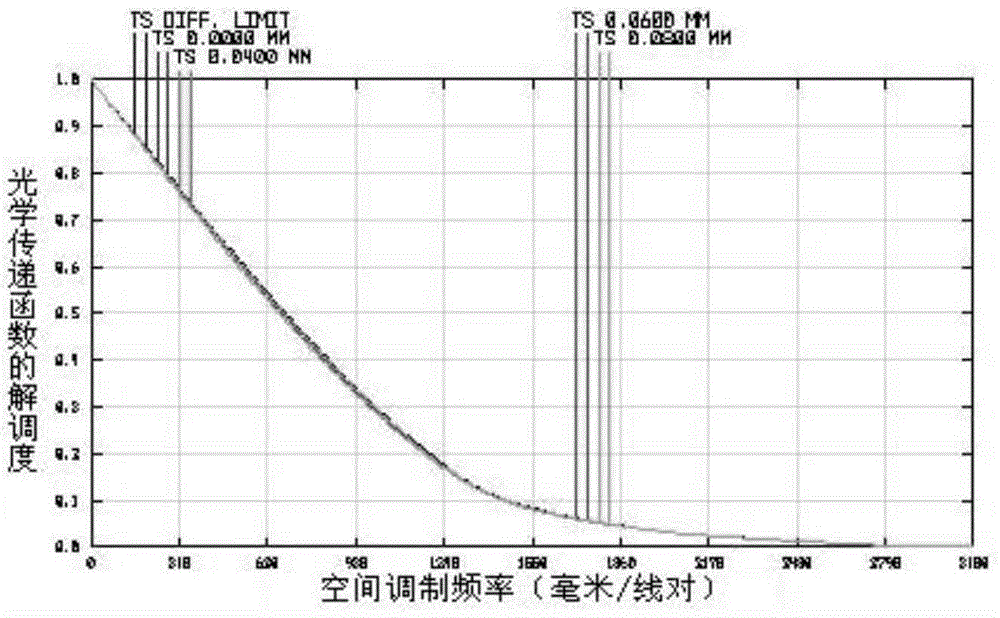

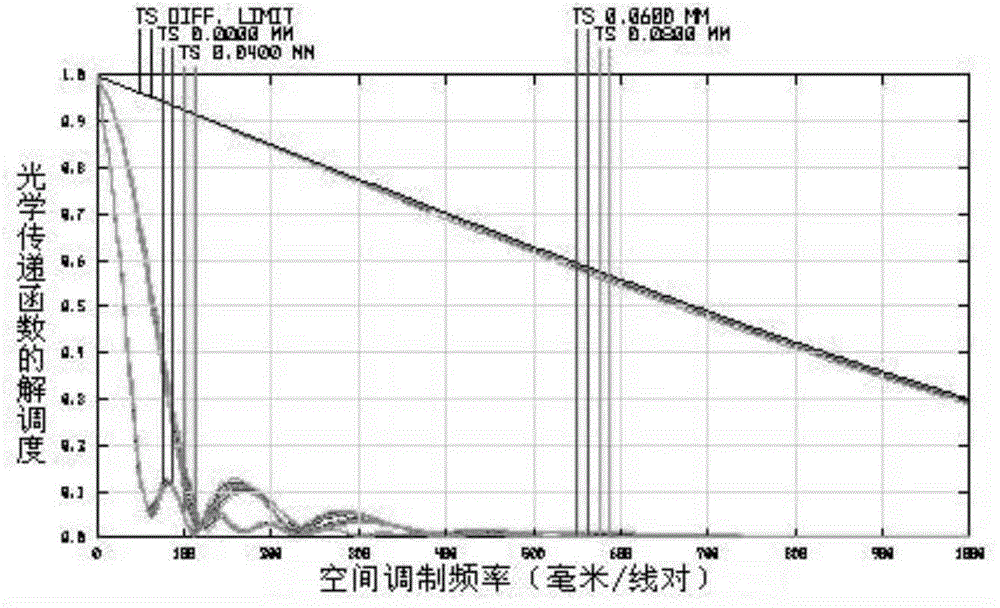

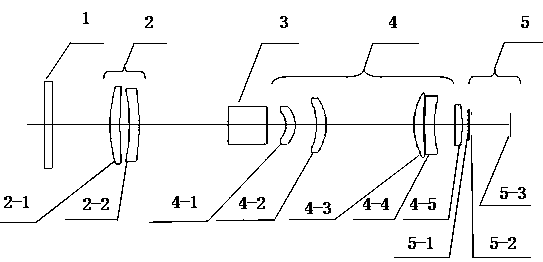

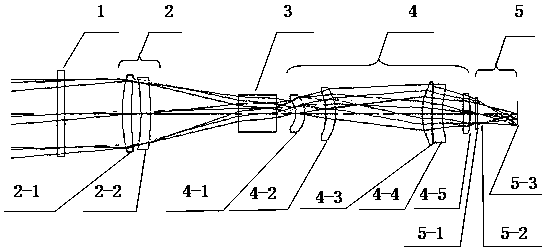

Wide-waveband and large-field-depth microscope objective optical system used for flow cytometry

InactiveCN104459967AHigh-resolutionEnhance the imageMicroscopesIndividual particle analysisOptical diffractionExit pupil

The invention belongs to the field of design of imaging optical systems and discloses a wide-waveband and large-field-depth microscope objective optical system used for a flow cytometry. The wide-waveband and large-field-depth microscope objective optical system used for the flow cytometry aims at solving the problems that an existing microscope objective of the flow cytometry is narrow in waveband and small in field depth in the prior art. The wide-waveband and large-field-depth microscope objective optical system used for the flow cytometry comprises a first lens assembly, a second lens assembly, a cubic phase board, a third lens assembly, an eighth lens, a fourth lens assembly and a fifth lens assembly which are sequentially arranged along the optical axis from left to right; the fifth lens assembly is a plus lens assembly and comprises a binary diffraction optical element, the flow face, close to the flow cytometry, of the binary diffraction optical element is a binary optical diffraction face, the base face is a plane, the cubic phase board is located at the exit pupil position of the microscope objective optical system, and the face, deviating from a flow cytometry flow chamber, of the binary diffraction optical element is a cubic surface. After the binary diffraction optical element is introduced, chromatic aberration is well corrected. Meanwhile, after the cubic phase board is introduced, the field depth of the microscope objective is extended by twenty times to reach + / -16.8 micrometers.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

