Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Improve lithography efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

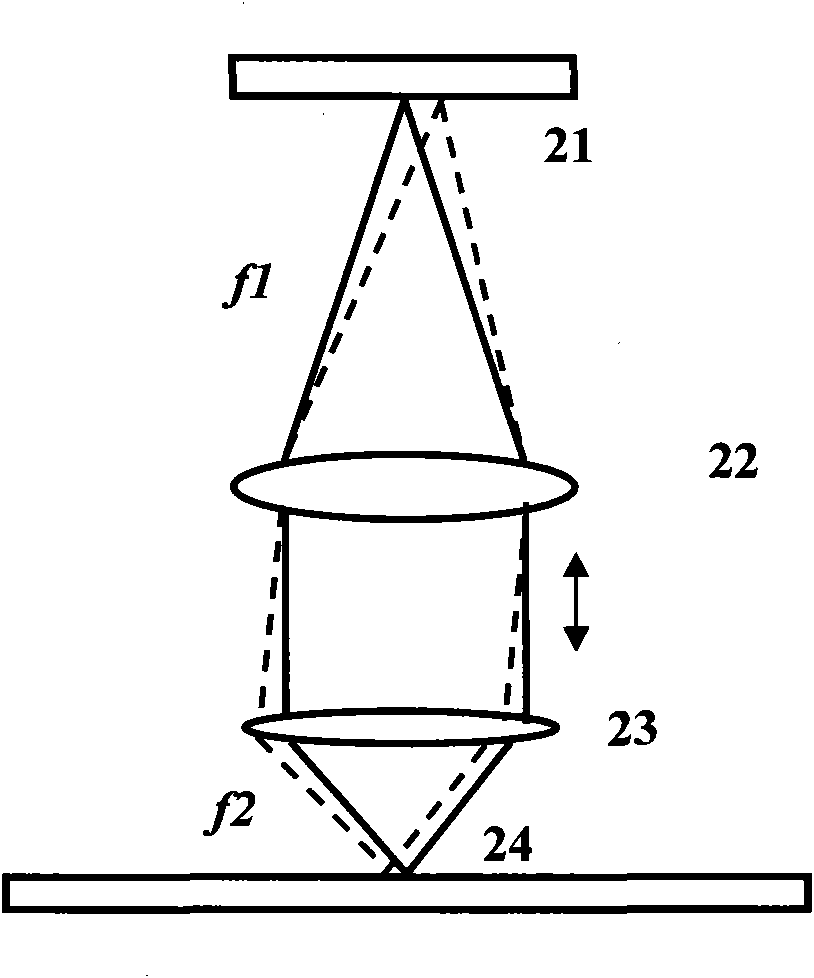

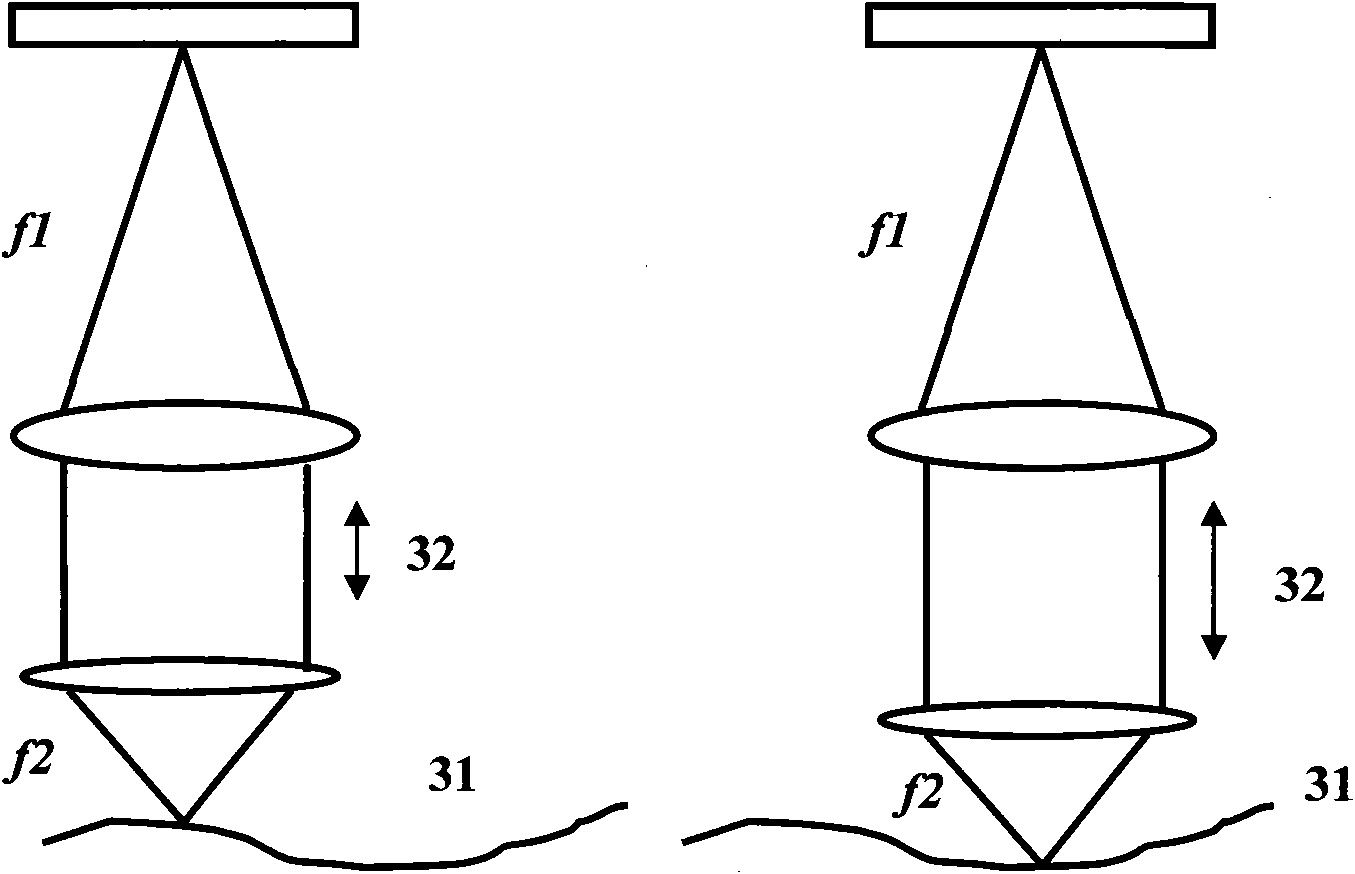

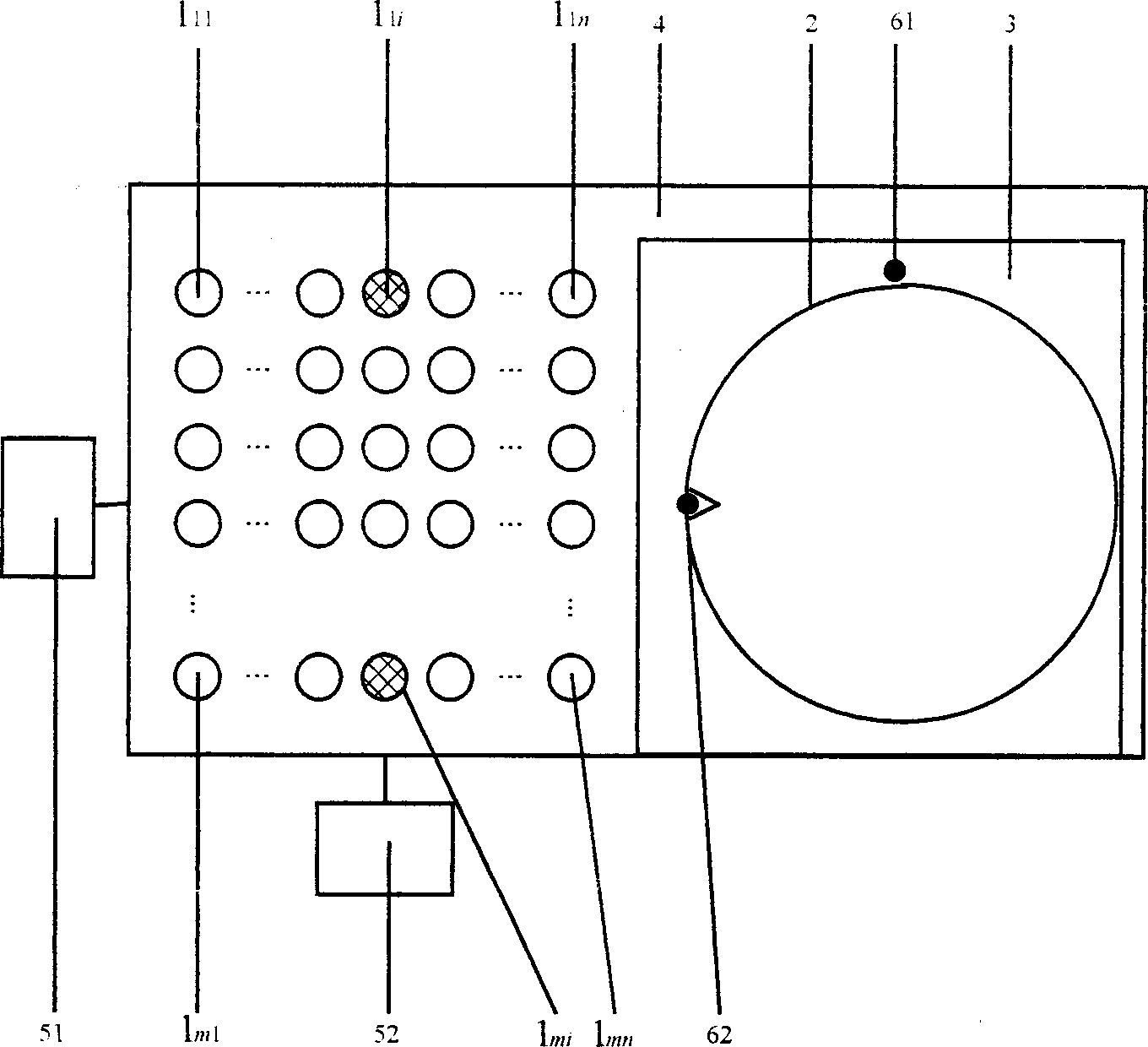

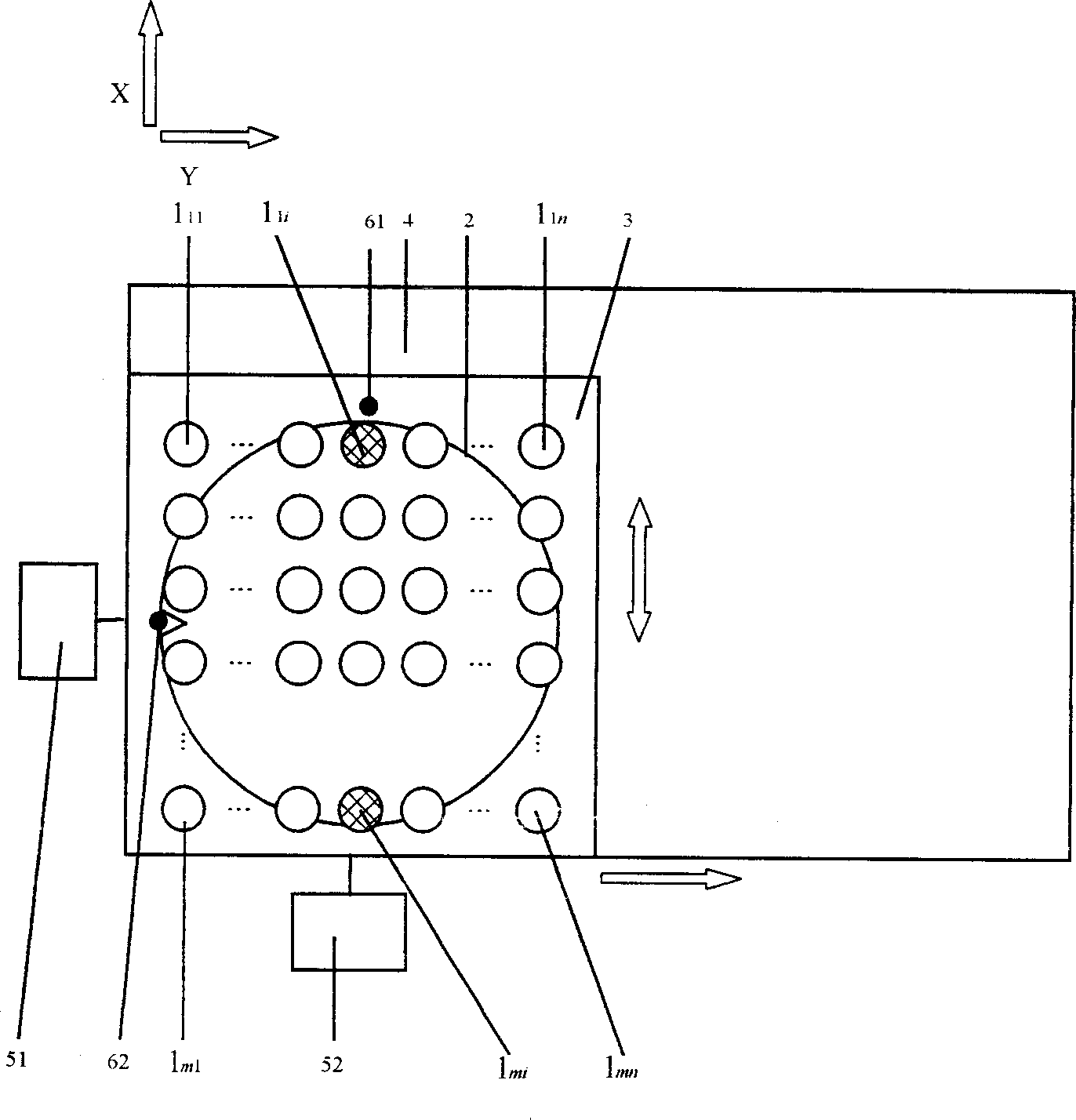

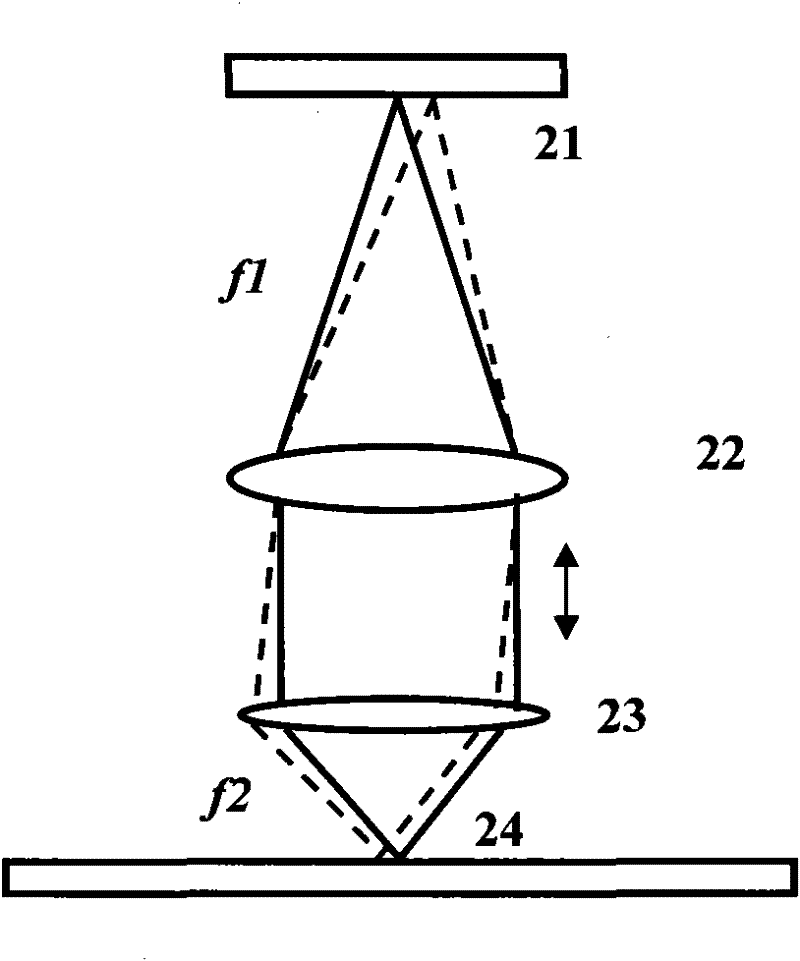

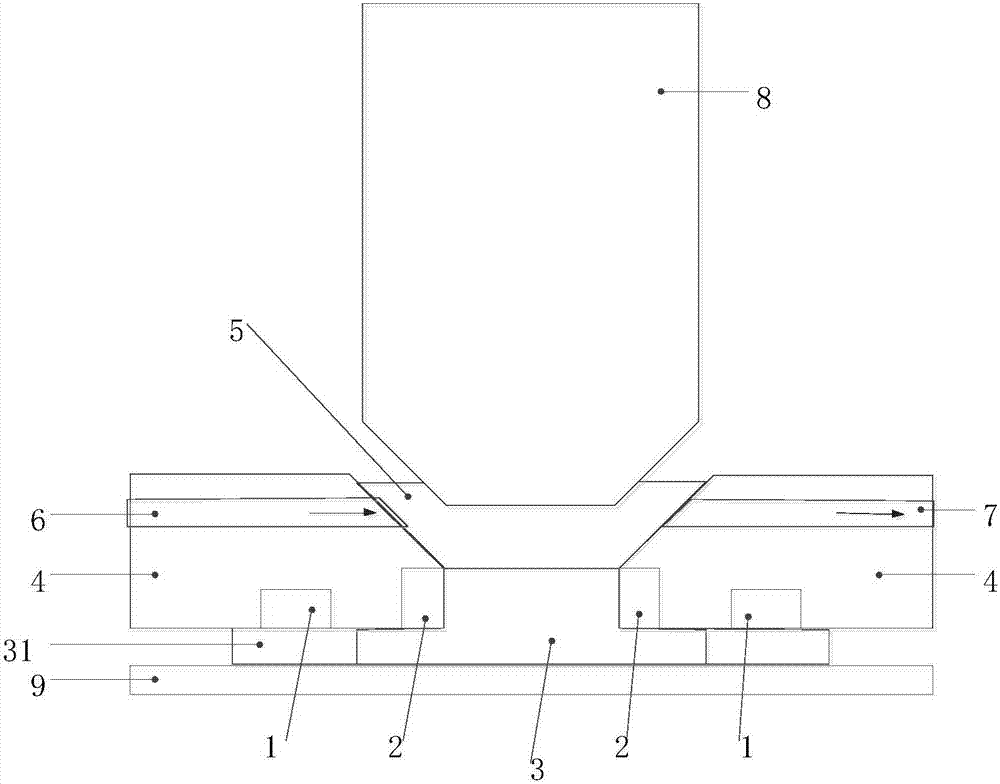

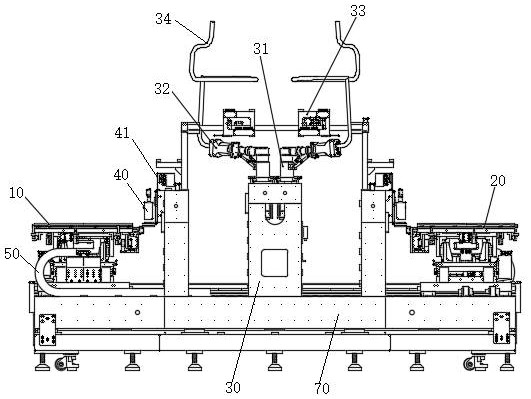

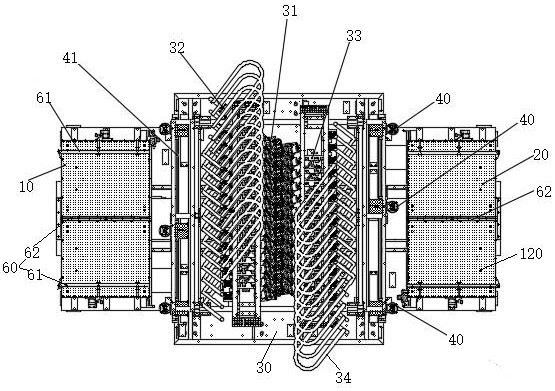

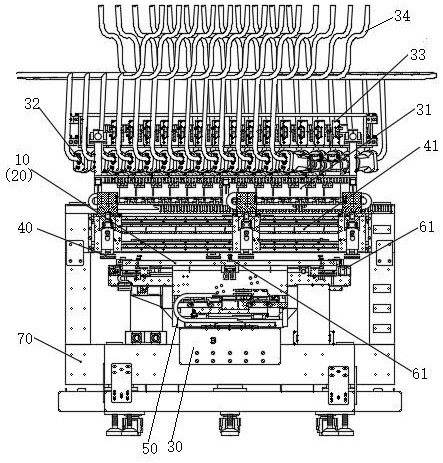

Parallel photoetching write-through system

ActiveCN101846890ARealize 3D structure fabricationImprove lithography efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusMicro structureControl system

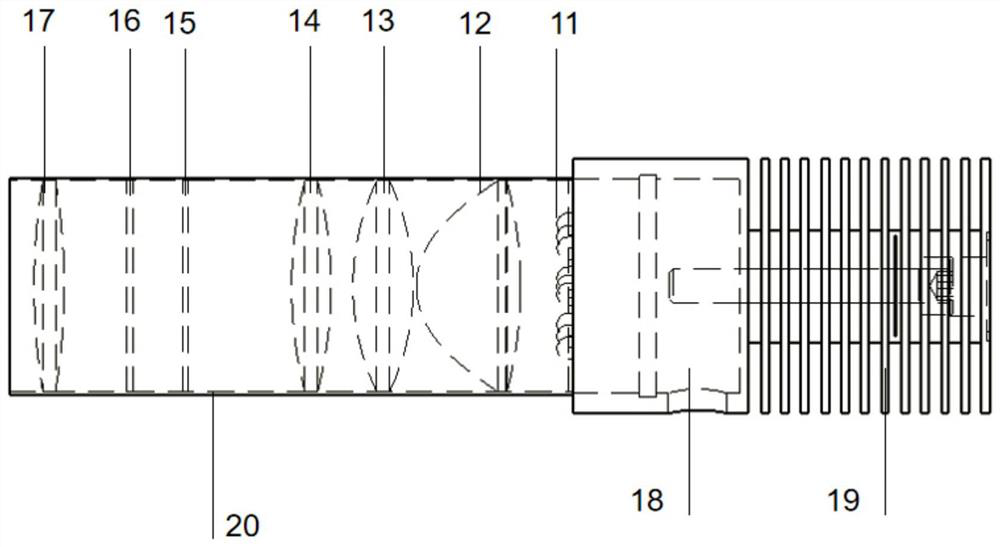

The invention discloses a parallel photoetching write-through system which comprises a light source, a pattern generating system, an optical system, a control system, a moving system and a workpiece platform. The parallel photoetching write-through system is characterized by also being provided with a focusing servo system, the focusing servo system comprises a detection light path, a sensor and a focusing device, the optical system comprises a micro-system and a detection light path, wherein the micro-system adopts a double axifugal optical system, the detection light path comprises a detection light source, a first light splitter arranged in the double axifugal optical system and a second light splitter arranged between the detection light source and the first light splitter; detection light enters the double axifugal optical system through the first light splitter and irradiates on a workpiece of the workpiece platform; reflective light is received by the sensor through the first light splitter and the second light splitter; and the control system controls the action of the focusing device according to signals of the sensor to realize servo focusing. The invention can realize accurate photoetching of a submicron micro-structure by combining with a focusing imaging servo system.

