High-efficiency laser direct-writing photoetching method capable of realizing long-focal-depth small-focal-spot structure

A laser direct writing, high-efficiency technology, used in microlithography exposure equipment, optics, opto-mechanical equipment, etc. The effect of deep and long, small focal spot, improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the scanning scheme of the present invention, a further detailed description will be made below in conjunction with the accompanying drawings.

[0025] The present invention is a high-efficiency laser direct writing lithography method capable of realizing long focal depth and small focal spot structure, and the specific steps are as follows:

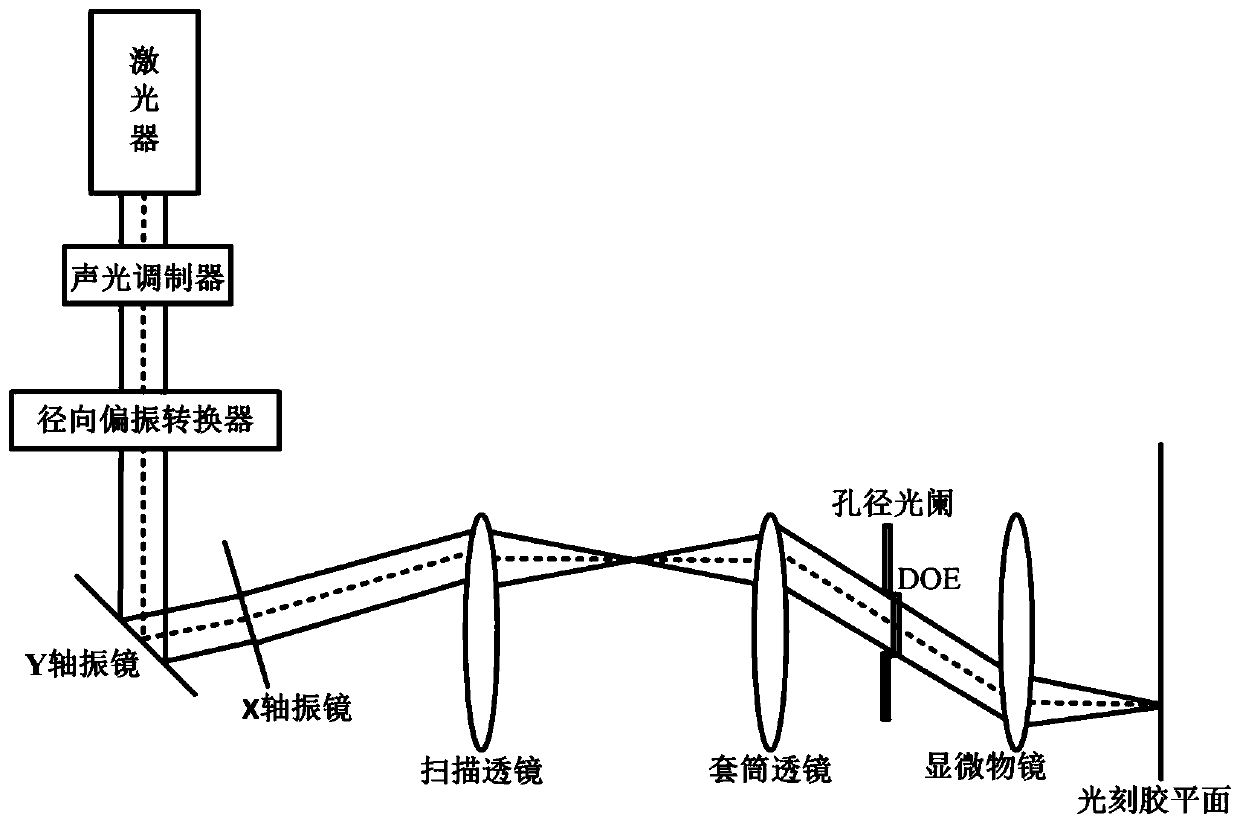

[0026] Step 1: Combine the two-dimensional galvanometer system, scanning lens, tube lens, diaphragm, DOE, and high numerical aperture microscope objective such as figure 1 Adjust to coaxial contour as shown;

[0027] Step 2: If figure 2 As shown, adjust the center of the X-axis galvanometer of the two-dimensional galvanometer system to coincide with the object focus of the scanning lens, the image focus of the scan lens coincides with the object focus of the sleeve lens, and the image focus of the sleeve lens It is coincident with the focal point of the object side of the high numerical aperture mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com