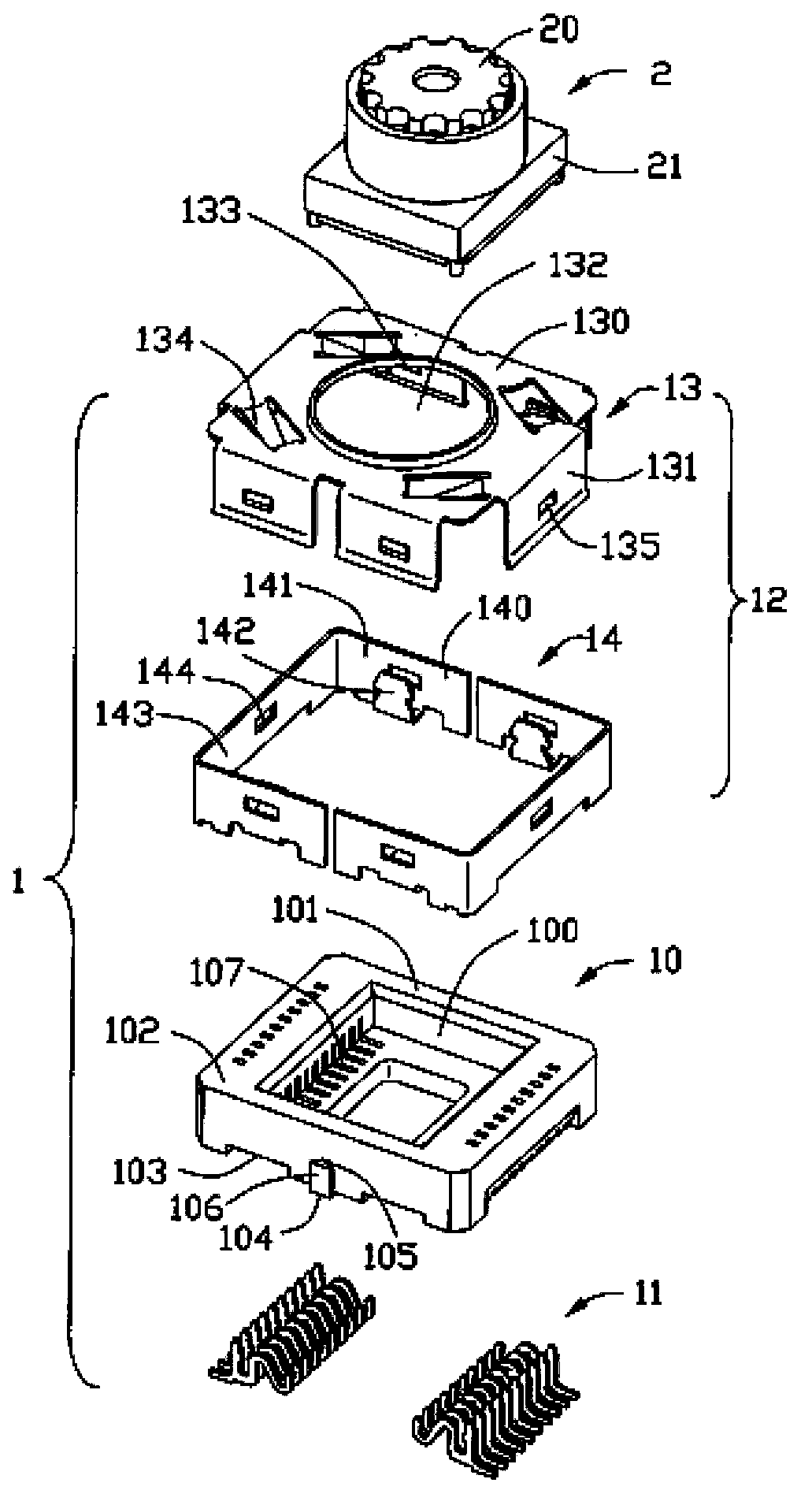

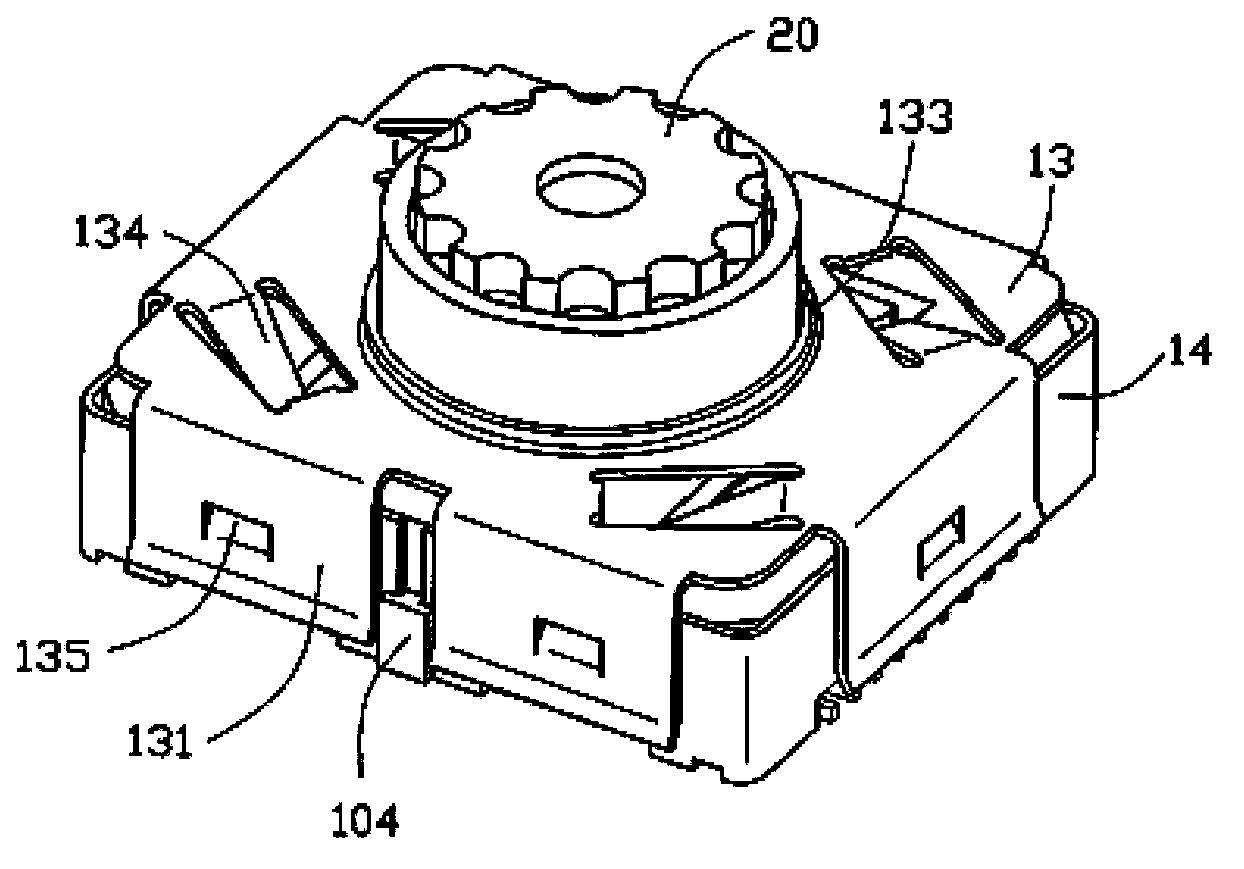

Camera module

InactiveCN103809262AImprove image qualitySmall sizeTelevision system detailsColor television detailsImaging qualityComputer module

Disclosed is a camera module. The camera module comprises an electric coupler, and the electric coupler is mounted on a circuit board of a portable information terminal for assembling the camera module into the portable information terminal. The camera module is characterized by sequentially comprising a first meniscus lens with a focal distance of f1, a second meniscus lens with a focal distance of f2 and an image sensor for receiving an image; one surface of the second meniscus lens is provided with a binary optic structure; at least two surfaces of the first meniscus lens as well as the second meniscus lens are aspheric surfaces; f1 / f2 is between -0.85 and -2.3. The camera module is convenient to assemble with the portable information terminal, high in imaging quality and small in size.

Owner:WUXI CINSEC INFORMATION TECH

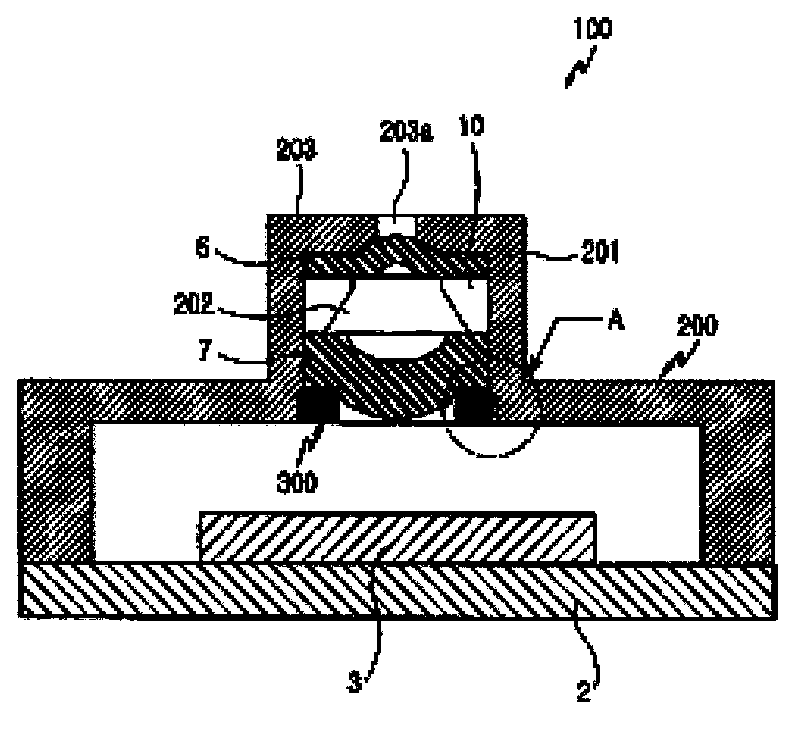

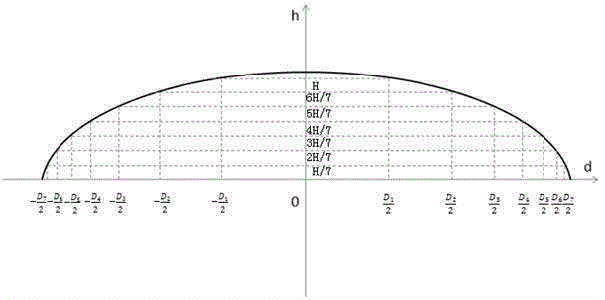

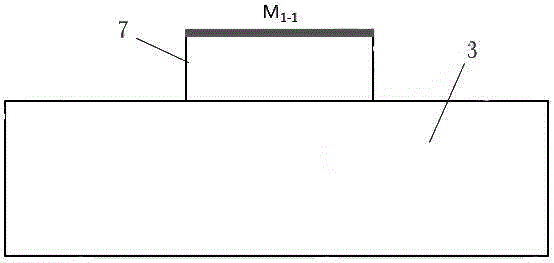

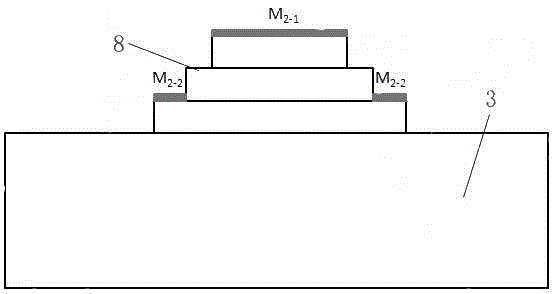

Method for manufacturing silicon dioxide microlens

ActiveCN105278010AAchieve process controllabilityMeet the theoretical design requirementsLensEtchingSilicon dioxide

The invention discloses a method for manufacturing a silicon dioxide microlens. Firstly, the lens height and the photoetching frequency are determined; according to a distance between two intersection points of a horizontal line at each equally-divided height section of the lens height H and a microlens surface characteristic function, a cylinder diameter at the corresponding height in a coaxial cylinder stacked structure is determined; the depth of each lens etching is determined; and using a binary optics technology, a 2N-level stepped structure is formed through N-times register photoetching. The photoetching frequency is low, the lens surface form which is practically manufactured can be well meet theoretical design requirements, and processing controllability of the lens surface form is achieved.

