Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Variable thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

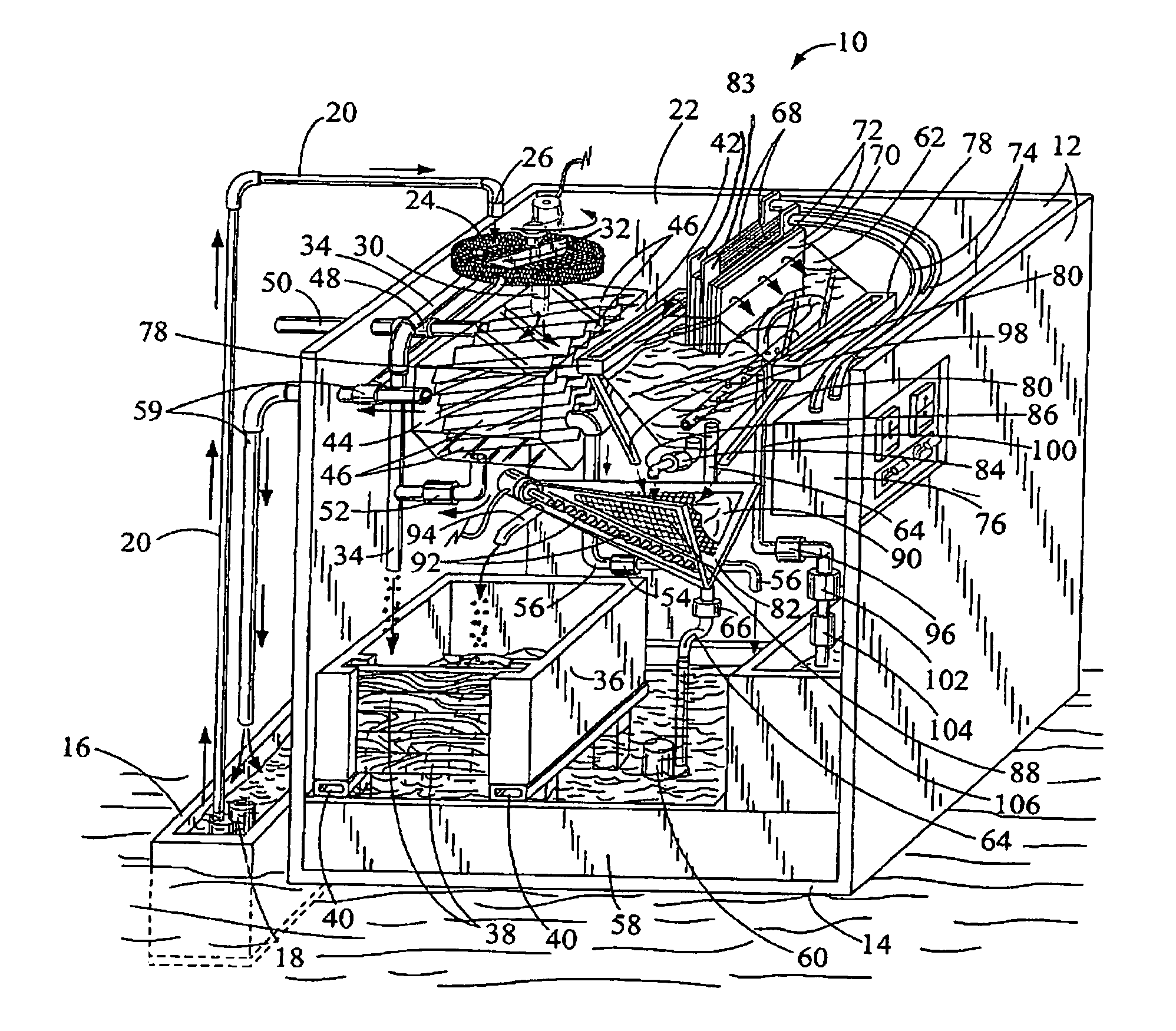

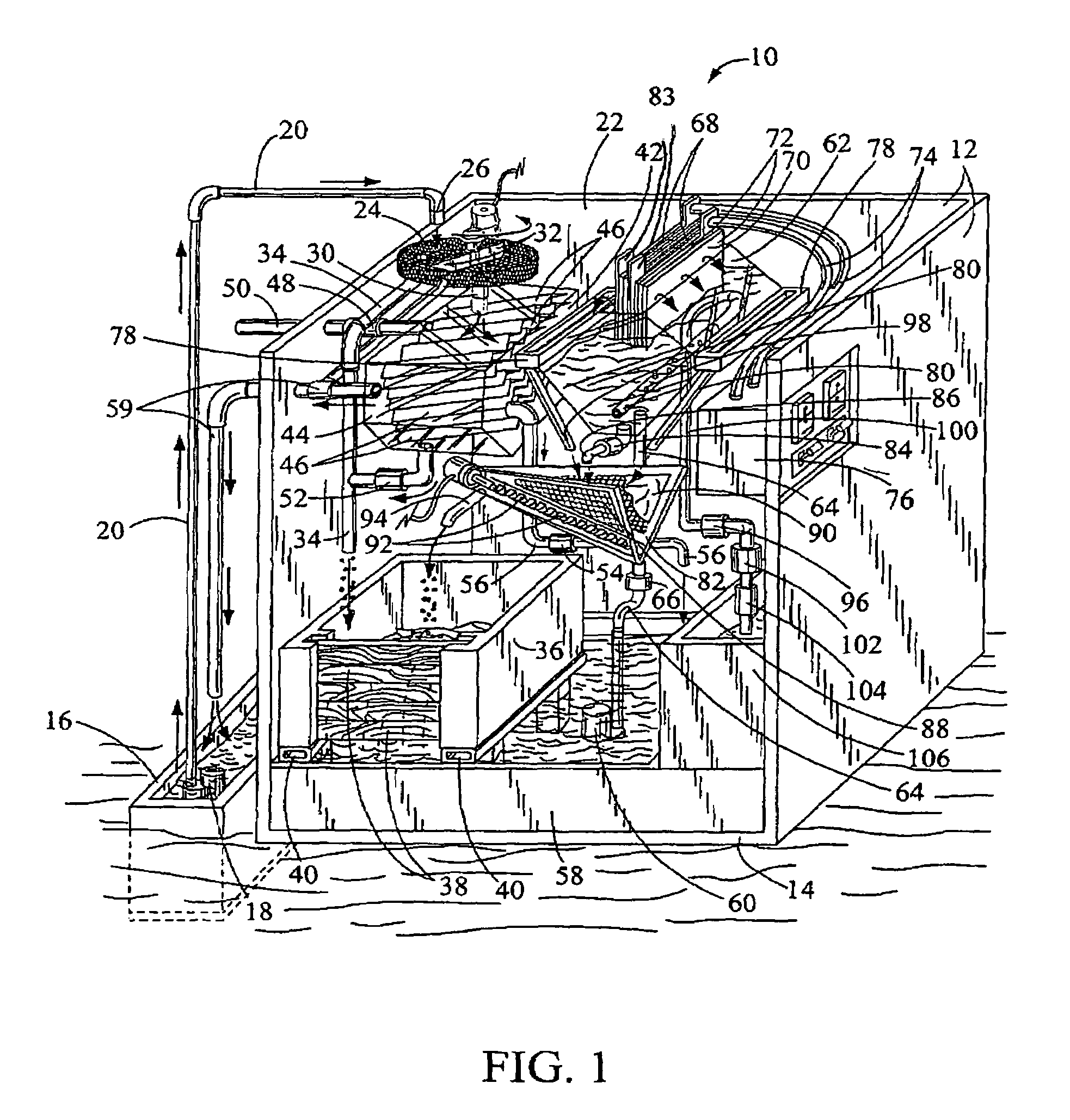

Electrocoagulation waste water batch tank treatment system

InactiveUS7258800B1Lower levels of contaminationEasy to replaceTreatment involving filtrationLiquid displacementSurge tankWater treatment system

A waste water treatment system and process for treating waste water received in a batch tank. The waste water is discharged in a headwork screen for removing large solids in the water. The solids are into a sludge drying bin. The screened water is transferred into a top of an influent surge tank with an oil / water separator. The oil / water separator includes a plurality of coalescing plates for separating free oil from the waste water. Heavy solids in the surge tank are drained into the sludge drying bin. The waste water is now dropped into a containment pan. From the containment pan, the waste water is pumped into a water treatment tank. The water treatment tank includes two or more electrodes mounted in the top thereof. The electrodes are separated using insulating support spacers for providing proper electrode spacing and insulation between the electrodes. The electrodes are used for providing current to the waste water and separating the contaminates in the water by electrocoagulation. The treated water in the water treatment tank is discharged after a completion of a period of settling or dwell time into a clean water tank.

Owner:H2O TECH

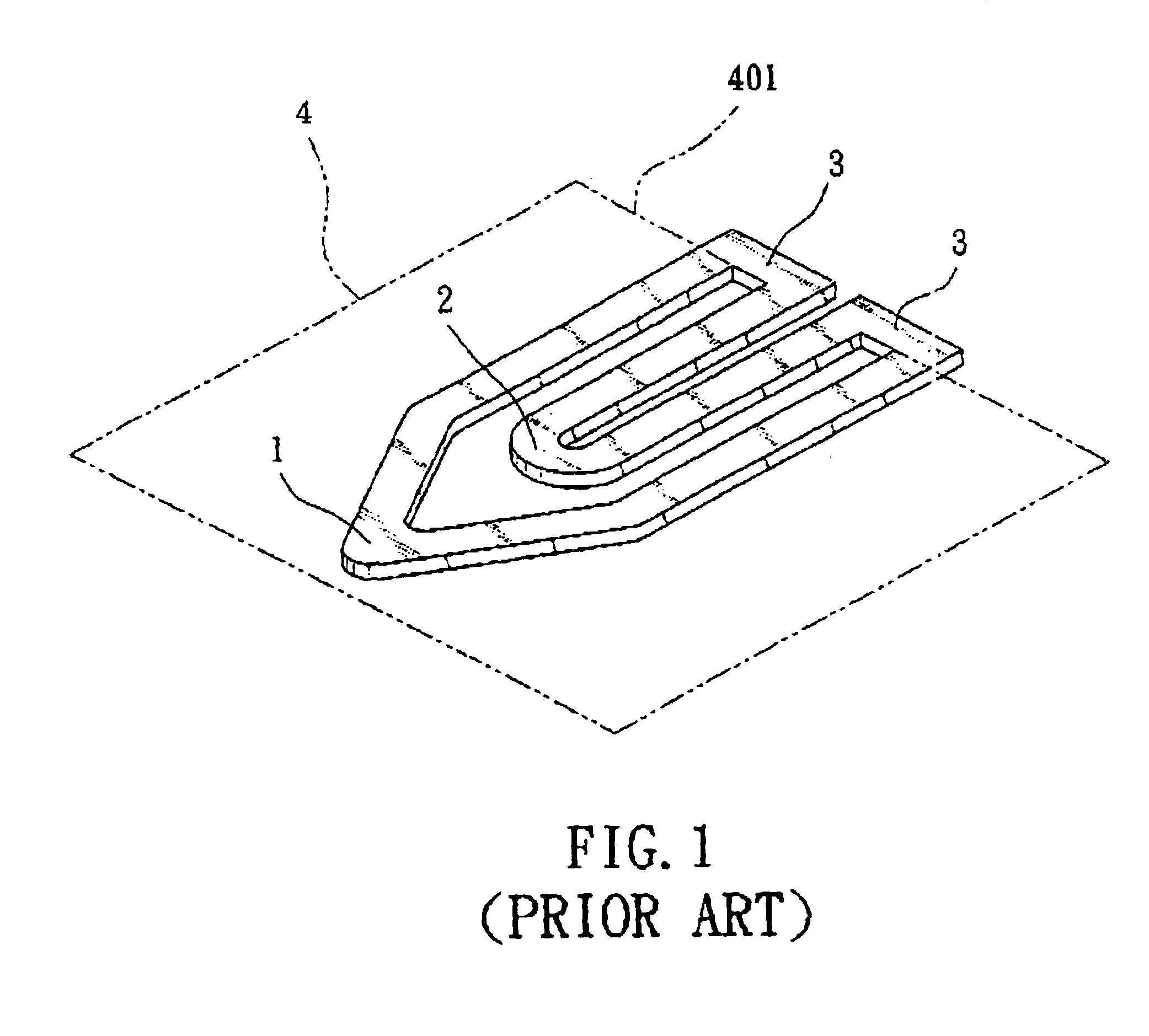

Paper clip

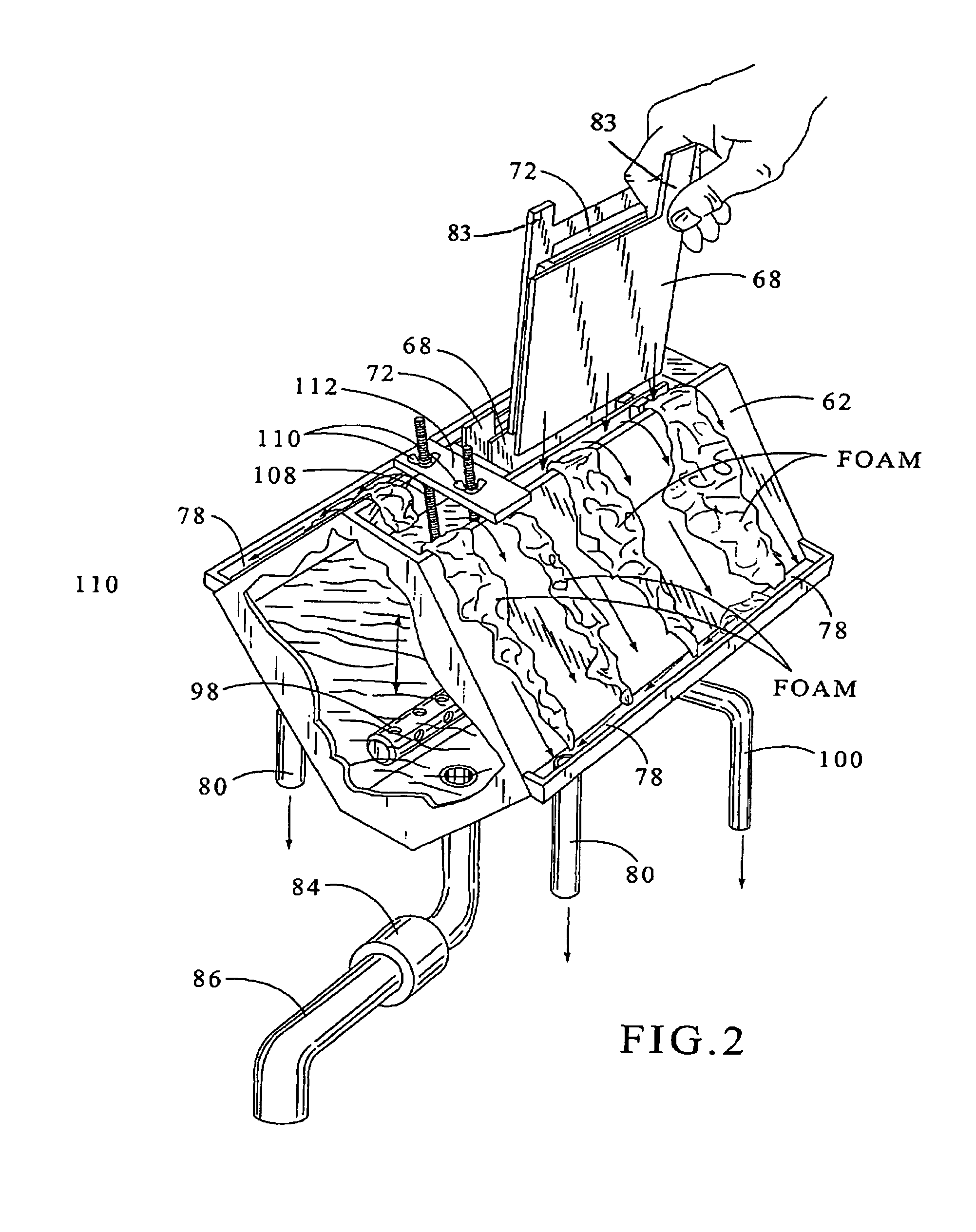

InactiveUS6973700B2Variable thicknessWide applicationSnap fastenersClothes buttonsRough surfaceEngineering

The present invention relates to an improved paper clip which is suitable for holding documents of different thicknesses. The improved paper clip includes three elements, which are a first clipping piece, a second clipping piece and a support beam. The first clipping piece is formed with a sunken slot therethrough and is connected to a bottom side of the support beam. The second clipping piece has a bending curve part and is connected to a top side of the support beam. The bending curve part is partially protruding into the sunken slot and is roughened to become a rough surface for increasing friction to tightly clamp documents. The inner surface of the support beam is a flat plane so as to provide a guiding function when the document is received between the first and second clipping pieces. The first and second clipping pieces are both adjoined to the inner surface of the support beam, such that the outer surface of the support beam substantially forms part of the outer contour of the paper clip.

Owner:HSIAO RAY LING

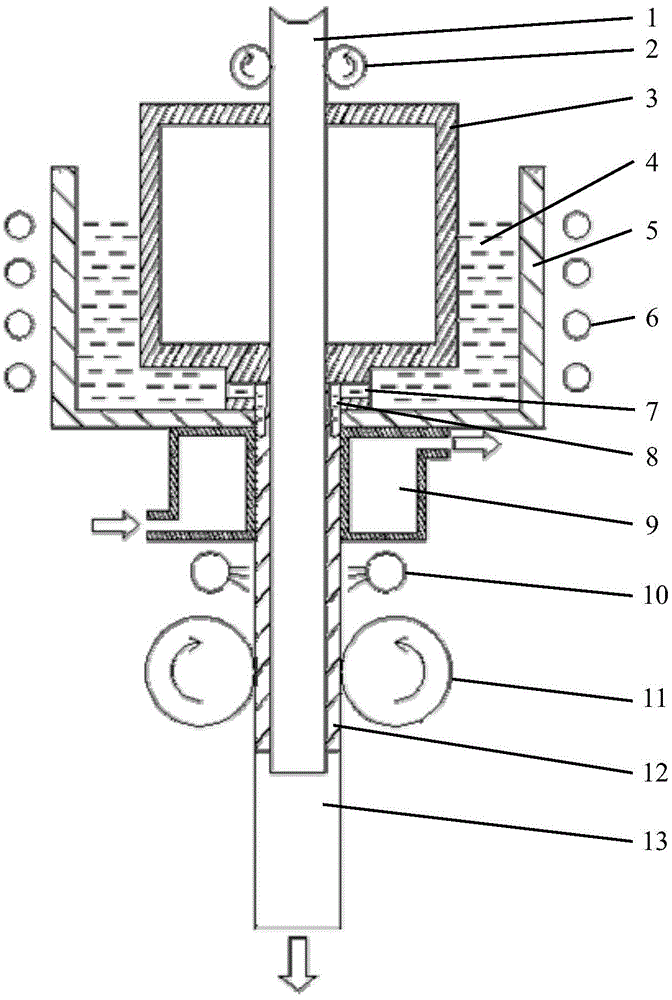

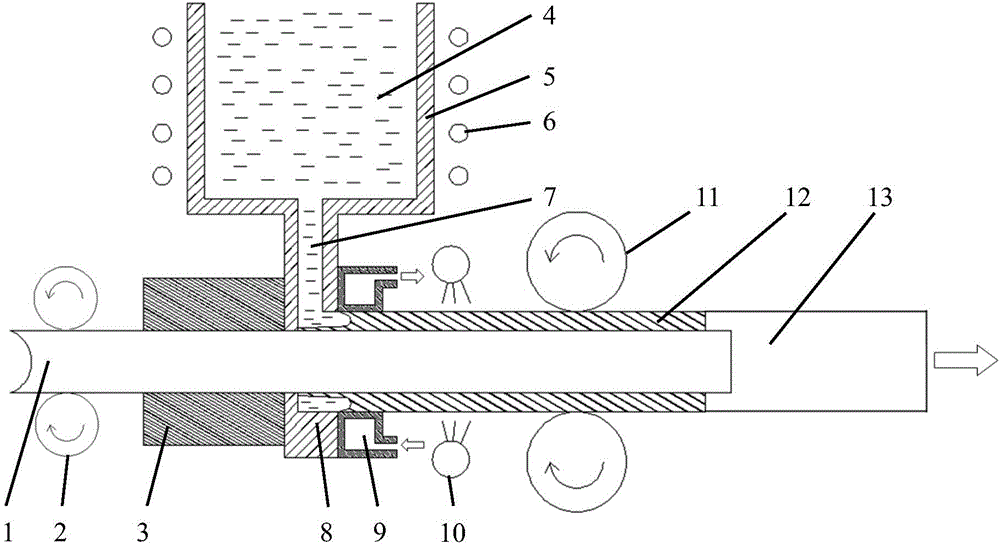

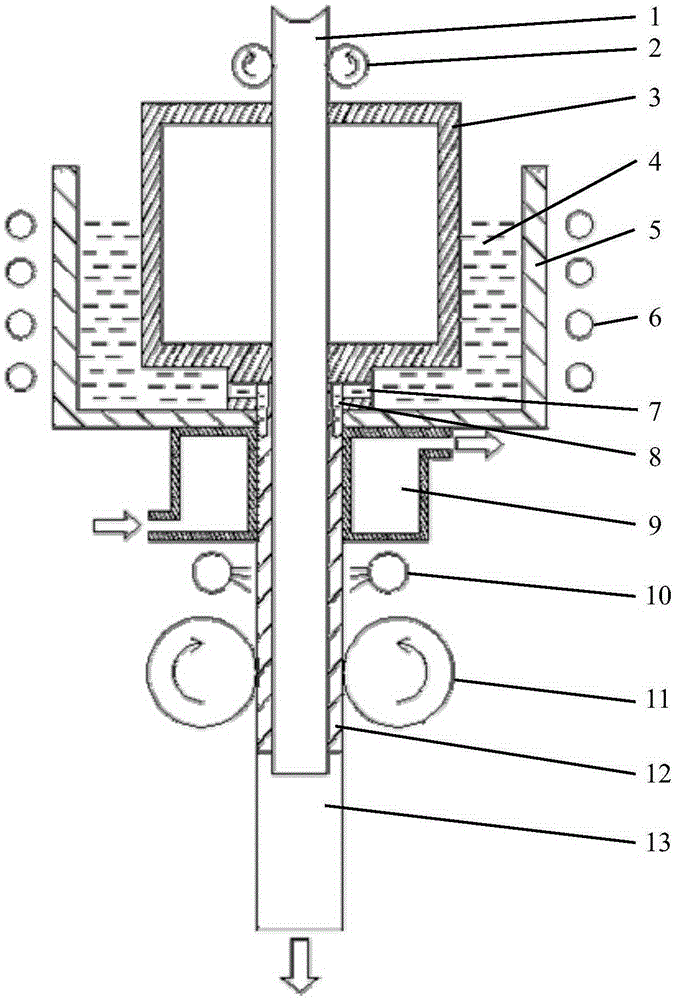

Clad material solid/liquid composite dual-solidification continuous casting and forming equipment and method

The invention belongs to the technical field of clad material continuous casting, in particular to clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method. The clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method are characterized in that inversion solidification and forward solidification continuous casting and forming are combined, the measures that core materials are not heated in advance, an inversion solidification device with small capacity is designed, the core materials are prevented from penetrating through clad layer melt metal for a long time, the melt metal flows out from the bottom of a crucible by relying on self-weight, and the size of the inversion solidification device and the size of a water-cooled crystallizer are controlled effectively are taken, the high quality clad materials of needed shapes and sizes are formed through continuous casting, and the equipment and the method are especially suitable for continuous casting forming of the high quality clad materials with the melting point of the clad layer metal lower than that of the core material metal. The equipment and method have the advantages that the equipment is simple in structure, parts are easy to replace, operation and maintenance are convenient to carry out, layout is reasonable and compact, investment is small, industrialized application and popularization are facilitated, the procedure of the forming process is short, energy is saved, environment is protected, cost is low, the combination freedom of the clad layer metal and the core material metal is large, and the prepared clad materials are good in quality and performance.

Owner:UNIV OF SCI & TECH BEIJING

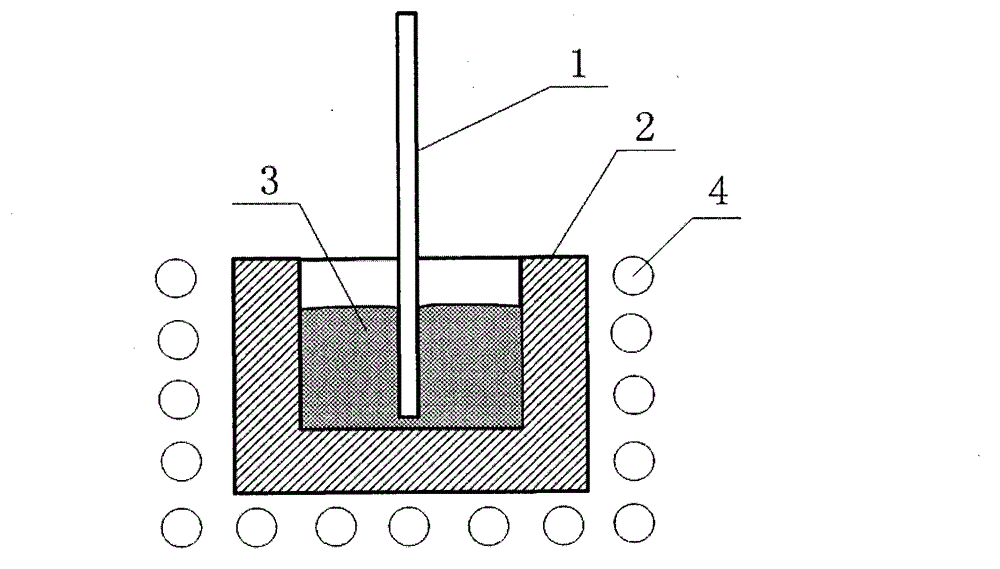

Ultrasonic assisted flame brazing method for titanium and aluminum dissimilar metal

ActiveCN103143804AGood wetting and spreadingReduce the difficulty of brazingWelding/cutting media/materialsWelding/soldering/cutting articlesReaction layerFiller metal

The invention relates to an ultrasonic assisted flame brazing method for titanium and aluminum dissimilar metal, which comprises the steps of conducting hot dip aluminum plating on a titanium plate before brazing to form an aluminizing layer in a certain thickness on the surface of the titanium plate, heating with combustible gas flame to melt an NOCOLOK brazing flux and aluminum silicon brazing filler metal, applying ultrasonic vibration on an overlapping part of a joint till the aluminum silicon brazing filler metal is solidified, and obtaining a titanium and aluminum overlap joint. The method has the main characteristics that the subsequent titanium and aluminum brazing is changed into the brazing of an aluminum plate and the aluminizing layer; the method improves wet spreading ability of the aluminum silicon brazing filler metal on the surface of the aluminized titanium plate and solves the problem that the aluminum silicon brazing filler metal difficultly wets a titanium base during the brazing; layered continuous distribution of an intermetallic compound on a brazing interface reaction layer of the joint is broken; the intermetallic compound is granulated and diffused; and the method facilitates acquirement of the high-quality titanium and aluminum dissimilar metal brazed joint.