Owner:SVG TECH GRP CO LTD +1

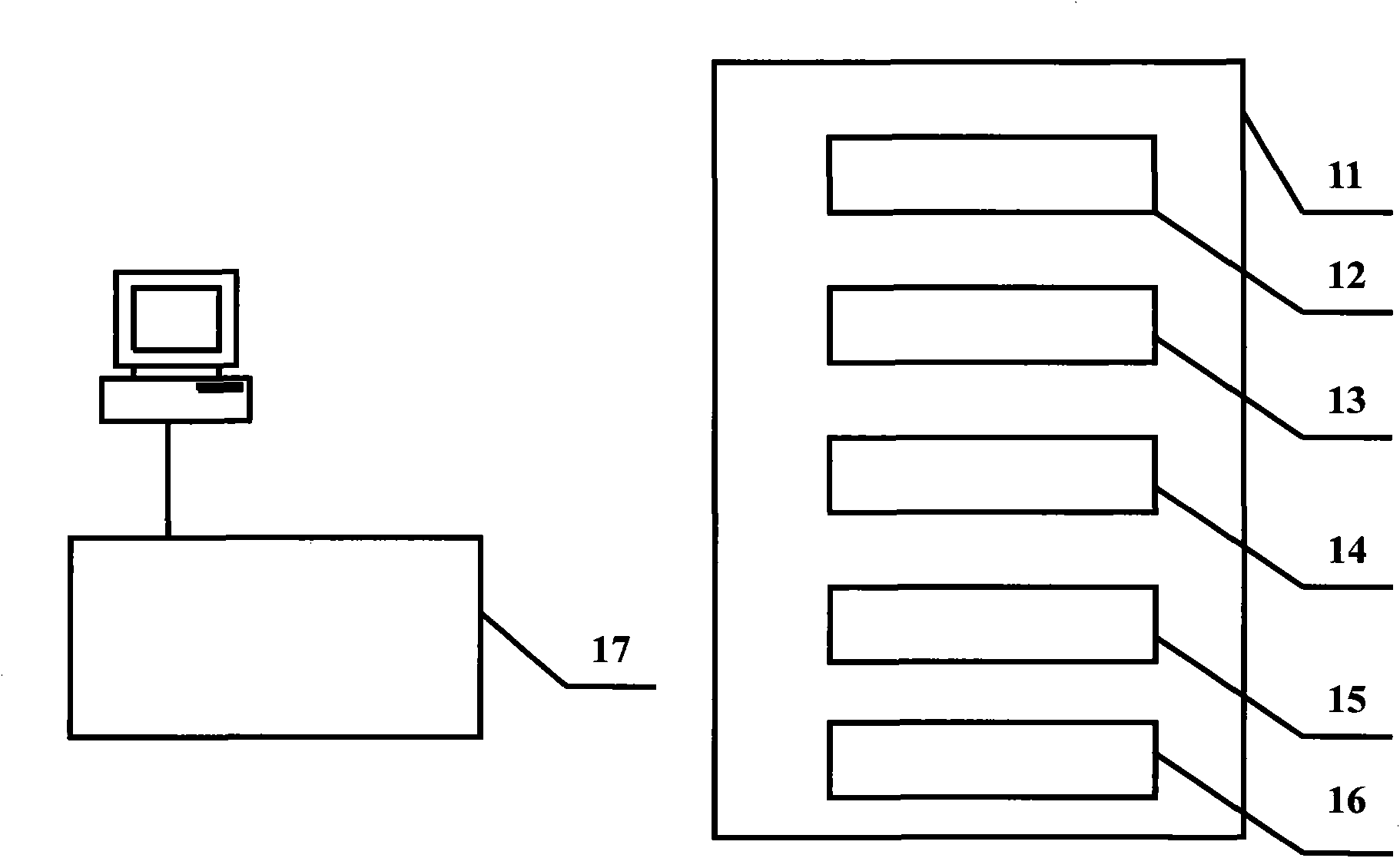

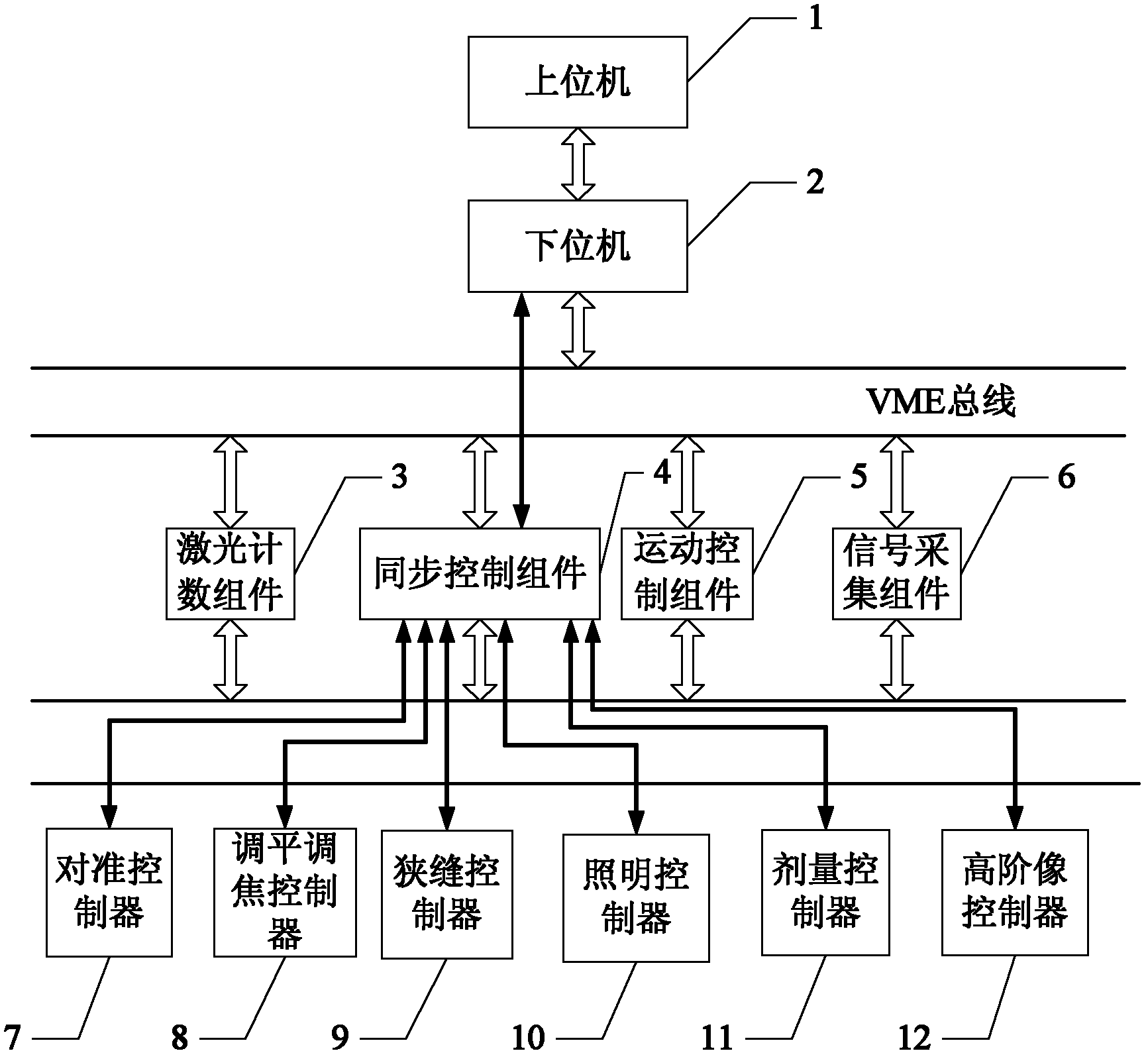

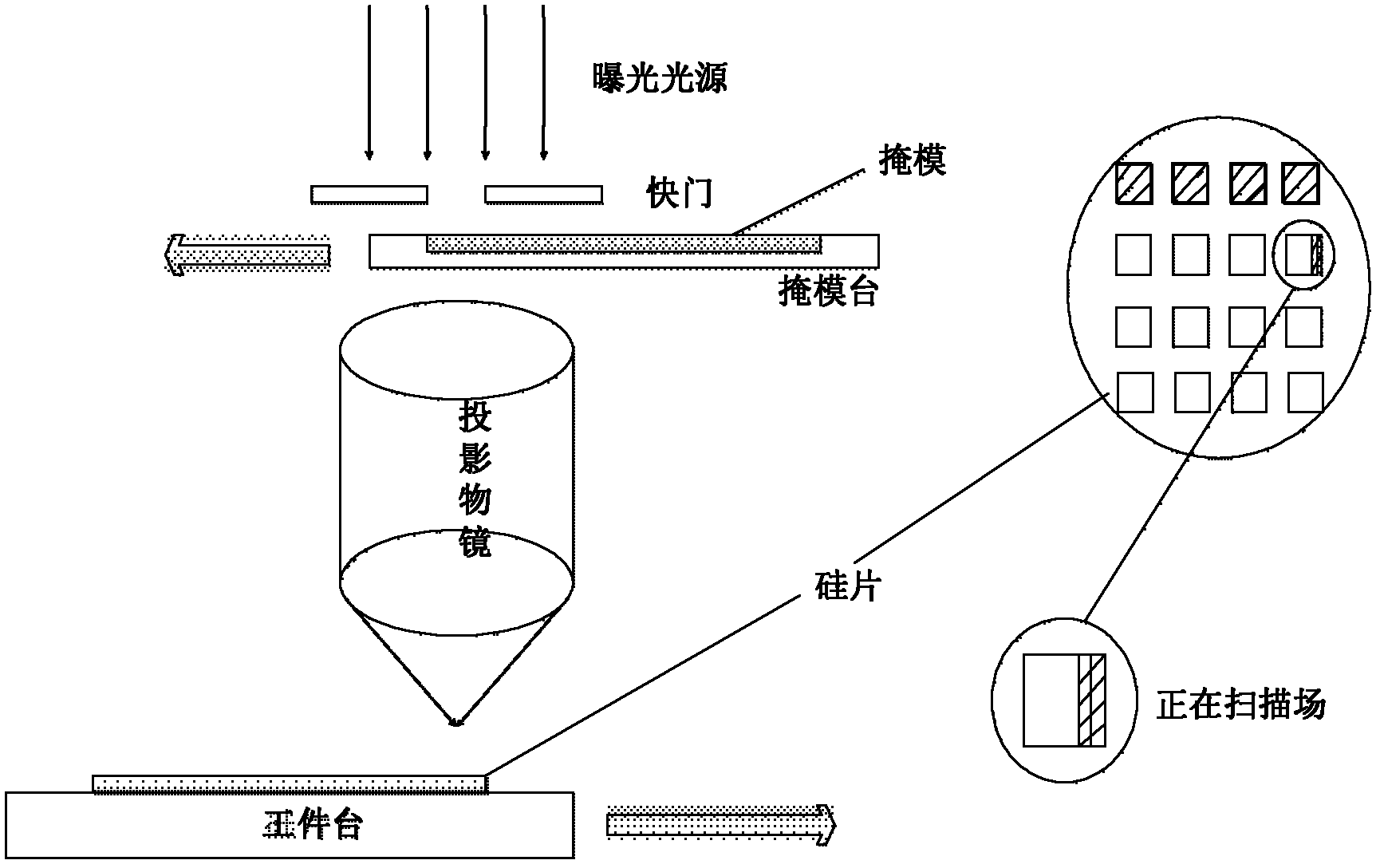

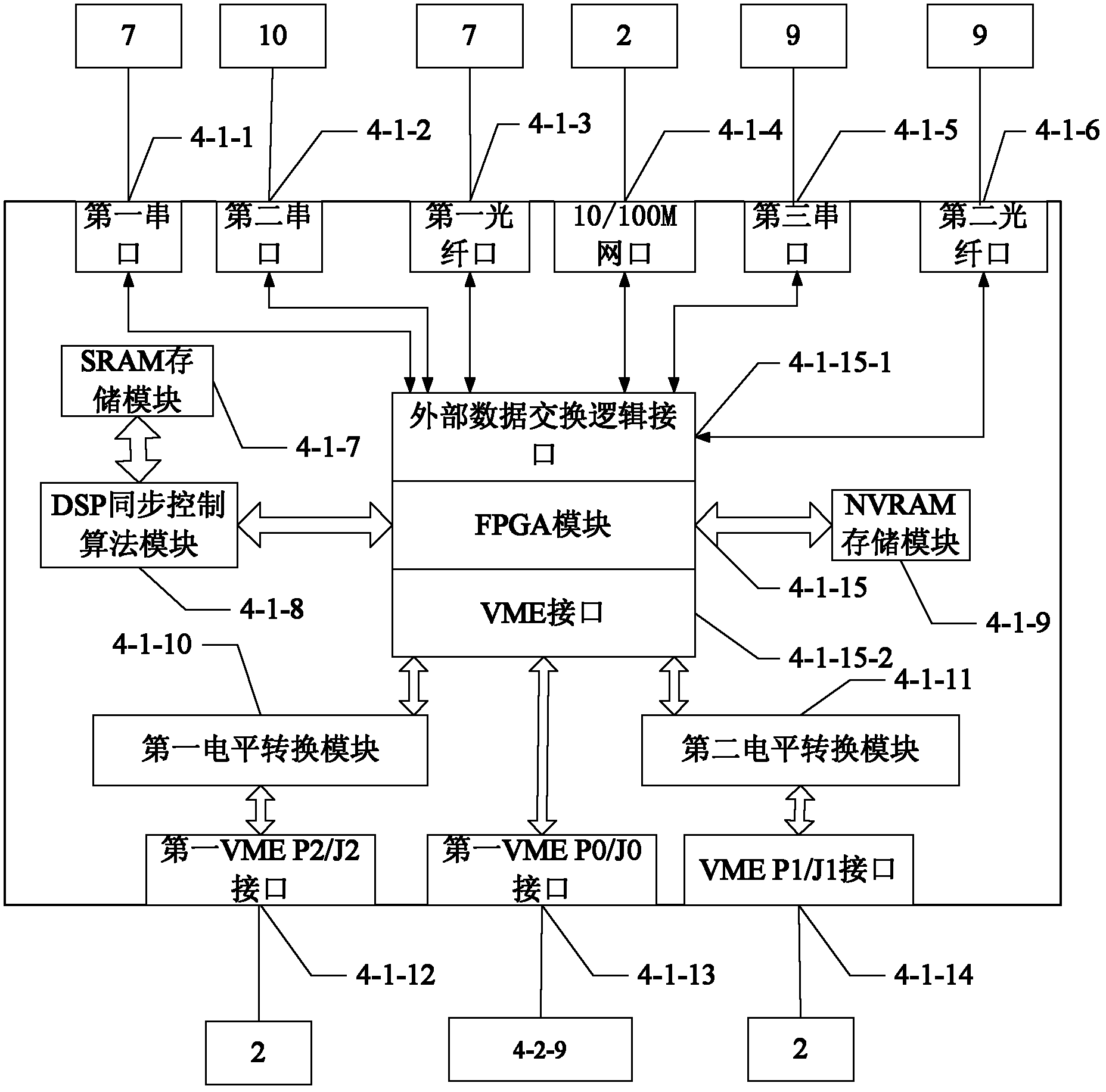

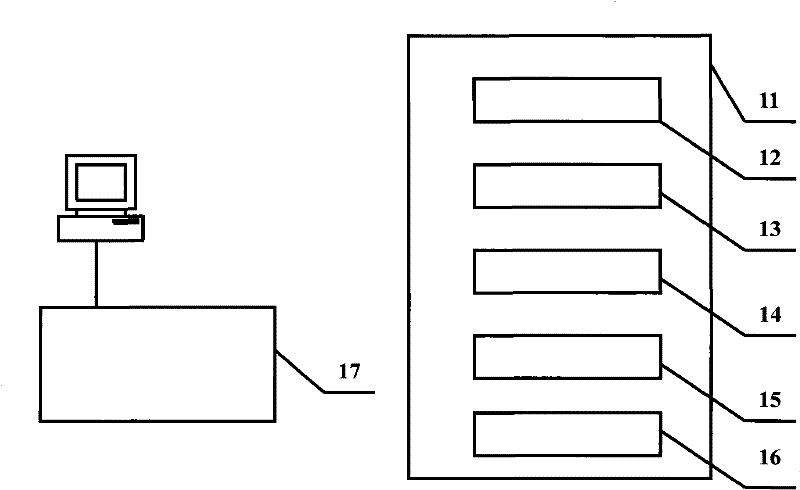

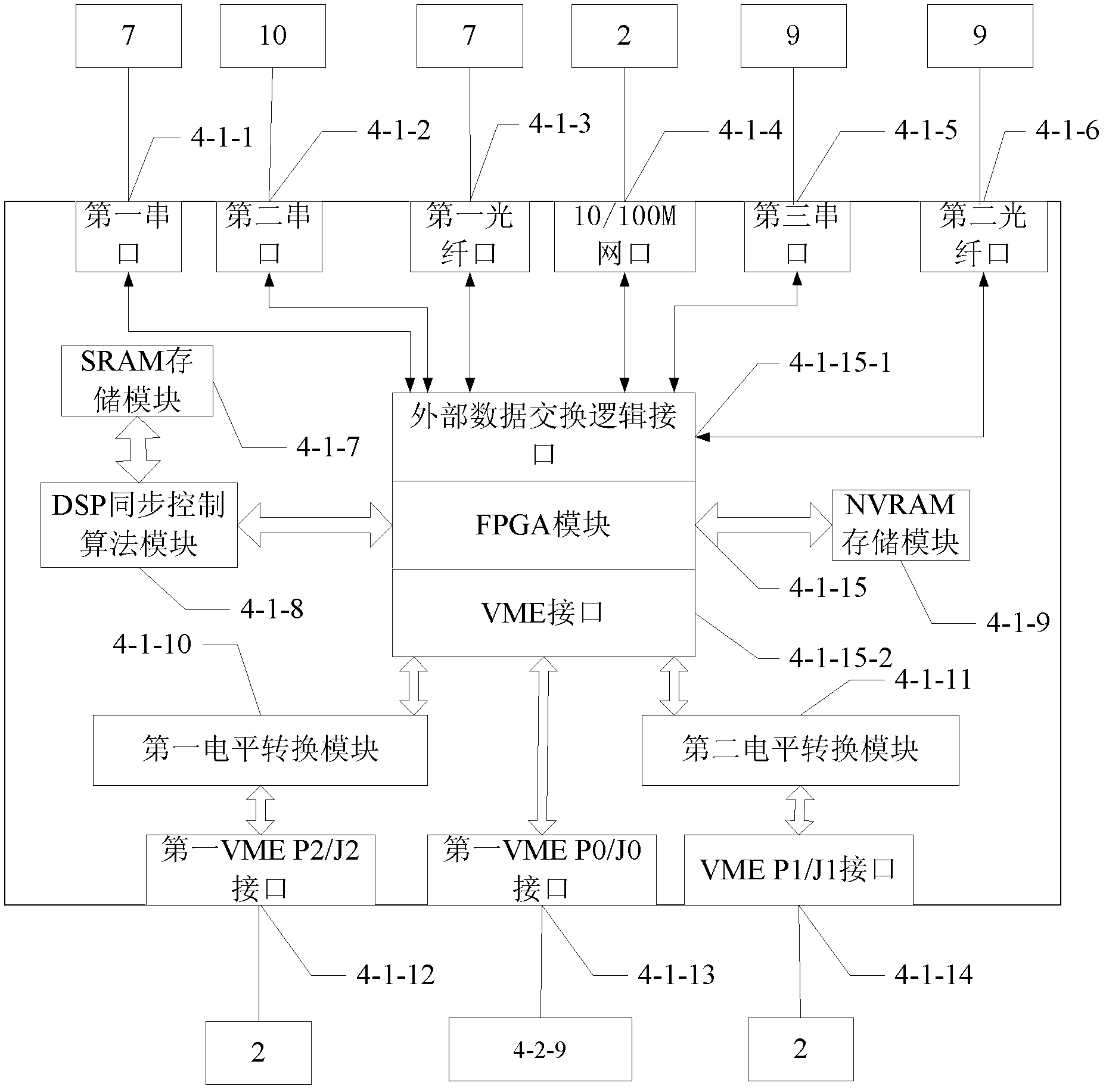

Synchronous control system of step scanning photoetching machine based on VME (Virtual Mobile Engine) bus and synchronous control method thereof

InactiveCN102621826AControl and reduce synchronization errorsImprove lithography efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusSynchronous controlMovement control

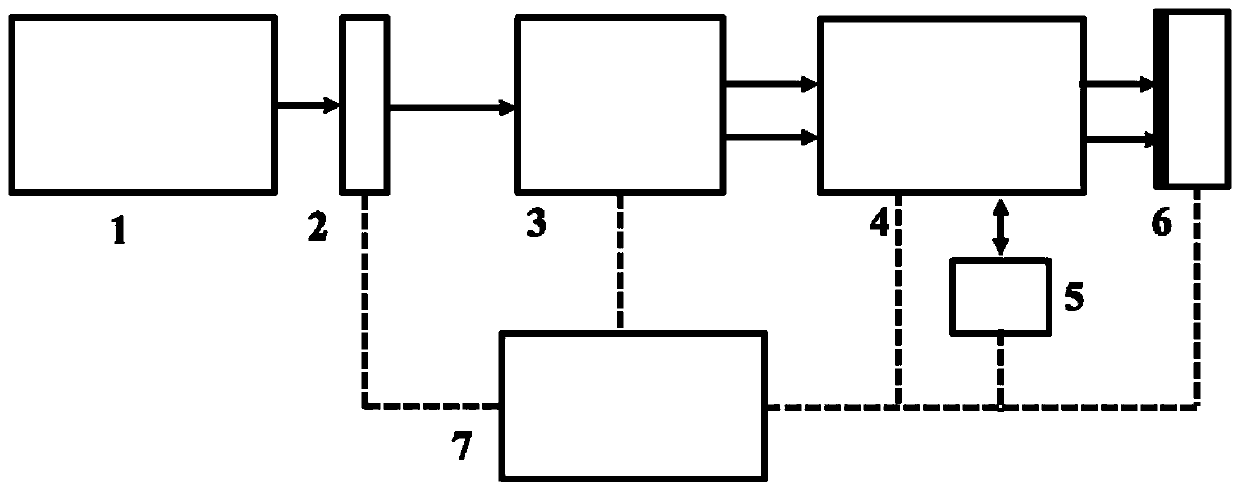

The invention provides a synchronous control system of a step scanning photoetching machine based on a VME (Virtual Mobile Engine) bus and a synchronous control method thereof, which are to solve problems of large synchronization error and low photoetching efficiency in the exposure process of the step scanning photoetching machine. According to the invention, an upper machine is connected with alower machine by an Ethernet; a synchronous control module is connected with the lower machine by a VME64 standard bus; the synchronous control module is connected with a laser counting module and a motion control module by VME64 user-defined protocol buses; a network port of the synchronous control module is connected with a network port of the lower machine by a network wire; and the VME bus comprises VME64 user-defined protocol buses and a VME64 standard bus. According to the invention, purposes of controlling and reducing the synchronization error in the step scanning process and increasing the photoetching efficiency are achieved. The synchronous control system and the synchronous control method, provided by the invention, are suitable for the field of scanning photoetching machines.