Owner:HENAN SHIJIA PHOTONS TECH

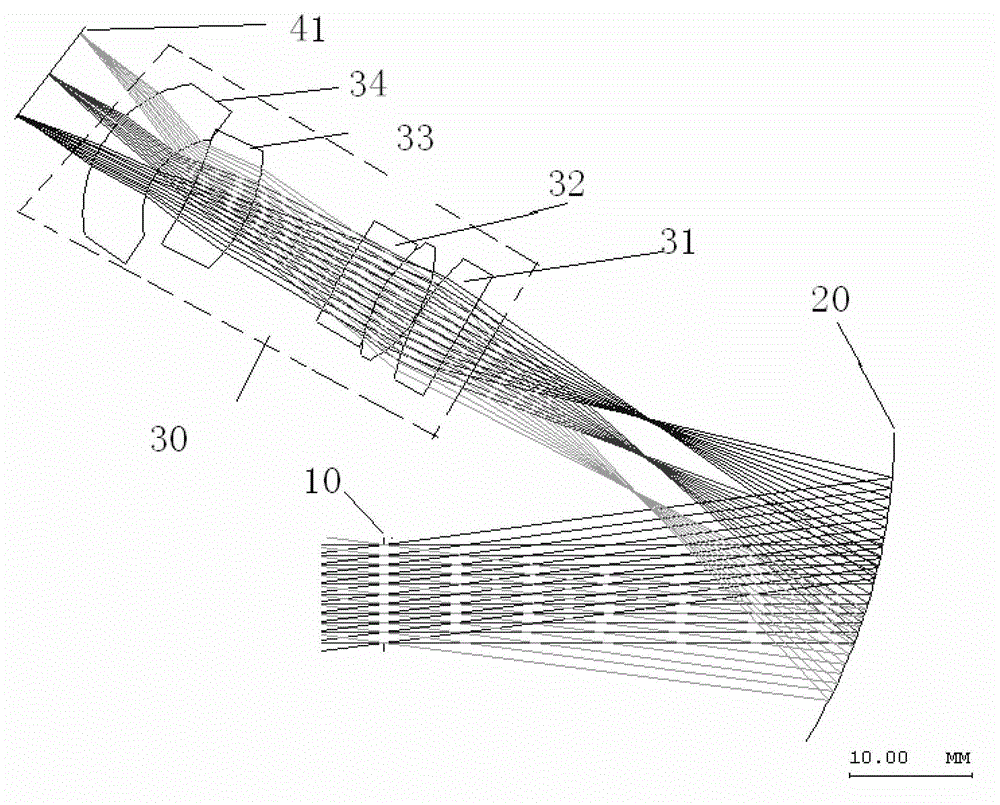

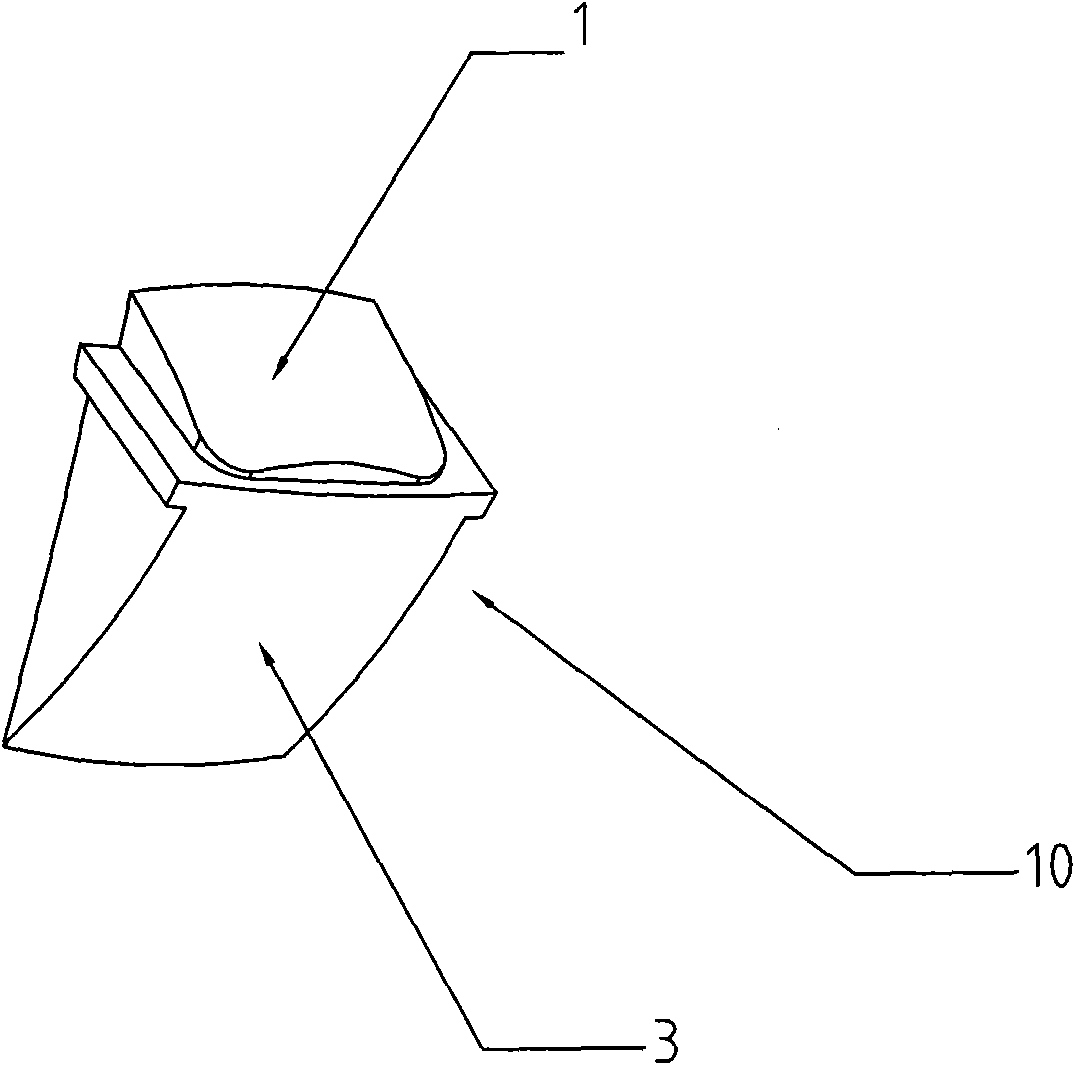

Binary optical lens optical system of refractive-reflective free curved plane

The invention relates to an optical lens system, in particular to a refractive-diffractive mixed optical lens optical system consisting of a refractive-reflective free curved plane and a diffractive plane. The optical system comprises a refractive-reflective free curved plane binary optical lens, wherein the refractive-reflective free curved plane binary optical lens comprises an incident plane of the diffractive plane, a refractive plane of the refractive-reflective free curved plane and a spherical reflective plane; lights emitted by a display chip are converged into the lens by using the incident plane; lights entering the lens from the incident plane are all reflected to the reflective plane by using an emergent plane; lights reflected by the emergent plane are secondarily reflected by using the reflective plane, reflected to the emergent plane and finally refracted to parallel lights by using the emergent plane so as to enter pupils; and thus an image amplified by the refractive-reflective free curved plane binary optical lens can be seen. The refractive-diffractive mixed optical lens optical system provided by the invention has the following advantages: the structure of the optical system has the characteristics of small light energy loss, small color difference, clear imaging quality, light weight, convenience for wearing, less optical parts, simple structural form, convenience for assembling and simplicity for adjusting.

Owner:SHENZHEN ESTAR DISPLAYTECH

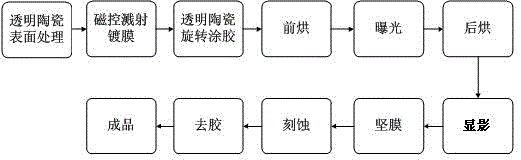

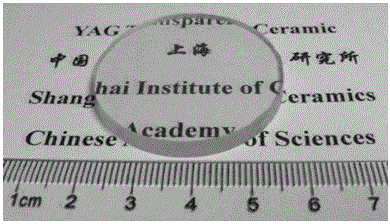

Method for manufacturing binary optical element with transparent ceramic as substrate material

The invention discloses a method for manufacturing a binary optical element with transparent ceramic as a substrate material. According to the method for manufacturing the binary optical element with the transparent ceramic as the substrate material, the non-doped yttrium yttrium aluminum garnet transparent ceramic is taken as the substrate material of the binary optical element, a compact anti-oxidant metal film is sputtered on the surface of the transparent ceramic through a magnetic-control sputtering system device, and binary optical element microstructures such as an optical grating in a mask plate are transferred into the metal film of the transparent ceramic by means of a touch type photoetching system so as to be reserved on the transparent ceramic. The substrate material has the advantages of being resistant to high temperature, high pressure and corrosion, high in hardness and high in transmittance in the infrared band and is suitable for manufacturing of transmission type or reflection type binary optical elements, and the defect that a traditional non-transparent silicon substrate material can not be used for manufacturing binary optical elements and can not be applied in special environments can be overcome.

Owner:NANCHANG HANGKONG UNIVERSITY

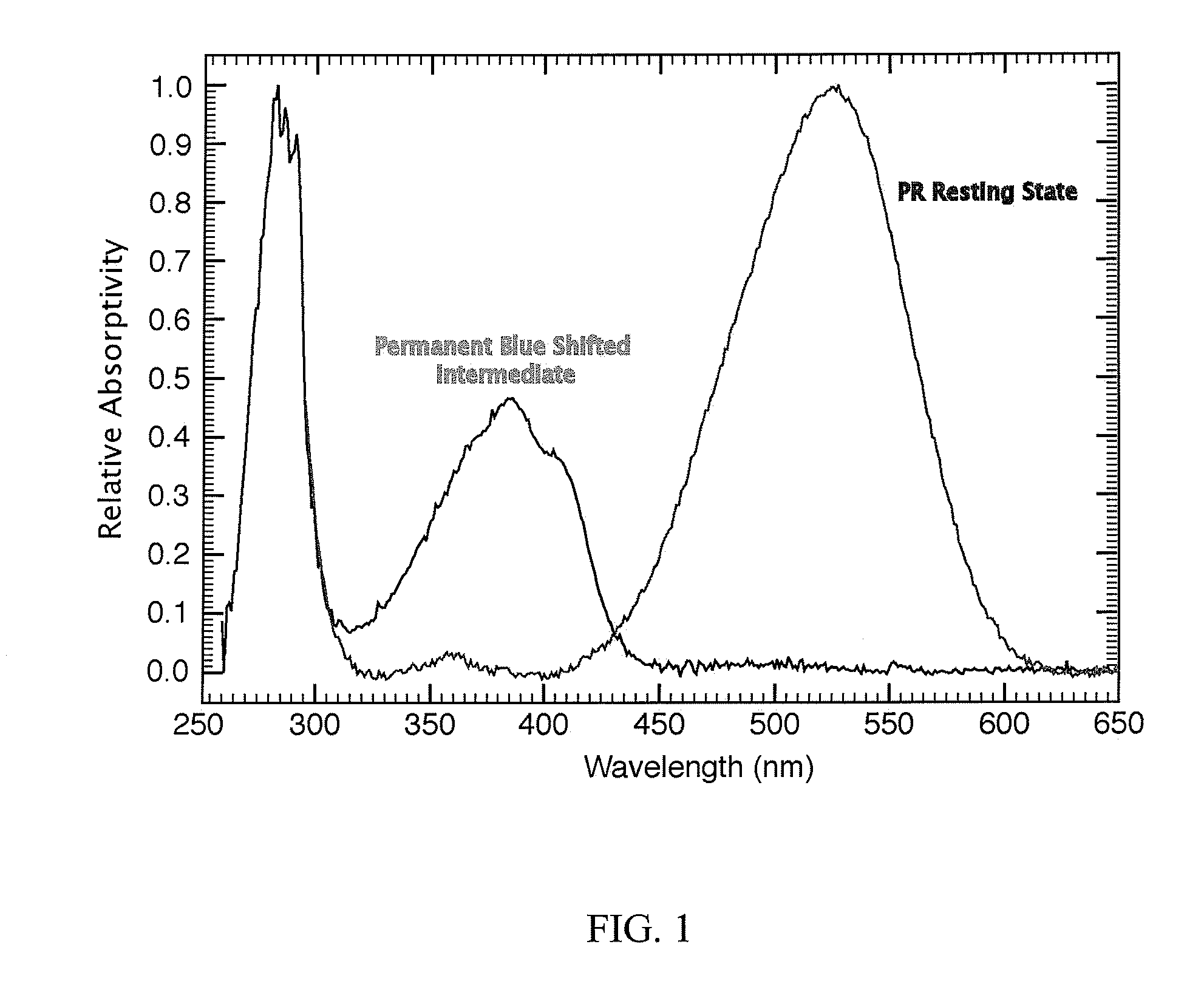

Binary Optical Compound and Method of Manufacture

InactiveUS20080057490A1High selectivityBioreactor/fermenter combinationsBiological substance pretreatmentsResponsivityChemicals exposure

A bacteriorhodopsin based chemical sensing architecture based upon the collective response of bacteriorhodopsin and a number of its mutants; the wild type protein and a selection of genetically-engineered variants was able to respond differentially to a selection of amines. The observable response to the presence of a target chemical was manifested through a modulation of bacteriorhodopsin's photokinetic properties, which are monitored through pump-probe techniques using a custom prototype flash photolysis system. Differential responsivity exists at two levels; (1) bacteriorhodopsin proteins (wild-type and genetically-engineered variants) respond differentially upon exposure of a target chemical, and (2) the response pattern exhibited by the proteins differs from chemical to chemical. This dichotomy forms the basis for a BR-mediated chemical sensing technology that is highly sensitive and selective and may therefore discriminate between different chemicals.

