Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94 results about "Base exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Business process management for a message-based exchange infrastructure

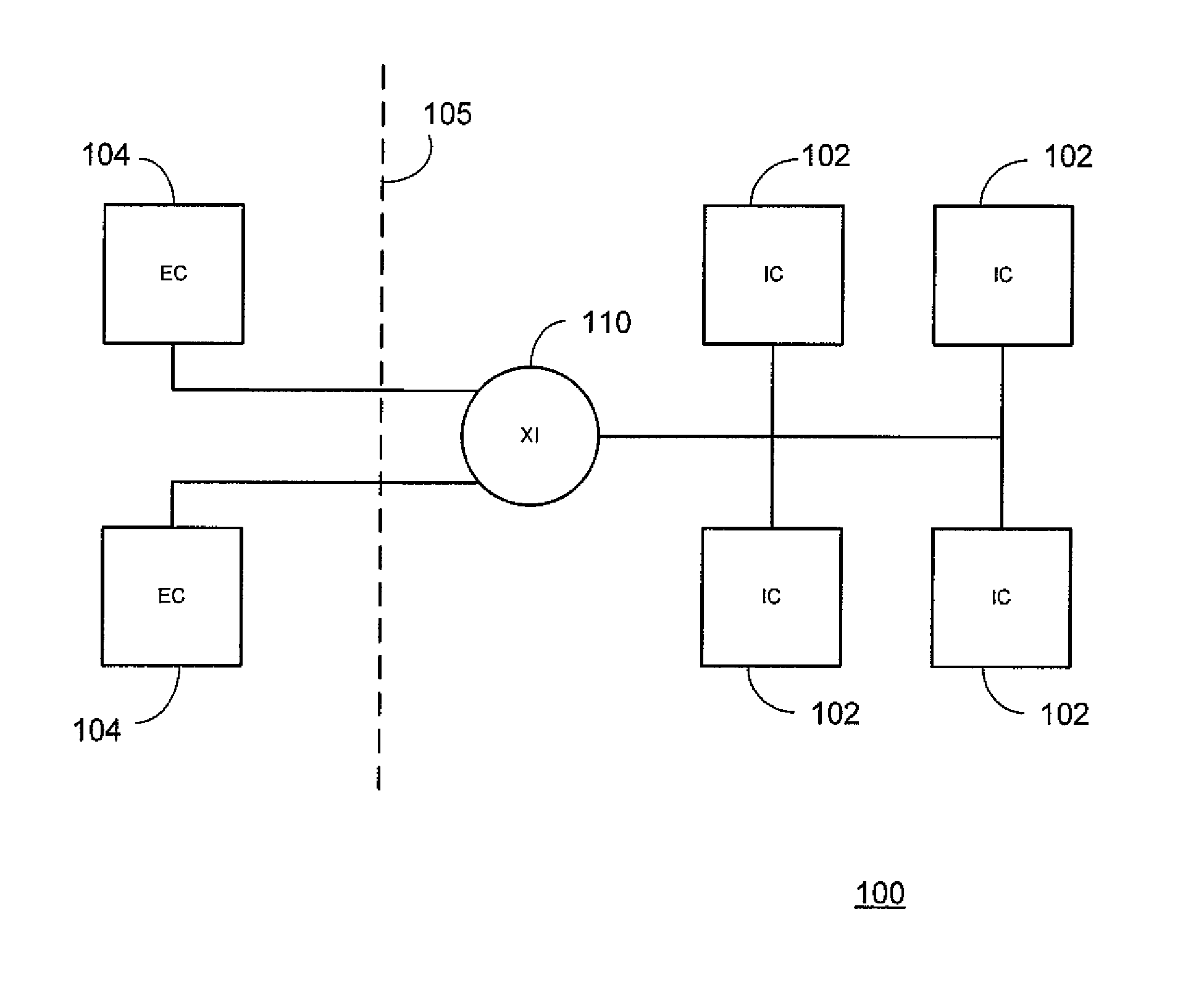

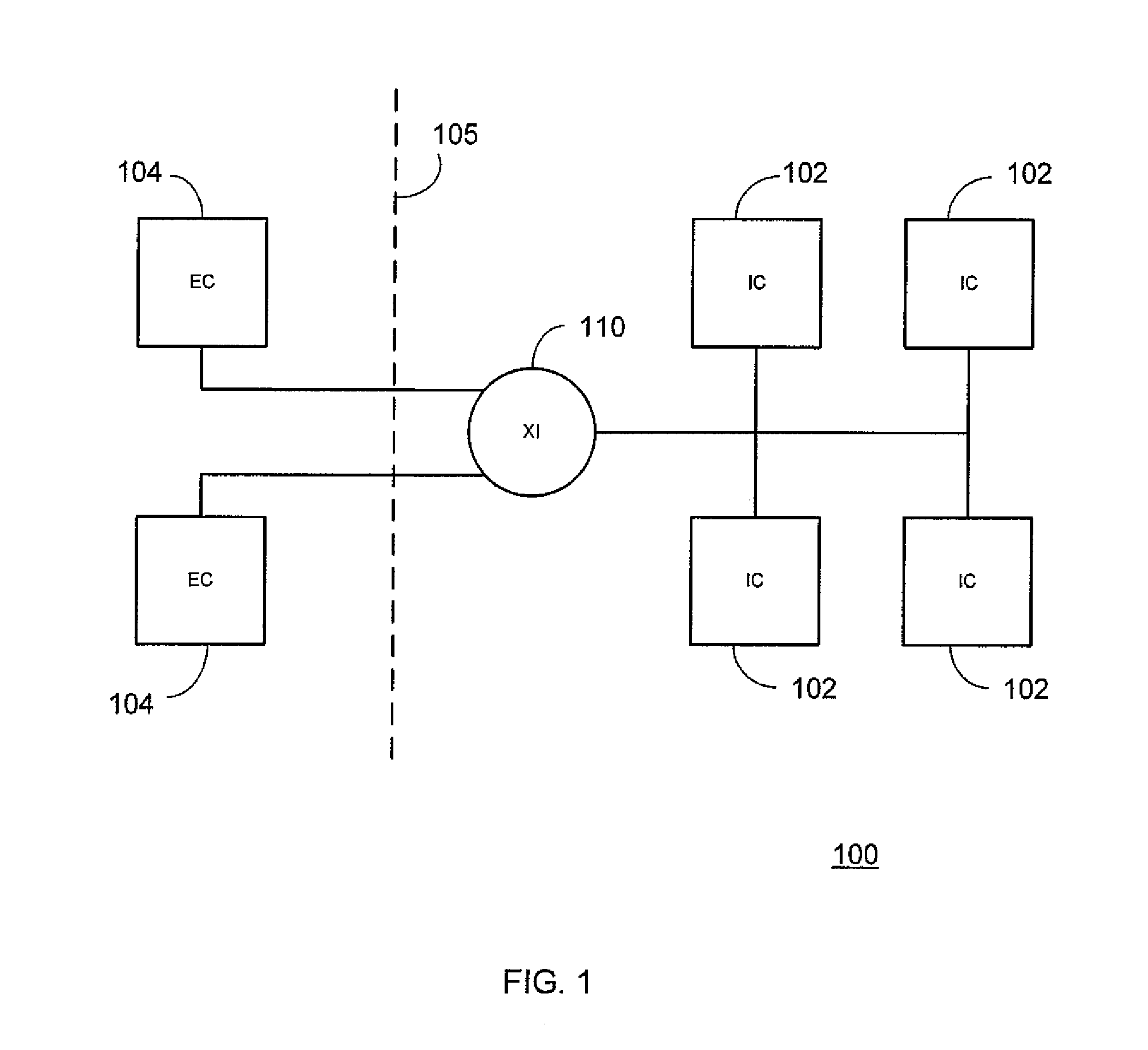

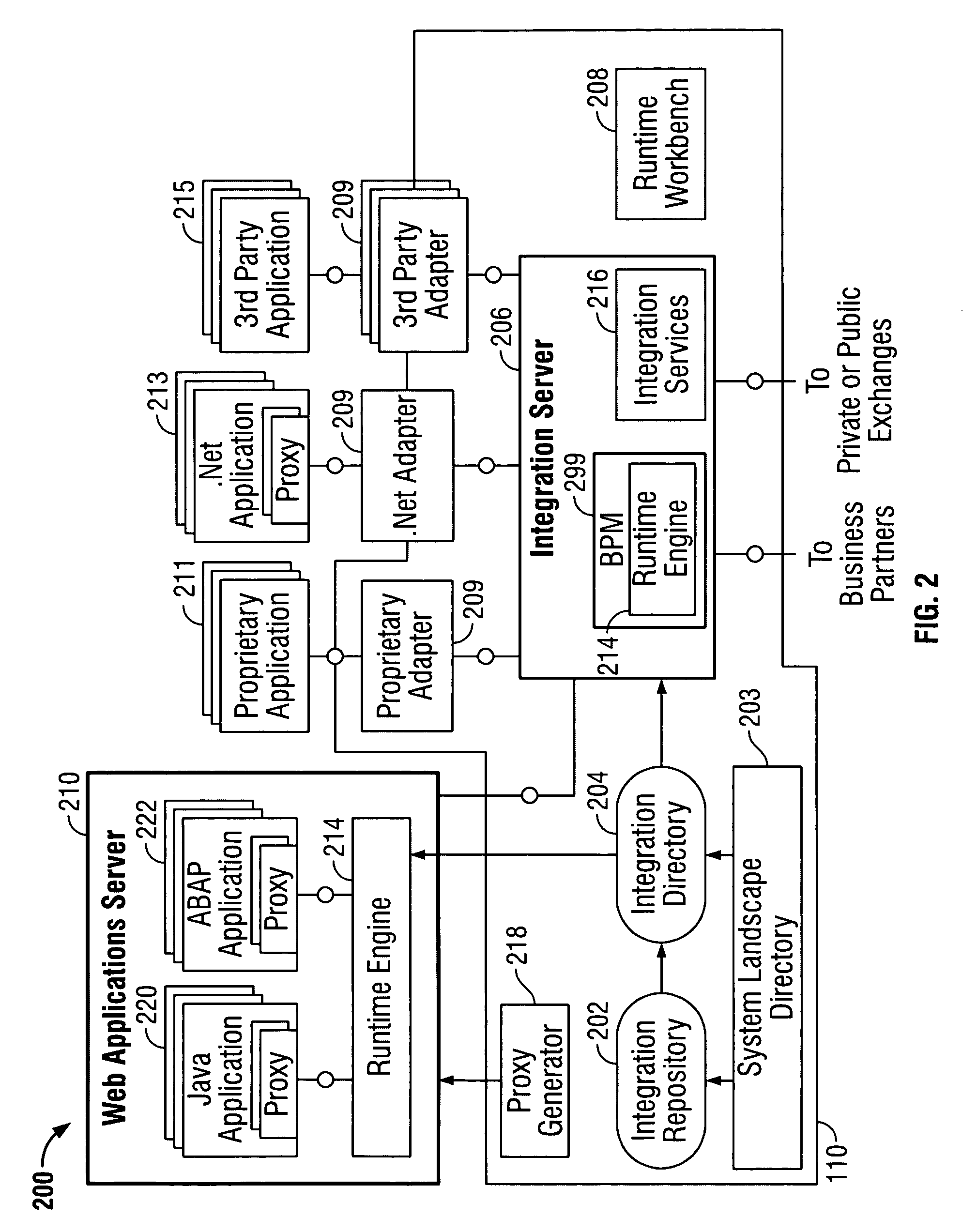

Methods and systems for managing integration of a heterogeneous application landscape are disclosed. The landscape is defined by one or more business process. A business process management system includes an integration server connected between two or more applications in the landscape. The integration server includes a business process engine configured to execute one or more business processes that define message-based interactions between the two or more applications. The business process management system further includes a runtime engine, under direction of the business process engine, for executing one or more messaging services on the message-based interactions between the two or more applications.

Owner:SAP AG

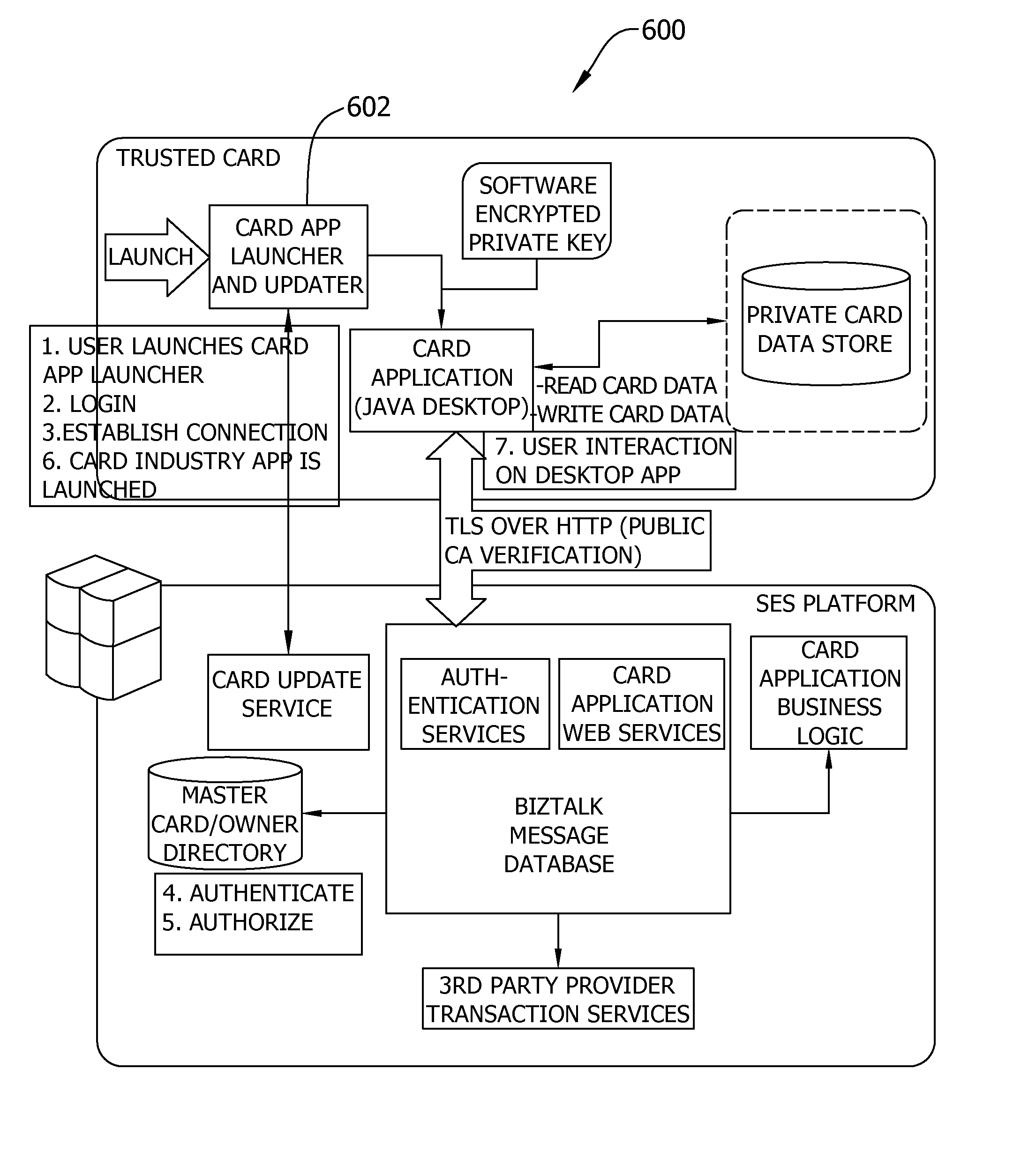

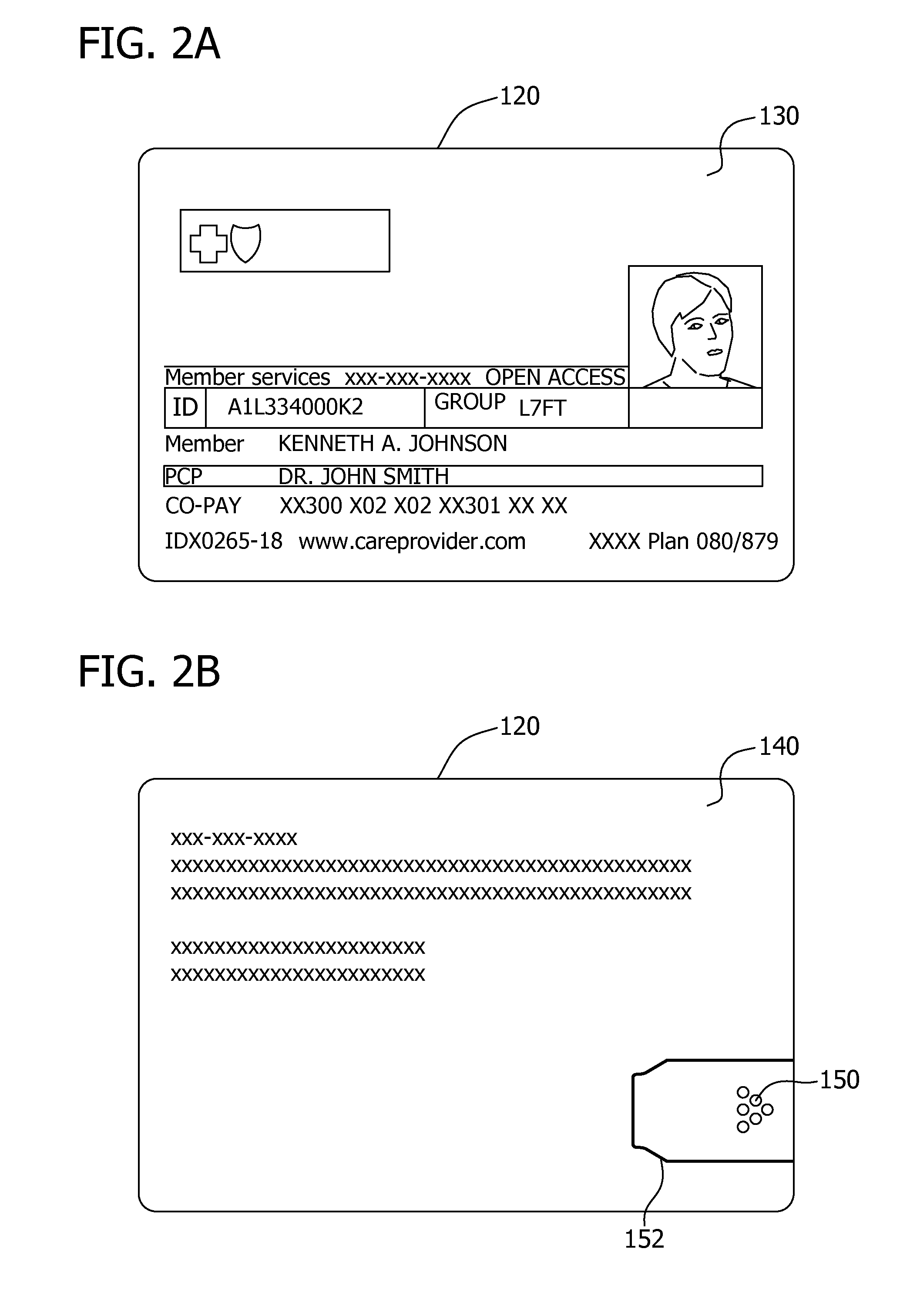

Trusted card system using secure exchange

InactiveUS20100042846A1Safe storageLimited accessDigital data processing detailsUser identity/authority verificationAccess methodCoupling

A system for secure, role-based exchange of information between a client and providers of services is described. The system includes a client device having a memory that includes a portion of the data relating to the client, a user access component, and an enforcement agent. The system also includes a central server running an authentication methodology and a roles server. The central server includes the data relating to the client. The system further includes an interface device capable of communications with the central server and capable of communicative coupling with the client device. The system is operable to, upon a communicative coupling between the interface device and the client device, activate the user access method, in conjunction with the authentication method, to ensure that the client is the proper holder of the client device. The enforcement agent is operable with the roles server and user interface input from the client to define access rights to the client data for the providers of services, who also have access to the central server.