Owner:HARBIN INST OF TECH

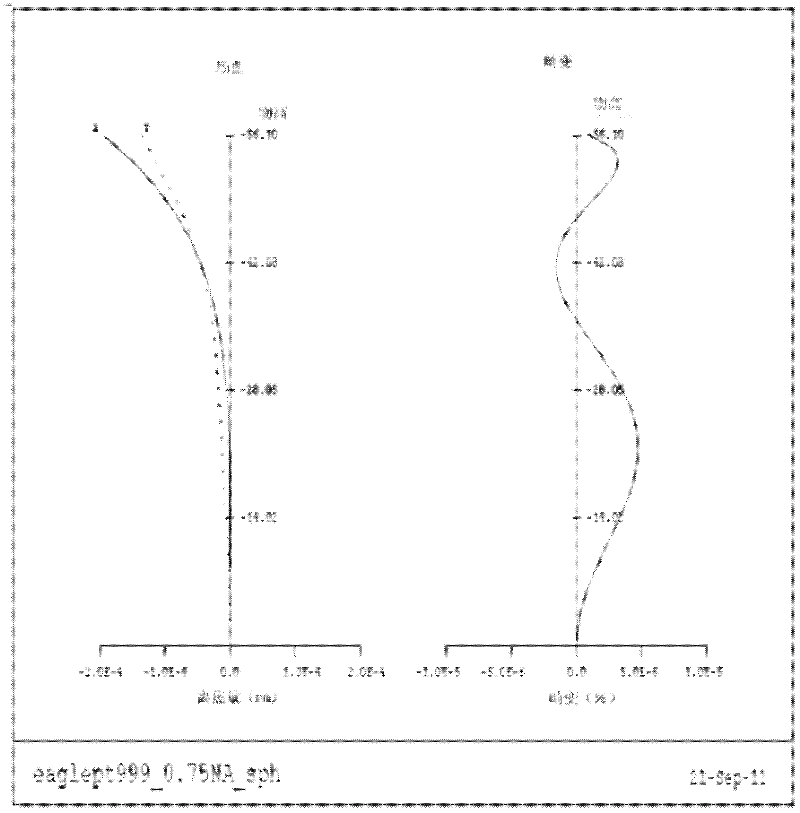

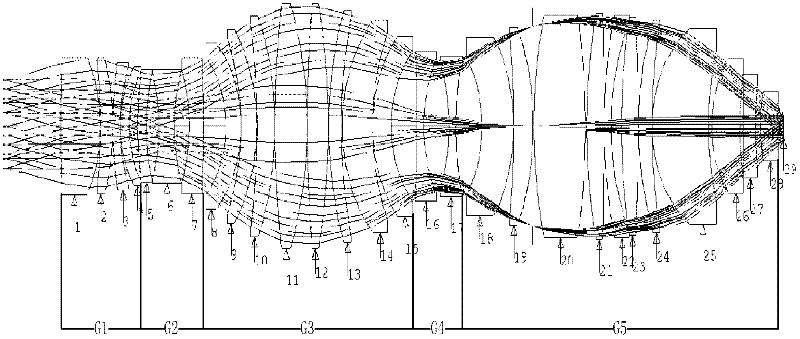

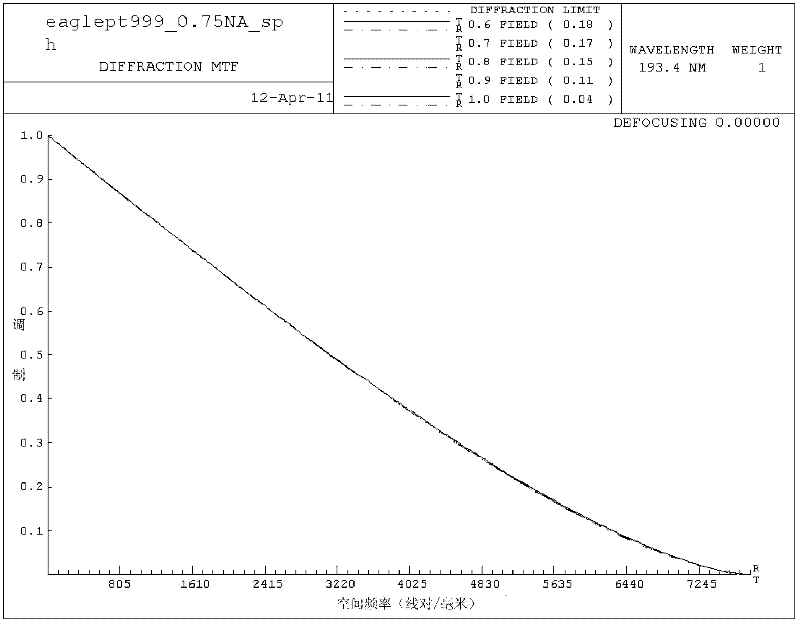

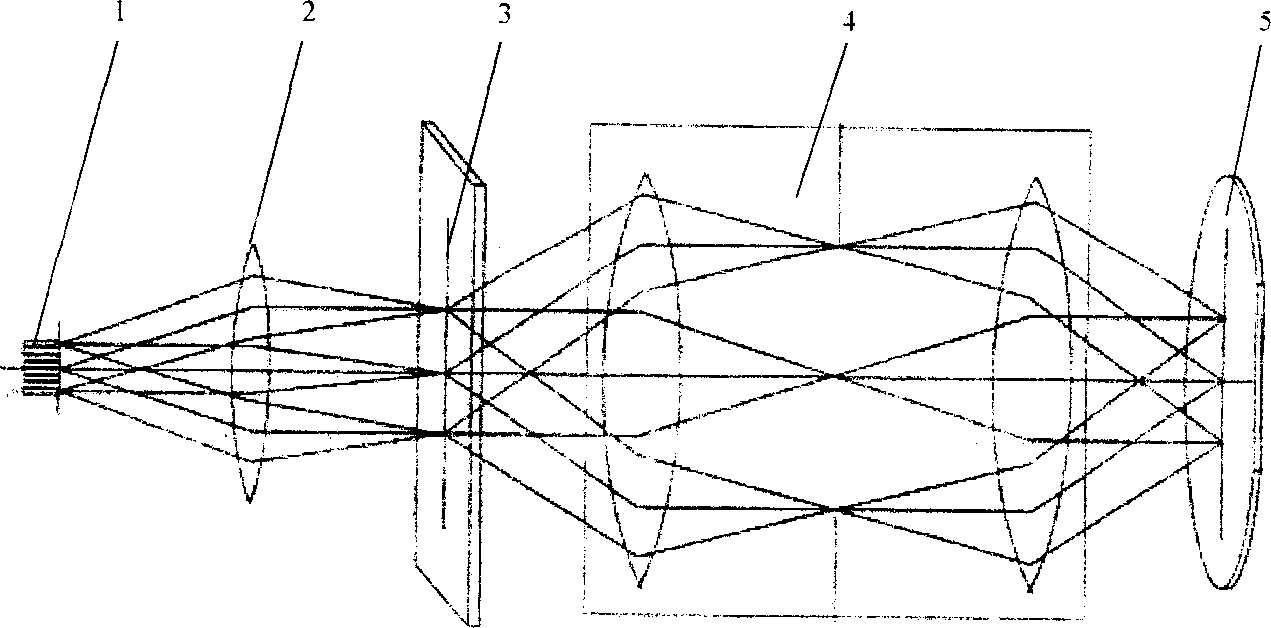

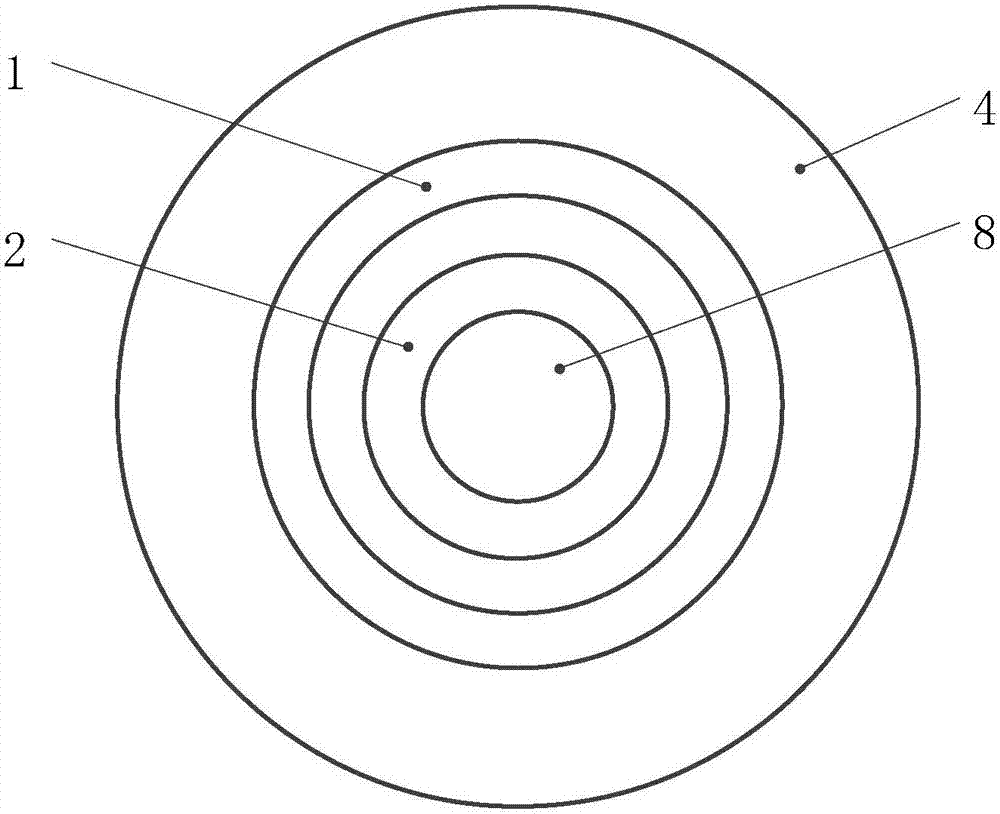

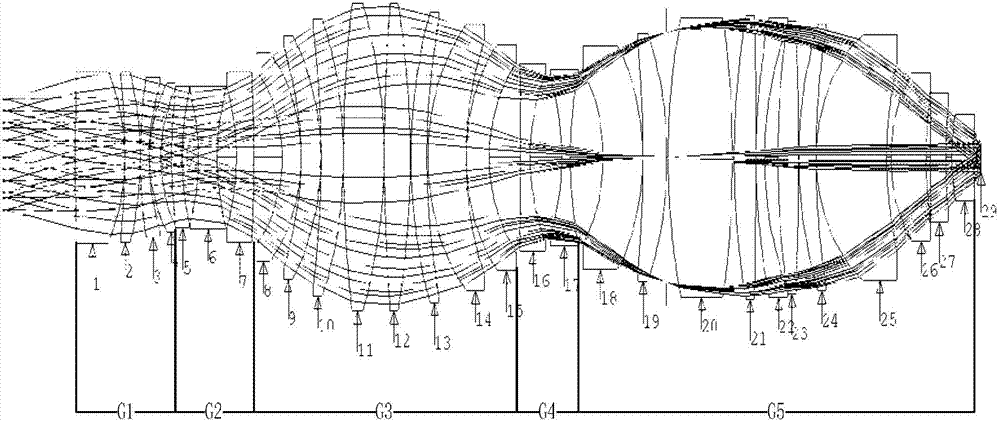

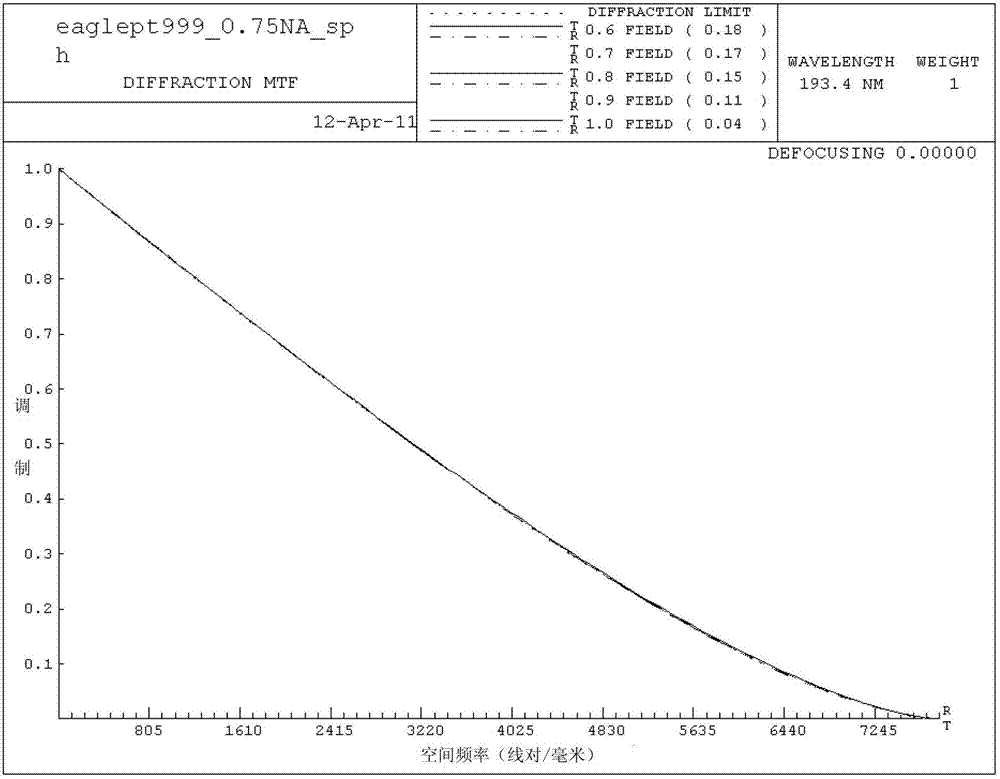

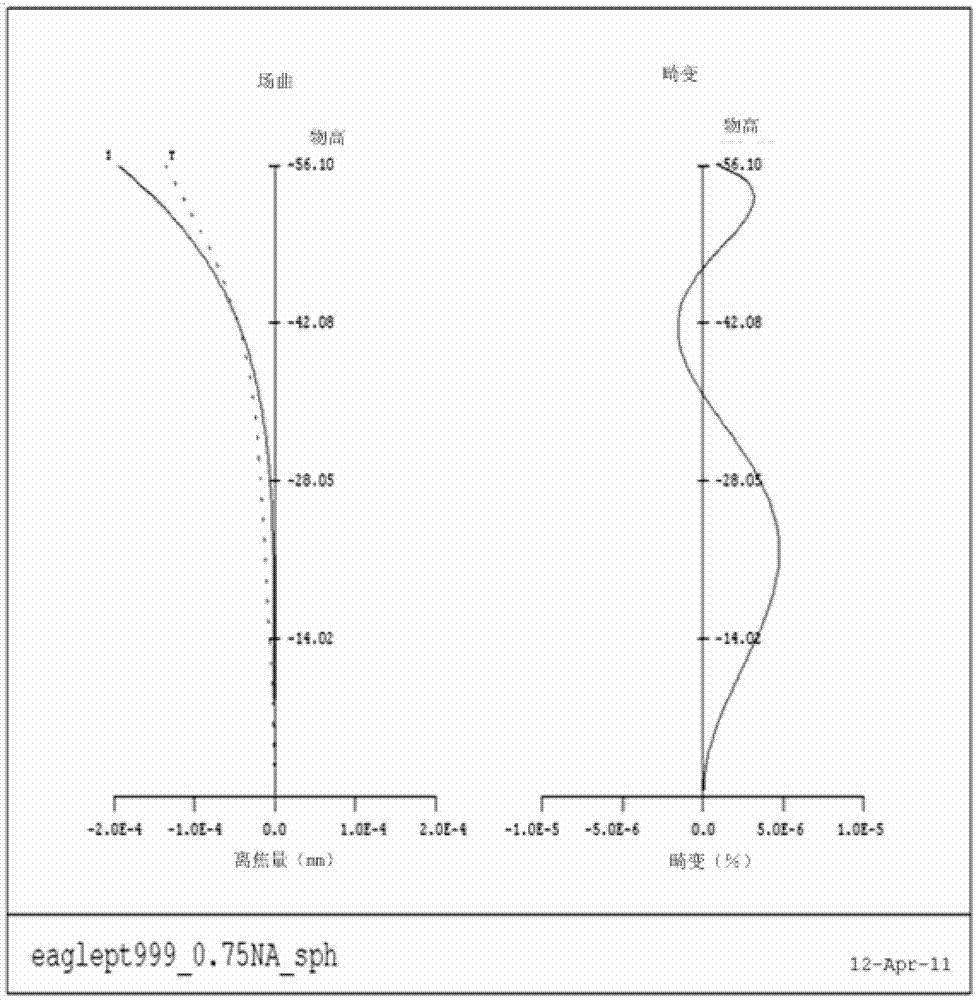

Fully-spherical projection objective

InactiveCN102331616AEasy to correctAberration correctionPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical axisImaging quality

The invention provides a fully-spherical projection objective which is used for forming an image of an object plane into an image plane. The fully-spherical projection objective, along the direction of an optical axis, comprises a first lens group, a second lens group, a third lens group, a fourth lens group and a fifth lens group; and in a sequence of the incident direction of a light beam, the first lens group G1 has a positive focal power, the second lens group G2 has a negative focal power, the third lens group G3 has the positive focal power, the fourth lens group G4 has the negative focal power, and the fifth lens group G5 has the positive focal power. All lenses in the fully-spherical projection objective are spherical lenses, not aspherical lenses. By adoption of the fully-spherical projection objective, aberration can be better compensated, imaging quality is improved, system resolution is improved, and photoetching efficiency is improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Array type optical probe scanning IC photoetching method

InactiveCN1333553AReduce widthShort wavelengthSemi-permeable membranesPhotomechanical apparatusVery large scale integrated circuitsWire width

The present invention belongs to the field of microfine engineering manufacture technology, and is characterizedb by that a kind of array optical probe scanning photoetching process is used to make integrated circuit so as to can make mininum wire width of integrated circuit less than 0.1 micrometer, at the same time it features quick speed and high efficiency. It can greatly simplify production process of integrated circuit, and provides a new effective pathway for making super-large-scale integrated circuit.

Owner:TSINGHUA UNIV

Parallel photoetching write-through system

ActiveCN101846890BRealize 3D structure fabricationImprove lithography efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusMicro structureControl system

The invention discloses a parallel photoetching write-through system which comprises a light source, a pattern generating system, an optical system, a control system, a moving system and a workpiece platform. The parallel photoetching write-through system is characterized by also being provided with a focusing servo system, the focusing servo system comprises a detection light path, a sensor and a focusing device, the optical system comprises a micro-system and a detection light path, wherein the micro-system adopts a double axifugal optical system, the detection light path comprises a detection light source, a first light splitter arranged in the double axifugal optical system and a second light splitter arranged between the detection light source and the first light splitter; detection light enters the double axifugal optical system through the first light splitter and irradiates on a workpiece of the workpiece platform; reflective light is received by the sensor through the first light splitter and the second light splitter; and the control system controls the action of the focusing device according to signals of the sensor to realize servo focusing. The invention can realize accurate photoetching of a submicron micro-structure by combining with a focusing imaging servo system.

Owner:SVG TECH GRP CO LTD +1

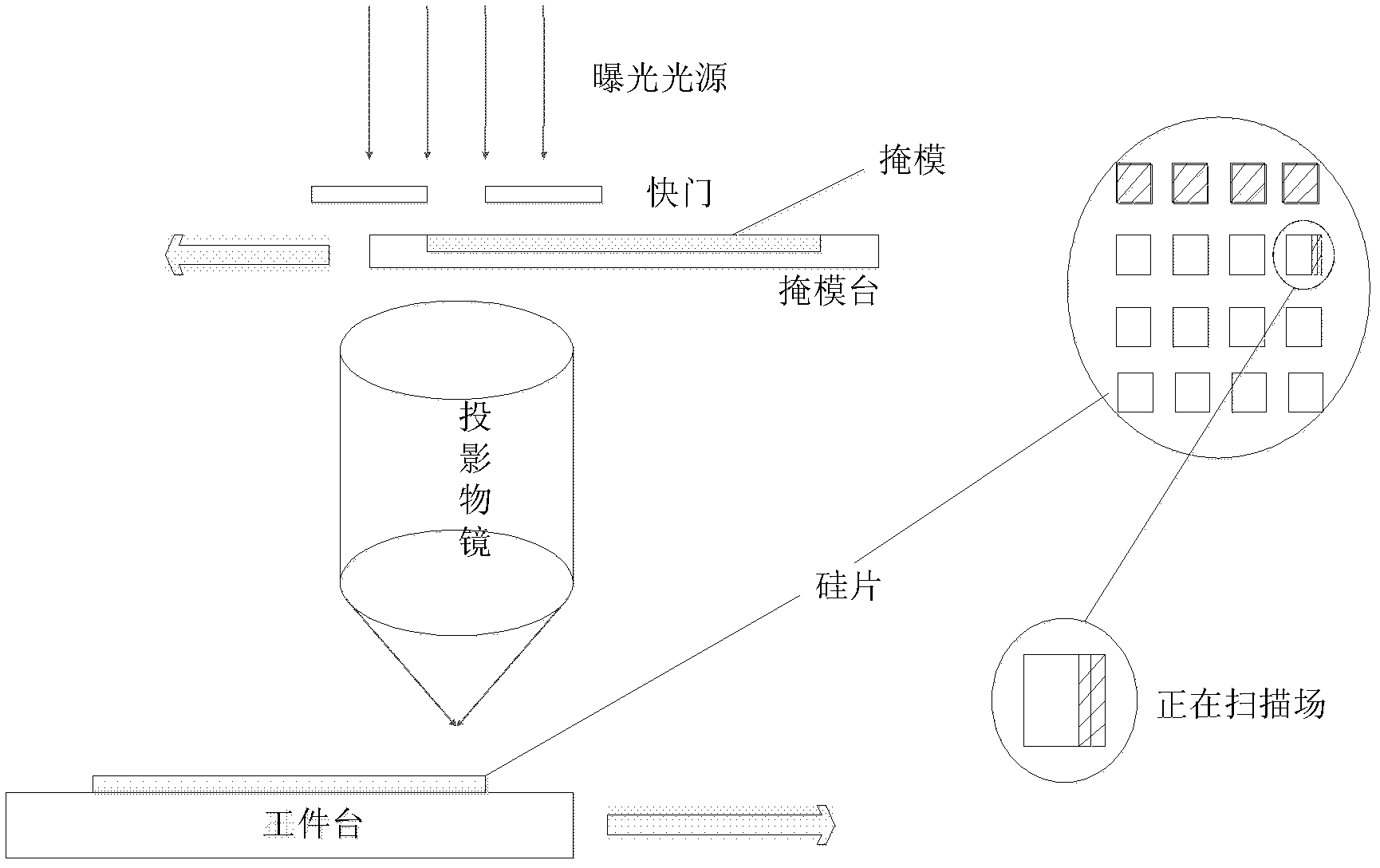

Stepping exposure method based on UV-LED photoetching light source

InactiveCN111796488AImprove luminous efficiencyReduce energy consumptionPhotomechanical exposure apparatusMicrolithography exposure apparatusWaferLight spot

The invention discloses a stepping exposure method based on a UV-LED photoetching light source, and the method comprises the steps: employing the UV-LED light source as the photoetching light source,so as to form an exposure field with uniformly distributed light intensity; aligning the mask mark with the wafer mark through a mask alignment system; collimating the emergent light beam of the UV-LED light source through a micro lens array, and forming a square exposure light spot on the surface of the mask; and transferring the mask pattern to the wafer coated with the photoresist through stepping exposure. According to the invention, an infinite exposure area can be realized, the submicron mask alignment precision can be realized, and a foundation is laid for realizing high-precision photoetching.

Owner:BEIJING U PRECISION TECH

Compact maskless photoetching system and exposure method thereof

InactiveCN112965340AIncrease profitImprove lithography efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusLight energyOptical axis

The invention discloses a compact maskless photoetching system and an exposure method thereof, belongs to the field of maskless digital photoetching, and aims to solve the problem that ultraviolet light energy is sharply reduced due to light path folding in the prior art. According to the compact maskless photoetching system and the exposure method thereof, purple light and red light are integrated on the same plane, so that it can be ensured that the purple light and the red light form a coaxial light source; the red light is used for illumination and exposure pattern alignment; the purple light is used for exposure distribution andthe periphery of an optical axis; and thus, the problem of overlarge size of an existing maskless photoetching system caused by complex structure and excessive used elements in the existing maskless photoetching system is solved, and the problem that the photoetching efficiency of the photoetching system is low due to low light energy utilization rate caused by a complex light path is also solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

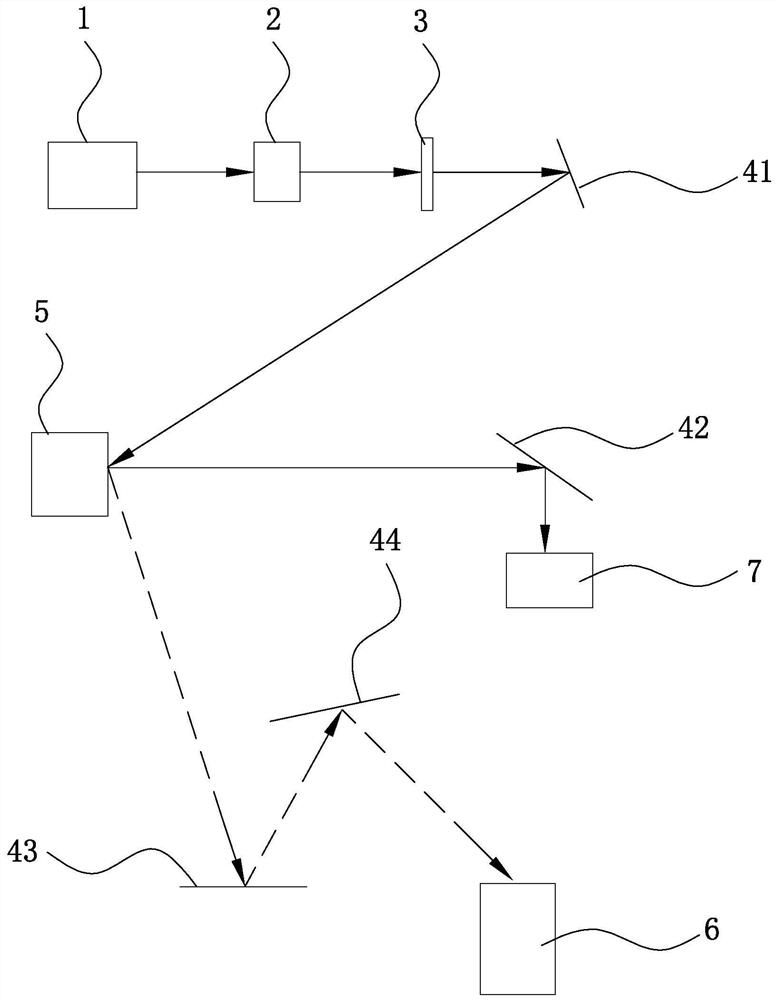

Mask-free direct writing photolithography system

InactiveCN110441991AAchieve independent controlImprove lithography efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusEnergy controlDirect writing