Owner:SYRACUSE UNIVERSITY +1

Bimetallic sensitive layer-based laser direct-writing grayscale mask manufacturing method

InactiveCN102043179AProcess stabilityGood repeatabilityPhotomechanical apparatusDiffraction gratingsEtchingExposure control

The invention relates to a bimetallic sensitive layer grayscale mask manufacturing method used for batch production of binary optical elements, which comprises the following three steps of: manufacturing a bimetallic sensitive layer, designing a grayscale mask exposure control program, and performing laser exposure, namely plating a bimetallic film on the surface of a mask substrate to form the bimetallic sensitive layer; and exposing the bimetallic sensitive layer by adopting a laser direct-writing method according to sensitive characteristic of transmissivity of the bimetallic sensitive layer relative to laser intensity so as to form a grayscale mask of which the transmissivity is matched with diffraction microstructure design information of a binary optical element, wherein the grayscale mask comprises phase information of a plurality of binary optical elements, and the needed binary optical element is obtained through primary photoetching process and etching. Because the grayscale mask can be repeatedly used, the grayscale mask can be used for batch production of the binary optical elements.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

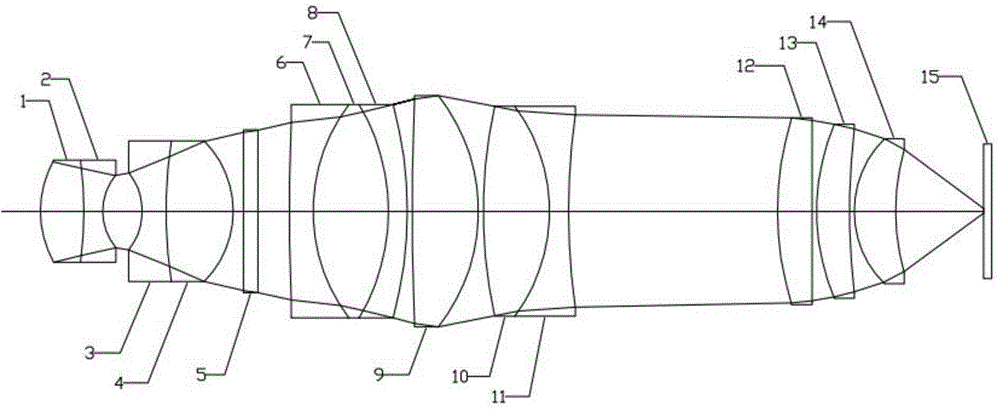

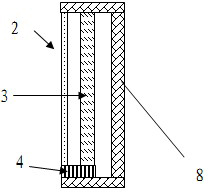

Infrared optical system

The invention provides an infrared optical system and relates to an infrared imaging guidance optical system in infrared / laser dual mode guidance. The infrared optical system is sequentially and coaxially provided with a fairing (1), a first lens group (2), a prism (3), a second lens group (4) and an infrared imaging detector (5) from the object plane to the image plane. By adopting a refraction secondary imaging structure, the demand of large visual filed is met, meanwhile, cold diaphragm efficiency of 100% is achieved, a field diaphragm is arranged in the middle of the image plane, stray light can be restrained effectively, and in addition, the infrared optical system is suitable for small pixel detectors and improves imaging resolution of the system. By adopting aspheric surface and binary optics technology, the infrared optical system effectively improves imaging quality of the system, and simplifies the structure of the system. Thus, the infrared optical system has the advantages of being large in visual field, and high in resolution and accuracy.

