Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Uneven suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

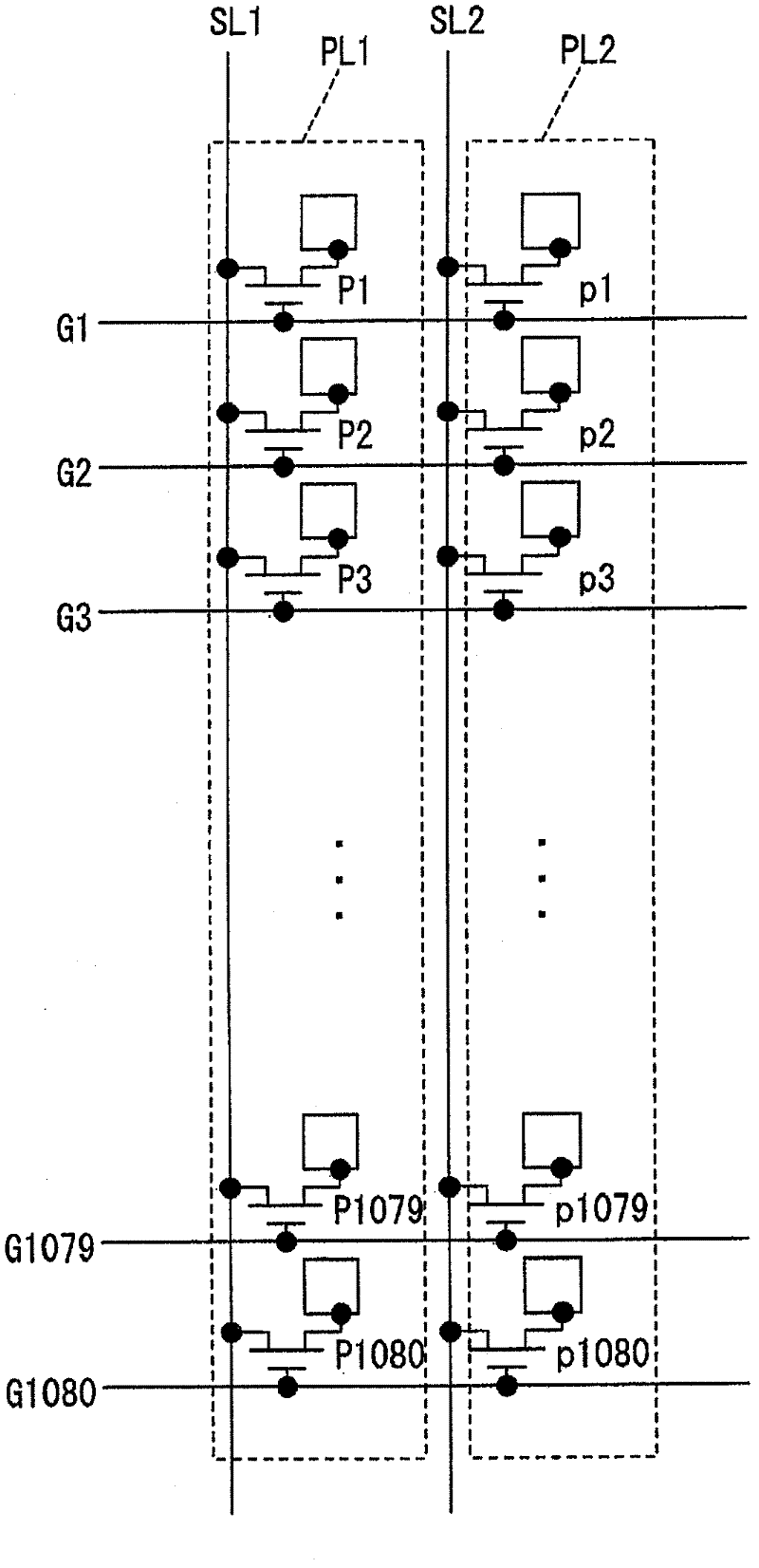

Touch panel

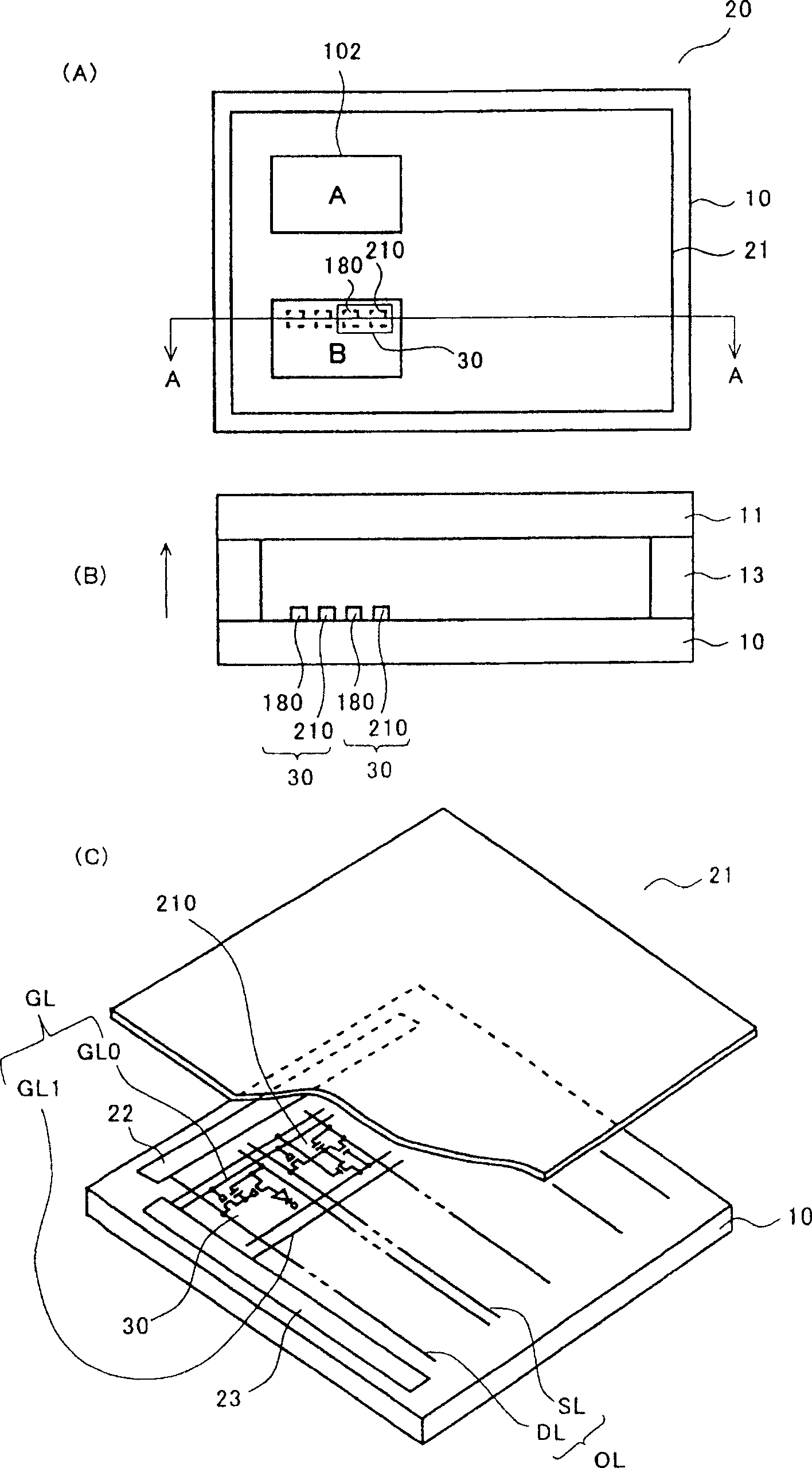

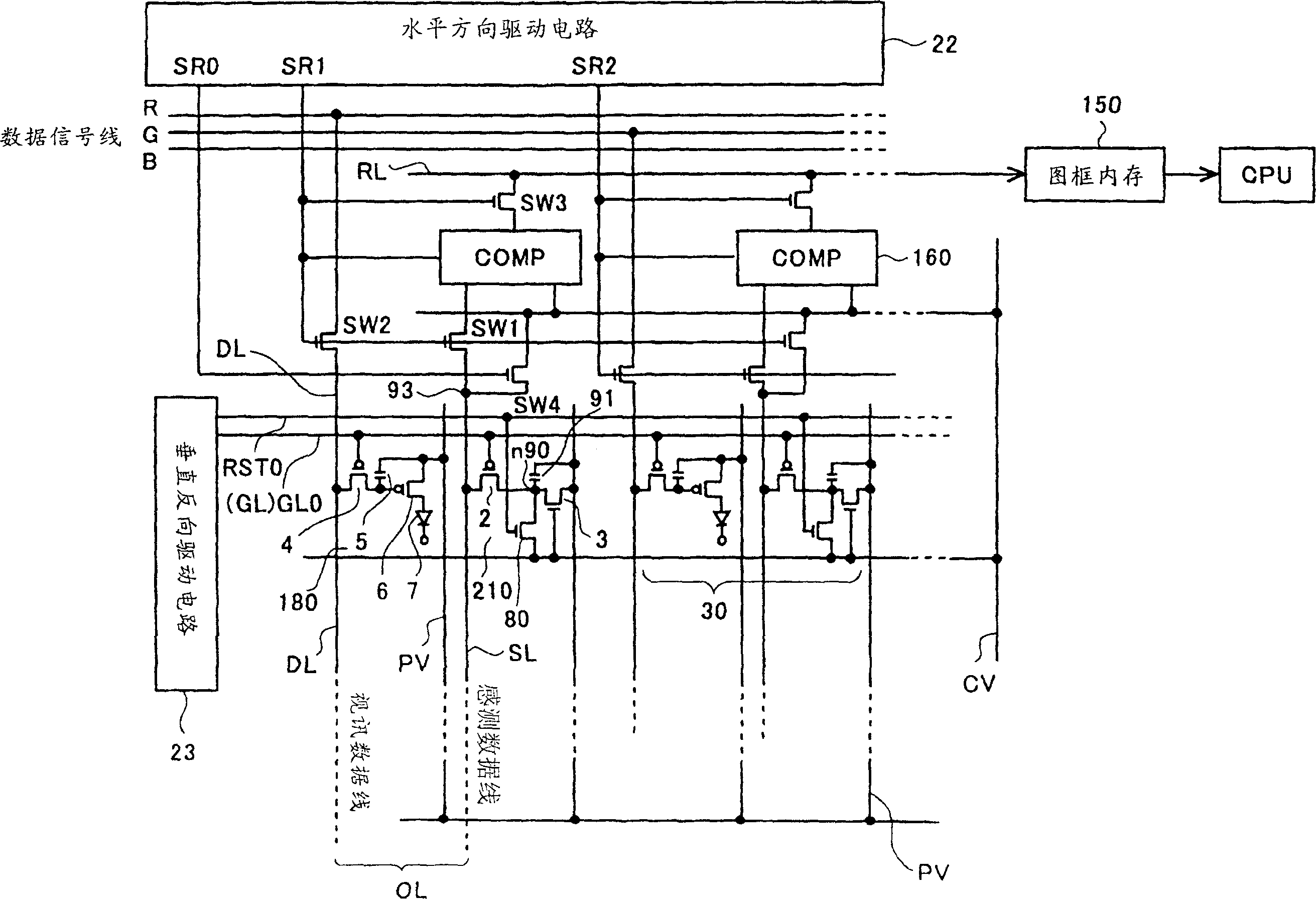

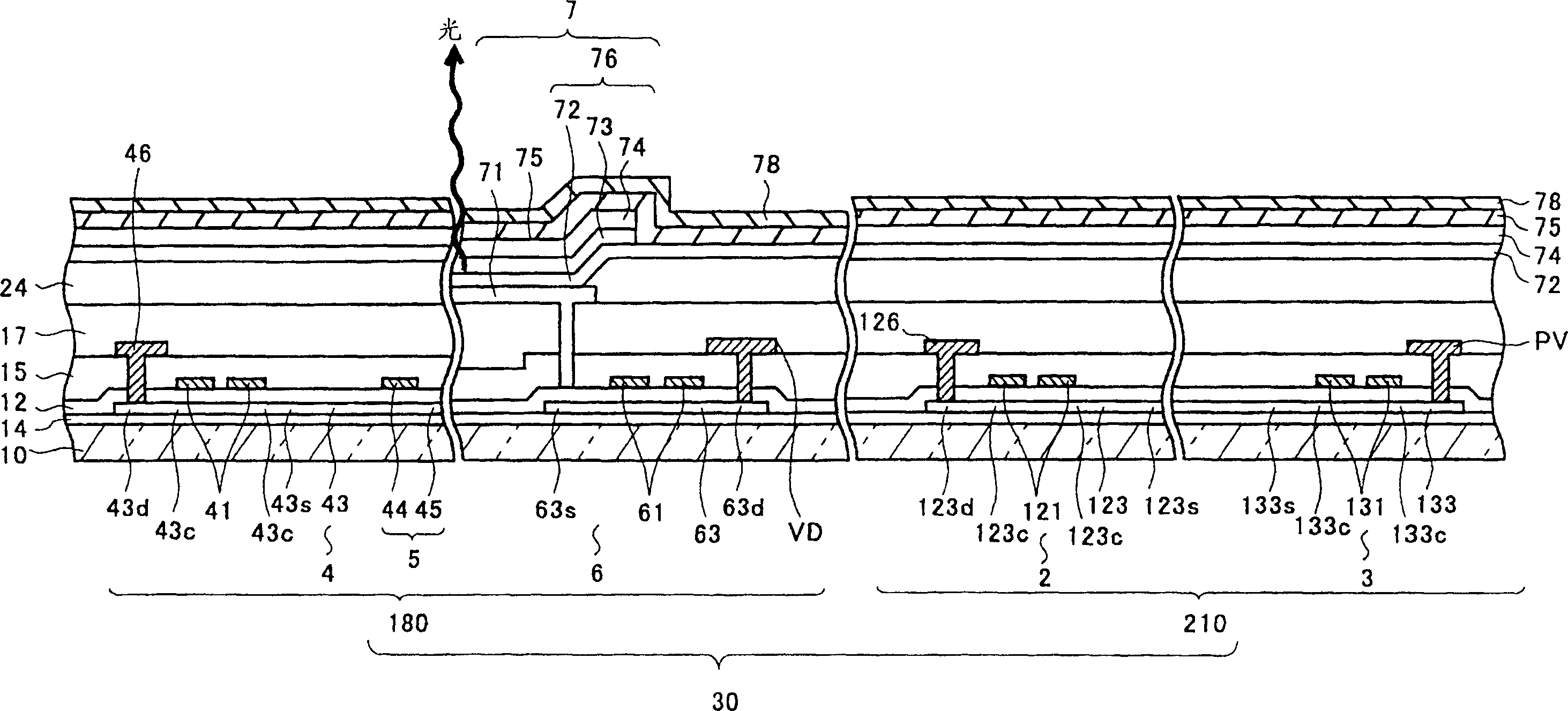

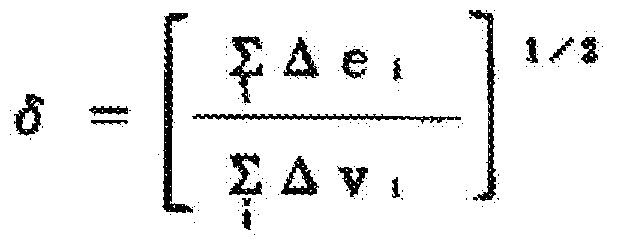

InactiveCN1758197AIncrease the display areaInhibit deteriorationGraph readingMechanical pattern convertionMiniaturizationEngineering

The present invention relates to a touch panel, and a photosensor and the display part are fabricated on the same substrate. Input coordinates are specified by comparing the light quantities among positions (pixels) of contact or non-contact by a finger or the like by using a comparator. This allows TFTs constituting the photosensor to be fabricated on the same substrate in the same process as the pixels, and it is thereby possible to reduce the manufacturing cost and the number of components. A region for disposing a sensor in the outer portion becomes unnecessary, which allows downsizing of the device. Moreover, effective use of the display part is possible because blind spots are eliminated from the display part. It is possible to improve the precision of input recognition and to perform detection uniformly over the entire display part. Furthermore, since the photosensor comprises a photoreceptor circuit capable of adjusting the light-receiving sensitivity, it is possible to achieve uniform light-receiving (detection) sensitivity for the display part.