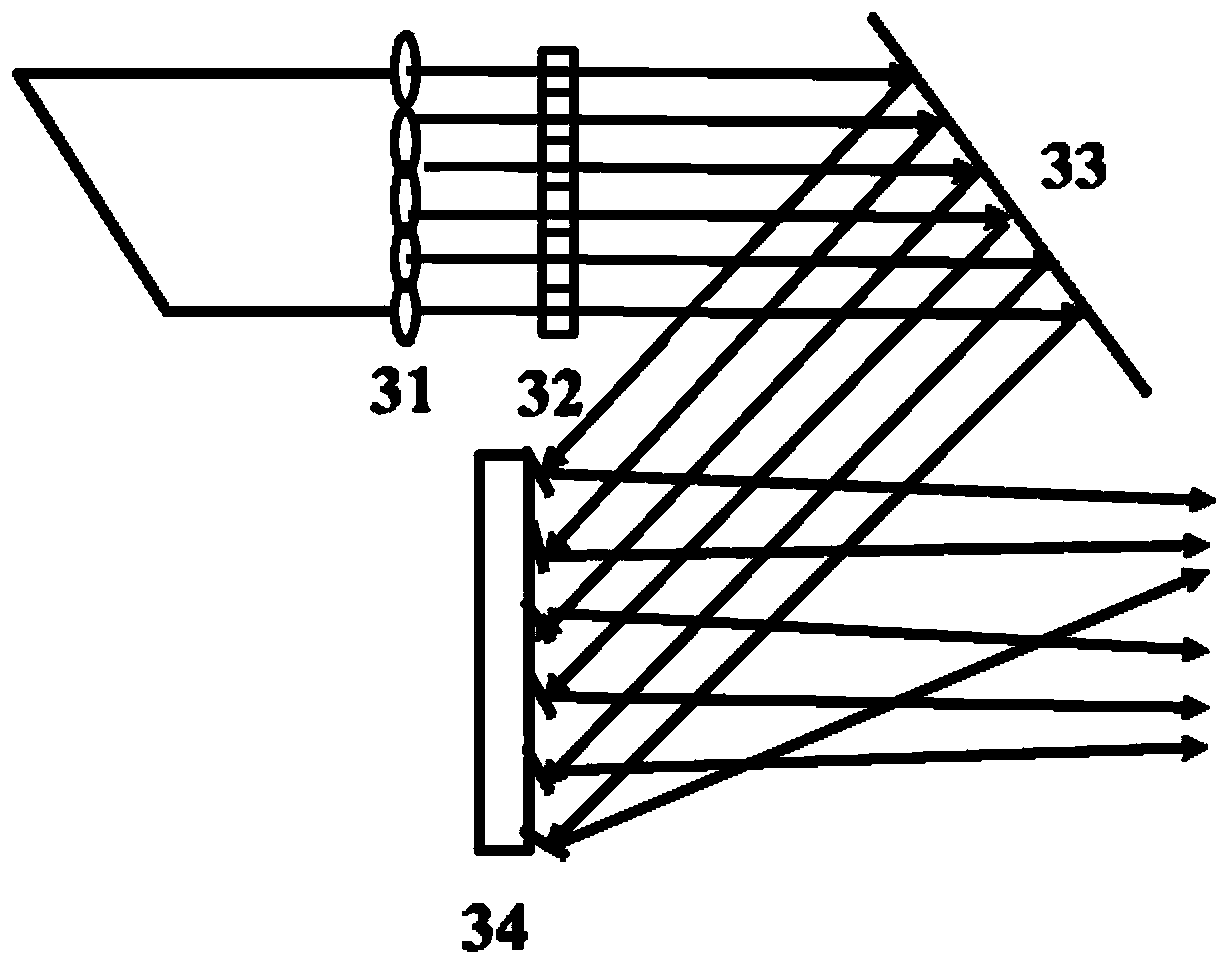

The invention discloses a mask-free direct writing photolithography system; the mask-free direct writing photolithography system comprises a direct writing light source, an energy control unit, a laser beam splitting control and scanning unit, a focusing servo unit, a red light detection unit, a multi-axis workpiece platform and a control unit. Under the overall control of the control unit, the light emitted by the direct writing light source irradiates onto the laser beam splitting control and scanning unit through the control of the energy control unit; after being controlled by the laser beam splitting control and scanning unit, the light is focused by the focusing servo unit and detected by the red light detection unit; and finally the multiple paths of light beams are focused on photoresist in parallel for direct writing. According to the photolithography system, independent control of multiple light beams, parallel direct writing and two-dimensional galvanometer scanning can be realized, and the photolithography efficiency is improved in a multiplied mode compared with a single-point scanning system. The scanning speed and the scanning freedom degree of a direct writing photolithography machine are improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

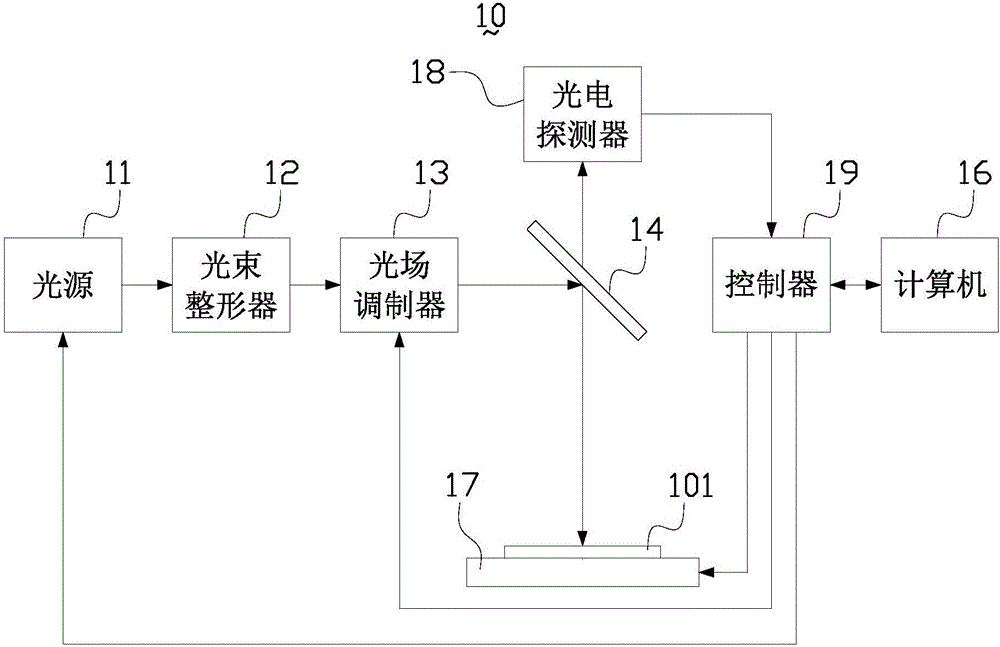

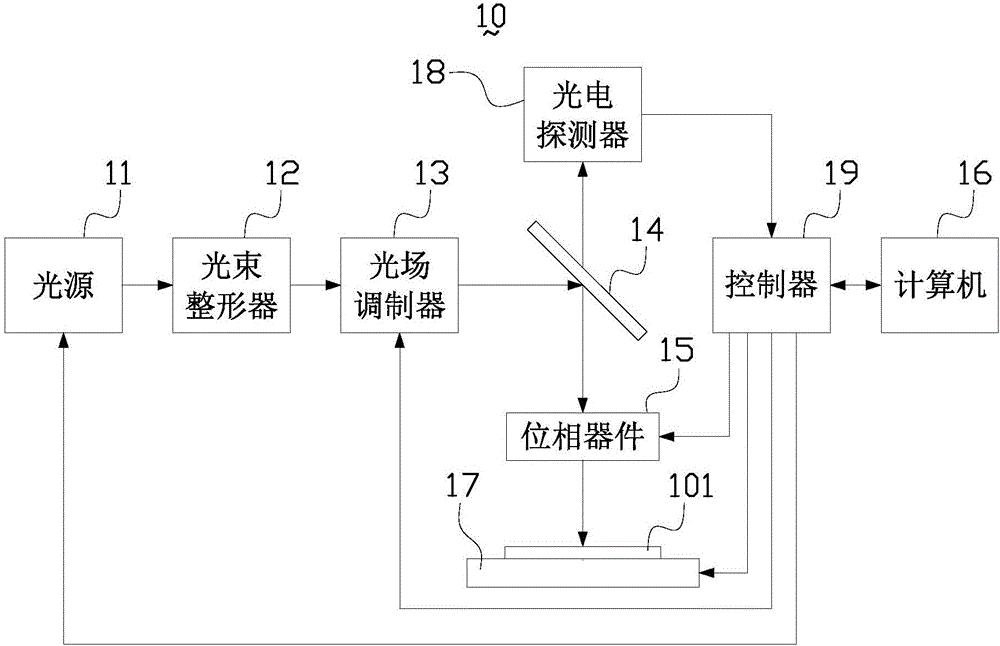

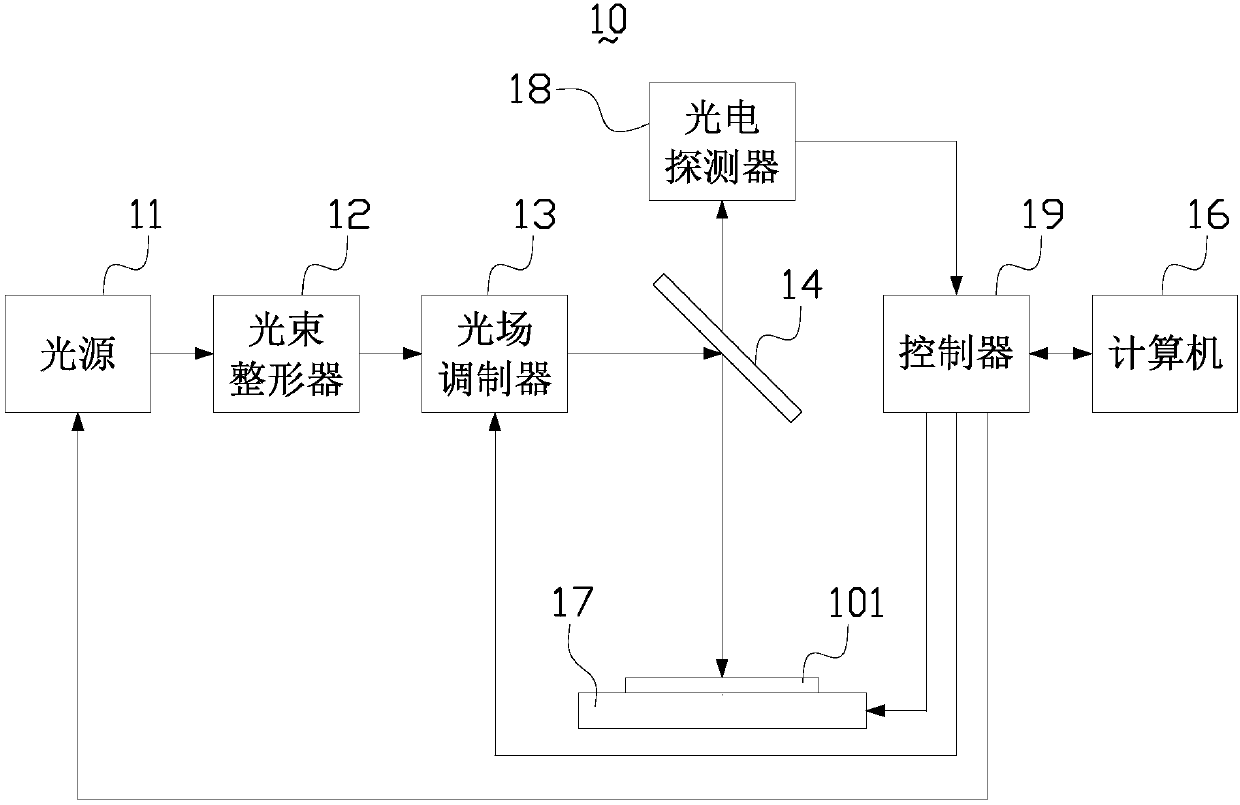

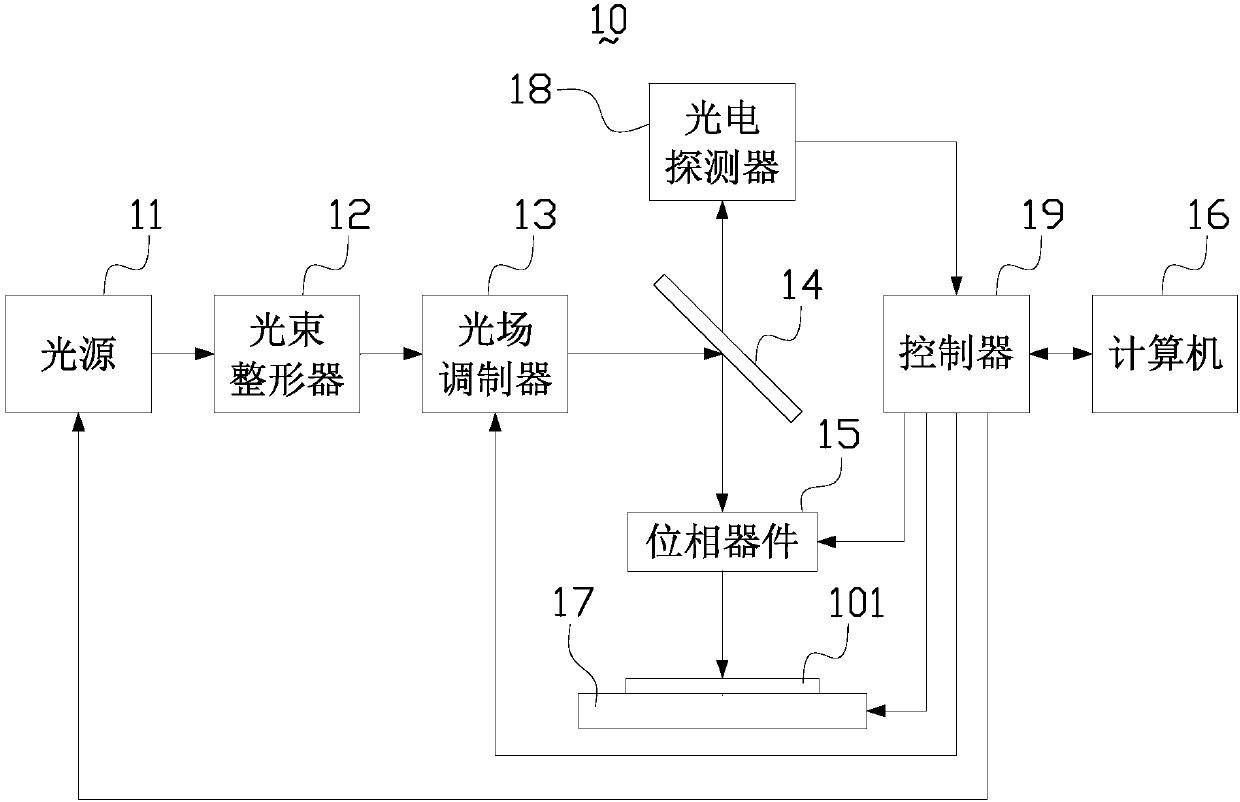

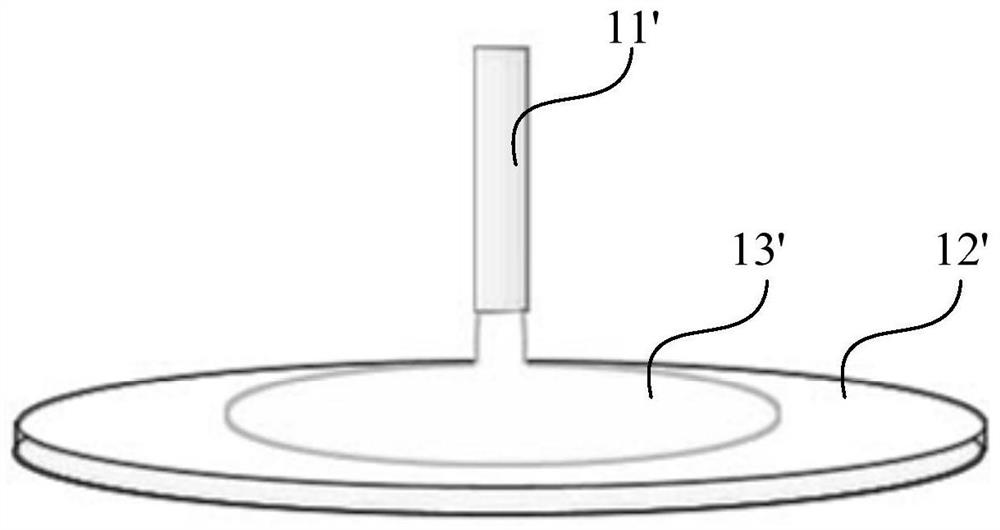

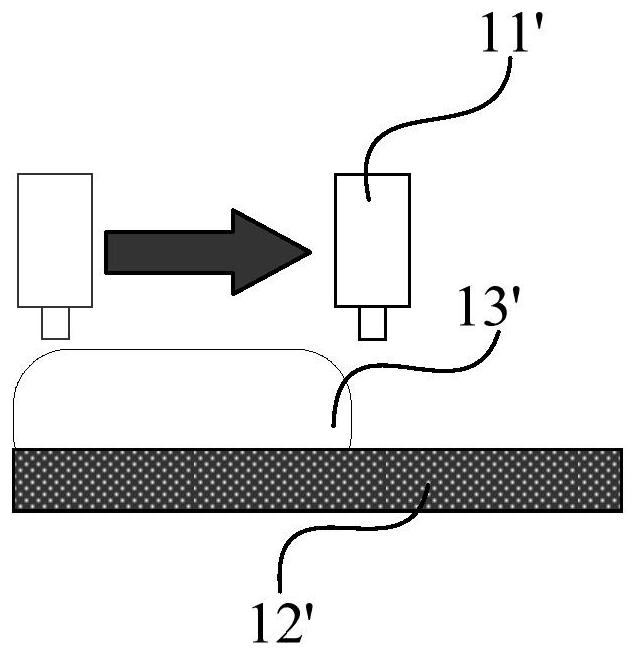

Mixed lithographic system and mixed lithographic method

ActiveCN106681106AImprove lithography efficiencyLower Lithography CostsPhotomechanical exposure apparatusMicrolithography exposure apparatusMicro nanoNanolithography

A mixed lithographic system comprises a light source, a beam shaper, a light field modulator, a mirror, an imaging optical system and a phase element, wherein the beam shaper is used for shaping beams emitted by the light source; the light field modulator is used for generating graphic light from the shaped beams; the imaging optical system and the mirror are used for transmitting a light field to the surface of a to-be-exposed lithographic piece to realize direct writing lithography; the phase element is used for forming an interference exposure field on the surface of the lithographic piece to realize interference lithography. The mixed lithographic system has direct writing lithography and interference lithography functions, can perform mixed lithography, increases the nano-lithography efficiency and has great significance in promoting application of micro-nano structure related devices and materials. The invention further relates to a mixed lithographic method.

Owner:SVG TECH GRP CO LTD +1

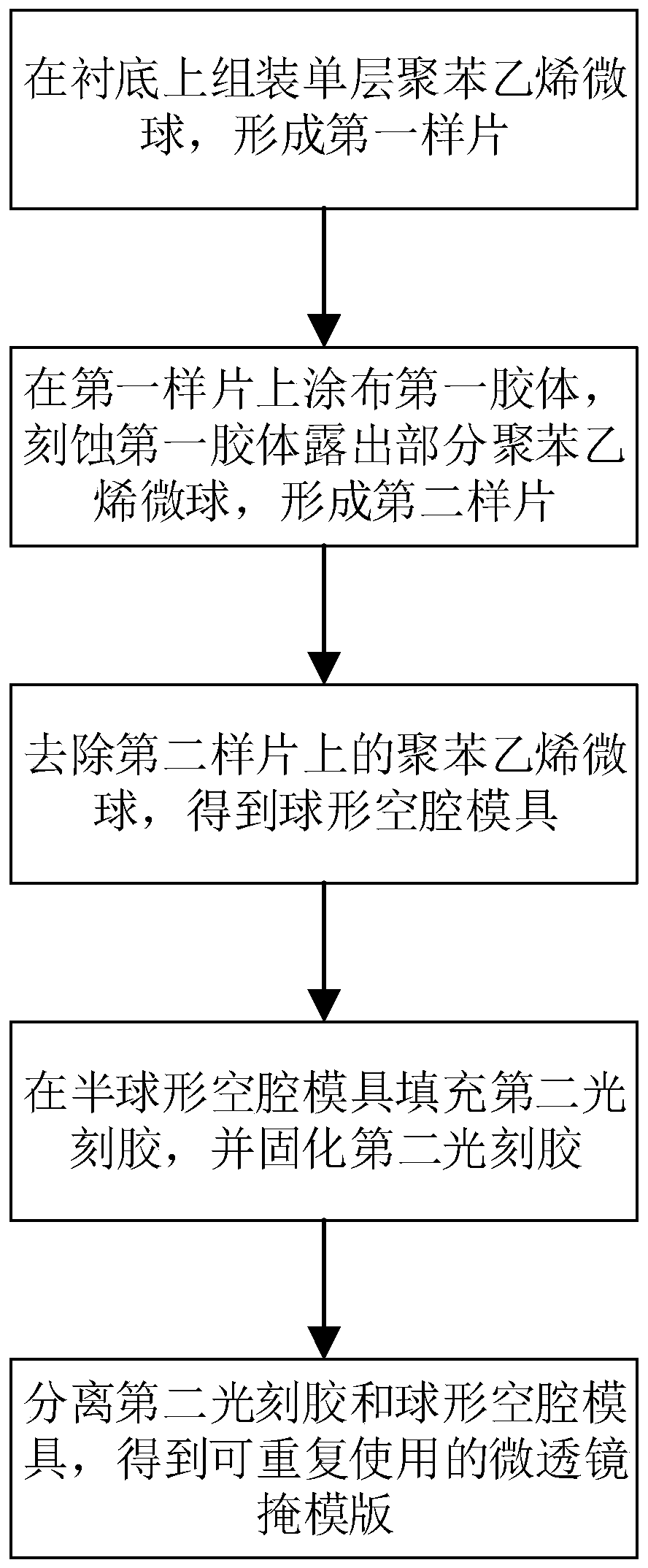

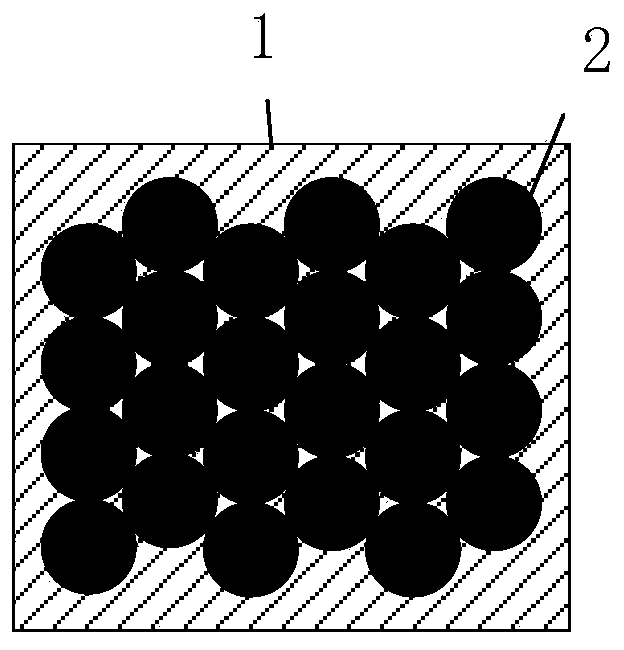

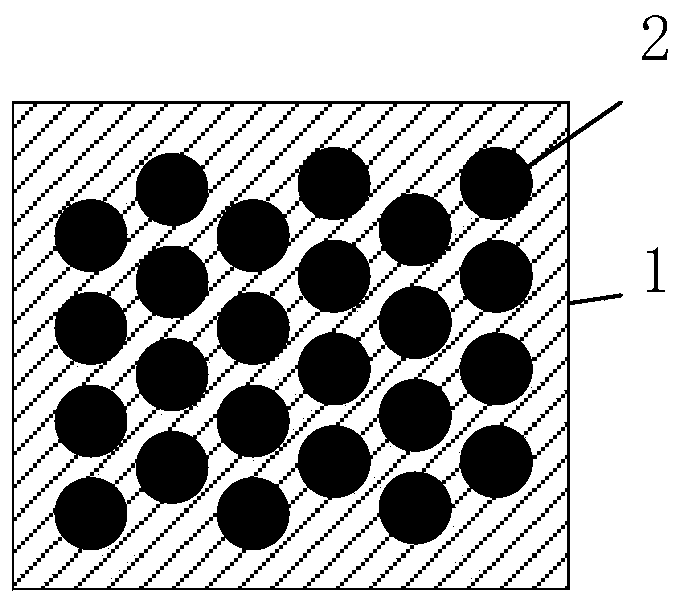

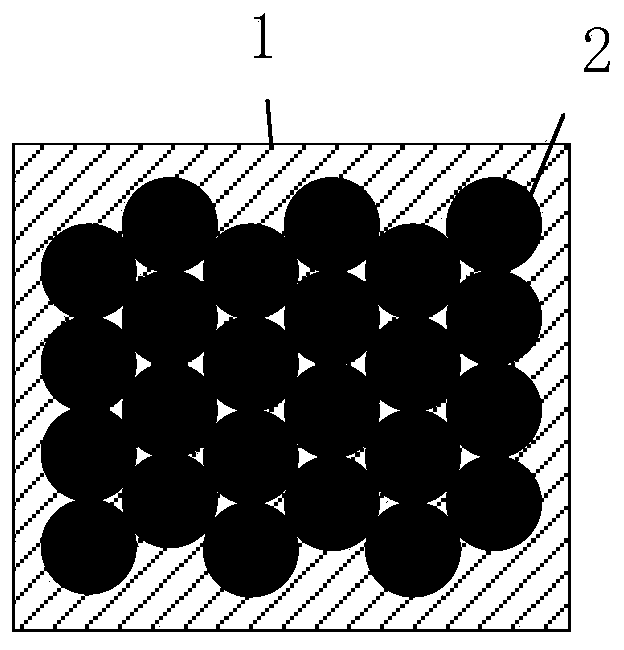

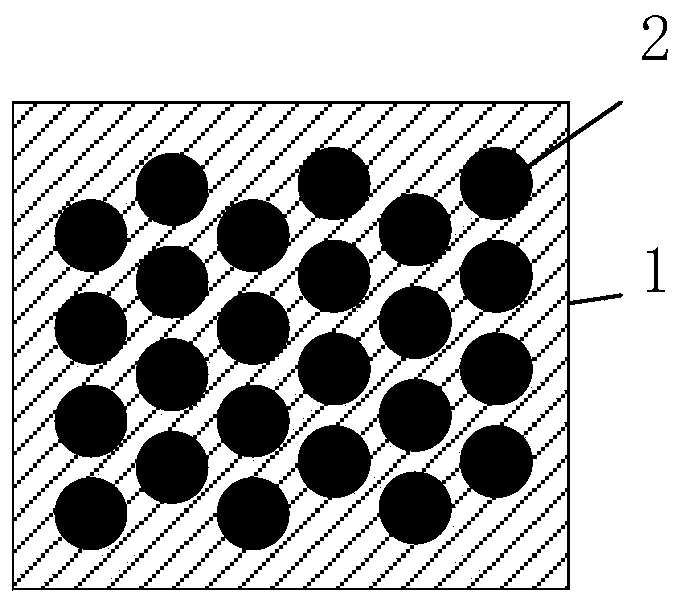

Micro lens mask and preparation method thereof

ActiveCN110187599AHigh energyHigh resolutionOriginals for photomechanical treatmentLensMicro nanoColloid