Owner:严格集团股份有限公司

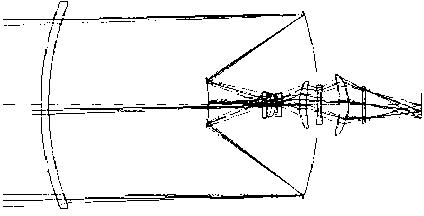

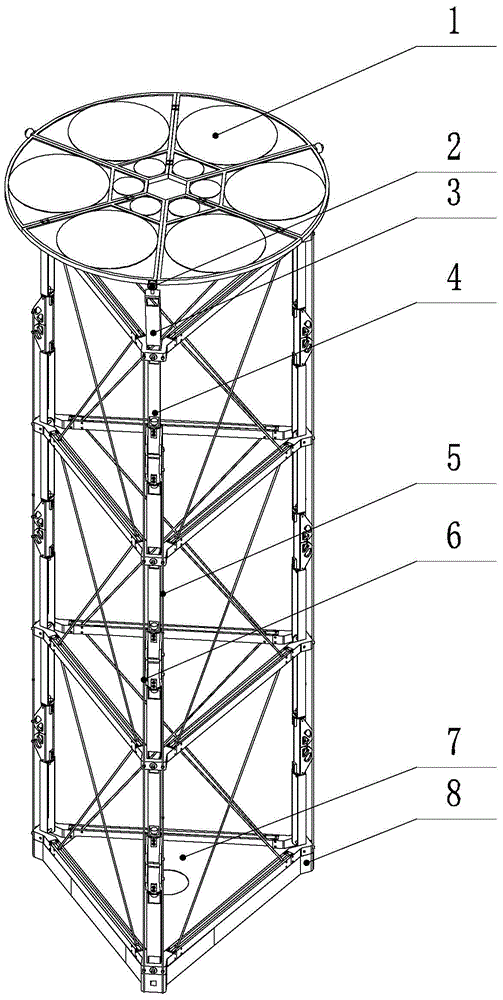

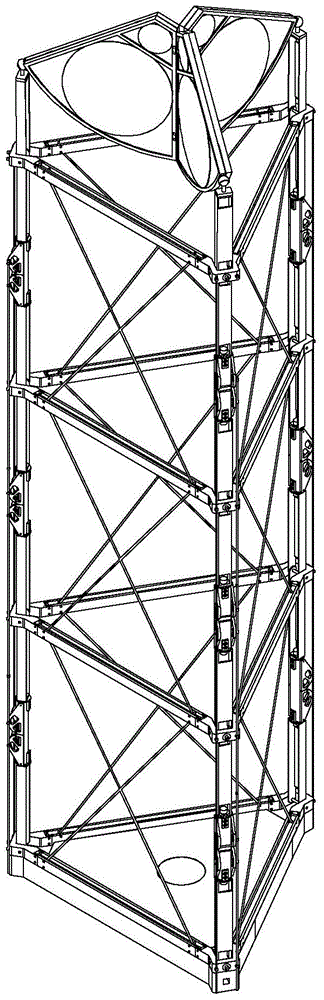

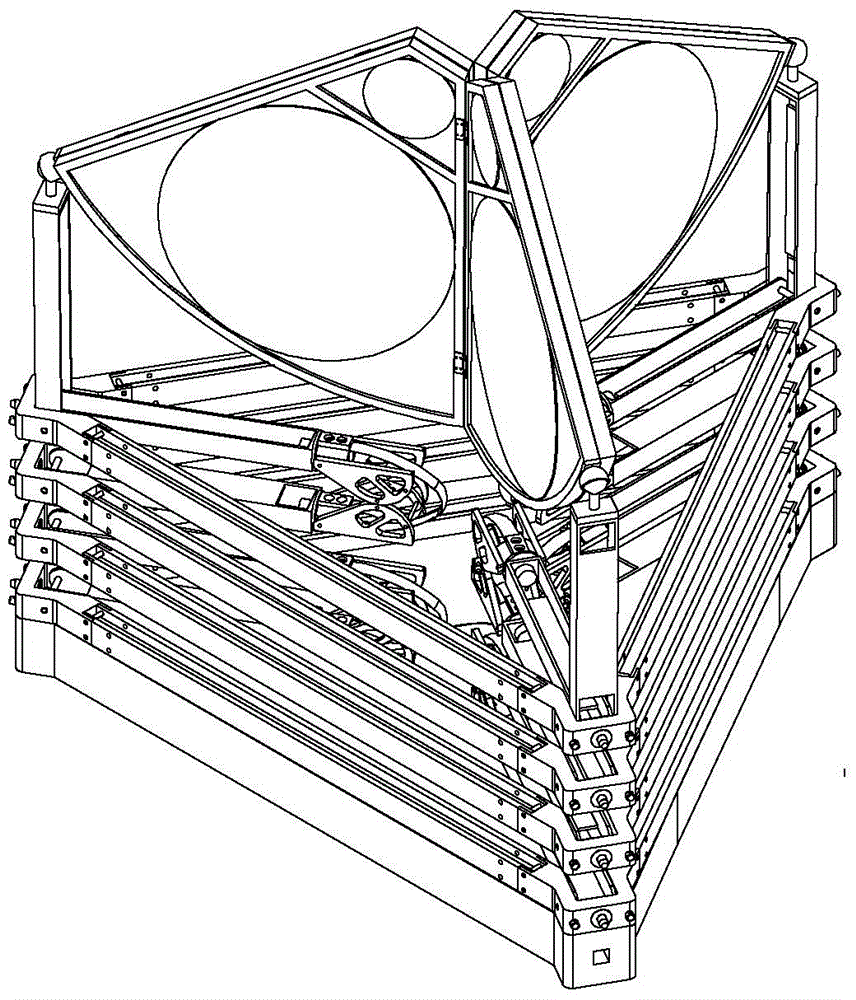

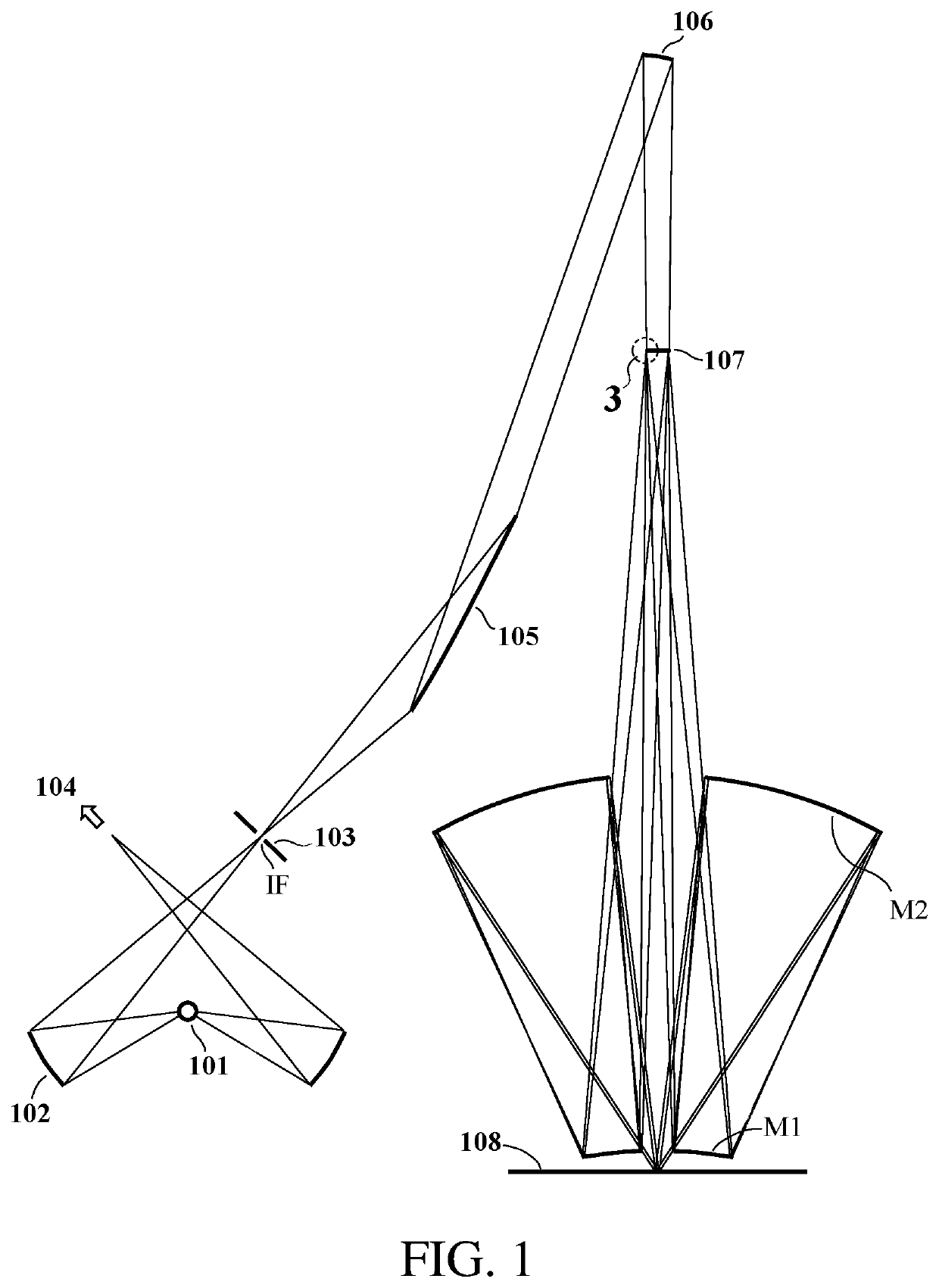

Space stretchable truss type binary optical camera and its working method on orbit

The invention provides a telescopic truss type binary optical space camera and an on-orbit work method thereof and belongs to the field of spaceflight space repeatable unfolding. The telescopic truss type binary optical space camera aims to solve the problems that an existing space foldable and spreadable framework type supporting arm is complicated in structure, heavy and difficult to repeatedly fold and unfold. A partitioned type spreadable optical main lens of the telescopic truss type binary optical space camera is installed on a supporting arm through three ball hinges. The supporting arm comprises multiple framework type foldable units. The on-orbit work method comprises the steps that during launching, the supporting arm and the partitioned type spreadable optical main lens are in a folded mode, and the optical camera is in a launch closed mode; after injection, the supporting arm is switched to a unfolding mode and is unfolded; after the supporting arm is unfolded appropriately, the space camera is switched to an on-orbit operation mode, and the partitioned type spreadable optical main lens is unfolded; when the space camera is switched to an on-orbit closed mode, the supporting arm is folded, and the partitioned type spreadable optical main lens is unfolded. The telescopic truss type binary optical space camera is a large-caliber space camera.