Owner:SANYO ELECTRIC CO LTD

High temperature resistant thermal insulation coating

InactiveCN102241936AImprove high temperature resistanceReduce surface temperatureCoatingsEmulsionThermal insulation

The invention discloses a high temperature resistant thermal insulation coating, containing acrylic emulsion, fluorinated silicone rubber, film forming aid, a dispersing agent, pigment filler, water, and the like. The coating has the advantage of excellent high-temperature resistance so that the coating can be used on the surface of an object at a temperature of -80 DEG C to 1100 DEG C; meanwhile, the coating has the advantage of excellent thermal insulation effect so that the temperature of the surface of the object can be obviously reduced and more than 30% of heat loss can be decreased. The coating can be applied to inside and outside surfaces of all kinds of high temperature pipelines, furnaces and kilns.

Owner:开平市日固力涂料有限公司

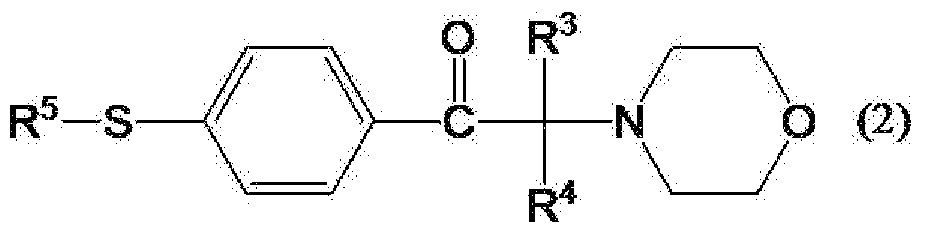

Adhesive composition curable with actinic energy ray, polarizer, optical film, and image display device

ActiveCN103298897AIncreased durabilityImprove water resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesVitrificationPolarizer

An adhesive composition curable with actinic energy rays which comprises 20-60 wt.% radical-polymerizable compound (A) that has an SP value of 29.0-32.0 (kJ / m3)1 / 2, 10-30 wt.% radical-polymerizable compound (B) that has an SP value of 18.0-21.0 (kJ / m3)1 / 2, excluding 21.0 (kJ / m3)1 / 2, and 20-60 wt.% radical-polymerizable compound (C) that has an SP value of 21.0-23.0 (kJ / m3)1 / 2, wherein the radical-polymerizable compounds (A), (B), and (C) each gives a homopolymer which has a glass transition temperature (Tg) of 60 C or above.