Owner:安徽万宇机械设备科技有限公司

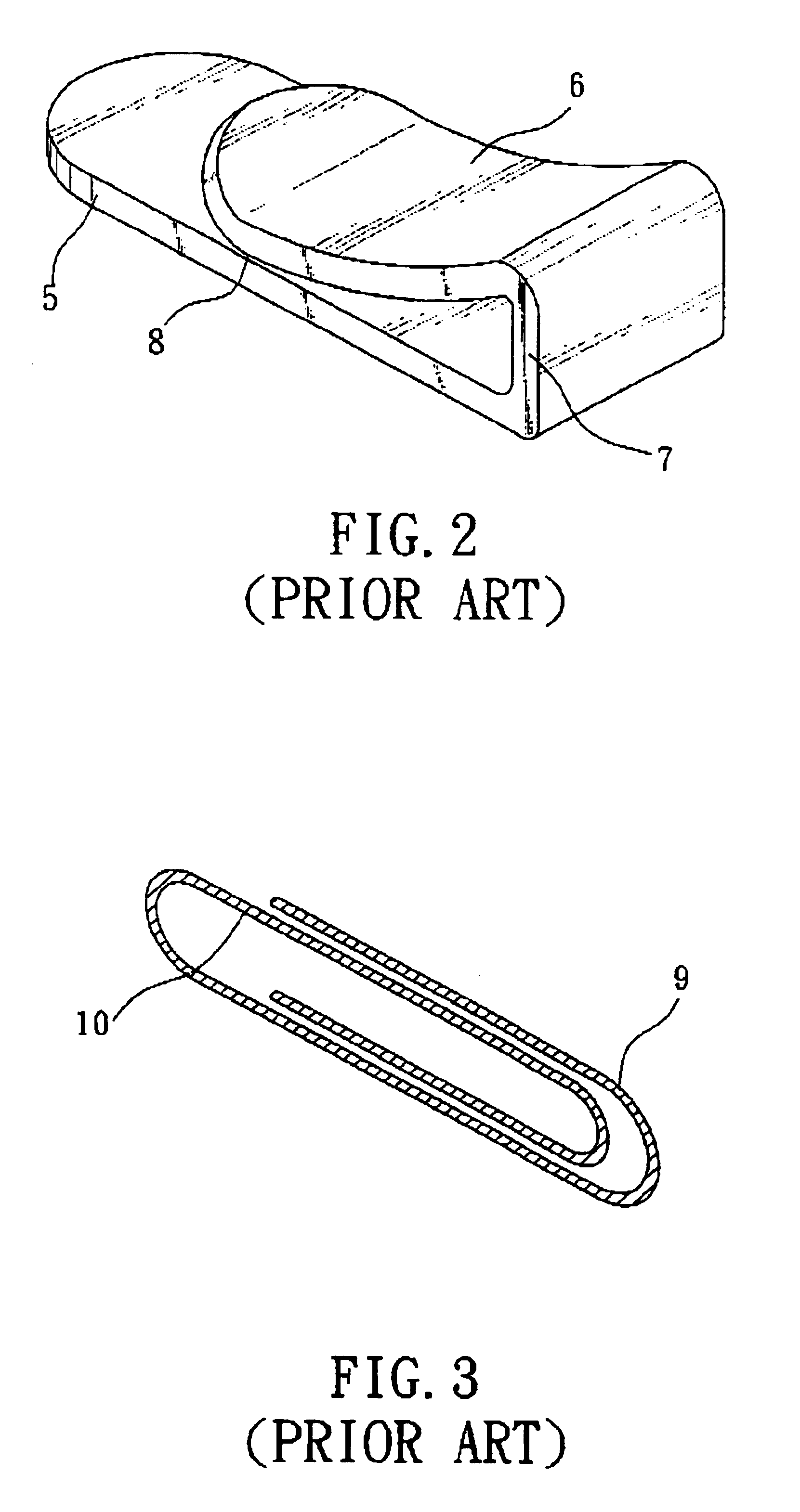

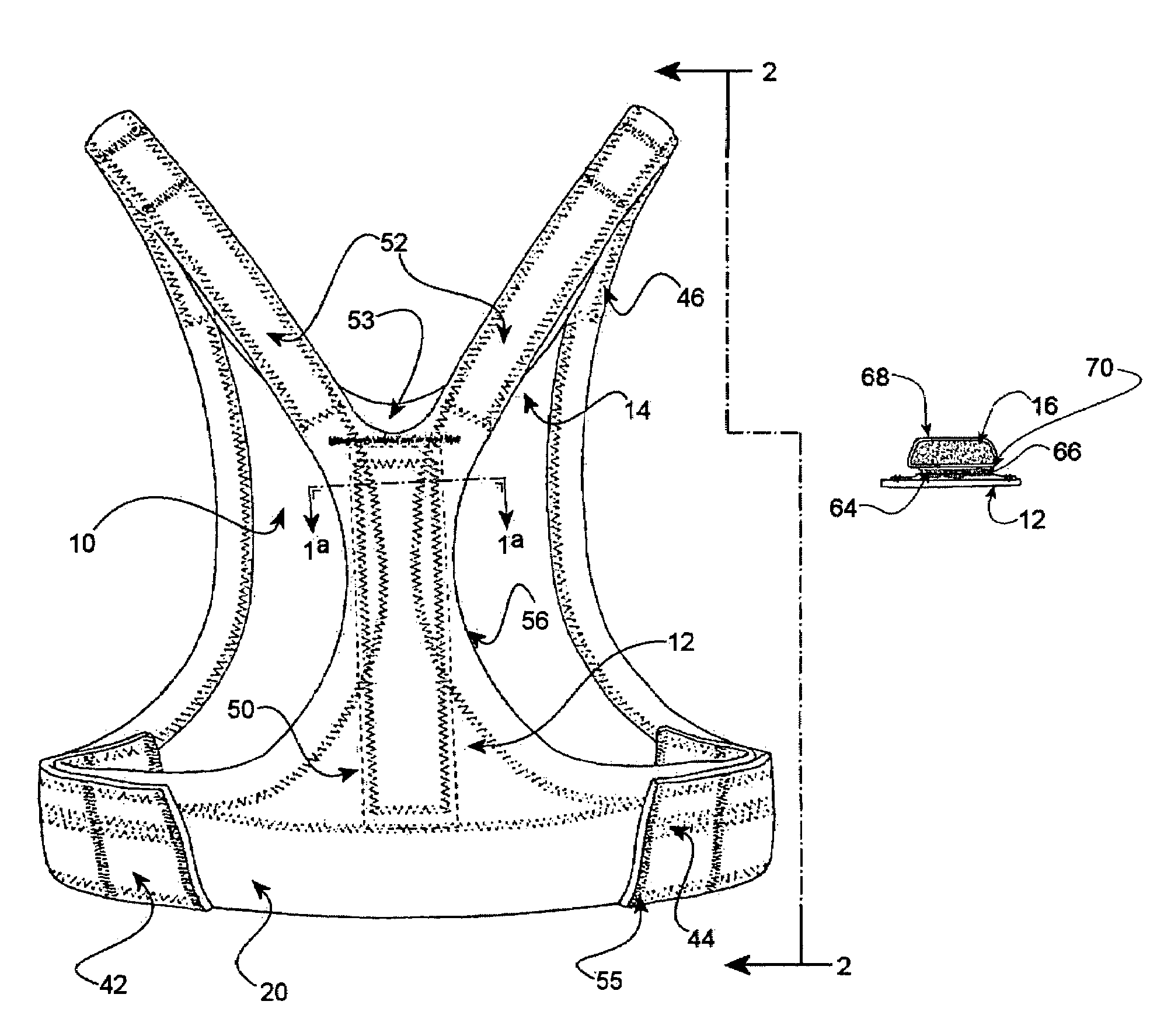

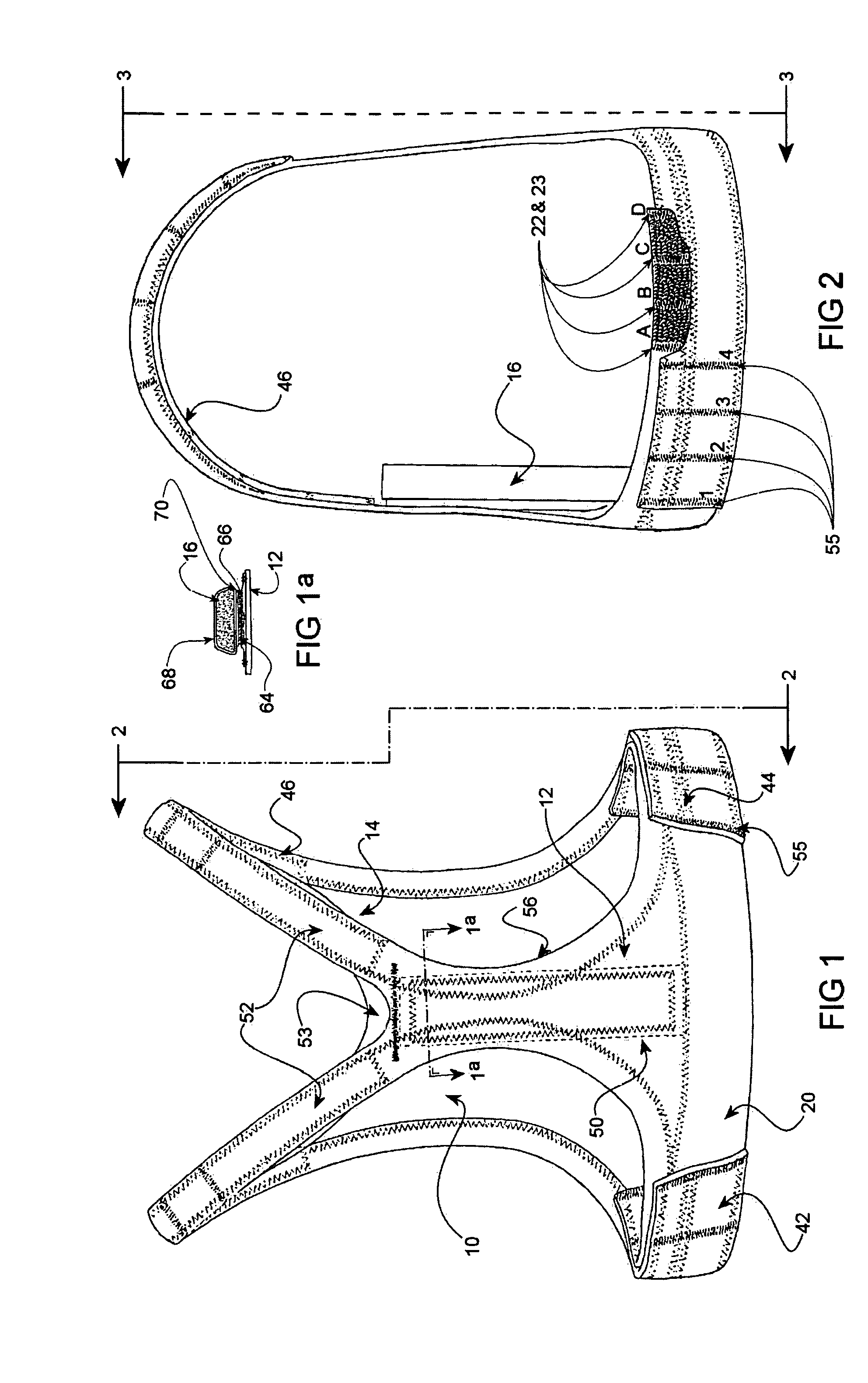

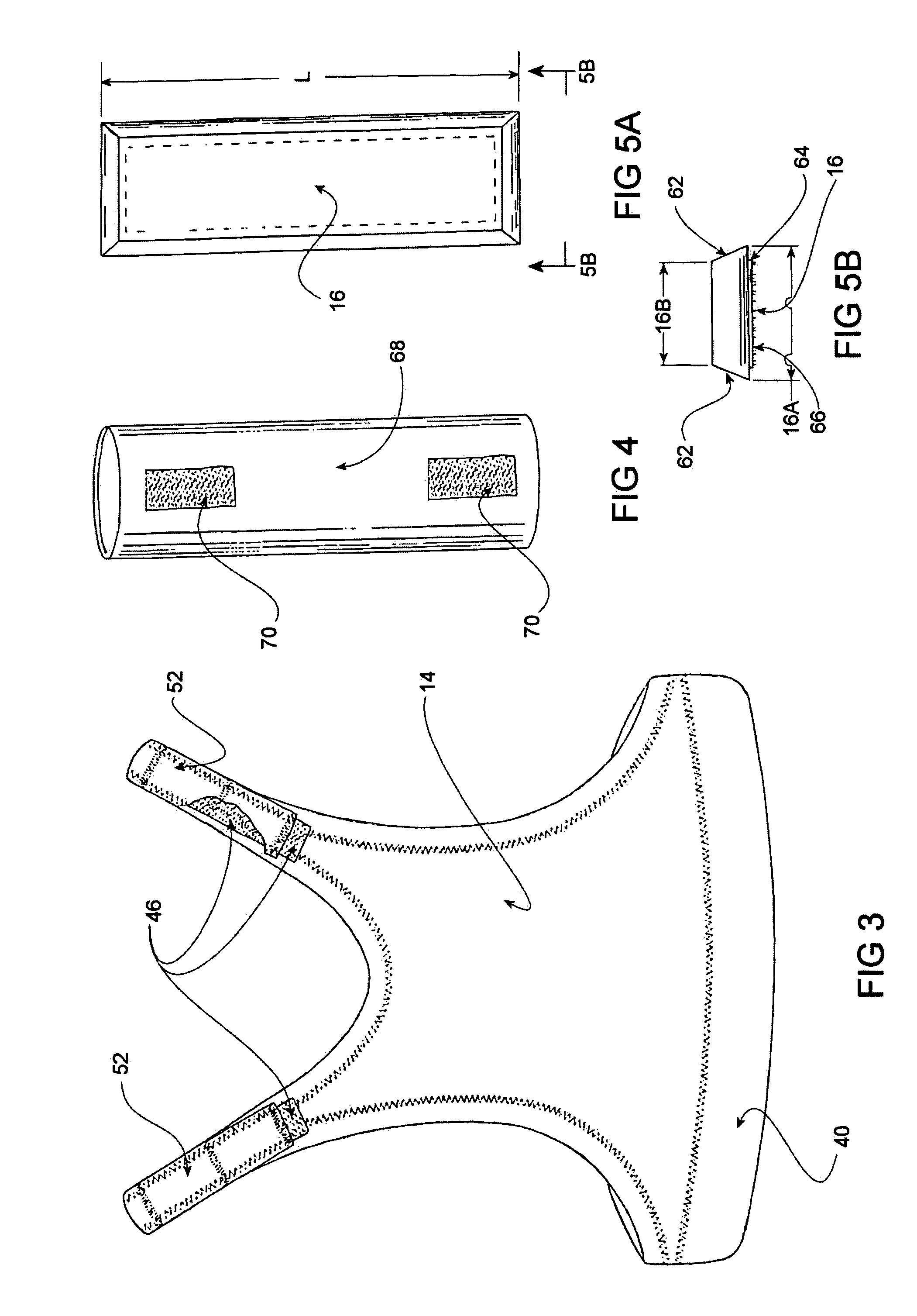

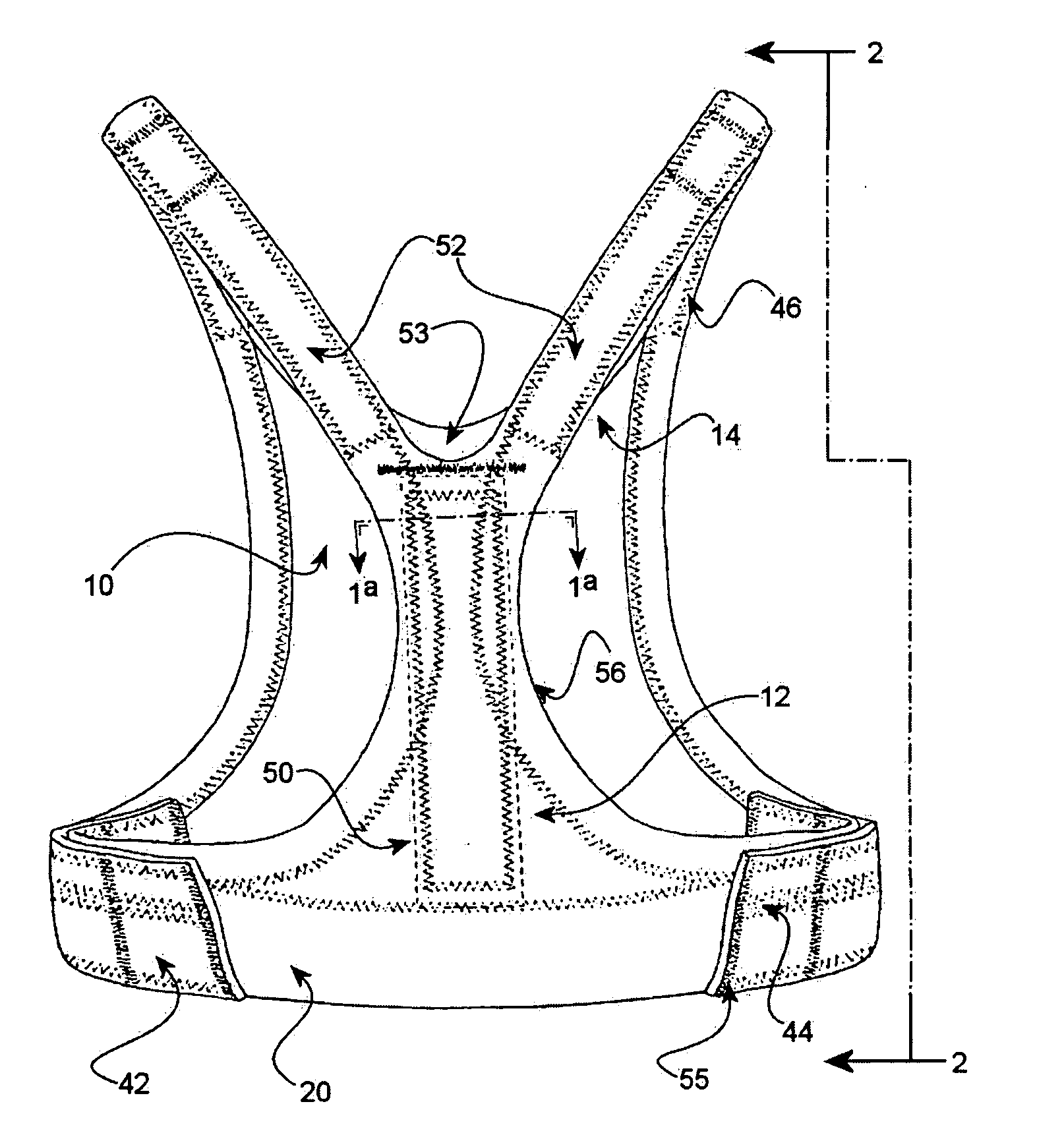

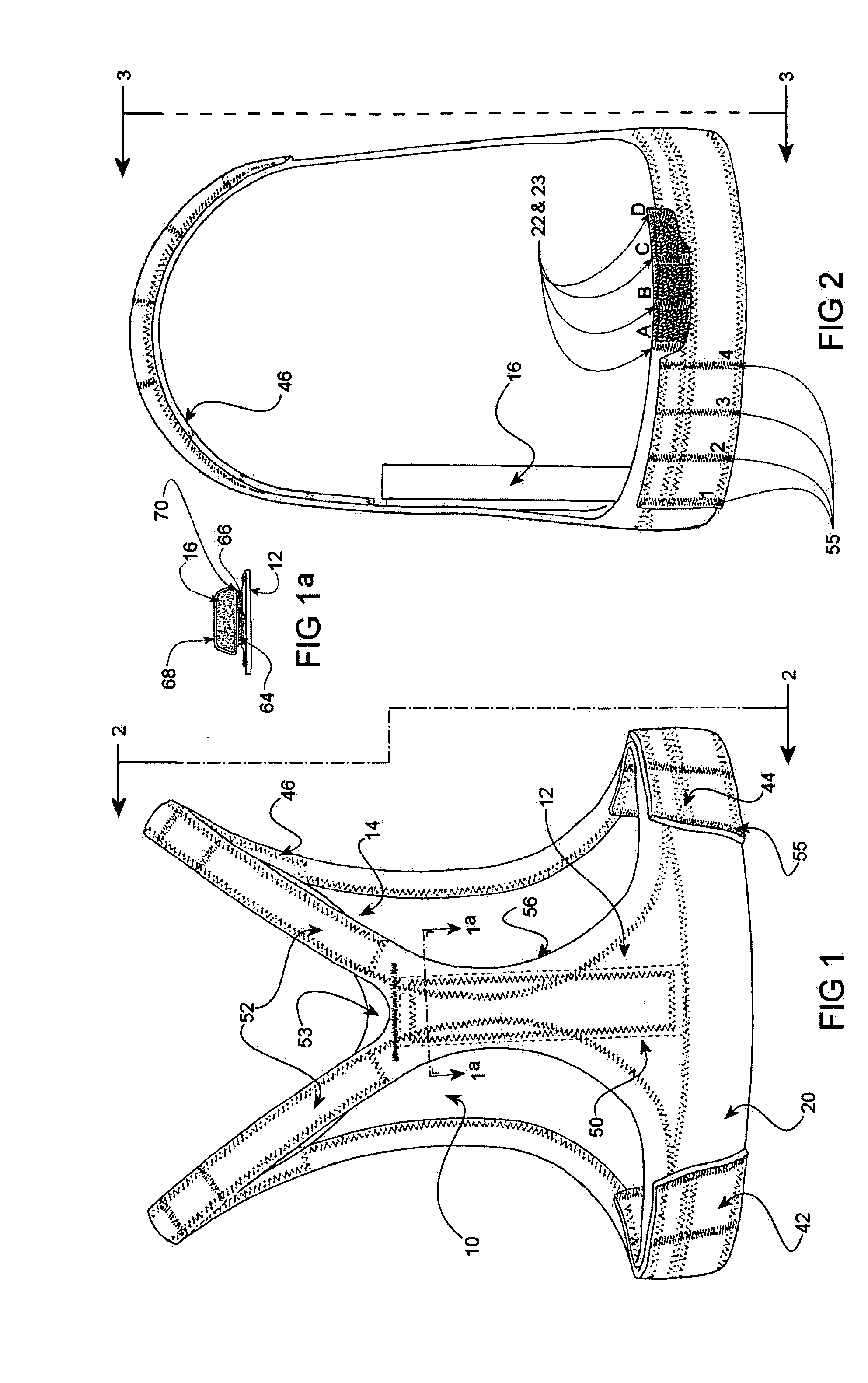

Post surgical chest support garment

This invention is directed to patients who need vertical support in the cleavage area due to symmastia repair or reconstruction of the chest cleavage for breast reconstruction after mastectomy. The support garment is designed not to support the breast or nipple area of the chest. The Y support which fits the patient close to the neck and between the breasts is attached to a full back panel using self adjusting velcro closures. This unique design creates a force much like a bow to provide constant pressure from front to back on the cleavage area only to allow scar tissue to form during the healing process. The cross link high density foam insert maintains even pressure during healing and does not lose its resiliency or permit permanent deformation.