Owner:HARBIN INST OF TECH

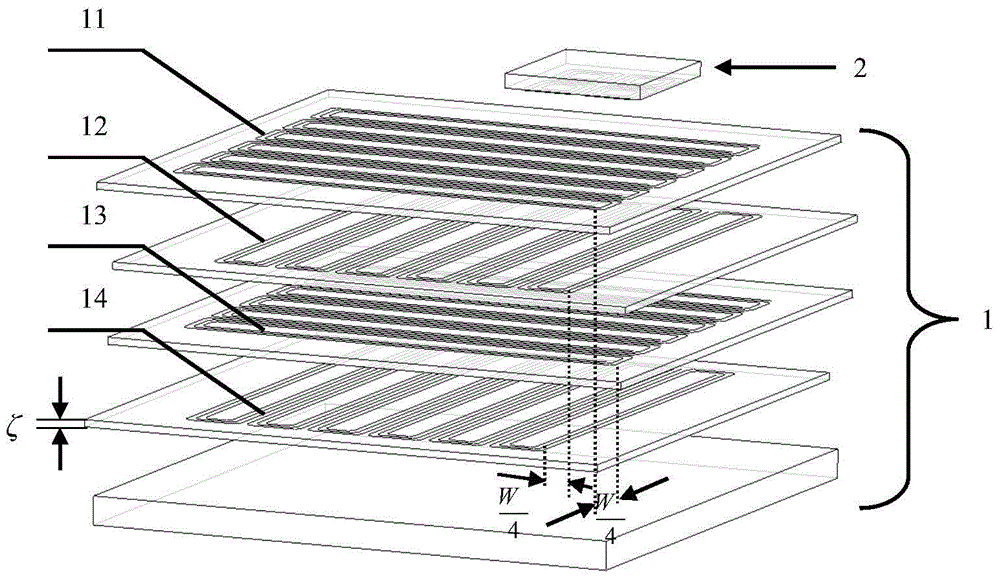

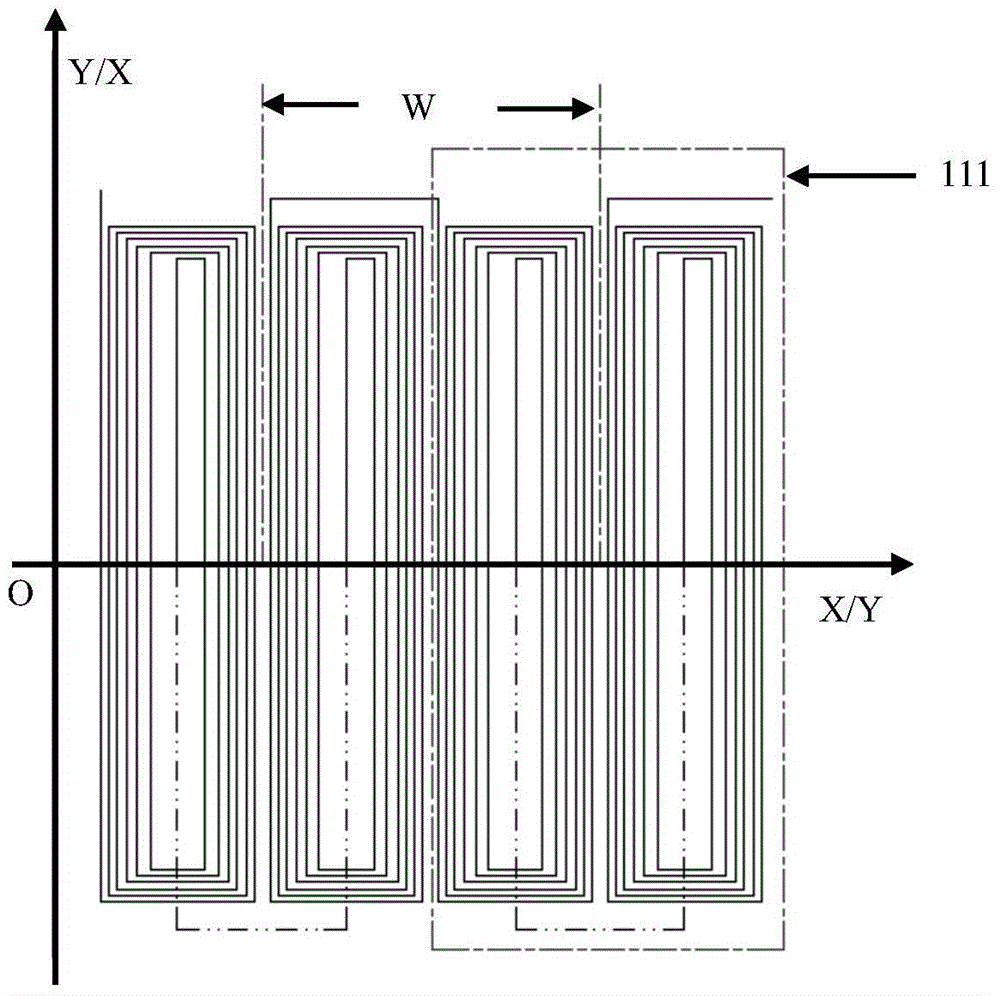

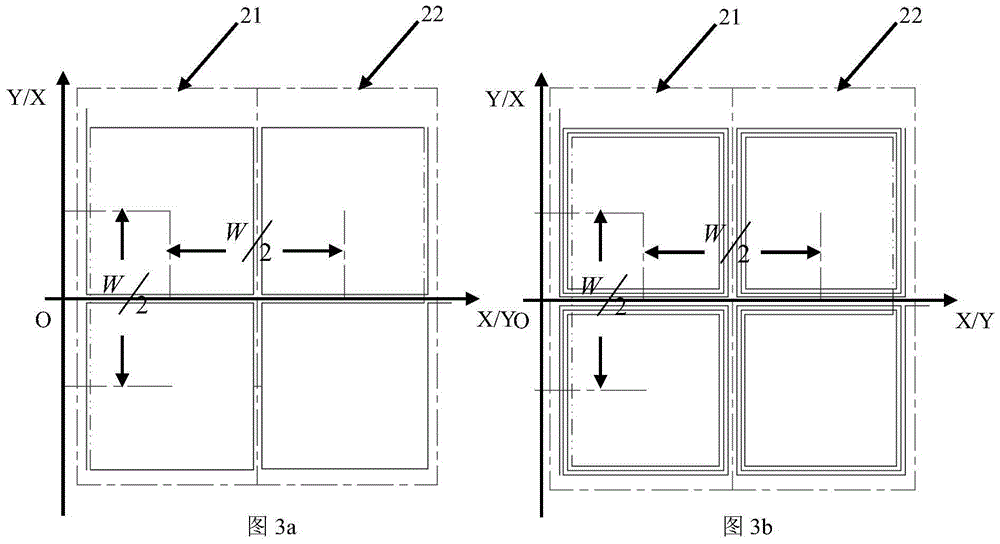

A planar two-dimensional time grating displacement sensor

The invention proposes a planar two-dimensional time grating displacement sensor, which is composed of two parts, a fixed array surface and a dynamic array surface arranged in parallel and oppositely up and down. The fixed array is composed of a base of the fixed array and excitation coils arranged on the surface of the base of the fixed array; the moving array is composed of the base of the moving array and the induction coil arranged on the surface of the base of the moving array. Using a single moving array surface to obtain magnetic signals at different positions on a fixed array surface through the principle of electromagnetic induction, using the theory of space-time coordinate transformation, the magnetic signal (spatial information) is converted into an electrical signal (time information) for processing, so as to obtain a two-dimensional space displacement. The present invention does not need to vertically install two linear displacement sensors, does not need binary optical devices prepared by complicated processes, and does not need complicated optical path design, and adopts ordinary semiconductor processing technology to prepare the dynamic array surface and the fixed array surface, so it has simple structure, Low cost, strong resistance to oil dust and shock vibration.

Owner:CHONGQING UNIV OF TECH

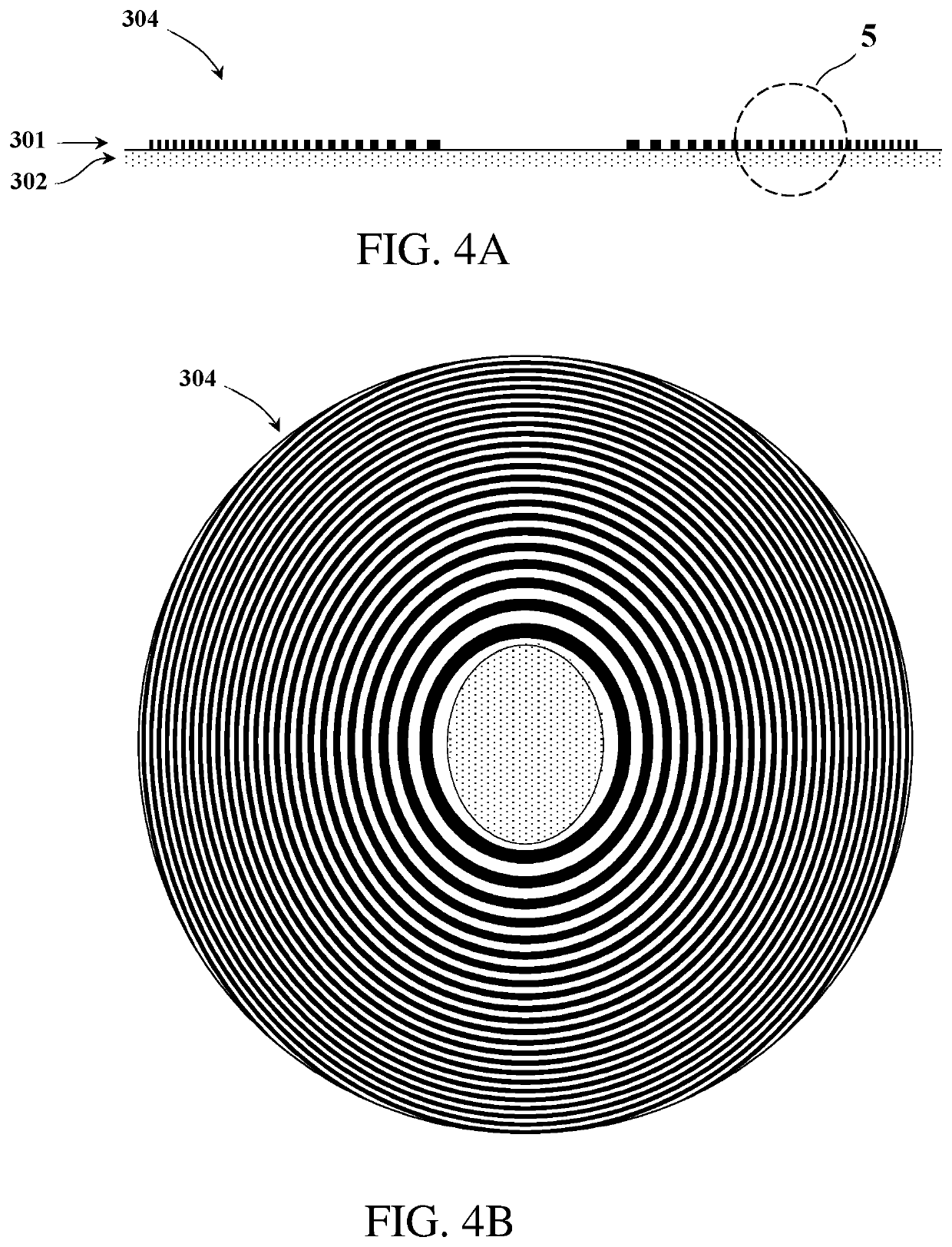

EUV Lithography System with Diffraction Optics

ActiveUS20220107568A1Chromatic aberrationOffsetting effectDiffraction gratingsPhotomechanical exposure apparatusLight spotEngineering

A maskless, extreme ultraviolet (EUV) lithography scanner uses an array of microlenses, such as binary-optic, zone-plate lenses, to focus EUV radiation onto an array of focus spots (e.g. about 2 million spots), which are imaged through projection optics (e.g., two EUV mirrors) onto a writing surface (e.g., at 6X reduction, numerical aperture 0.55). The surface is scanned while the spots are modulated to form a high-resolution, digitally synthesized exposure image. The projection system includes a diffractive mirror, which operates in combination with the microlenses to achieve point imaging performance substantially free of geometric and chromatic aberration. Similarly, a holographic EUV lithography stepper can use a diffractive photomask in conjunction with a diffractive projection mirror to achieve substantially aberration-free, full-field imaging performance for high-throughput, mask-projection lithography. Maskless and holographic EUV lithography can both be implemented at the industry-standard 13.5-nm wavelength, and could potentially be adapted for operation at a 6.7-nm wavelength.

