Carbon fiber-based composite material and preparation method thereof

A composite material and carbon fiber technology, which is applied in metal material coating process, ion implantation plating, pressure inorganic powder plating, etc., can solve the problems that internal fibers are difficult to be plated with metal, the coating thickness is limited, and the actual application distance is long. , to achieve the effect of stabilizing the interface bonding force, improving the interface bonding force, and ensuring functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

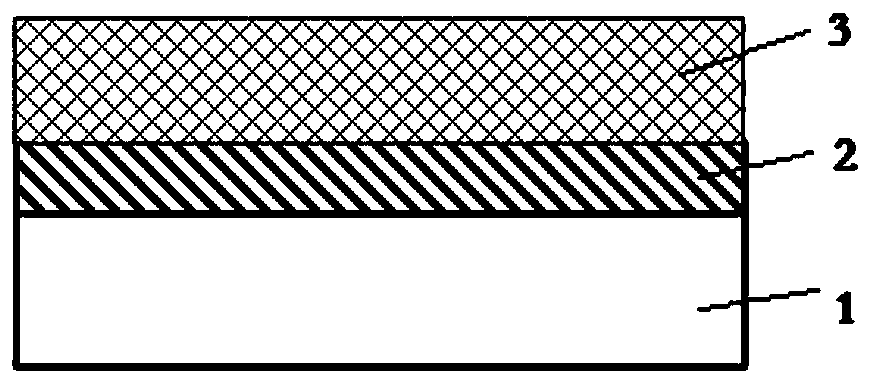

[0035] A carbon fiber matrix composite material such as figure 1 As shown, it includes a carbon fiber substrate 1, an undercoat 2 and a topcoat 3 in sequence; the carbon fiber substrate 1 is a carbon fiber plate, the undercoat 2 is a copper coating deposited by arc ion plating, and the topcoat 3 is silver conductive coating.

[0036] The preparation method of the carbon fiber matrix composite material of the present embodiment comprises the following steps:

[0037] 1) Carry out high-temperature heating and degumming treatment on the carbon fiber board: raise the temperature of the box-type electric furnace to 350 degrees, place the carbon fiber board in the furnace, keep it warm for 30 minutes, and cool down with the furnace;

[0038] 2) Place the above-mentioned carbon fiber plate in a vacuum cathodic arc ion plating machine and fix it on the workpiece frame. The workpiece frame can revolve or rotate, and then clean in the furnace, and use ions to bombard the surface of the...

Embodiment 2

[0043] The structure and preparation method of a carbon fiber-based composite material are basically the same as in Example 1, the difference is that in step 2) of the preparation method of the carbon fiber-based composite material of this embodiment:

[0044] The specific parameters of arc ion plating are as follows: the target is Cu target, the auxiliary gas is N 2 and Ar, the air pressure is 4Pa, the purity is 99.99%, the electromagnetic coil voltage is 25V, the target current is 150A, the negative bias voltage is 80V, the workpiece revolution speed is 4r / min, the coating time is 480min, and the deposited film thickness is controlled at 10-15μm.

[0045] The interfacial bond strength of the carbon fiber-based composite material in this example is >30MPa.

Embodiment 3

[0047] The structure and preparation method of a carbon fiber-based composite material are basically the same as in Example 1, the difference is that in step 2) of the preparation method of the carbon fiber-based composite material of this embodiment:

[0048] The specific parameters of arc ion plating are as follows: the target is Cu target, the auxiliary gas is N 2 And Ar, the gas pressure is 2Pa, the purity is 99.99%, the electromagnetic coil voltage is 10V, the target current is 50A, the negative bias voltage is 20V, the workpiece revolution speed is 3r / min, the coating time is 400min, and the deposited film thickness is controlled at 10-15μm.

[0049] The interfacial bonding strength of the carbon fiber matrix composite material in this example is <10MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com