Owner:THONGBRA INC

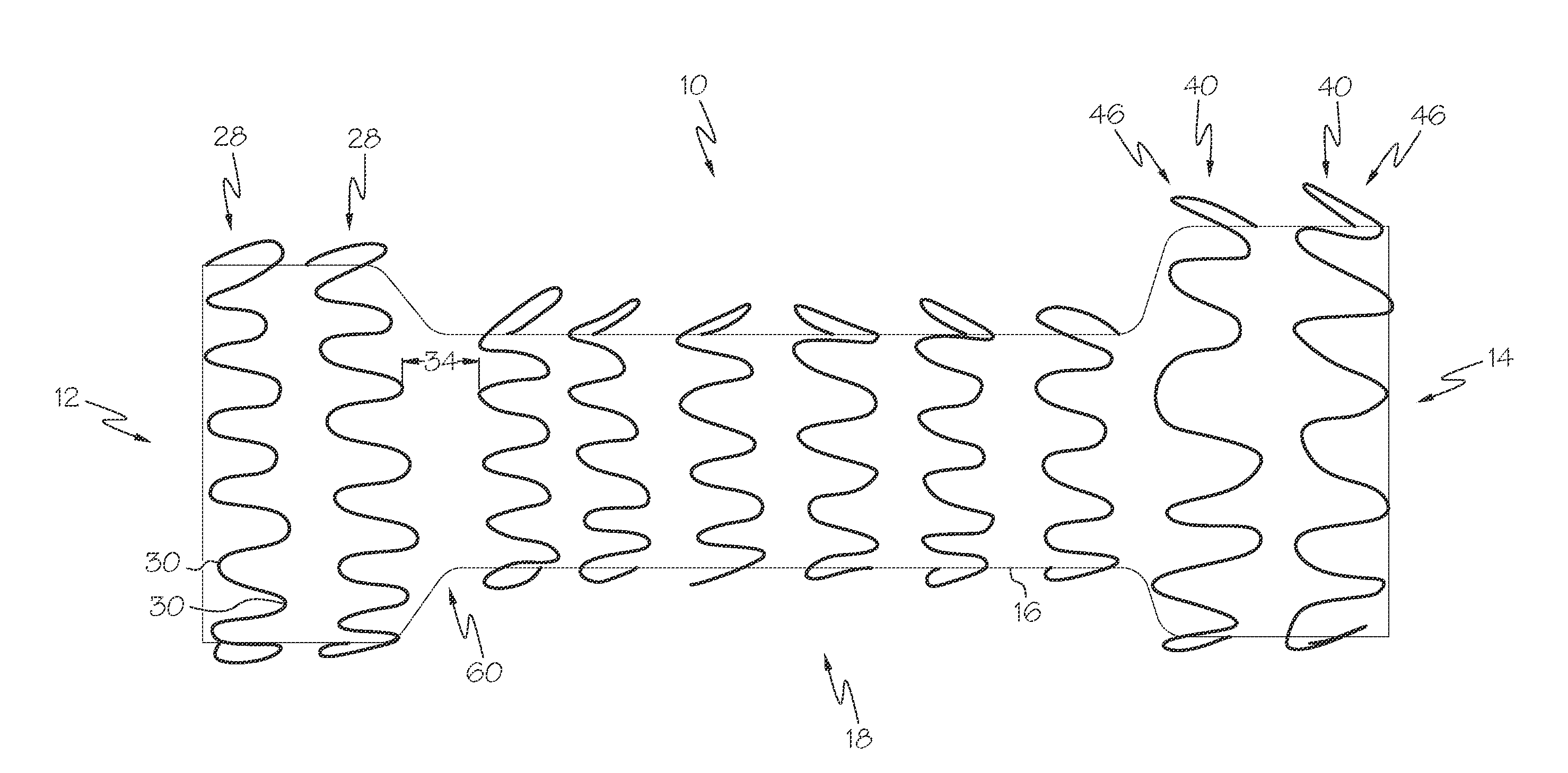

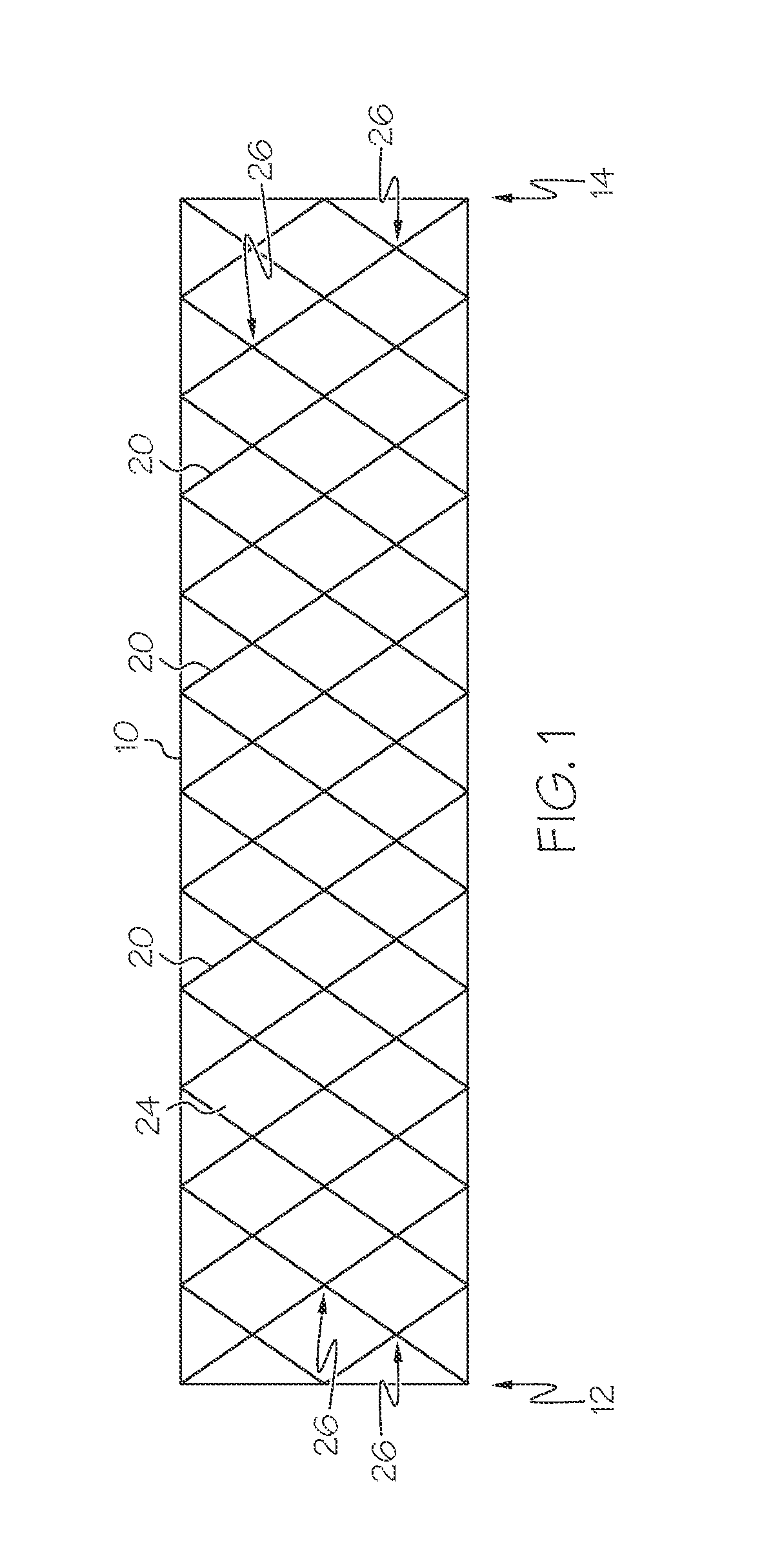

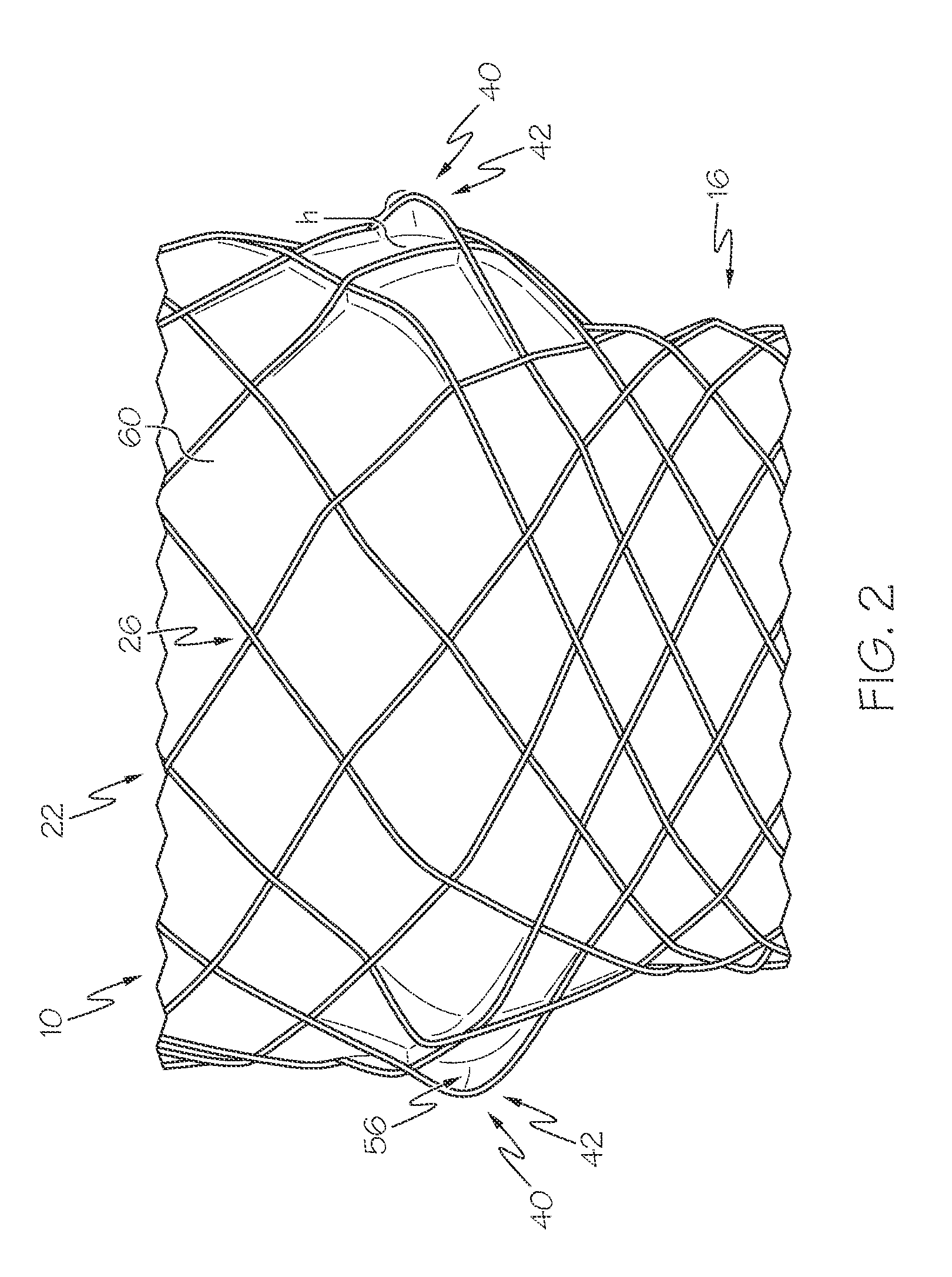

Controlled ingrowth feature for antimigration

ActiveUS20160095724A1Variable thicknessUniform thicknessStentsBlood vesselsProsthesis ImplantationBiomedical engineering

A tubular prosthesis that includes a scaffolding formed by at least one scaffolding filament; a cover; and at least one controlled ingrowth feature constructed and arranged to abut an inner surface of a lumen wall when the prosthesis is implanted in the body lumen. The controlled ingrowth feature may extend inwards or outwards from the prosthesis outer surface. The controlled ingrowth feature may be formed by a scaffolding filament; by a separate filament; by the cover; and combinations thereof.

Owner:BOSTON SCI SCIMED INC

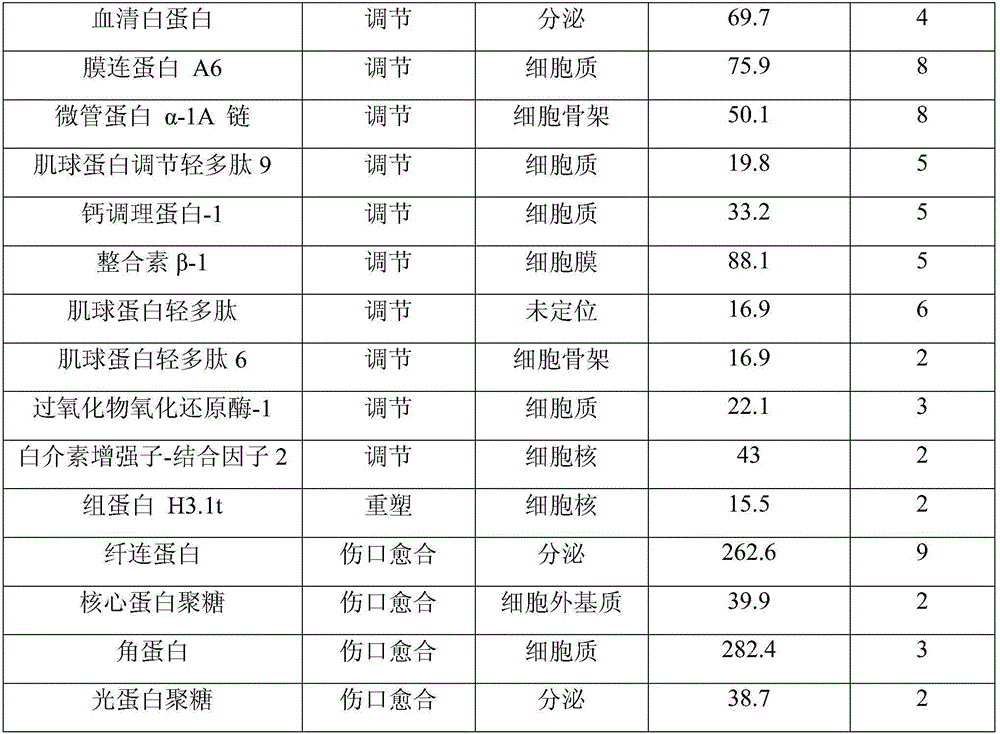

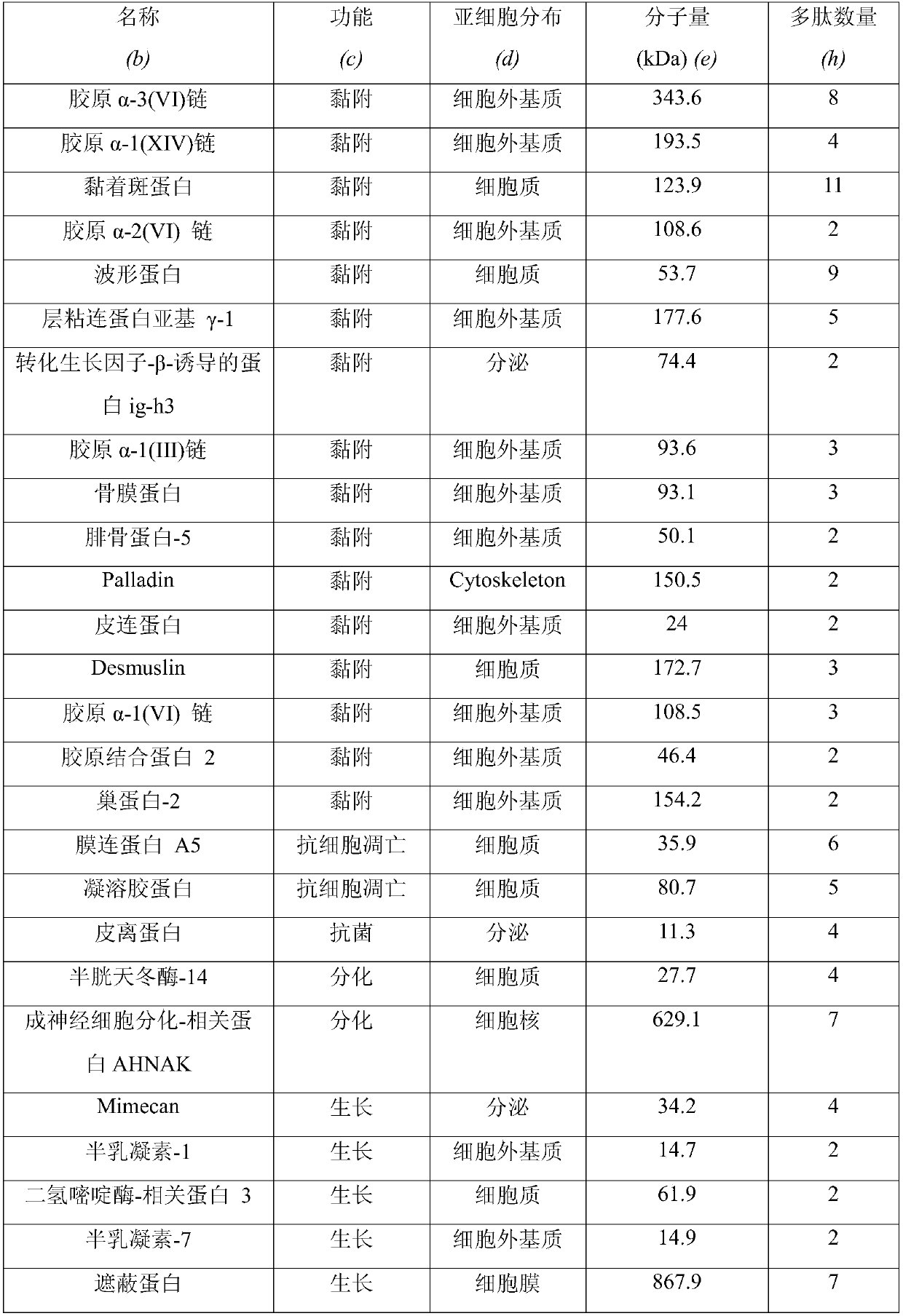

Composite extracellular matrix ingredient biological material

ActiveCN105920669ALight adhesionImprove adhesionTissue regenerationProsthesisCell-Extracellular MatrixAdditive ingredient