Owner:JOHNSON KENNETH CARLISLE

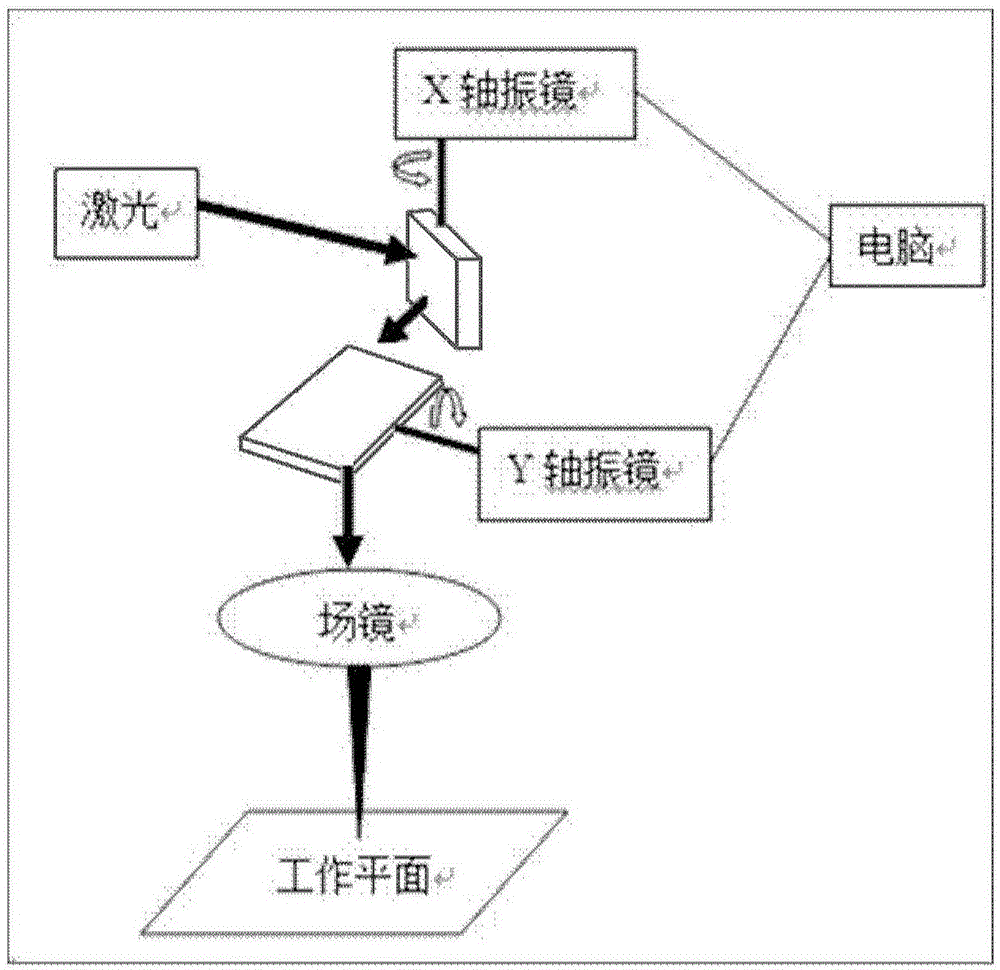

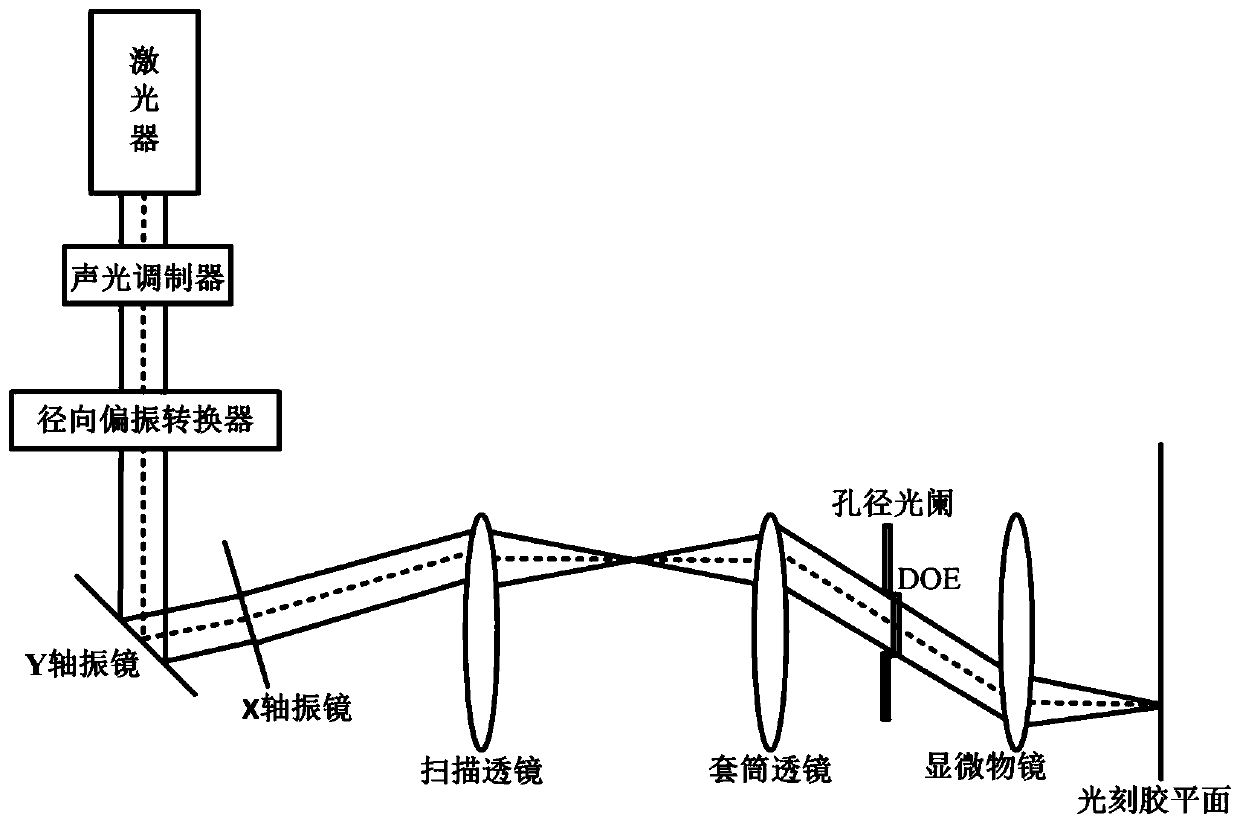

High-efficiency laser direct-writing photoetching method capable of realizing long-focal-depth small-focal-spot structure

ActiveCN110837215AJiao ShendaSmall focal spotPhotomechanical exposure apparatusMicrolithography exposure apparatusHigh numerical apertureImage resolution

The invention discloses a high-efficiency laser direct-writing photoetching method capable of realizing a long-focal-depth small-focal-spot structure. Phase modulation is carried out through DOE, so that the diffraction limit can be exceeded, and the resolution and the focal depth of an optical pin are improved; movement of the optical pin on a photoresist plane can be achieved through optical scanning, and the laser direct writing photoetching speed is increased. The optical scanning system utilizes a two-dimensional galvanometer system to generate small-angle deflection of -10 degrees to +10degrees in the X-axis direction and the Y-axis direction. An X-axis galvanometer vibrates along the X-axis direction, a Y-axis galvanometer vibrates along the Y-axis direction, the galvanometers arerespectively driven by two drivers, incident radial polarized light passes through the X-axis galvanometer and the Y-axis galvanometer and then obliquely enters through a scanning lens, a sleeve lens,a pure-phase binary optical element and a high-numerical-aperture microscope objective in sequence, and then an optical pin which moves along the X axis and the Y axis and has resolution, focal depthand uniformity not affected by angle deflection is generated near a focal plane. And the resolution, the focal depth and the direct writing efficiency of laser direct writing photoetching are improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

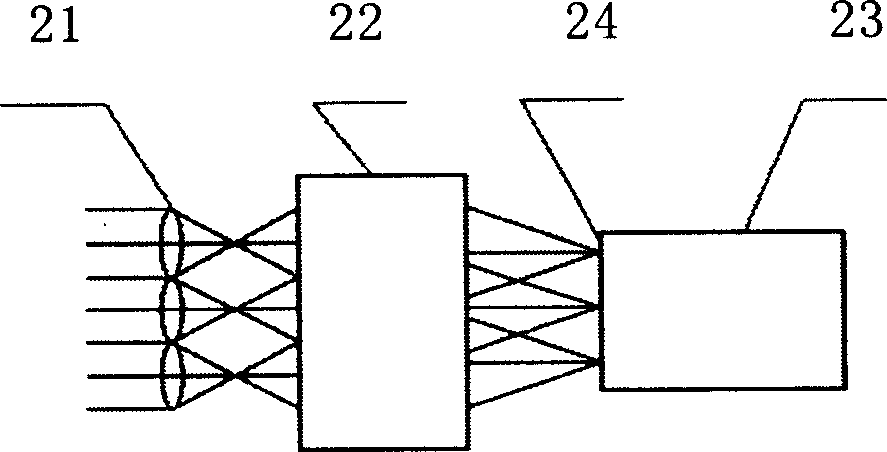

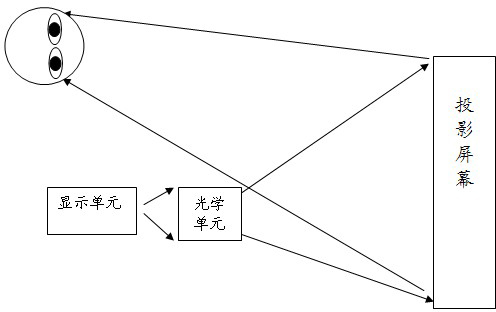

Energy-saving display system based on binary optics

InactiveCN102213902ARealize energy savingGuaranteed viewingBuilt-on/built-in screen projectorsProjection screenComputer science

The invention relates to an energy-saving display system based on binary optics, comprising a display unit, an optical unit, a projection screen and an adjusting device, wherein the display unit is used for transmitting an image to the optical unit; the optical unit is used for projecting an optical signal of the image to the projection screen; the projection screen is used for directionally reflecting the optical signal of the image to double eyes of a viewer to be imaged; and the adjusting device is used for adjusting the projection direction and the projection position of the optical signal of the image of the optical unit. The energy-saving display system has the advantages of reduced display energy consumption, simple structure, low cost, and the like.