Owner:SECURE EXCHANGE SOLUTIONS

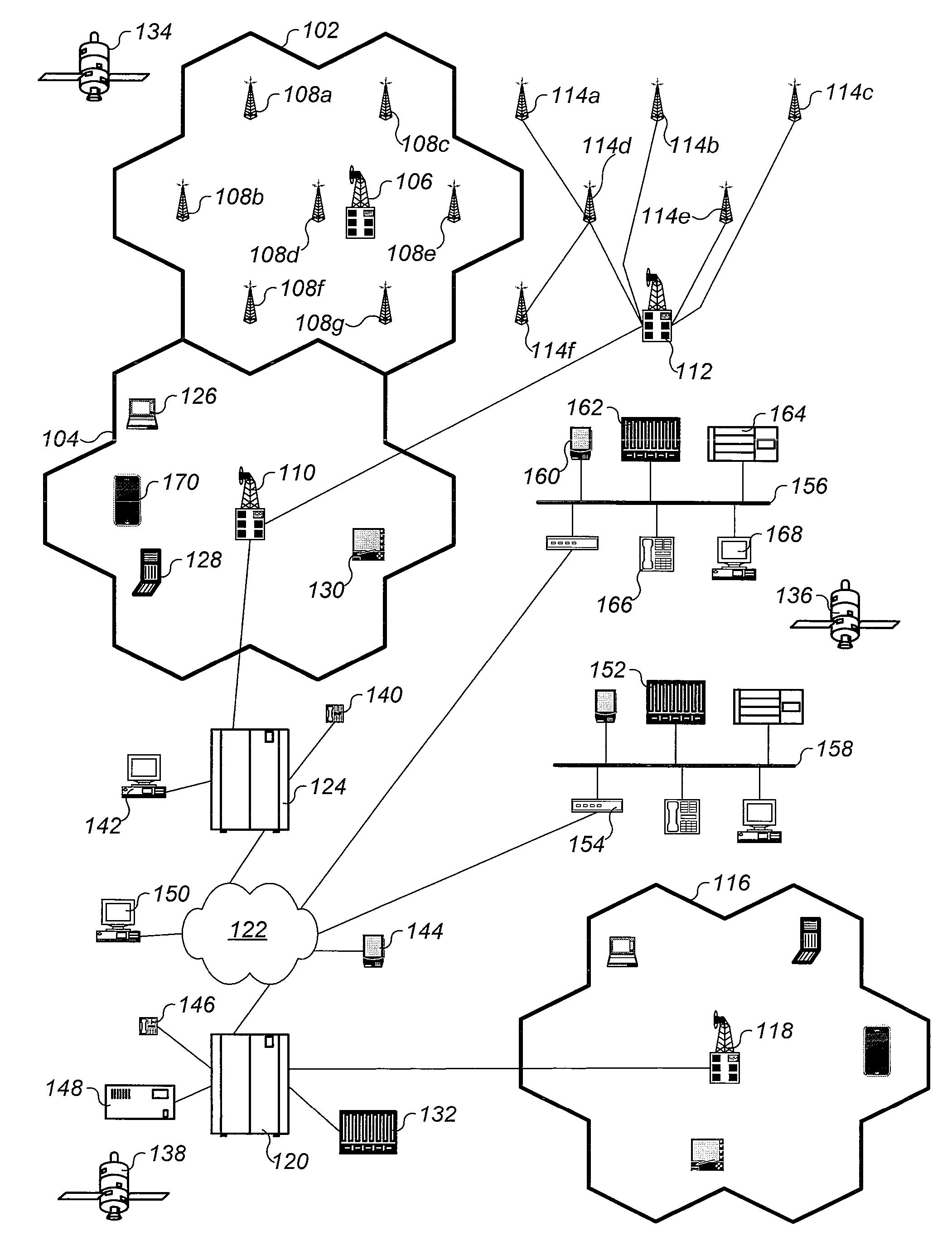

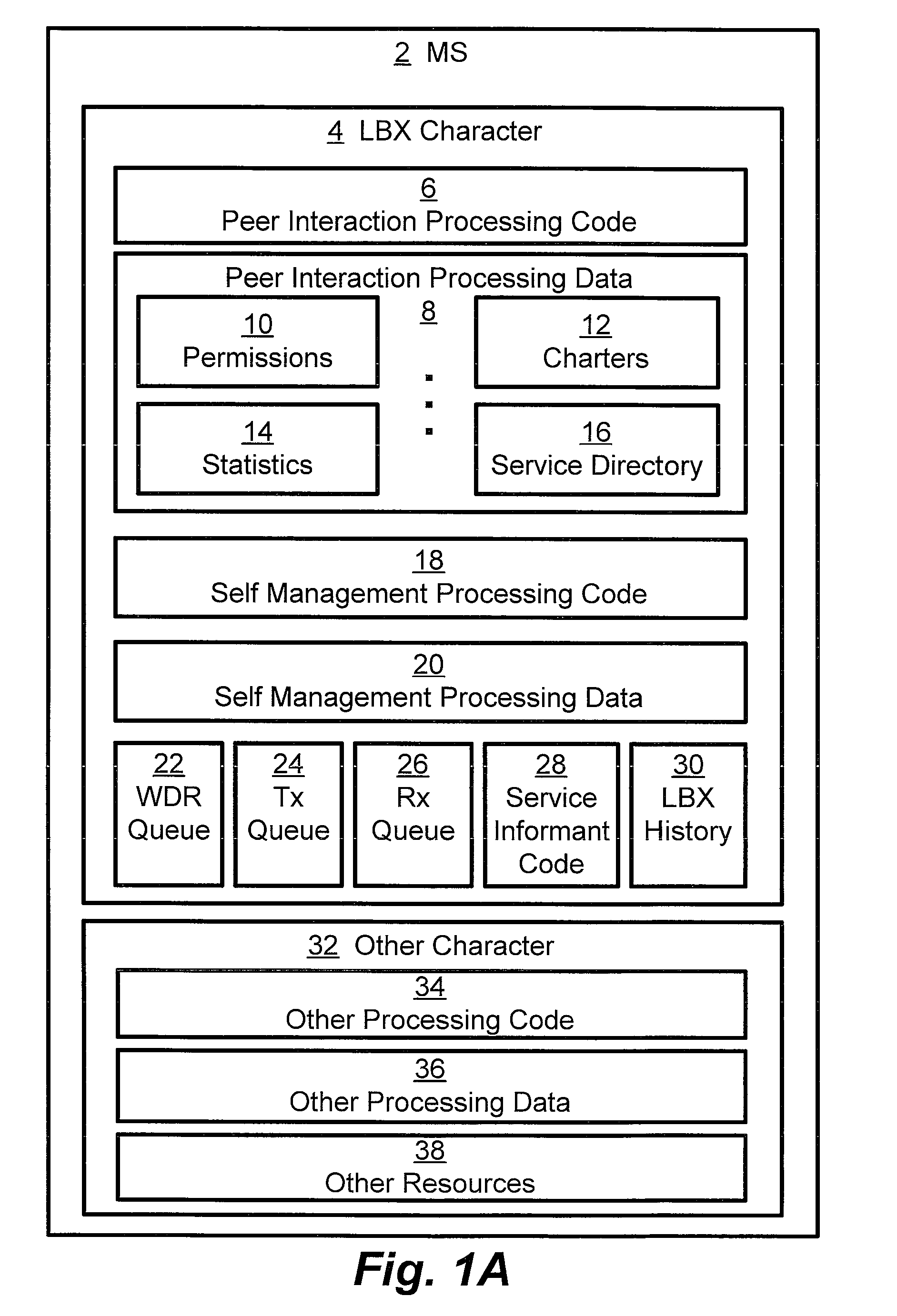

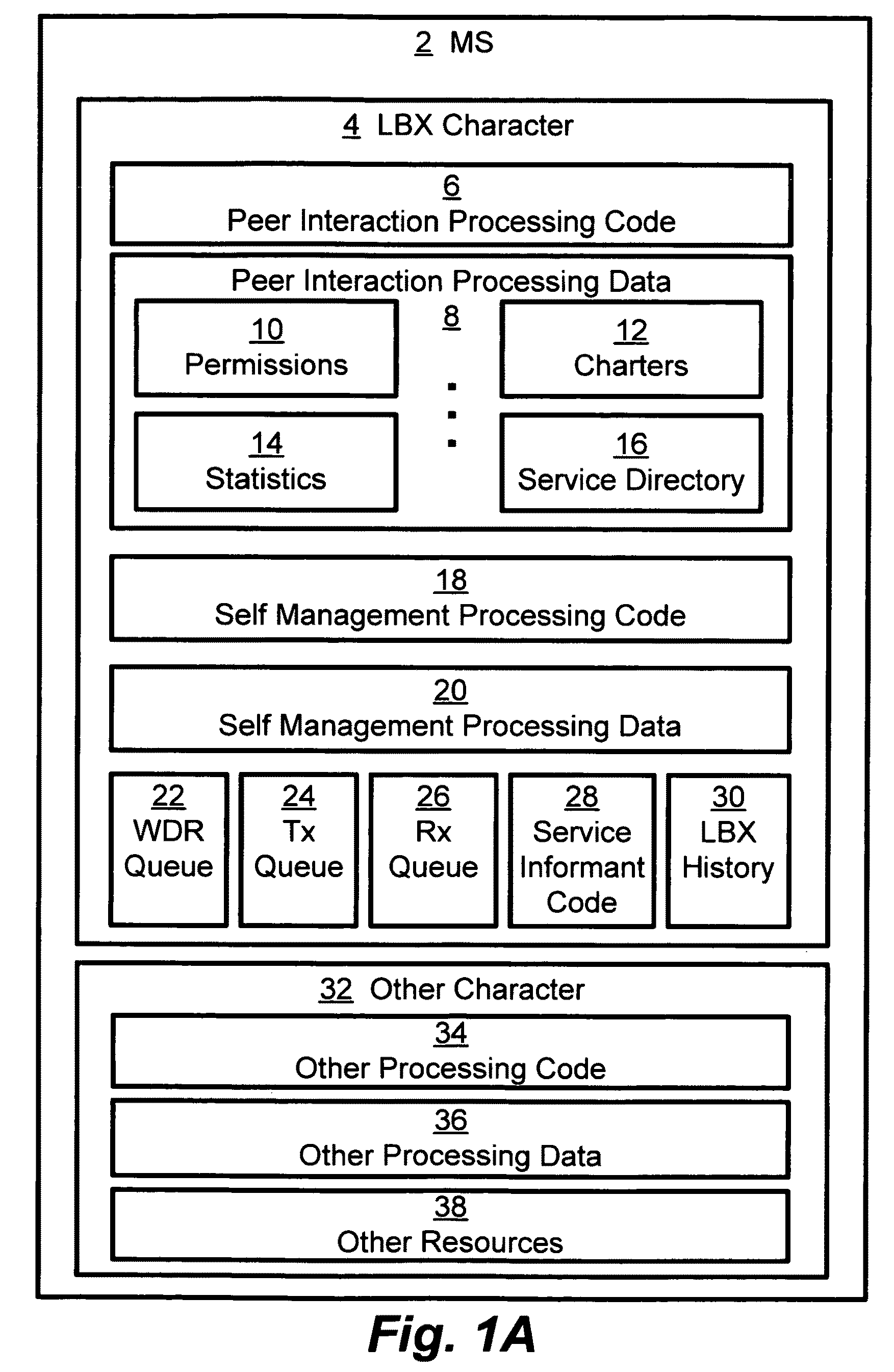

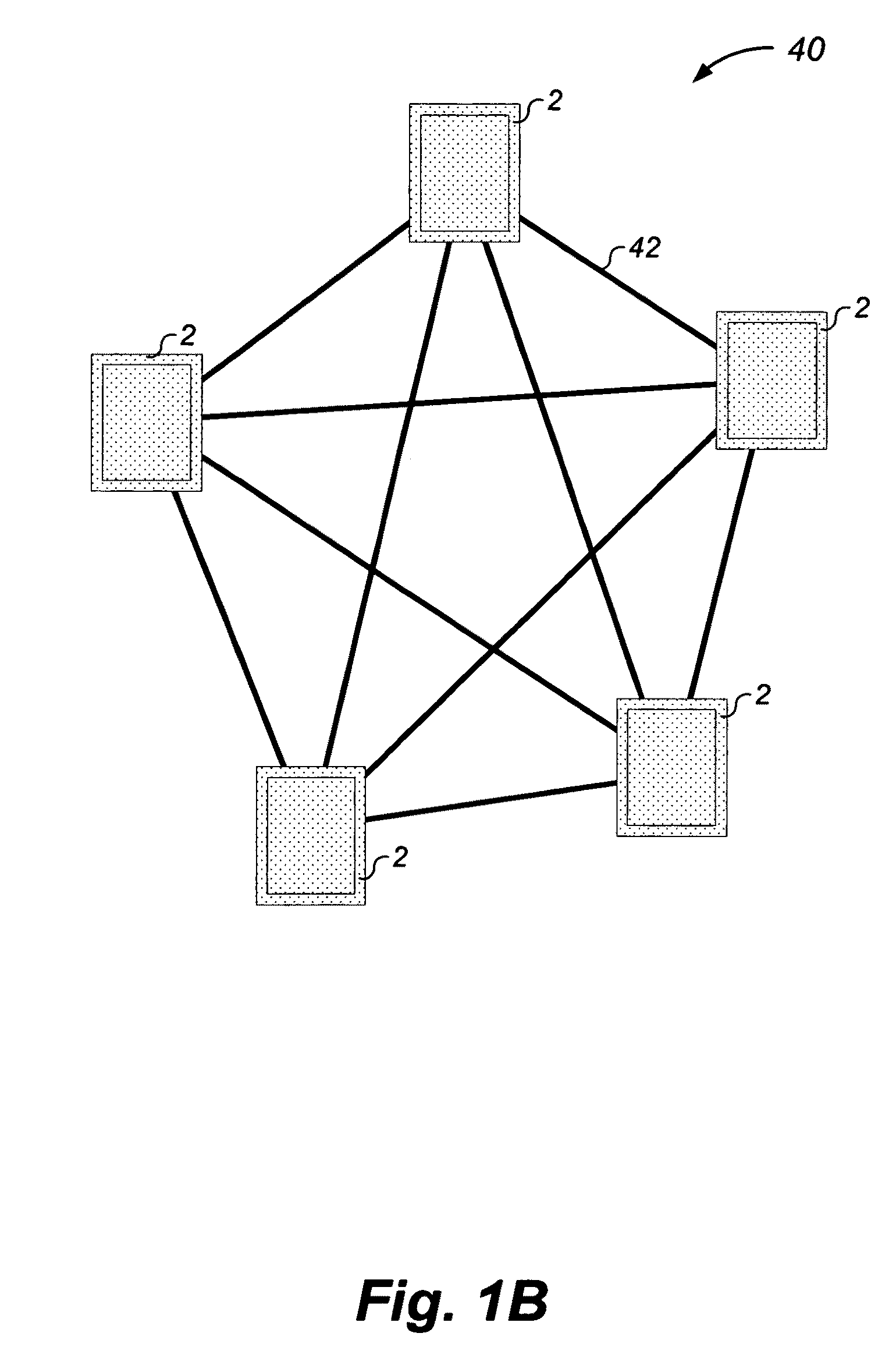

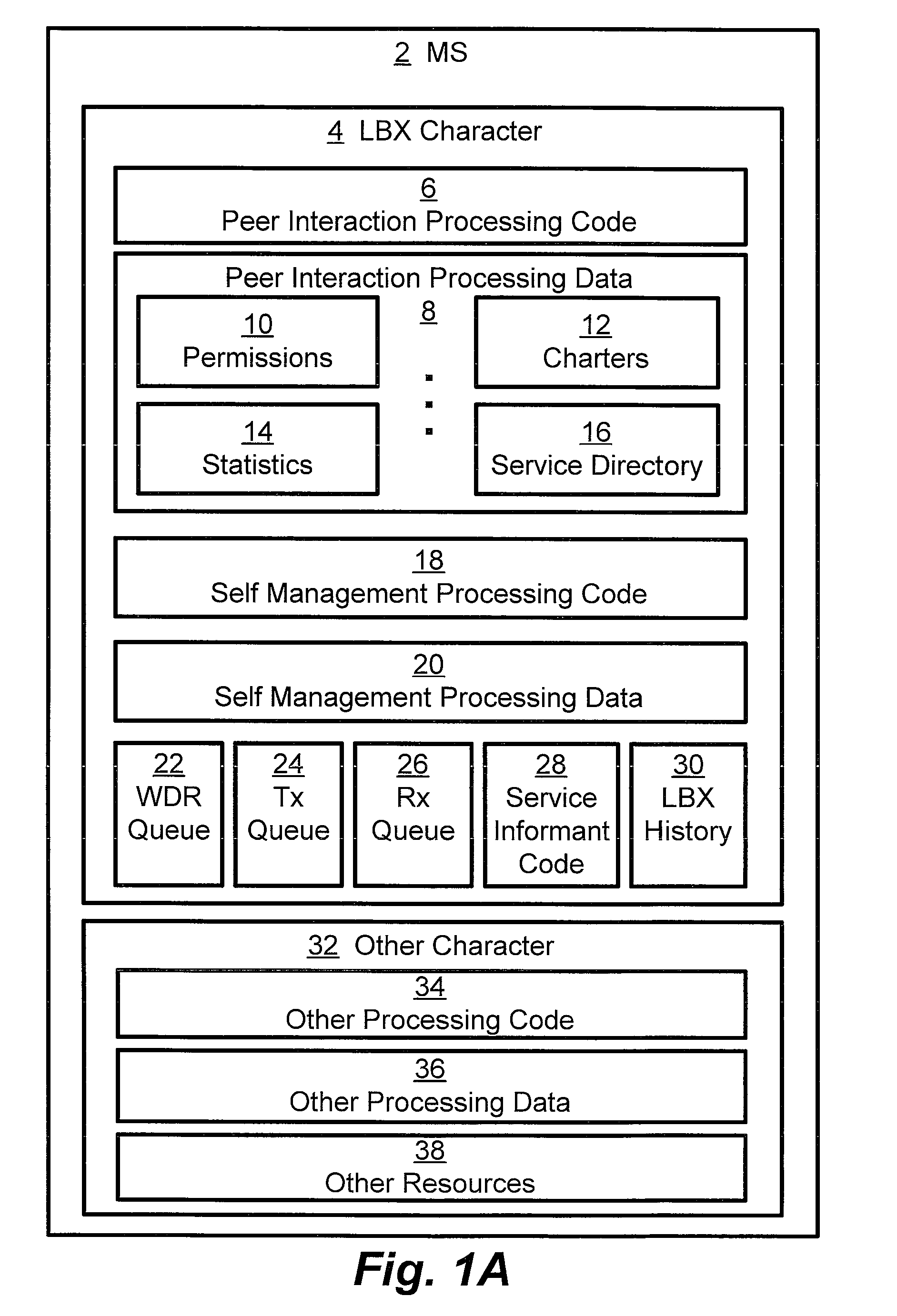

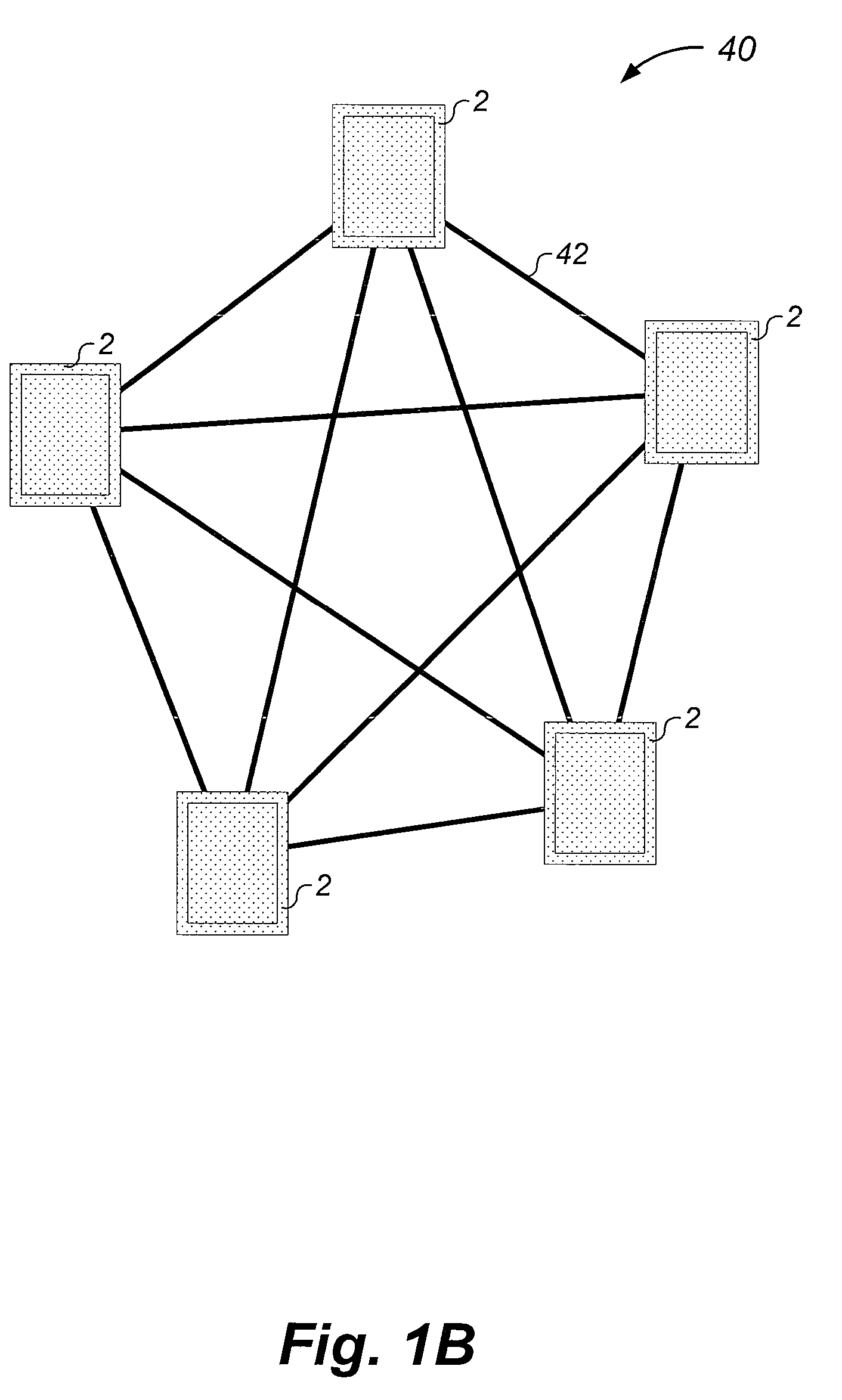

System and method for location based exchanges of data facilitating distributed locational applications

InactiveUS20090233622A1Facilitate novel LBX applicationReduce stepsDigital data information retrievalAccounting/billing servicesData processing systemBase exchange

Provided is a distributed system and method for enabling new and useful location dependent features and functionality to mobile data processing systems. Mobile data processing systems interact with each other as peers in communications and interoperability. Indirectly located mobile data processing systems are located relative other mobile data processing systems, and are automatically located using whereabouts data of directly located mobile data processing systems and / or whereabouts data of other indirectly located mobile data processing systems. A mobile data processing system may dynamically take on roles of being directly located or indirectly located, depending on the environment and capabilities available at a particular time. Reference whereabouts data is appropriately shared between mobile data processing systems to carry out automatic location techniques ensuring mobile data processing systems are kept up to date with their own whereabouts and whereabouts of others, regardless of the freely moving travels of any of the mobile data processing systems involved, and the location technologies that may or may not be available when needed. A confidence is associated to whereabouts data shared for facilitating selection of the best candidate data used in determining new whereabouts information.