Owner:SHANGHAI EXCELLENCE MEDICAL TECH CO LTD

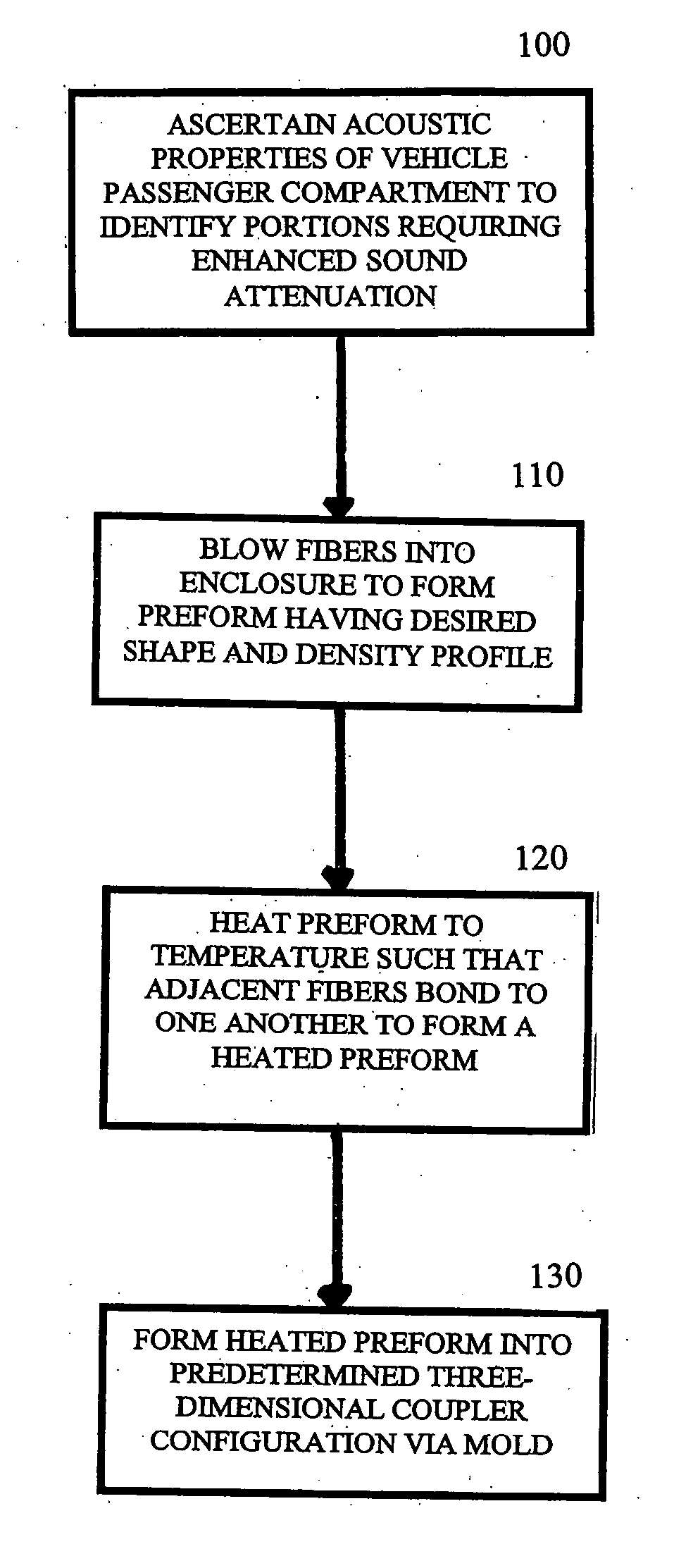

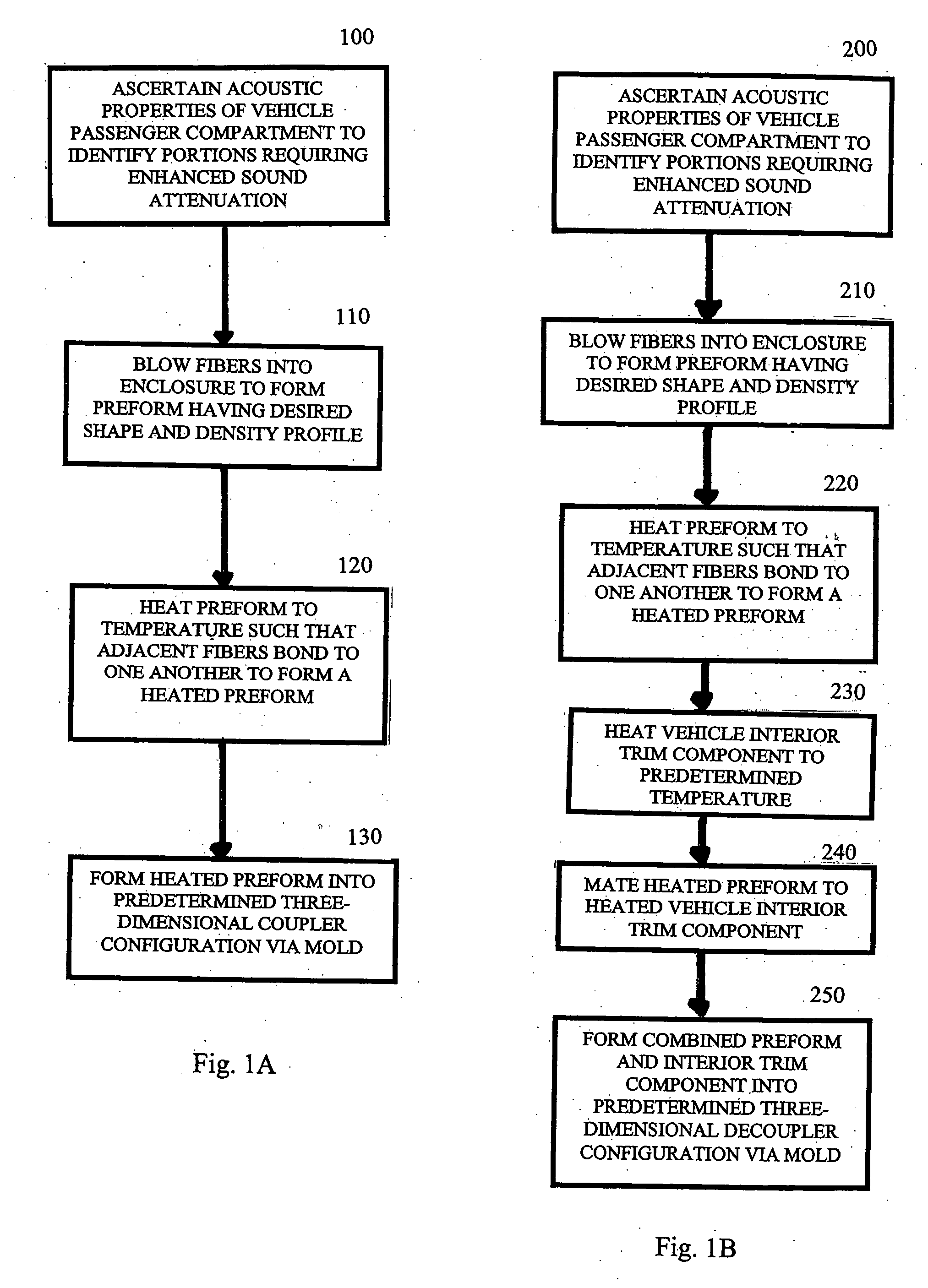

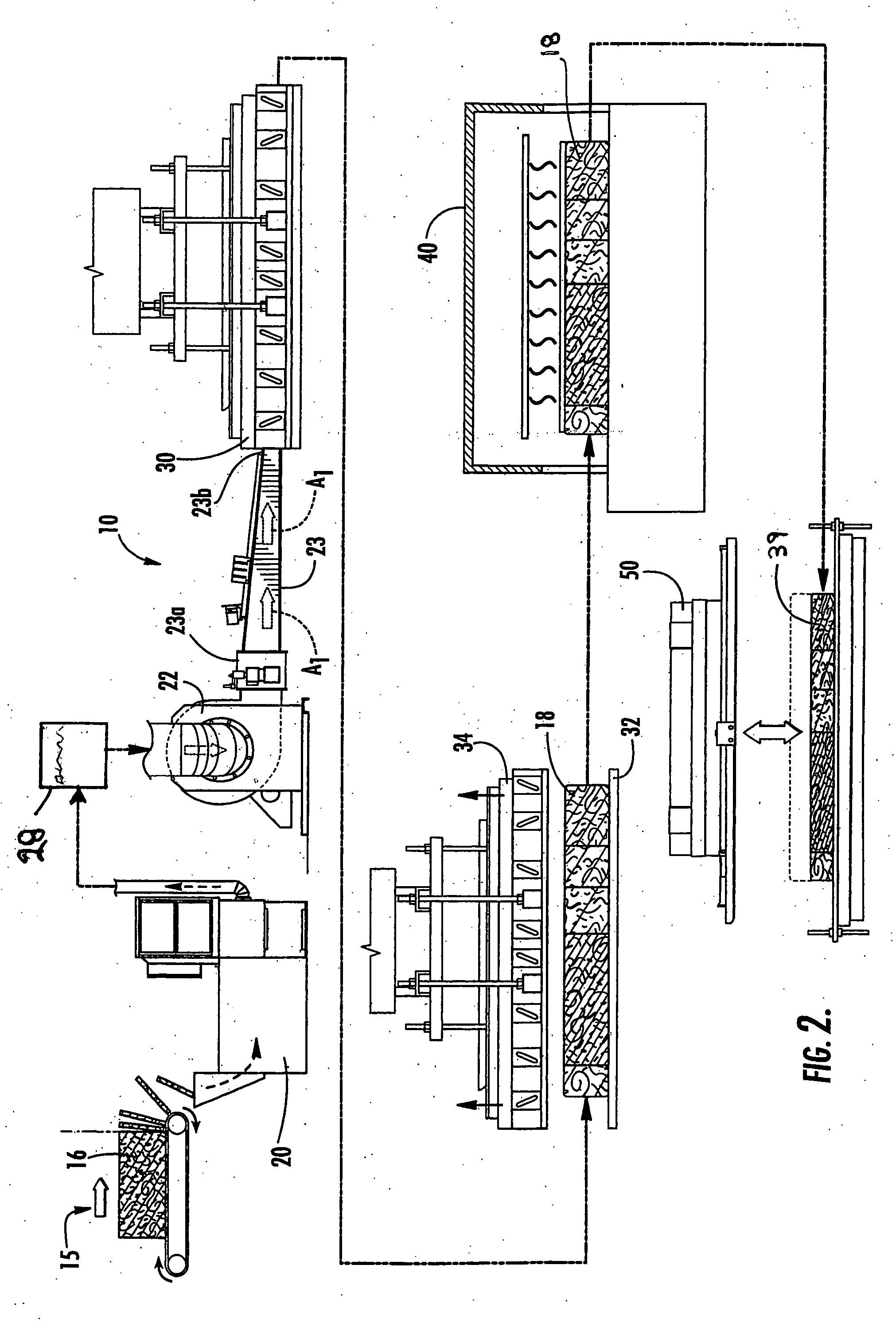

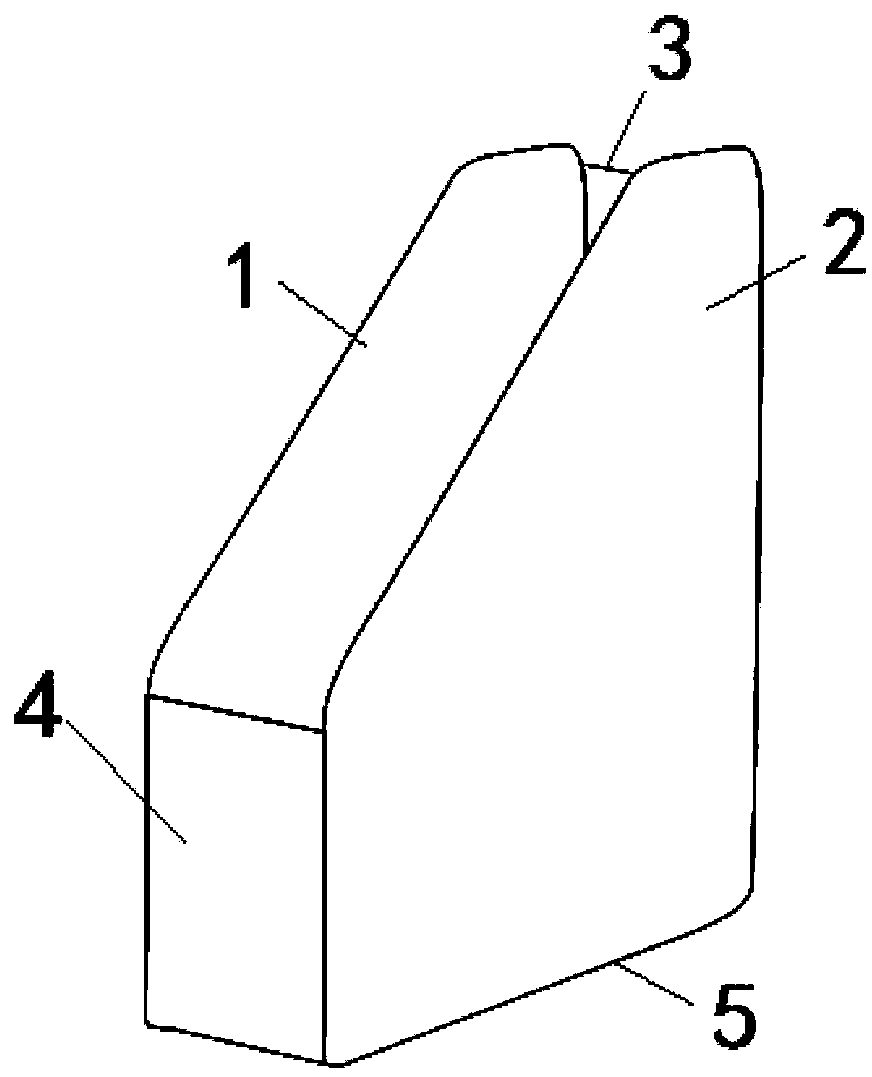

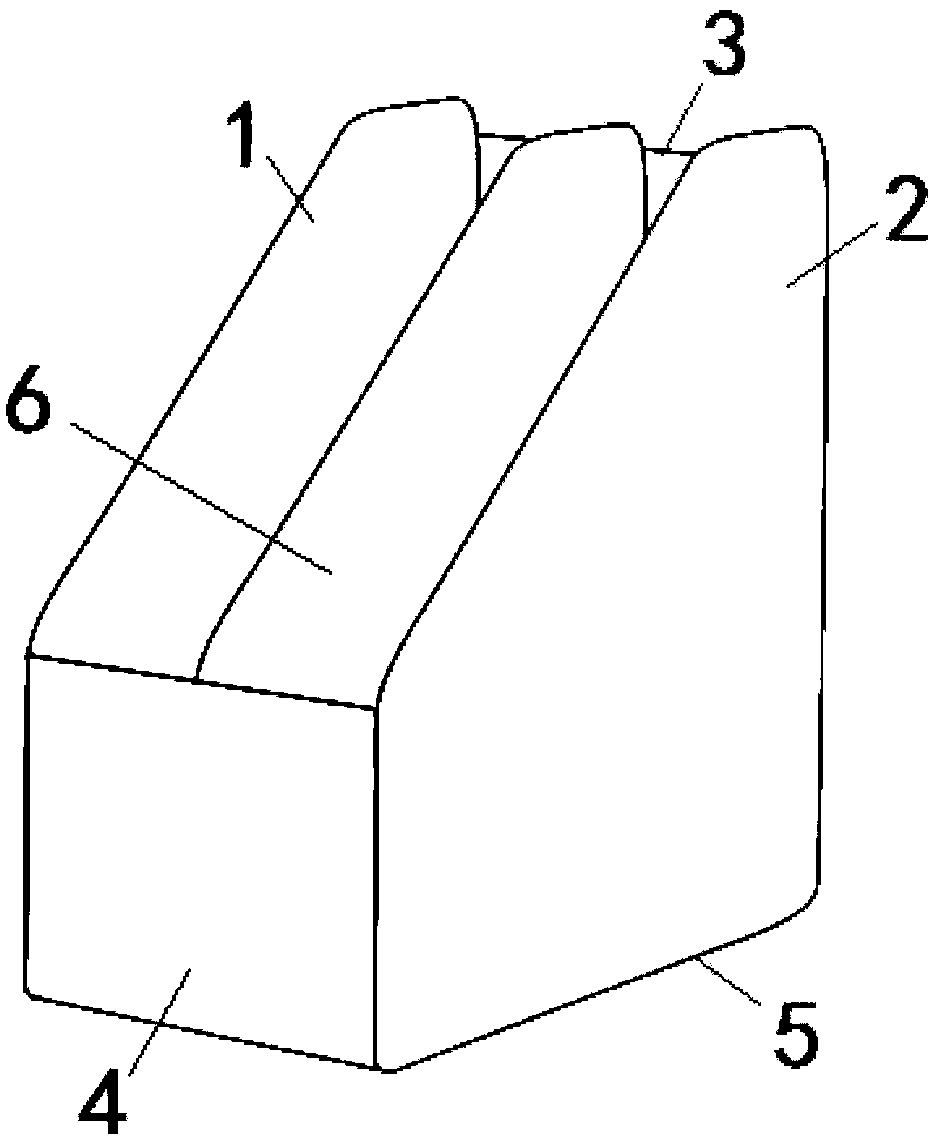

Rotary apparatus for forming decouplers for vehicle interior components

A method of manufacturing an article having controlled density, such as a decoupler for a vehicle interior trim component, is disclosed which uses an indexing, preferably rotary, apparatus. The method comprises the conveying of materials, preferably fibers, into an enclosure to form a preform having a shape of the enclosure, transferring the preform to a mold on an indexing apparatus where the preform is heated to a temperature such that adjacent fibers bond to one another upon cooling, and moving the mold to a press where the heated preform is molded into a predetermined three-dimensional decoupler configuration. The enclosure has a perforated portion and at least one panel movable relative to the enclosure so as to selectively expose portions of the perforated portion. The density of the preform may be varied as the at least one panel is removed to expose the perforated portion of the enclosure.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

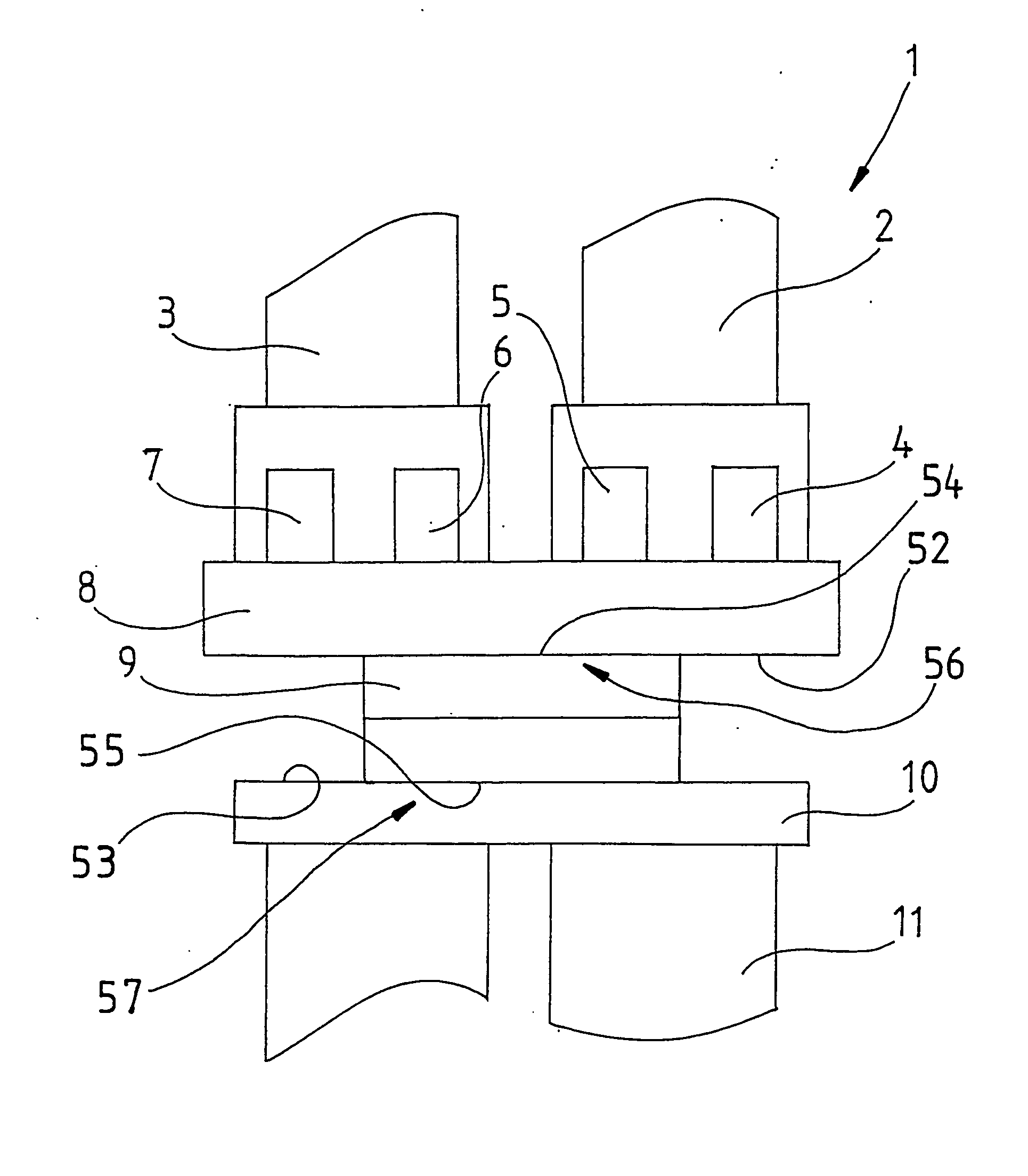

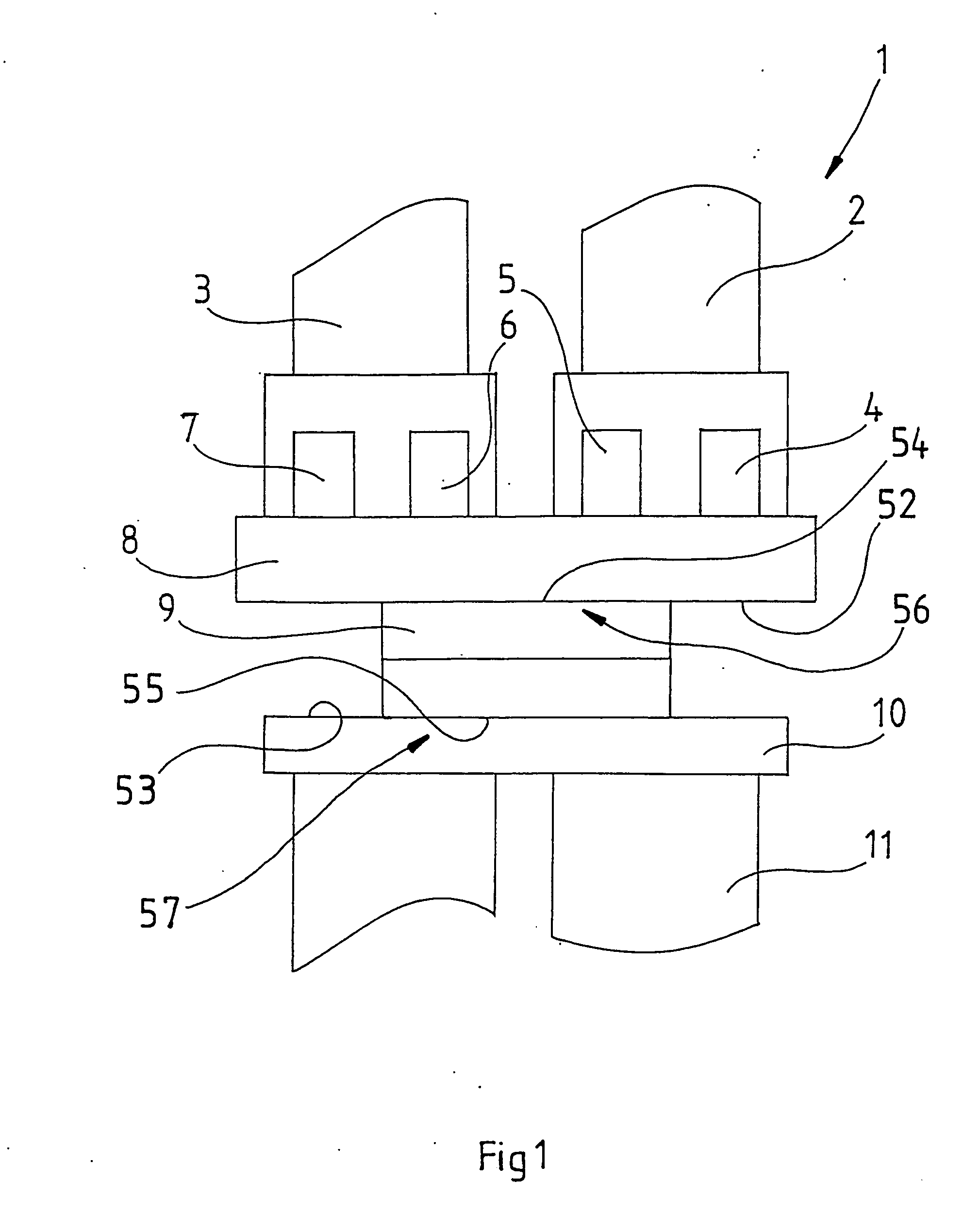

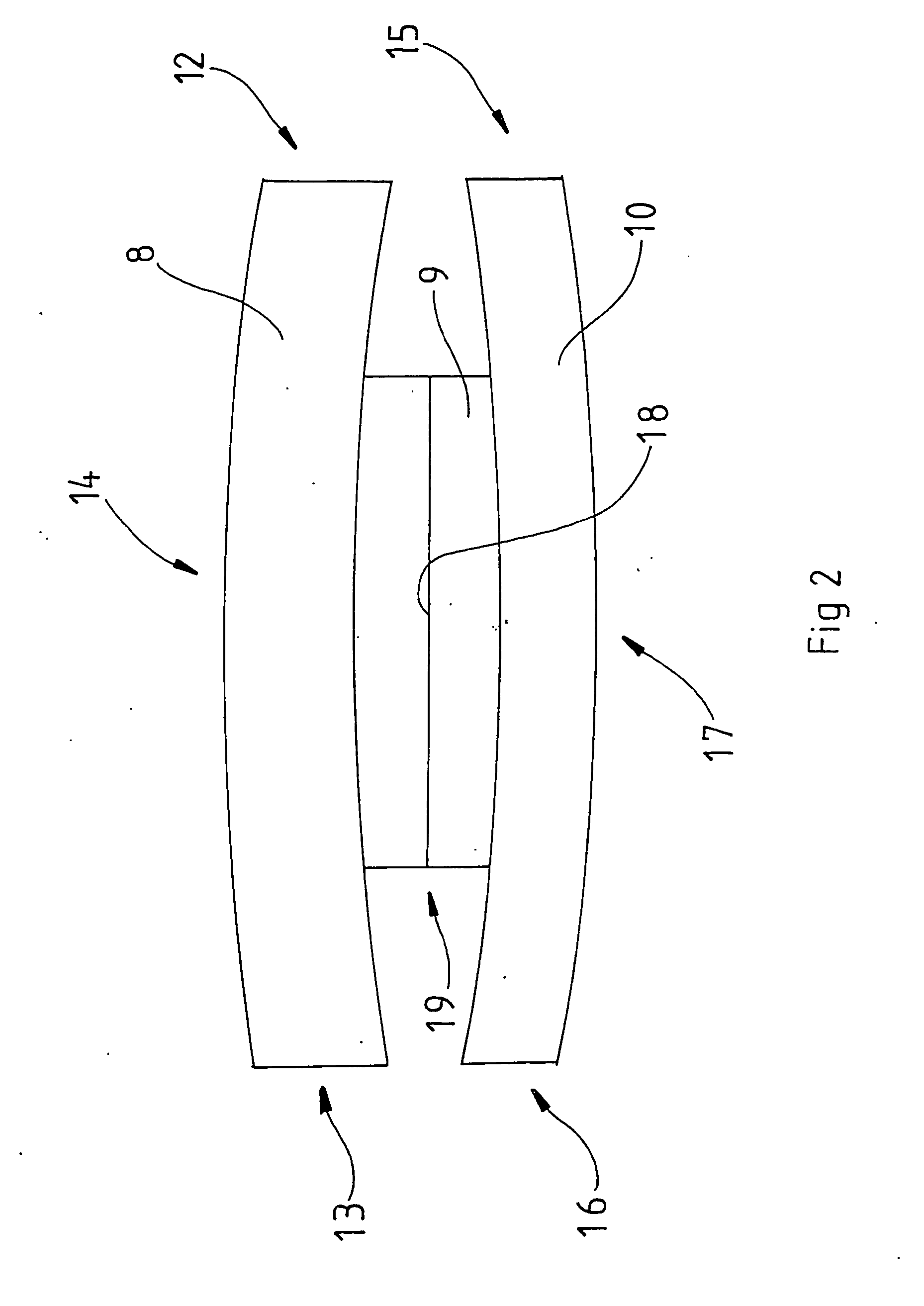

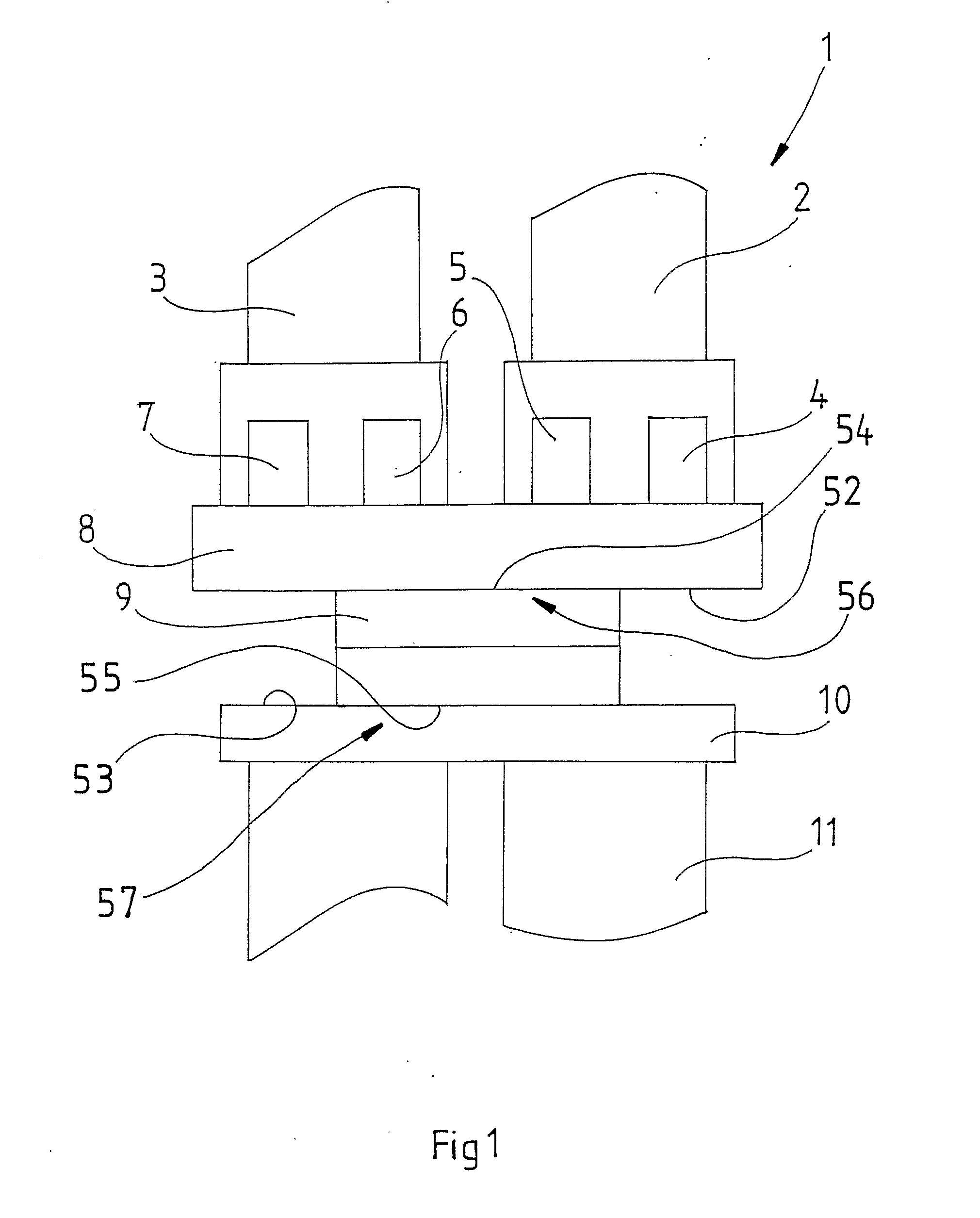

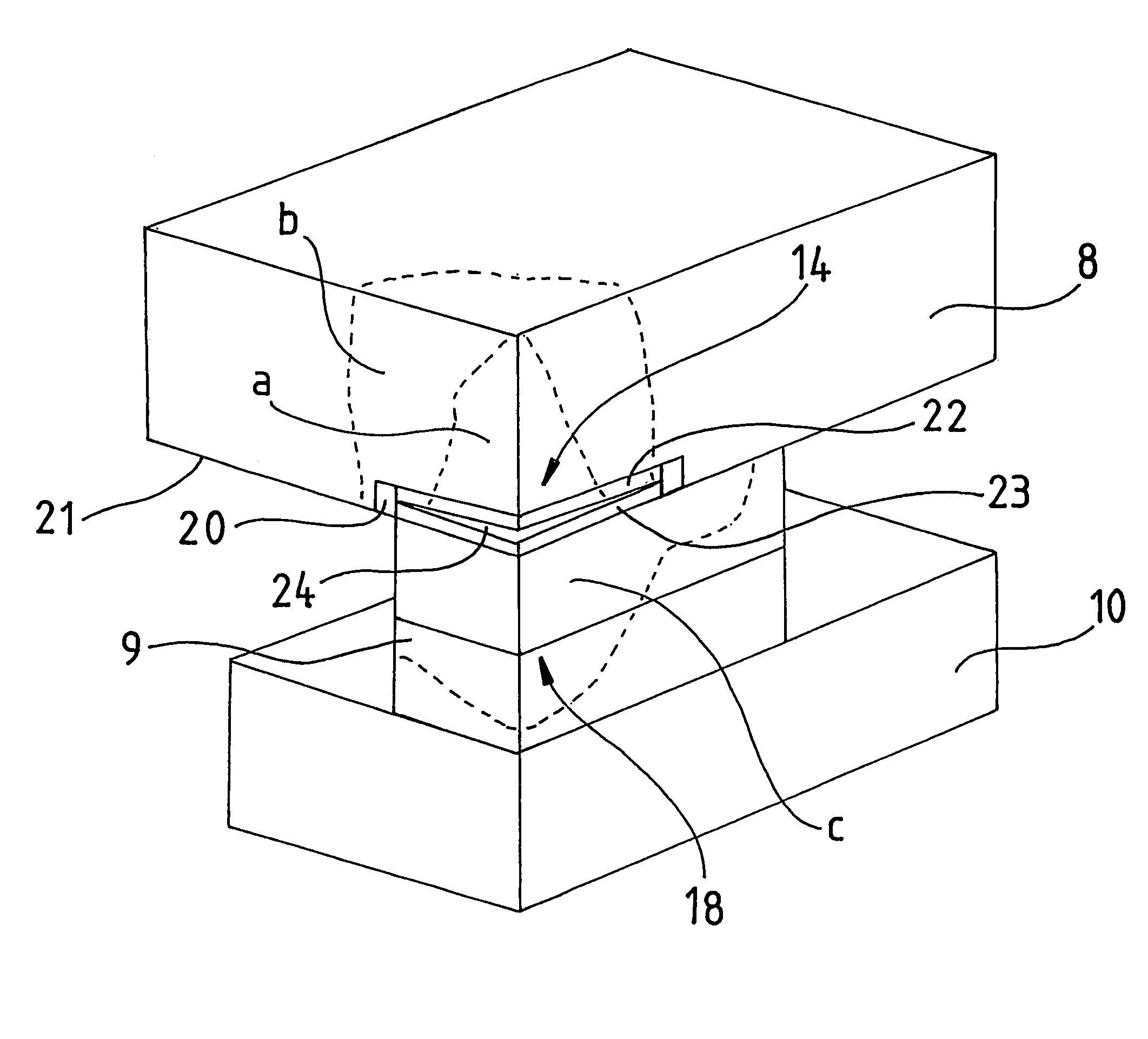

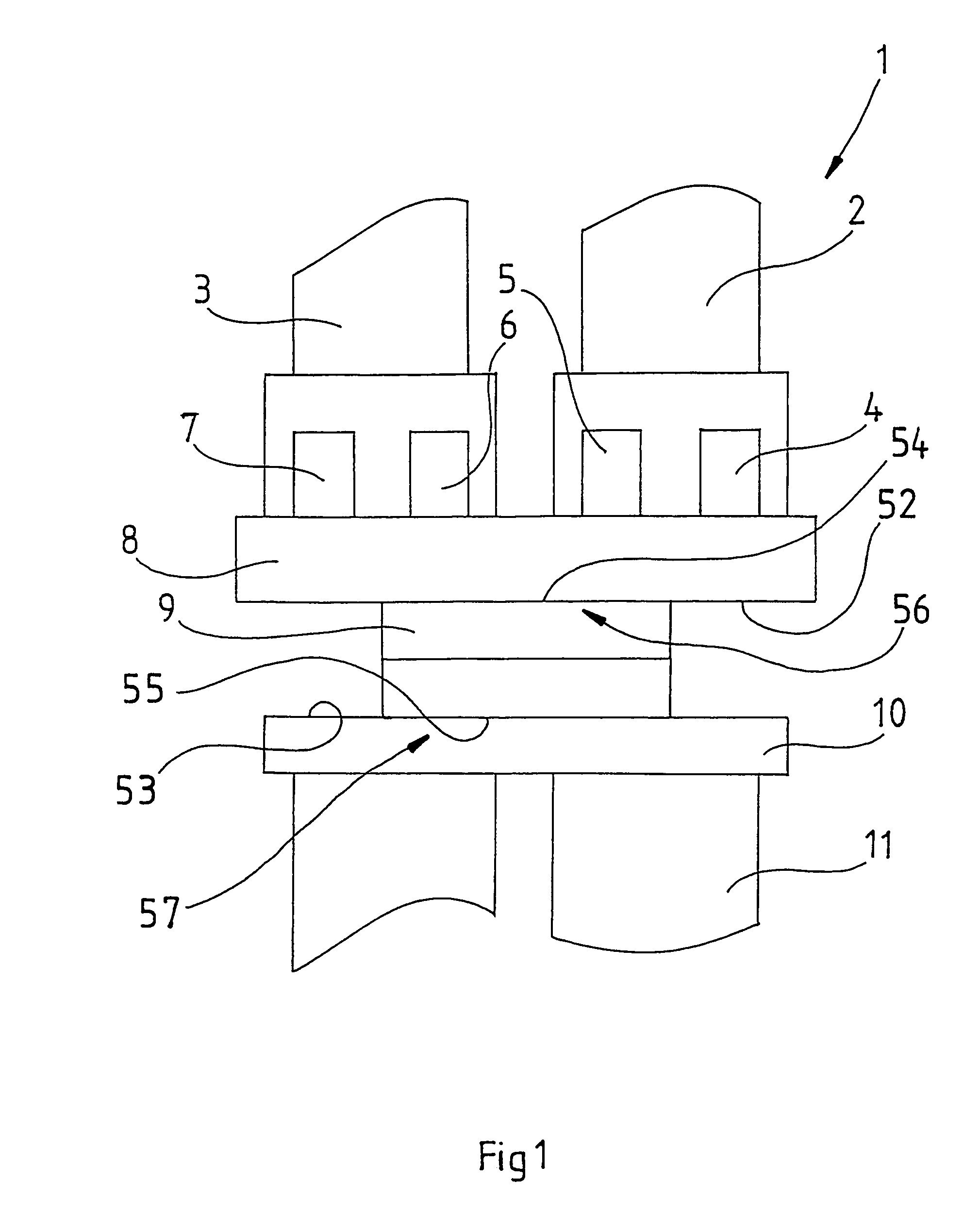

Apparatus and method for compensations for stress deformations in a press

InactiveUS20070295054A1Uniform compression depthCompensation for deformationShaping toolsForging/hammering/pressing machinesEngineeringAbutment