Owner:NITTO DENKO CORP

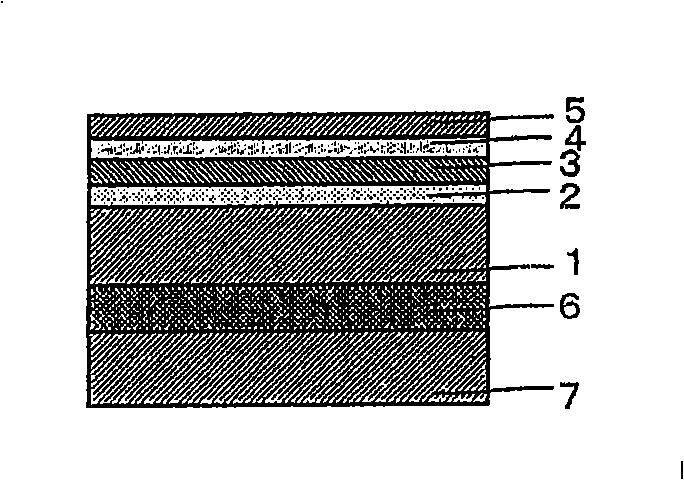

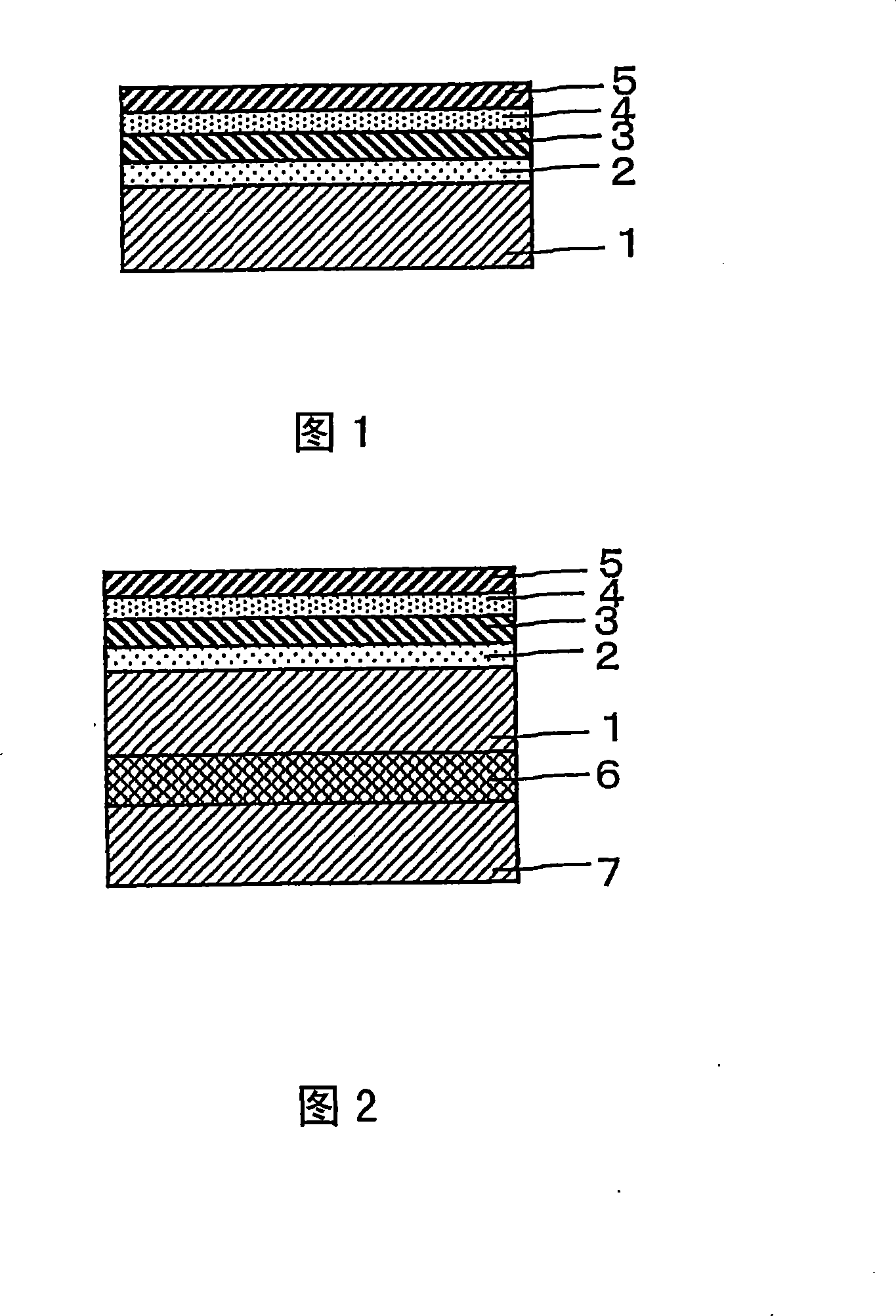

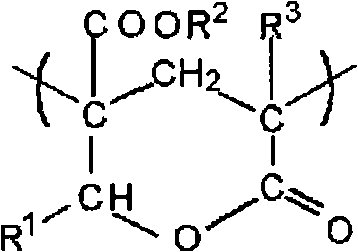

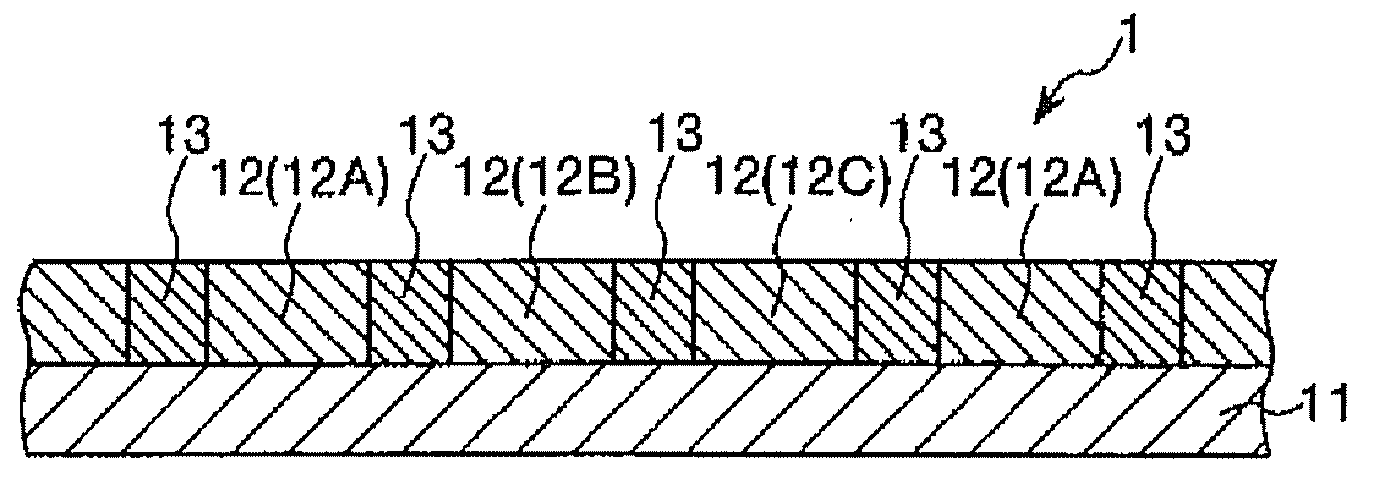

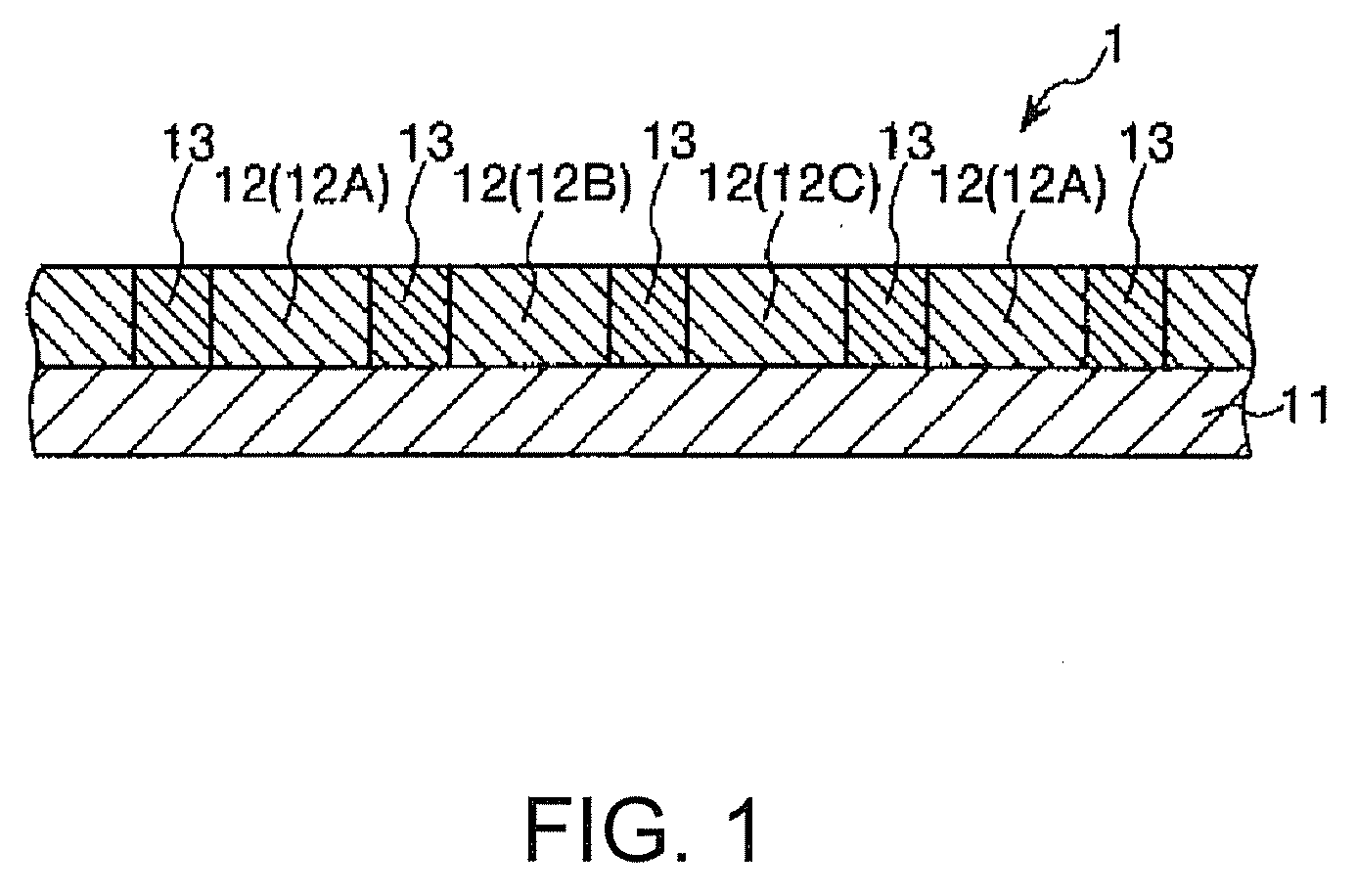

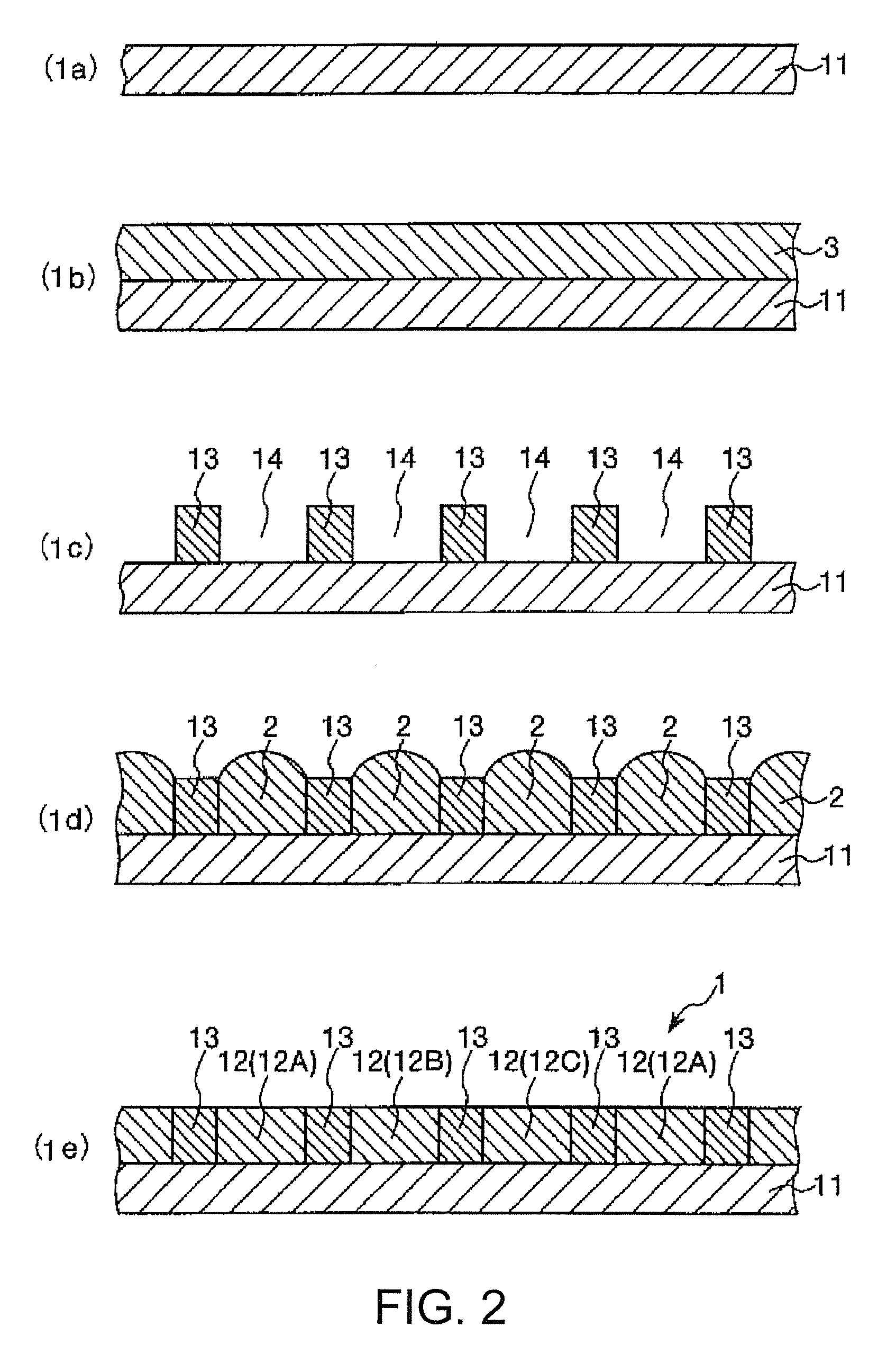

Pressure-sensitive adhesive optical film and image display

ActiveCN101303419AUneven suppressionLow moisture permeabilityLiquid crystal compositionsSynthetic resin layered productsMeth-Antioxidant

A pressure-sensitive adhesive optical film of the present invention comprises: an optical film comprising a transparent base film and a discotic liquid crystal layer provided on one side of the transparent base film; an undercoat layer; and a pressure-sensitive adhesive layer provided on the discotic liquid crystal layer with the undercoat layer interposed therebetween, the undercoat layer comprises a polymer and an antioxidant; and the pressure-sensitive adhesive layer comprises a (meth)acrylic polymer (A) comprising 80 to 99.5% by weight of an alkyl (meth)acrylate monomer unit and 0.05 to 3% by weight of a hydroxyl group-containing monomer unit and having a weight average molecular weight of 1,000,000 to 2,500,000; ; a (meth)acrylic oligomer (B) comprising 80 to 99.9% by weight of an alkyl (meth)acrylate monomer unit and 0.1 to 3% by weight of a carboxyl group-containing monomer unit and having a weight average molecular weight of 3,000 to 8,000; a crosslinking agent (C); and a silane coupling agent (D), and the pressure-sensitive adhesive layer comprises 10 to 40 parts by weight of the (meth)acrylic oligomer (B) based on 100 parts by weight of the (meth)acrylic polymer (A). The pressure-sensitive adhesive optical film has durability and can suppress display unevenness in a peripheral portion of a display screen and window frame unevenness in a state that a backlight is on.