Owner:BILLJCO LLC

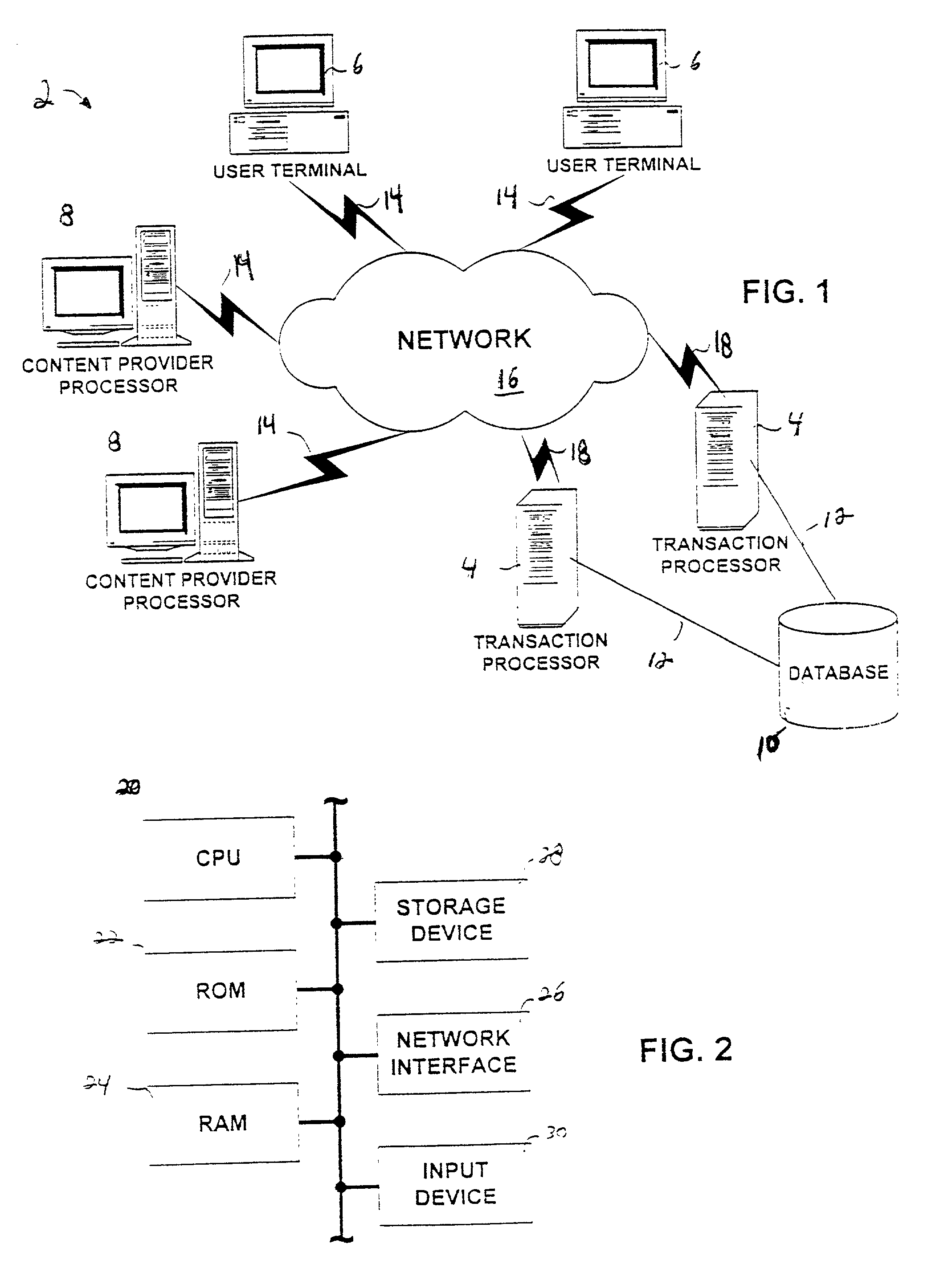

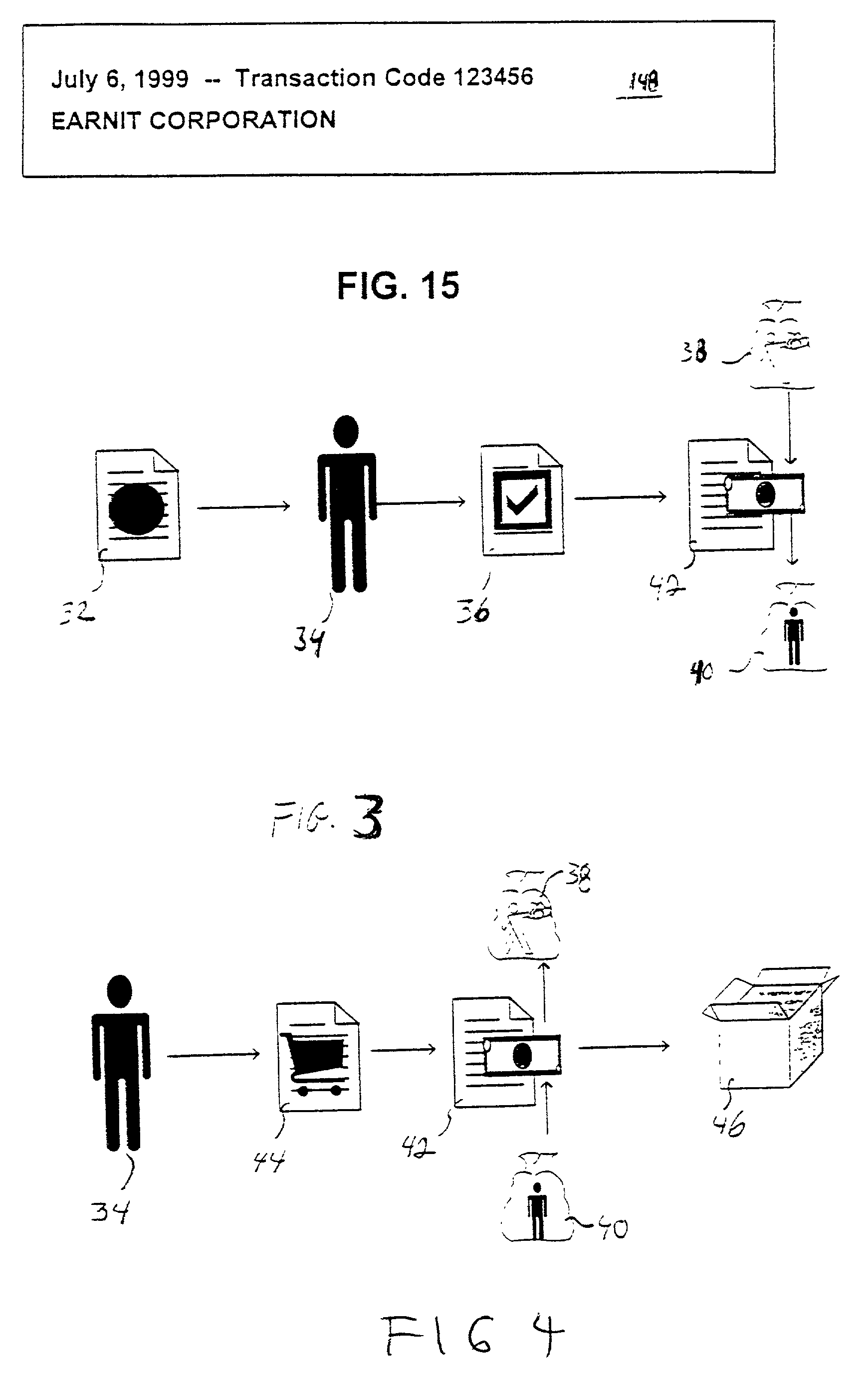

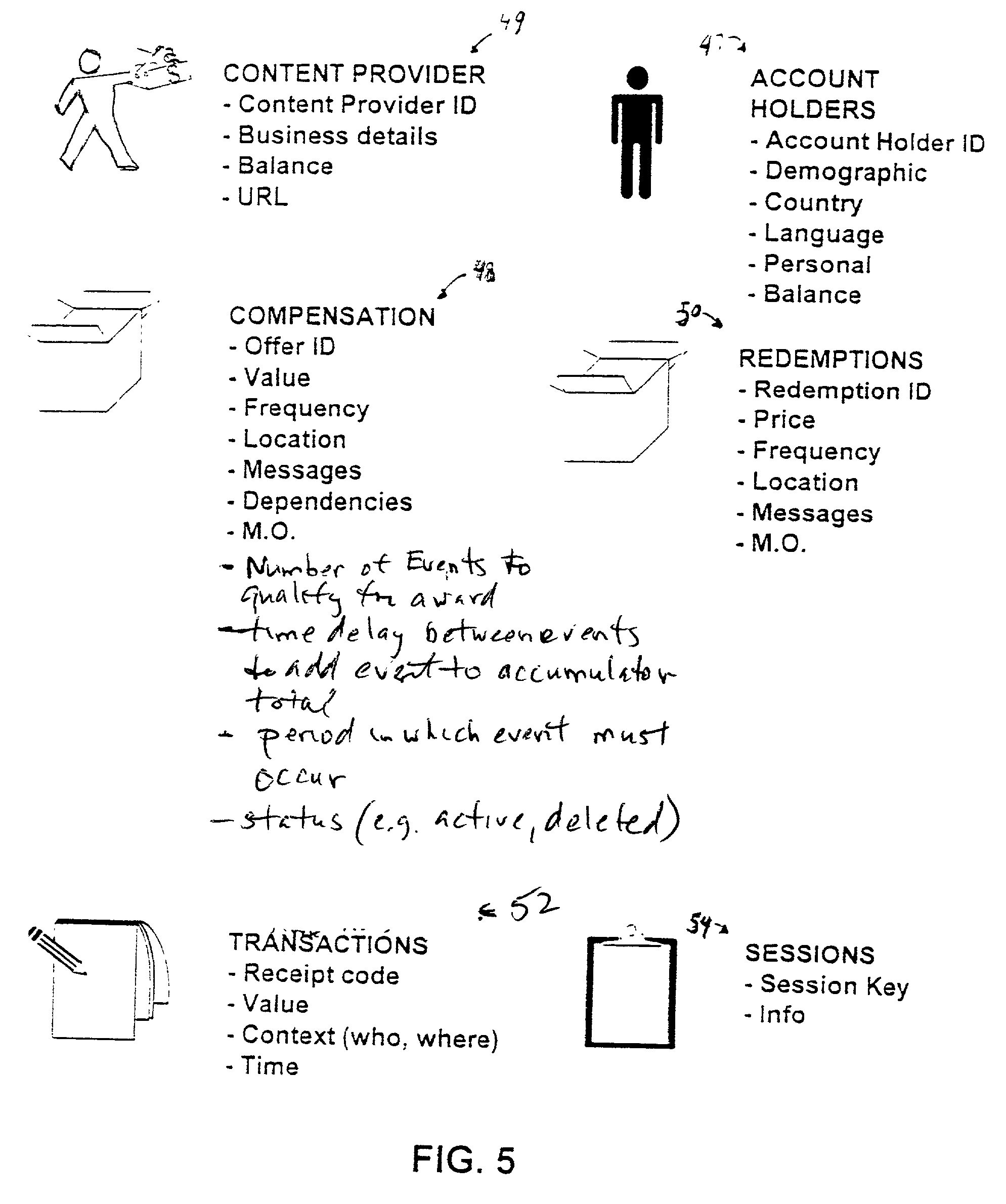

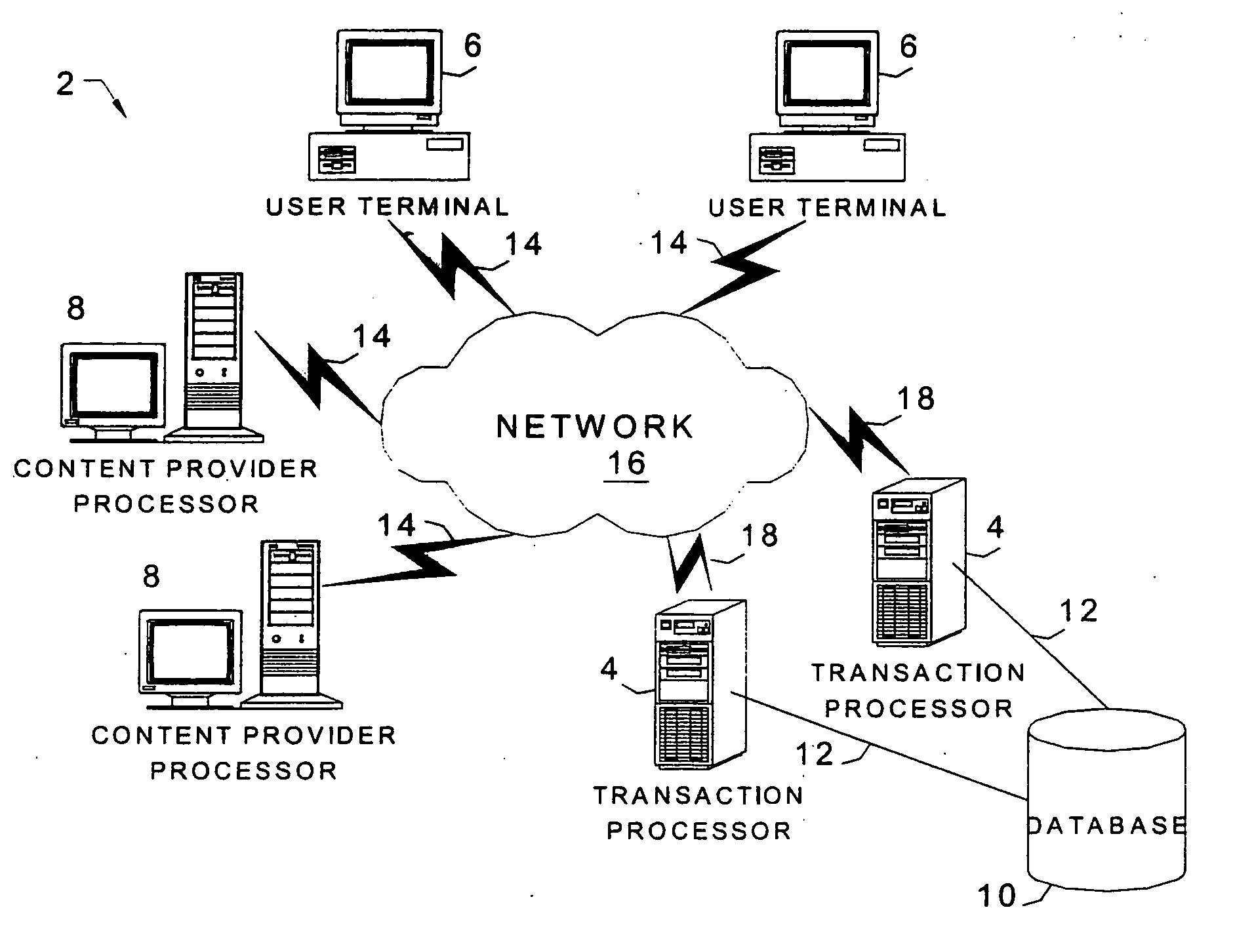

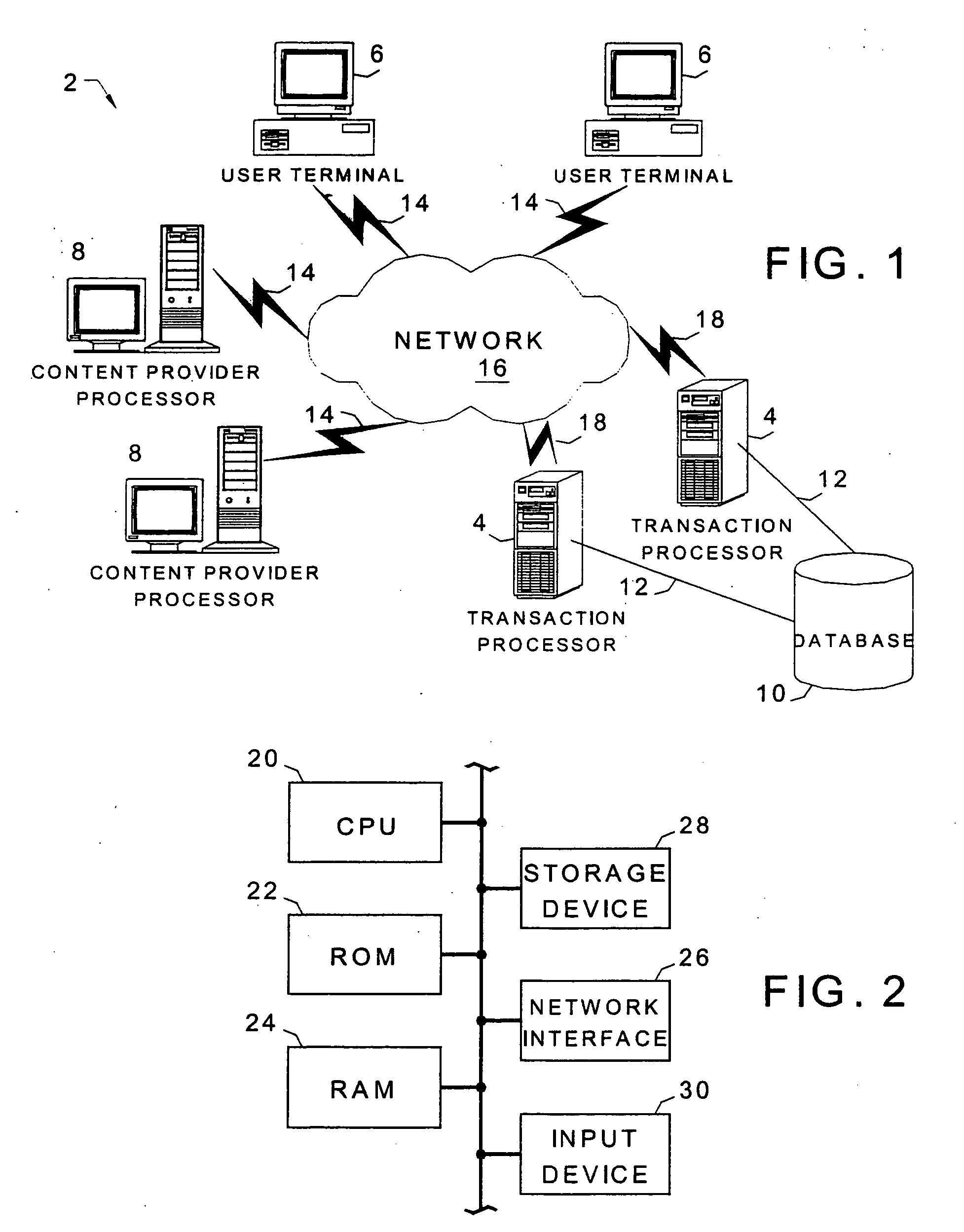

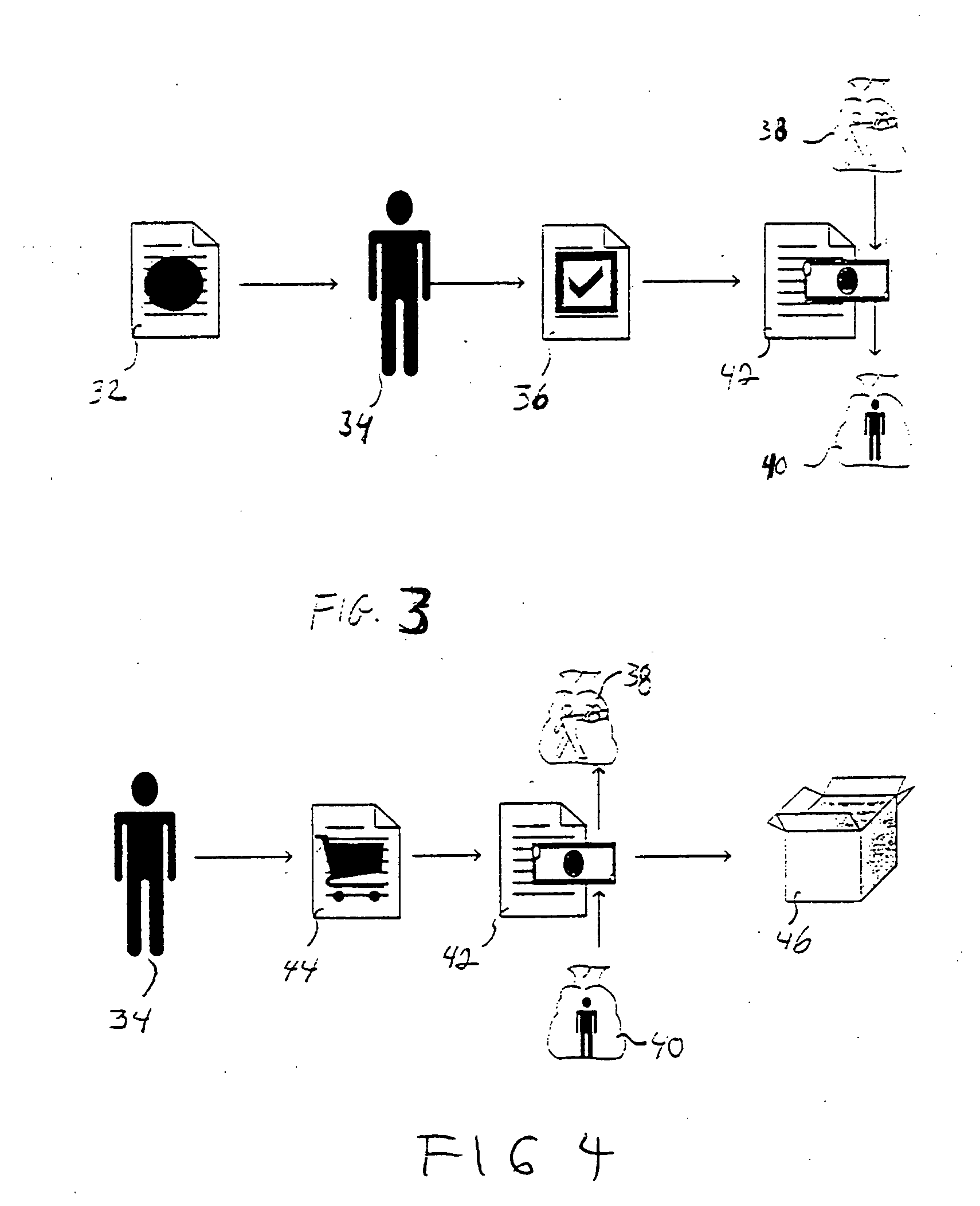

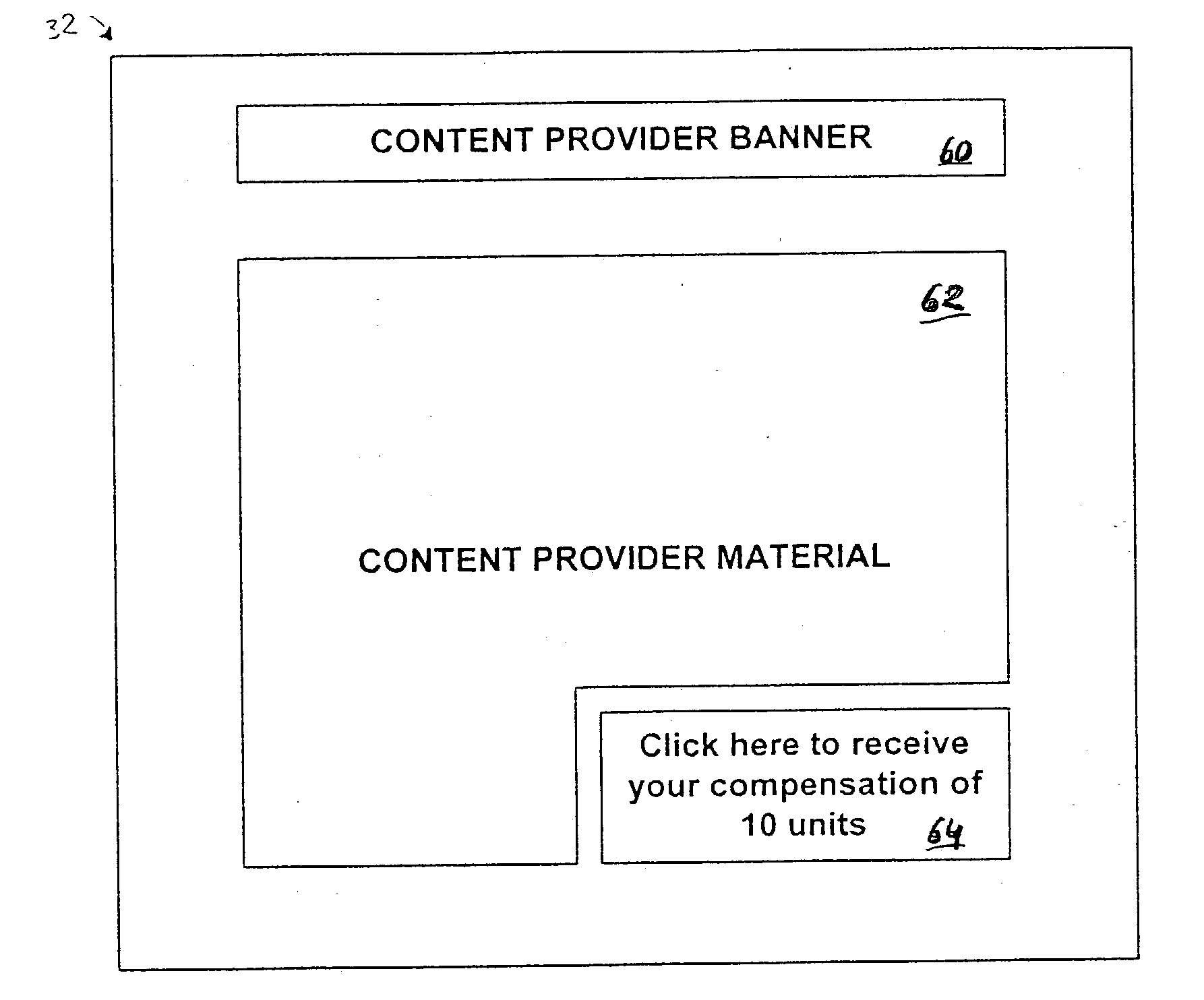

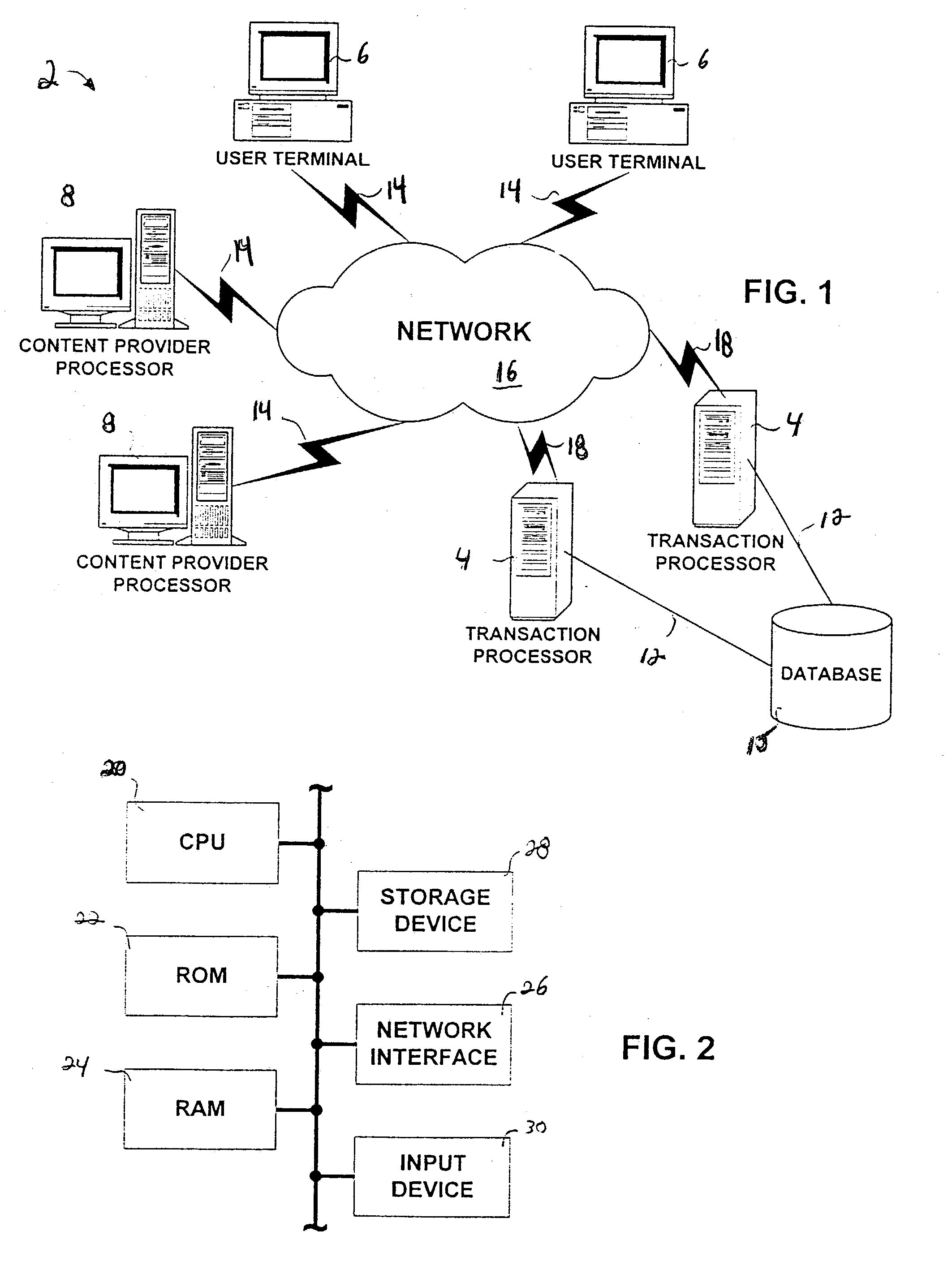

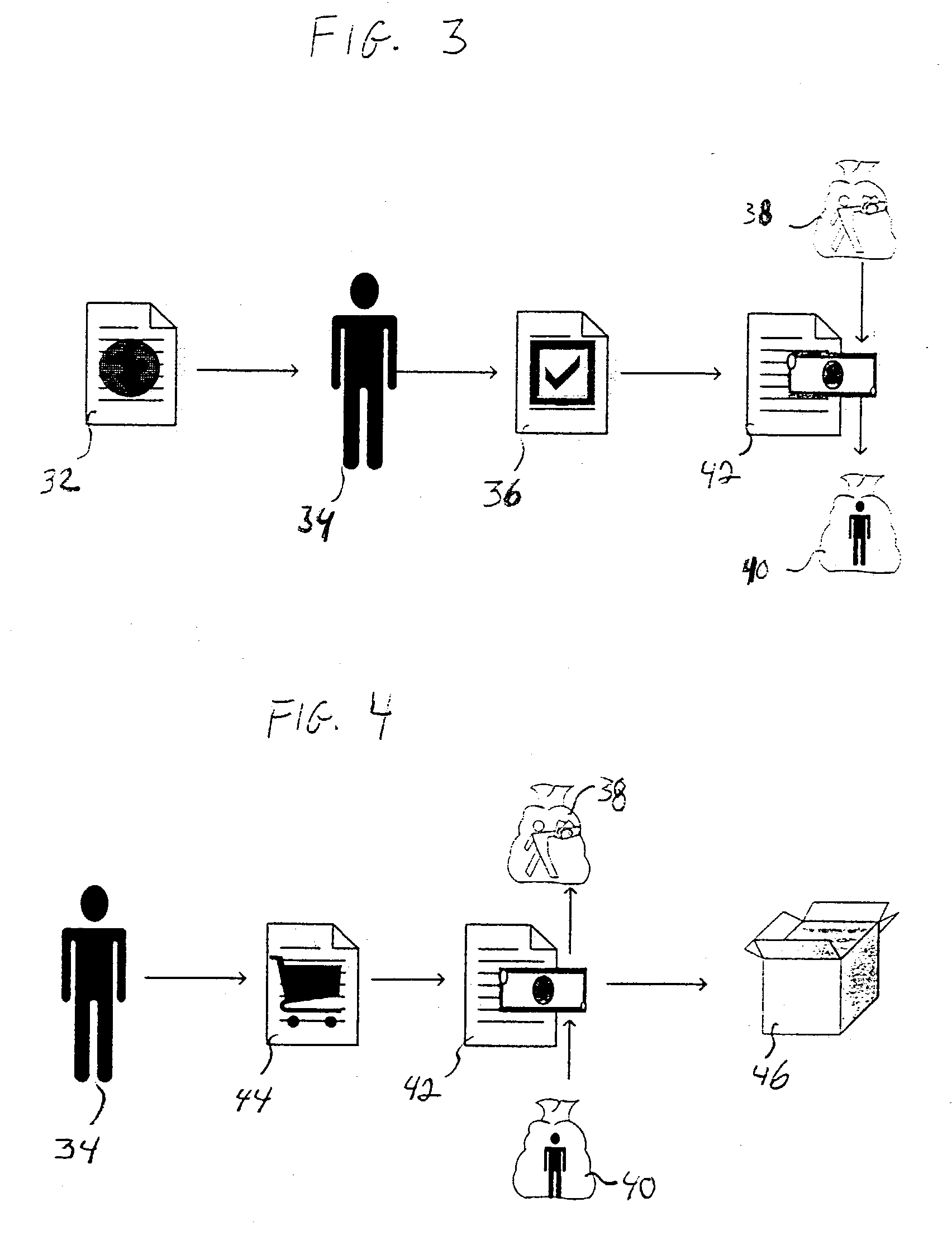

Compensation driven network based exchange system and method

A method and system using a communication network, such as the Internet, to compensate at least one user in exchange for work undertaken by the at least one user. The communication network is used to perform work, the work being defined by a content provider in a manner which does not target specific user profiles. Compensation units are offered to the user in exchange for the performed work. The user uses a user terminal to accept the offered compensation units. The accepted compensation units are transferred from a content provider account to a user account, the content provider account corresponding to the content provider offering the compensation units and the user account corresponding to user who completed the work. The user can spend earned compensation units on goods and services offered by are deeming content provider. The compensation units are provided in a closed system. The issuing content provider does not control how, when or where earned compensation units may be spent

Owner:BEENZ COM IRELAND

Real time network exchange with seller specified exchange parameters and interactive seller participation

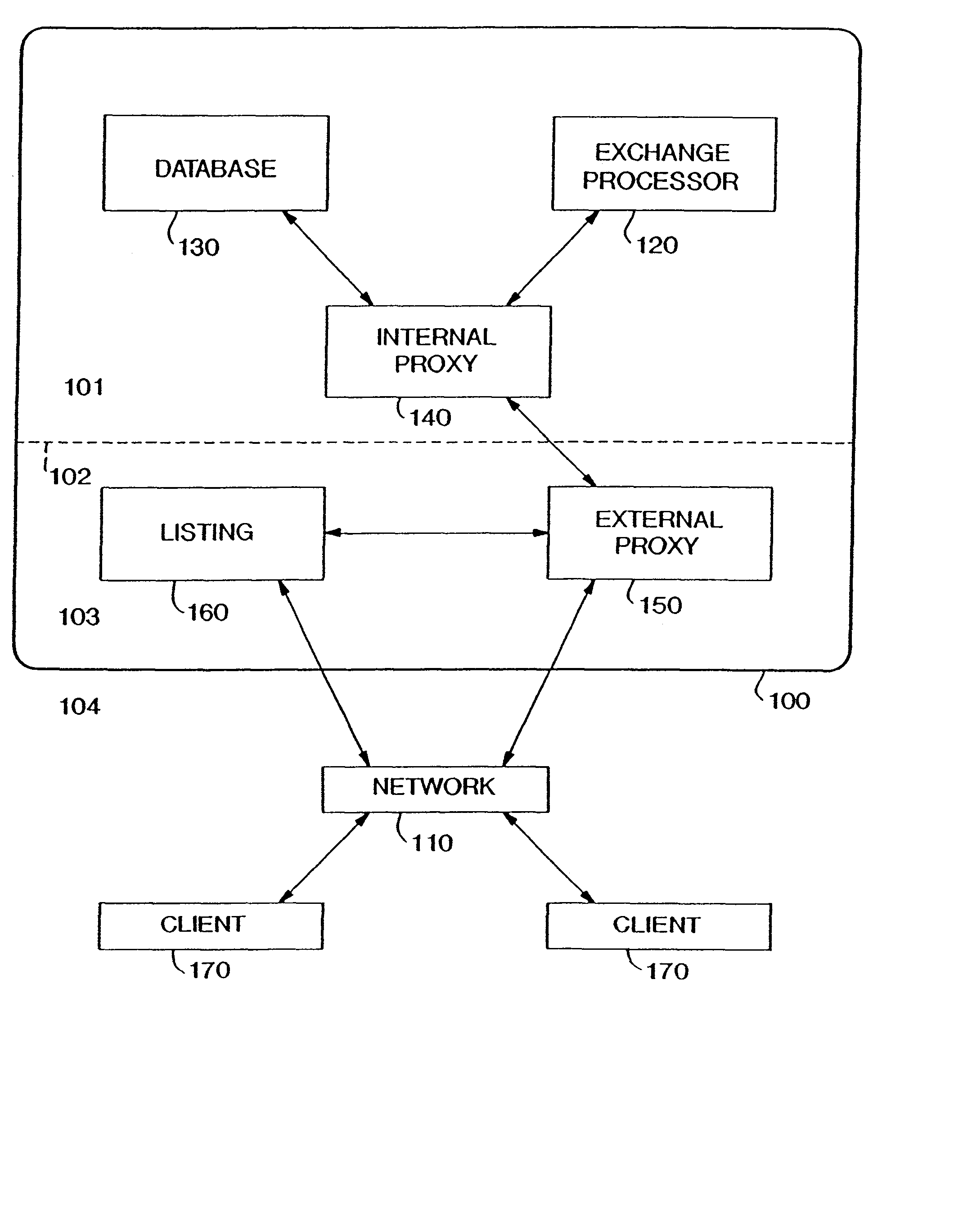

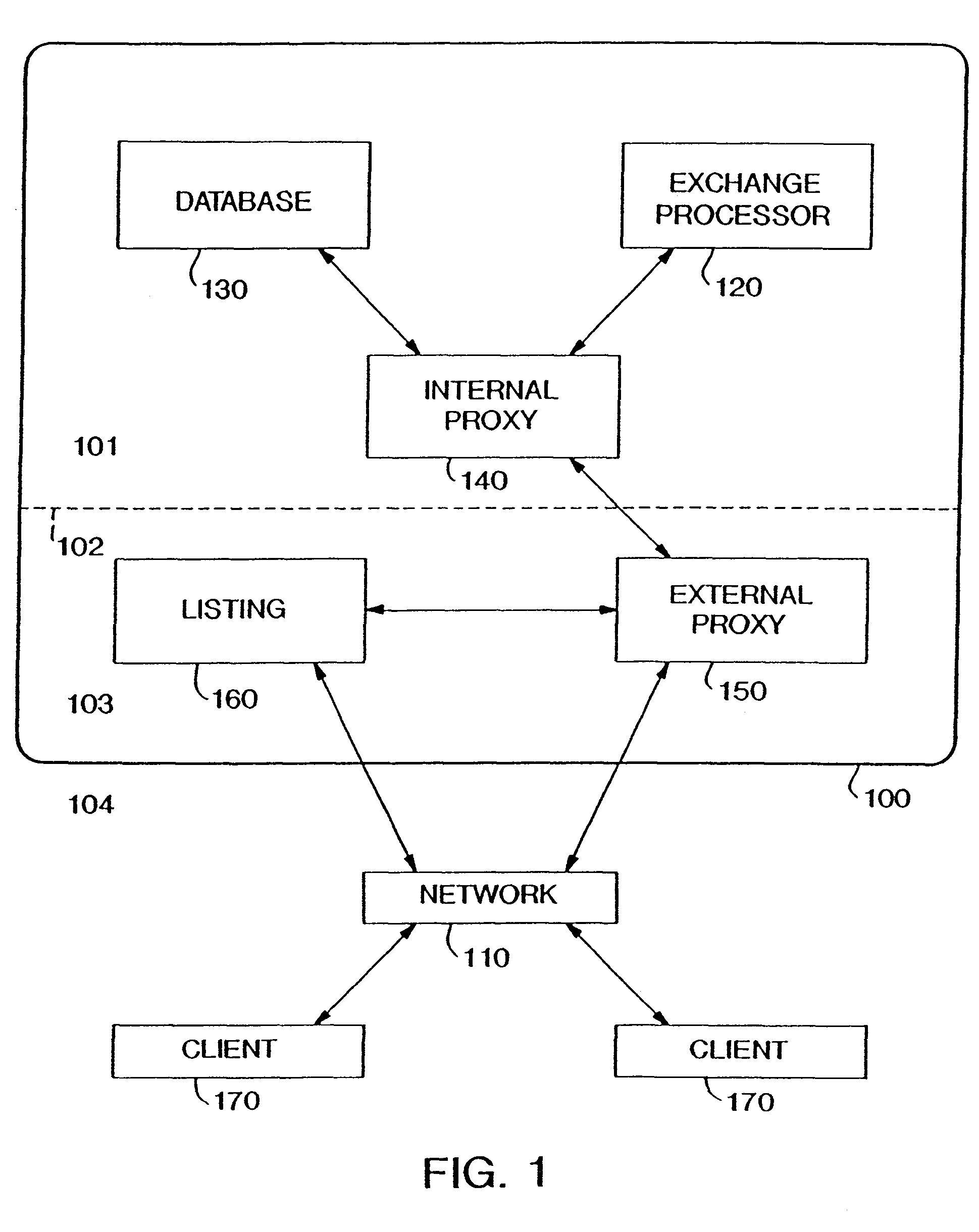

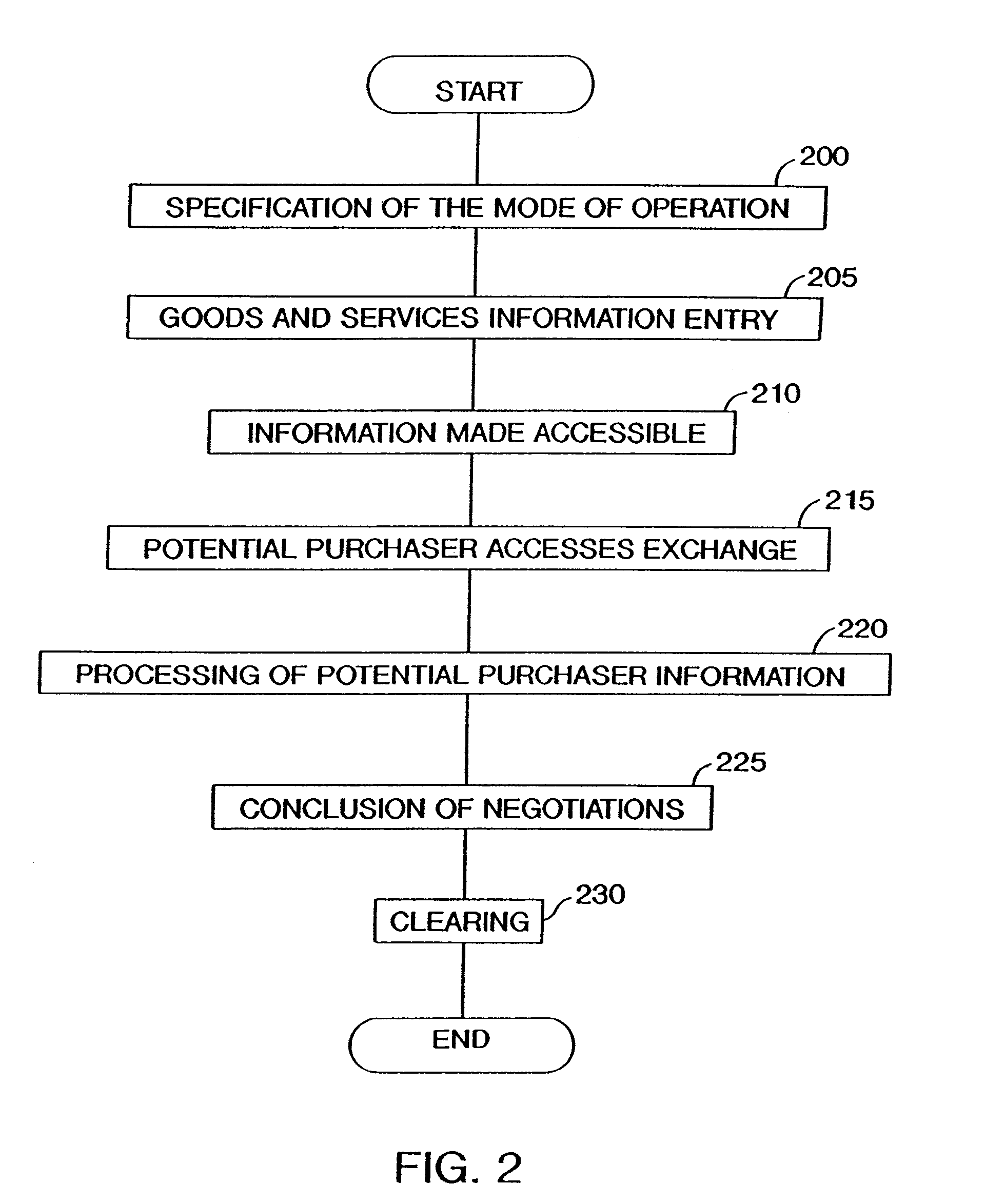

<heading lvl="0">Abstract of Disclosure< / heading> A system and method for networked exchange are disclosed. A system for networked exchange comprises an internal proxy (140); an exchange processor (120) in communication with the internal proxy (140); a database (130) in communication with the internal proxy (140); an external proxy (150) in communication with the internal proxy (140); and, a communications network (110) connected to the external proxy. A method for networked exchange comprises 8 steps. Those steps are (1) specifying a mode of operations for an exchange; (2) identifying a commodity for the exchange; (3) listing information about the commodity; (4) accessing of the listing by a potential purchaser; (5) accessing the network-based exchange by the potential purchaser; (6) processing information generated by the potential purchaser, the information comprising a negotiation; (7) concluding the negotiation; and, (8) clearing the concluded negotiation.