The invention discloses a micro lens mask and a preparation method thereof, which belong to the technical field of nanophotonic devices. The method includes the following steps: assembling a single layer of polystyrene microspheres on a substrate to form a first sample; coating the first sample with a first colloid, and etching the first colloid to expose part of the polystyrene microspheres to form a second sample; removing the polystyrene microspheres on the second sample to obtain a spherical cavity mould; filling the spherical cavity mould with second photoresist, and solidifying the second photoresist by setting and exposing; and separating the second photoresist from the spherical cavity mould to obtain a reusable micro lens mask. The micro lens mask prepared by the invention can beused repeatedly in large-area assisted photolithography of micro-nano patterns, and has the advantages of low cost, short cycle and high efficiency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

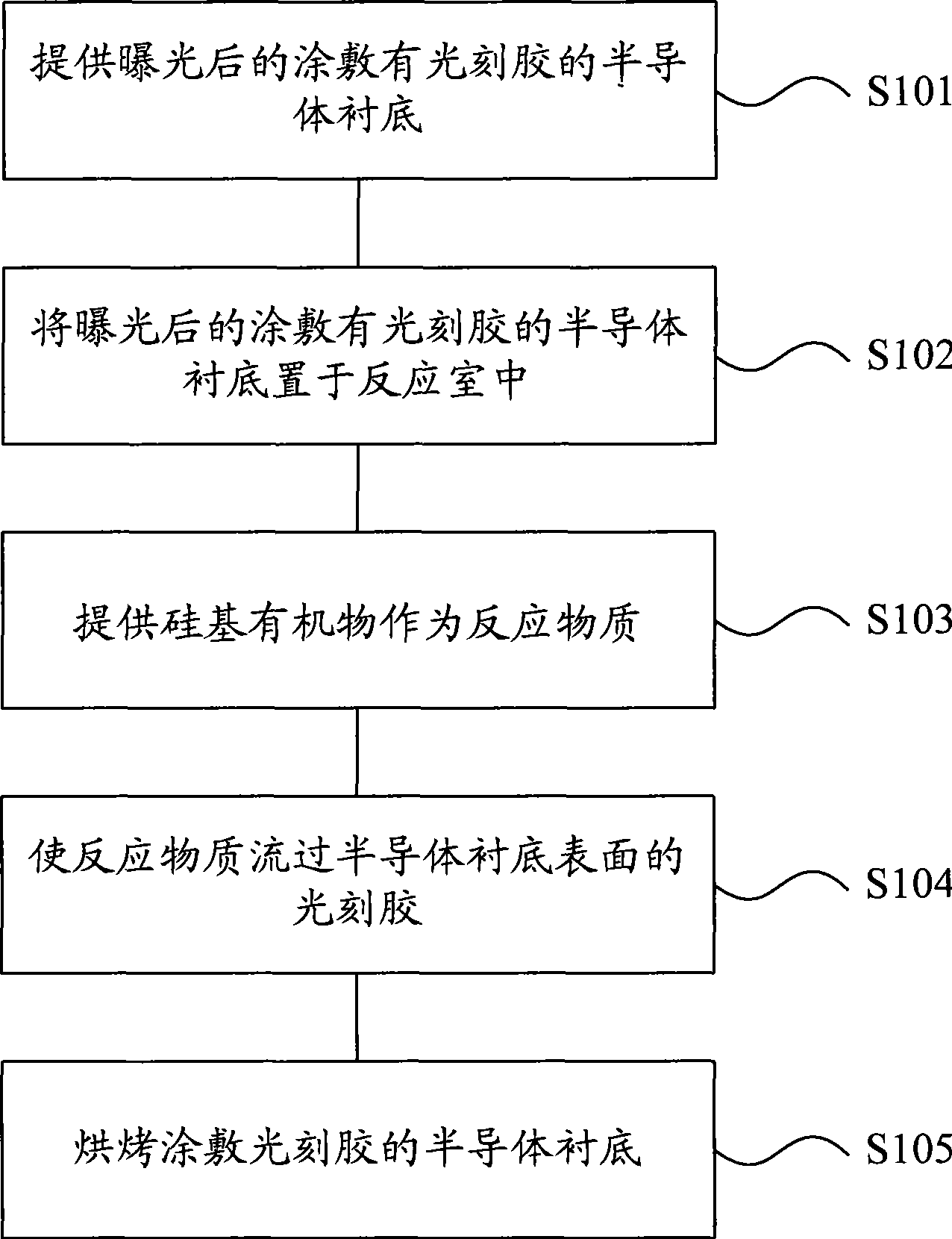

Photoresist silicification method and method for forming photoresist mask pattern

InactiveCN101458460AReduce thicknessLow costSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistPhotoresist

The invention relates to a method for silicifying photosensitive resist, which comprises: providing an exposed semiconductor substrate with the surface coated with the photosensitive resist; placing the exposed semiconductor substrate coated with the photosensitive resist into a reaction chamber; providing reaction material comprising a silicon-based organic substance, and causing the reaction material to flow through the photosensitive resist on the surface of the semiconductor substrate. The invention also provides a method for forming a mask pattern of the photosensitive resist. The technical proposal has the following advantages: as the silicifying process is adopted to treat a mask of the photosensitive resist, the method improves the strength of the photosensitive resist, so as to reduce the thickness of the photosensitive resist and save the cost of materials; and as the thickness of the photosensitive resist is reduced, the energy required by exposure is correspondingly reduced, so as to shorten exposure time and improve photoetching efficiency.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Photoetching equipment and photoetching method

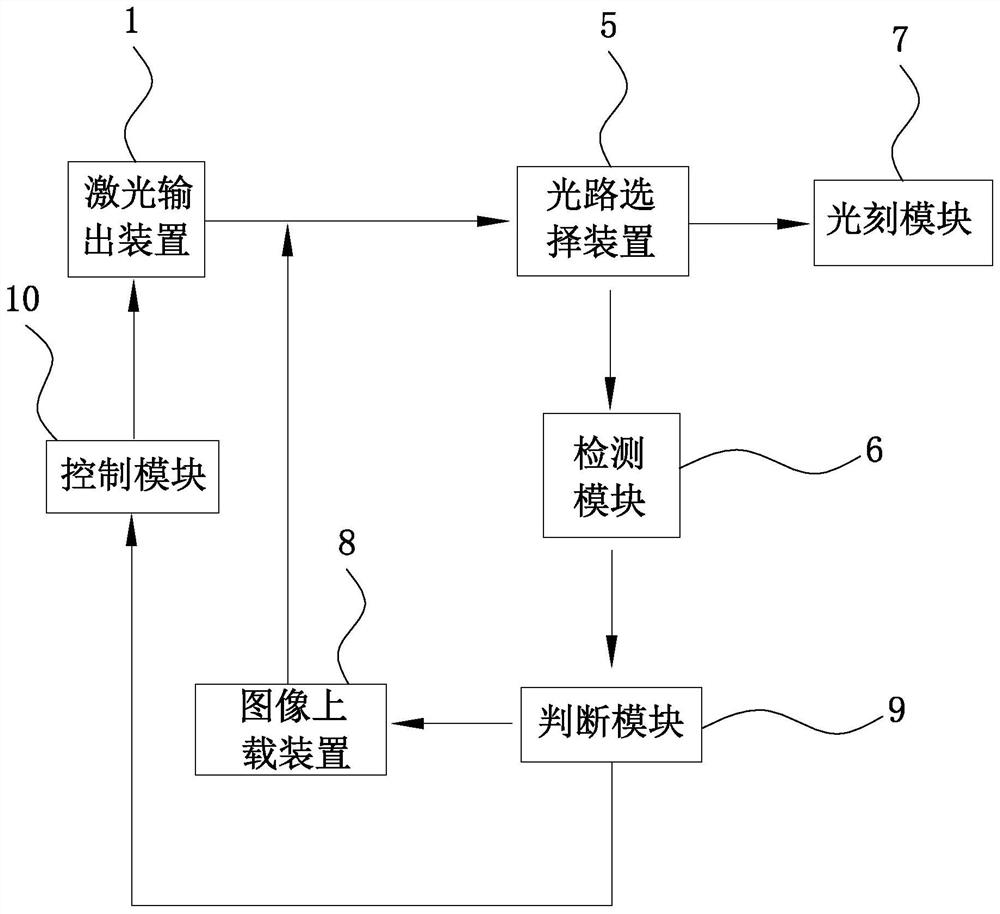

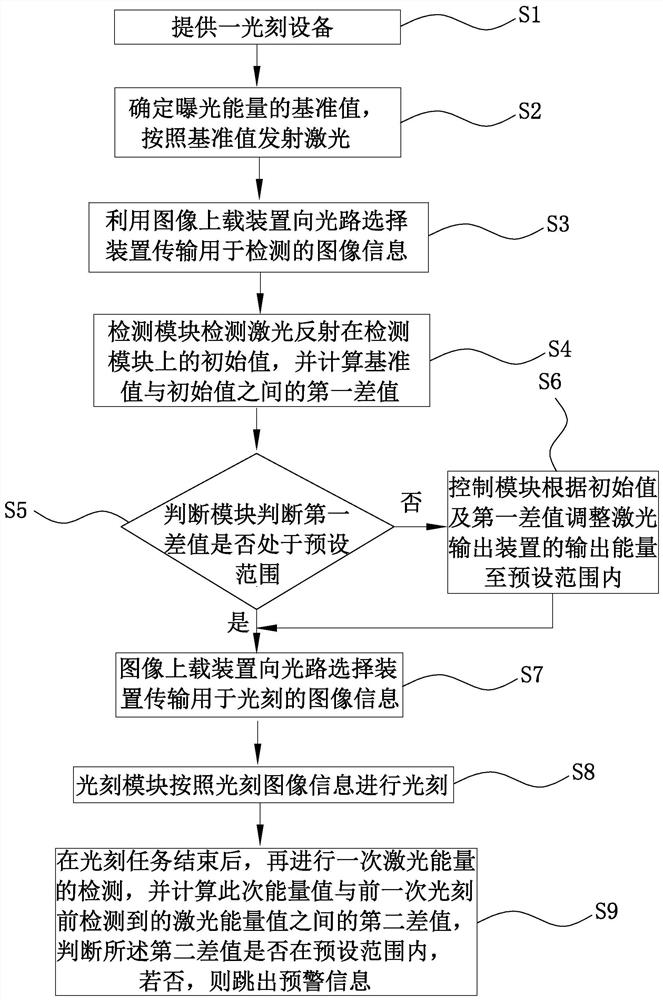

PendingCN113495432AReal-time detection of exposure energyGuaranteed lithographic effectPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMaterials science

The invention discloses photoetching equipment which comprises a laser output device, a light path selection device, a detection module and a photoetching module. The laser output device emits laser to the light path selection device, and the light path selection device selects to reflect the laser to the photoetching module or the detection module. The invention also discloses a photoetching method which is used for photoetching by utilizing the photoetching equipment. The light path selection device selects to reflect the laser to the photoetching module or the detection module, so that the photoetching equipment can detect the exposure energy in real time, the photoetching effect is ensured, the photoetching efficiency is improved, and the yield of products is improved.

Owner:SVG TECH GRP CO LTD +1

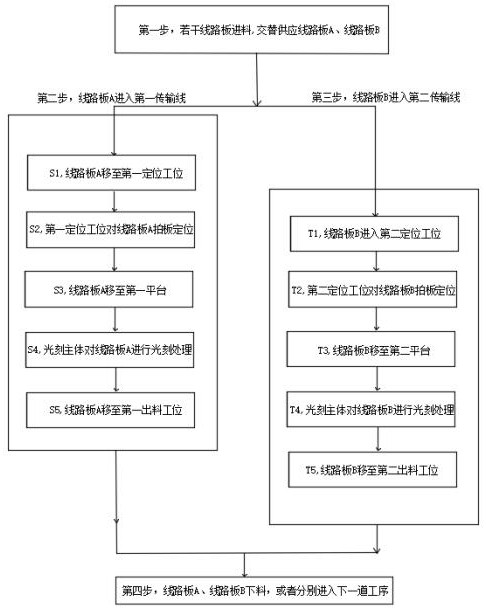

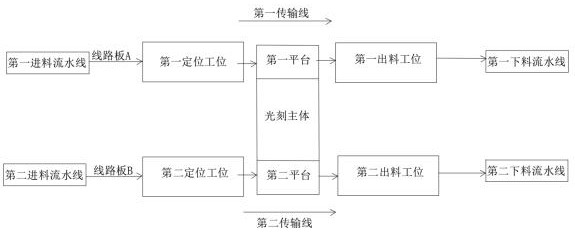

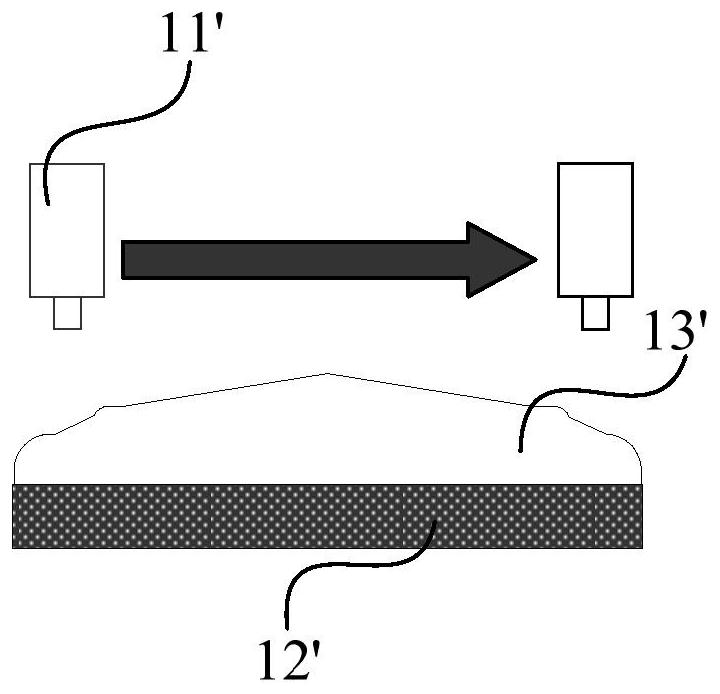

Digital photoetching method of circuit board and digital photoetching system of circuit board applying digital photoetching method

PendingCN114803445AImprove lithography efficiencyShorten the timePhotomechanical exposure apparatusMicrolithography exposure apparatusSystems engineeringTransmission line

The invention provides a digital photoetching method of a circuit board, a digital photoetching system of the circuit board comprises a photoetching main body, a first transmission line and a second transmission line, the first transmission line comprises a first positioning station, a first platform and a first discharging station, and the second transmission line comprises a second positioning station, a second platform and a second discharging station. The digital photoetching method of the circuit boards comprises the following steps: 1, feeding a plurality of circuit boards, and alternately supplying a circuit board A and a circuit board B; 2, the circuit board A enters a first transmission line; thirdly, the circuit board B enters the second transmission line, and the second step and the third step are carried out at the same time. According to the invention, the circuit board is shunted to the two transmission lines, and the photoetching main body alternately carries out digital photoetching treatment on the circuit boards on the two platforms, so that the photoetching efficiency is greatly improved, the time is saved, and the cost is saved.

Owner:广东科视光学技术股份有限公司

Synchronous control system of step scanning photoetching machine based on VME (Virtual Mobile Engine) bus and synchronous control method thereof

InactiveCN102621826BControl and reduce synchronization errorsImprove lithography efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusSynchronous controlEthernet

The invention provides a synchronous control system of a step scanning photoetching machine based on a VME (Virtual Mobile Engine) bus and a synchronous control method thereof, which are to solve problems of large synchronization error and low photoetching efficiency in the exposure process of the step scanning photoetching machine. According to the invention, an upper machine is connected with a lower machine by an Ethernet; a synchronous control module is connected with the lower machine by a VME64 standard bus; the synchronous control module is connected with a laser counting module and a motion control module by VME64 user-defined protocol buses; a network port of the synchronous control module is connected with a network port of the lower machine by a network wire; and the VME bus comprises VME64 user-defined protocol buses and a VME64 standard bus. According to the invention, purposes of controlling and reducing the synchronization error in the step scanning process and increasing the photoetching efficiency are achieved. The synchronous control system and the synchronous control method, provided by the invention, are suitable for the field of scanning photoetching machines.

Owner:HARBIN INST OF TECH

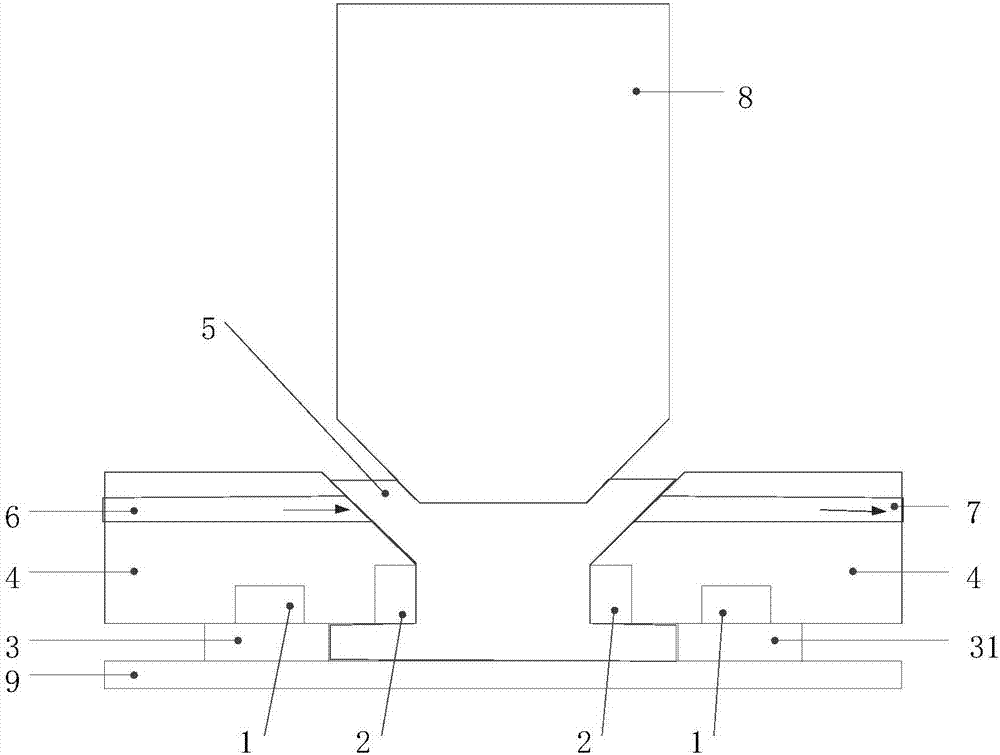

Immersion lithography system and immersion flow field maintaining method

ActiveCN107305318AShorten the timeImprove lithography efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistSilicon

The invention provides an immersion lithography system and an immersion flow field maintaining method. An immersion liquid curing apparatus is arranged in an immersion head; in an exposure process, the immersion liquid between the immersion head and a silicon wafer is cured to form a sealed wall by the immersion liquid curing apparatus; the immersion head, the sealed wall and the silicon wafer form an accommodating container for accommodating the immersion liquid; the immersion liquid in the sealed wall forms a medium; the immersion liquid field of the immersion liquid is maintained between a projection objective lens and the silicon wafer; after exposure is completed, all immersion liquid in contact with the silicon wafer is cured by the immersion liquid curing apparatus, so that after the silicon wafer is removed from a working table, the immersion liquid does not fall off due to gravity; after a new non-exposed silicon wafer is loaded on the working table, the cured immersion liquid is in contact with the silicon wafer, and next, the cured immersion liquid is liquefied by the immersion liquid curing apparatus to perform exposure of the next round. Therefore, by adoption of the apparatus and the process, re-building of the liquid field after replacement of the silicon wafer is not needed, so that time is saved and lithography efficiency is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