Owner:NITTO DENKO CORP

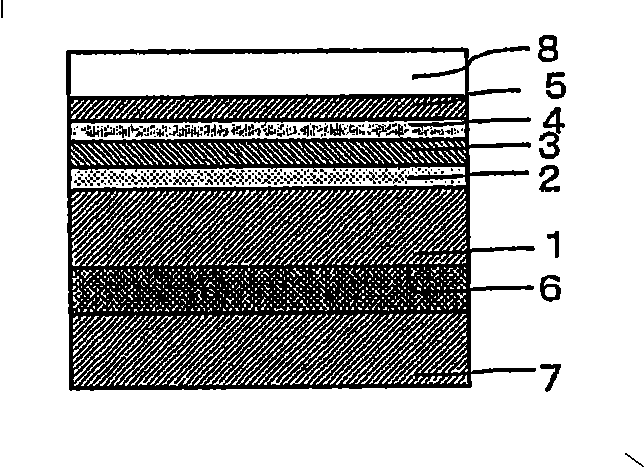

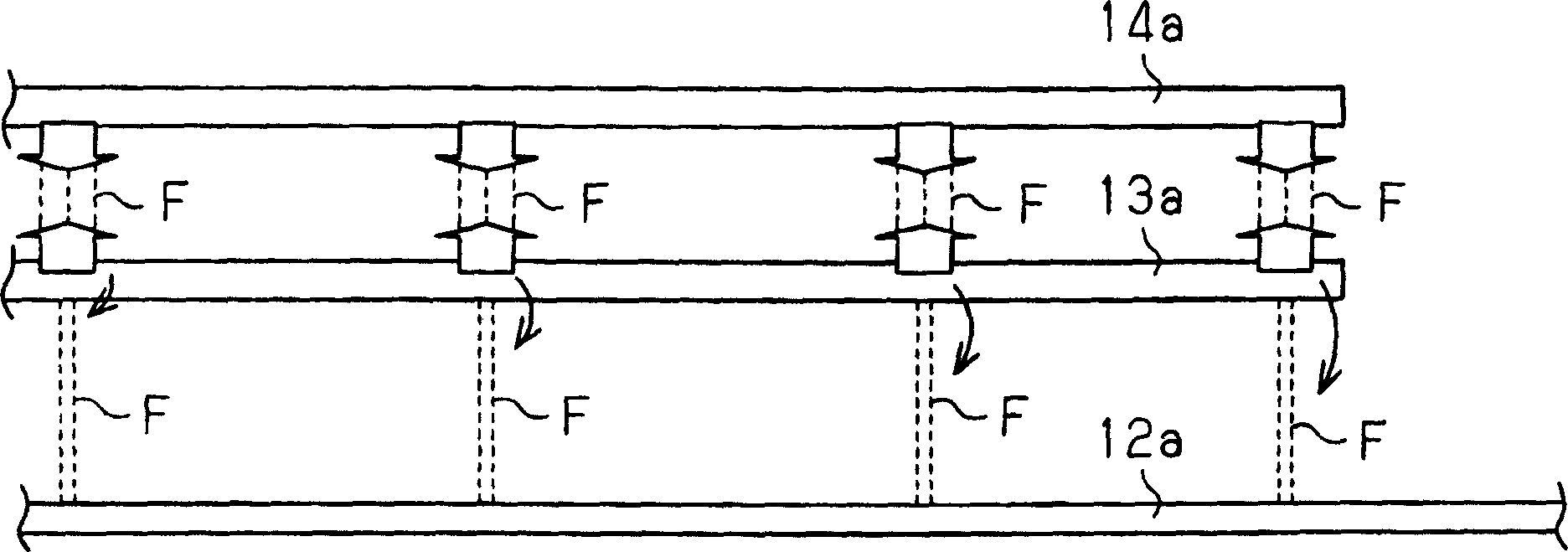

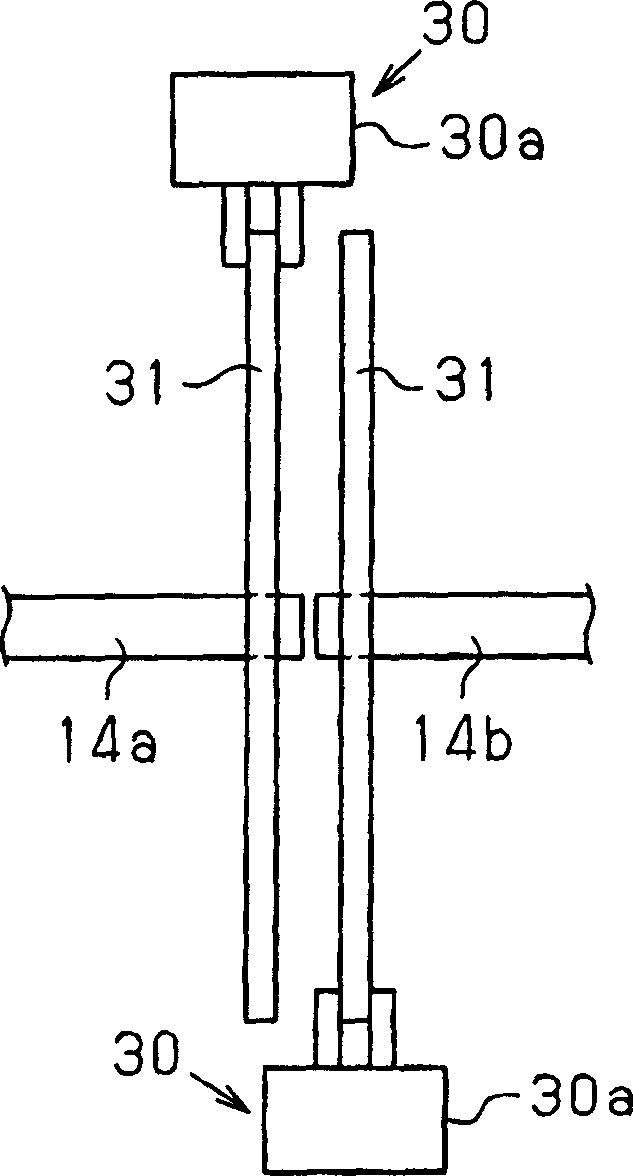

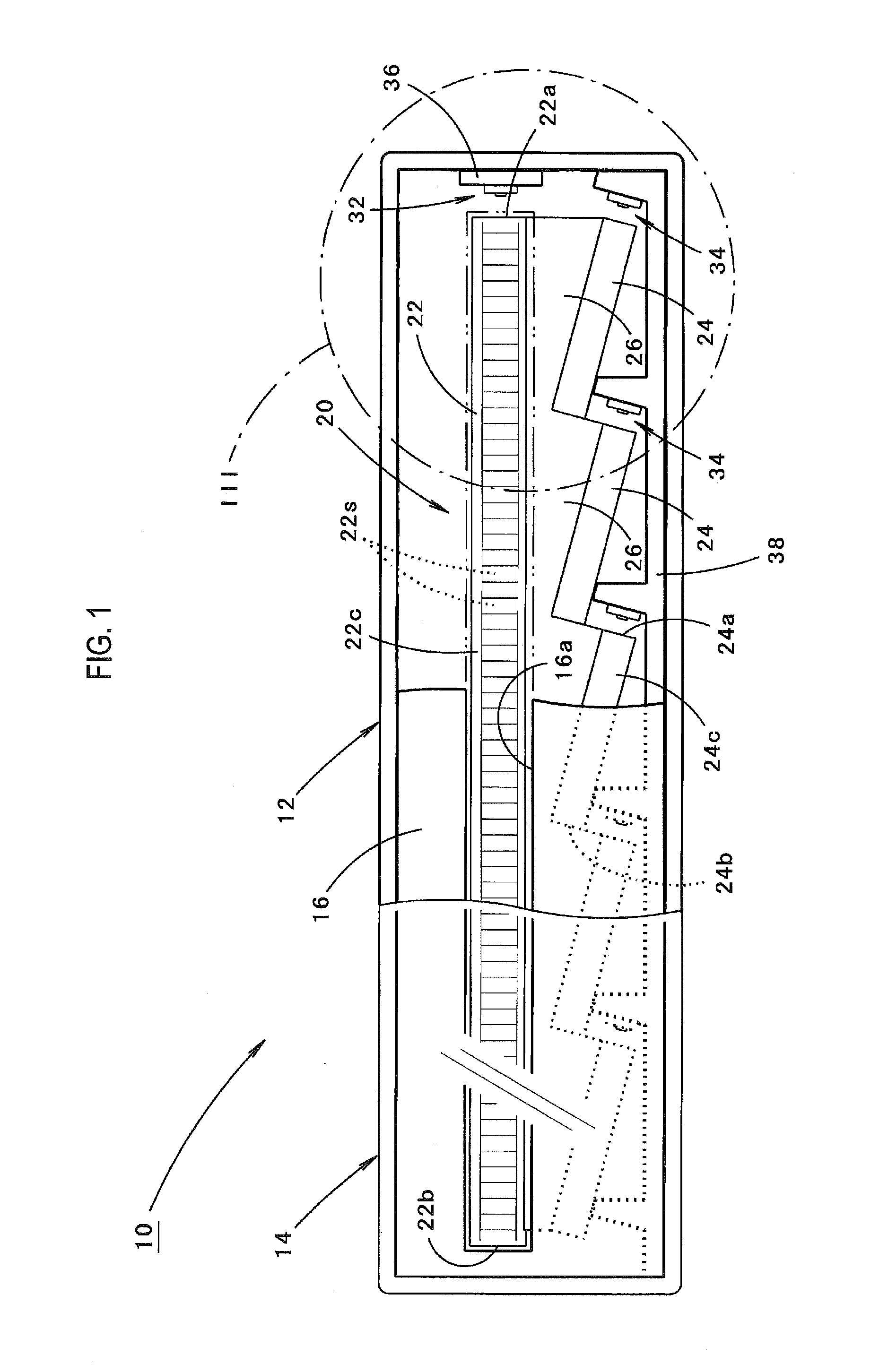

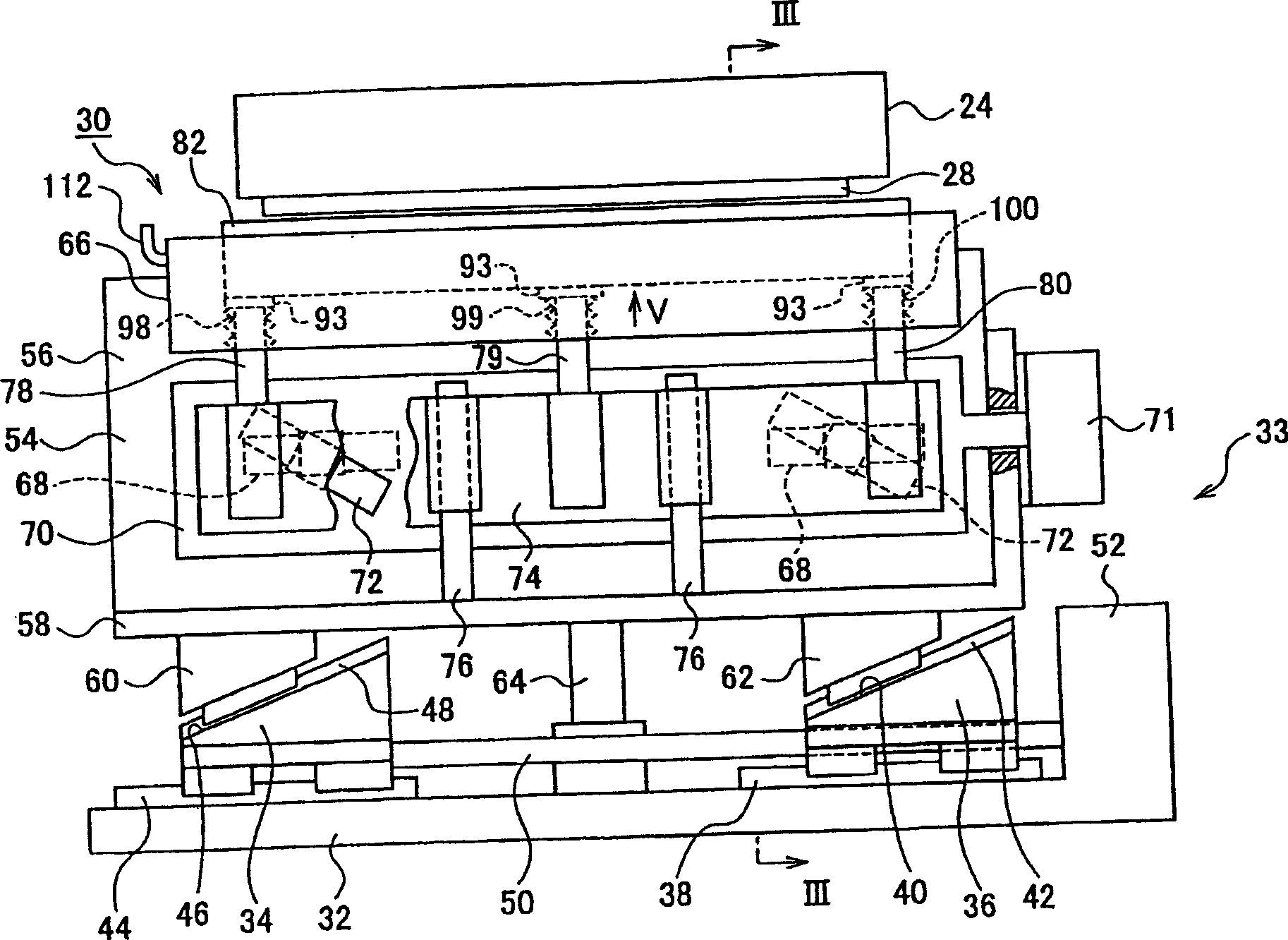

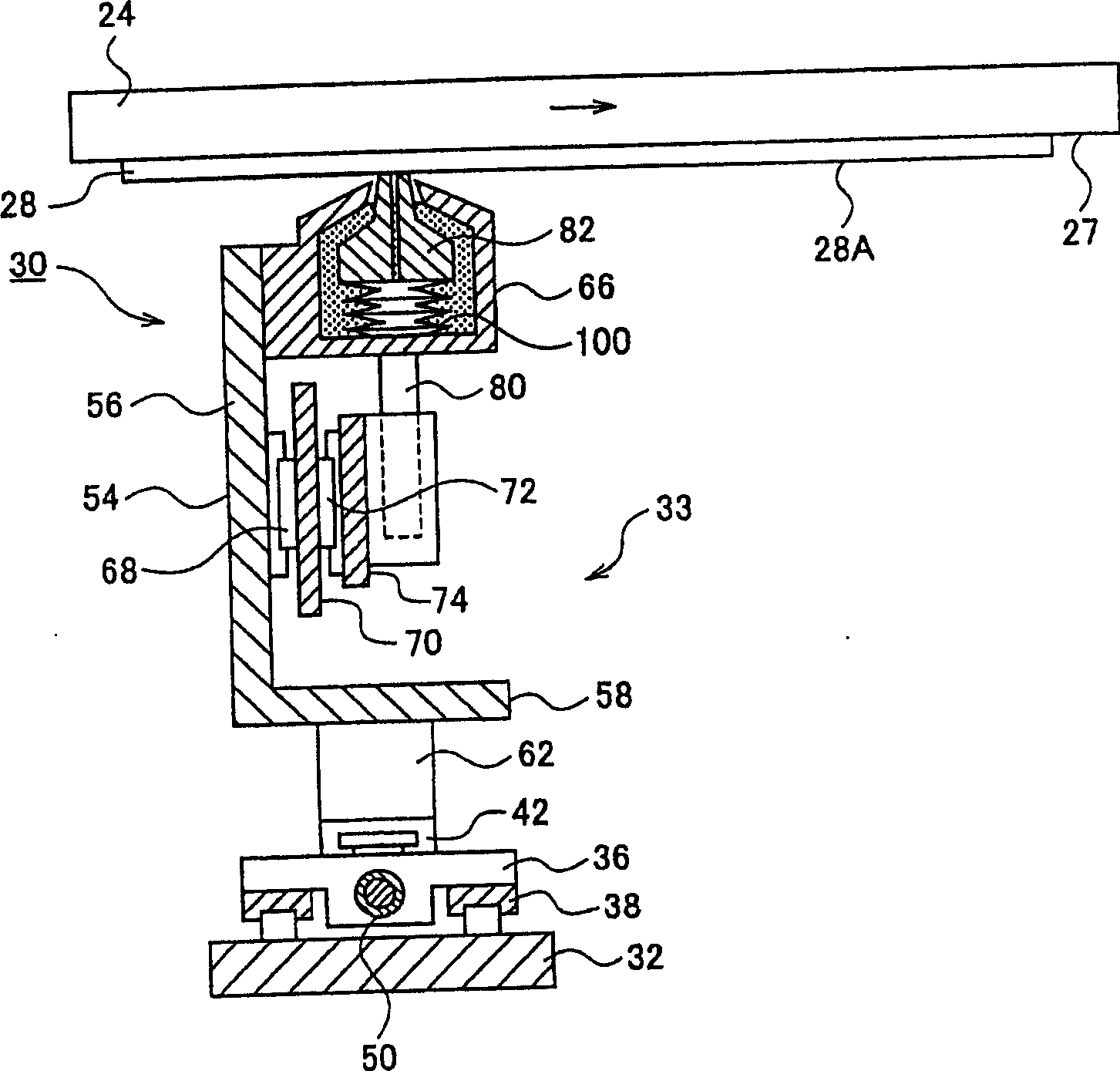

Draft apparatus in spinning machine and control method of the same

ActiveCN1900394AInhibit excess deliveryUneven suppressionDrafting machinesContinuous wound-up machinesFiberYarn

The drafting device (11) in the spinning machine has the front bottom roller (12), the middle bottom roller (13), the rear bottom roller (14), and is used to independently drive these rollers (12, 13, 14) A plurality of motors (15, 16a, 16b, 17a, 17b). The locking mechanism (21) has the function of preventing at least the rear bottom roller (14) from rotating in the normal direction during at least a predetermined period from when the spinning machine stops spinning. Therefore, it is possible to suppress excessive feeding of fibers caused by twisting of the bottom roller while the machine is stopped, thereby suppressing unevenness of the yarn when the machine is started.

Owner:TOYOTA IND CORP

Pressure-sensitive adhesive optical film and image display

A pressure-sensitive adhesive optical film of the present invention comprises: an optical film comprising a transparent base film and an optical compensation liquid crystal layer provided on one side of the transparent base film; a pressure-sensitive adhesive layer provided on the optical compensation liquid crystal layer; and an undercoat layer that is interposed between the optical compensation liquid crystal layer and the pressure-sensitive adhesive layer and contains a polymer and an antioxidant. The pressure-sensitive adhesive optical film can suppress window frame unevenness when a backlight is turned on.

Owner:NITTO DENKO CORP

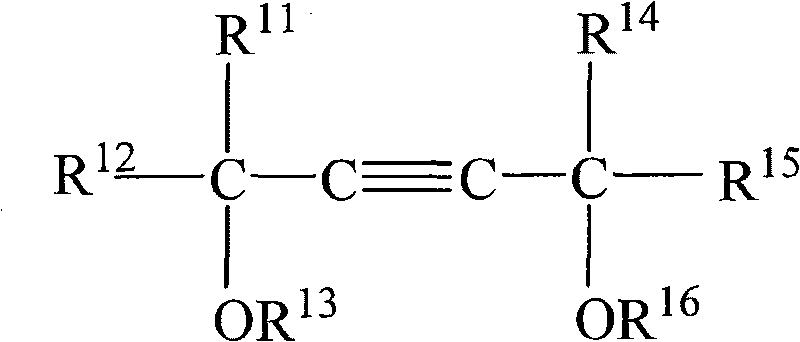

Adhesive for polarizing plate, polarizing plate, manufacturing method therefor, optical film and image display

ActiveCN101692133AUneven suppressionIncrease production capacityNon-macromolecular adhesive additivesSynthetic resin layered productsTectorial membranePolyvinyl alcohol

To provide an adhesive agent for a polarizing plate capable of satisfying a wetting property when a transparent protection film is coated with it and satisfying an optical characteristic, in which the obtained polarizing plate has water-resistance at a high temperature. The adhesive agent for the polarizing plate used for providing the transparent protection film on at least one surface of a polarization element is a resin solution containing a polyvinyl alcohol based resin, a crosslinking agent and a leveling agent containing a compound having an acetylene skeleton. The leveling agent is formulated at a ratio of 0.01-10 pts.wt. relative to 100 pts.wt. of the polyvinyl alcohol based resin.

Owner:NITTO DENKO CORP

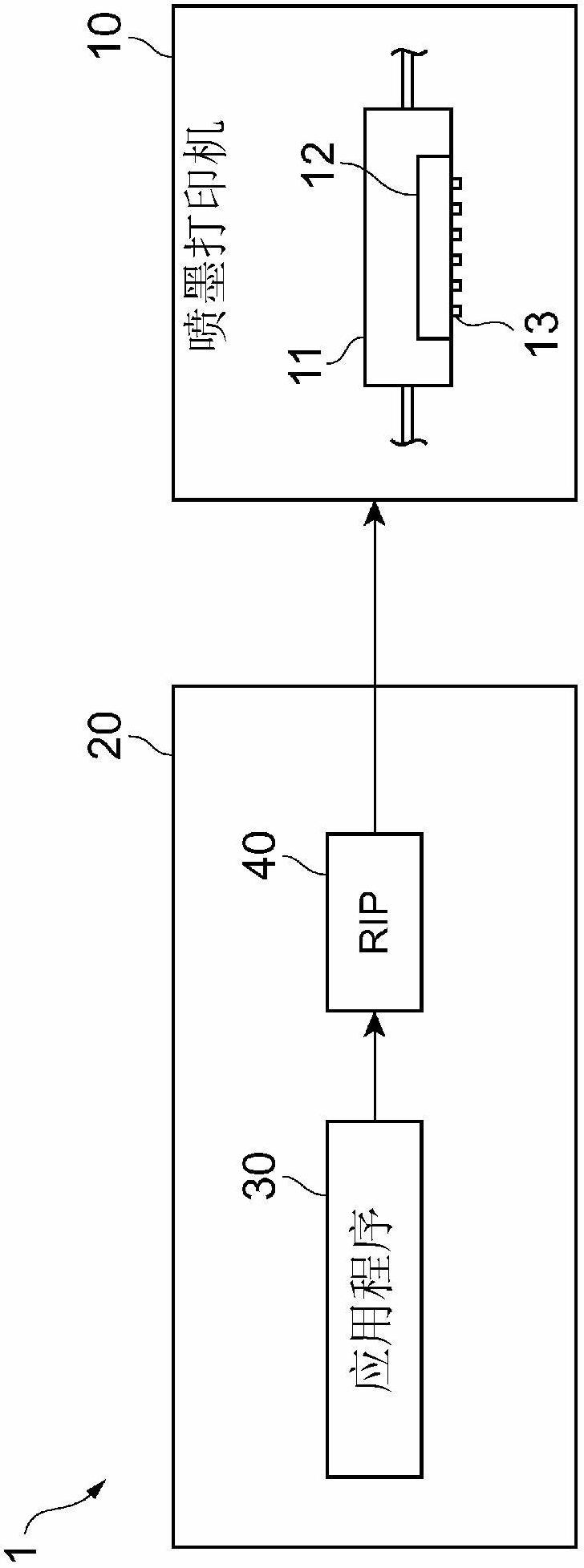

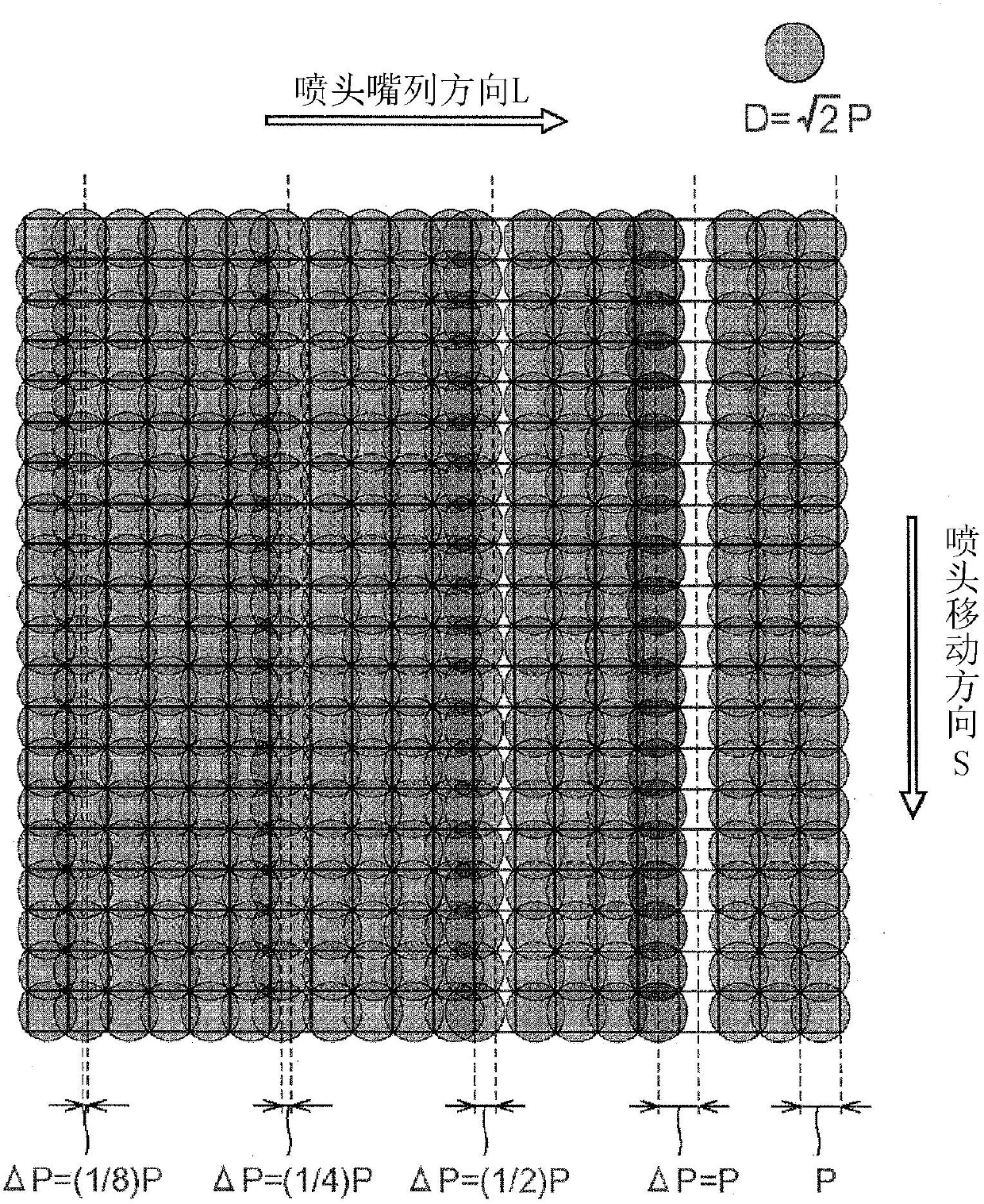

Print data generating device, print data generating method, and print data generating program