Owner:HANGER SOLUTIONS LLC +1

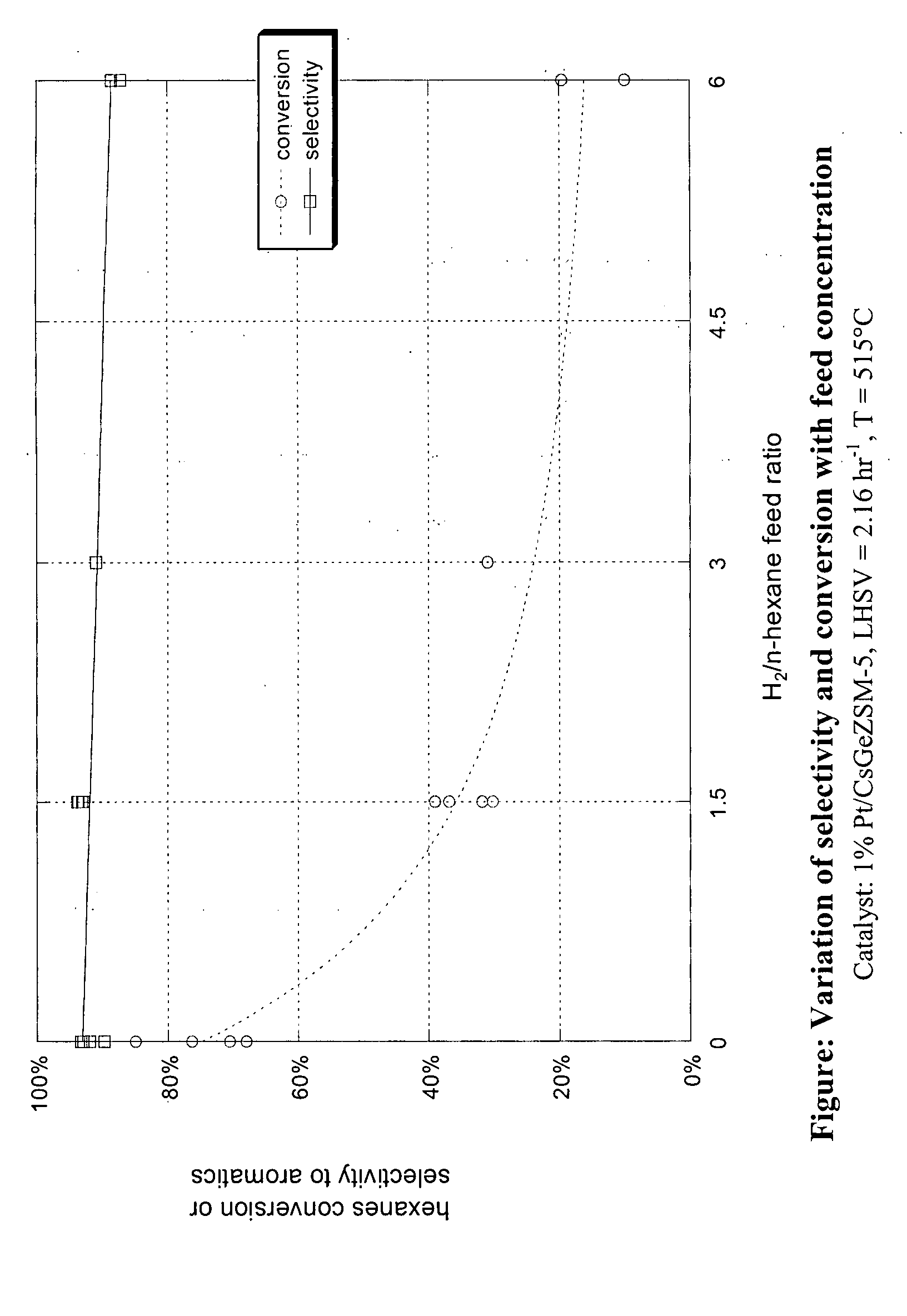

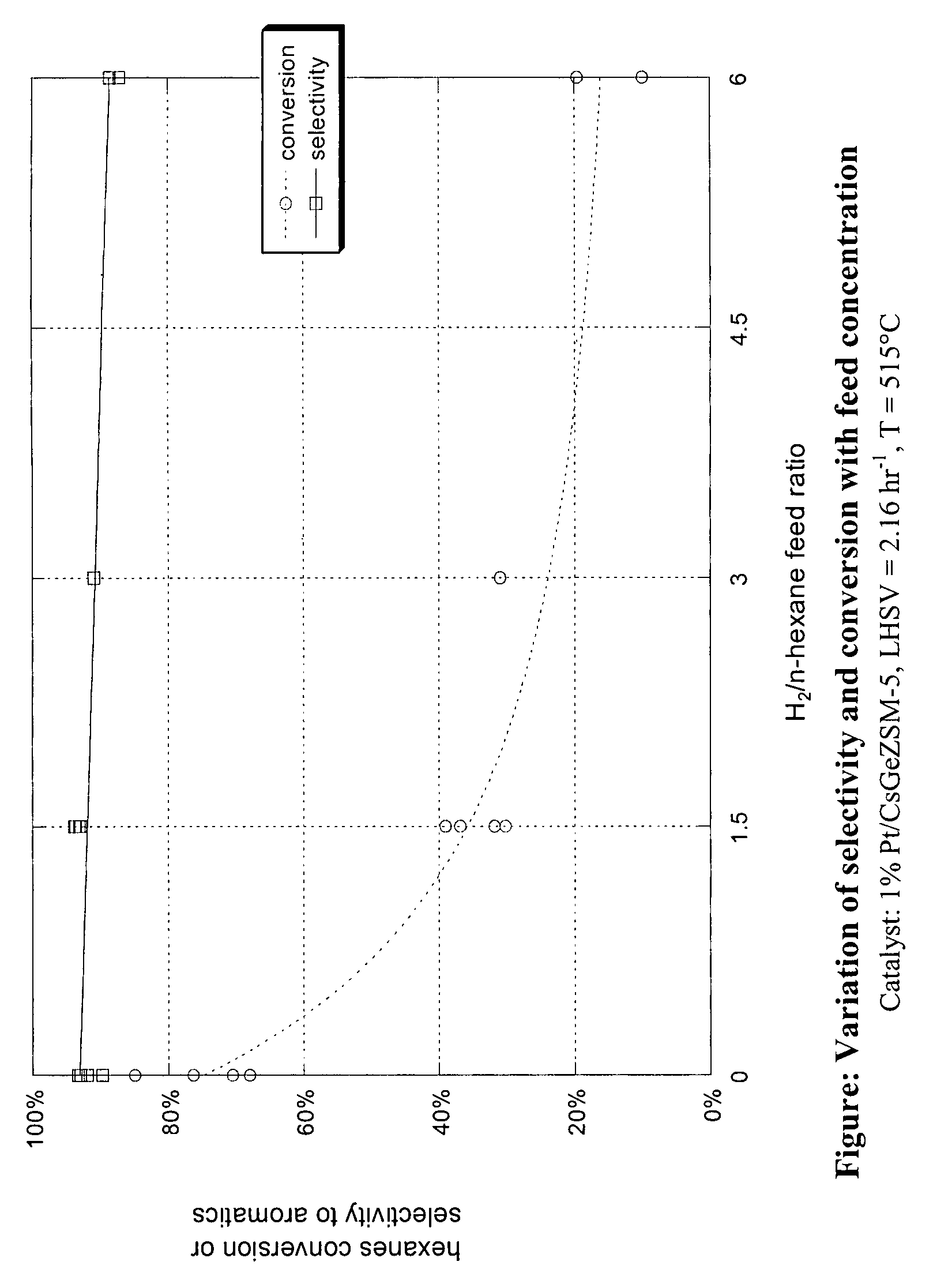

Aromatization of alkanes using a germanium-zeolite catalyst

ActiveUS20080255398A1Molecular sieve catalystsRefining to change hydrocarbon structural skeletonAlkaneAlkaline earth metal

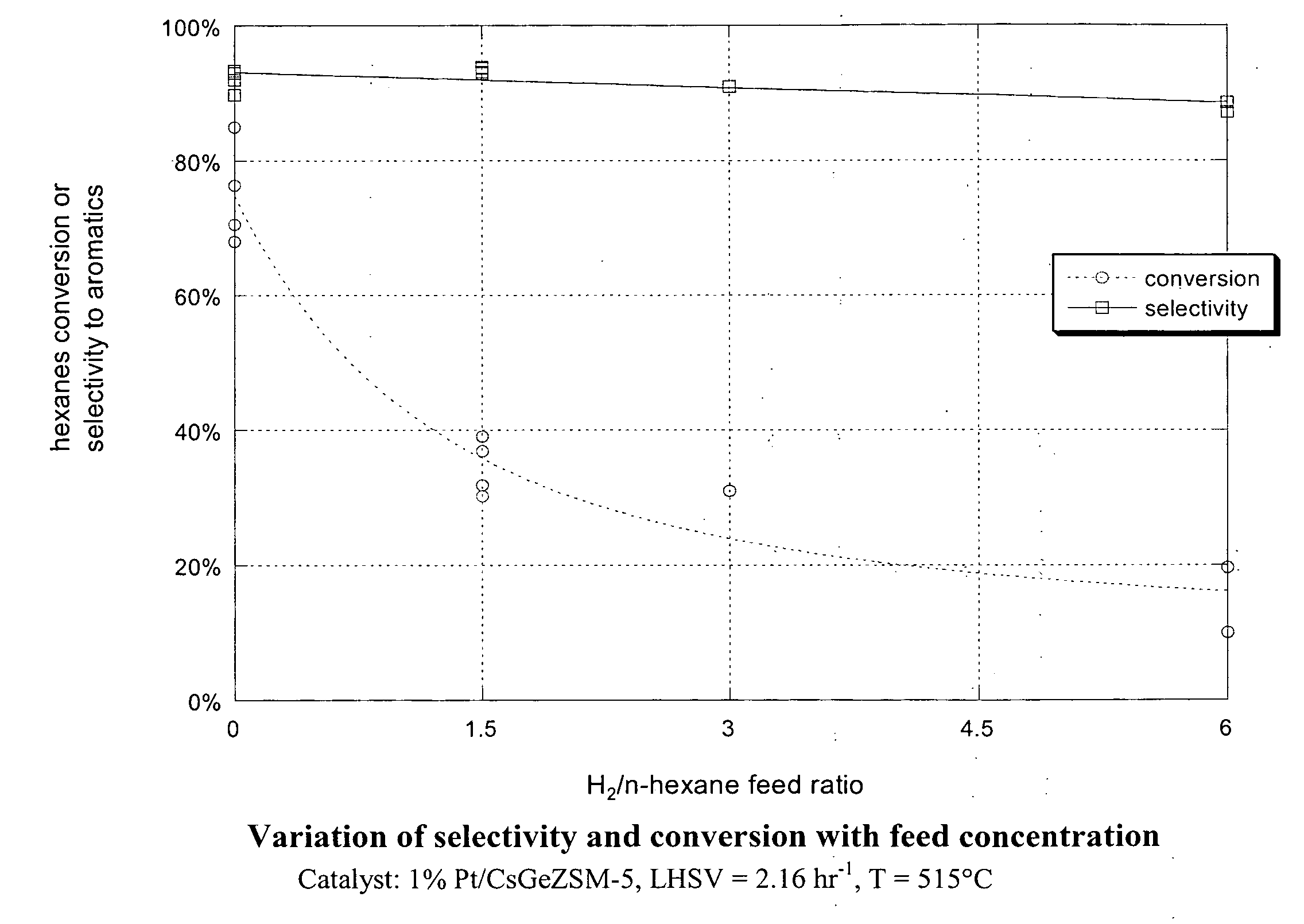

This invention relates to a process for the aromatization of C6 to C12 alkanes, such as hexane, heptane and octane, to aromatics, such as benzene, ethyl benzene, toluene and xylenes, with a germanium-containing zeolite catalyst. The catalyst is a non-acidic aluminum-silicon-germanium zeolite on which a noble metal, such as platinum, has been deposited. The zeolite structure may be of MFI, BEA, MOR, LTL or MTT. The zeolite is made non-acidic by being base-exchanged with an alkali metal or alkaline earth metal, such as cesium, potassium, sodium, rubidium, barium, calcium, magnesium and mixtures thereof, to reduce acidity. The catalyst is sulfur tolerant and may be pretreated with a sulfur compound, i.e., sulfided. The hydrocarbon feed may contain sulfur up to 1000 ppm. The present invention could be applicable to a feedstream which is predominantly paraffinic and / or low in naphthenes. Lowering the hydrogen to hydrocarbon ratio increases conversion and aromatics selectivity.

Owner:SAUDI BASIC IND CORP SA

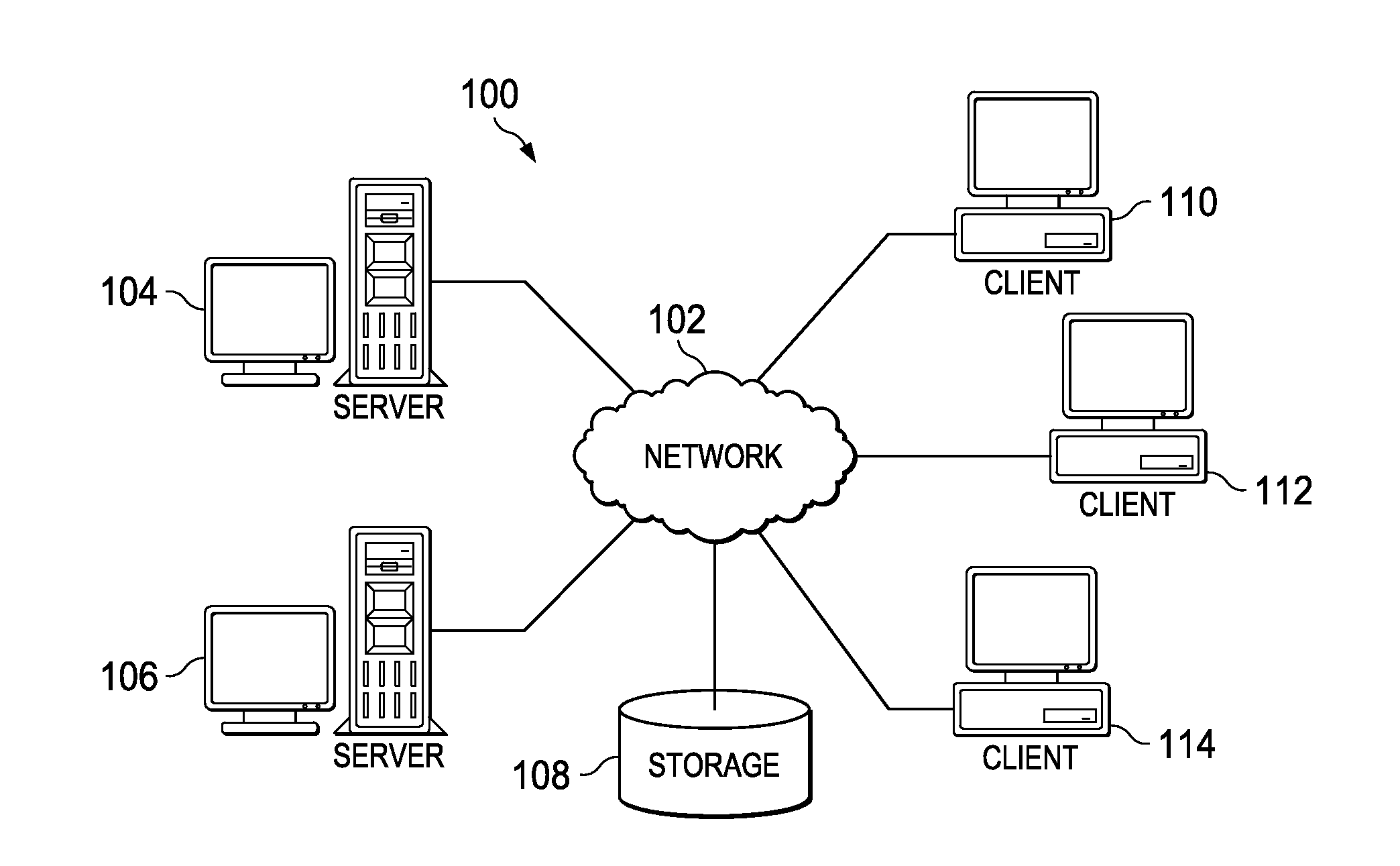

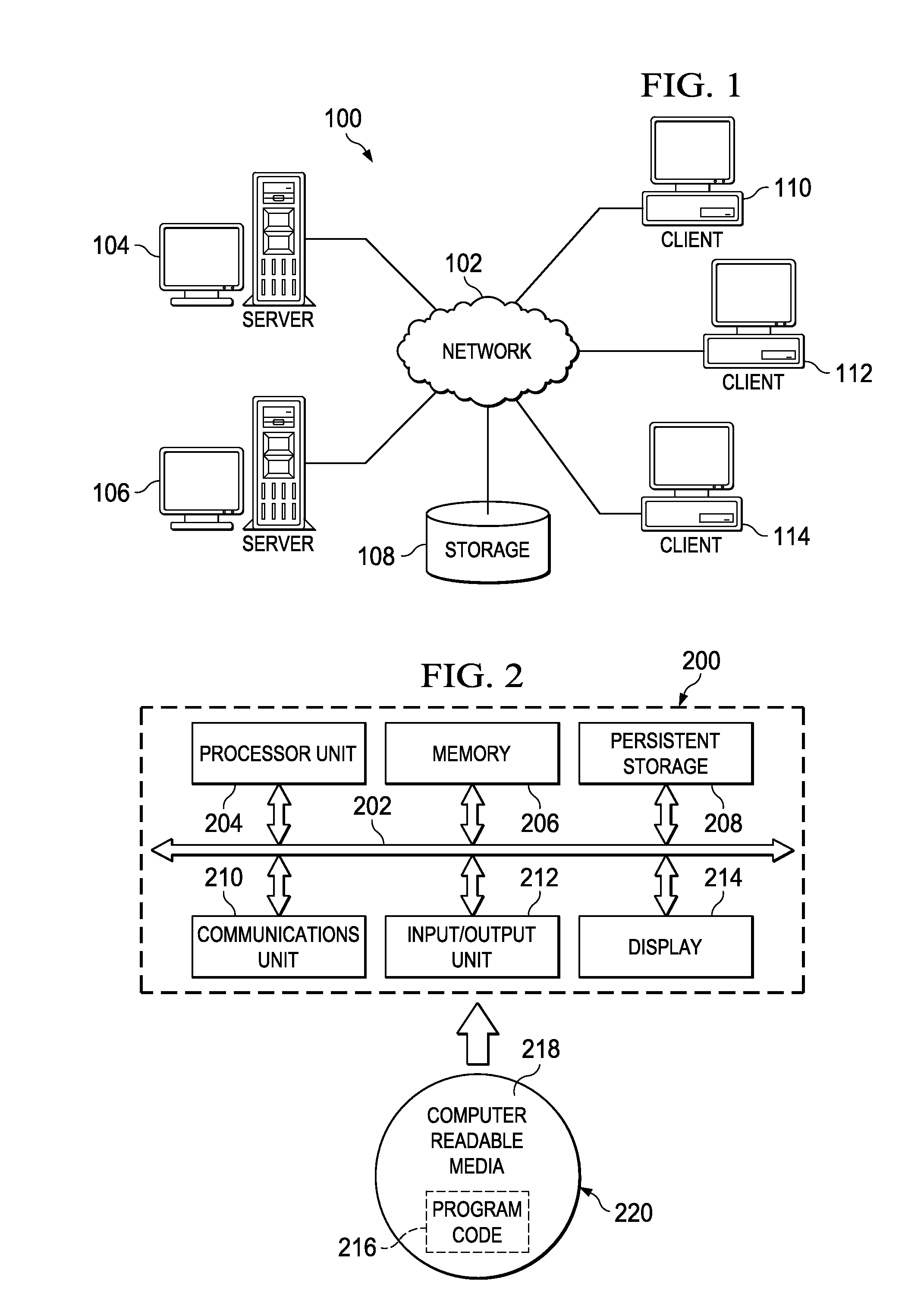

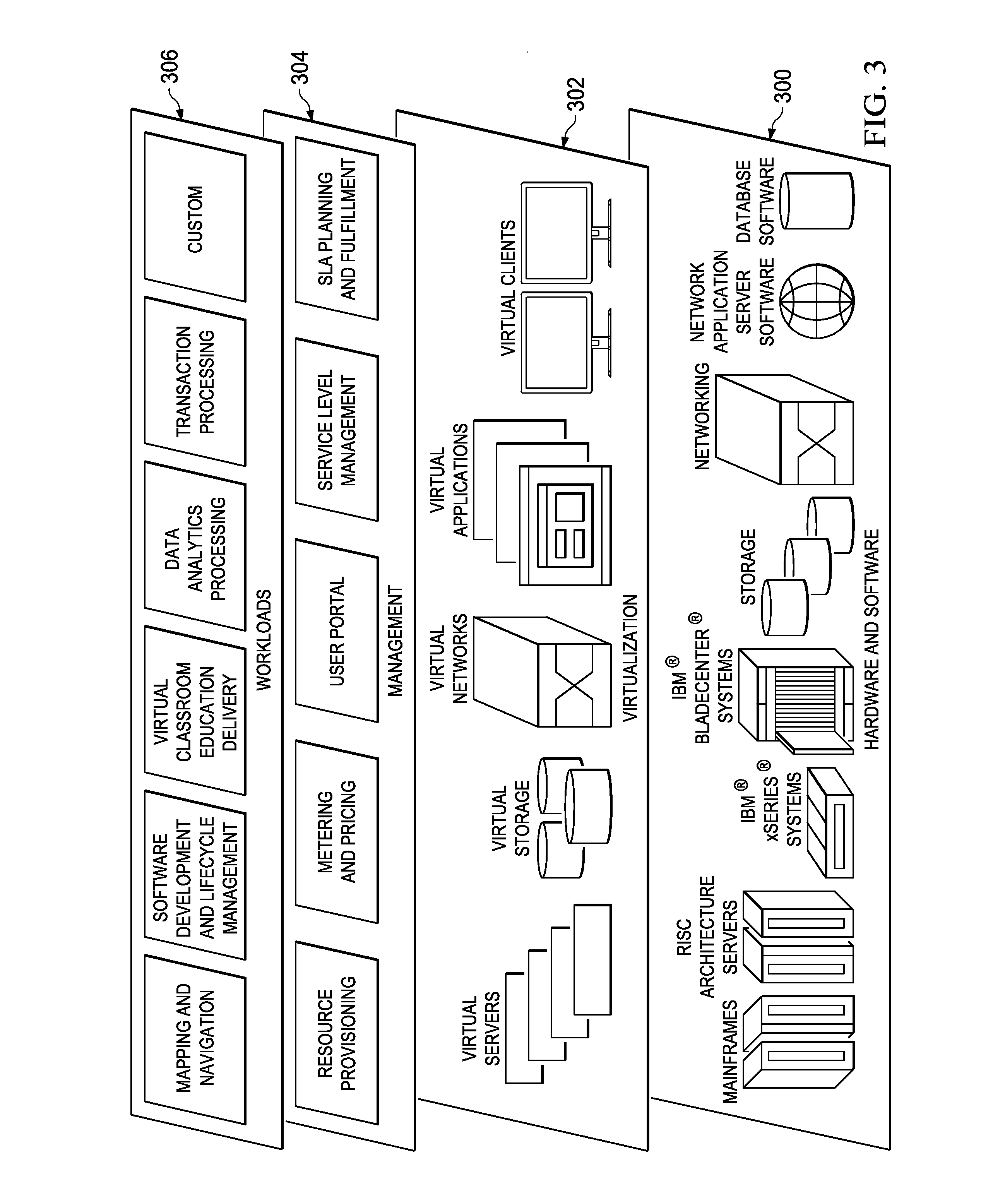

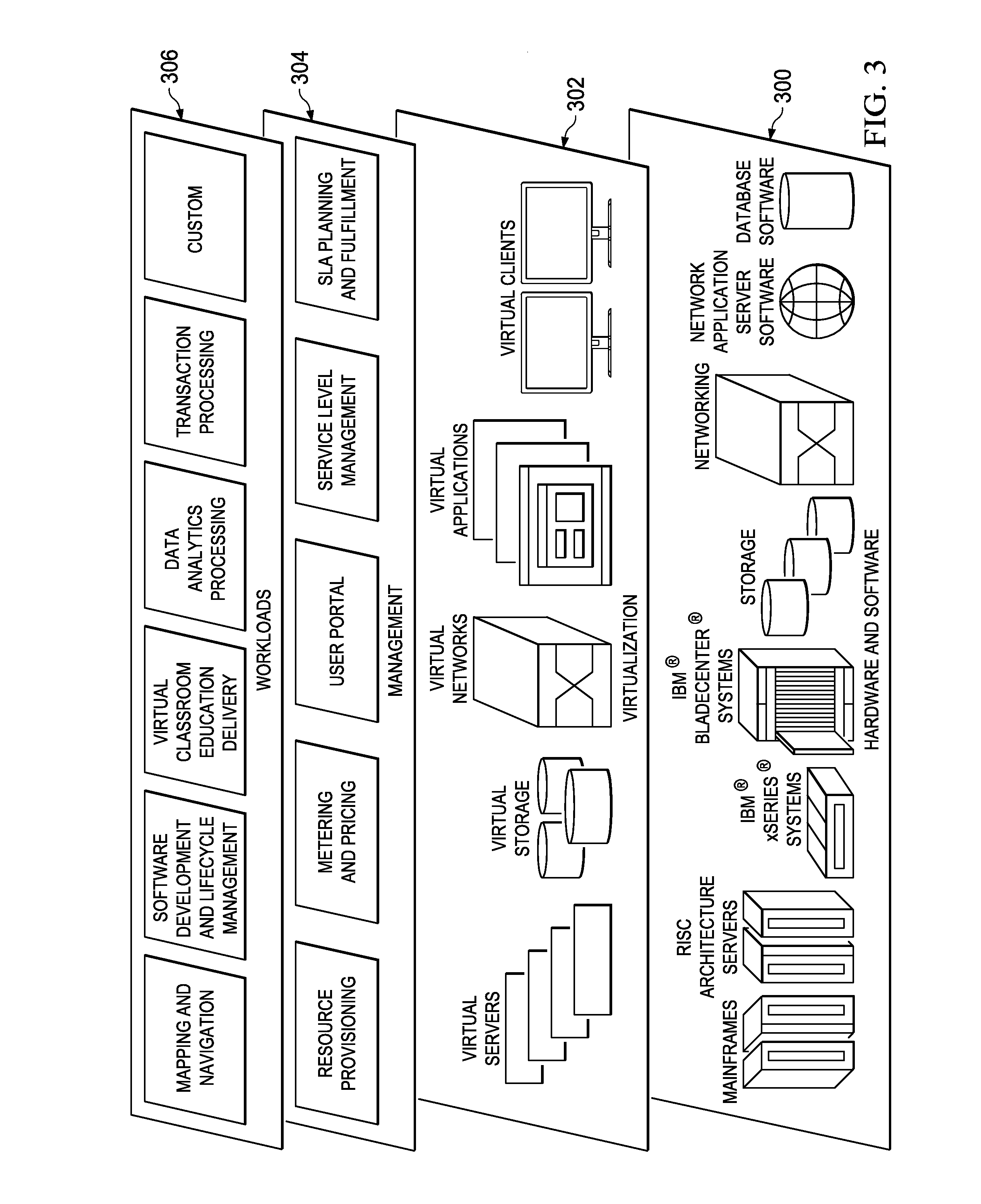

Extending infrastructure security to services in a cloud computing environment

InactiveUS20140317716A1SSO is facilitatedDigital data processing detailsMultiple digital computer combinationsTrust relationshipBase exchange

A cloud deployment appliance (or other platform-as-a-service (IPAS) infrastructure software) includes a mechanism to deploy a product as a “shared service” to the cloud, as well as to enable the product to establish a trust relationship between itself and the appliance or IPAS. The mechanism further enables multiple products deployed to the cloud to form trust relationships with each other (despite the fact that each deployment and each product typically, by the nature of the cloud deployment, are intended to be isolated from one another). In addition, once deployed and provisioned into the cloud, a shared service can become part of a single sign-on (SSO) domain automatically. SSO is facilitated using a token-based exchange. Once a product registers with a token service, it can participate in SSO. This approach enables enforcement of consistent access control policy across product boundaries, and without requiring a user to perform any configuration.

Owner:IBM CORP

Compensation driven network based exchange system and method

A method and system using a communication network, such as the Internet, to compensate at least one user in exchange for work undertaken by the at least one user. The communication network is used to perform work, the work being defined by a content provider in a manner which does not target specific user profiles. Compensation units are offered to the user in exchange for the performed work. The user uses a user terminal to accept the offered compensation units. The accepted compensation units are transferred from a content provider account to a user account, the content provider account corresponding to the content provider offering the compensation units and the user account corresponding to user who completed the work. The user can spend earned compensation units on goods and services offered by a redeeming content provider. The compensation units are provided in a closed system. The issuing content provider does not control how, when or where earned compensation units may be spent

Owner:COHEN CHARLES +1

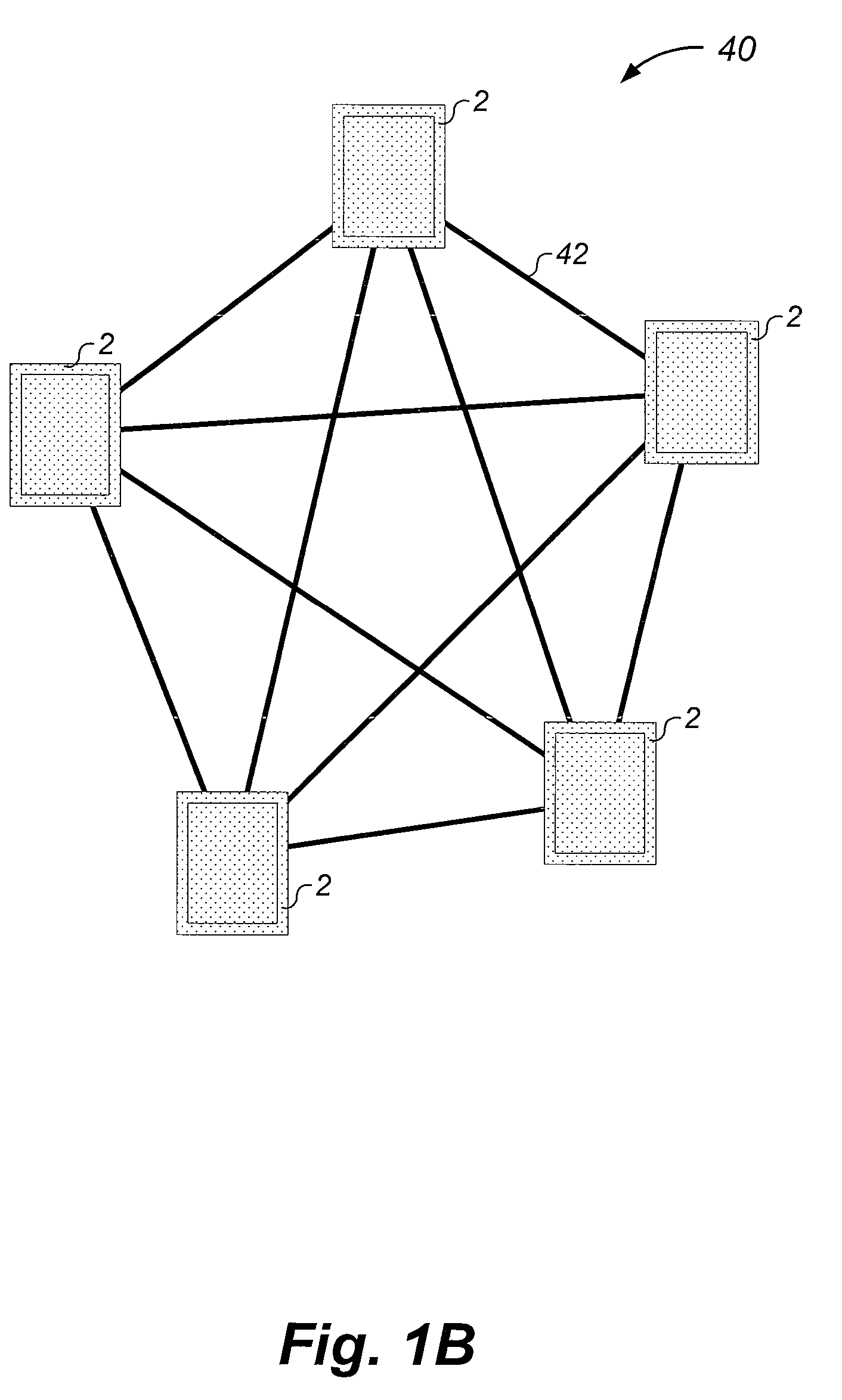

System and method for location based exchanges of data facilitating distributed locational applications

ActiveUS8639267B2Brought quicklyIncrease rangeDatabase queryingNetwork topologiesData processing systemBase exchange

Provided is a distributed system and method for enabling new and useful location dependent features and functionality to mobile data processing systems. Mobile data processing systems (MSs) interact with each other as peers in communications and interoperability. Indirectly located mobile data processing systems are located relative other mobile data processing systems, and are automatically located using whereabouts data of directly located mobile data processing systems and / or whereabouts data of other indirectly located mobile data processing systems. A mobile data processing system may dynamically take on roles of being directly located or indirectly located, depending on the environment and capabilities available at a particular time. Data is shared between mobile data processing systems to carry out novel Location Based eXchanges (LBX) of data for new mobile applications. Information which is transmitted inbound to, transmitted outbound from, or is in process at, a mobile data processing system, is used to trigger processing of actions in accordance with user configured permissions, charters, and other configurations. In a preferred embodiment, a user configurable platform is provided for quickly building well behaving LBX applications at MSs and across a plurality of interoperating MSs.