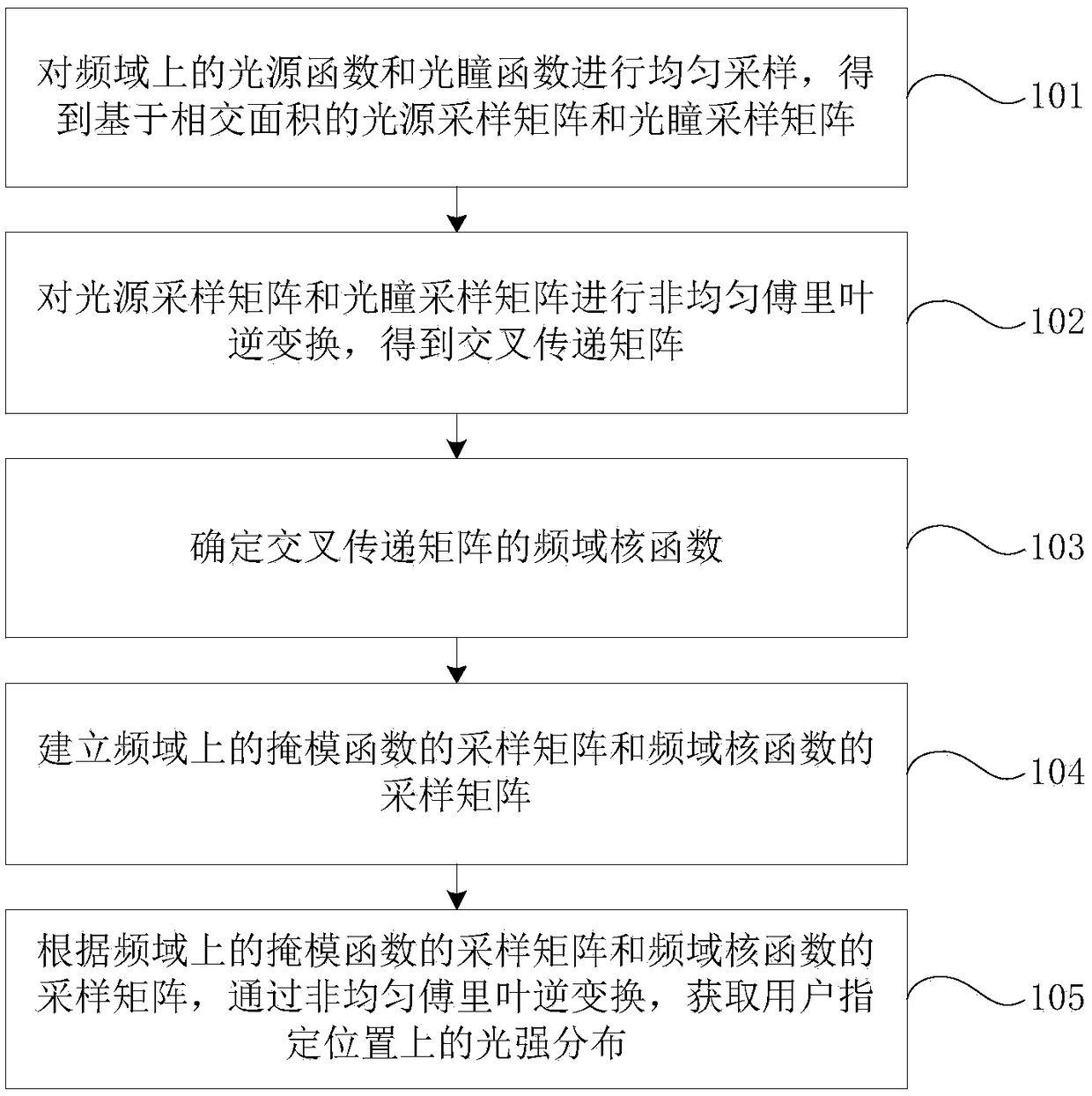

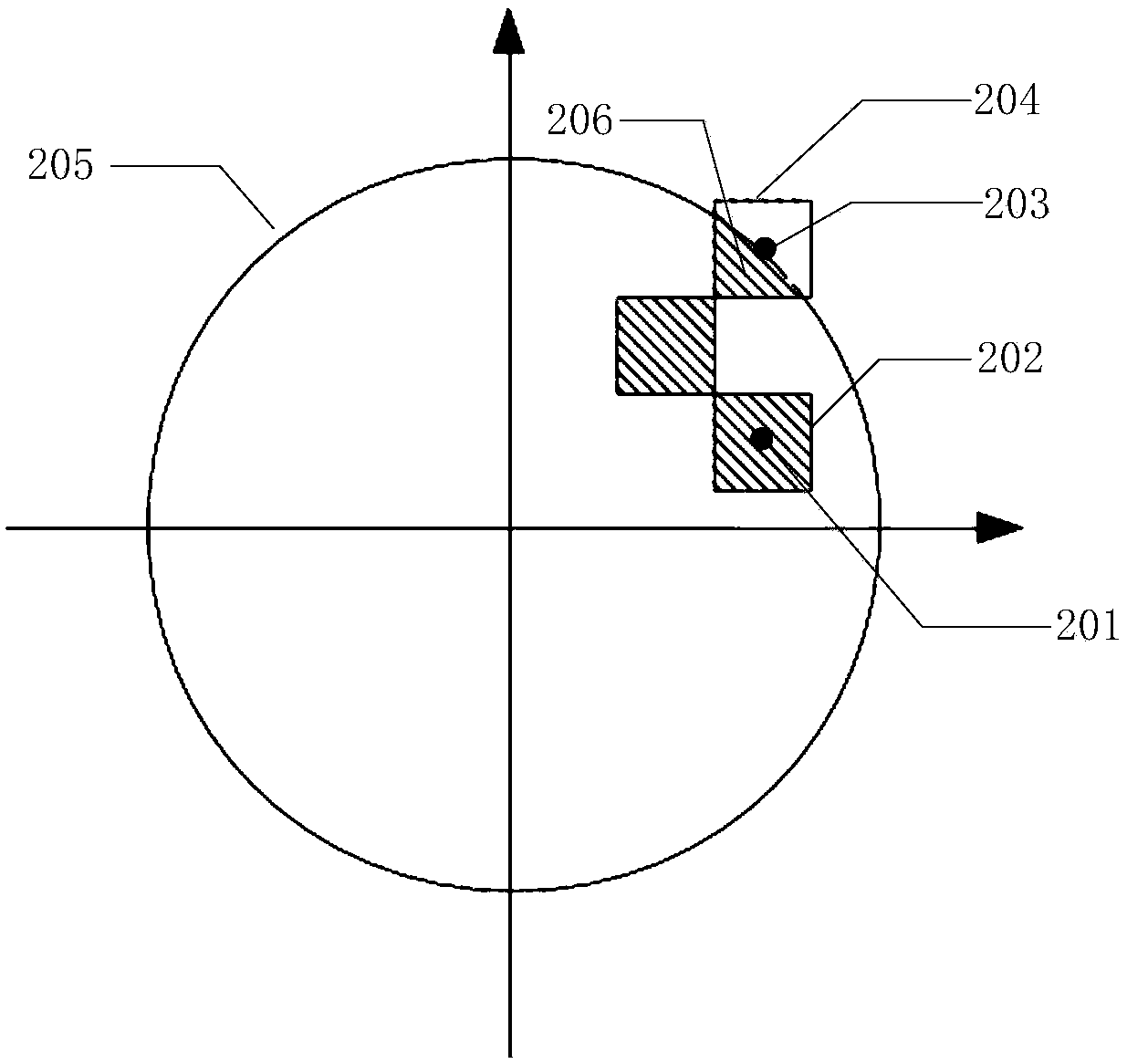

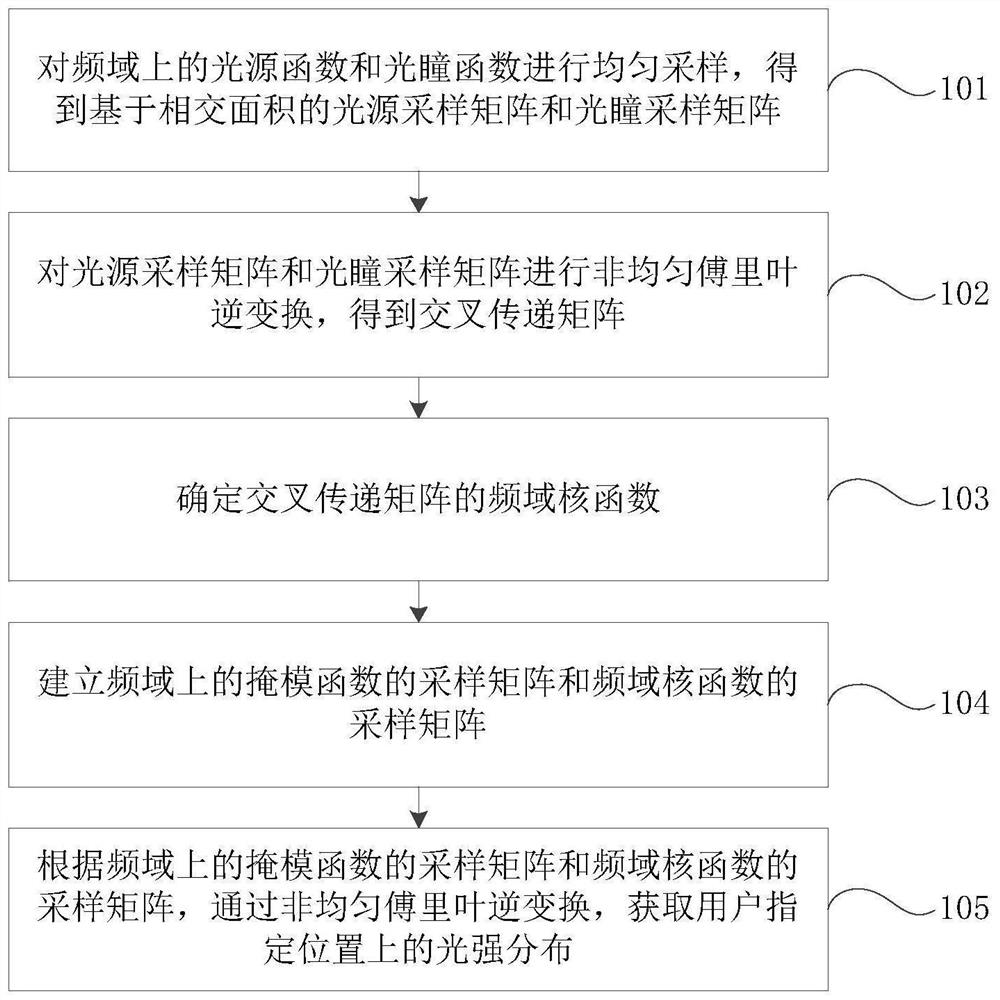

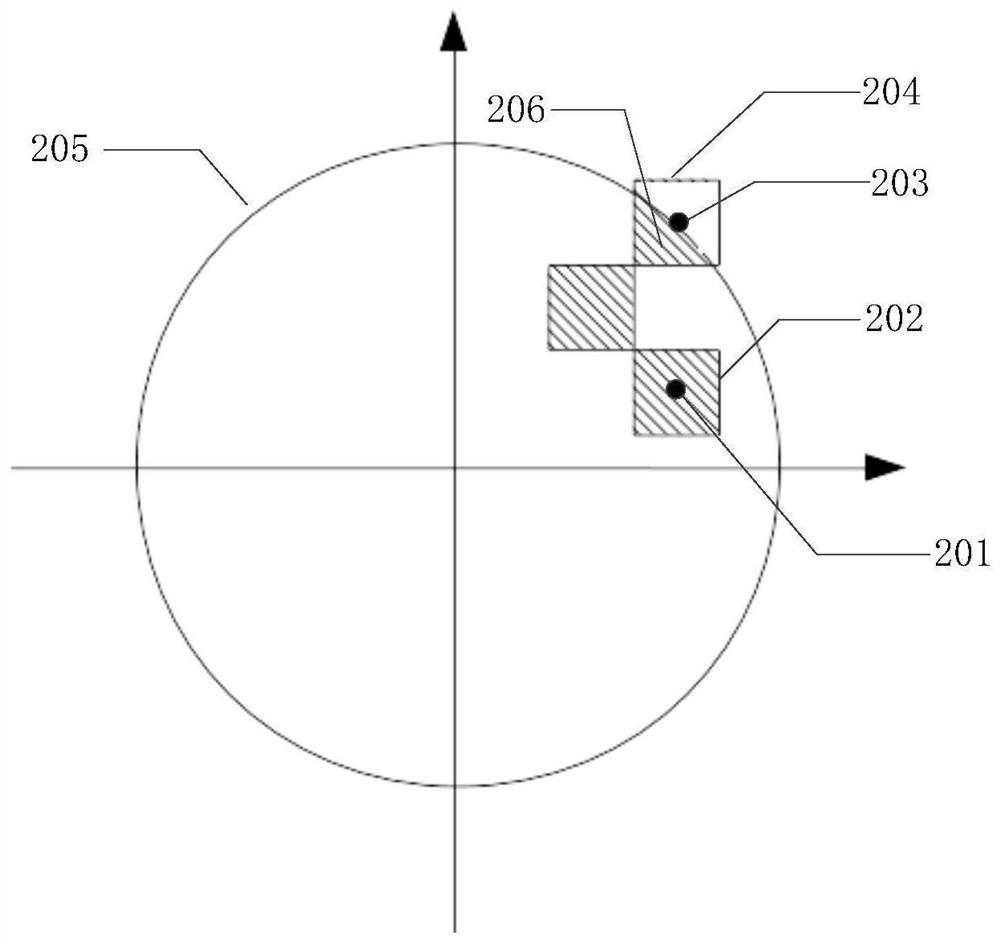

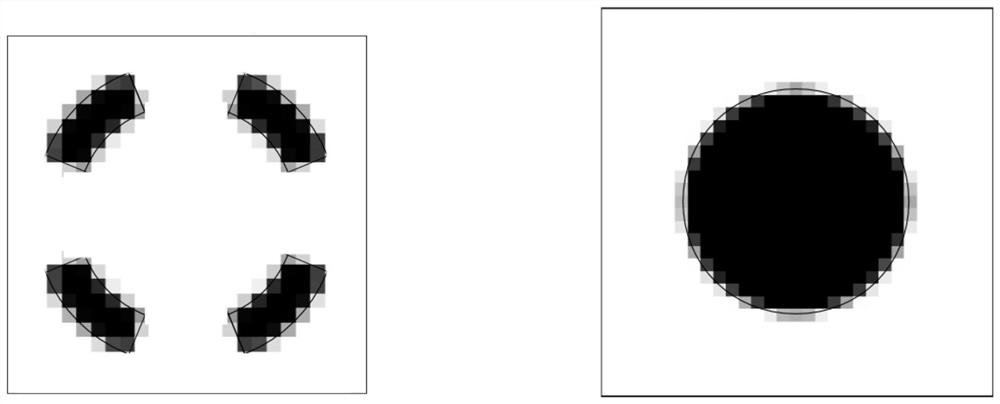

Method and device for obtaining light intensity distribution based on non-uniform calculation

ActiveCN109212913AImprove lithography efficiencyImprove sampling accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistPupil function

The invention discloses a light intensity distribution obtaining method and device based on non-uniform calculation. The method comprises the following steps: uniformly sampling a light source function and a pupil function in a frequency domain to obtain a light source sampling matrix and a pupil sampling matrix based on an intersecting area; The non-uniform inverse Fourier transform is applied tothe sample matrix of light source and pupil to obtain the cross transfer matrix. Determining a frequency domain kernel function of the cross transfer matrix; The sampling matrix of the mask functionin frequency domain and the sampling matrix of the kernel function in frequency domain are established. According to the sampling matrix of the mask function in frequency domain and the sampling matrix of the kernel function in frequency domain, the light intensity distribution in the specified position of the user is obtained through the inverse non-uniform Fourier transform. In the present application, since the sampling method based on the intersecting area is adopted, the calculation accuracy is improved, and at the same time, the inverse non-uniform Fourier transform is adopted, and underthe same sampling density, the calculation amount of the light intensity distribution can be reduced, thereby shortening the calculation time and improving the efficiency of photoresist lithography.

Owner:MOYAN COMPUTATIONAL SCI NANJING PTE LTD

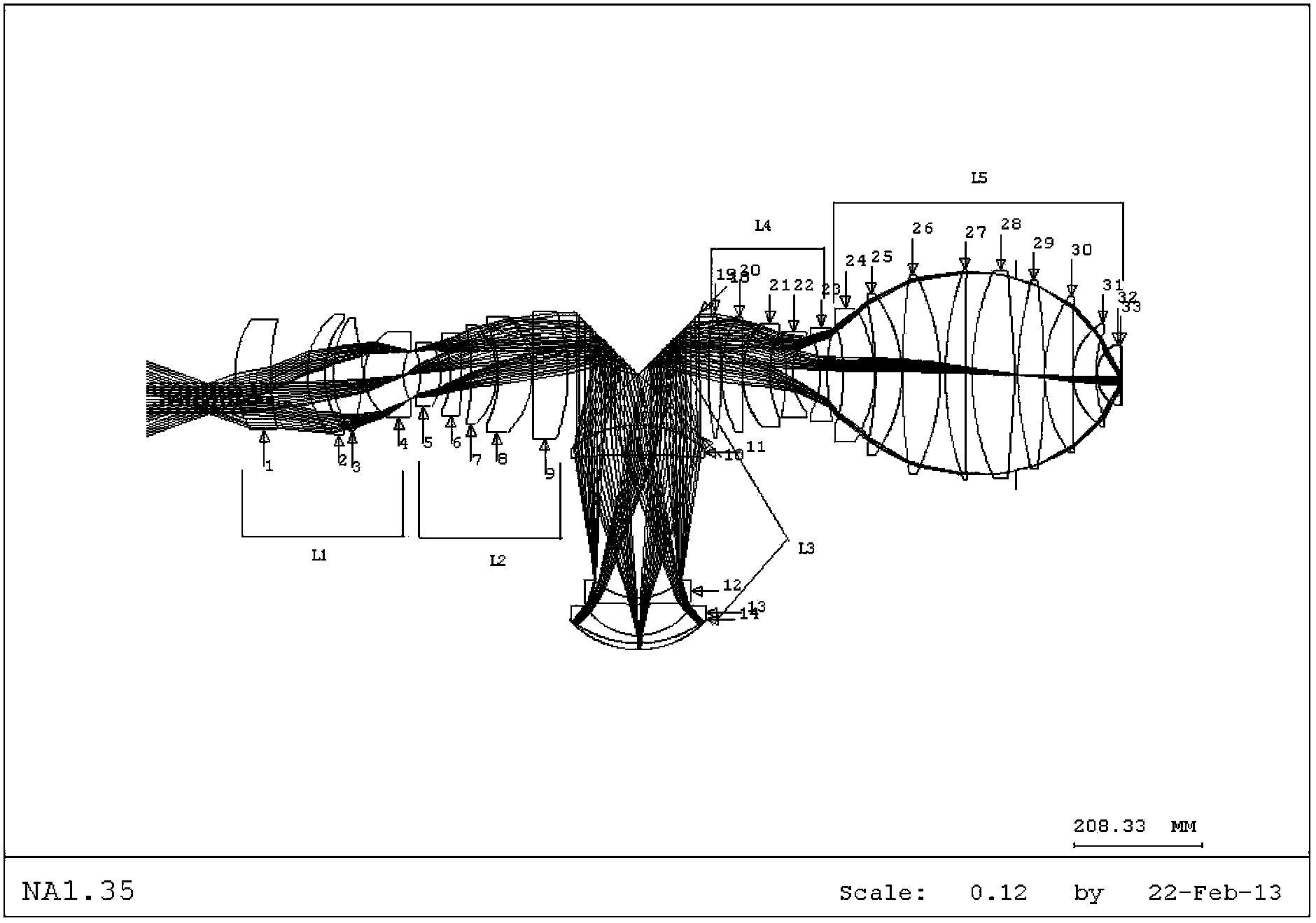

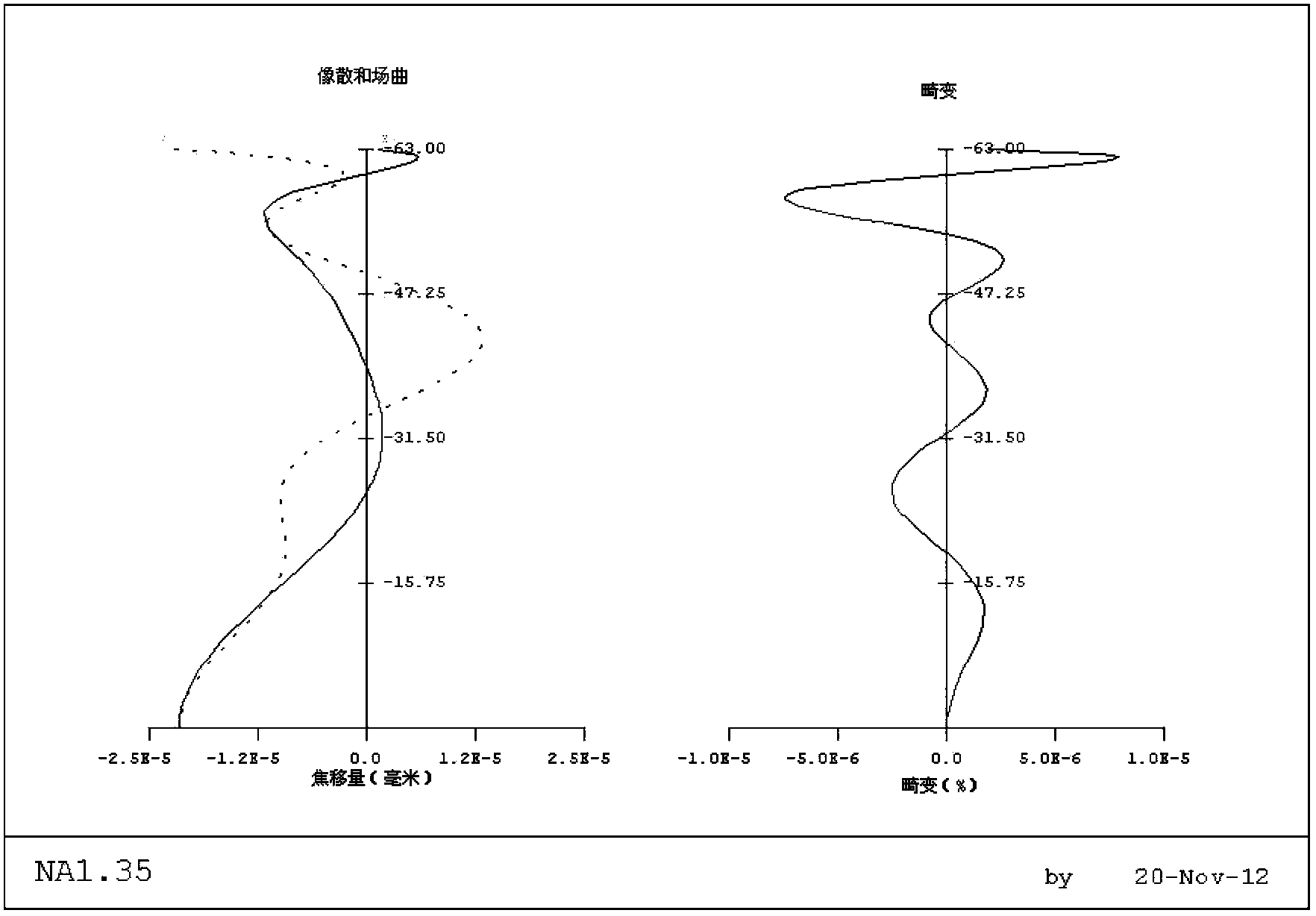

Immersed ultraviolet optical system

InactiveCN103149808BGood compensationImprove image qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusImaging qualityOptical axis

The invention provides an immersed ultraviolet optical system, which is used for forming an image of an object plane into an image plane. The immersed ultraviolet optical system comprises a first unit, a second unit, a third unit, a fourth unit and a fifth unit in the direction of an optical axis of the system. The first unit group L1 with positive refractive power, the second unit group L2 with positive refractive power, the third unit group L3 with positive refractive power, the fourth unit group L4 with negative refractive power and the fifth unit group L5 with negative refractive power are orderly arranged in the incidence direction of light beams. The immersed ultraviolet optical system provided by the invention can compensate aberration better, improve imaging quality, promote system resolution and improve photoetching efficiency.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Fully-spherical projection objective

InactiveCN102331616BEasy to correctAberration correctionPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical axisImaging quality

The invention provides a fully-spherical projection objective which is used for forming an image of an object plane into an image plane. The fully-spherical projection objective, along the direction of an optical axis, comprises a first lens group, a second lens group, a third lens group, a fourth lens group and a fifth lens group; and in a sequence of the incident direction of a light beam, the first lens group G1 has a positive focal power, the second lens group G2 has a negative focal power, the third lens group G3 has the positive focal power, the fourth lens group G4 has the negative focal power, and the fifth lens group G5 has the positive focal power. All lenses in the fully-spherical projection objective are spherical lenses, not aspherical lenses. By adoption of the fully-spherical projection objective, aberration can be better compensated, imaging quality is improved, system resolution is improved, and photoetching efficiency is improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

