Hartmann wavefront sensor based on micro-prism array for pulse light beam quality detection

A beam quality and micro-prism technology, applied in the field of micro-prism Hartmann wavefront sensors, can solve the problems of different focal length errors of micro-lens units, affecting sensor accuracy, expensive and other problems, achieving easy mass production, simplified installation and adjustment, The effect achieved by the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

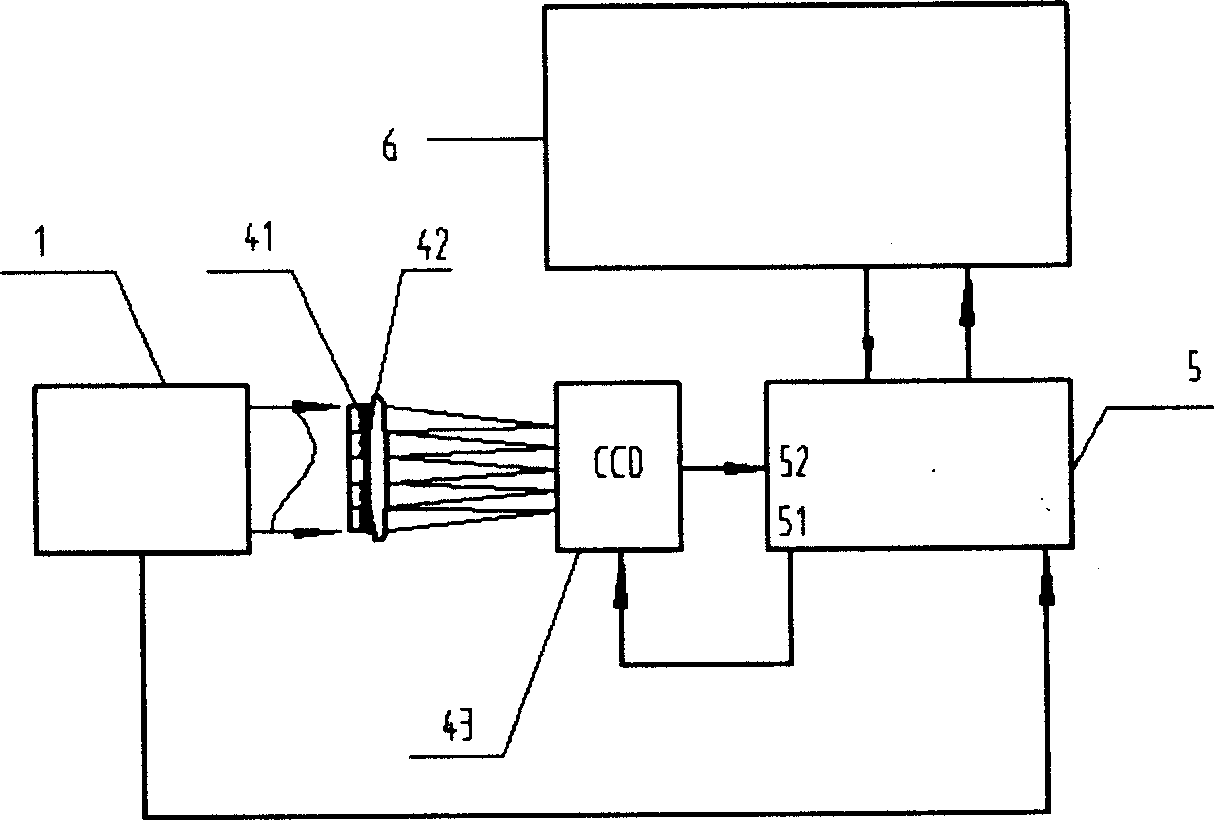

[0025] Such as image 3 As shown, the laser beam emitted by the laser light source 1 is irradiated on the microprism array 41, and is imaged by the Fourier lens 42. The entire beam aperture is evenly divided and forms a spot array on the photosensitive target surface of the CCD43; the laser light source simultaneously provides a synchronous signal to Data collection device 5, data collection device 5 sends synchronous signal 51 to CCD43, makes it start the exposure of certain length of time, after exposure is finished, CCD43 outputs the data information (analog or digital) of collection to data by data cable 52 The acquisition device 5 transmits the information to the computer 6 by the data acquisition device 5, and the computer 6 processes the obtained information to obtain the corresponding parameters of the laser beam.

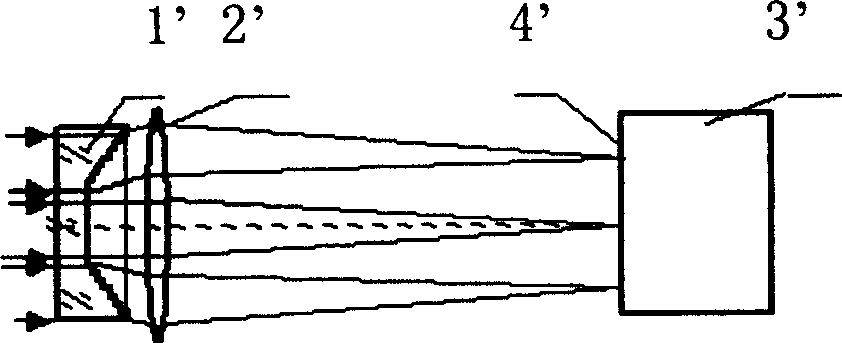

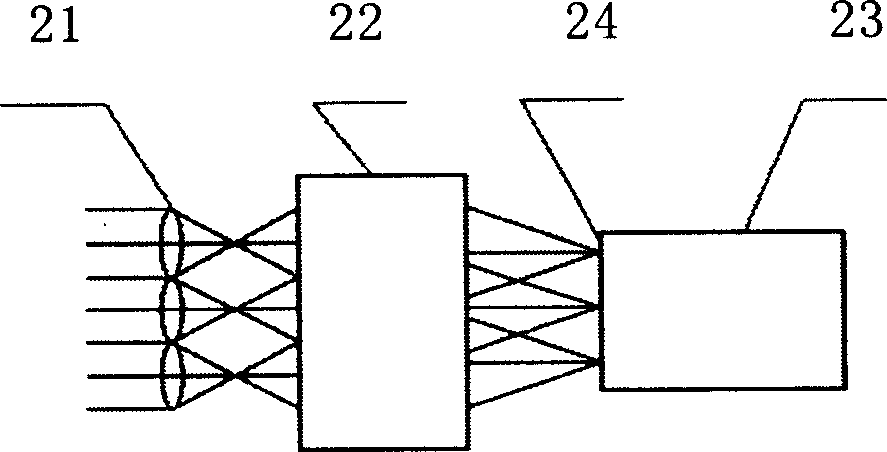

[0026] Such as Figure 4 As shown, the microprism Hartmann wavefront sensor is composed of a microprism array 41 with a variable period two-dimensional sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com