Owner:BILLJCO LLC

Preparation method for coal combustion improver

The invention relates to a preparation method for a coal combustion improver. After common coal is added with coal additives for combustion, the effect of energy saving and emission reduction is obvious and effective. The preparation method comprises the following steps that: 1. high-stability sodium chlorate and potassium chloride react with each other to produce potassium chlorate when water is added and the sodium chlorate and the potassium chloride are dissolved; 2. leavening agent sodium acetate is introduced to conduct base exchange with humate in coal, low ignition point humate is produced and the ignition performance of the coal is reduced; and 3. ferric oxide required by the formula is compound insoluble in water. Thereby, ferric chloride and calcium oxide are used to react with each other to produce ferric oxide when water is added and the ferric chloride and the calcium oxide are dissolved. Other products in the market do not at all have the preparation and application characteristics of the three compounds.

Owner:GUANGHUA SCI & TECH SHANGHAI +1

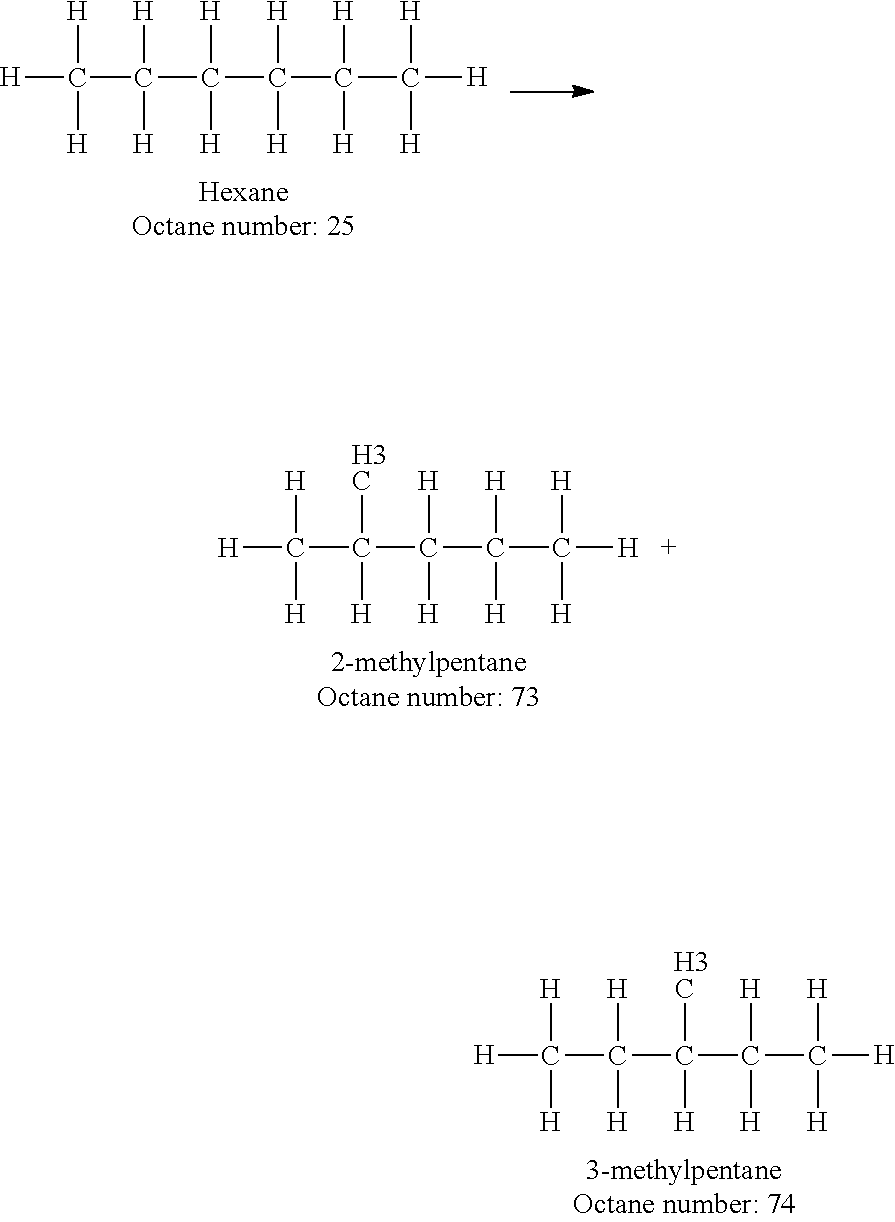

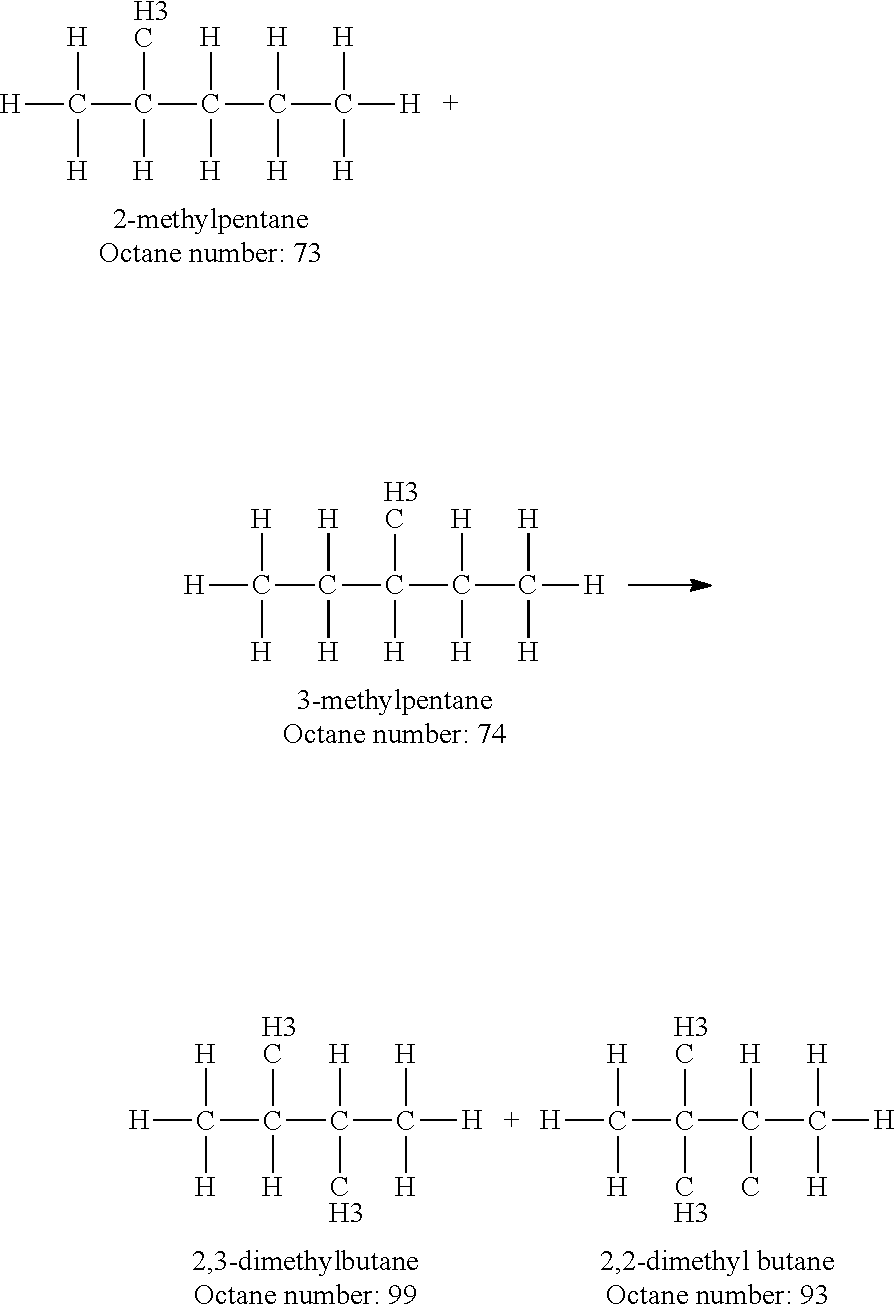

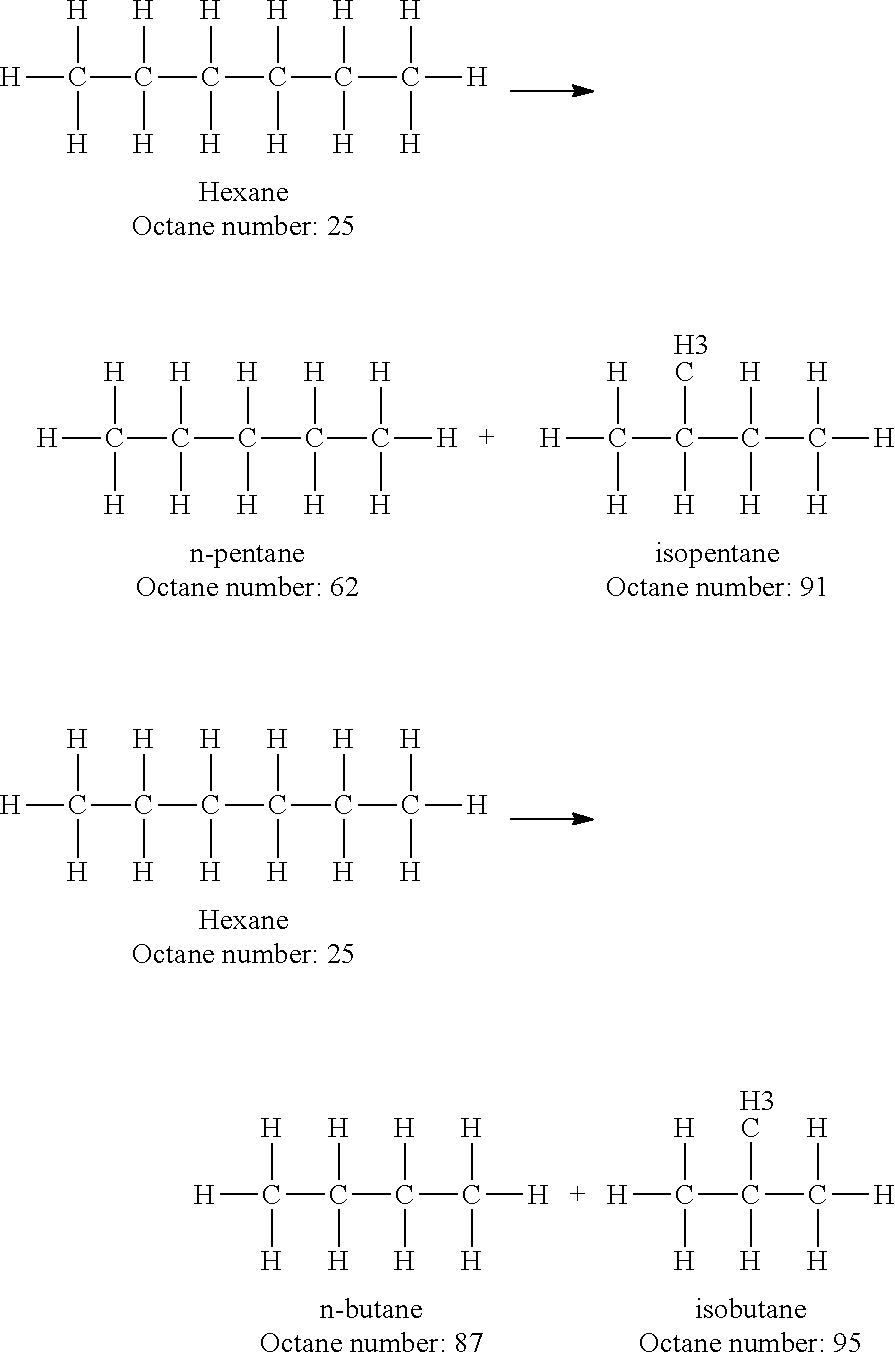

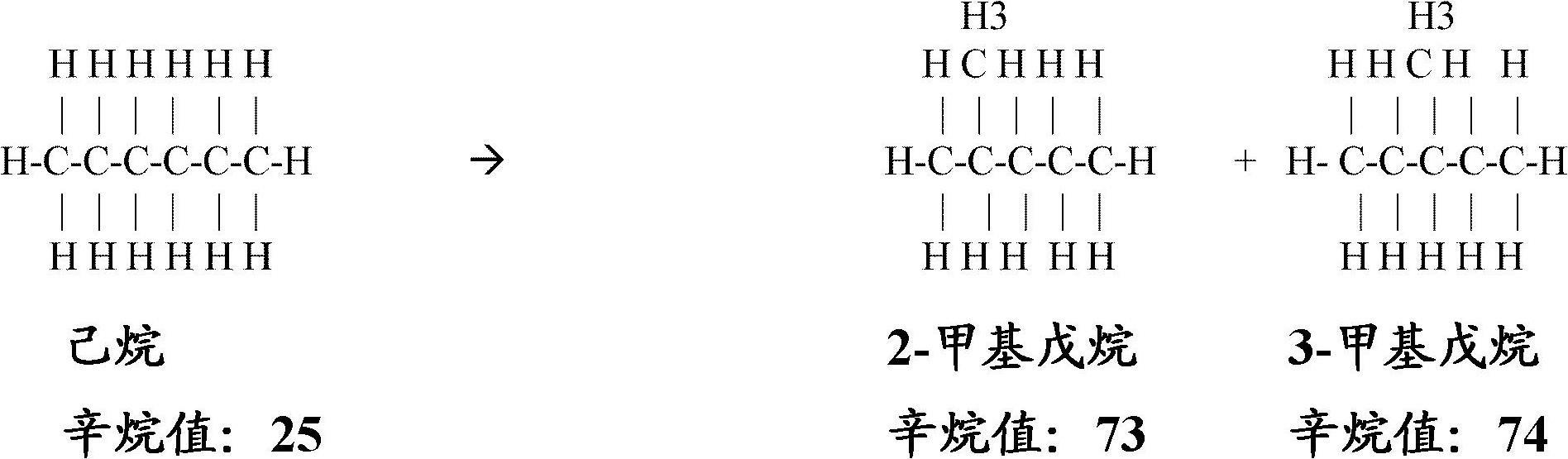

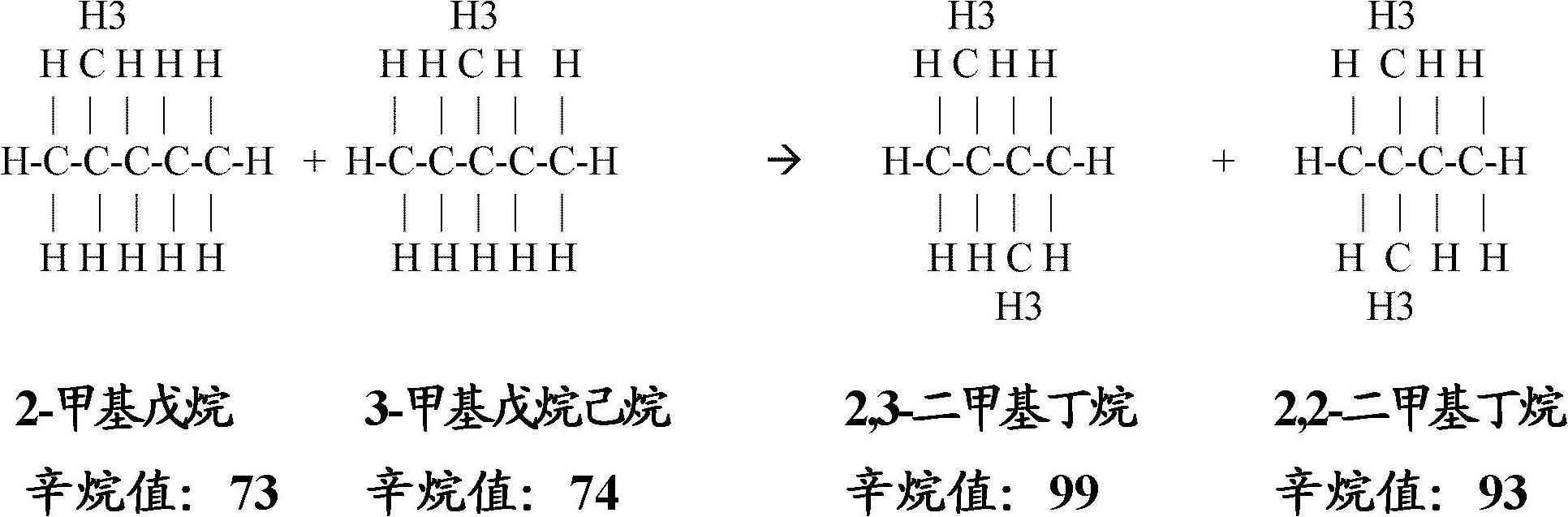

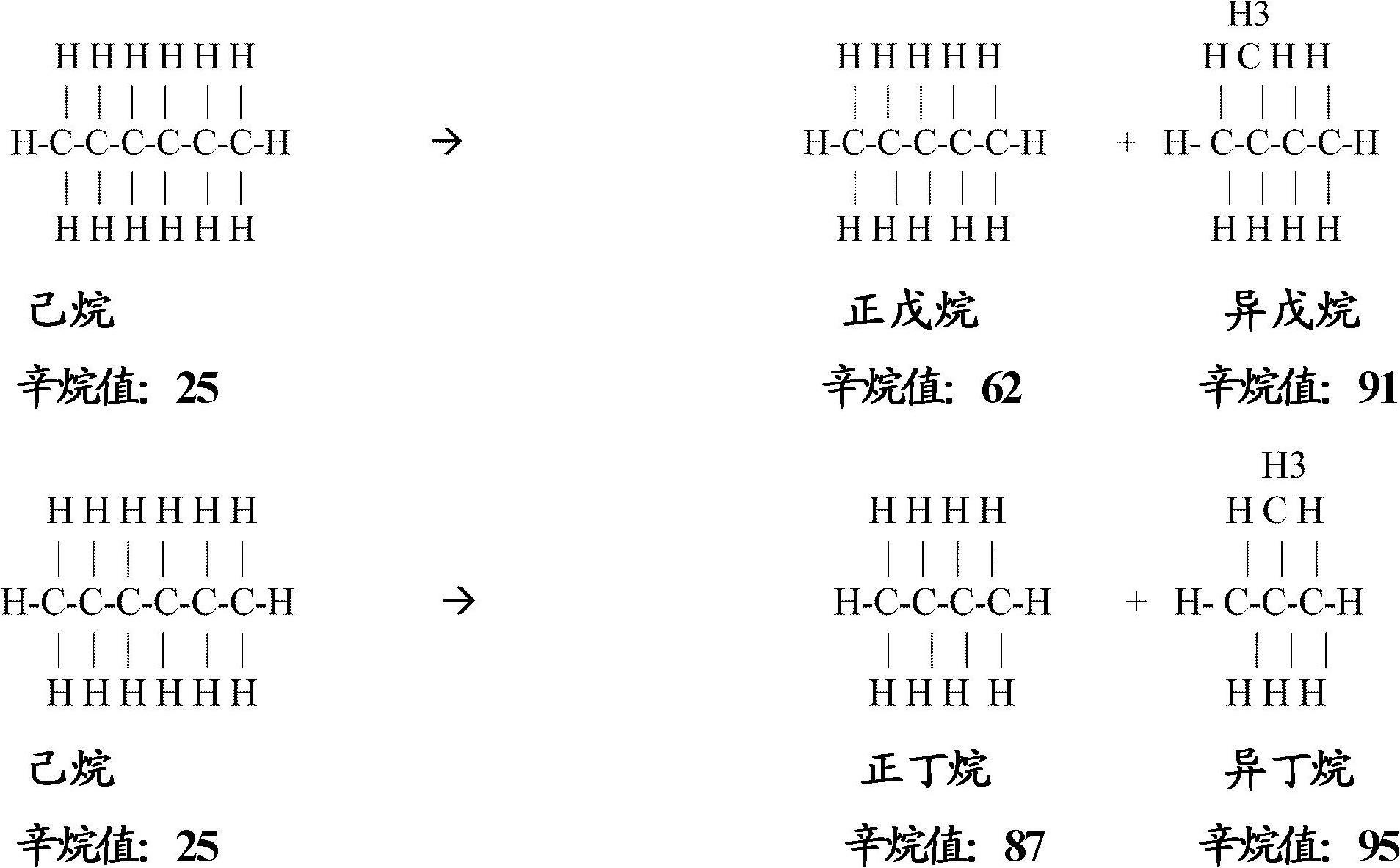

Increasing octane number of light naphtha using a germanium-zeolite catalyst

InactiveUS20110132804A1Boost octaneMolecular sieve catalystsHydrocarbon by hydrogenationAlkaneAlkaline earth metal

This invention relates to a process for the increasing the octane number of a naphtha hydrocarbon feed having a predominantly paraffin content with a germanium-containing zeolite catalyst. The catalyst is a non-acidic germanium zeolite on which a noble metal, such as platinum, has been deposited. The zeolite structure may be of MTW, MWW, MEL, TON, MRE, FER, MFI, BEA, MOR, LTL or MTT. The zeolite is made non-acidic by being base-exchanged with an alkali metal or alkaline earth metal, such as cesium, potassium, sodium, rubidium, barium, calcium, magnesium and mixtures thereof, to reduce acidity. The catalyst is sulfur tolerant. The hydrocarbon feed may contain sulfur up to 1000 ppm. The present invention could be applicable to a feedstream which is predominantly naphthenes and paraffins.

Owner:SAUDI BASIC IND CORP SA

Compensation driven network based exchange system and method

A method and system using a communication network, such as the Internet, to compensate at least one user in exchange for work undertaken by the at least one user. The communication network is used to perform work, the work being defined by a content provider in a manner which does not target specific user profiles. Compensation units are offered to the user in exchange for the performed work. The user uses a user terminal to accept the offered compensation units. The accepted compensation units are transferred from a content provider account to a user account, the content provider account corresponding to the content provider offering the compensation units and the user account corresponding to user who completed the work. The user can spend earned compensation units on goods and services offered by a redeeming content provider. The compensation units are provided in a closed system. The issuing content provider does not control how, when or where earned compensation units may be spent

Owner:BEENZ COM IRELAND

Aromatization of alkanes using a germanium-zeolite catalyst

ActiveUS7902413B2Molecular sieve catalystsRefining to change hydrocarbon structural skeletonAlkaneAlkaline earth metal