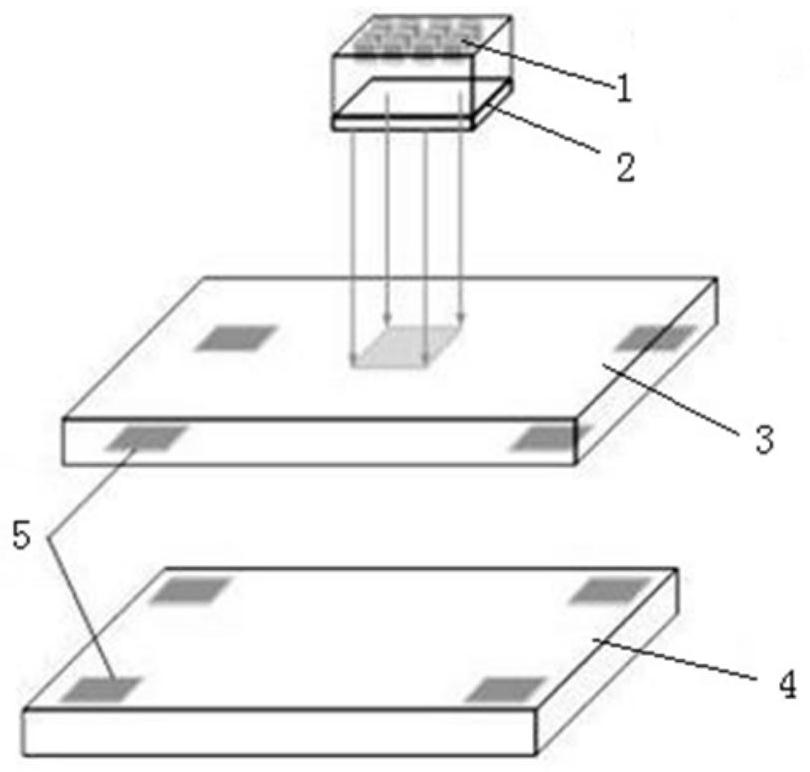

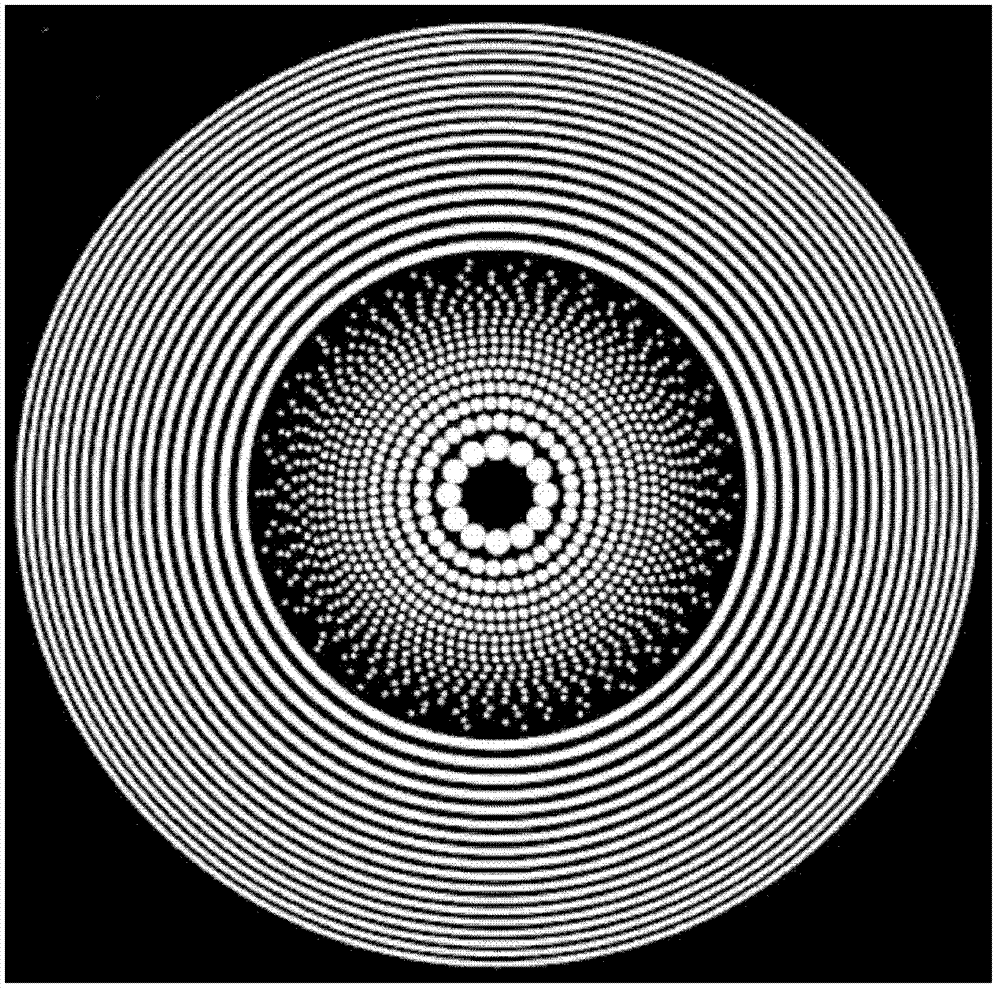

Hybrid lithography system and hybrid lithography method

ActiveCN106681106BImprove lithography efficiencyLower Lithography CostsPhotomechanical exposure apparatusMicrolithography exposure apparatusNanolithographyMicro nano

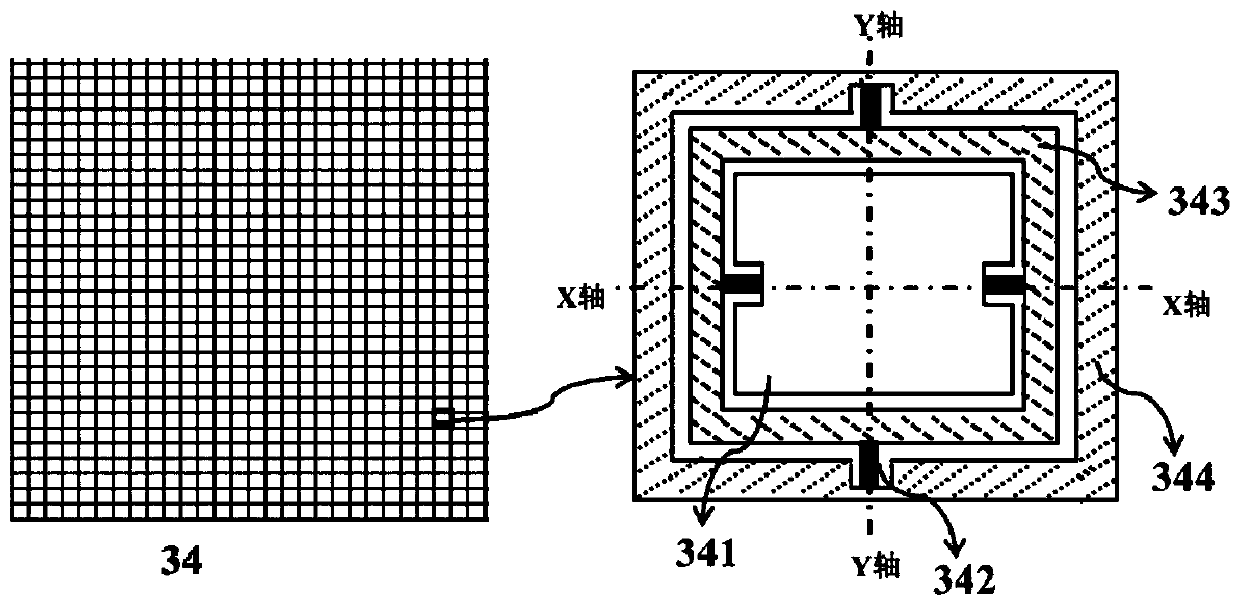

A hybrid lithography system (10) and a hybrid lithography method. The system comprises a light source (11), a light beam shaper (12), a light-field modulator (13), a reflector (14), an imaging optical system and a phase device (15), wherein the beam shaper (12) is used for shaping light beams emitted by the light source (11). the light-field modulator (13) is used for generating pattern light with the shaped light beams; the imaging optical system and the reflector (14) are used for transferring a light field to the surface of a lithographic member (101) to be exposed, so as to realize direct writing lithography; and the phase device (15) is used for forming an interference exposure field on the surface of the lithographic member (101), so as to realize interference lithography. The hybrid lithography system (10) has two functions of direct writing lithography and interference lithography, and can perform hybrid lithography, thereby improving the nanometre lithography efficiency and having great significance in promoting the application of devices and materials related to micro-nano structures.

Owner:SVG TECH GRP CO LTD +1

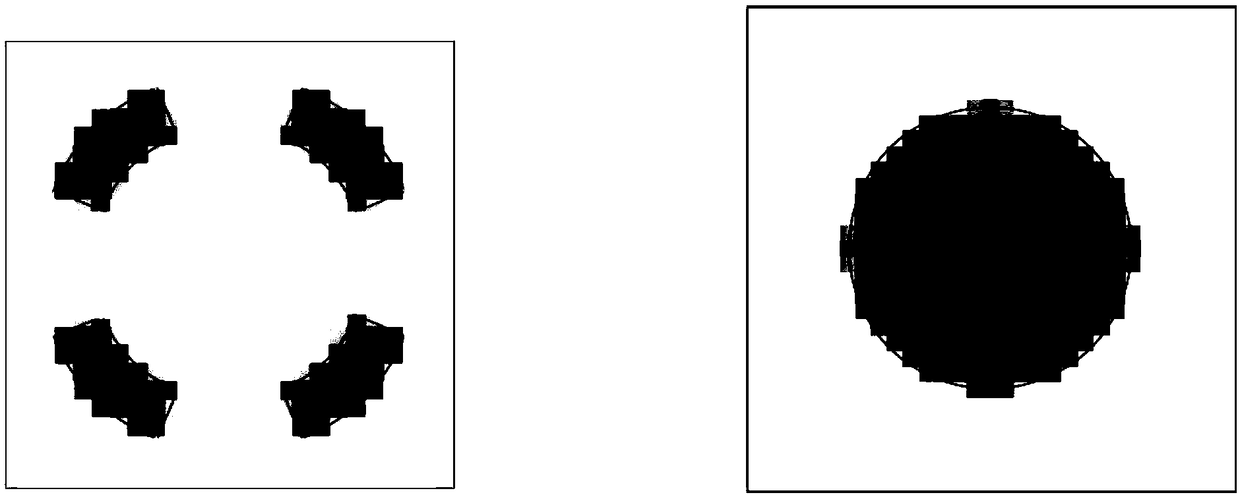

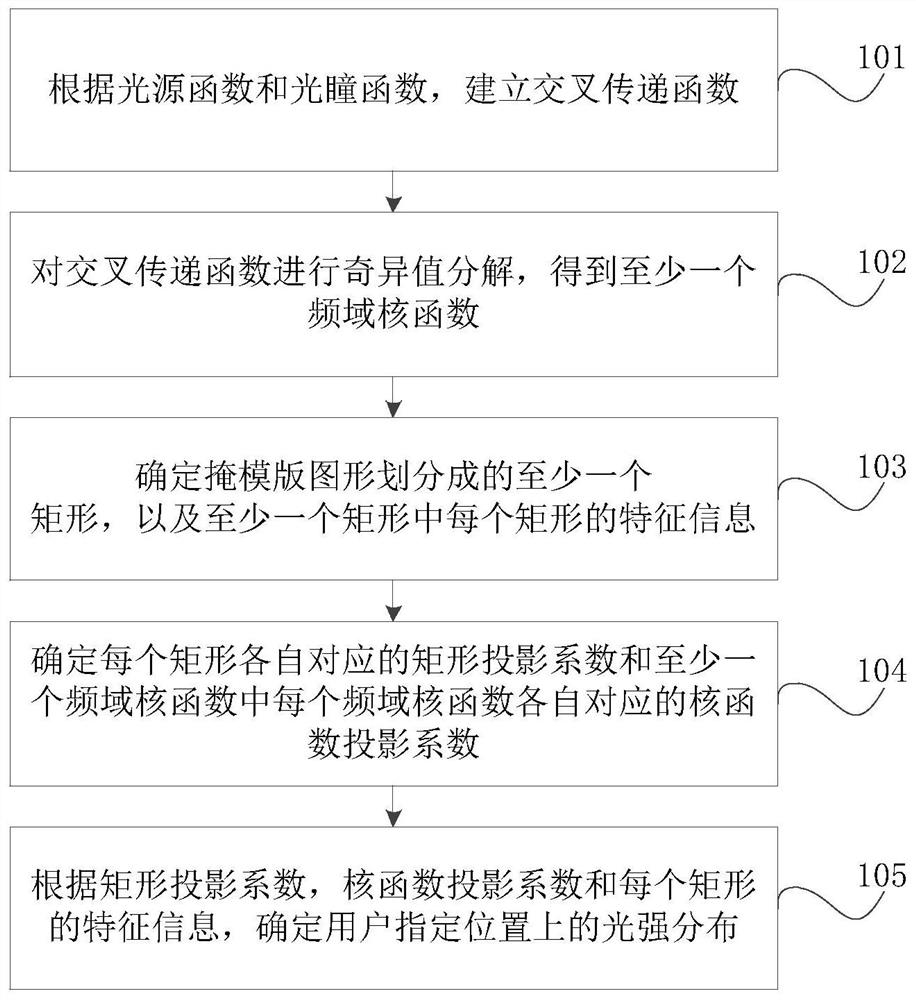

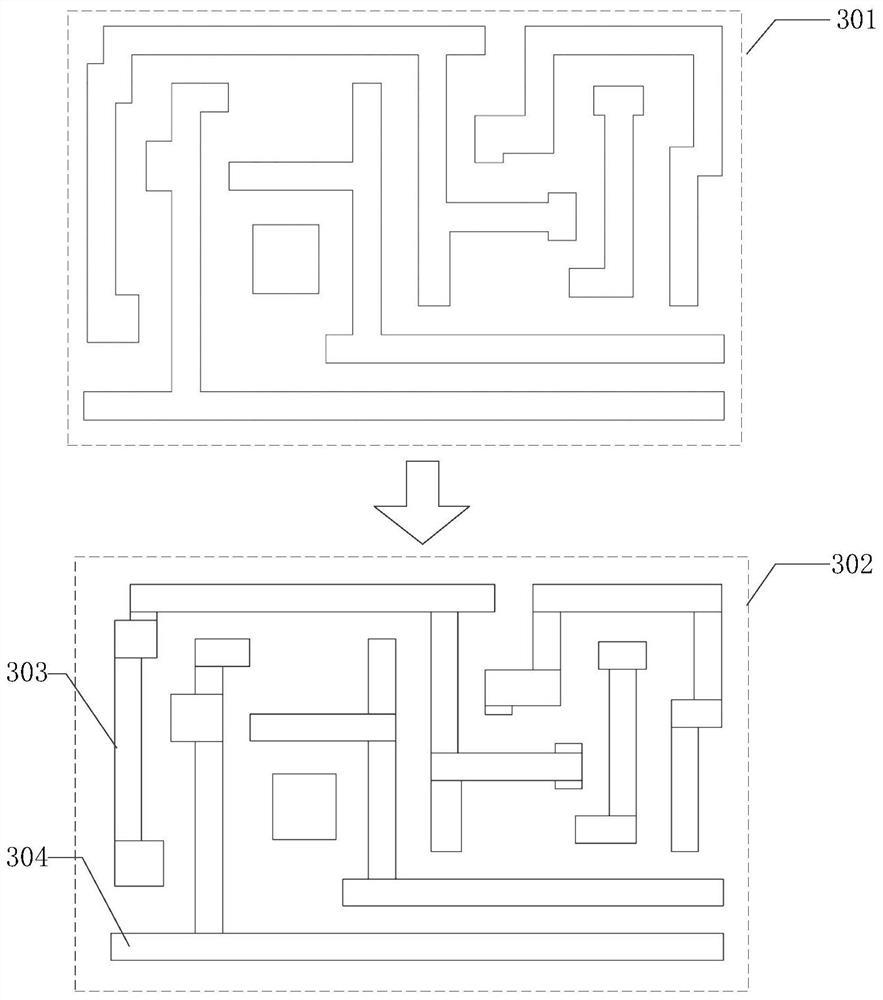

Method and device for quickly determining light intensity distribution based on mask pattern processing

ActiveCN109164683BQuick fixAvoid double countingPhotomechanical exposure apparatusCAD circuit designGraphicsSingular value decomposition

The present application discloses a light intensity distribution fast determination method and device based on mask graphics processing. The method comprises the following steps of: establishing a cross transfer function according to a light source function and a pupil function; Performing singular value decomposition on the cross transfer function to obtain at least one frequency domain kernel function; Determining at least one rectangle into which the mask pattern is divided, and characteristic information of each rectangle in the at least one rectangle; Determining a rectangular projectioncoefficient corresponding to each rectangle and a kernel function projection coefficient corresponding to each kernel function in at least one frequency domain; According to the rectangular projectioncoefficients, the kernel projection coefficients and the characteristic information of each rectangle, the light intensity distribution at the specified position of the user is determined. In the present application, the light intensity distribution is quickly determined by the kernel function projection coefficient and the rectangular projection coefficient. Due to the existence of repetitive rectangles in the rectangles divided by the mask pattern, repetitive calculation can be avoided when calculating the rectangular projection coefficients, the calculation time can be reduced, and the lithographic efficiency can be improved.

Owner:MOYAN COMPUTATIONAL SCI NANJING PTE LTD

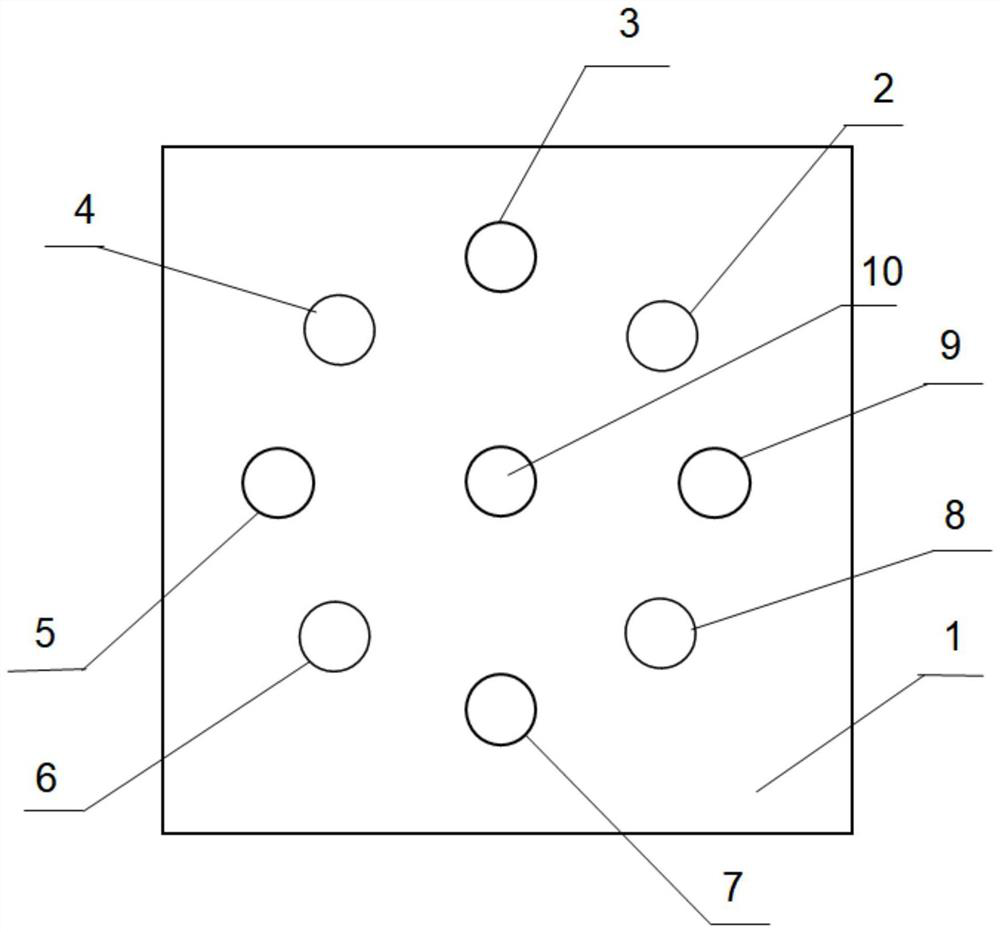

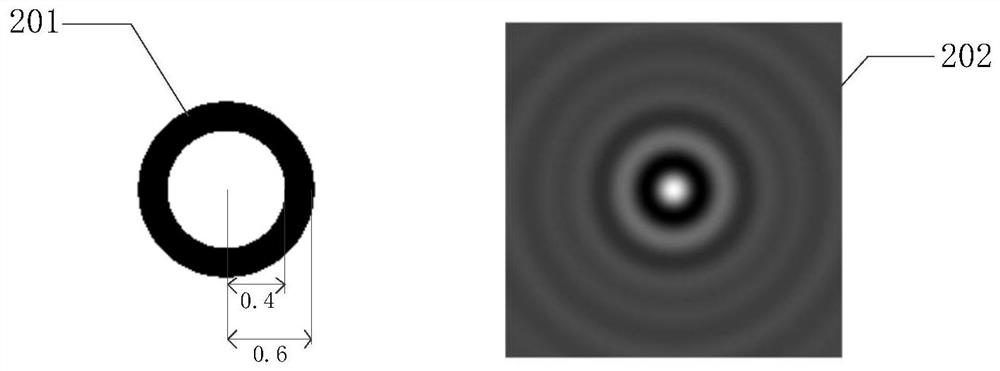

Projection photoetching system with composite photon sieve

ActiveCN102289157BImprove efficiencyFast High-Volume LithographyScreening processesPhotomechanical exposure apparatusLighting systemPhotolithography

The invention relates to the technical field of micro-nanometer processing and discloses a projection photoetching system with a composite photon sieve. The system comprises a lighting system, a mask plate, the composite photon sieve and a substrate, which are sequentially arranged, wherein the lighting system is used for generating an incident light and emitting the incident light to the mask plate; the mask plate is used for providing an object space for imaging the composite photon sieve and emitting the incident light to the composite photon sieve through the mask plate; the composite photon sieve is used for realizing an imaging function and imaging a graph on the mask plate on the substrate; and the substrate is used for receiving an image, formed by the composite photon sieve, of the graph on the mask plate. The composite photon sieve projection photoetching system has the advantages that: because the composite photon sieve is adopted to replace a projection objective in the conventional projection photoetching system, the advantage of high efficiency of the conventional projection photoetching system can be reserved, quick massive photoetching is realized, photoetching efficiency is improved, cost can be effectively reduced, and the volume of the system is reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method and device for obtaining light intensity distribution based on non-uniform calculation

ActiveCN109212913BImprove lithography efficiencyImprove sampling accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusPupil functionPUPILLARY FUNCTIONS

Owner:MOYAN COMPUTATIONAL SCI NANJING PTE LTD

Photoresist coating device and method

InactiveCN113448172AImprove coating uniformitySimple structureSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusCoated surfacePhotoresist

The invention discloses a photoresist coating device and method, wherein the photoresist coating device comprises a liquid gasification module which is used for converting liquid photoresist into gaseous photoresist and conveying the gaseous photoresist to a photoresist coating module; the photoresist coating module comprises a steam coating unit, a cover plate and a bearing table; the steam coating unit comprises a steam channel and a steam spraying hole; the steam spraying holes penetrate through the cover plate; the bearing table is used for loading a substrate; the cover plate is arranged on the side, close to the substrate, of the bearing table; and the steam coating unit obtains the gaseous photoresist through the steam channel, and conveys the gaseous photoresist to a to-be-coated surface of the substrate on the bearing table through the steam spray holes to form a photoresist coating layer. The invention provides a photoresist coating device and method, and aims to solve the problem of non-uniform photoresist coating thickness.