Owner:SUN YAT SEN UNIV

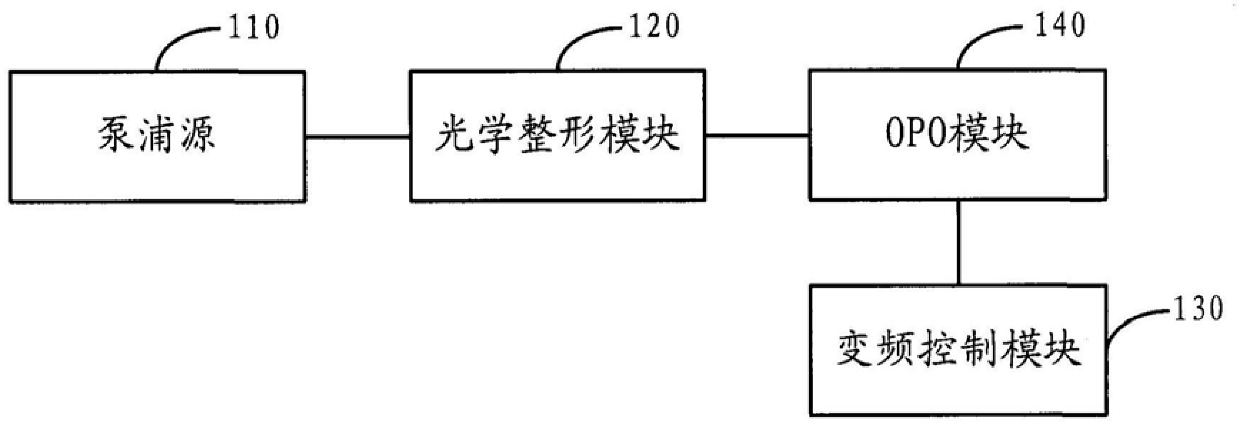

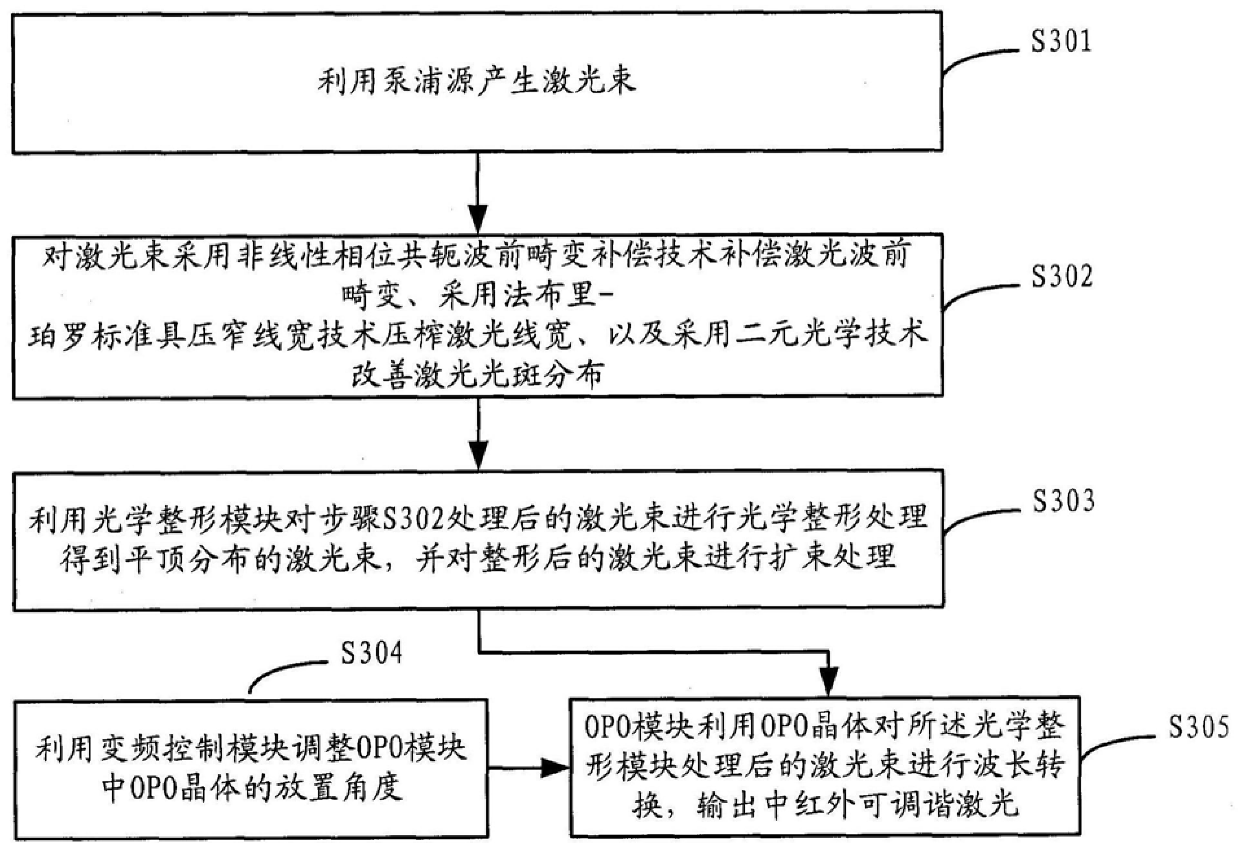

A high peak power mid-infrared tunable laser emitting device and method

The invention discloses a high peak power mid-infrared tunable laser emission device and method, the device includes: a pump source for generating a laser beam, and adopts nonlinear phase conjugate wavefront distortion compensation for the laser beam technology to compensate laser wavefront distortion, use Fabry-Perot etalon to narrow line width technology to squeeze laser line width, and use binary optical technology to improve laser spot distribution; optical shaping module is used to process the pump source The final laser is optically shaped to obtain a laser beam with a flat top distribution, and the shaped laser beam is expanded; the frequency conversion control module is used to adjust the placement angle of the OPO crystal in the OPO module; the OPO module is used to use the OPO The crystal performs wavelength conversion on the laser beam processed by the optical shaping module, and outputs a mid-infrared tunable laser. The invention can take into account both high peak power and tunability, and can achieve wider application in mid-infrared laser interference.

Owner:NO 27 RES INST CHINA ELECTRONICS TECH GRP

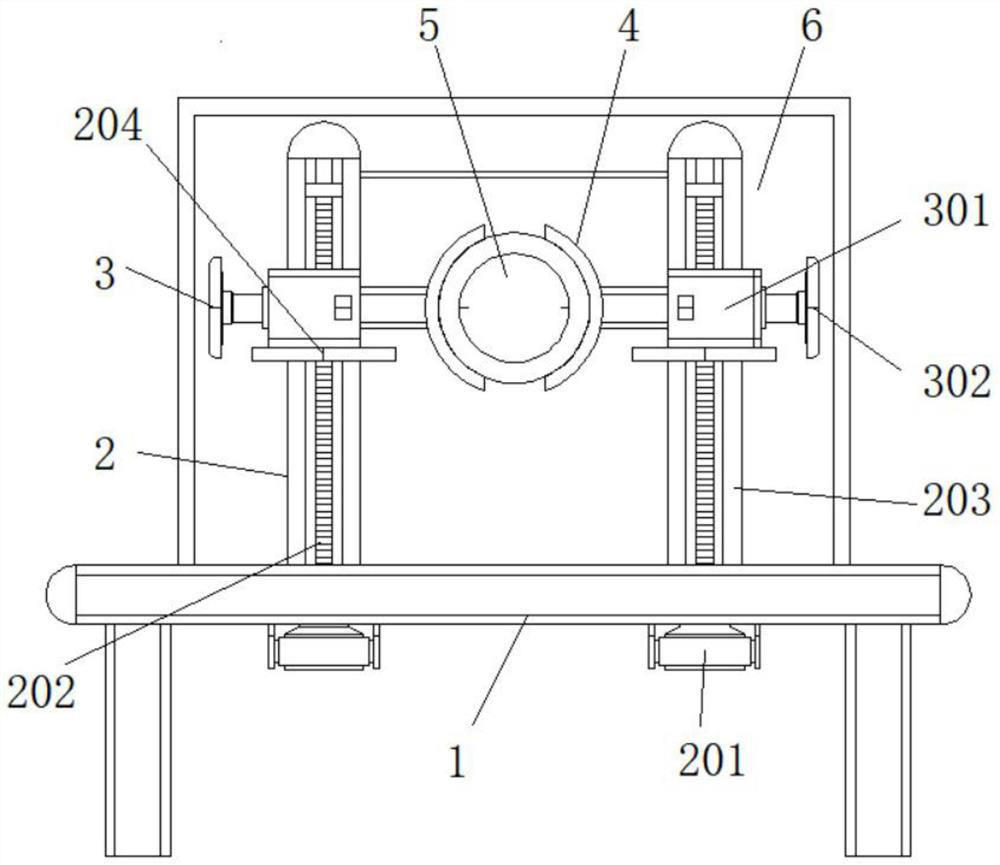

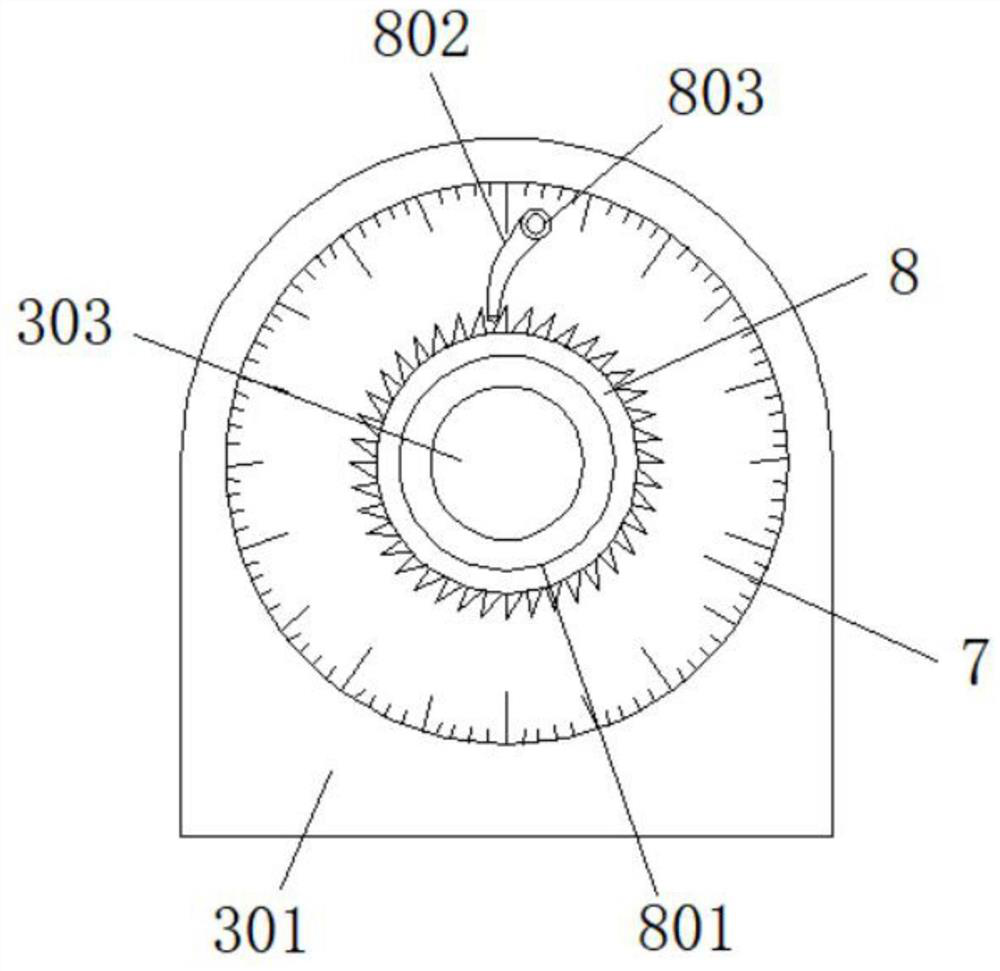

Binary optical lens with high dispersion and high refractive index

ActiveCN112034582AAutomatic height adjustmentGuaranteed stabilityMountingsRefractive indexMaterials science

The invention discloses a binary optical lens with high dispersion and high refractive index. The binary optical lens comprises a lens experiment bearing platform and a chromatography laying clampingstructure, binary optical lens height adjusting mechanisms are arranged on the two sides of the upper end of the lens experiment bearing platform, one side of each binary optical lens height adjustingmechanism is connected with a binary optical lens angle adjusting structure, the chromatography laying clamping structure is arranged behind the binary optical lens, angle scale marks are arranged onthe surface of the binary optical lens angle adjusting structures, and a lens angle locking structure is arranged on one side of each angle scale mark. After polychromatic light enters the binary optical lens, because the binary optical lens has different refractive indexes for light with various frequencies and the propagation directions of the polychromatic light have different degrees of deflection, the polychromatic light is respectively dispersed and forms a spectrum when leaving the binary optical lens, so that the spectrum can be compared with the arranged spectrum, and the use convenience of the binary optical lens can be improved.

Owner:NANTONG XIANGYANG OPTICAL ELEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com