Photoetching method and system

A technology of photolithography and photolithography technology, which is applied in the direction of micro-lithography exposure equipment, photolithography exposure device, electrical components, etc. Whether the engraving result is abnormal or not, so as to improve the efficiency of lithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

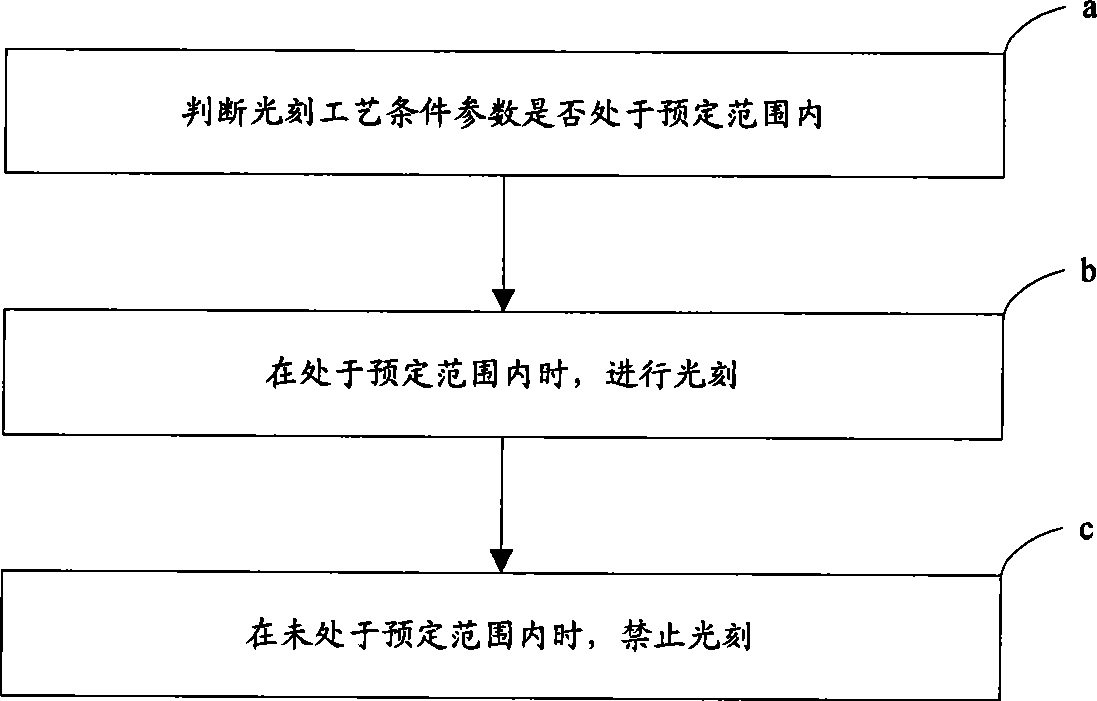

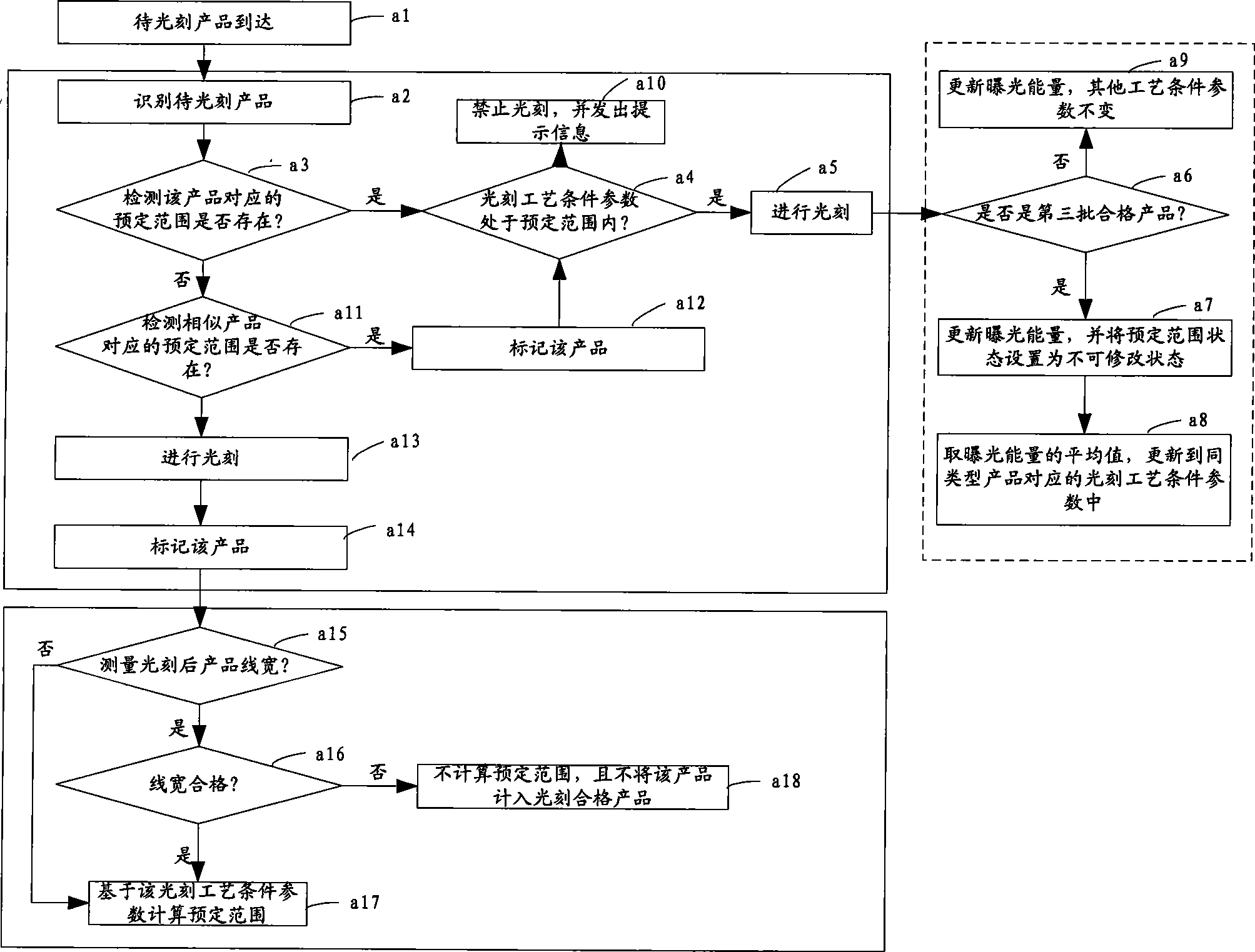

[0013] According to the analysis of the background technology, it can be seen that because the prior art may perform photolithography according to abnormal photolithography process condition parameters, the photolithography efficiency is reduced, so if the photolithography process condition parameters can be guaranteed to be reasonable, then it can be improved Lithography efficiency. Based on this consideration, the embodiment of the present invention proposes that the lithography efficiency can be improved through the following design idea: in the lithography process, based on the reasonable range of the lithography process condition parameters, it is judged whether the lithography process condition parameters can be used for lithography, if No, then the photolithography of the photolithography process conditions and parameters can be prohibited.

[0014] Based on the above design idea, the embodiment of the present invention proposes that the photolithography efficiency can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com