An apparatus is provided for compensating for such deformations as occur in operation in first and second clamping surfaces intended for a tool in a press. The clamping surfaces are reciprocally moveable towards and away from one another in order to move a first and second part of the tool towards and away from one another, and the first and second tool parts have a first and second abutment surface for abutment against the first and second clamping surfaces and the deformations cause uneven pressure in at least one contact region between the tool and the clamping surfaces. According to the present invention, there is disposed, in at least one contact region between a clamping surface and an abutment surface, a power unit which, on activation, is operative to press, away from the clamping surface located in the contact region at least a part of the abutment surface of the tool located there.

Owner:AUTOMATION PRESS & TOOLING AP&T

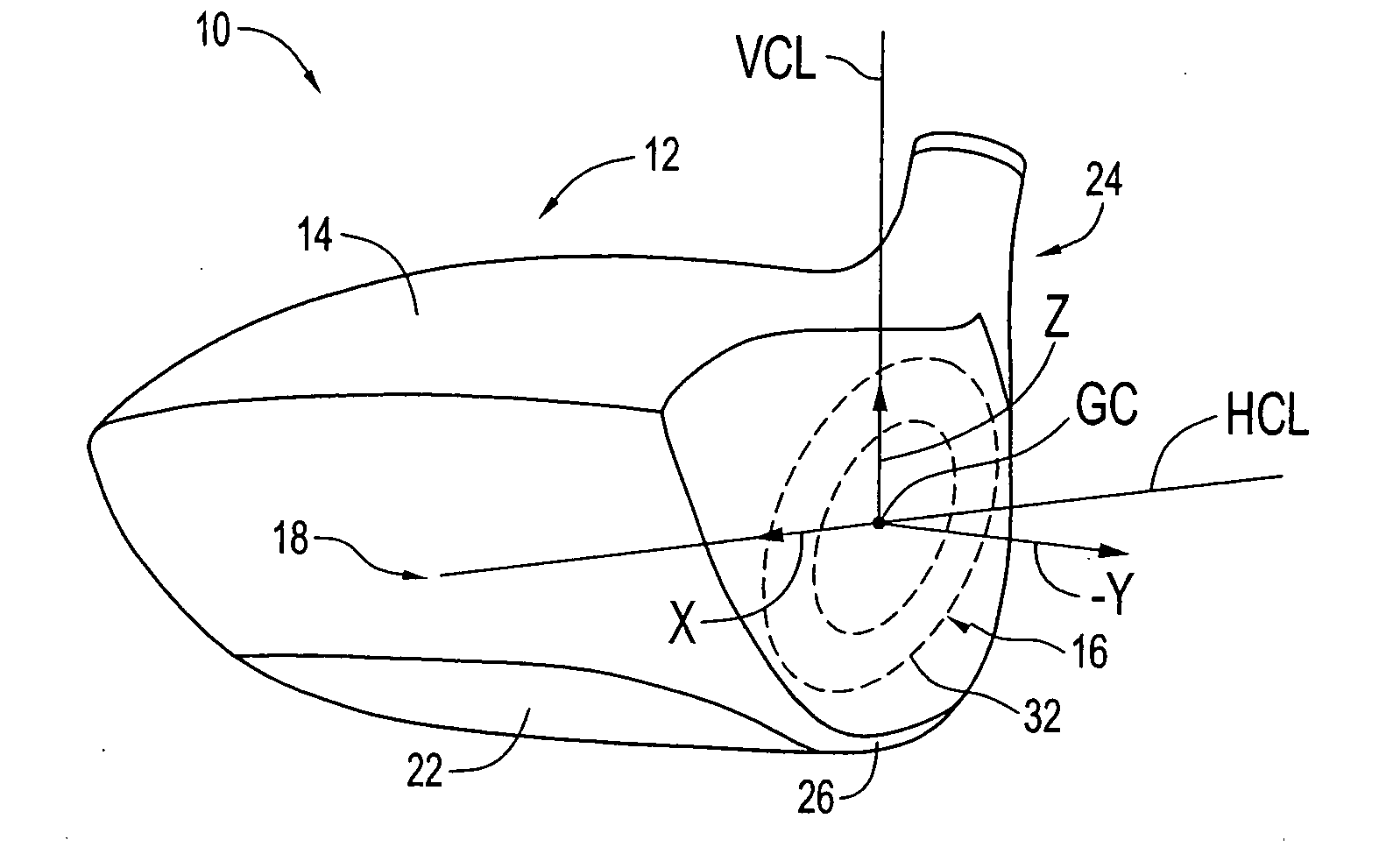

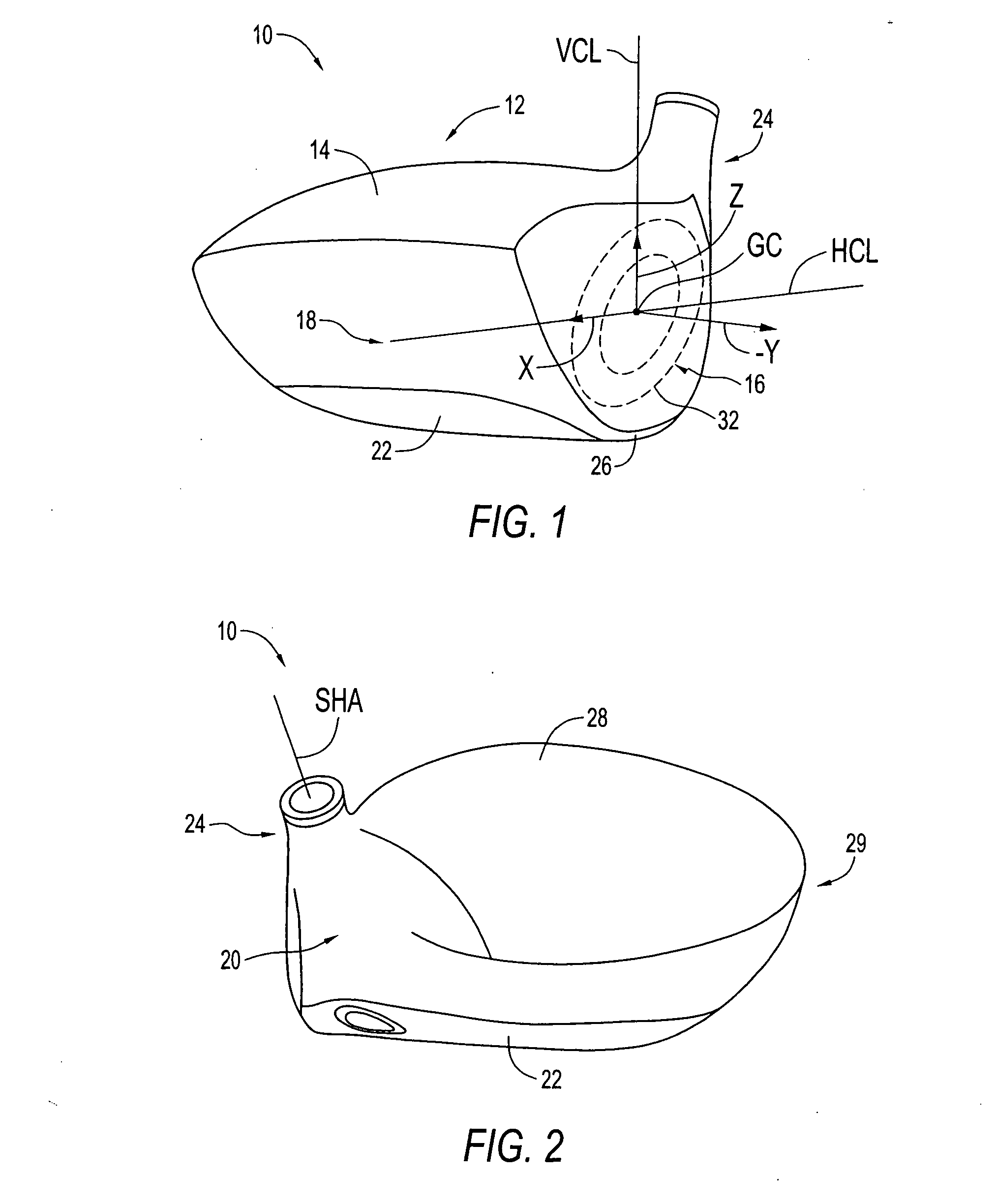

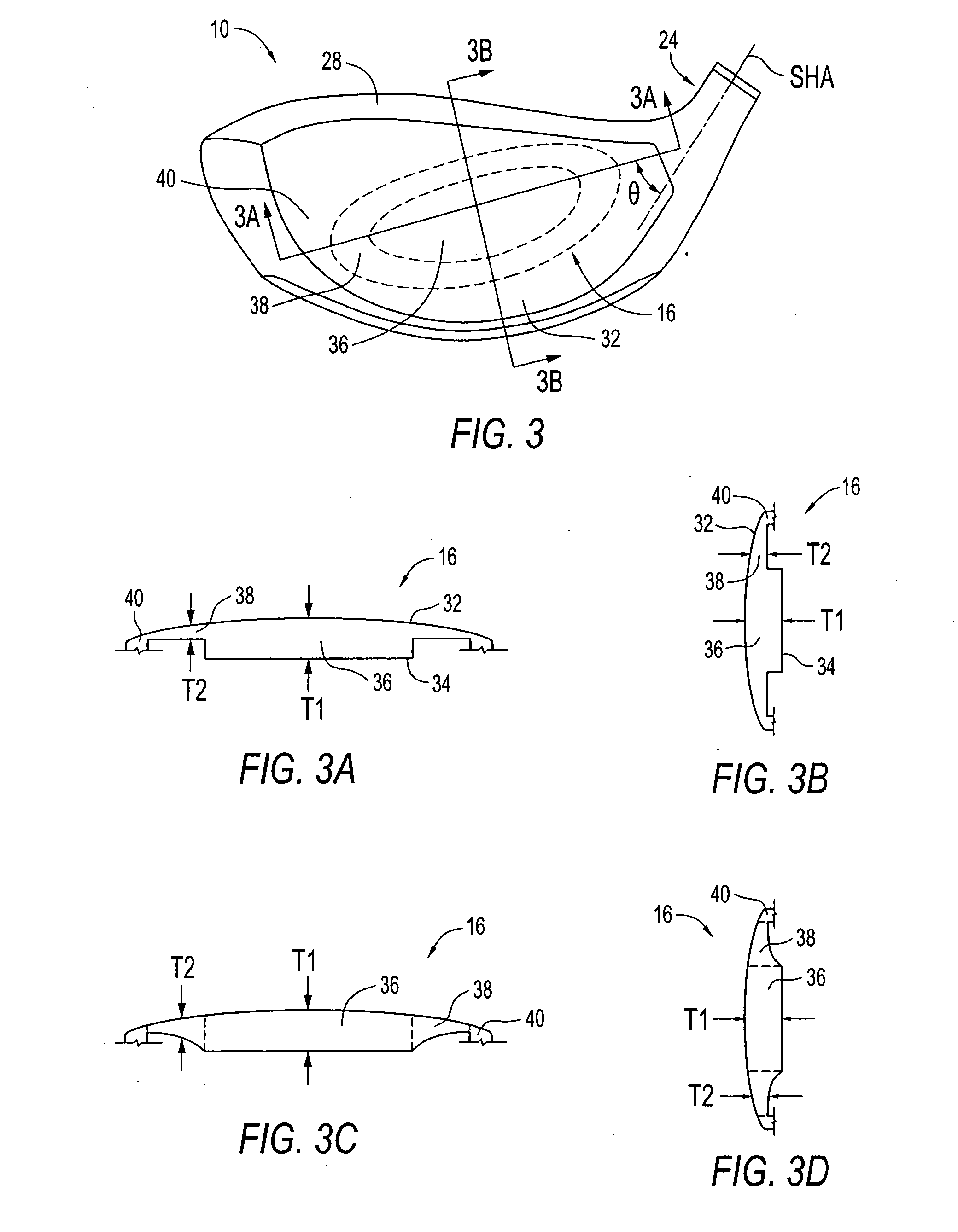

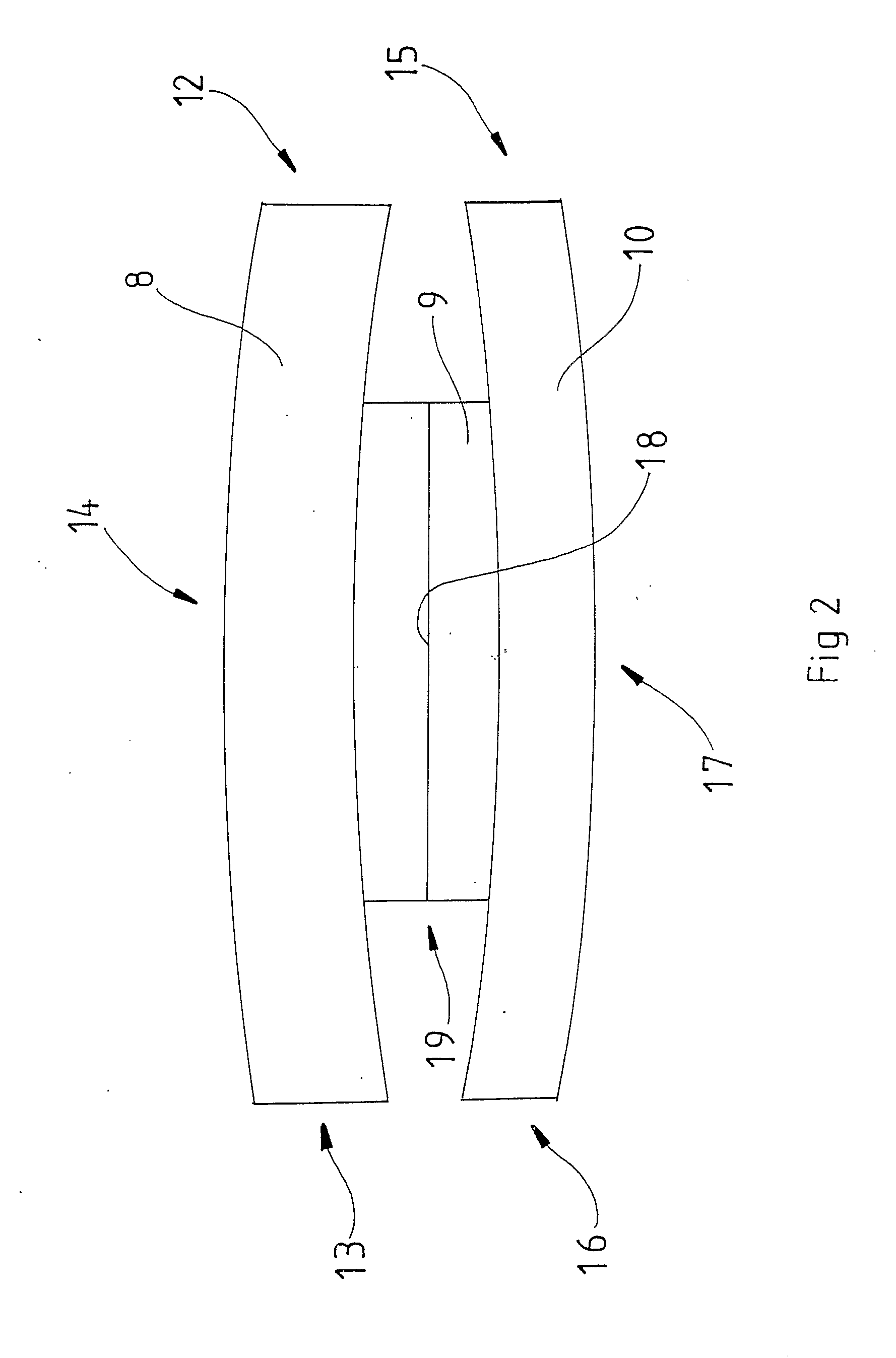

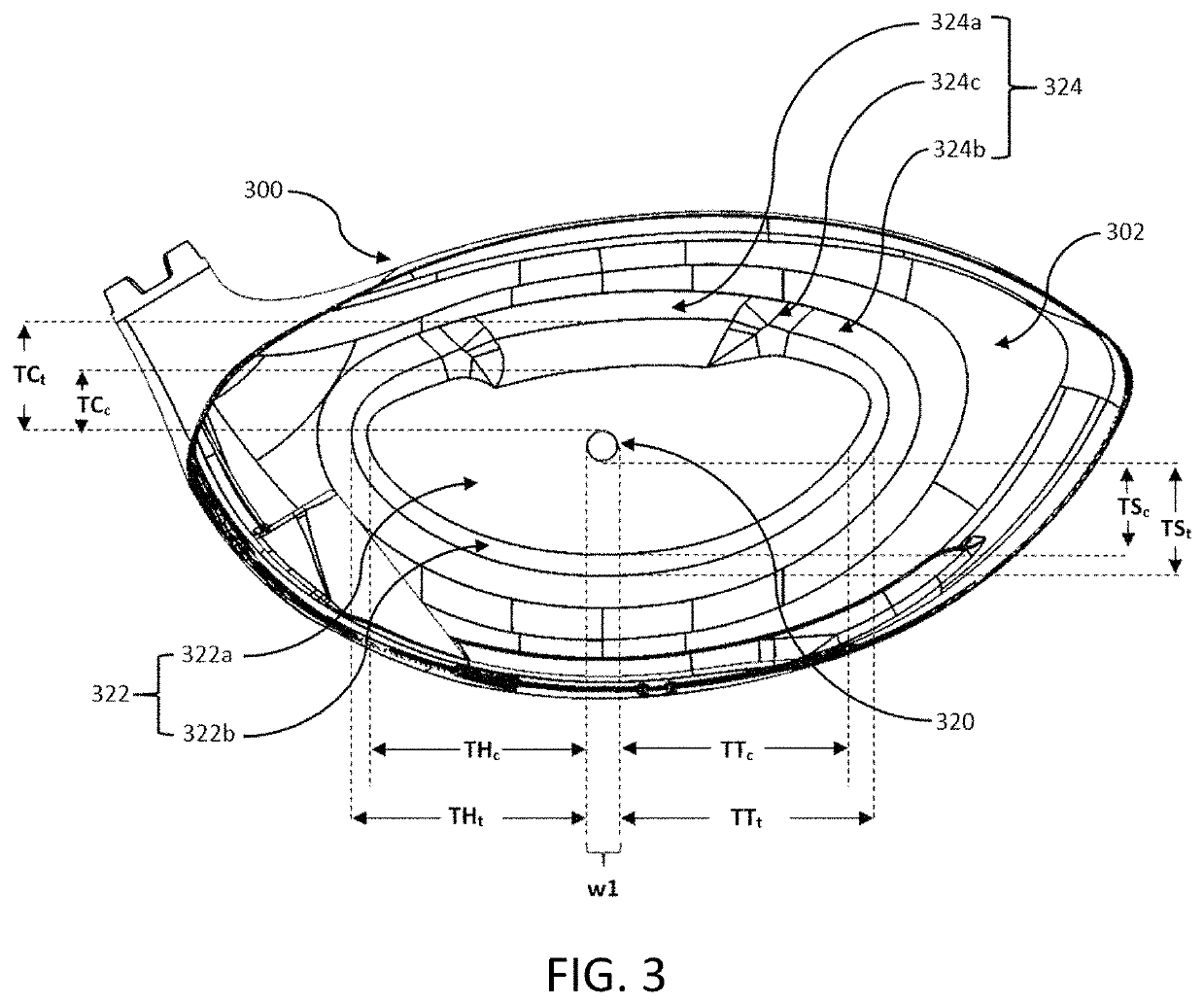

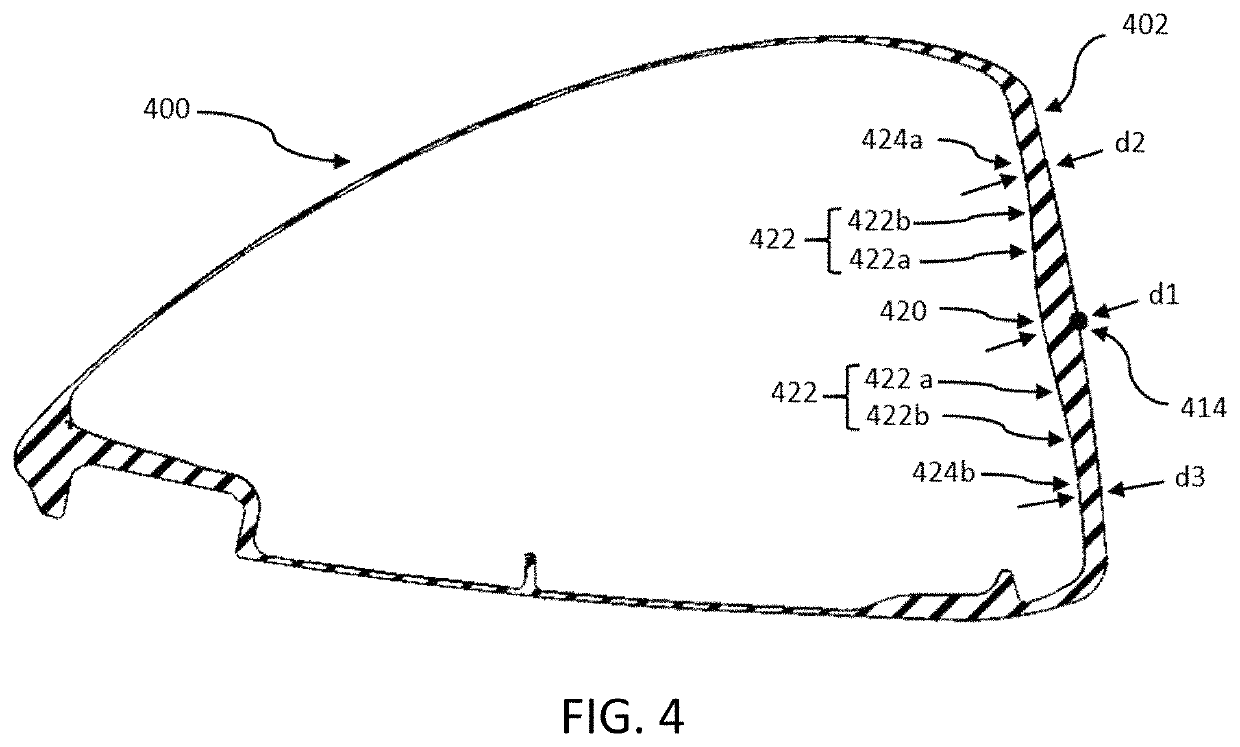

Composite metal wood club

InactiveUS20060287132A1Variable thicknessIncreased bending stiffnessAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsHigh densityEngineering

A metal wood golf club head adapted for attachment to a shaft, comprising of a body portion and a crown portion, each portion constructed of a different density material. Combining a high-density material in the body portion, with a low-density material in the crown portion, creates an ultra-low center of gravity relative to the geometric face center, resulting in higher launch angles and spin rate ratios. The material for the crown portion is preferably a composite. A vibration dampening gasket is disposed between the ledge and lip sections of the body and crown respectively.