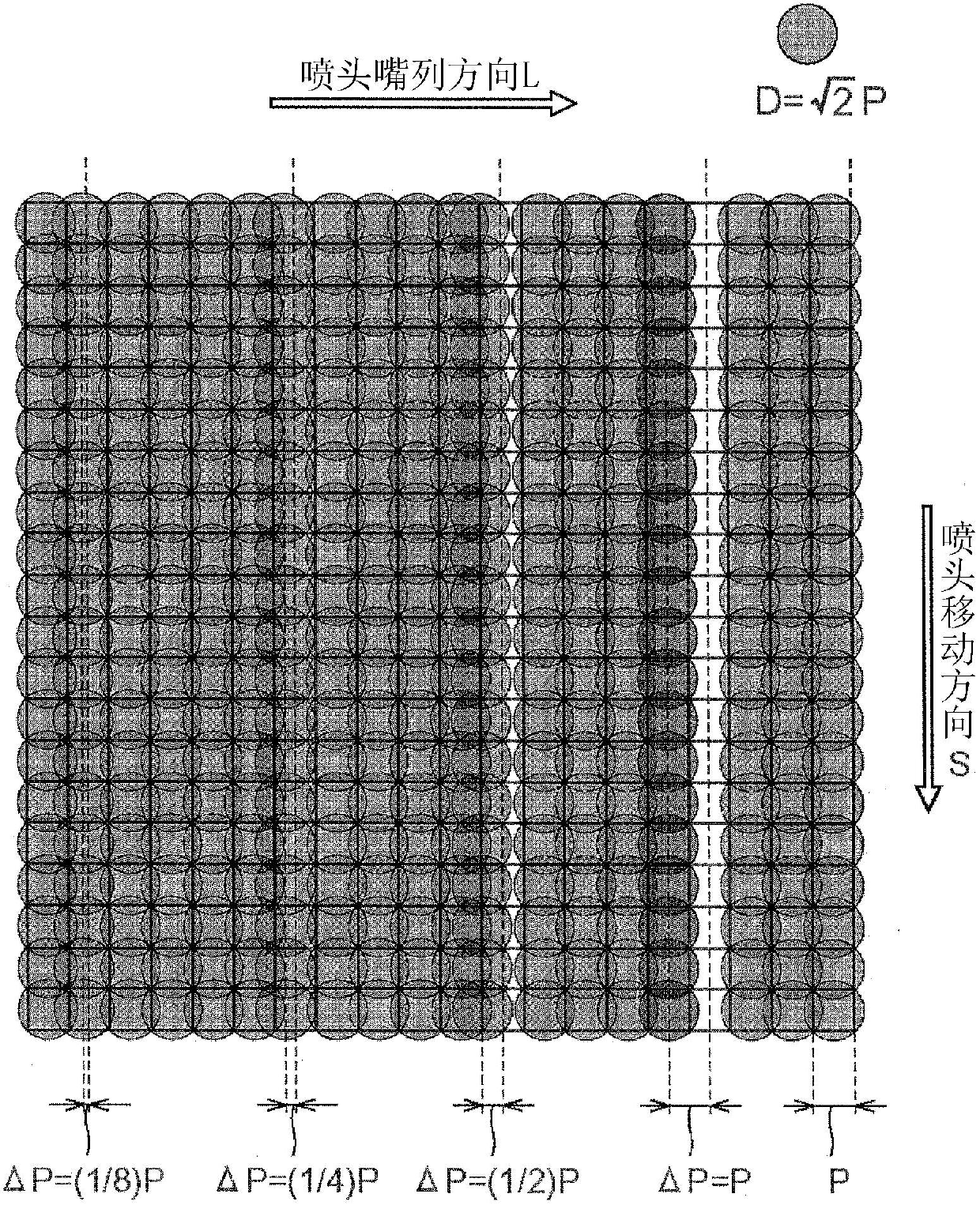

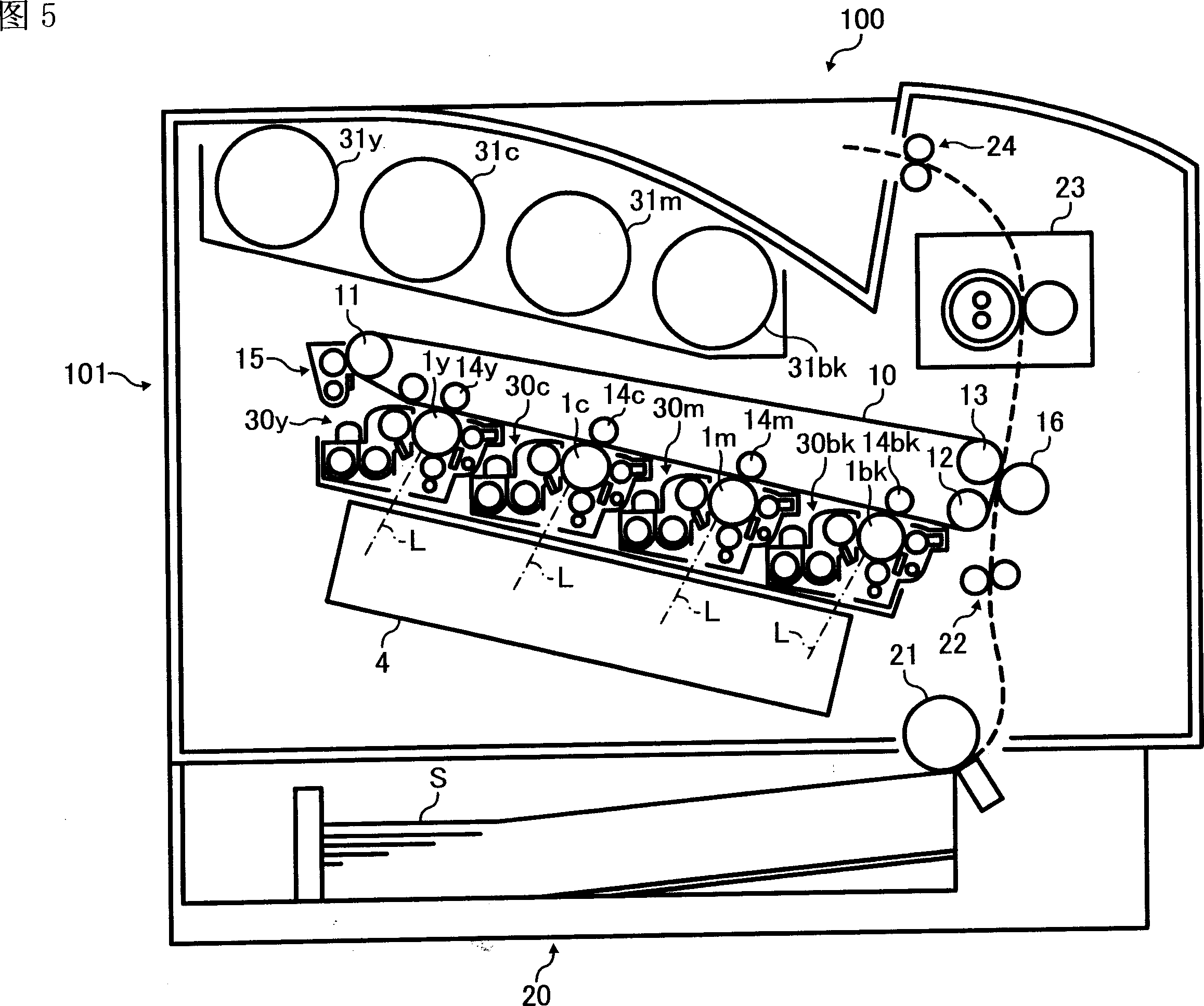

InactiveCN102666105AIncrease the number of spraysIncrease the amount of ejectionSpacing mechanismsOther printing apparatusImage resolutionVolumetric Mass Density

A print data generating device, a print data generating method, and a print data generating program suppress occurrence of streaks in an image printed by an inkjet printer. An RIP (40) is provided with: a dot displacement amount detection unit (41) which detects a displacement amount of the landing position of an ink; a contour detection unit (42) which detects one pixel corresponding to a contour; a dot size setting unit (43) which on the basis of the displacement amount detected by the dot displacement amount detection unit (41) and the pixel corresponding to the contour and detected by the contour detection unit (42), sets the dot size of each pixel to be larger than a resolution pitch; a density setting unit (44) which sets the ink density of the dot to be low; and a print data generation unit (45) on the basis of the dot size of the pixel set by the dot size setting unit (43) and the ink density set by the density setting unit (44), calculates the number of times of ejecting ink droplets and the amount of the ink droplets for each pixel and generates print data to form on a recording medium the dot in the dot size set by the dot size setting unit (43).

Owner:MIMAKI ENG

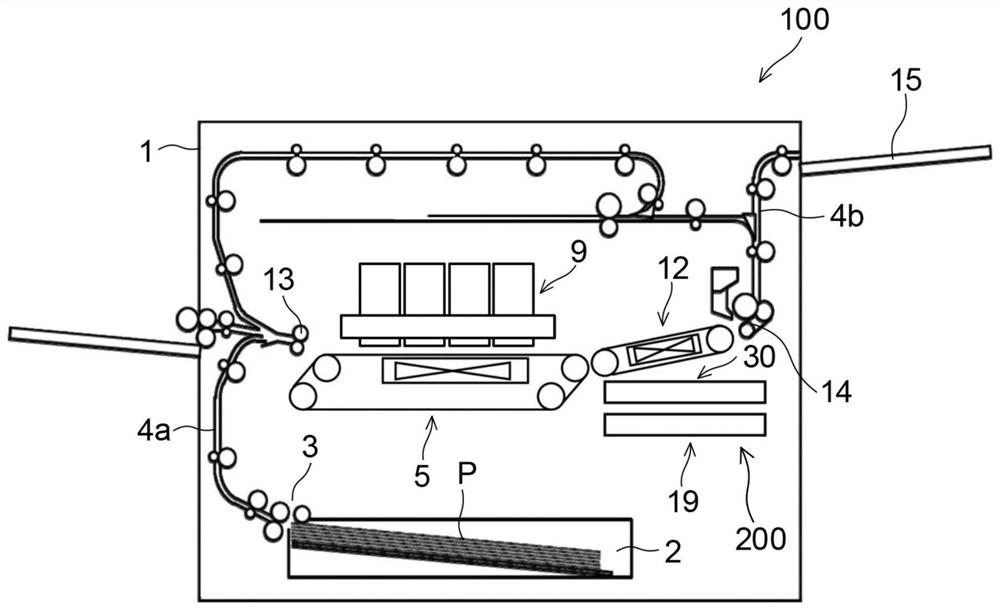

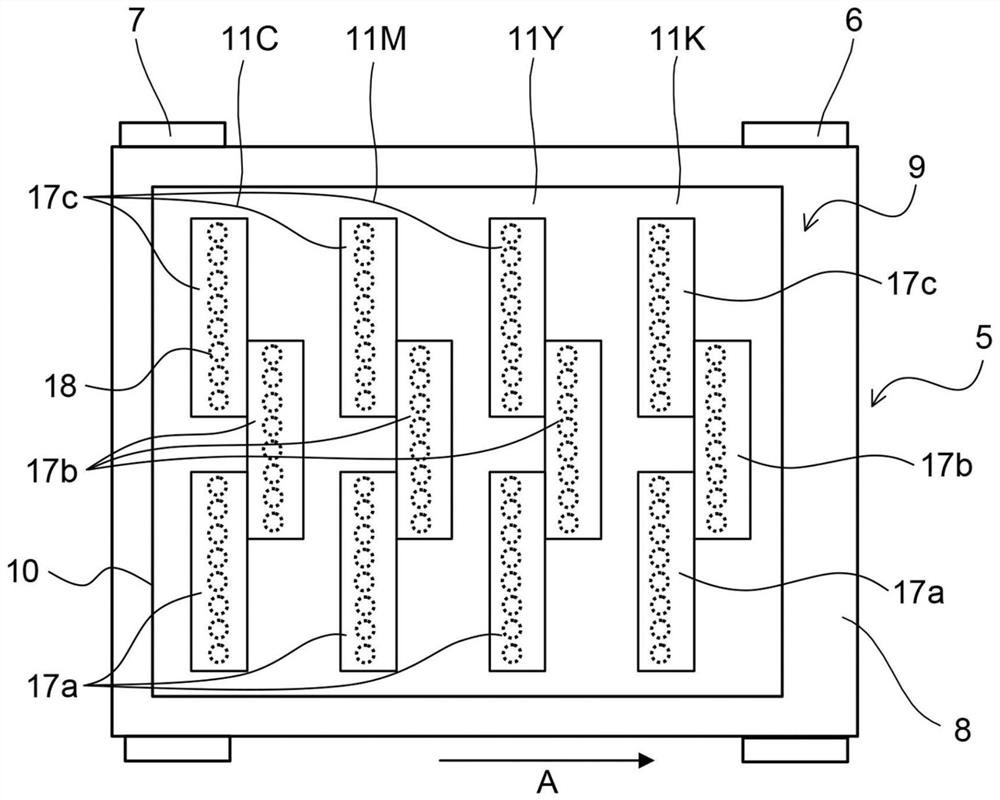

Processing cassette, image forming method and apparatus

InactiveCN1979357AQuality improvementUneven suppressionElectrographic processes using charge patternBand shapeImage formation

The invention relates to a processing box, an image forming device using thereof and an image forming method. A image carrier gyres at prtermined speed to connect with the lubricant coating brush 17a of cleaning apparatus 17, which gyring with the same direction of the image carrier at the contacted location, lubricant is coated on surface of the image carrier. Speed of the lubricant coating brush 17a is set higher than photo-conductor drum 1 as the image carrier, comparing with the situation of the image carrier and ubricant coated parts gyre with the same speed, lubricant amounts of lubricant coated parts is less. The invention prevents increasing torque, generating banded stripe images, enables coated lubricant 17b uniformly on the photo-conductor drum 1, and avoid brush injuries and conjunctiva.

Owner:RICOH KK

Vehicle lamp

ActiveUS20160369967A1Uneven suppressionUnevenness in light distribution is suppressedVehicle headlampsOptical signallingOptoelectronicsLight guide

A light guide body includes a first rod-like light guide portion and second rod-like light guide portions which are spaced from the first rod-like light guide portion in the vertical direction and plate-like light guide portions which are disposed so as to link their circumferential surfaces. Light that reaches the first rod-like light guide portion via the plate-like light guide portions after being emitted from light sources and entering the second rod-like light guide portions is emitted forward of the lamp from the circumferential surface of the first rod-like light guide portion.