Owner:CHANGXIN MEMORY TECH INC

A kind of microlens mask and preparation method thereof

ActiveCN110187599BHigh energyHigh resolutionOriginals for photomechanical treatmentLensMicrosphereColloidal lithography

The invention discloses a microlens mask and a preparation method thereof, belonging to the technical field of nanophotonic devices. The method comprises: assembling a single-layer polystyrene microsphere on a substrate to form a first sample; coating the first sample with Cloth the first colloid, etch the first colloid to expose part of the polystyrene microspheres to form a second sample; remove the polystyrene microspheres on the second sample to obtain a spherical cavity mold; fill the second sample in the spherical cavity mold The photoresist is shaped and exposed to cure the second photoresist; the second photoresist and the spherical cavity mold are separated to obtain a reusable microlens mask. The microlens reticle prepared by the invention can be repeatedly used in large-area assisted lithography micro-nano patterns, and has low cost, short period and high efficiency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

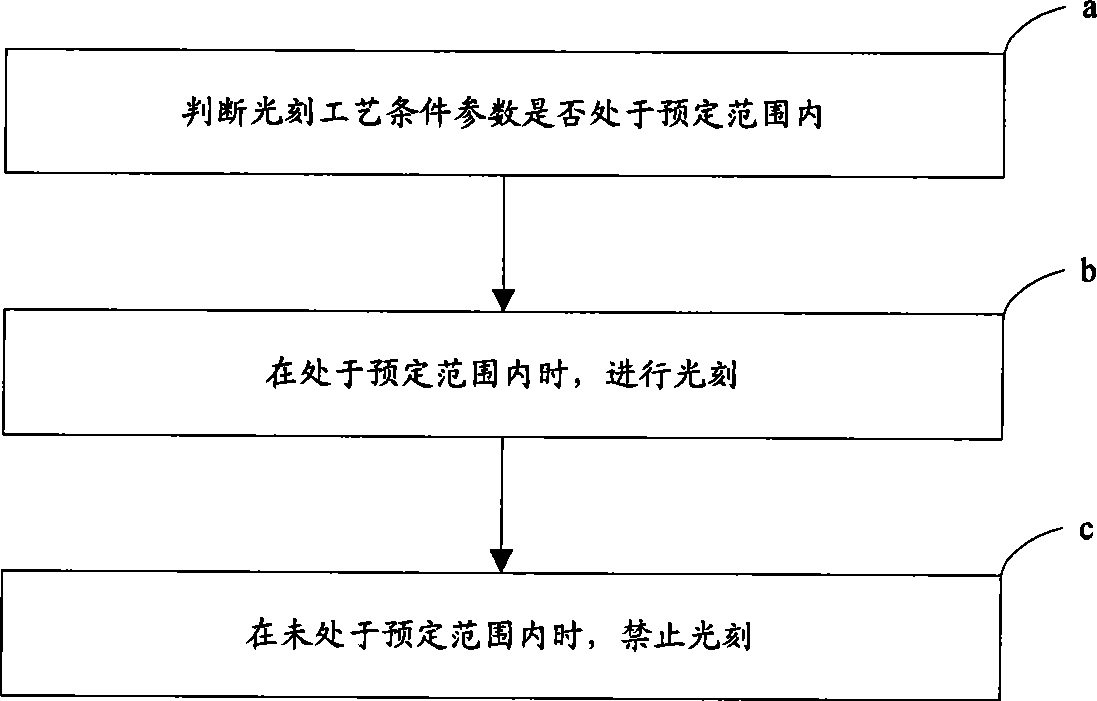

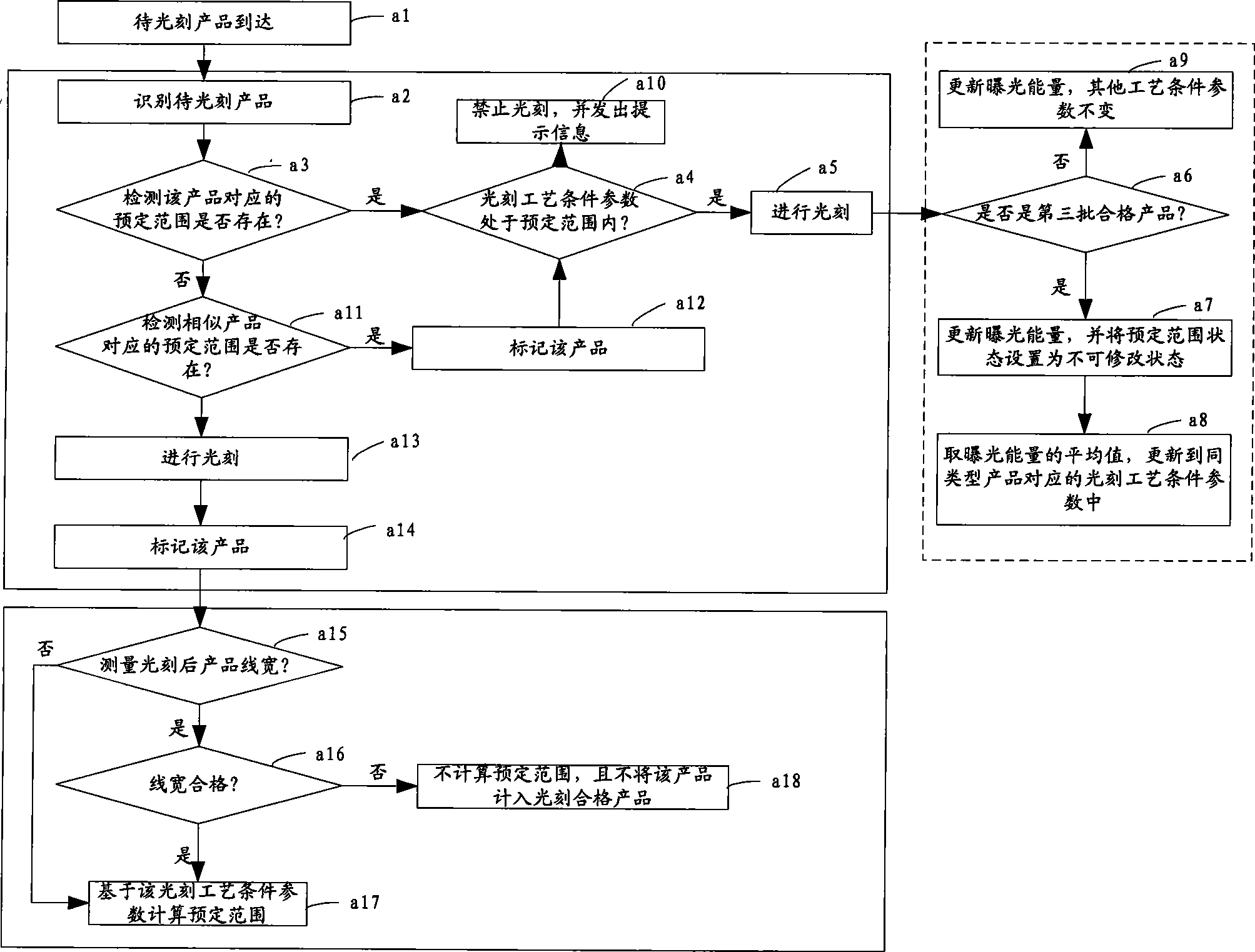

Photoetching method and system

ActiveCN101655666BImprove lithography efficiencySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusProcess conditionsComputer science

The invention provides a photoetching method and a photoetching system to improve photoetching efficiency. The method comprises the following steps: judging whether photoetching process condition parameters are in a predetermined range; when the photoetching process condition parameters are in the predetermined range, performing photoetching; and when the photoetching process condition parametersare not in the predetermined range, prohibiting the photoetching. The system comprises a judging unit for judging whether the photoetching process condition parameters are in the predetermined range,a photoetching unit for performing the photoetching when the judging unit judges that the photoetching process condition parameters are in the predetermined range, and a photoetching prohibiting unitfor prohibiting the photoetching when the judging unit judges that the photoetching process condition parameters are not in the predetermined range.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Single-sided digital photoetching system

InactiveCN114265287AAchieve target positioningHigh precisionFinal product manufacturePhotomechanical exposure apparatusEngineering physicsMaterials science

The invention provides a single-sided digital photoetching system. The single-sided digital photoetching system comprises a first platform, a second platform, a photoetching main body positioned between the first platform and the second platform, target point cameras arranged on two sides of the photoetching main body, and a transmission assembly for bearing the first platform and the second platform, the first platform and the second platform are both used for bearing a to-be-photoetched circuit board, the to-be-photoetched circuit board comprises a to-be-photoetched surface, and the transmission assembly is used for driving the first platform or the second platform to move towards the photoetched main body; and the target point camera is used for acquiring image information of a to-be-photoetched surface of the to-be-photoetched circuit board, so that the photoetching main body alternately performs digital photoetching treatment on the to-be-photoetched surface of the to-be-photoetched circuit board on the first platform and the second platform according to the image information. According to the single-sided digital photoetching system provided by the invention, the photoetching efficiency is improved, and the photoetching precision is improved.

Owner:广东科视光学技术股份有限公司

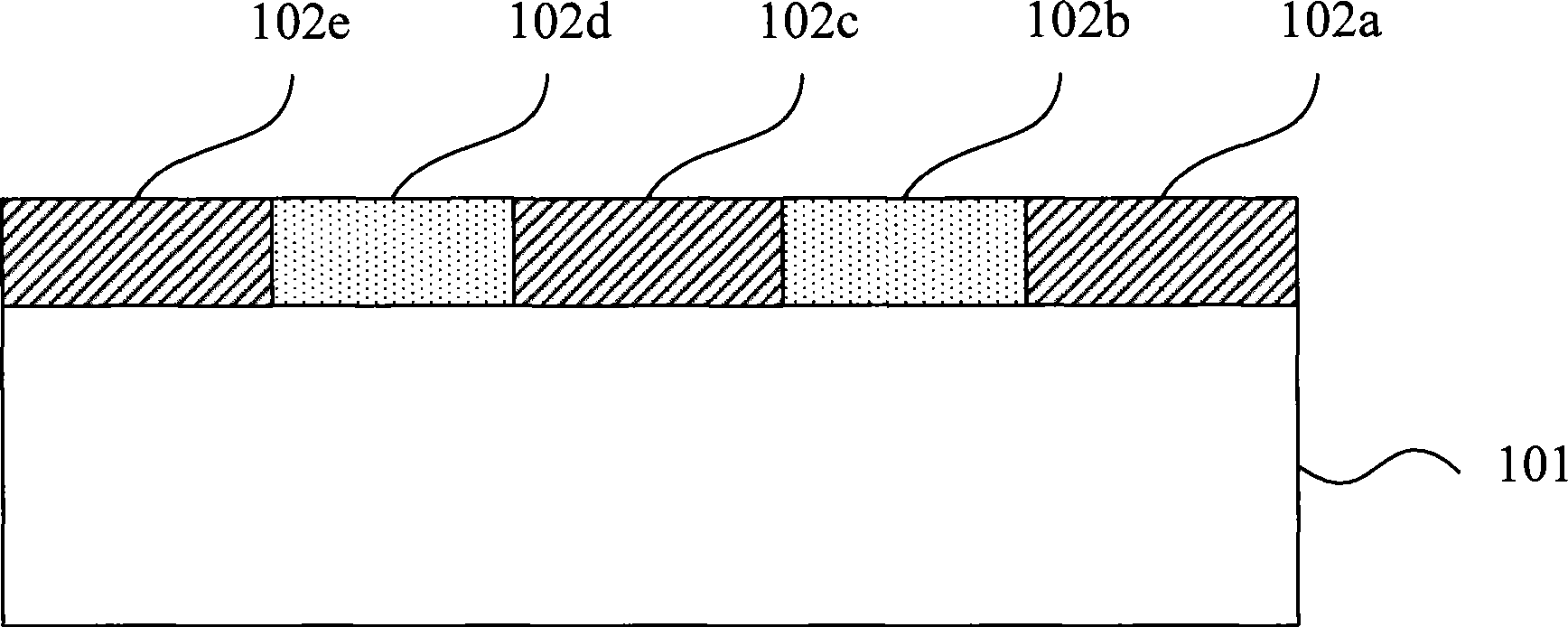

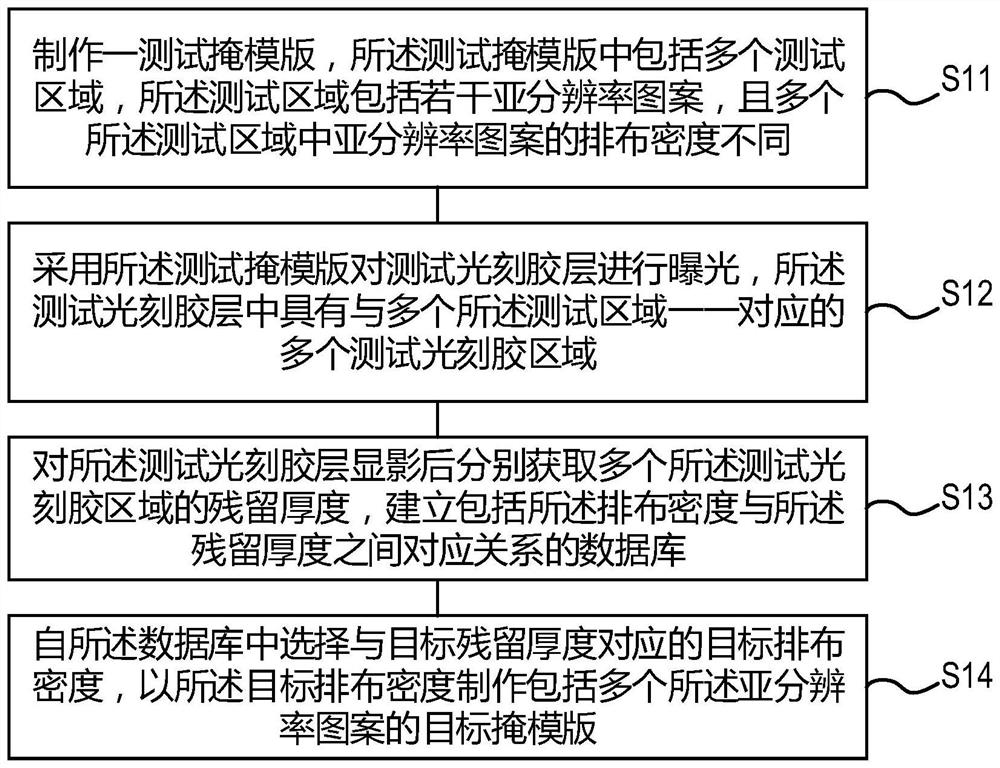

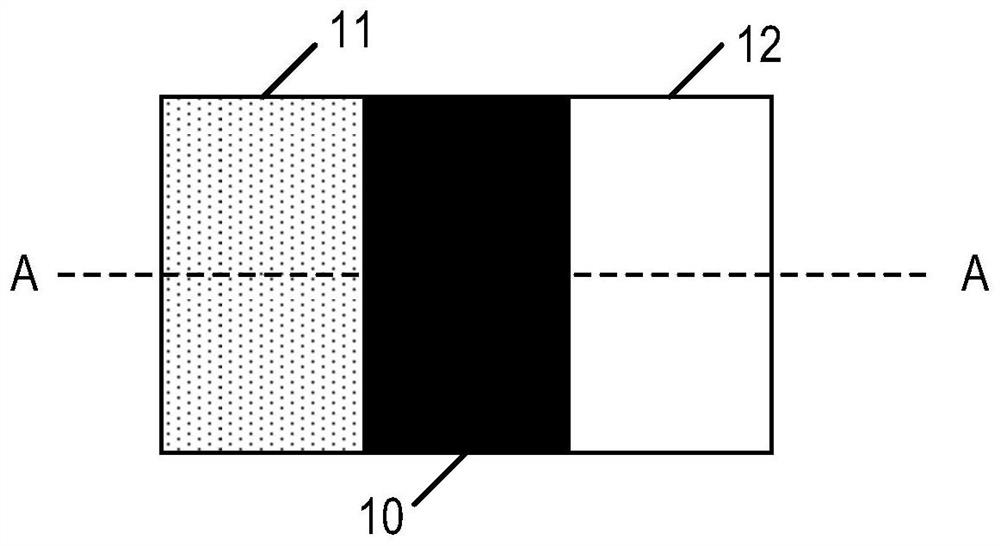

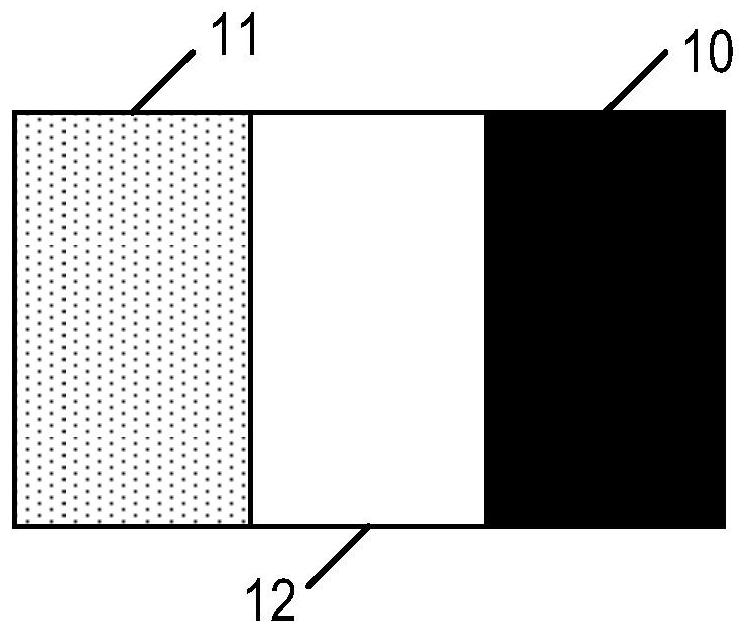

Mask forming method and mask

ActiveCN109752930BPromote rapid formationEasy to operatePhotomechanical exposure apparatusMicrolithography exposure apparatusImage resolutionEngineering

The invention relates to the technical field of semiconductor manufacturing, in particular to a method for forming a reticle, a photolithography method and a reticle. The method for forming a reticle includes the following steps: making a test reticle including a plurality of test areas, the test area includes several sub-resolution patterns, and the sub-resolution patterns in each test area have different arrangement densities; using the test reticle to pair The test photoresist layer is exposed; after developing the test photoresist layer, a database including the corresponding relationship between the arrangement density and the residual thickness is established; the target arrangement density corresponding to the target residual thickness is selected from the database, and the Fabricate a target reticle including a plurality of sub-resolution patterns according to the target arrangement density. The invention greatly simplifies the operation of forming a photoresist layer with a specific thickness on the surface of the wafer, reduces the cost of photolithography, and improves the efficiency of photolithography.

Owner:YANGTZE MEMORY TECH CO LTD

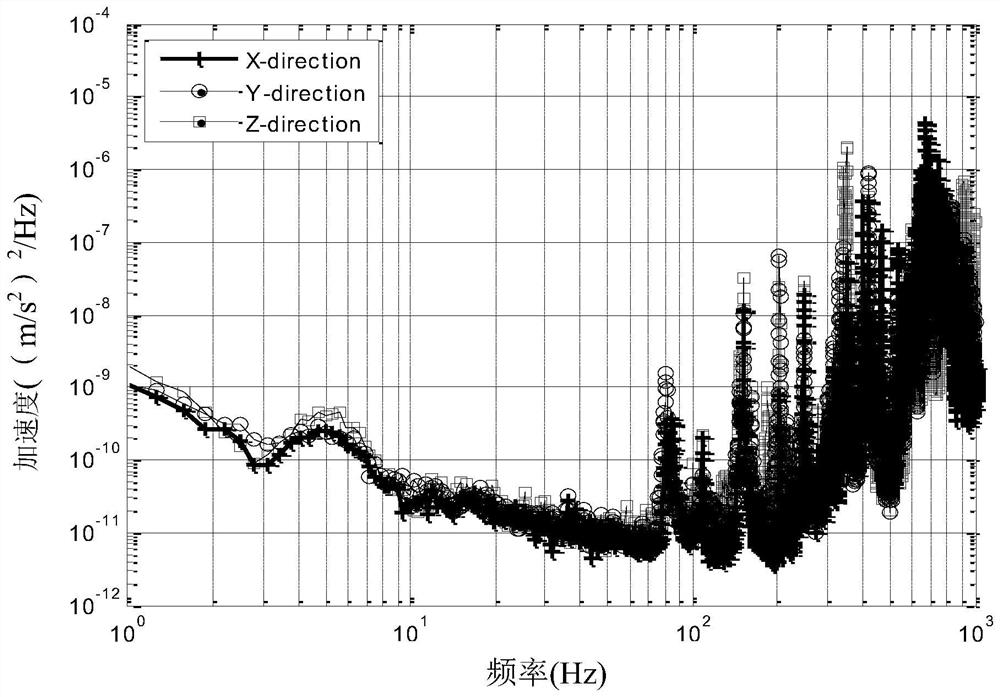

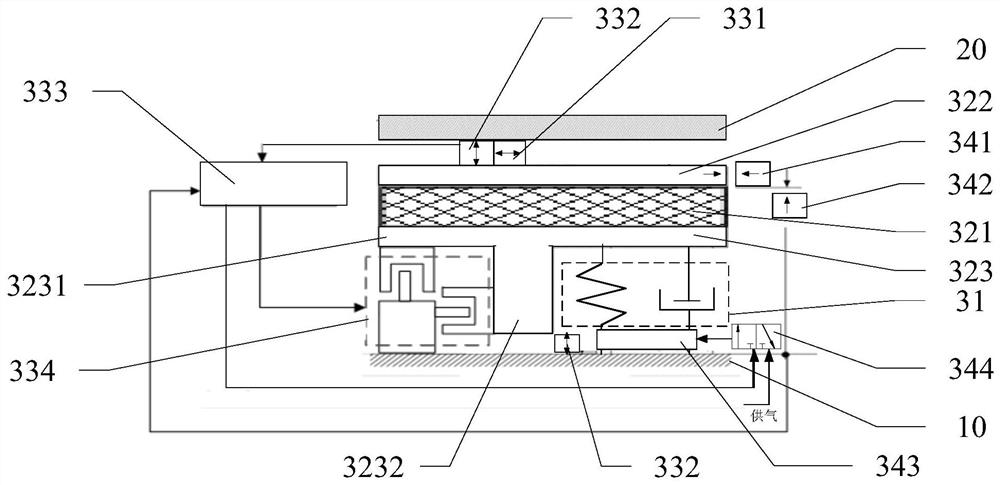

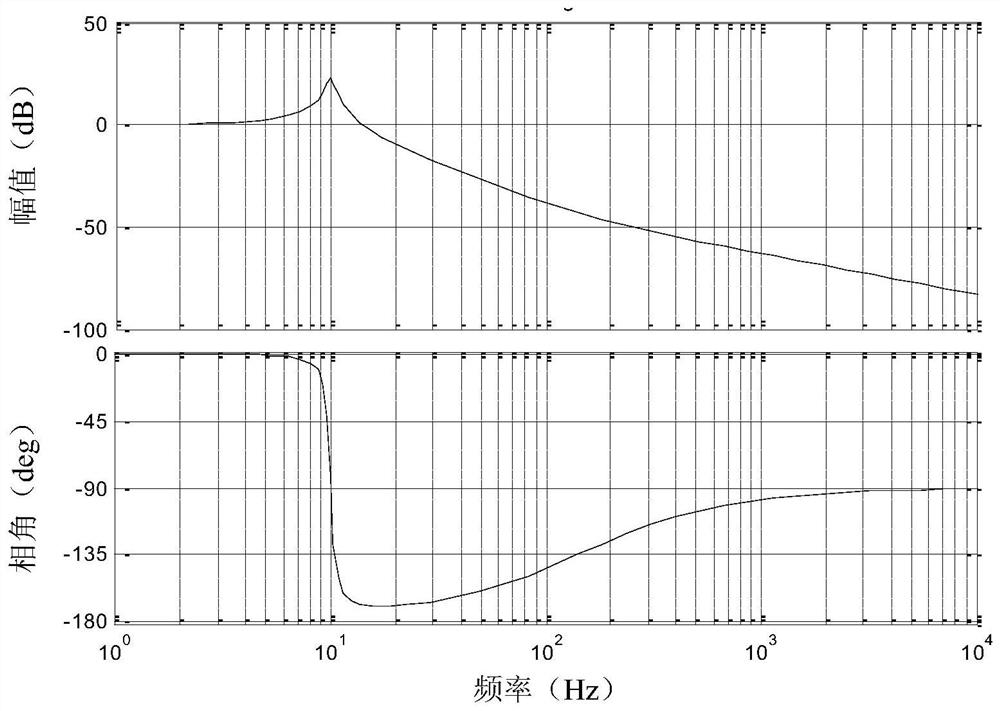

Vibration absorber, method of reducing disturbing vibration, and photolithography machine

ActiveCN107783382BImprove vibration damping effectSimple structurePhotomechanical exposure apparatusMicrolithography exposure apparatusIsolatorMachine

The invention discloses a method for reducing interference vibration, which includes steps of performing first isolation on interference vibration by a vibration isolator, and performing a secondary isolation on the disturbance vibration from the vibration isolator by adopting a damper. The method of reducing the interference vibration adopts two vibration reducing methods, thus the vibration reducing effect is improved. The invention further discloses an absorber, which is arranged between a substrate of the device and a machine load; the absorber can reduce the influence of the interferencevibration on the device and further eliminate the target position change of the machine load in relative the external world under the heavy load compression for a long time. The invention further discloses a photoetching machine applying the absorber. After adopting the absorber, the stability of the photoetching machine is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

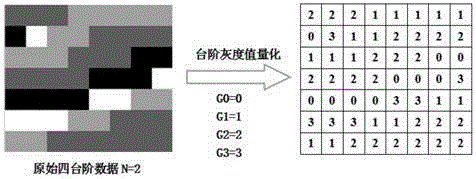

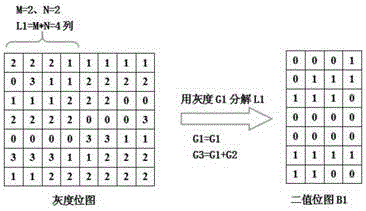

Laser direct writing method based on large-area multi-step binary optical element

ActiveCN104570619BPrecise Control of Exposure MeteringImprove lithography efficiencyDiffraction gratingsPhotomechanical exposure apparatusData fileComputer science

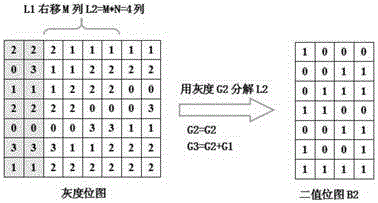

The invention discloses a laser direct writing method based on large-area multi-step binary optical element, which comprises the following steps: processing a 2N-order step data document into a gray BMP image with gray values starting from G0=0 to G2<N>-1=2<N>-1, decomposing the gray BMP image according to exposure metering accumulation formula P=P1+P2+....Pn, Pn=2<n-1>*P1 (n<=N), expressing the exposure metering of all the 2<N>step exposure through separately or accumulatively combination, to realize the covering of the exposure metering of all the steps by maximally overlapping N exposures (P=P1+P2+....Pn) at the position area in the Y stepping direction. The exposure metering of each step is decomposed into X and Y two-dimension unit meterings which are superposed. By adopting the mode of scanning the synchronous pulse triggering exposure, on one hand, the exposure metering is accurately controlled, on the other hand, the photoetching efficiency is improved, all the data are written only once in an entirely digital manner, alignment nesting is not required, and the error probability brought in the middle links can be reduced.

Owner:SVG TECH GRP CO LTD

Photoetching method of superfine structure

ActiveCN102591139BFix production issuesNo loss of efficiencySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOptoelectronicsElectron-beam lithography

The invention provides a photoetching method of a superfine structure. The photoetching method comprises the steps that: a structure material layer and a first hard mask material layer are formed on a substrate; a first photoetching is carried out for forming a first hard mask pattern; a second hard mask material layer is formed on the first hard mask pattern; and a second photoetching is carriedout for forming a second hard mask pattern, wherein light sources of the first photoetching and the second photoetching are different and are selected from either an i line mercury arc lamp or an electron beam exposure system. According to the photoetching method of the superfine structure provided by the invention, the traditional optical photoetching technology and the electronic beam photoetching technology are combined for use, the electronic beam exposure is used for realizing the superfine pattern manufacture, and the optical photoetching is used for completing other patterns, so the manufacture problem of the superfine pattern can be effectively solved, and the efficiency is not reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com