Owner:ACUSHNET CO

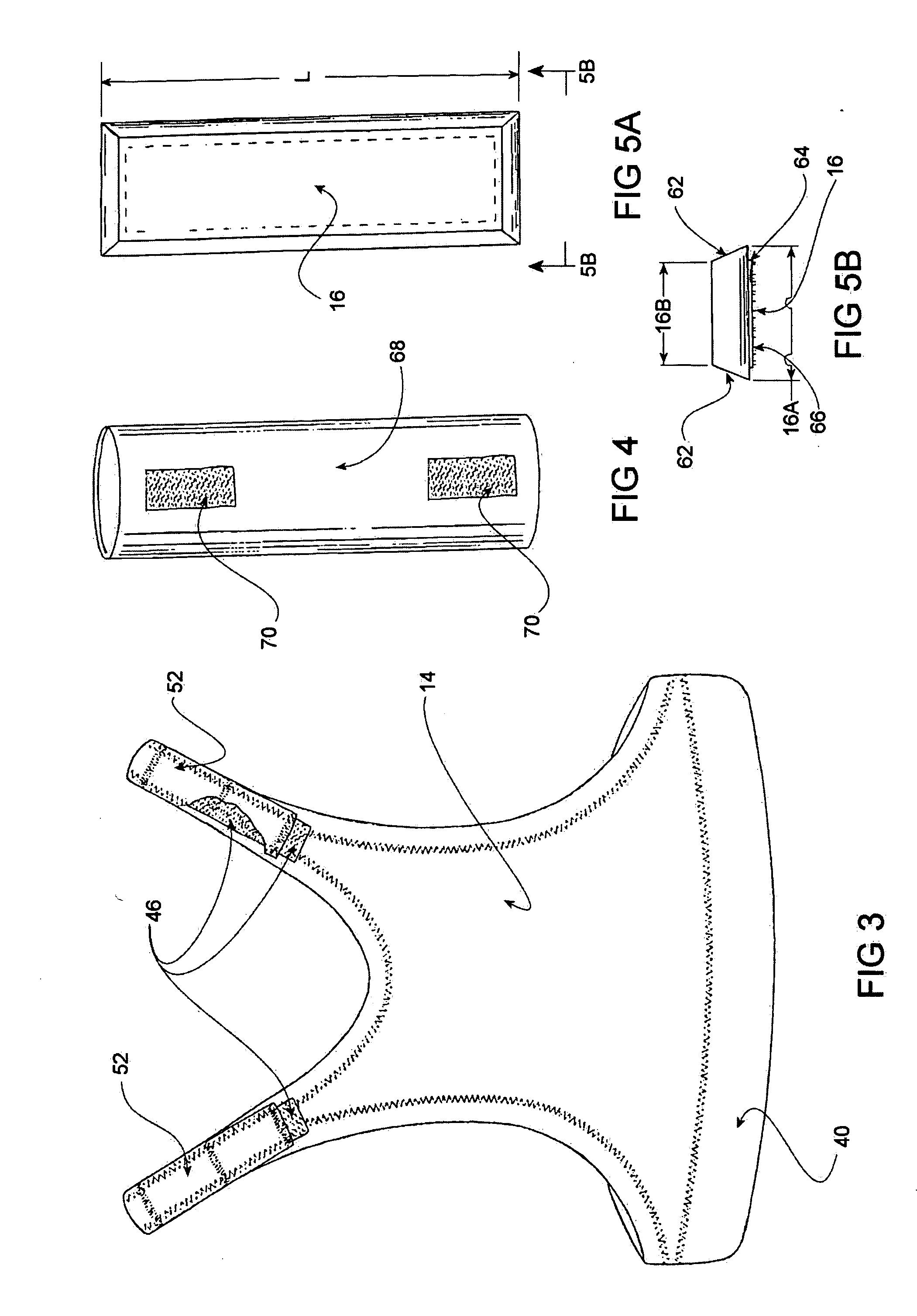

Post surgical chest support garment

ActiveUS20060194509A1Control pressureVariable widthBrassieresProtective garmentChest regionEngineering

A support garment adapted to be worn by a patient following breast surgery. The garment comprises front and rear panels and a compression pad mounted on the inner surface of the front panel confronting the cleavage area of the user. Each panel has upper extensions defining shoulder straps having means for detachably securing them in overlapping relation to snugly fit the user and midriff band portions adjacent the lower edge of the front and rear panels having means for snugly fitting the garment at the midriff area of the user. These elements combine to support the compression pad in pressure applying relation with the cleavage area of the user.

Owner:THONGBRA INC

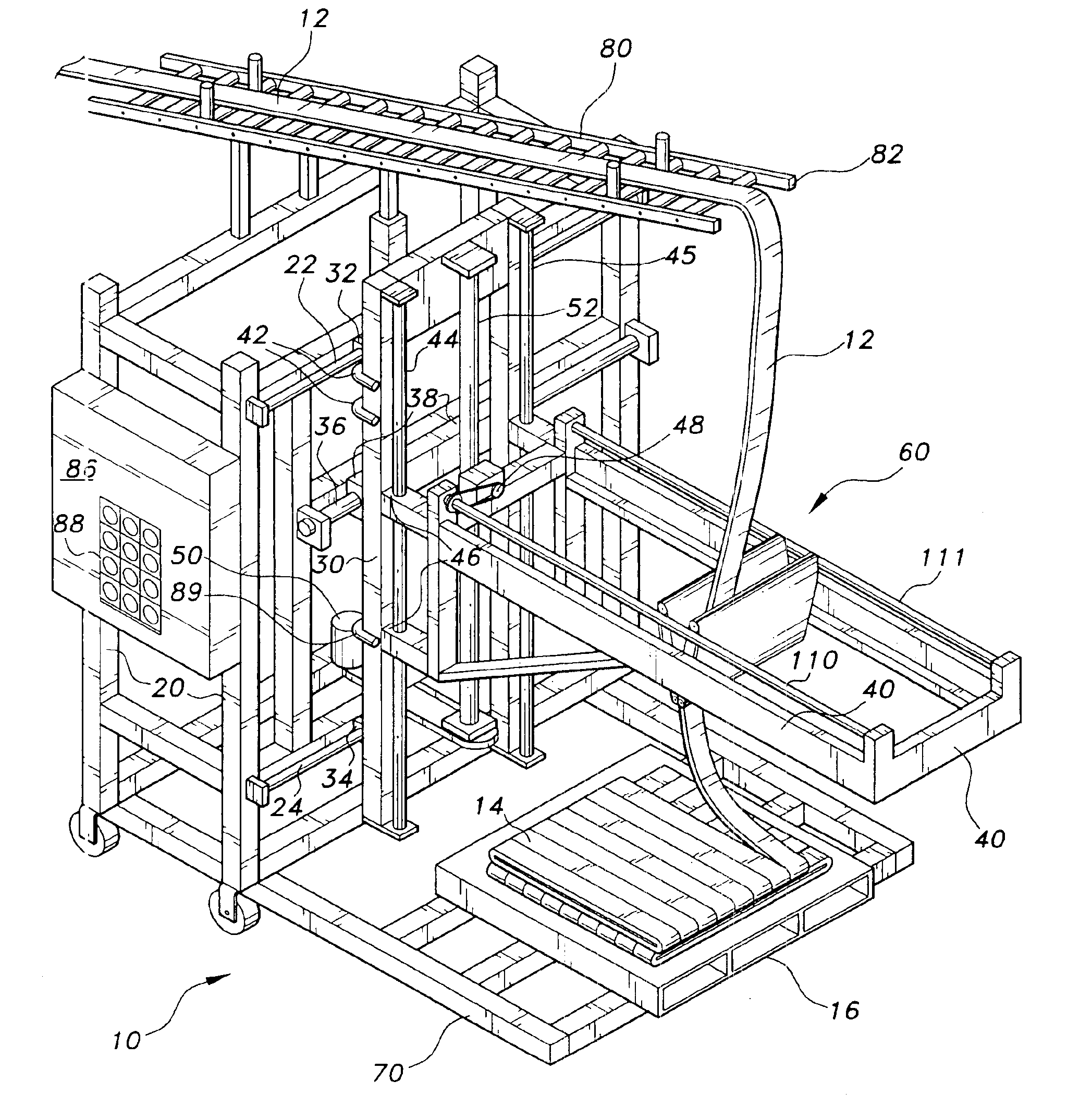

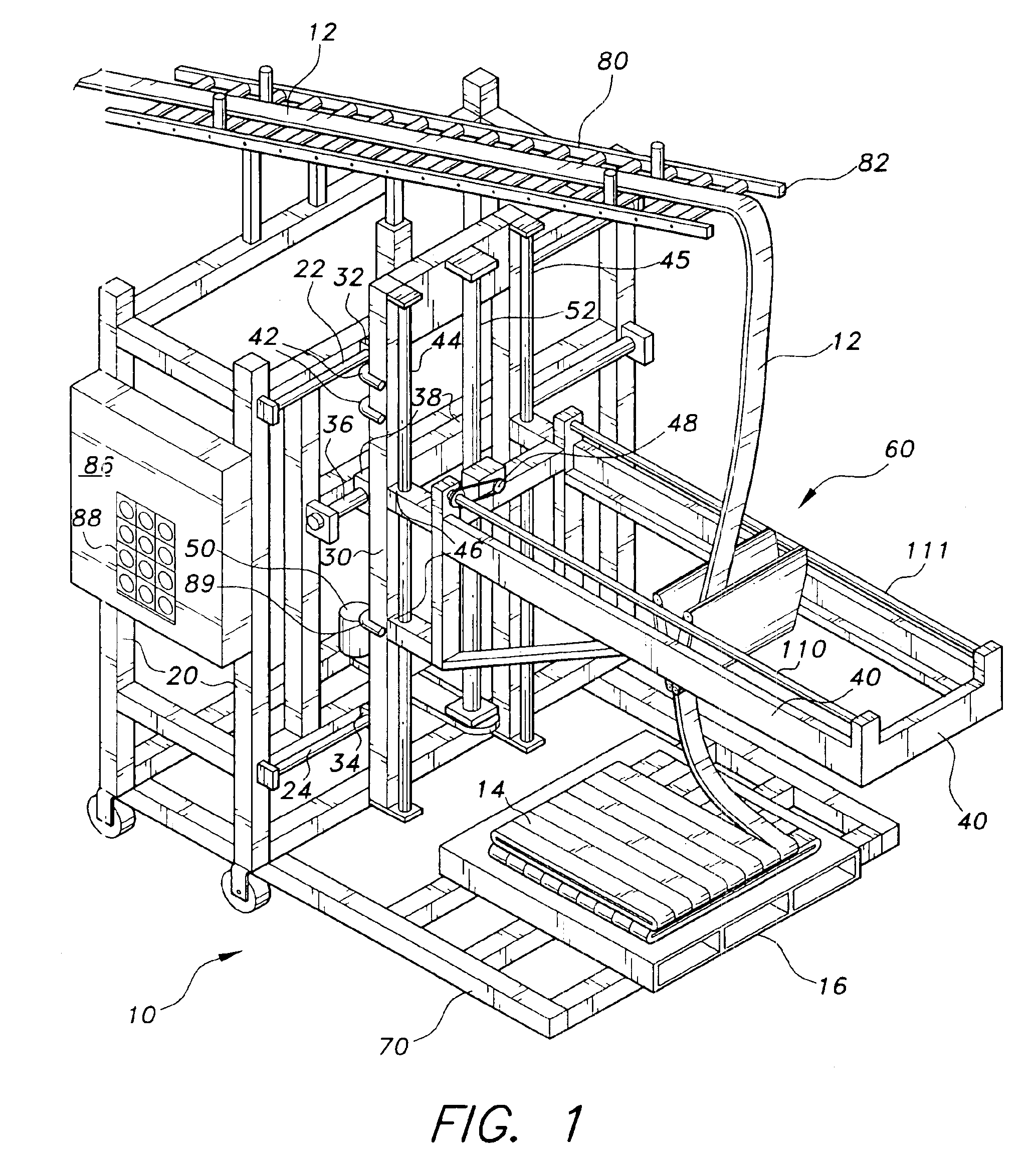

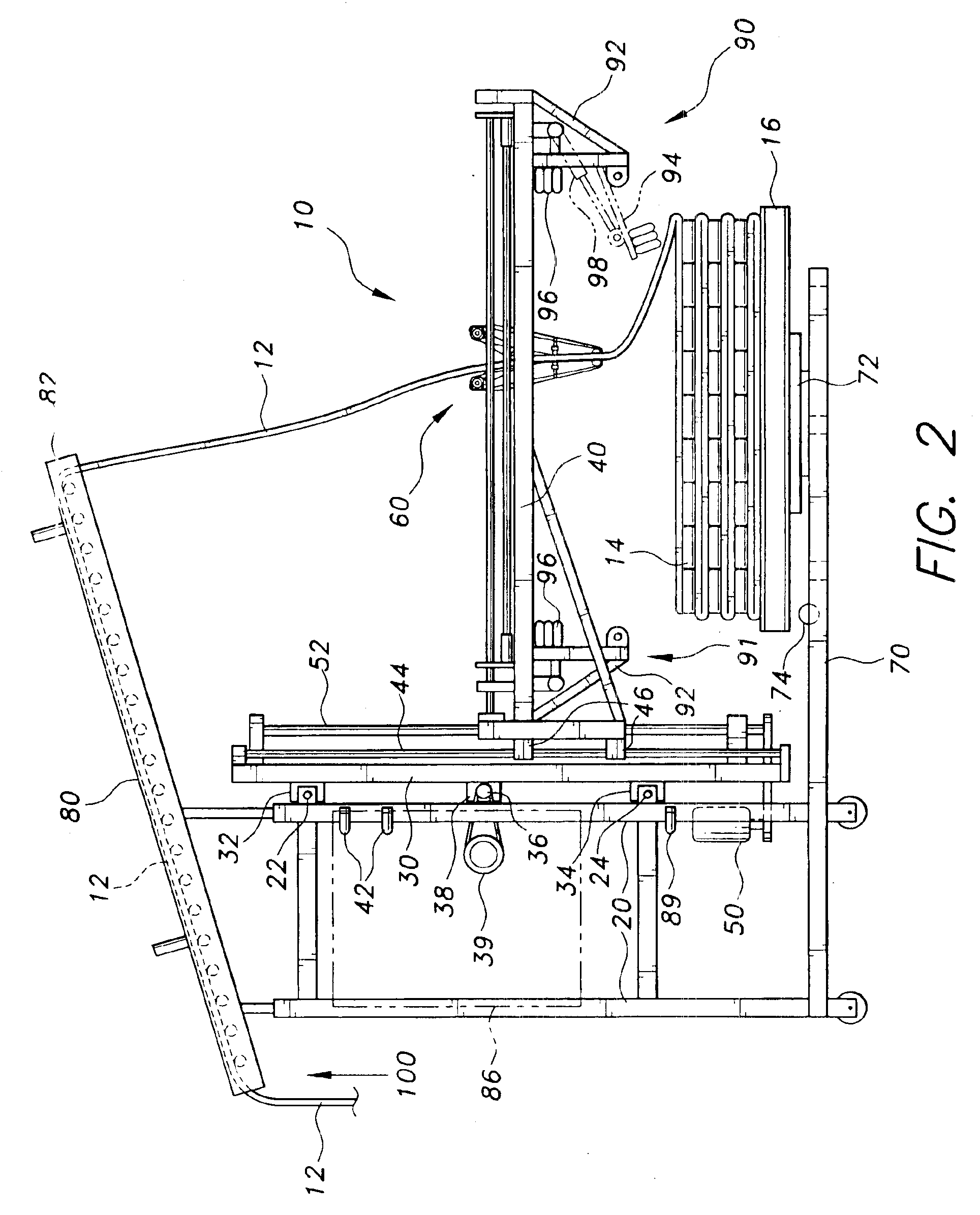

Automated reciprocal stacking assembly

InactiveUS6857629B2Wider entranceVariable thicknessMechanical working/deformationFilament handlingPalletEngineering

An automated reciprocal stacking assembly for stacking thin, narrow, continuous sheets of stock material. The automated reciprocal stacking assembly has a stationary outer frame, a laterally reciprocating inner frame, a vertically moveable carriage, a reciprocating distribution head, a base member, a pair of sheet retaining arms, a rotating platform for supporting a pallet and a conveyor belt. The reciprocating distribution head comprises a pair of feeding belts that are driven by a positive timing belt. The continuous sheet of stock material is supplied to the reciprocating distribution head by the conveyor through a large opening between the feeding belts of the reciprocating distribution head. The oppositely moving feeder belts force the stock material out of the reciprocating distribution head and onto a pallet.

Owner:FRITZ CHARLES W +1

Apparatus and method for compensating for stress deformation in a press

InactiveUS20100307217A1Good compensationImprove the level ofShaping toolsForging/hammering/pressing machinesInterior spaceLocal pressure

A method for locally increasing pressing pressure on a press tool having an abutment surface for being clamped onto a clamping surface in a press comprises providing a power unit smaller than the abutment surface and having an internal space, positioning the power unit between the clamping surface and the abutment surface, pressing the clamping surface against the abutment surface, connecting the internal space to a source of pressurized hydraulic fluid, and supplying the pressurized hydraulic fluid to the internal space thereby causing the power unit to expand and to exert a local pressure on the abutment surface.

Owner:AUTOMATION PRESS & TOOLING AP&T

Marker

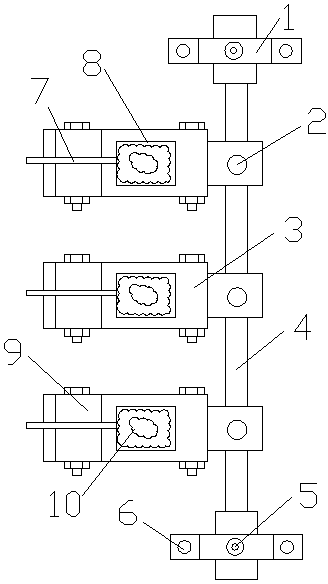

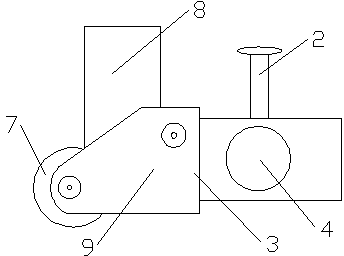

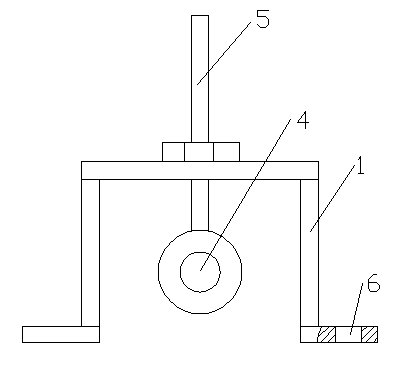

The invention belongs to the field of markers, and particularly relates to a marker marking on the surfaces of board parts. The marker comprises mounting seats and marker bodies, each marker body comprises a marking wheel, an ink box is connected onto each marking wheel, a fixing seat is arranged outside each marking wheel and each ink box, a fixing rod is connected onto the fixing seats, and the mounting seats are arranged at both ends of the fixing rod. The marker is simple in structure, convenient to mount and dismount, simple and convenient to operate and high in marking speed and marking accuracy, thicknesses of board parts which can be marked can be selected optionally, marking intervals can be set optionally, and marked lines of demarcation are clear.

Owner:ANHUI LONGHUA BAMBOO

Methods of forming decouplers for vehicle interior components

InactiveUS20060182935A1Less materialEasy to useVehicle arrangementsLaminationEngineeringSurface plate

A method of manufacturing an article, such as a decoupler for a vehicle interior trim component, is disclosed. The method comprises the conveying of materials into an enclosure to form a preform having a shape of the enclosure, heating the preform to a temperature such that adjacent materials may bond to one another upon cooling and forming the heated preform into a predetermined three-dimensional configuration via a mold. The enclosure has a perforated portion and at least one panel movable relative to the enclosure so as to selectively expose portions of the perforated portion. The density of the preform may be varied as the at least one panel is moved to expose the perforated portion of the enclosure. A system for manufacturing articles, such as decouplers, of the present invention is also disclosed.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

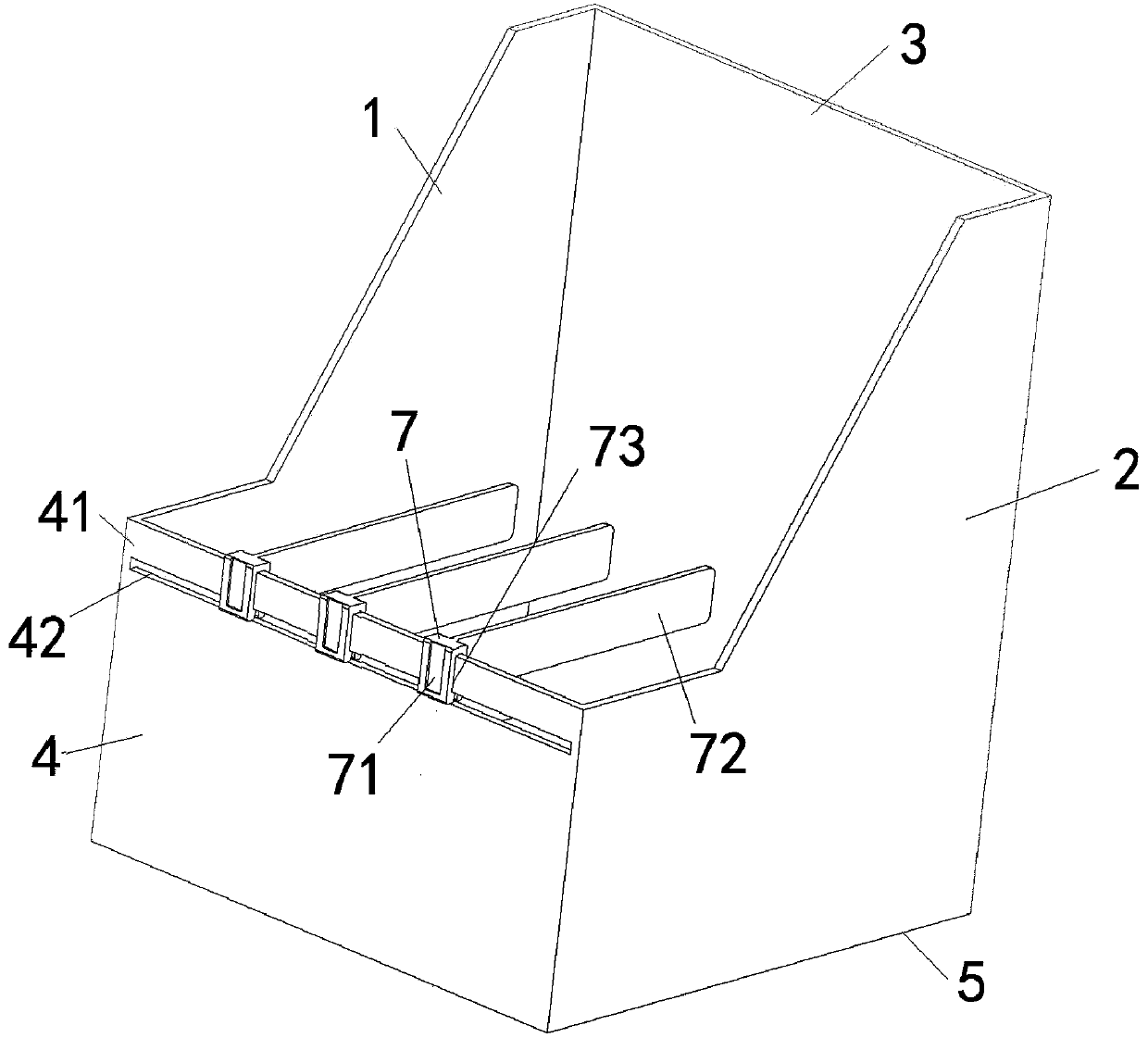

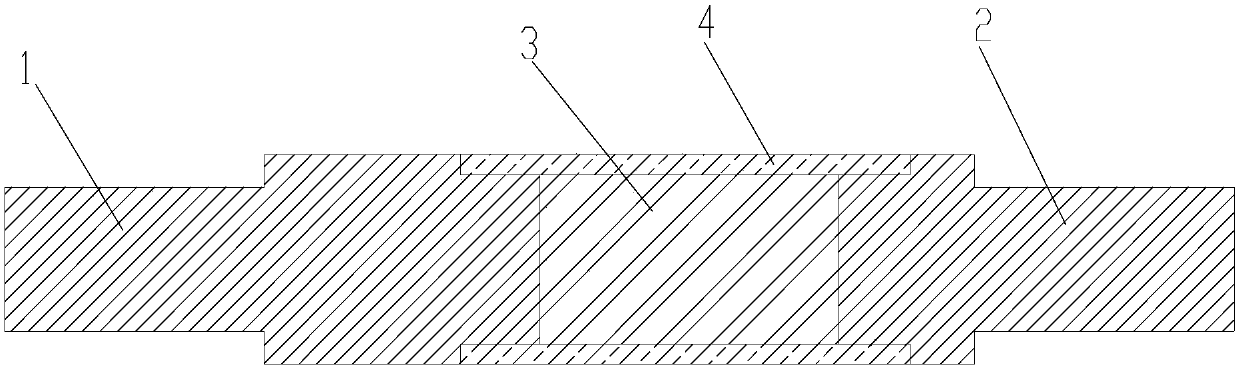

File holder with vernier-type indexes and separation pieces

ActiveCN103735049APrevent left and right tiltReduce usageBook cabinetsBook-troughsEngineeringLeft wall

The invention discloses a file holder with vernier-type indexes and separation pieces, and belongs to the technical field of file holders. The file holder comprises a left wall plate, a right wall plate, a rear wall plate, a front wall plate and a base plate. The front wall plate is lower than the rear wall plate. A straight track which is parallel to the base plate and extends leftwards and rightwards is arranged on the front wall plate. Vernier-type parts are matched with the straight track and can move leftwards and rightwards along a movement track. Each vernier-type part comprises three portions, index devices of the vernier-type parts are arranged at the front ends of the vernier-type parts respectively, track sleeving and hanging devices matched with the straight track are arranged close to the index devices, and the separation pieces of the vertical-stacking file holder are arranged at the other ends of the vernier-type parts. The file holder is easy to produce and simple and convenient to operate, the thickness of storage units can be adjusted by one hand, and the separation pieces can prevent leftward and rightward inclination of files; the separation pieces do not need to contact with the rear wall plate and the bottom plate, so that the area of each separation piece can be much smaller than the area of a separation plate of a conventional vertical-stacking file holder, and raw materials are greatly reduced.