Owner:KOITO MFG CO LTD

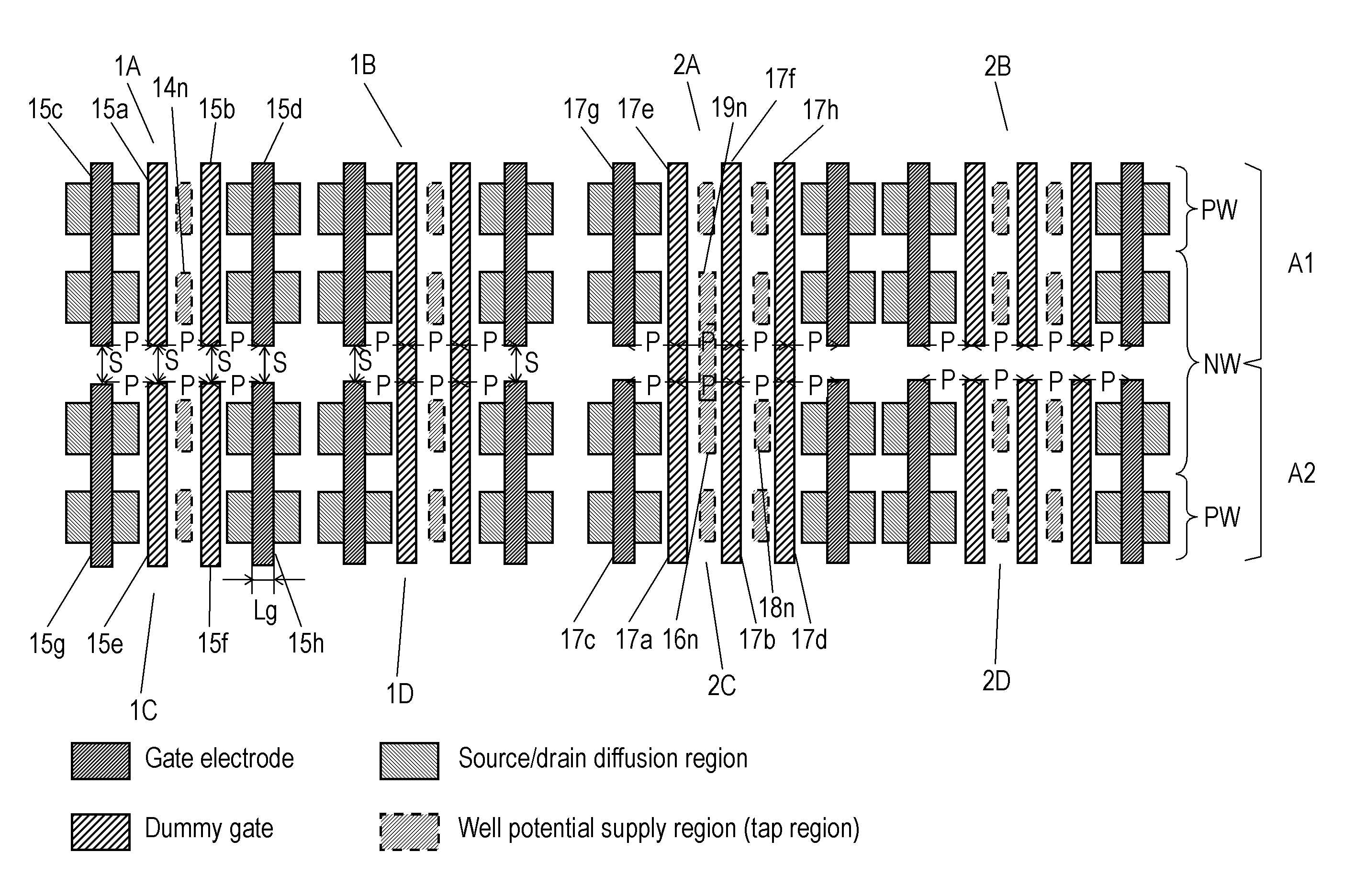

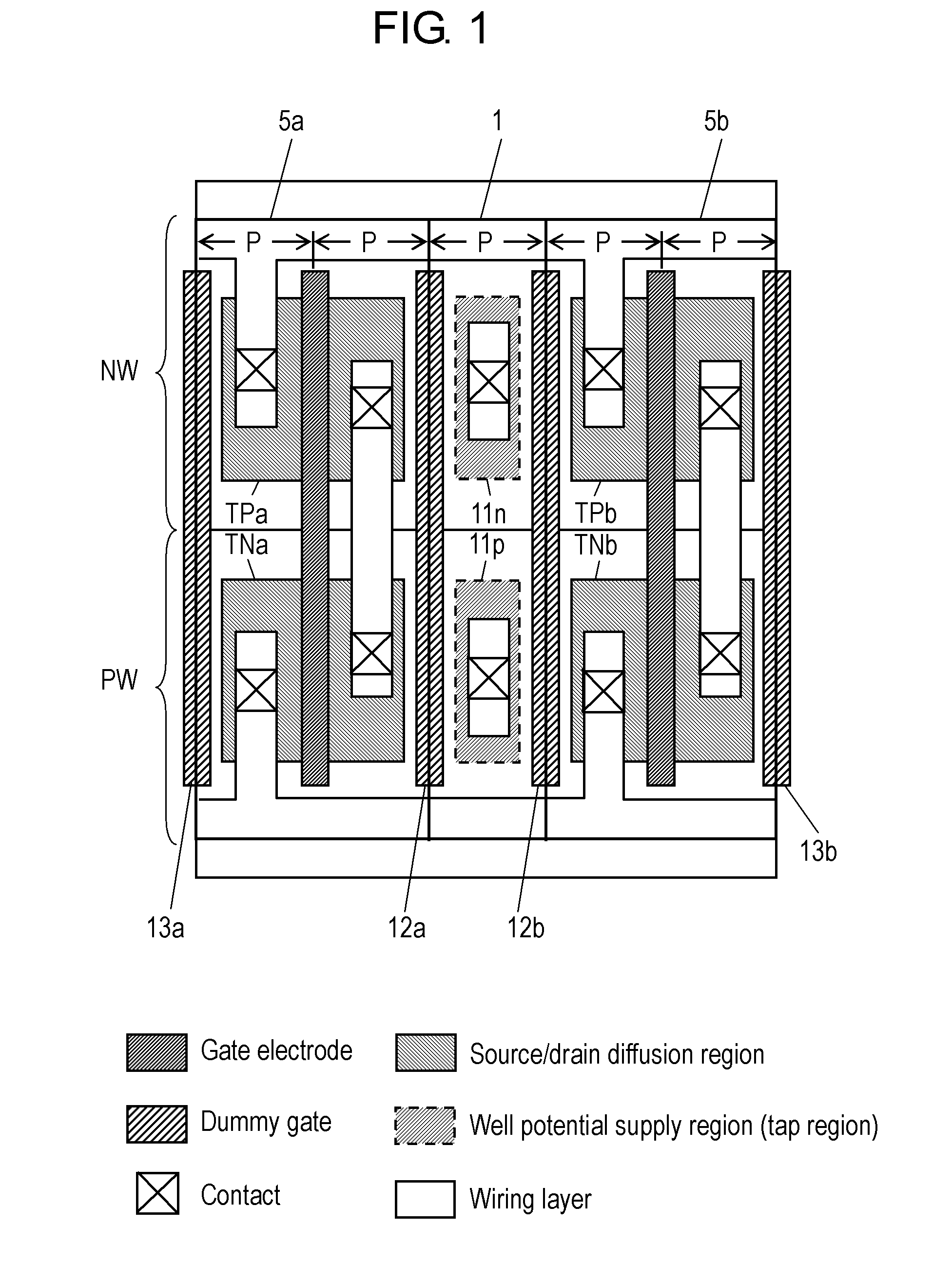

Semiconductor device

ActiveUS8692336B2Uneven suppressionIncrease layout areaTransistorSolid-state devicesEngineeringSemiconductor

A well potential supply region is provided in an N-type well region of a cell array. Adjacent gates disposed in both sides of the well potential supply region in the horizontal direction and adjacent gates disposed in further both sides thereof are disposed at the same pitch. In addition, an adjacent cell array includes four gates each of which is opposed to the adjacent gates in the vertical direction. In other words, regularity in the shape of the gate patterns in the periphery of the well potential supply region is maintained.

Owner:SOCIONEXT INC

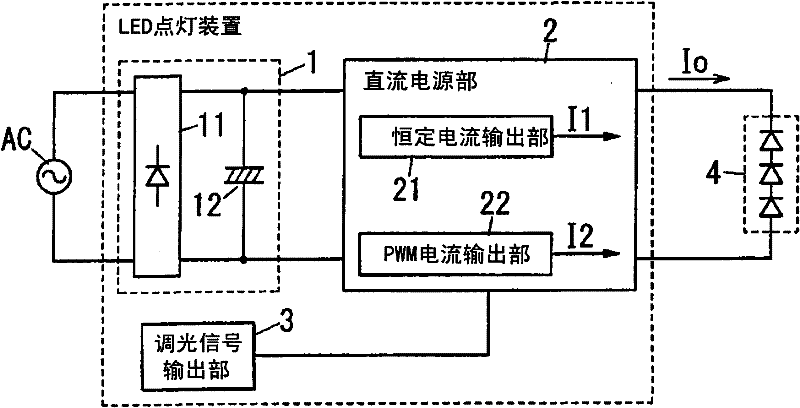

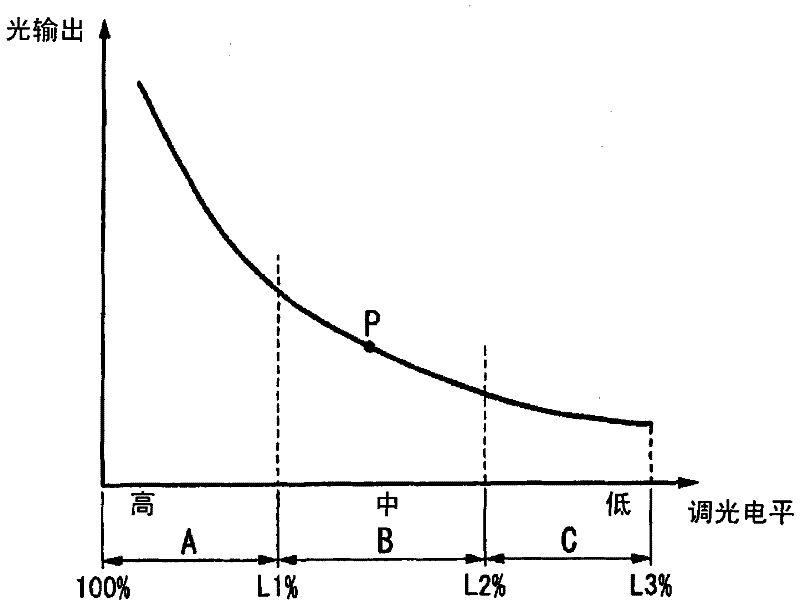

LED lighting device

ActiveCN102196634AUneven suppressionElectrical apparatusElectroluminescent light sourcesPower flowEffect light

The invention provides an LED lighting device capable of suppressing a flicker at an intermediate level in which a dimming level is moved between a high level and a low level. The LED lighting device includes a constant current output part 21 capable of variably adjusting an amplitude for supplying a constant current I1 with a fixed amplitude to an LED light-emitting part 4, and a PWM current output part 22 for variably adjusting an on-duty state in a PWM cycle by PWM control and supplying a PWM current with a predetermined on-duty state to the LED light-emitting part 4, wherein in an intermediate dimming range, the constant current output part 21 adjusts the amplitude of the constant current I1 in accordance with a dimming level and the PWM current output part 22 adjusts the on-duty state of the PWM current in accordance with the dimming level, so that the LED light-emitting part 4 is dimmed.

Owner:PANASONIC CORP

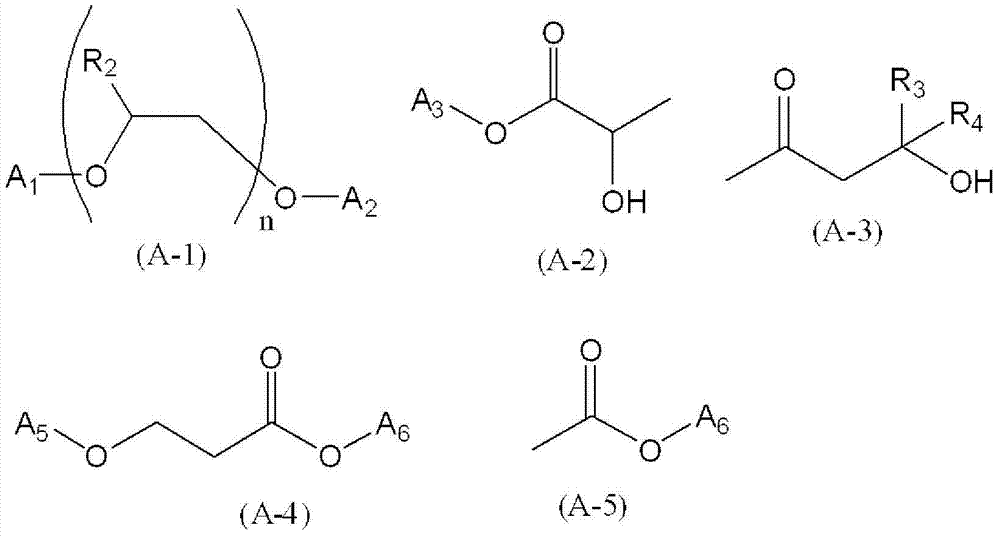

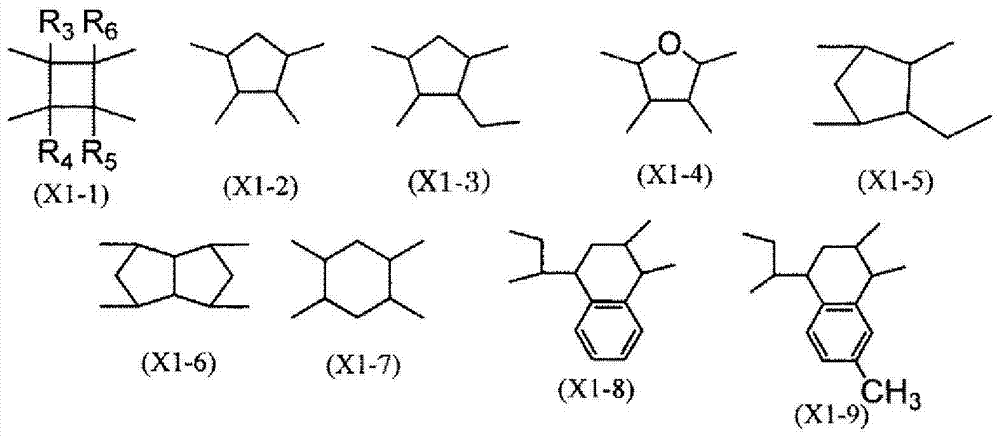

Method for manufacturing liquid crystal alignment film, liquid crystal alignment film, and liquid crystal display element

ActiveCN103946738AIncreased anisotropyHigh Orientation ConstraintNon-linear opticsCrystallographyLiquid-crystal display

Provided is a method for manufacturing a liquid crystal alignment film whereby anisotropy is increased and unevenness caused by processing can be suppressed. A film obtained by applying a liquid crystal alignment agent containing at least one type of polymer selected from the group consisting of a polyimide and a precursor of the polyimide on a substrate and firing the product is irradiated with polarized radiation, then treated by contact with a solution containing at least one type of organic solvent selected from the group consisting of formula (A-1), formula (A-2), formula (A-3), formula (A-4), and formula (A-5). (In the formulas, A1 represents a hydrogen atom or an acetyl group, A2 represents a C1-6 alkyl group, R2 represents a hydrogen atom or a methyl group, n represents 1 or 2, A3 represents a C1-4 alkyl group, R3 and R4 represent a hydrogen atom or a methyl group, A5 and A6 represent a C1-4 alkyl group, and A6 represents a C3-6 alkyl group or cycloalkyl group.)