Owner:SAUDI BASIC IND CORP SA

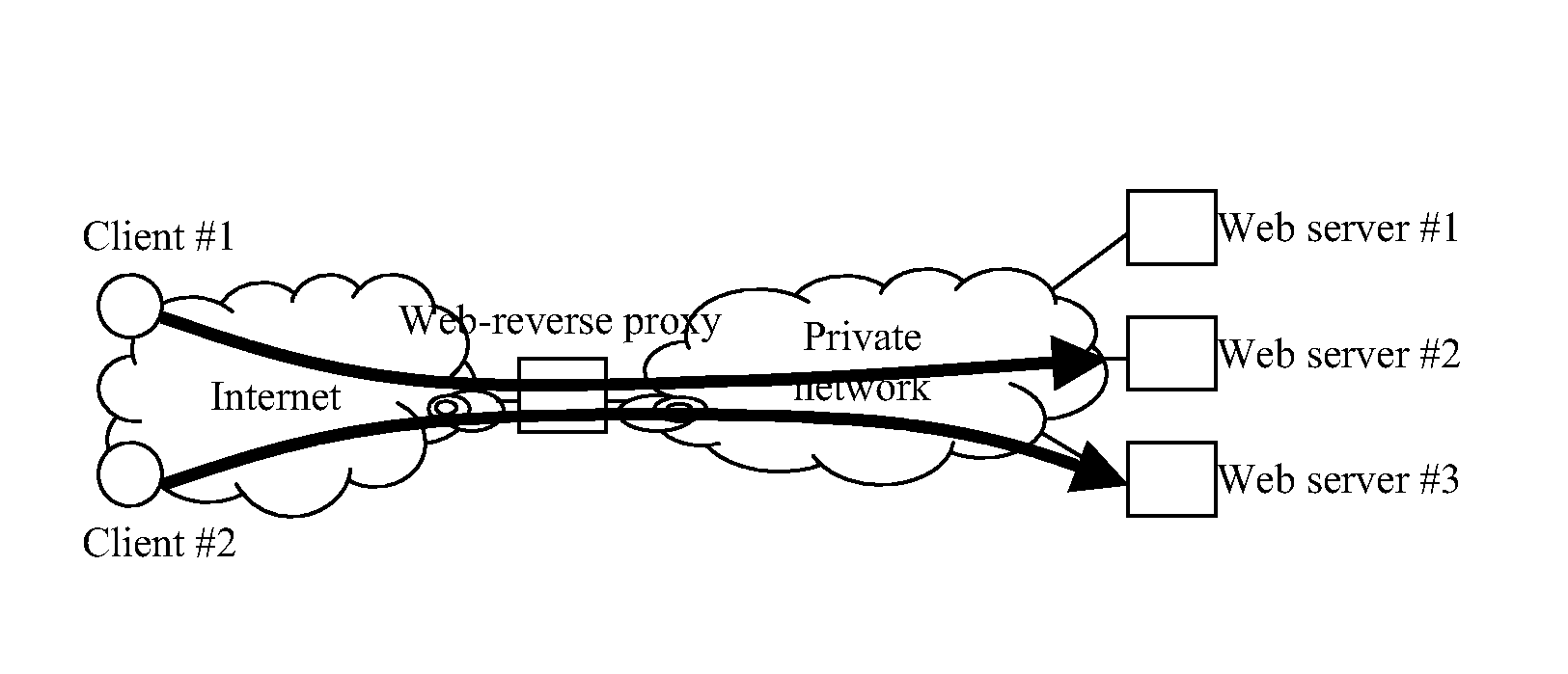

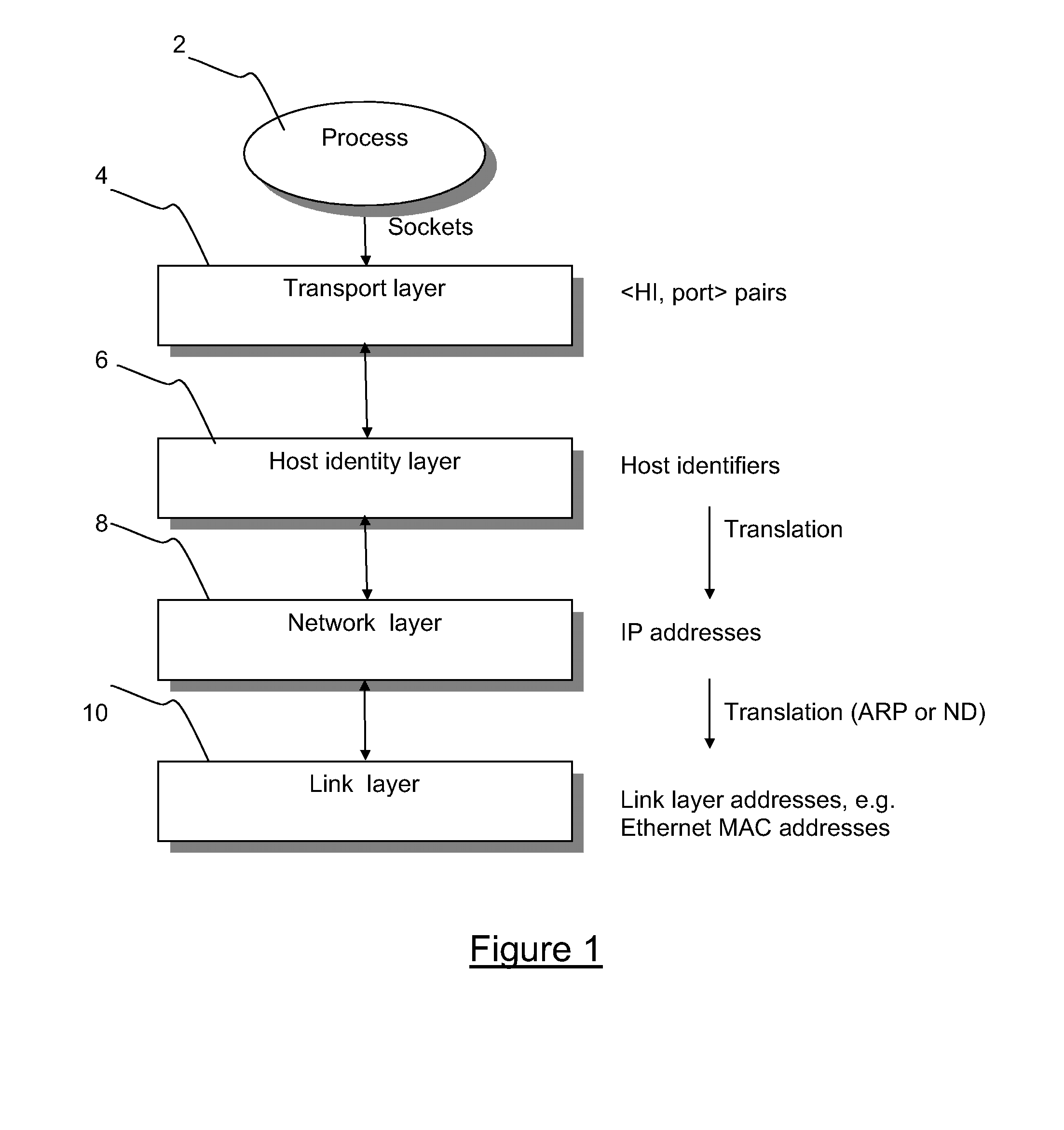

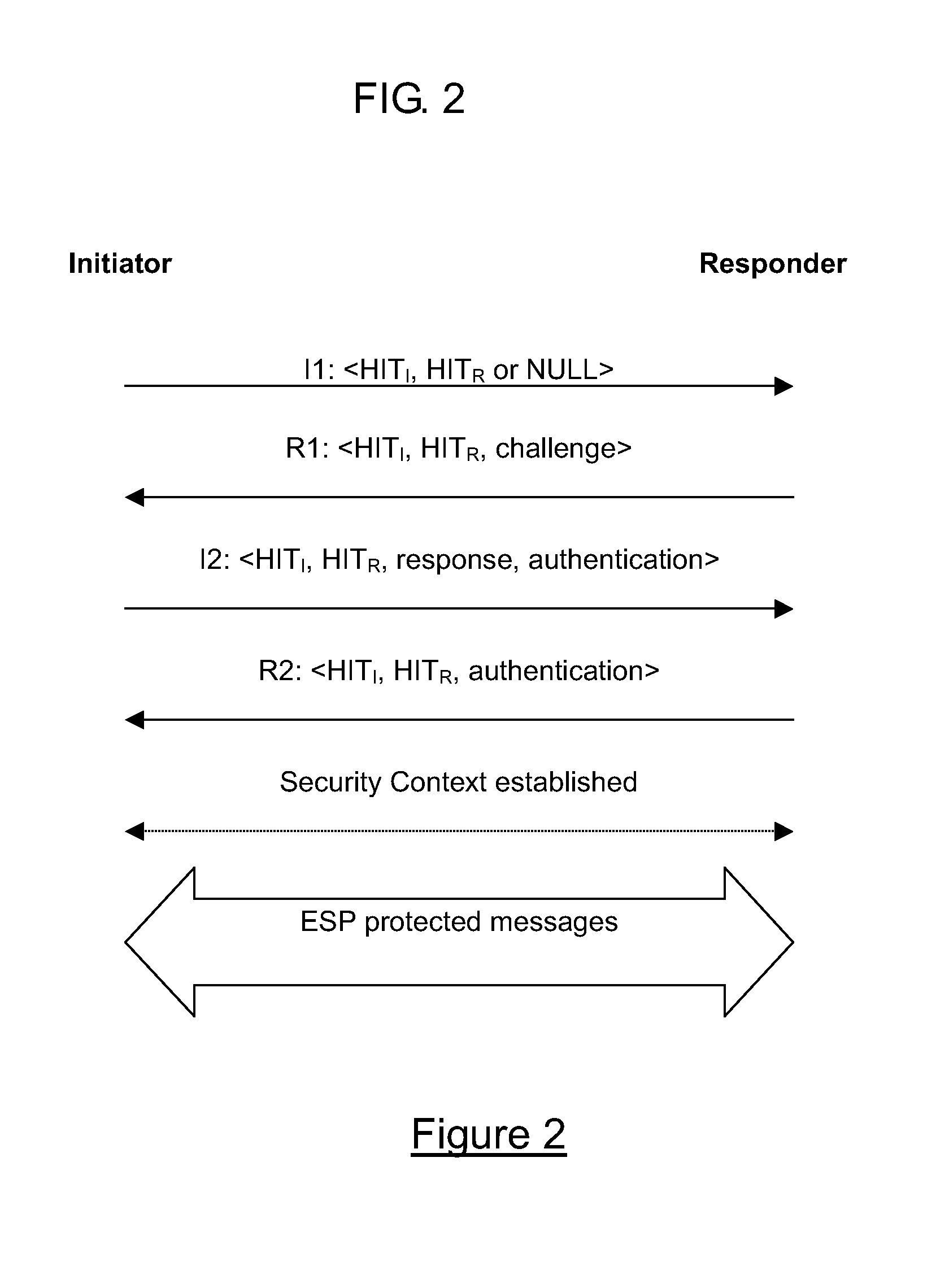

Addressing and routing mechanism for web server clusters

InactiveUS20090265541A1Good for load balancingUser identity/authority verificationTransmissionReverse proxyWeb service

A method of establishing a Host Identity Protocol session between first and second Host Identity Protocol enabled hosts, where at least said second host is located behind a reverse-proxy. The method comprises providing the reverse-proxy with Diffie-Hellman public keying material of the second host, sending said Diffie-Hellman public keying material from the reverse-proxy to the first host as part of the Host Identity Protocol base exchange procedure, this material being bound to the Host Identity of the reverse-proxy for the purpose of the Host Identity Protocol session, and, at the first host, using the Host Identity of the reverse-proxy as the correspondent Host Identity for the Host Identity Protocol session, and, at the second host, using the Host Identity of the reverse-proxy as the originating Host Identity for the Host Identity Protocol session.

Owner:TELEFON AB LM ERICSSON (PUBL)

Chitosan/rectorite nano composite materials and method for preparing the same

The invention discloses the method for preparation of chitosan / rectorite nano composite material used for antibacterial agent. The chitosan / rectorite nano composite material, which mainly comprises chitosan and rectorite, is made by entering chitosan intercalation into clay band. The method comprises the following steps: carrying out base exchange by natural rectorite and modifier to make organic rectorite, in the condition of stirring, adding the chitosan solution into the organic rectorite suspending liquid at twice, adding caustic soda solution, washing the solution until the neutral solution, drying, and getting the chitosan or rectorite nano composite material. Compared with the pure chitosan, the microorganism resistance and fire-resisting property of chitosan or rectorite nano composite material are better.

Owner:WUHAN UNIV

Orr formular

InactiveUS8088310B2Effective distributionFlake off easily and be blown awayFire rescueBoring toolsCalcium biphosphateWild life

Each year wildfires, forest fires and out of control camp fires do untold damage to millions of acres of land, while causing billions of dollars in damages to property, wild life, and human life. The Orr Formula is designed to aid in, and assist the extinguishment of such fires. The Orr Formula is a composition that comprises: 1) 10% by weight Calcium Phosphate which acts as a binder; 2) 10% by weight Corn Starch which aids in flaking of the remaining composition off the site to which the composition was applied after the fire has been extinguished and cooled; and 3) 80% by weight of a mixture of Sodium Silicate with a base exchange Silicate of Sodium Aluminum.

Owner:ORR CHARLES L

System and method for location based exchanges of data facilitating distributed locational applications

InactiveUS8600341B2Avoid performanceRaise the possibilityDigital data information retrievalAccounting/billing servicesData processing systemPosition dependent

Provided is a distributed system and method for enabling new and useful location dependent features and functionality to mobile data processing systems. Mobile data processing systems interact with each other as peers in communications and interoperability. Indirectly located mobile data processing systems are located relative other mobile data processing systems, and are automatically located using whereabouts data of directly located mobile data processing systems and / or whereabouts data of other indirectly located mobile data processing systems. A mobile data processing system may dynamically take on roles of being directly located or indirectly located, depending on the environment and capabilities available at a particular time. Reference whereabouts data is appropriately shared between mobile data processing systems to carry out automatic location techniques ensuring mobile data processing systems are kept up to date with their own whereabouts and whereabouts of others, regardless of the freely moving travels of any of the mobile data processing systems involved, and the location technologies that may or may not be available when needed. A confidence is associated to whereabouts data shared for facilitating selection of the best candidate data used in determining new whereabouts information.

Owner:BILLJCO LLC

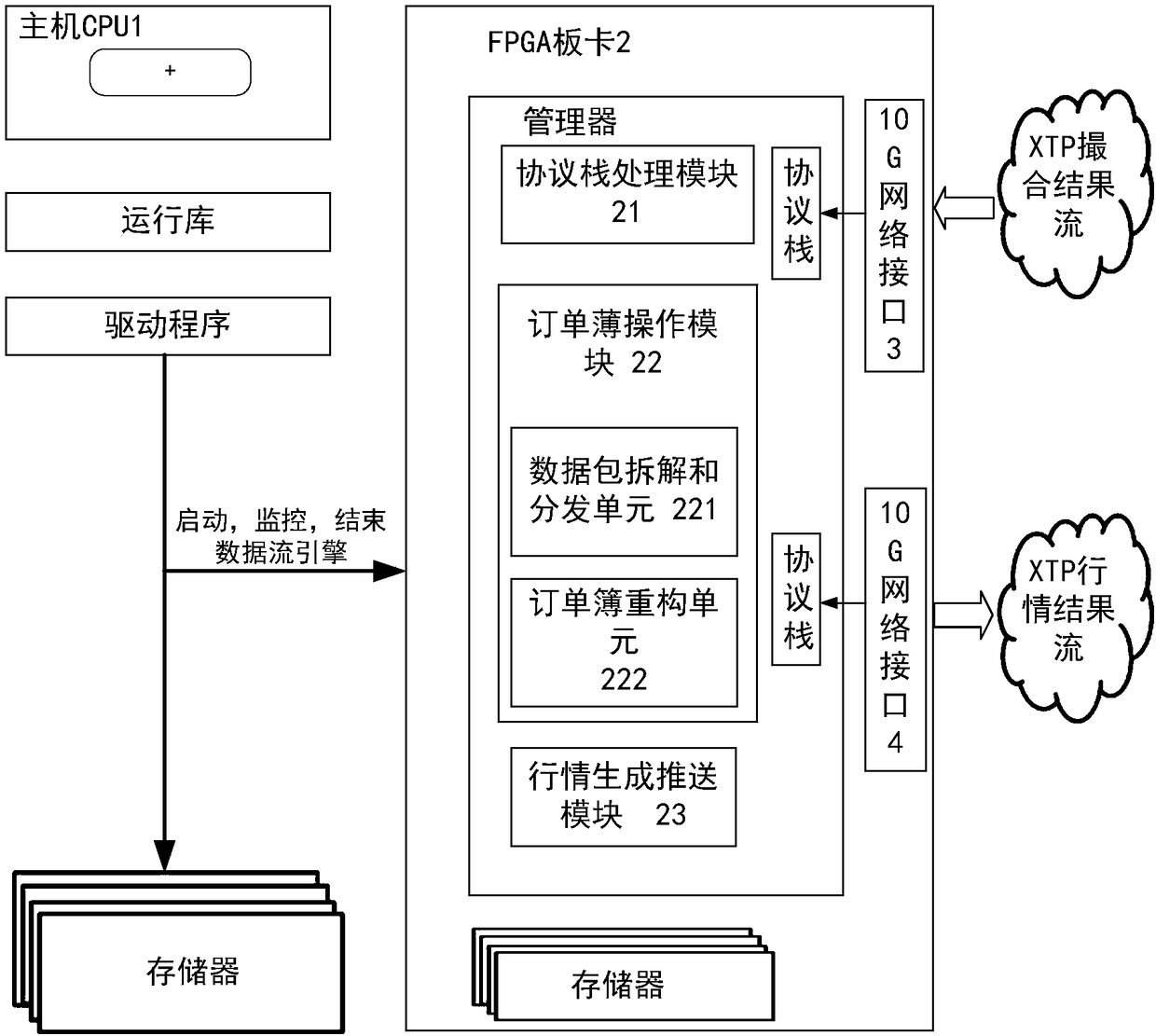

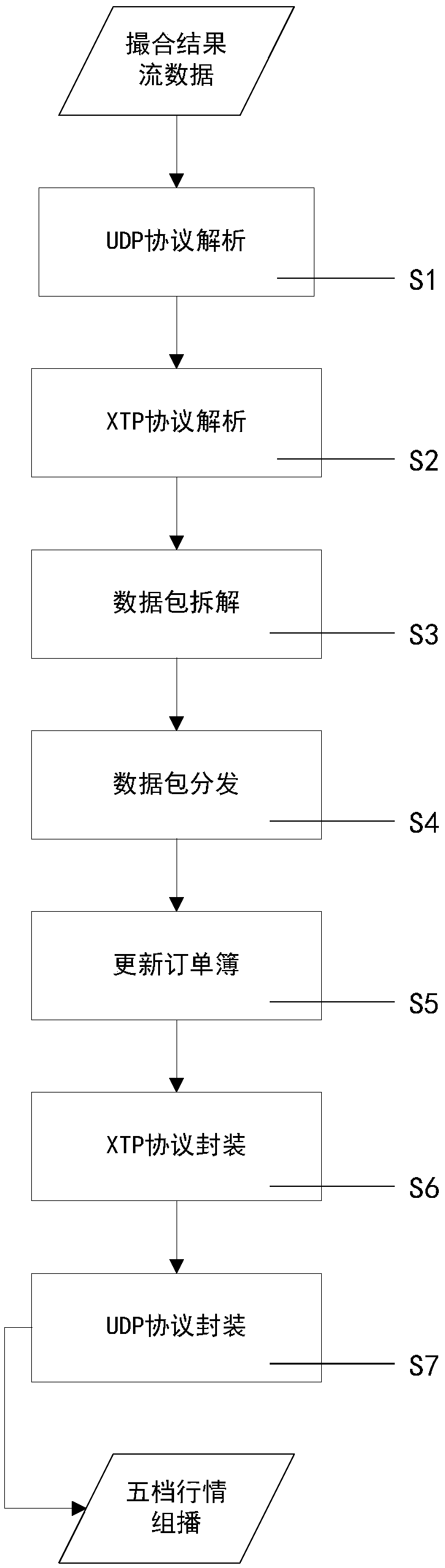

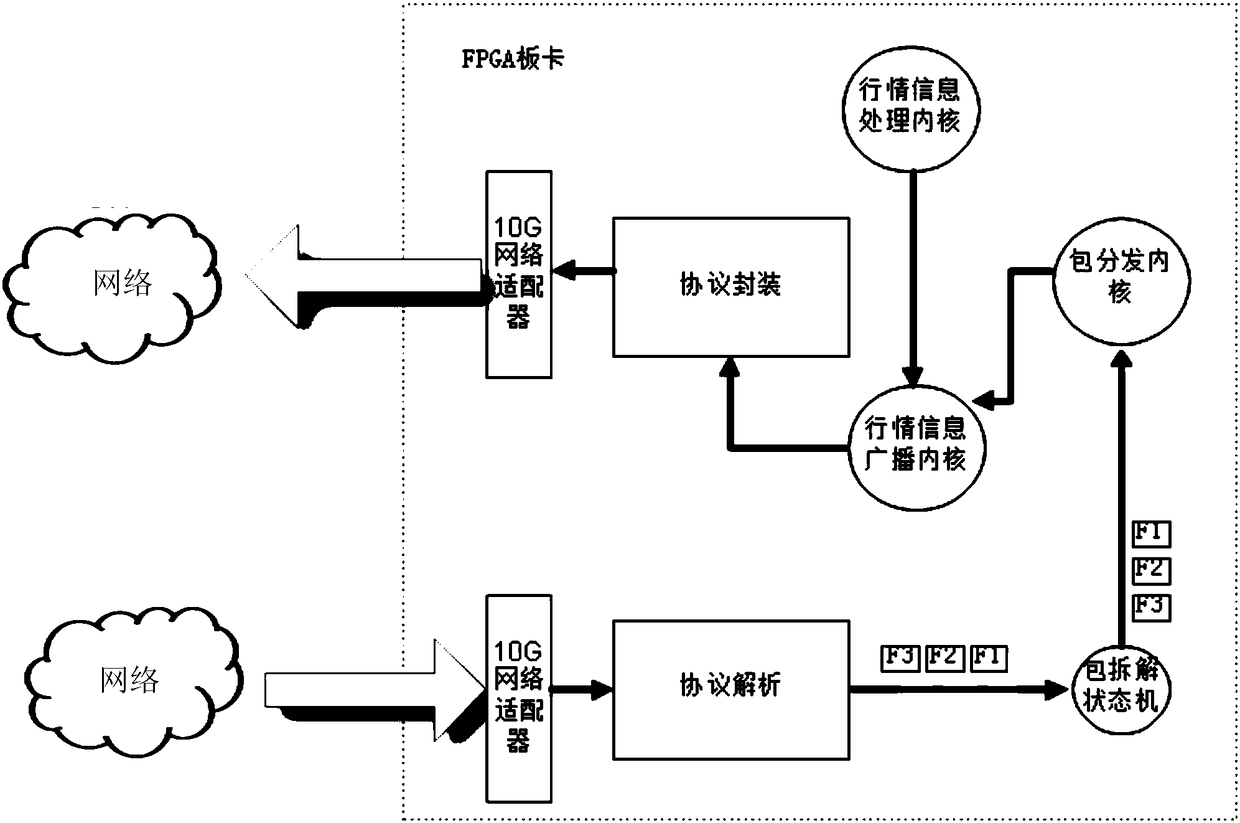

FPGA-based exchange market information processing method and system

InactiveCN108269188ARealize identificationCollaborative workFinanceTransmissionInformation processingHardware modules

The invention discloses an FPGA-based exchange market information processing method and system. The trading system market information processing capacity is enhanced, the system delay performance is enhanced, the system coupling degree is reduced, and the characteristics of market calculation real-time performance, low delay and high throughput can be met. The technical scheme is that the FPGA-based ethernet protocol stack oriented multilevel leap analysis packaging is adopted so that the processing delay of the host-based storage forwarding network protocol stack is reduced; the problems of field alignment and protocol domain matching are solved by using the state machine disassemble data packet so as to facilitate subsequent module pipelined processing; parallel processing of different hardware modules is used on the market information processing course by using the data packet distribution method so as to accelerate generation of the market information; the software and hardware design division method with the FPGA acting as the principle and the CPU acting as the auxiliary and the on-chip high speed cache allocation are adopted to alleviate the conflict between the FPGA performance and the resource; and the market is pushed by using the multicast mode so that the unfair access problem caused by polling and the user identity authentication problem caused by broadcasting canbe solved.

Owner:上海金融期货信息技术有限公司

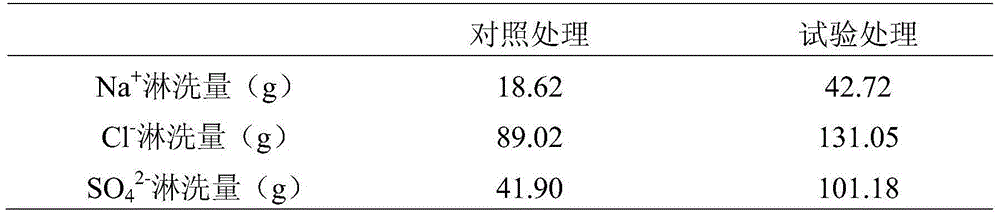

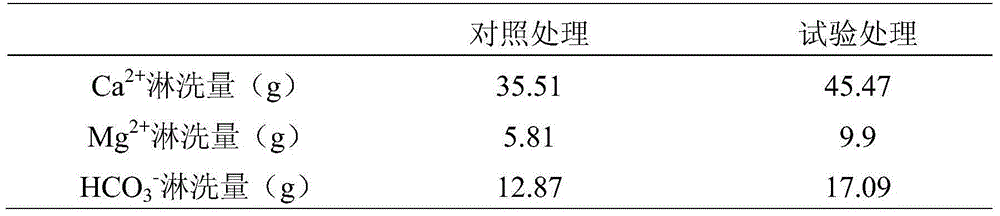

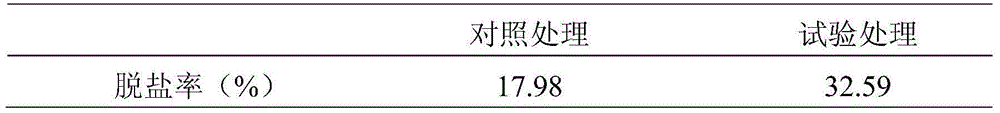

Water-soluble soil salinization improver and preparation method and application of improver

ActiveCN104449756ALight weightHigh porosityAgriculture tools and machinesOther chemical processesPorosityPhosphate

The invention discloses a water-soluble soil salinization improver and a preparation method and an application of the improver. The water-soluble soil salinization improver is prepared from guar gum, nonionic polyacrylamide, potassium polyacrylate, potassium polysilicate, citric acid and monoammonium phosphate according to a mass ratio of (5-8) to (10-16) to (10-16) to (8-18) to (30-50) to (10-20). The preparation method of the water-soluble soil salinization improver comprises the following steps: mixing guar gum, nonionic polyacrylamide, potassium polyacrylate, potassium polysilicate, citric acid and monoammonium phosphate according to a ratio, and prilling to prepare the water-soluble soil salinization improver. The application of the water-soluble soil salinization improver is characterized by spraying or irrigating the soil salinization improver to the salinization soil. The water-soluble soil salinization improver has the advantages that micro-aggregates are formed by the soil after the improver is applied to the salinization soil, the volume weight of the soil can be reduced, the total porosity of the soil is increased, the air permeability and water permeability are improved, the rate of gathering the salt of the deep soil to the earth surface is reduced, the rate of washing the salt is increased, the base exchange capacity is increased, the pH value is regulated, and the utilization value of the soil is increased.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

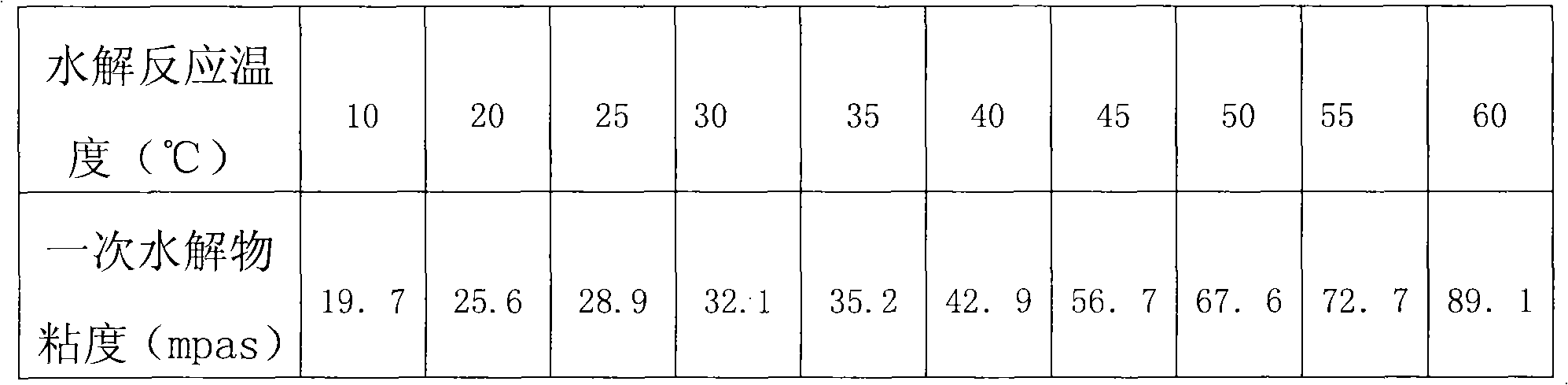

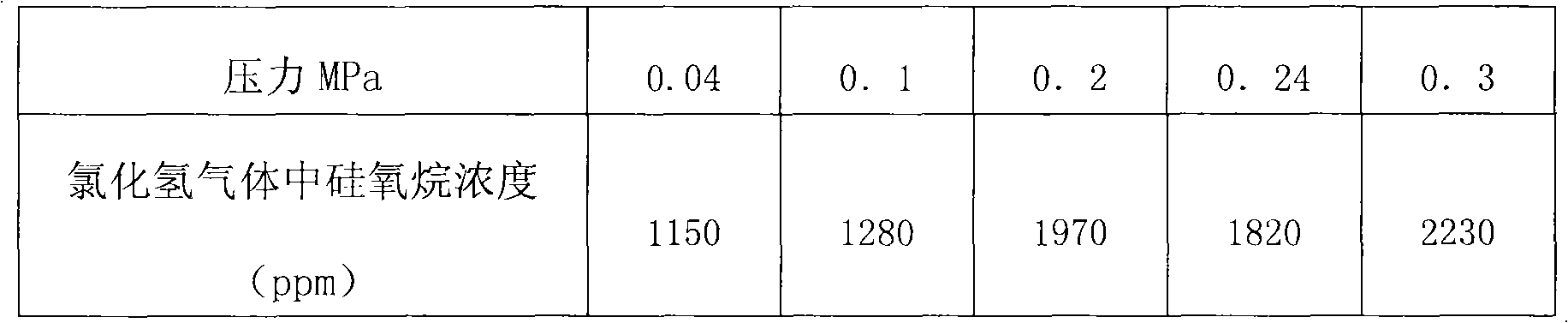

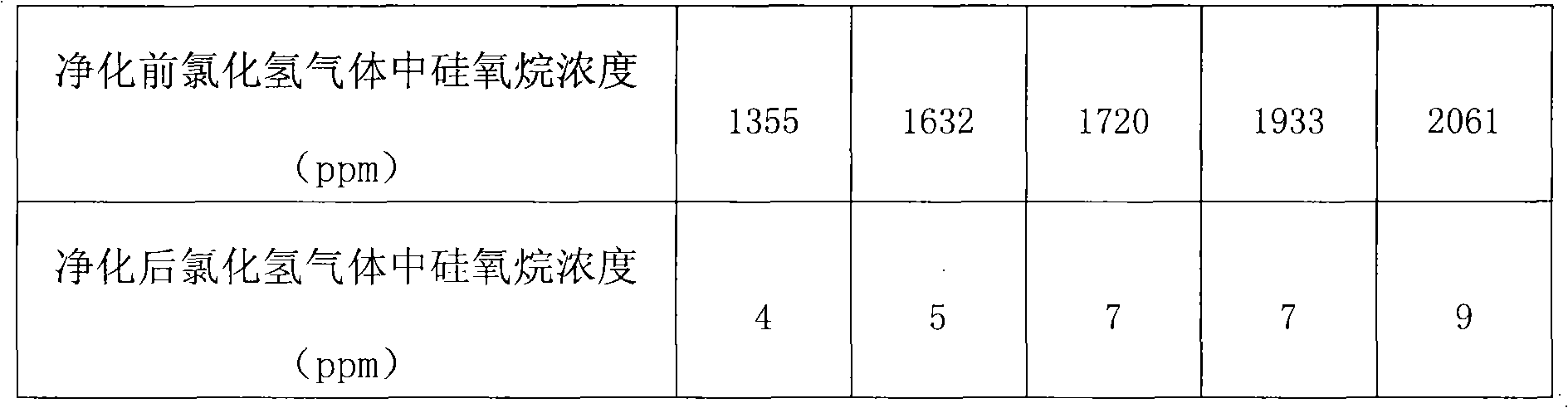

Method for preparing polysiloxane by hydrolyzing dimethyl dichlorosilane

The invention relates to a method for preparing polysiloxane by hydrolyzing dimethyl dichlorosilane, which comprises two continuous hydrolysis steps (1) and (2) and a neutralization step (3): step (1), dimethyl dichlorosilane, concentrated hydrochloric acid of the concentration greater than 35 percent and dilute generated by secondary hydrolysis are hydrolyzed at 10-60DEG C and under the pressure of 0-0.3MPa according to the weight ratio of 1: 1.5: 0.5-1: 1.5: 3; step (2), hydrolysis is carried out in excess water, and the reaction temperature is normal temperature; and step (3), the neutralization reaction is carried out, resin is adopted to adsorb a filter unit, the stuffing is cation-base exchange resin with large surface area, and the height of the stuffing is 2-4 meters; the content of the hydrolysate Cl- is less than 10ppm, the product siloxane prepared in the method has the viscosity less than 50mPa.S, and the content of impurity in hydrogen chloride gas is less than 10ppm.