Owner:王春明

Rotor shaft assembly, rotor and motor

ActiveCN108054867AAchieve axial positioningAvoid prone to axis misalignment problemsBearing assemblyMagnetic circuitEngineeringMechanical engineering

The invention provides a rotor shaft assembly, a rotor and a motor. The rotor shaft assembly comprises a magnetic core, a first end shaft, a second end shaft and a protection sleeve. A first through hole, a second through hole and a third through hole are formed in the protection sleeve in sequence, the first end shaft penetrates through the first through hole, at least part of the magnetic core is arranged in the second through hole, and the second end shaft penetrates through the third through hole; the minimum distance between the center line of the protection sleeve and the hole wall of the first through hole is a, the minimum distance between the center line of the protection sleeve and the hole wall of the second through hole is b, and the minimum distance between the center line ofthe protection sleeve and the hole wall of the third through hole is c, wherein one or two of a and c are not equal to b. According to rotor shaft assembly, the problem is solved that in the prior art, when the end shafts and magnetic steel of a rotor shaft assembly are assembled, and the axis is not easily centered.

Owner:GREE ELECTRIC APPLIANCES INC

A solid/liquid composite horizontal continuous casting forming equipment and method for coating material

The invention discloses clad material solid / liquid composite horizontal continuous casting and forming equipment and method, and belongs to the technical field of clad material continuous casting. According to the clad material solid / liquid composite horizontal continuous casting and forming equipment and method, the measures that a core material protection device, a flow guide pipe, an inversion solidification device and the like are adopted and mounted below a crucible, core materials are not heated in advance, the inversion solidification device with small capacity is designed, the core materials are prevented from penetrating through clad layer melt metal for a long time, the melt metal flows out from the bottom of the crucible by relying on self-weight, and the size of the inversion solidification device and the size of a water-cooled crystallizer are controlled effectively are taken, the high quality clad materials of needed shapes and sizes are formed through horizontal continuous casting, and the equipment and the method are especially suitable for horizontal continuous casting forming of the large-size clad materials which are hard to reel up and has the melting point of the clad layer metal lower than that of the core material metal. The equipment and method have the advantages that the equipment is simple in structure, parts are easy to replace, operation and maintenance are convenient to carry out, layout is reasonable and compact, production efficiency is high, investment is small, automatic control is easy to achieve, large-scale industrial production is facilitated, the procedure of the forming process is short, energy is saved, environment is protected, efficiency is high, cost is low, the combination freedom of the clad layer metal and the core material metal is large, and the prepared clad materials are good in quality and performance.

Owner:UNIV OF SCI & TECH BEIJING

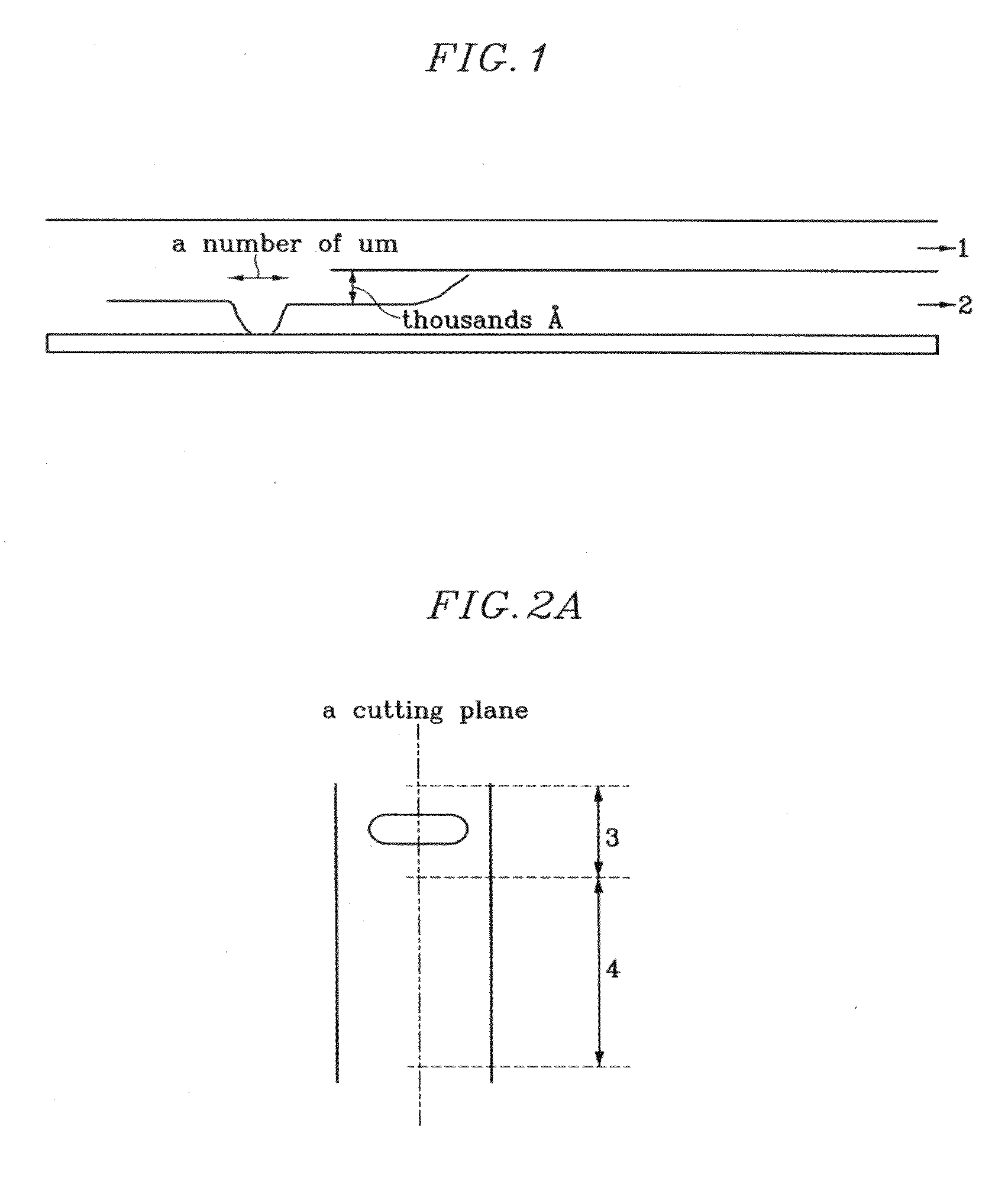

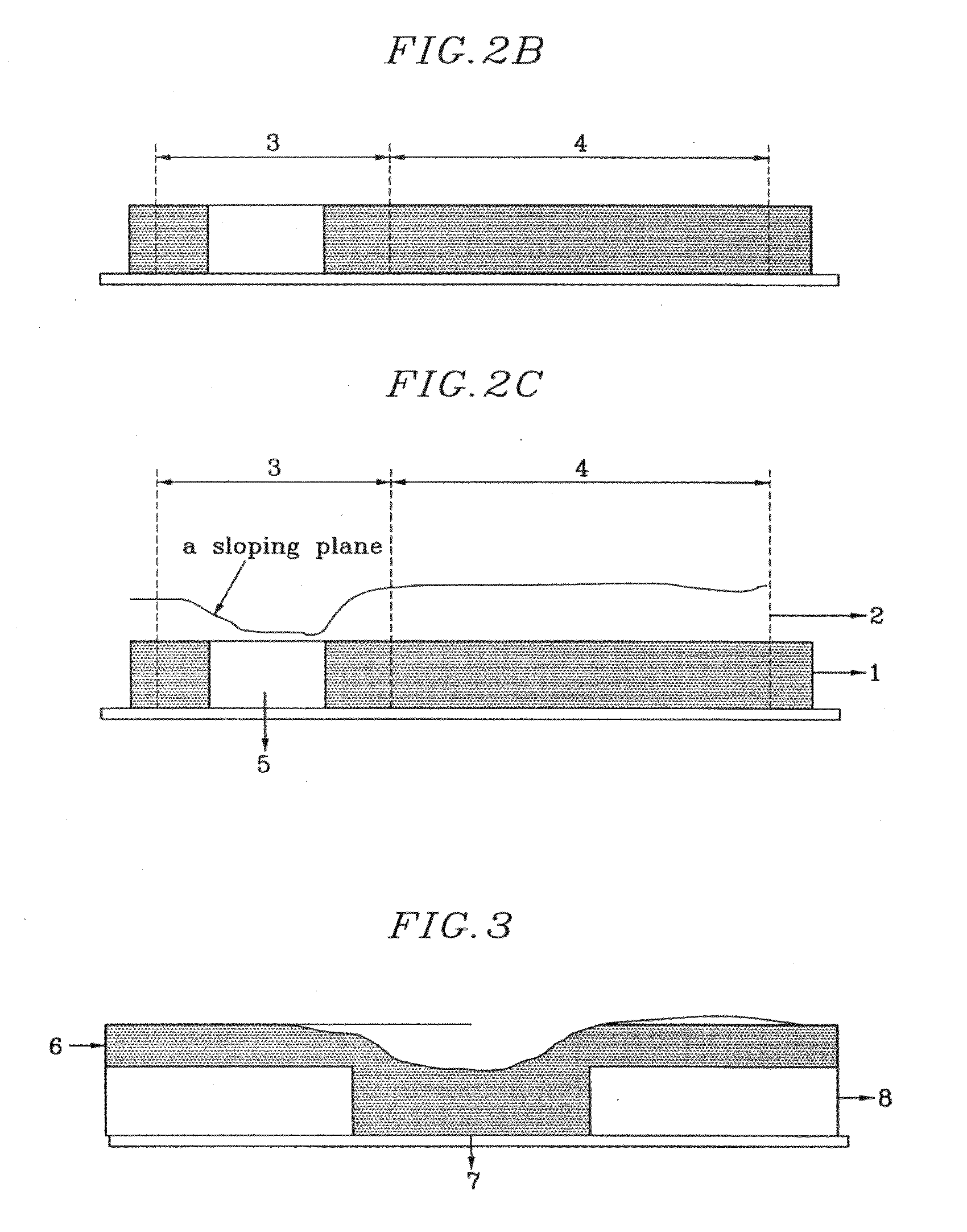

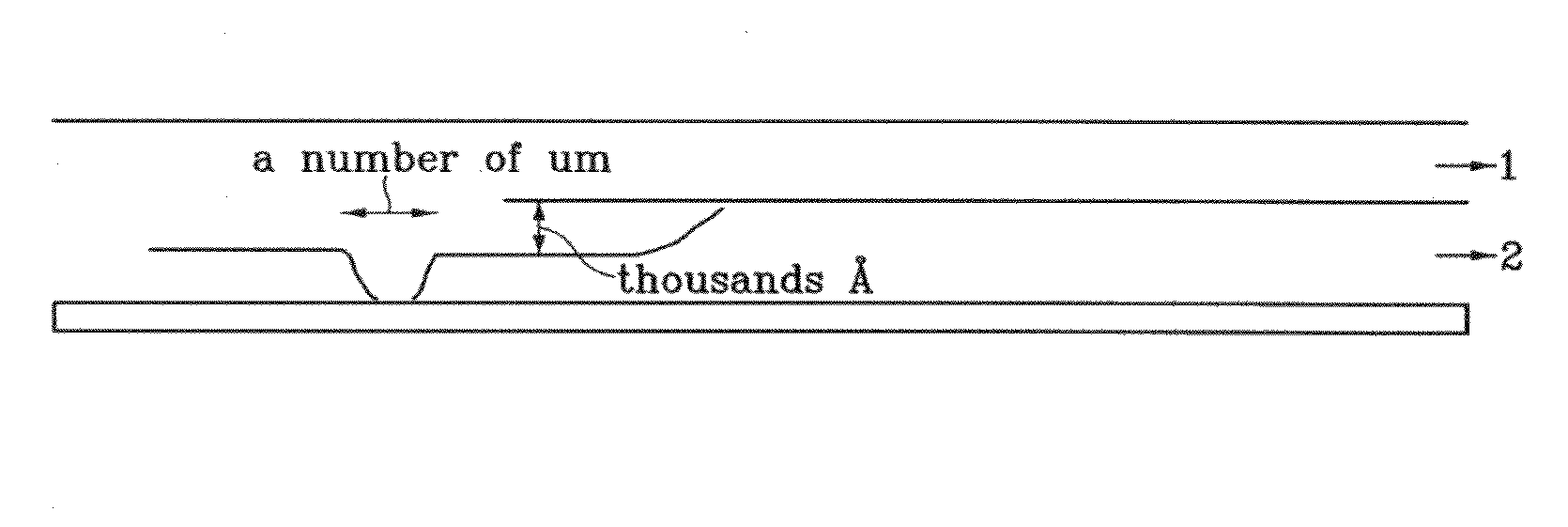

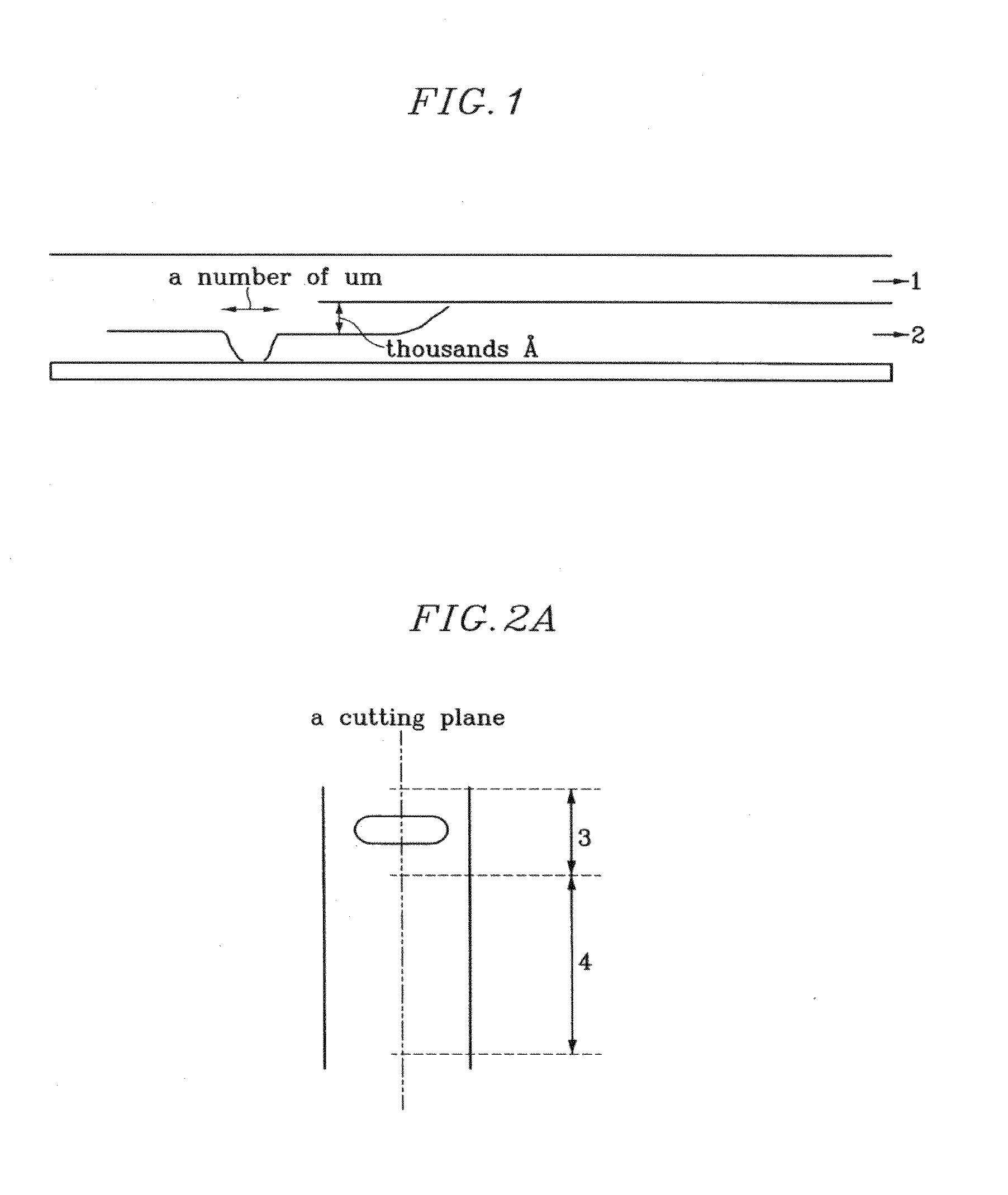

Photosensitive resin composition controlling solubility and pattern formation method of double-layer structure using the same

InactiveUS20090191484A1Gradual solubilityPreventing film breakupPhoto-taking processesPhotosensitive materialsSolubilityLiquid-crystal display

The present invention relates to a new photosensitive resin composition capable of solubility control and a pattern formation method of a double-layer structure using the same, and more particularly to a photosensitive resin composition that can control the -value using a new photopolymerization initiator and lower layer hardener and that can control a film thickness according to the exposure energy without pattern breakup, even with low exposure energy. This photosensitive resin composition is useful for color filters and overcoating materials of LCD (liquid crystal display) manufacturing processes.

Owner:SAMSUNG DISPLAY CO LTD

Photosensitive resin composition controlling solubility and pattern formation method of double-layer structure using the same

InactiveUS7611826B2Gradual solubilityPreventing film breakupPhoto-taking processesPhotosensitive materialsLiquid-crystal displayDisplay device

The present invention relates to a new photosensitive resin composition capable of solubility control and a pattern formation method of a double-layer structure using the same, and more particularly to a photosensitive resin composition that can control the -value using a new photopolymerization initiator and lower layer hardener and that can control a film thickness according to the exposure energy without pattern breakup, even with low exposure energy. This photosensitive resin composition is useful for color filters and overcoating materials of LCD (liquid crystal display) manufacturing processes.

Owner:SAMSUNG DISPLAY CO LTD

Golf club head with improved variable thickness striking face

A golf club head with improved striking face performance is disclosed herein. More specifically, a golf club head includes a striking face with a thickened central region surrounded by transition region that reduces radially in thickness as it extends away from the central region is disclosed. The striking face geometry results in more uniform characteristic time measurements across a large percentage thereof.

Owner:ACUSHNET CO

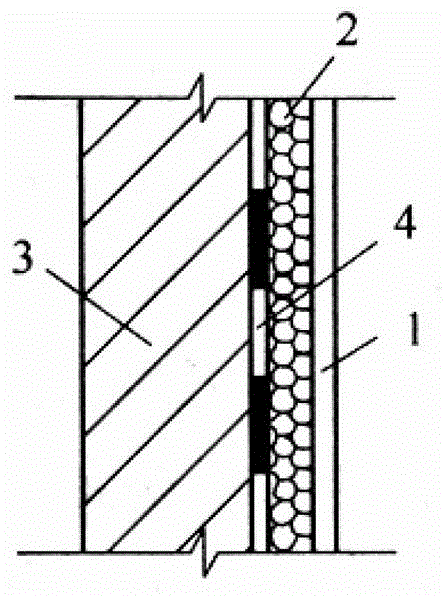

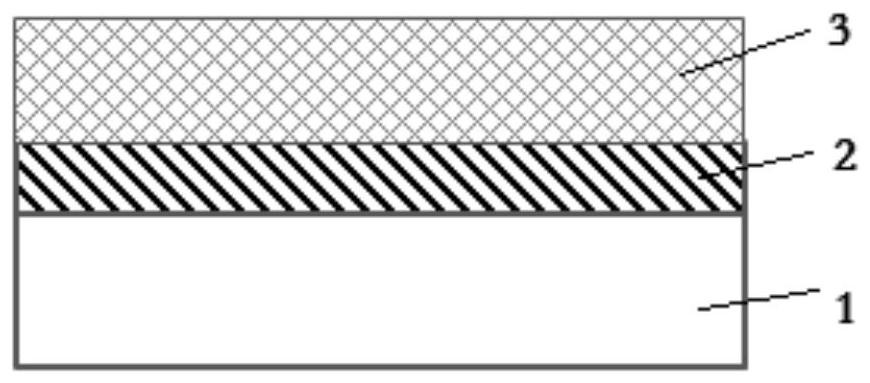

Composite interior thermal insulation wall

The invention discloses a composite interior thermal insulation wall which comprises an interior surface layer, an insulating layer, a base wall body and a bonding layer. The bonding layer is arranged on the outer side of the base wall body, the insulating layer is arranged on the other side of the bonding layer, and a light building board layer or the interior surface layer is arranged on the other side of the insulating layer. The base wall body is constructed by shale perforated bricks and / or air bricks. The insulating layer is composited by thermal insulating materials. The light building board layer is gypsum boards, calcium silicate boards, fiber cement boards or GRC boards. The composite interior thermal insulation wall has the advantages of being good in thermal insulating effect and convenient to construct and maintain.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