Owner:NISSAN CHEM IND LTD

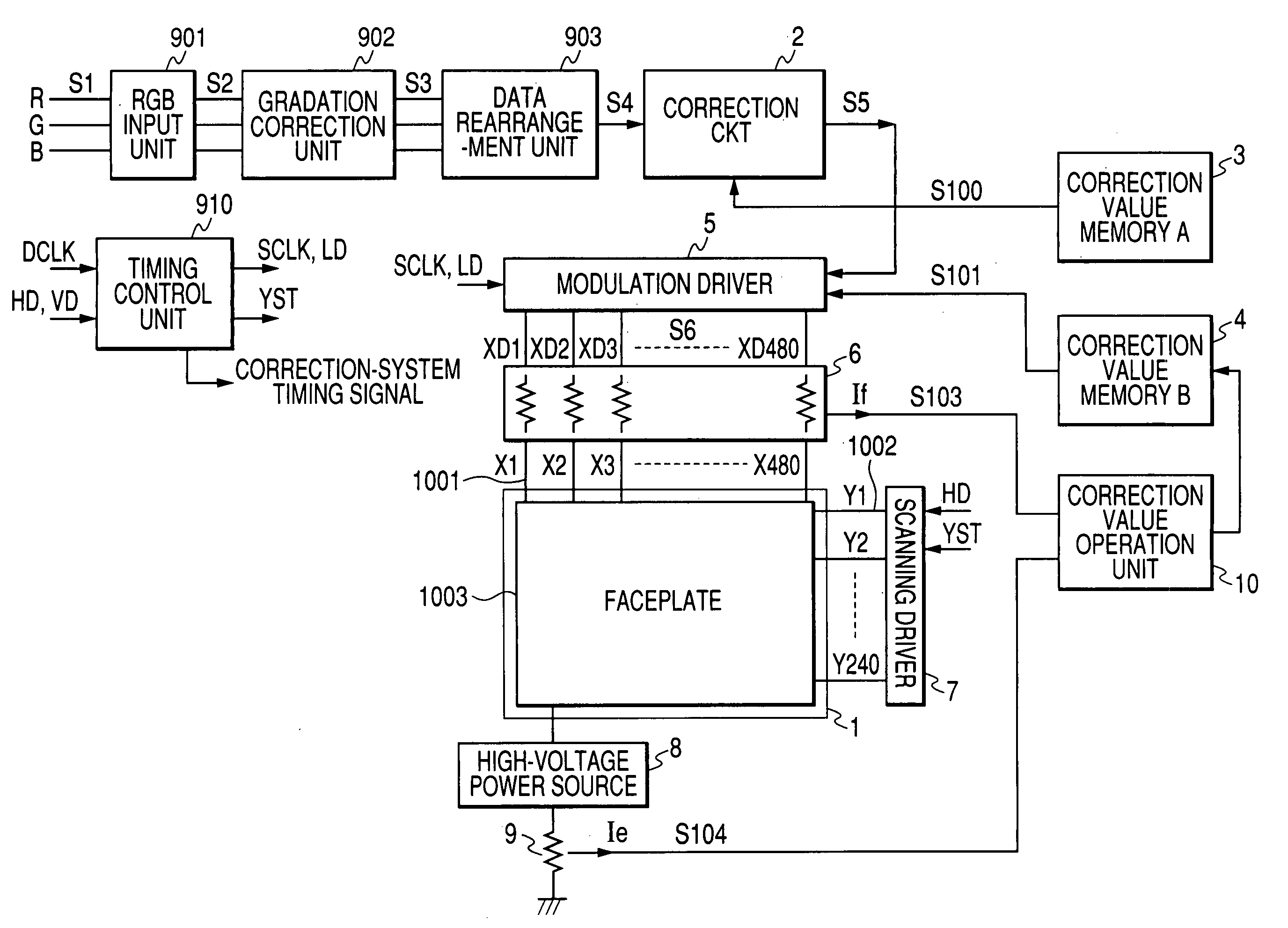

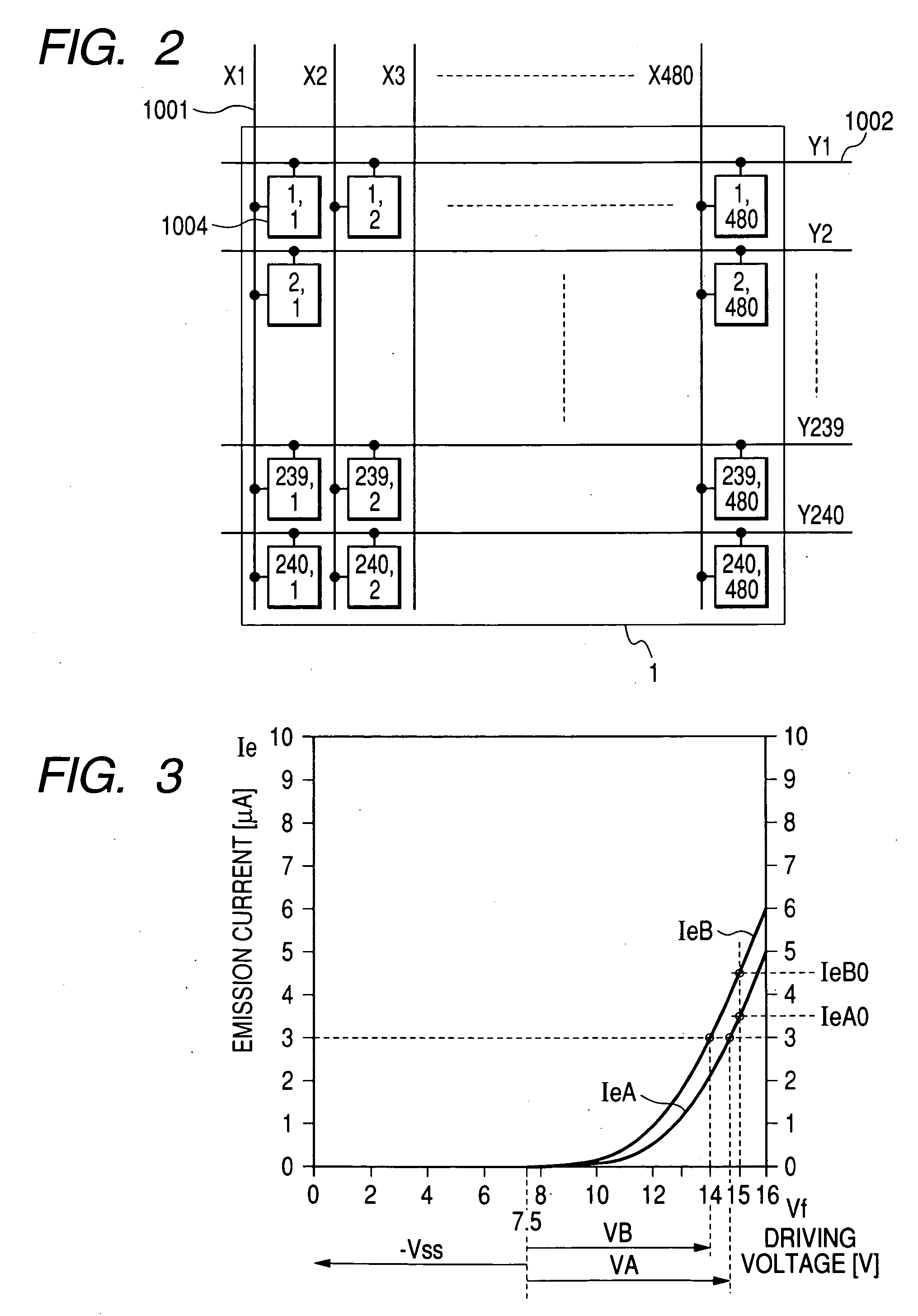

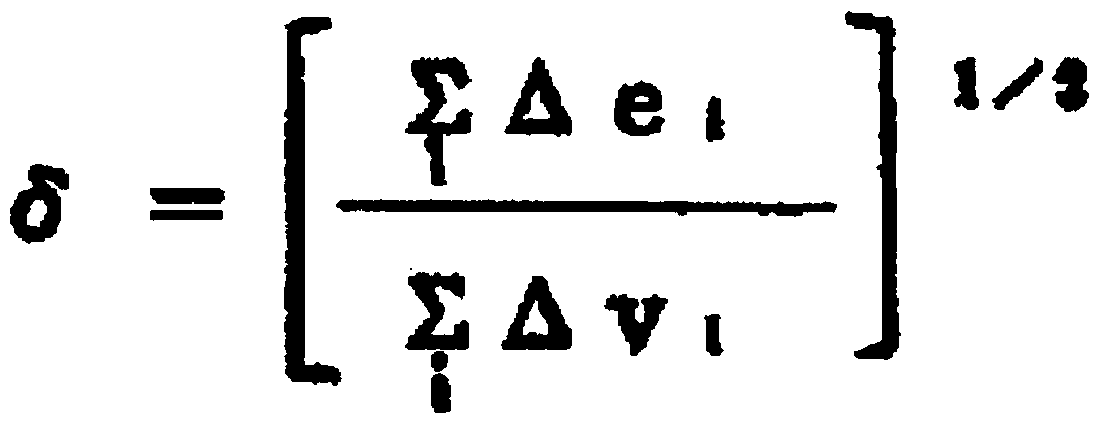

Image display method and image display device

InactiveUS20060001369A1Correction for variationUniform imagingTelevision system detailsSolid cathodesFluorescenceDisplay device

Provided is an image display method for an image display device including a plurality of electron emission elements and a fluorescent substance that emits light by electron irradiation from the electron emission elements, the method including: storing a fluorescent substance correction value for correcting variation in the light emitted from the fluorescent substance; continually updating an emission current correction value for correcting variation in an emission current; and driving the image display device based on the fluorescent substance correction value and the updated emission current correction value. According to the method, it is possible to correct both the variation in emission currents and the variation in light emitted from fluorescent substances, and to suppress the unevenness of light emitted in the image display device.

Owner:CANON KK

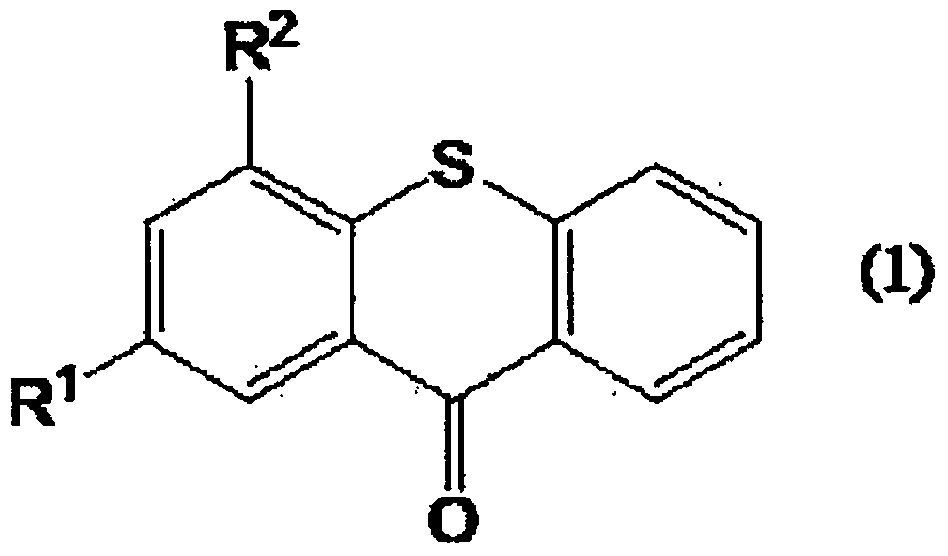

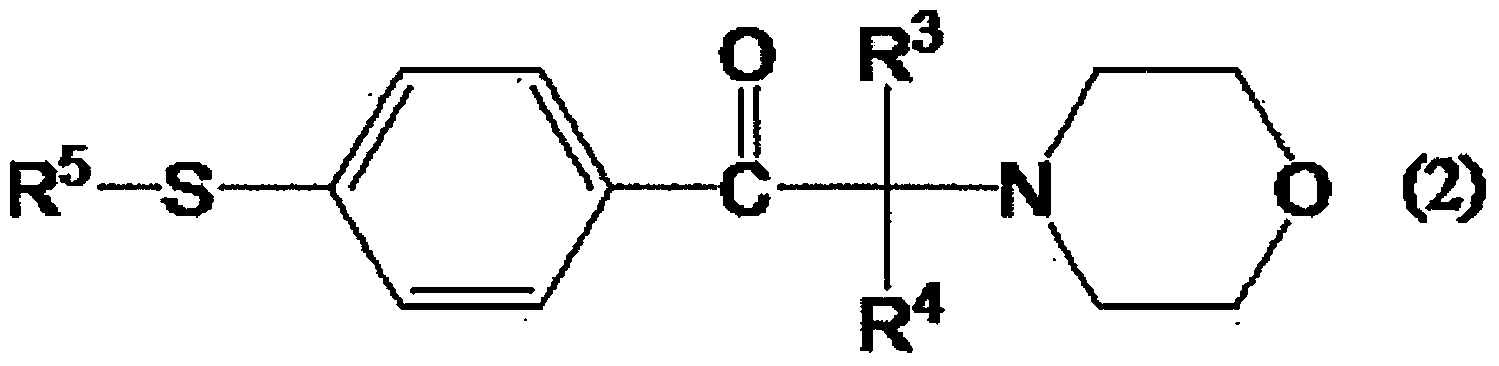

Active energy ray curable adhesive composition, polarizing film and method for producing same, optical film and image display device

ActiveCN104395420AIncreased durabilityImprove water resistanceAdhesive processesNon-macromolecular adhesive additivesOrganic chemistryChemistry

An active energy ray curable adhesive composition comprises radical polymerizable compounds (A), (B) and (C), as curable components, the composition being characterized by containing, when the total amount of the composition is 100 weight%, the radical polymerizable compound (A) having an SP value of 29.0 (kJ / m3)1 / 2 to 32.0 (kJ / m3)1 / 2 in an amount of 1.0 to 30.0 weight%, the radical polymerizable compound (B) having an SP value of 18.0 (kJ / m3)1 / 2 or more and less than 21.0 (kJ / m3)1 / 2 in an amount of 35.0 to 98.0 weight%, and the radical polymerizable compound (C) having an SP value of 21.0 (kJ / m3)1 / 2 to 23.0 (kJ / m3)1 / 2 in an amount of 1.0 to 30.0 weight%.