Owner:PETROCHINA CO LTD

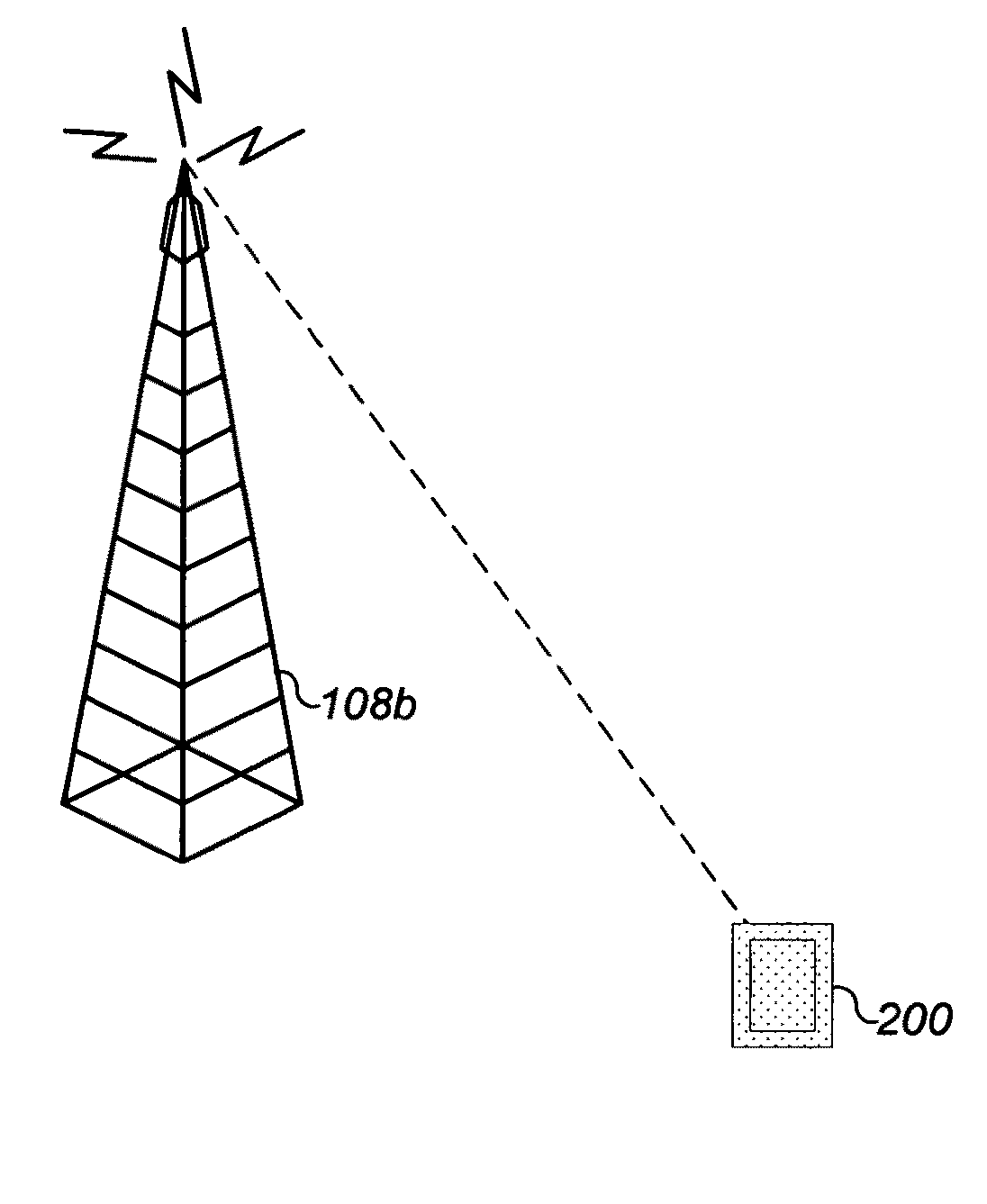

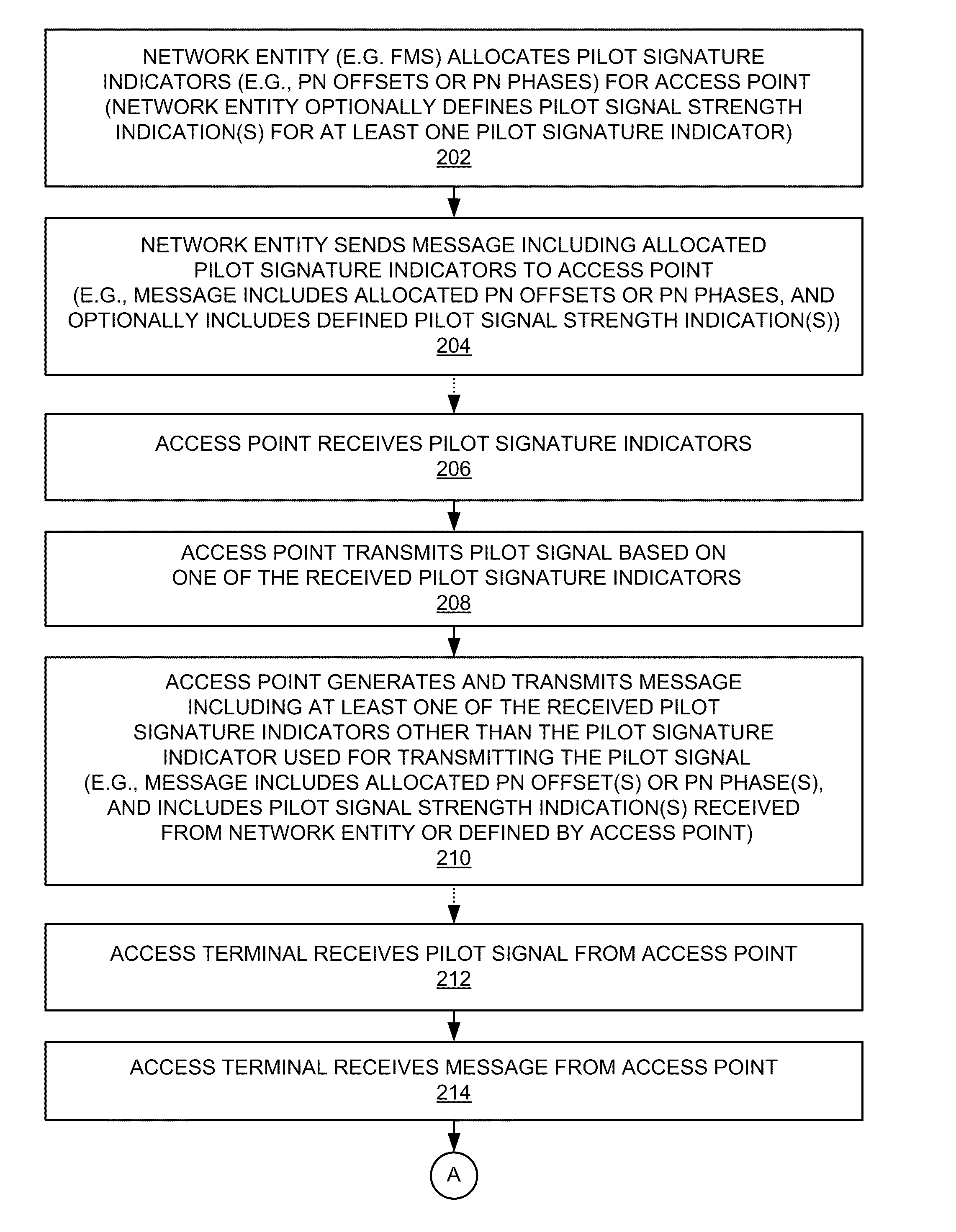

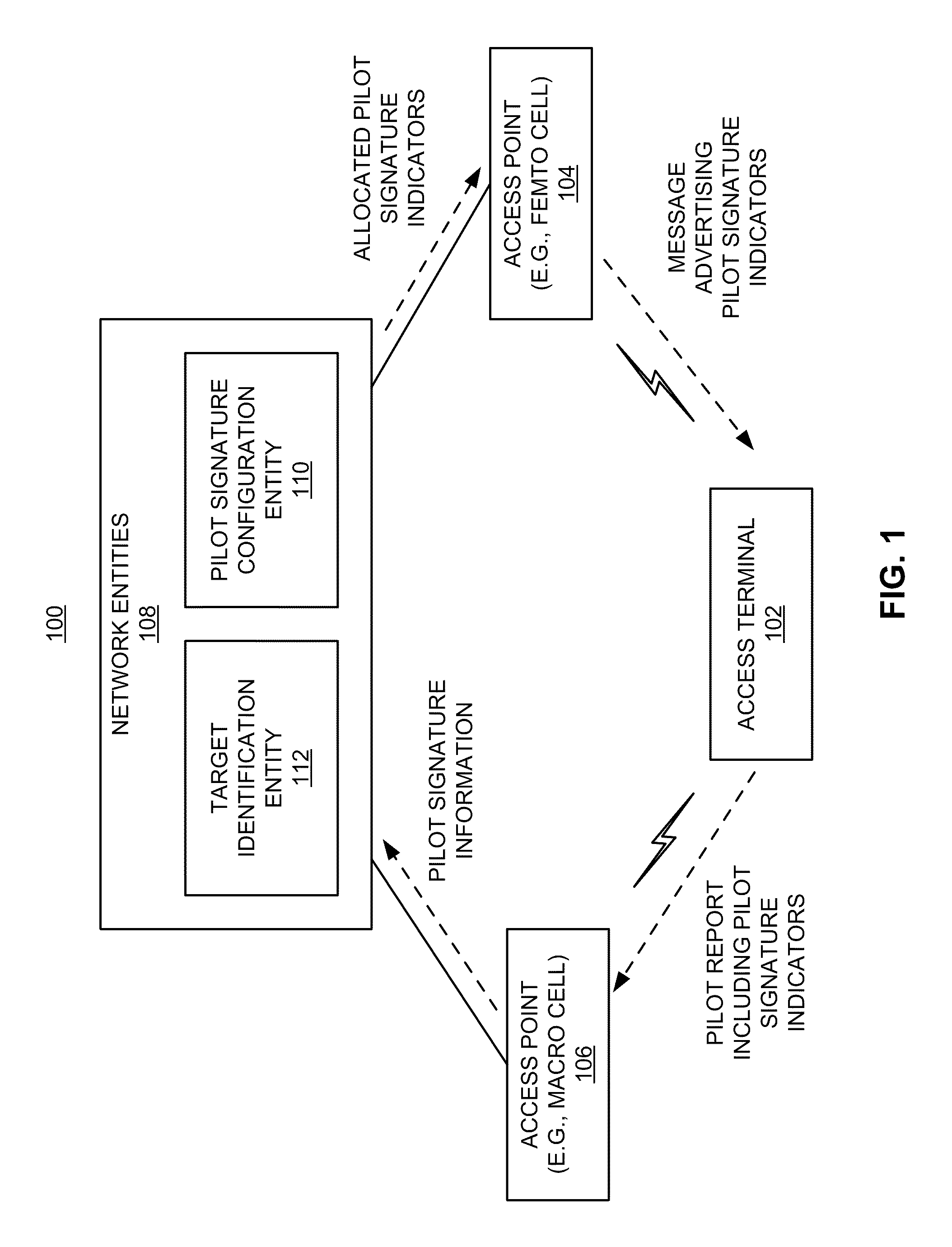

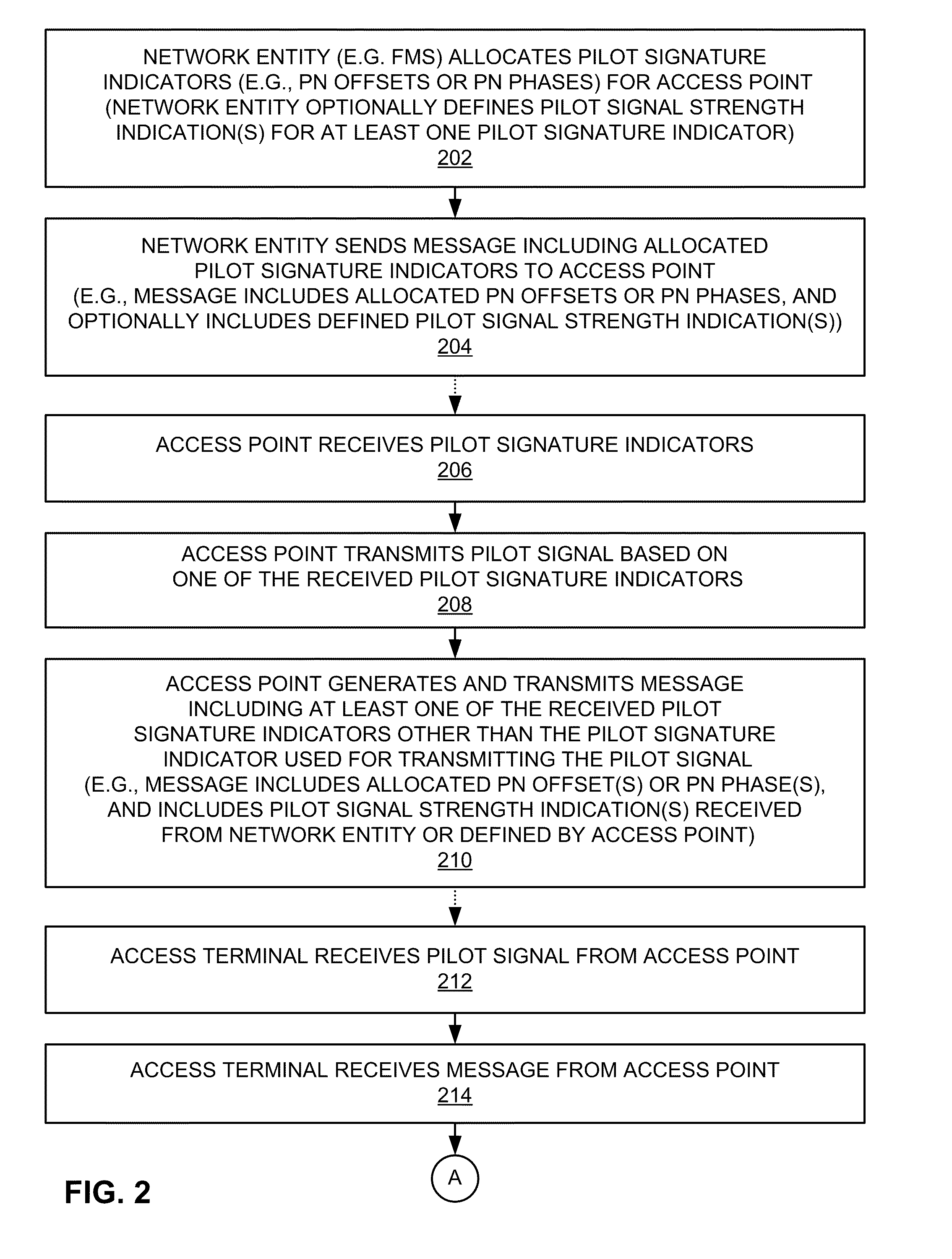

Message-based exchange of access point pilot signature indicators

InactiveUS20110189986A1Accurate identificationAssess restrictionNetwork topologiesPilot reportBase exchange

An access point is identified based on a plurality of pilot signatures. Here, in addition to transmitting a pilot signal that is encoded (e.g., spread / scrambled) using a particular pilot signature, an access point transmits a message that includes at least one indication of at least one other pilot signature. For example, an access point may use one PN offset to generate a pilot signal and transmit a message that identifies at least one other PN offset. An access terminal that receives the pilot signal and the message may then generate a pilot report that identifies all of these pilot signatures. Upon receiving a handover message including this pilot-related information, a target network entity with knowledge of the pilot signatures assigned to that access point may then accurately identify the access point as a target for handover of the access terminal.

Owner:QUALCOMM INC

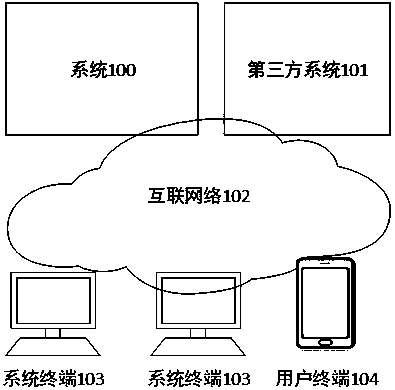

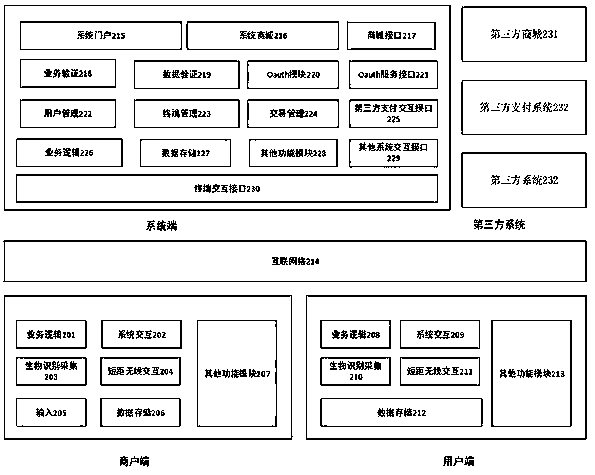

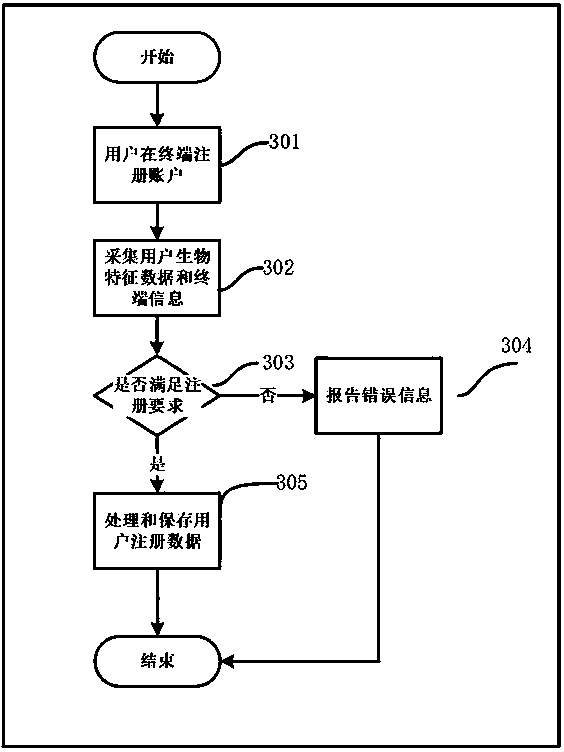

Bio-identification-based exchange method and system

InactiveCN107609877AFulfil requirementsImprove friendly experienceMarketingProtocol authorisationUser needsTerminal equipment

The invention discloses a bio-identification-based exchange method and system. The system comprises a user terminal, a system, a corresponding service, a merchant terminal and the like. A user registers in the system; bio-feature identification data of the user is collected through the terminal; the system stores user registration information; the user pays for purchased services or commodities online; after payment succeeds, the system stores payment information and purchase information; when the user needs to perform exchange on site, bio-identification is performed through the user terminal, the system or the merchant terminal; the system is requested to verify read bio-feature information; the system verifies user information and paid information; and if the verification is passed, a merchant is notified to allow the user to obtain the corresponding service. Through the bio-identification capability, convenient business experience of exchange without carrying a physical bill or a mobile phone terminal device is provided for the user.

Owner:SHANGHAI BOLU INFORMATION TECH

Extending infrastructure security to services in a cloud computing environment

InactiveUS9426155B2SSO is facilitatedDigital data processing detailsTransmissionTrust relationshipBase exchange

A cloud deployment appliance (or other platform-as-a-service (IPAS) infrastructure software) includes a mechanism to deploy a product as a “shared service” to the cloud, as well as to enable the product to establish a trust relationship between itself and the appliance or IPAS. The mechanism further enables multiple products deployed to the cloud to form trust relationships with each other (despite the fact that each deployment and each product typically, by the nature of the cloud deployment, are intended to be isolated from one another). In addition, once deployed and provisioned into the cloud, a shared service can become part of a single sign-on (SSO) domain automatically. SSO is facilitated using a token-based exchange. Once a product registers with a token service, it can participate in SSO. This approach enables enforcement of consistent access control policy across product boundaries, and without requiring a user to perform any configuration.

Owner:INT BUSINESS MASCH CORP

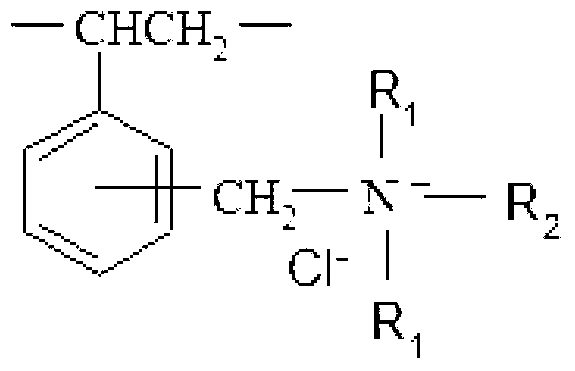

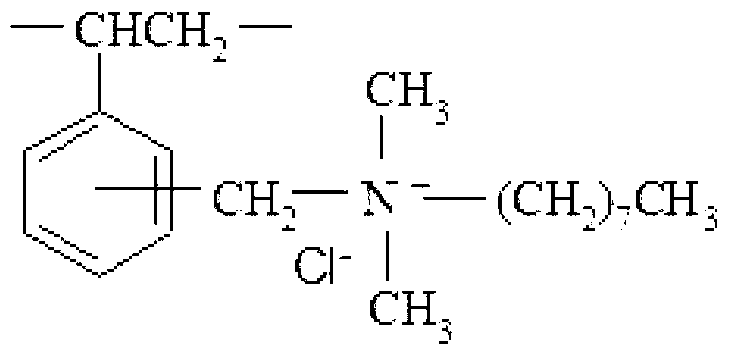

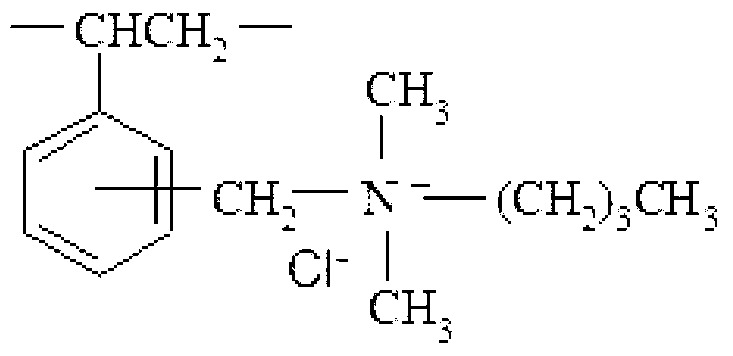

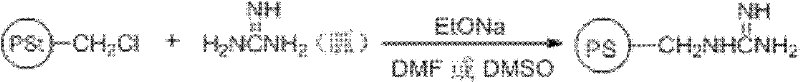

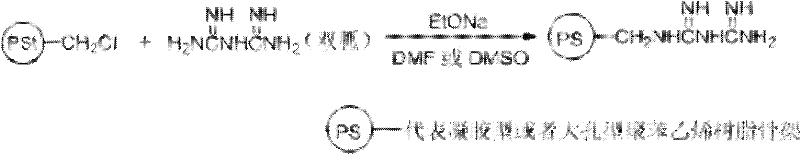

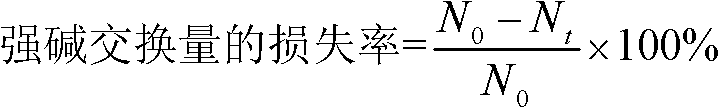

Selective strong-base anion exchange resin and preparation method thereof

The invention relates to selective strong-base anion exchange resin and a preparation method thereof. The selective strong-base anion exchange resin comprises the following basic structural unit, wherein R1 is alkyl with at most 3 carbon chains, R2 is alkyl with 3-18 carbon chains. The strong-base exchange capacity of the resin is 0.8-4.65 mmol / g, and the resin is synthesized through the following steps of: (1) sufficiently swelling a chloromethylation styrene-divinylbenzene copolymer, namely a chlorine ball, by utilizing an inert organic solvent, and filtering the chlorine ball; (2) mixing tertiary amine with alkyl chains in different lengths as an amination reagent with the chlorine ball, and stirring for amination reaction; and (3) filtering, extracting and drying to obtain the selective strong-base anion exchange resin.

Owner:SOUTHEAST UNIV

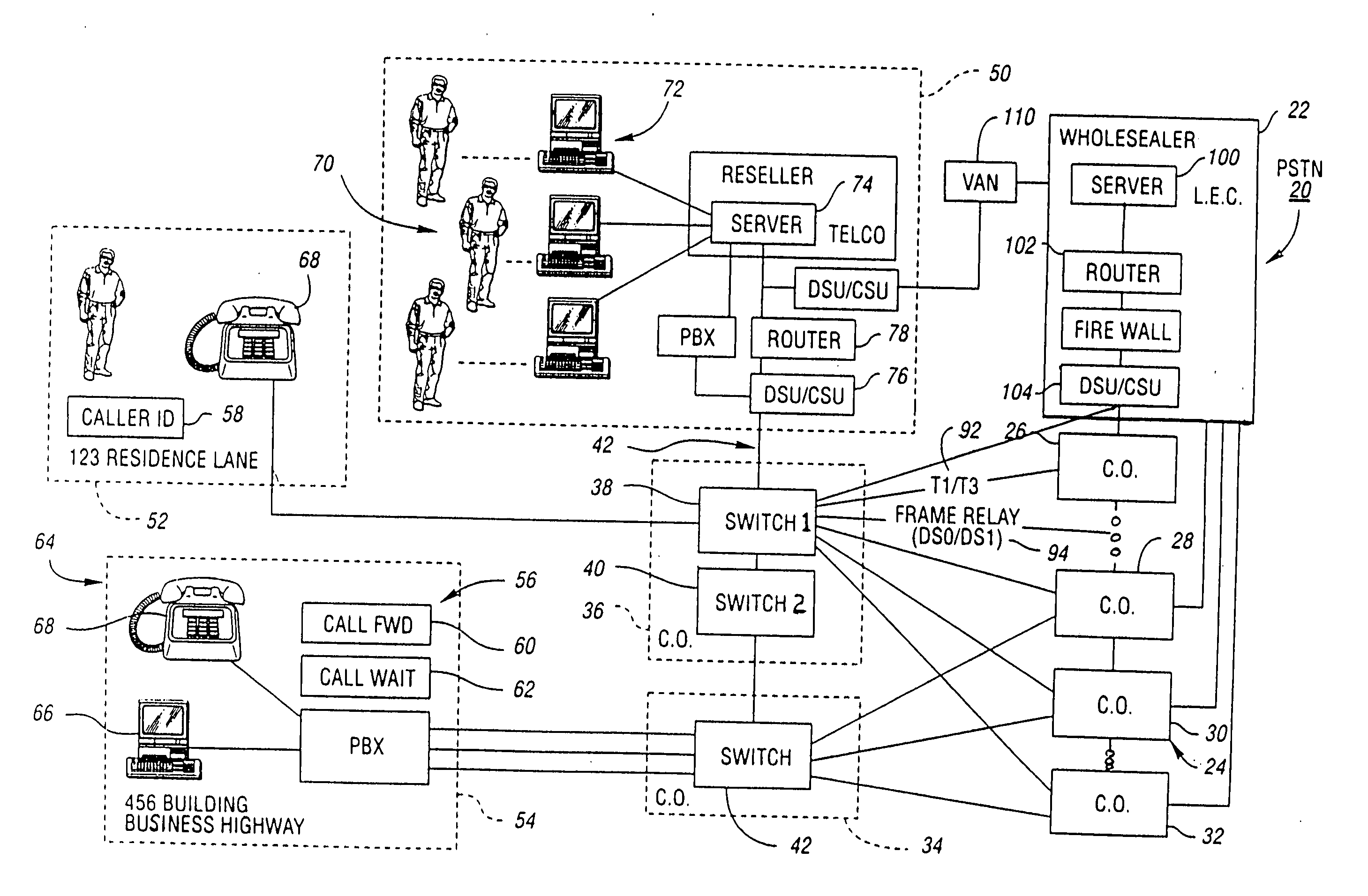

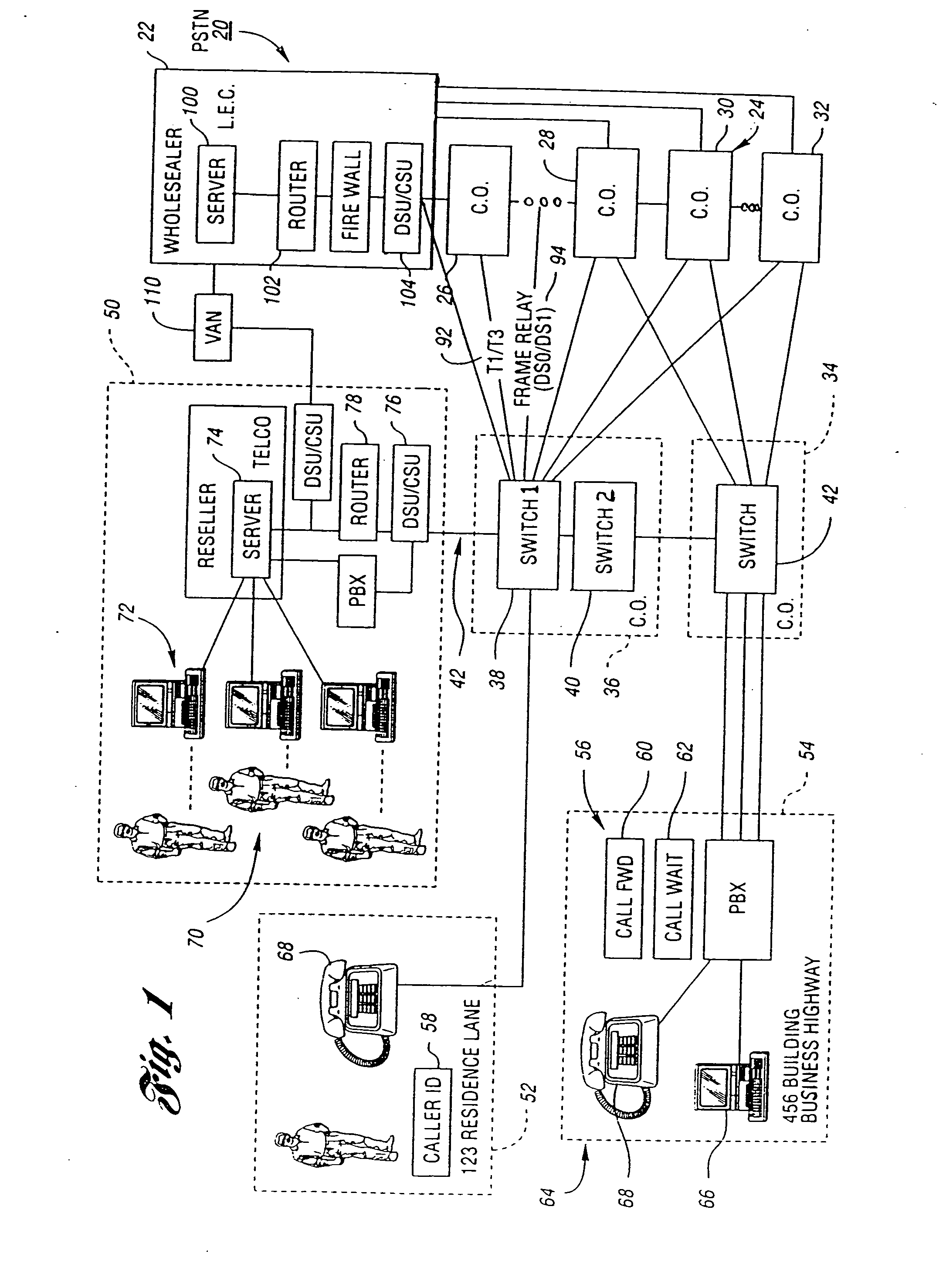

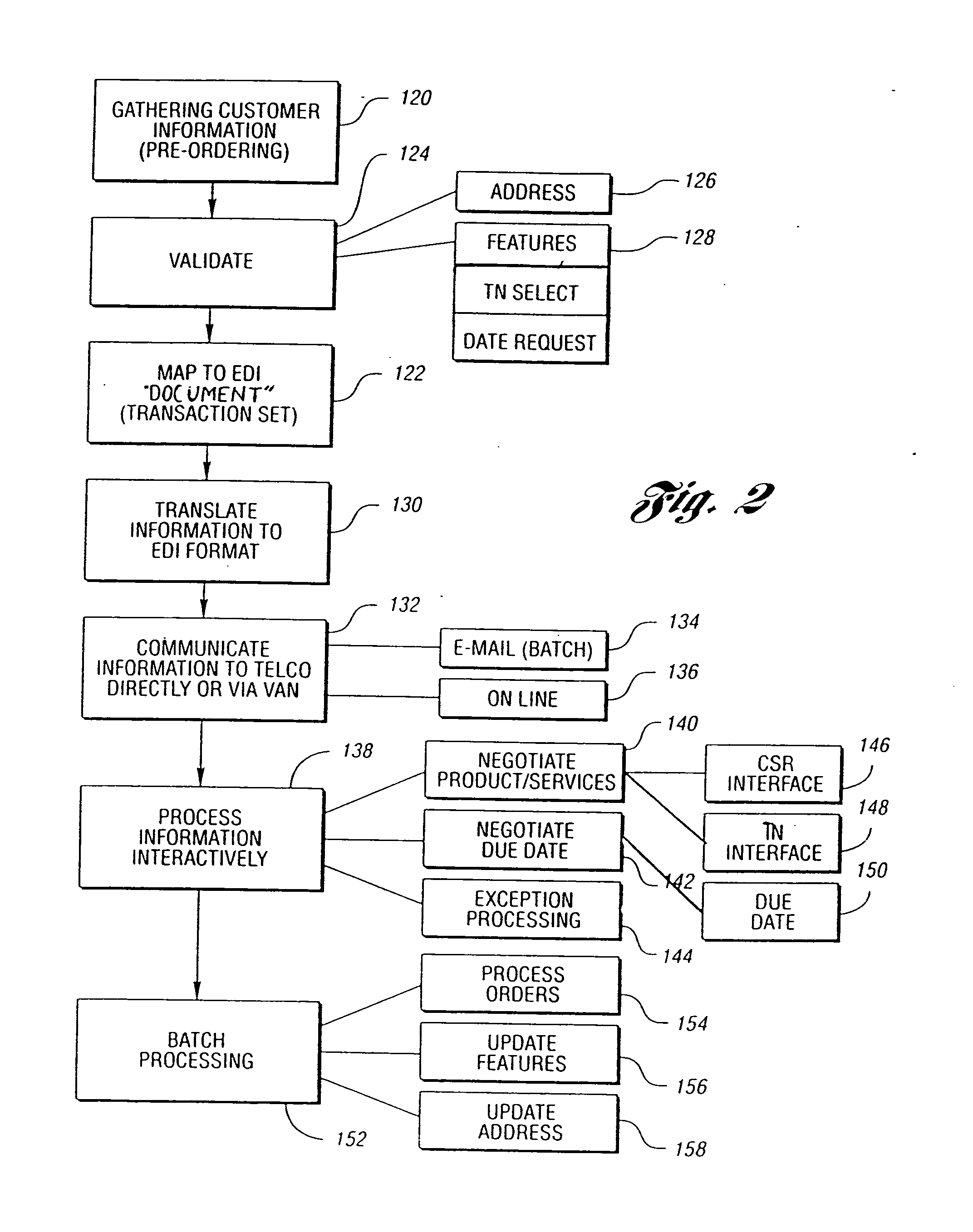

Transaction sets for automated electronic ordering of telecommunications products and services

InactiveUS20050135576A1Interconnection arrangementsSpecial service for subscribersBase exchangeElectronic transaction

A system and method for electronically exchanging information related to telecommunication services includes separating data representing the information to be exchanged into predefined segments corresponding to telecommunication services, associating a segment identification code with each segment, and grouping each segment identification code with corresponding data. The system and method also include concatenating the segment identification codes and associated data according to a predefined sequence to form an electronic transaction and transmitting the electronic message to a telecommunications wholesaler or reseller. Preferably, the information is exchanged over a TCP / IP connection in an interactive, transaction-based exchange.