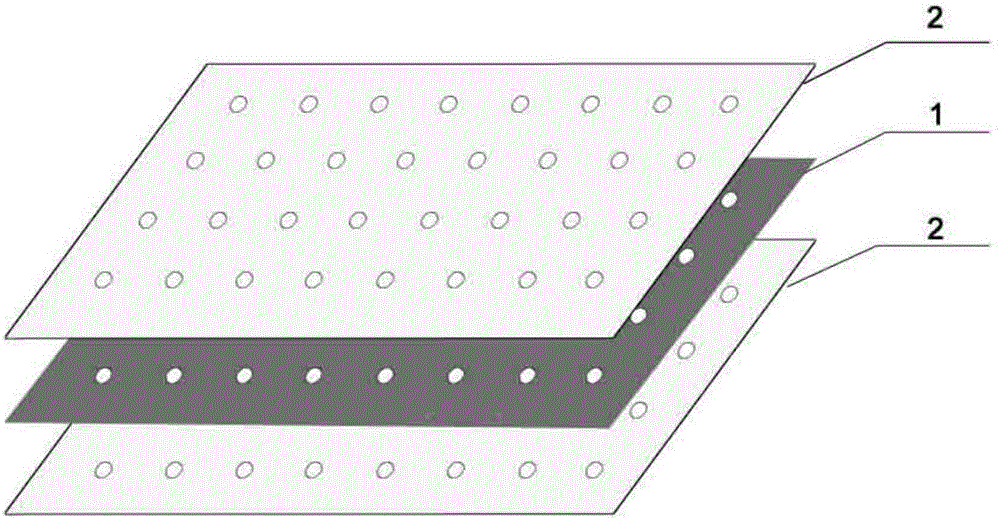

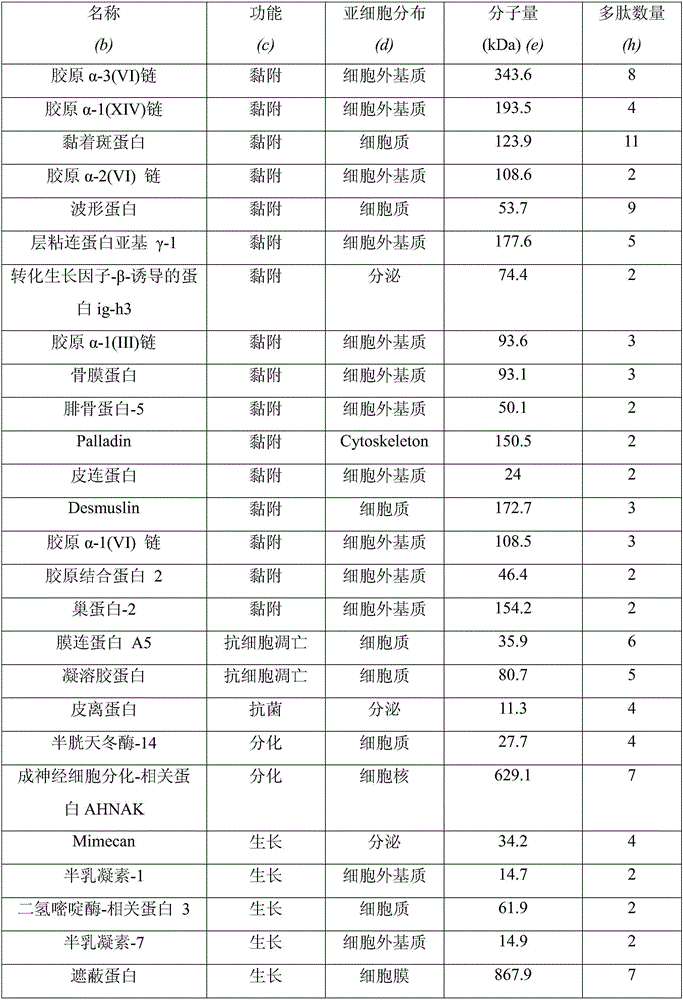

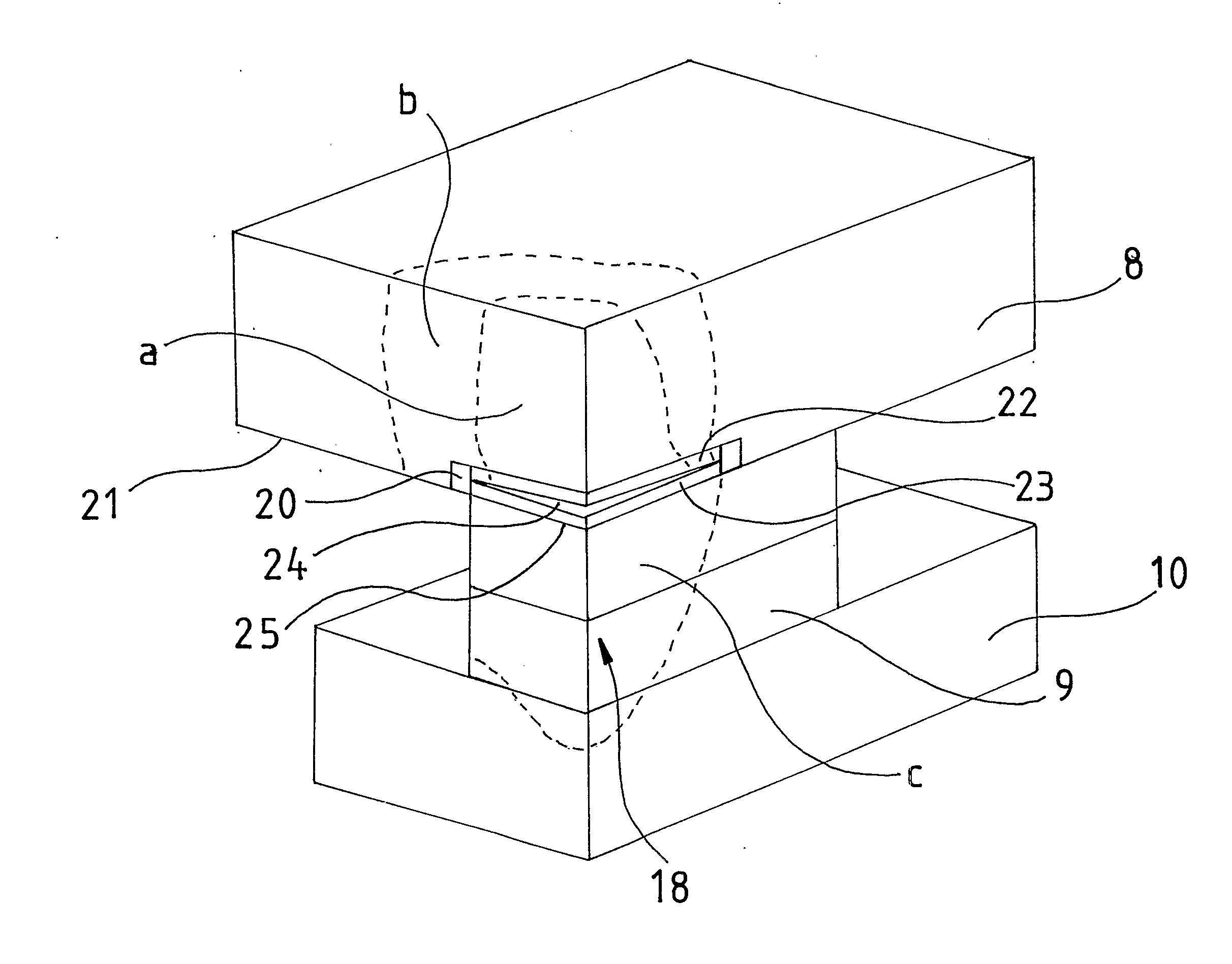

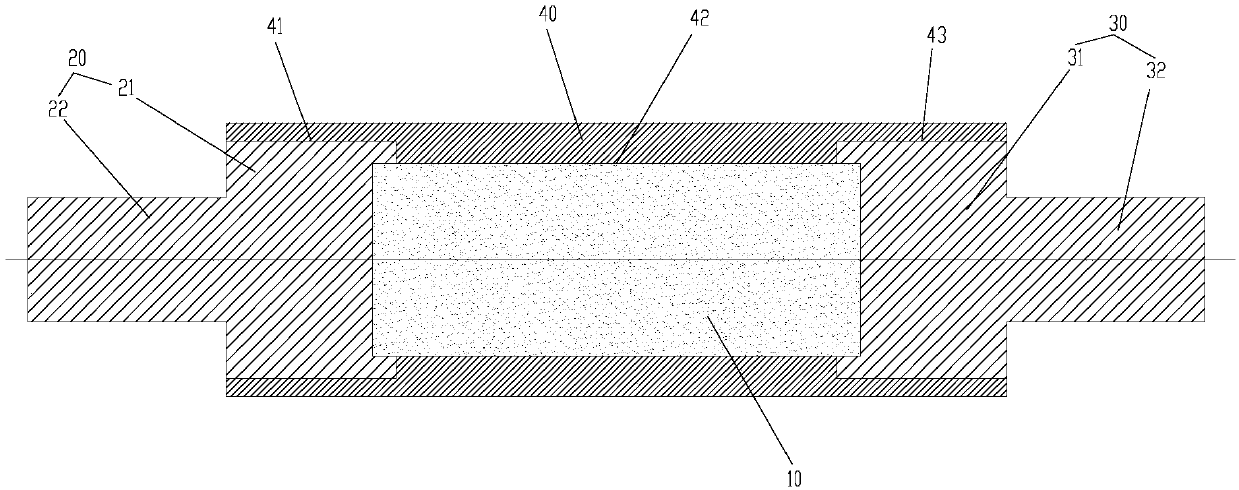

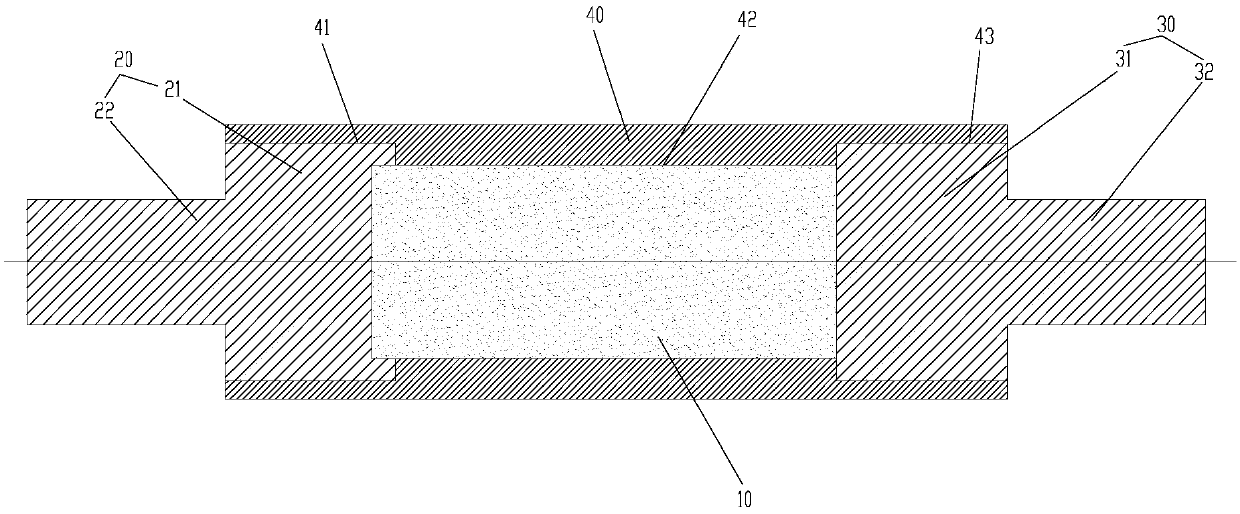

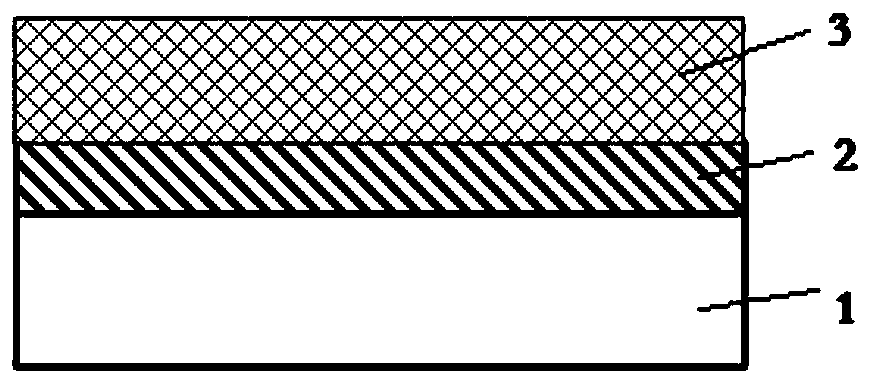

A composite extracellular matrix component biomaterial

ActiveCN105920669BLight adhesionImprove adhesionTissue regenerationProsthesisCell-Extracellular MatrixPelvic diaphragm muscle

A composite extracellular matrix biomaterial, with a middle layer comprising a decellularized small intestinal submucosa (SIS) (1), and a top layer and a bottom layer comprising a decellularized urinary bladder matrix (UBM) (2). The top and bottom layers completely cover the middle layer, thereby forming a sandwich structure. The sandwich structure allows the UBM (2) to isolate an antigenic property of the SIS (1) and to allowing the UBM to directly contact a host tissue, thereby realizing a high tissue compatibility. The SIS (1) can compensate for a shortcoming of low mechanical strength of the UBM (2). The composite extracellular matrix biomaterial can be used to fill, strengthen, repair, or reconstruct a damage or defect of a fascia, meninges, pleura, pelvic floor, dermis, solid organ, and various types of soft tissues.

Owner:EXCELLENCE MEDICAL TECH SUZHOU CO LTD +1

Carbon fiber-based composite material and preparation method thereof

ActiveCN111005026AThe interface binding force is stableImprove the interface binding forceMolten spray coatingVacuum evaporation coatingCeramic coatingCermet

The invention discloses a carbon fiber-based composite material and a preparation method thereof. The carbon fiber-based composite material sequentially comprises a carbon fiber base body, a bottom coating and a surface coating, wherein the carbon fiber base body is a carbon fiber tube or a carbon fiber plate, the bottom coating is a copper coating deposited by adopting arc ion plating, and the surface coating is a metal coating or a metal ceramic coating. According to the carbon fiber-based composite material disclosed by the invention, the copper coating prepared by adopting an electric arcion plating process is used as the bottom coating, so that the limitation on the shape of the carbon fiber base body is small, the plating structure is uniform, and the interface bonding force of thecarbon fiber-based composite material is improved; the metal coating or the metal ceramic coating is used as the surface coating, the components, the thickness and the process of the surface coating can be selected according to actual requirements, the functionality of the composite material is ensured, and finally diversified application is achieved.

Owner:GUANGDONG INST OF NEW MATERIALS

Biological anti-adhesion repairing auxiliary material and preparation method thereof

The invention relates to a biological anti-adhesion repairing auxiliary material and a preparation method thereof. A synthetic material or a cross-linked materialis used as an intermediate anti-adhesion layer of the biological anti-adhesion repairing auxiliary material, natural extracellular matrix is upper and lower surface layers, and the surface layers cover the intermediate anti-adhesion layerto form a sandwich structure. The biological anti-adhesion repairing auxiliary material can releasemany growth factors during degradation, provide a good physiological environment for inhibiting fibrosis, inhibiting inflammation and reducing bleeding for damaged tissue regeneration, thereby promoting healing, can be used as a good tissue substitute before a damaged part is regenerated, and can effectively prevent the occurrence of adhesion.

Owner:BEIJING DATSING BIO TECH

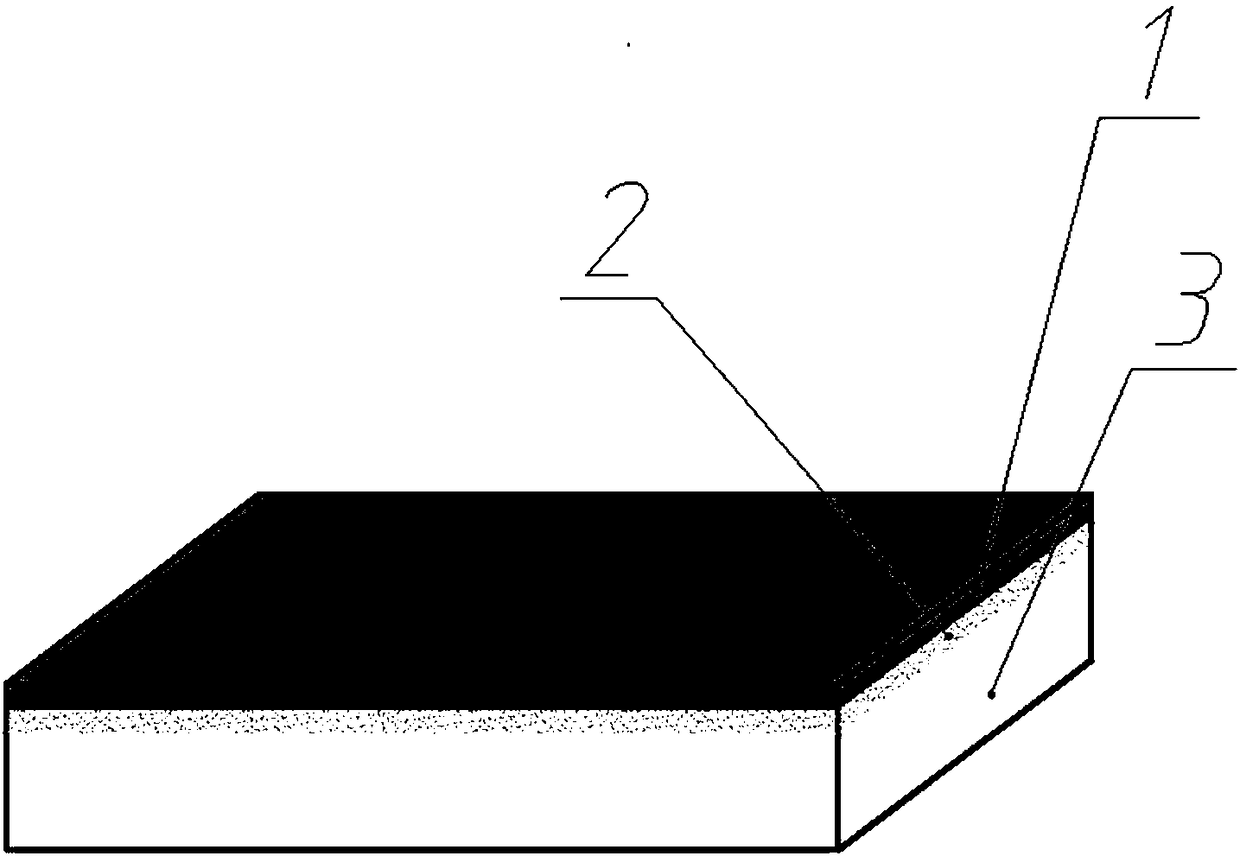

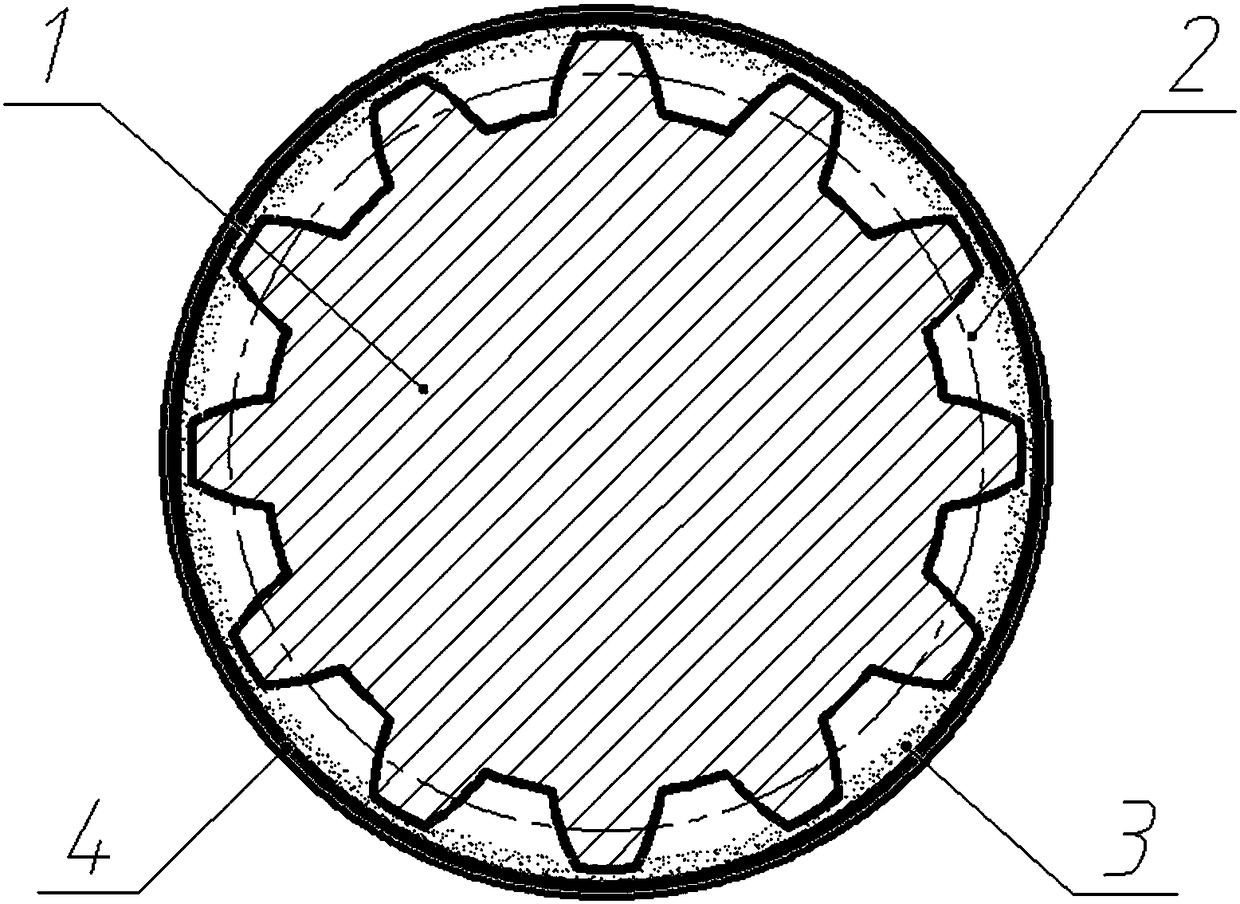

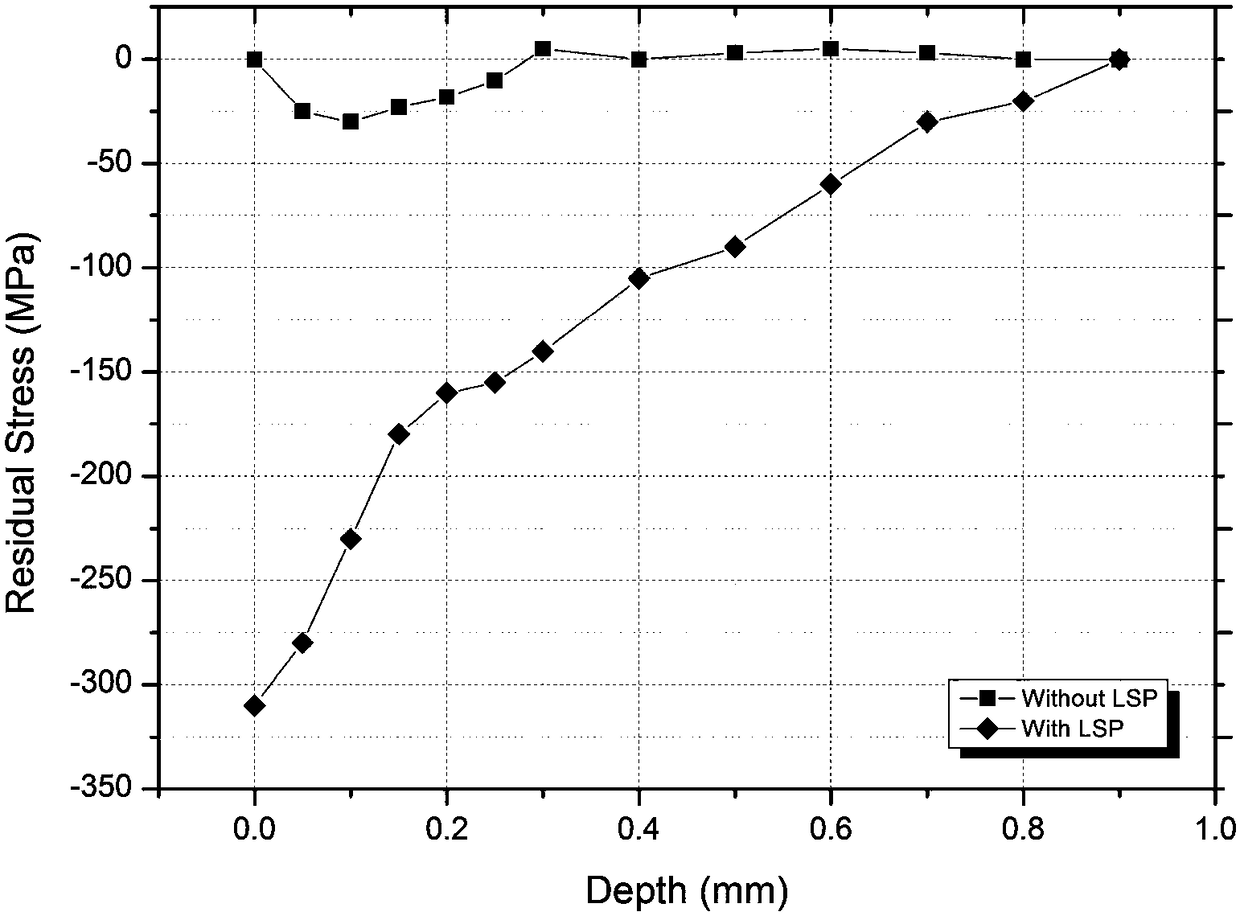

A flexible variable absorbing layer of thickness and its preparation and use method

ActiveCN105936961BVariable thicknessEasy to cleanFurnace typesHeat treatment furnacesVariable thicknessShock treatments

Owner:XINGHUA SANCHENG PRECISION FORGING

A kind of carbon fiber matrix composite material and preparation method thereof

ActiveCN111005026BThe interface is firmly bondedGuaranteed functionalityMolten spray coatingVacuum evaporation coatingMetal coatingCarbon fibers

Owner:GUANGDONG INST OF NEW MATERIALS

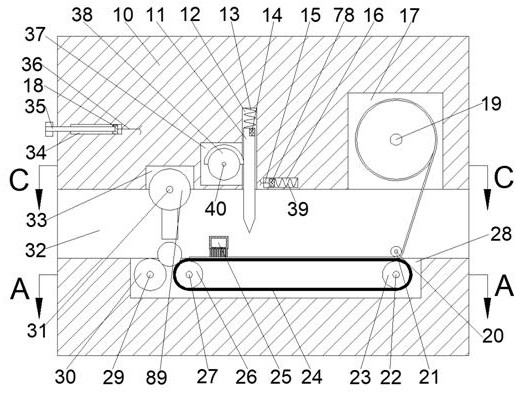

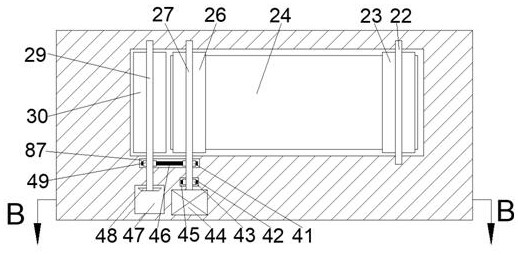

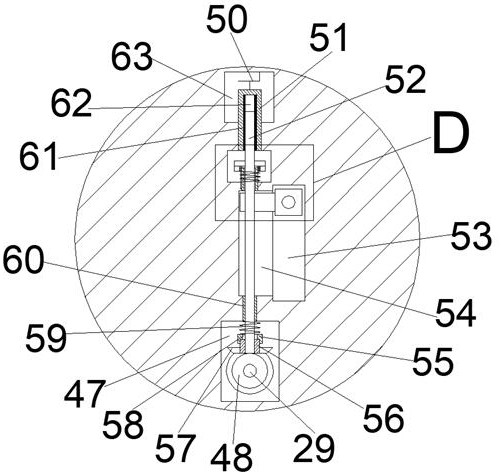

Device suitable for coiling and forming carbon fiber pipes with different diameters and different wall thicknesses

InactiveCN112265291ACoiled tubing is tightly formedCutting length can be changedTubular articlesFiberCarbon fibers

The invention relates to the related field of new materials, and discloses a device suitable for coiling and forming carbon fiber pipes with different diameters and different wall thicknesses. The device comprises a main box body, wherein a feeding cavity is formed in the main box body in a left-right penetrating mode, the upper side of the feeding cavity communicates with a carbon fiber storage cavity, and the lower side of the feeding cavity communicates with a conveying belt cavity; the upper side of the feeding cavity communicates with a pipe core pressing wheel cavity, the upper side of the feeding cavity communicates with a cutting knife sliding cavity, and the left side of the cutting knife sliding cavity communicates with a half gear cavity. Carbon fibers are automatically cut offduring coiling and forming, the step of cutting the carbon fibers before pipe coiling is omitted, the pipe coiling efficiency is greatly improved, and meanwhile the carbon fiber cutting length can bechanged; and the pipe coiling thickness is variable, the applicability of the device is guaranteed, the device is suitable for the pipe coiling process of pipe cores with different diameters due to automatic clamping of a pipe core pressing wheel, meanwhile, the pipe cores are clamped in three directions through a rotating wheel, the pipe core pressing wheel and a left conveying wheel, carbon fiber pipe coiling and forming are more compact, and the forming quality of the carbon fiber pipes is greatly improved.

Owner:TAIZHOU LUQIAO NANRUI INTELLIGENT EQUIP TECH CO LTD

Solid/liquid composite double solidification continuous casting forming equipment and method for coating material

The invention belongs to the technical field of clad material continuous casting, in particular to clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method. The clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method are characterized in that inversion solidification and forward solidification continuous casting and forming are combined, the measures that core materials are not heated in advance, an inversion solidification device with small capacity is designed, the core materials are prevented from penetrating through clad layer melt metal for a long time, the melt metal flows out from the bottom of a crucible by relying on self-weight, and the size of the inversion solidification device and the size of a water-cooled crystallizer are controlled effectively are taken, the high quality clad materials of needed shapes and sizes are formed through continuous casting, and the equipment and the method are especially suitable for continuous casting forming of the high quality clad materials with the melting point of the clad layer metal lower than that of the core material metal. The equipment and method have the advantages that the equipment is simple in structure, parts are easy to replace, operation and maintenance are convenient to carry out, layout is reasonable and compact, investment is small, industrialized application and popularization are facilitated, the procedure of the forming process is short, energy is saved, environment is protected, cost is low, the combination freedom of the clad layer metal and the core material metal is large, and the prepared clad materials are good in quality and performance.

Owner:UNIV OF SCI & TECH BEIJING

Apparatus and method for compensating for stress deformations in a press

InactiveUS8342085B2Good compensationImprove the level ofShaping toolsForging/hammering/pressing machinesAbutmentBiological activation

An apparatus is provided for compensating for such deformations as occur in operation in first and second clamping surfaces intended for a tool in a press. The clamping surfaces are reciprocally moveable towards and away from one another in order to move a first and second part of the tool towards and away from one another, and the first and second tool parts have a first and second abutment surface for abutment against the first and second clamping surfaces and the deformations cause uneven pressure in at least one contact region between the tool and the clamping surfaces. According to the present invention, there is disposed, in at least one contact region between a clamping surface and an abutment surface, a power unit which, on activation, is operative to press, away from the clamping surface located in the contact region at least a part of the abutment surface of the tool located there.

Owner:AUTOMATION PRESS & TOOLING AP&T

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com