Owner:AT&T INTPROP I L P

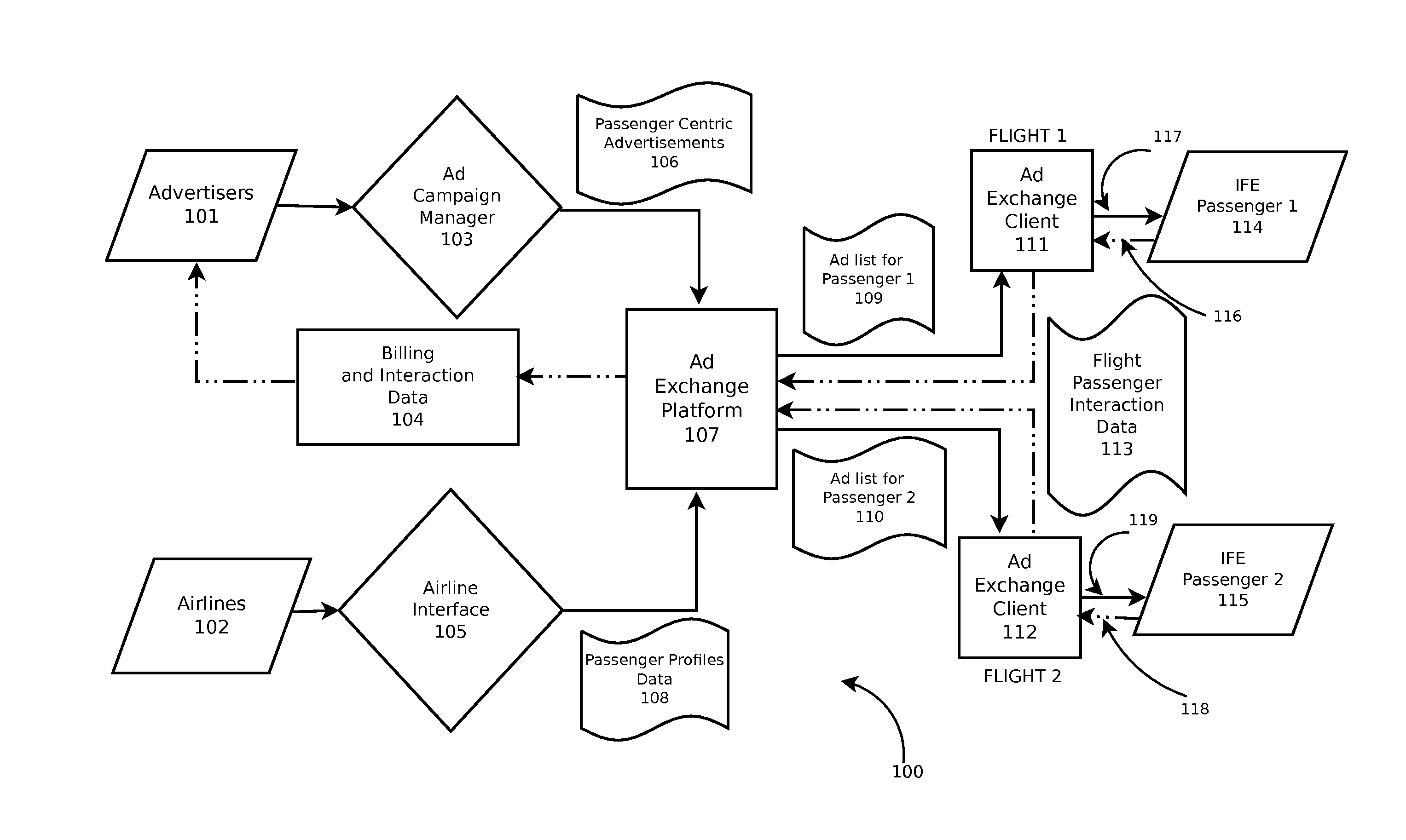

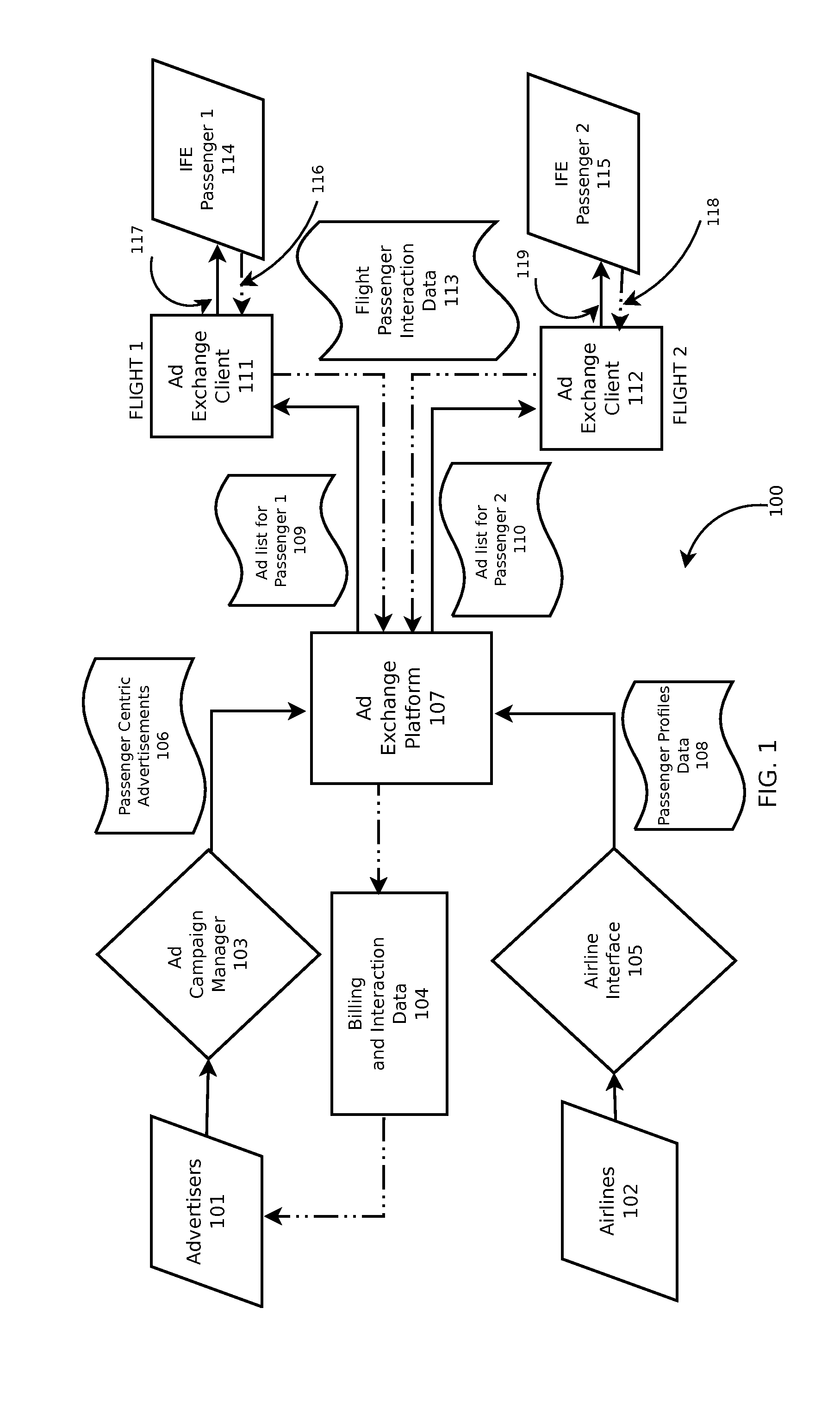

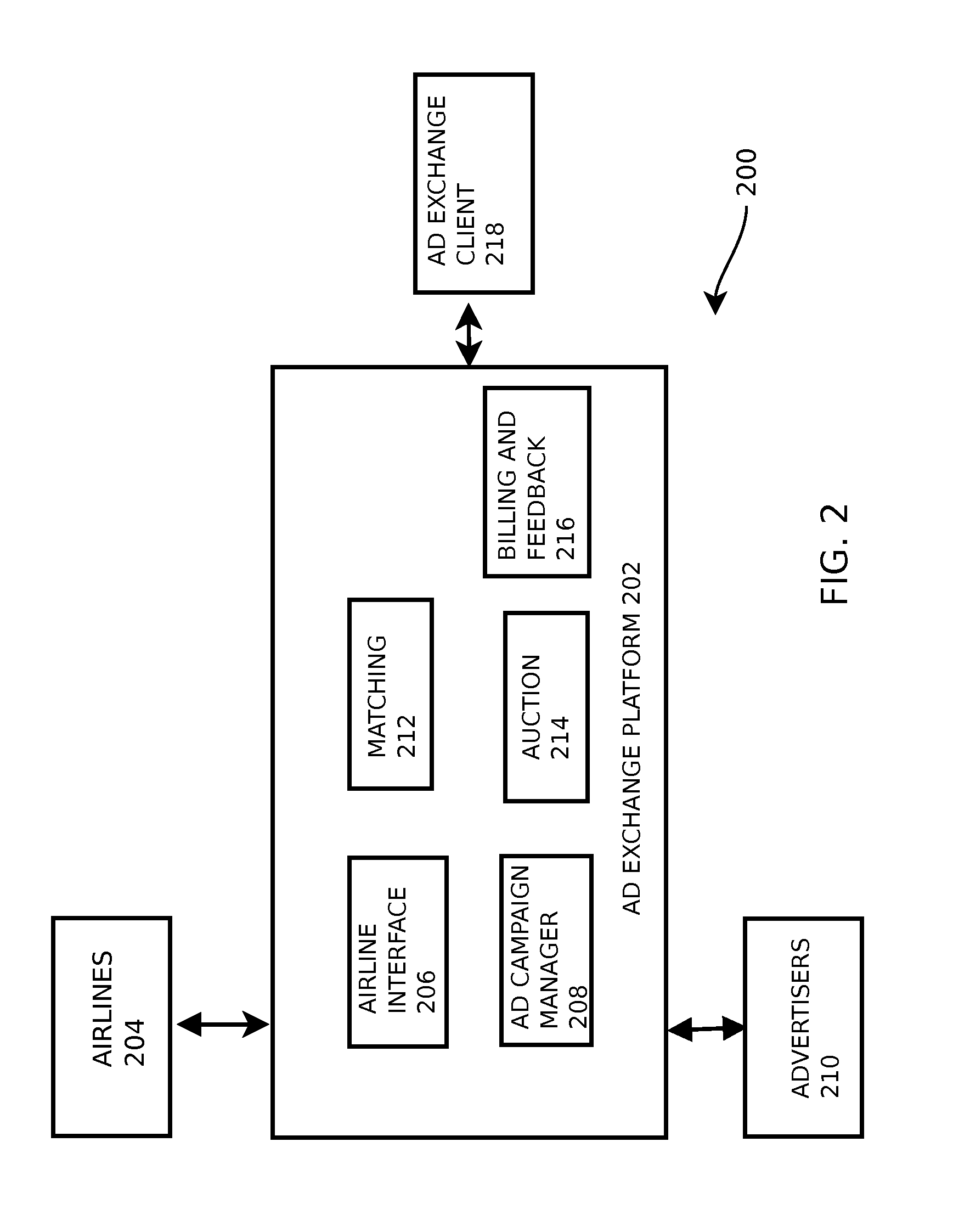

Deliver passenger centric advertisements to in-flight entertainment system using auction based exchange

A system and method for delivering passenger-centric advertisements to in-flight entertainment systems using auction based exchange. An interface is provided for the airlines to provide the passenger profile data. Another interface is provided for the advertisers to bid on passenger profile data using an auction. A winning bid is selected from plurality of bids, and the relevant ads are placed in the media stream consumed by the specific passenger. A method is provided to insert ads in passenger media streams using an AD exchange client. A method is provided to send back the passenger interaction data and billing information to the advertisers.

Owner:GAUR VIVEK

Preparation method of fire coal improver

The invention relates to a preparation method of a fire coal improver. After a fire coal additive is added into ordinary fire coal for burning, remarkable and effective energy-saving and emission-reducing effects can be achieved. Firstly, white polylol hexanediol in a solid state is adopted, polylol is added to enhance a combustion supporting function, the polylol hexanediol is prepared into a solid fire coal combustion improver together with other aids, and convenience is brought to transport and storage; secondly, sodium acetate serving as a swelling agent is introduced for performing base exchange with humate in coal to generate humate with a low fire point, so that the ignitability of coal is reduced; and thirdly, ferric oxide needed in a formula is a water-dissoluble compound, so that ferric oxide is generated by making ferric chloride and calcium oxide react in a water adding dissolving process in the invention, and the preparation and application characteristics of the three compounds are not possessed by other products on the market.

Owner:杨成旺 +1

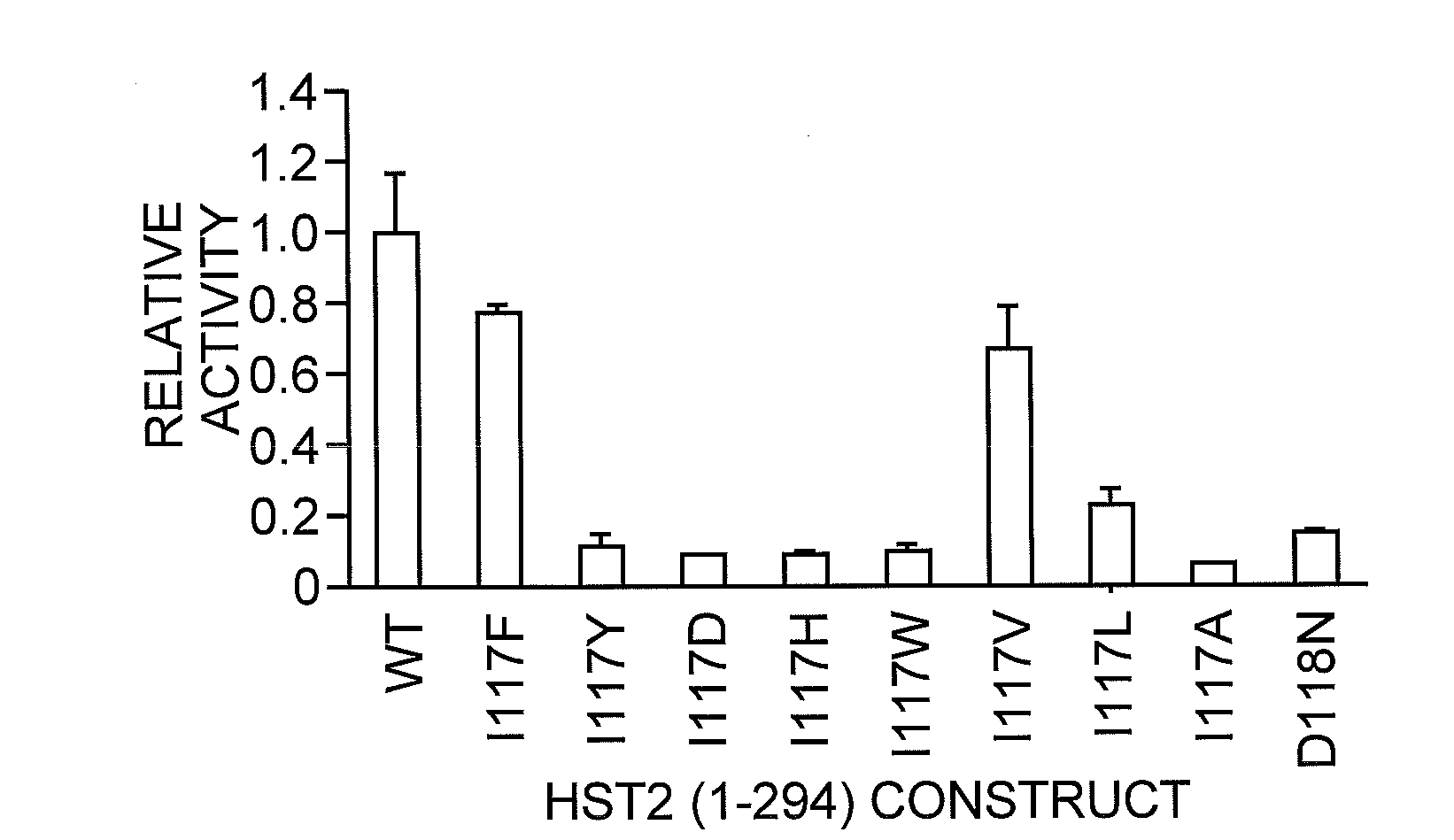

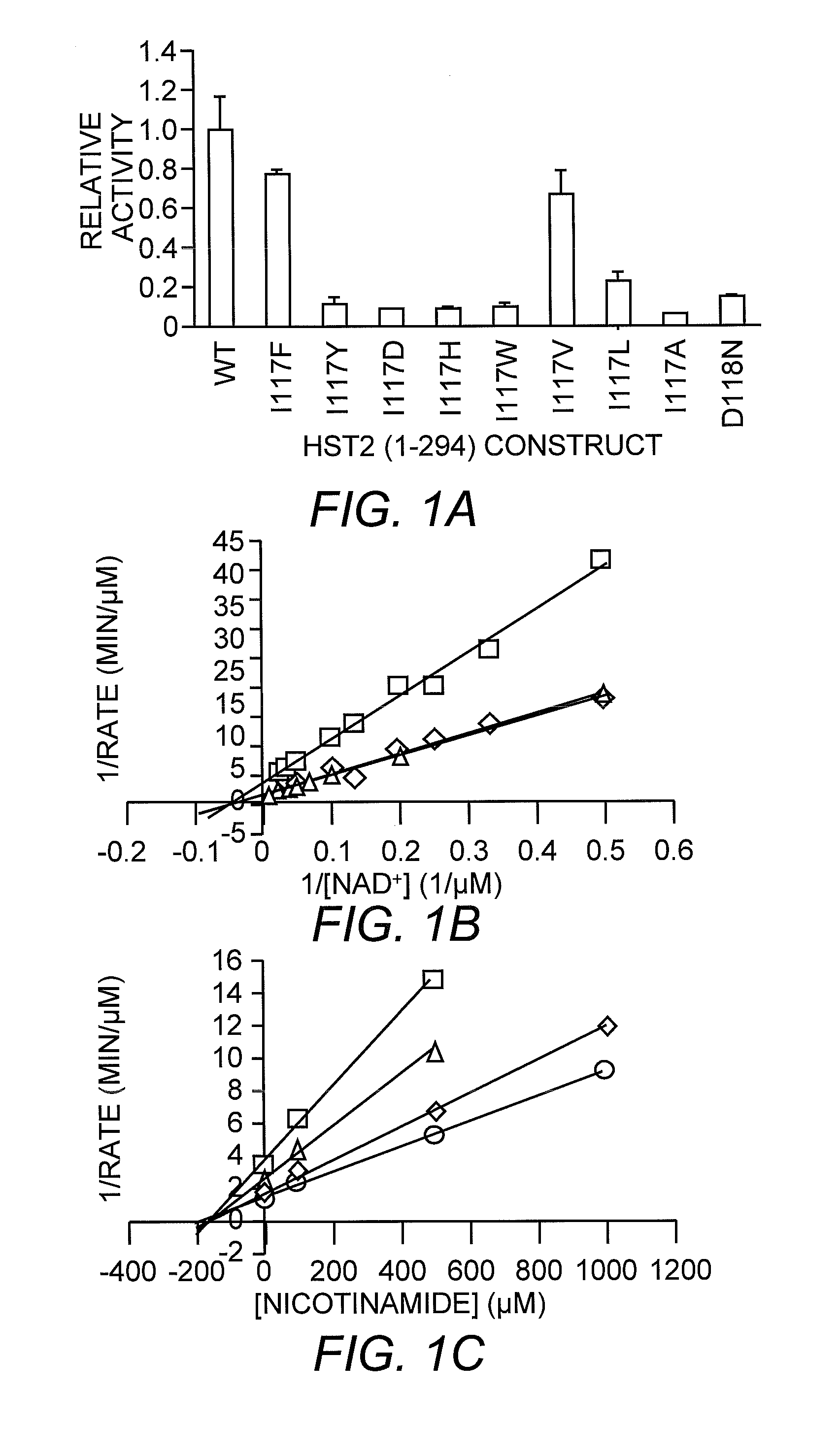

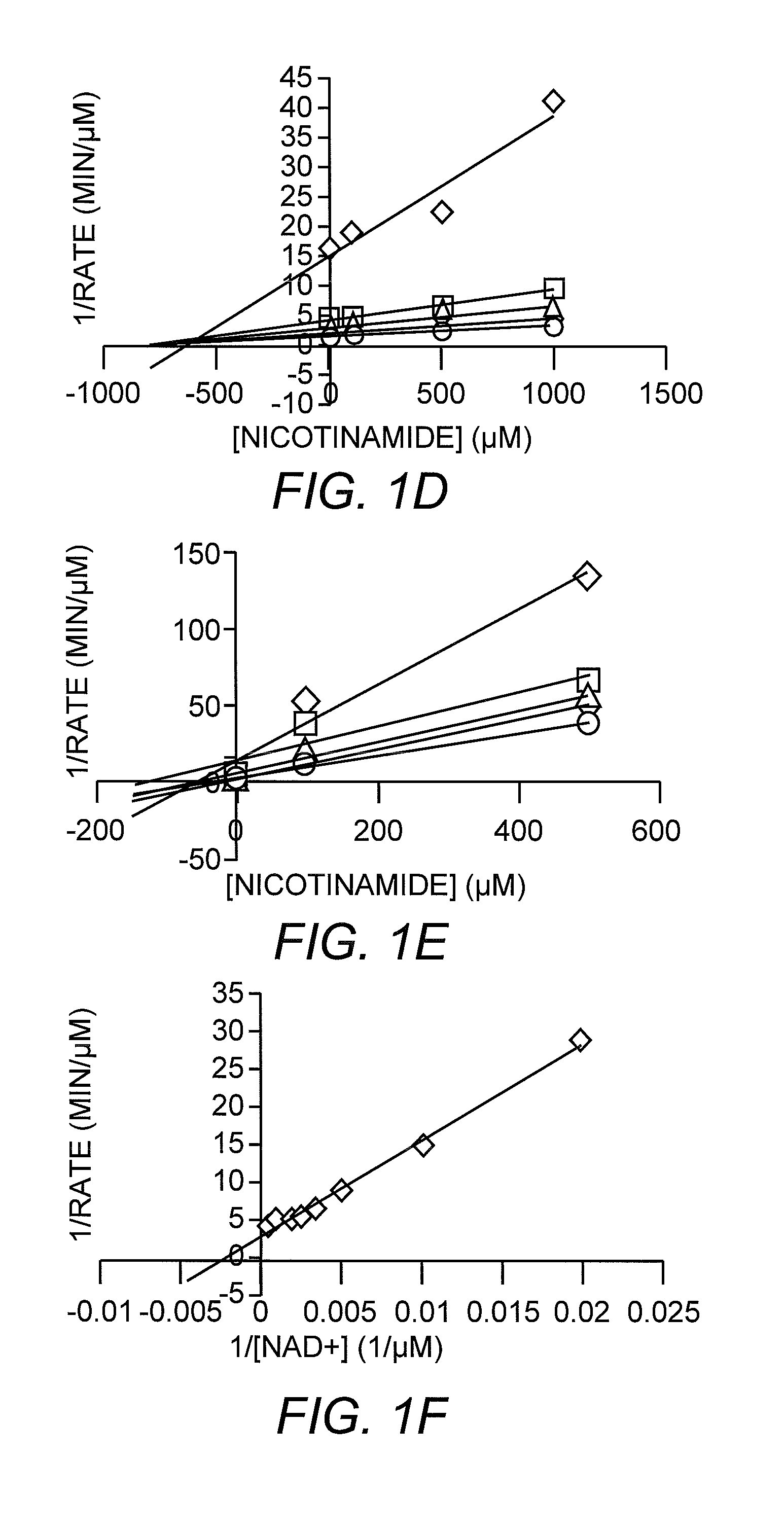

Method for identifying a compound that modulates SIR2 protein activity

The present invention relates to a method for identifying compounds that modulate the activity of sirtuin deacetylase protein family members. Compounds of the invention are identified by designing or screening for a compound which binds to at least one amino acid residue of the newly identified nicotinamide inhibition and base exchange site of Sir2 and testing the compound for its ability to modulate the activity of the Sir2 protein. Compositions and methods for preventing or treating diseases or disorders associated with Sir2 are also provided.

Owner:WISTAR INSTITUTE

Increasing octane number of light naphtha using a germanium-zeolite catalyst

InactiveCN102639472ABoost octaneHigh degree of branchingMolecular sieve catalystsHydrocarbon by hydrogenationAlkaneAlkaline earth metal

Owner:SAUDI BASIC IND CORP SA

High-temperature-resistant guanidine-based strong-basic anion exchange resin for strong base and synthesis method thereof

ActiveCN102212155AImprove thermal stabilityEasy to synthesizeAnion exchangersChemical reactionSynthesis methods

The invention relates to a high-temperature-resistant guanidine-based strong-basic anion exchange resin, which has a strong base exchange capability of 1.5-3.2 mmol / g based on N atom. The synthesis method of the high-temperature-resistant guanidine-based strong-basic anion exchange resin comprises the following steps of: dissolving a chloromethylated polystyrene resin and an organic guanidine in a solvent, and carrying out chemical reaction on a chloromethyl group of the resin frame and a guanidyl group for bonding the small molecule organic guanidine to the resin frame so as to obtain the resin. The invention has the advantages that: the high-temperature-resistant guanidine-based strong-basic anion exchange resin has a novel structure, and the heat stability is improved because the heat stability of the guanidyl group is improved; and compared with traditional production processes of quaternary ammonium anion exchange resin, the synthesis process of the resin is simple, has no obvious change in production cost, and has important significance in industrial mass production and application. The resin has a potential application prospect in ion exchange, catalysis reaction, high-purity water preparation, decoloring of natural extracts, removing of ionic impurities from environmental wastewater and the like in a high temperature environment.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com