Owner:NITTO DENKO CORP

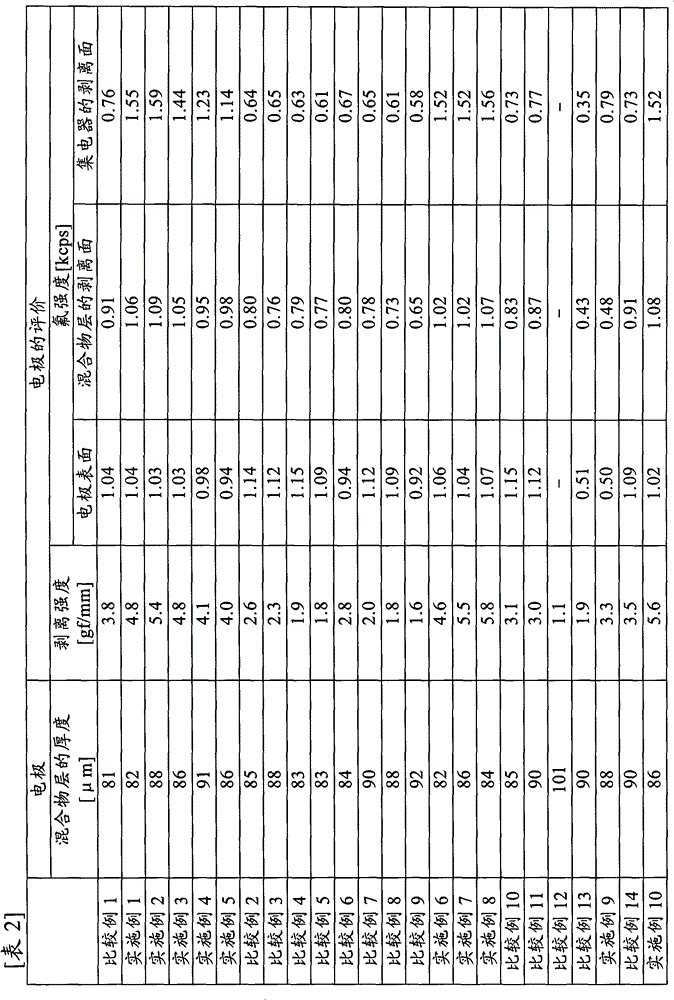

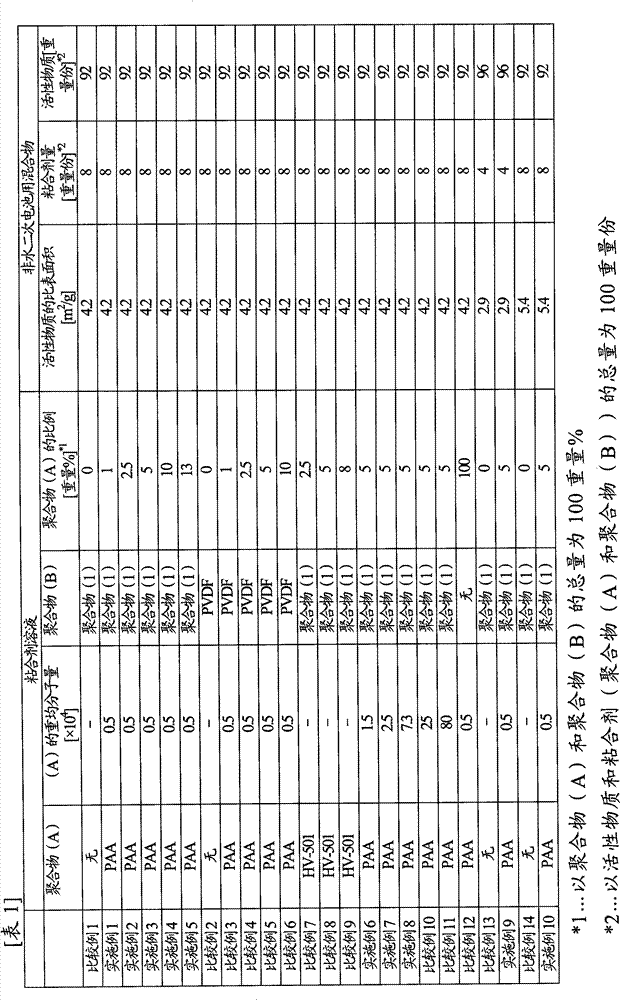

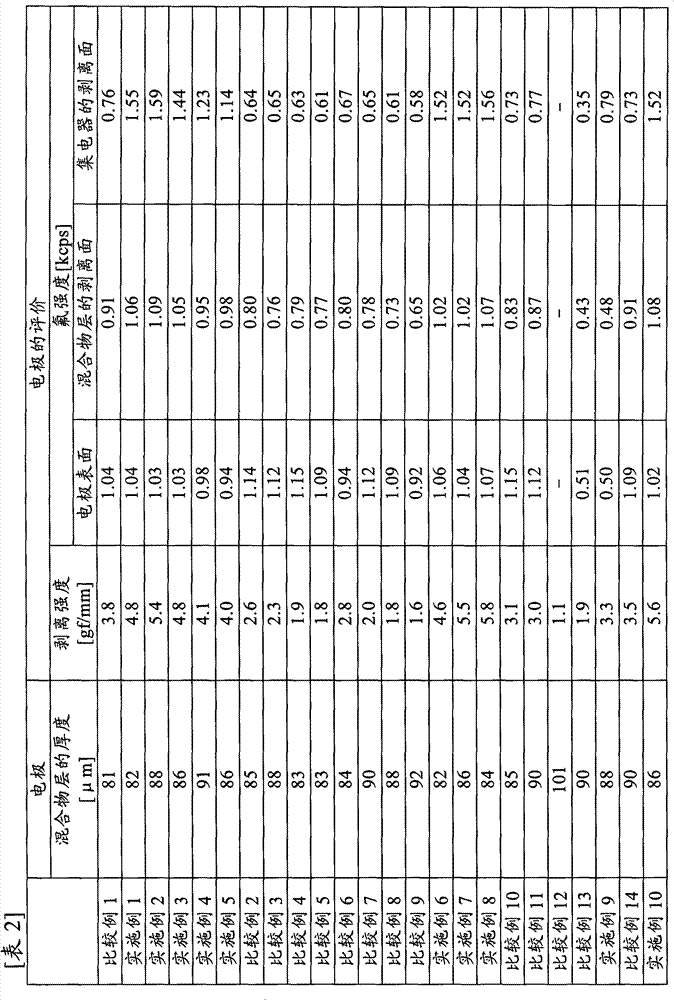

Mixture for non-aqueous electrolyte secondary battery, electrode for same, and non-aqueous electrolyte secondary battery

InactiveCN102725889AEfficient preparationUneven suppressionNon-aqueous electrolyte accumulator electrodesPolymer sciencePolyethylene oxide

An object of the present invention is to provide a mixture layer and mixture for a non-aqueous electrolyte secondary battery with excellent peeling strength from a power collector, that is highly productive in manufacturing a non-aqueous secondary battery electrode and a non-aqueous secondary battery, and suppresses mal-distribution of a binding agent in the mixture layer when manufacturing the electrode. The non-aqueous secondary battery mixture contains at least one type of unsaturated carboxylic acid polymer (A) selected from a polyacrylic acid and polymethacrylic acid, vinylidene fluoride polymer containing carboxyl (B), an electrode active material, and a weight-average molecular weight of 1,000 - 150,000 of polyethylene oxide conversion measured by GPC of the unsaturated carboxylic acid polymer (A).

Owner:KUREHA KAGAKU KOGYO KK

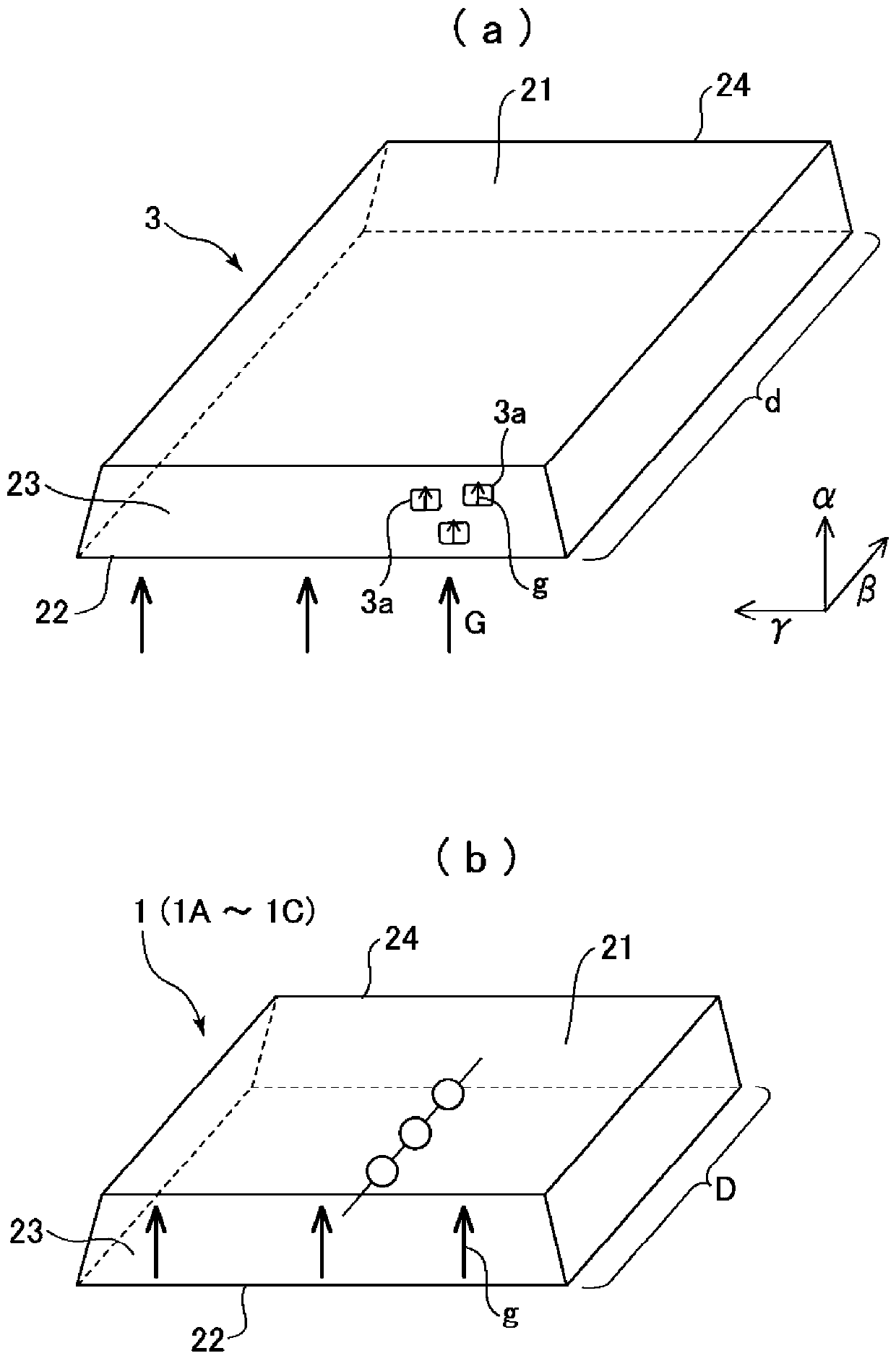

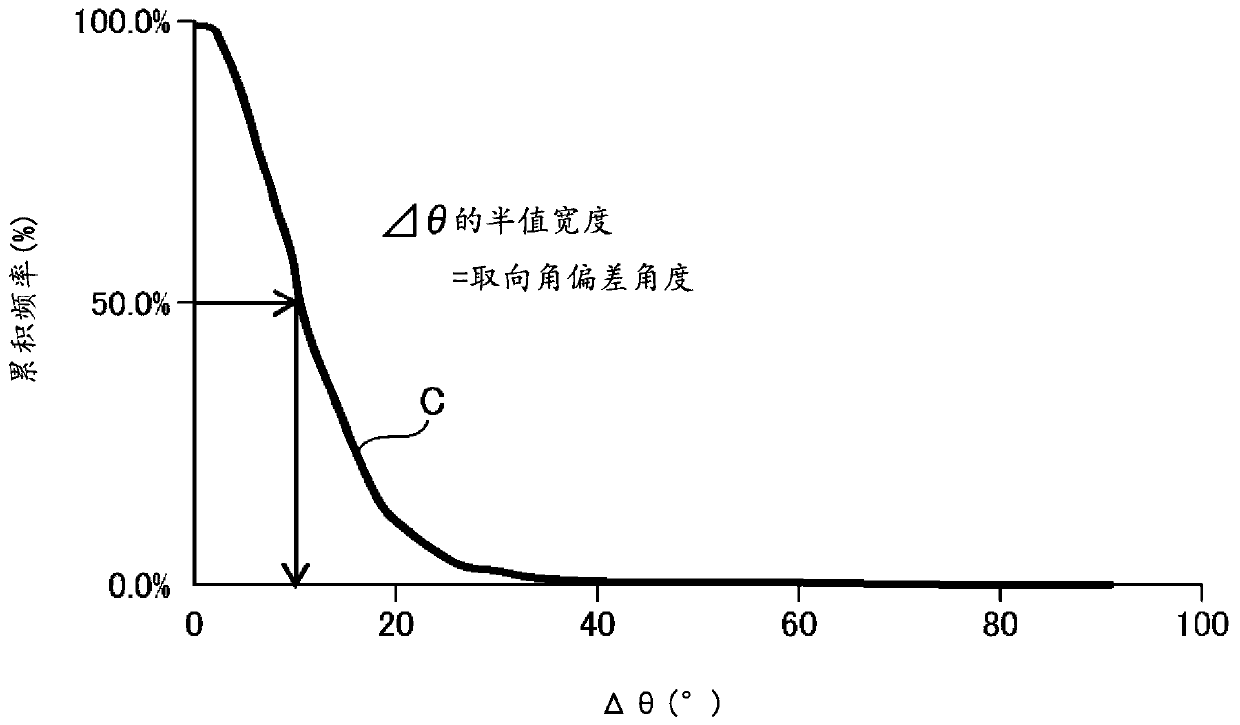

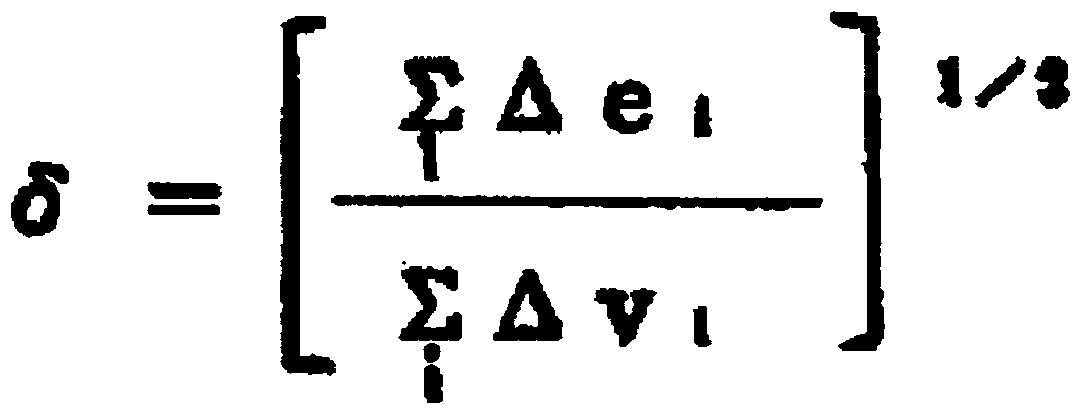

Sintered compact for forming rare earth sintered magnet, and method for manufacturing same

ActiveCN109791836AUneven suppressionDisadvantages of inhibiting pressure sinteringTransportation and packagingMetal-working apparatusSintered magnetsRare-earth magnet

Provided is a method of manufacturing a sintered compact for forming a rare earth sintered magnet of a desired shape with high magnetic properties by suppressing variations in magnetic structure caused by pressurization, which is a disadvantage of pressure sintering. Further provided is a rare earth sintered magnet and the like having prescribed properties. A material for forming a rare earth magnet containing magnet material particles is filled into a mold in a state in which the easy axis of magnetization is oriented in a single plane. While a pressurizing force of a prescribed magnitude isexerted on the material for forming the rare earth magnet that has been filled into the mold, the material for forming the rare earth magnet is sintered by being heated to a sintering temperature, thereby forming a sintered compact in which the magnet material particles are integrally sintered. Thereafter, while a pressure lower than that of the pressurizing force during sintering is applied to the sintered compact, a high temperature heat treatment is performed within a maximum temperature range of greater than 900 DEG C and lower than or equal to 1100 DEG C, with the difference between thismaximum temperature and the maximum temperature during pressure sintering being 250 DEG C or lower.

Owner:NITTO DENKO CORP

Active energy ray curable adhesive composition, polarizing film and method for producing same, optical film and image display device

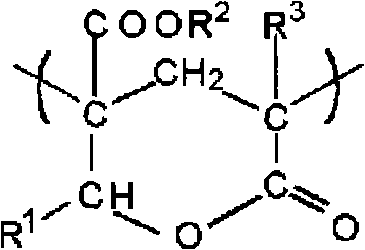

ActiveCN104395419AIncreased durabilityImprove water resistanceAdhesive processesNon-macromolecular adhesive additivesOligomerAcrylic monomers

An active energy ray curable adhesive composition comprising a radical polymerizable compound (A) having an SP value of 29.0 (kJ / m3)1 / 2 to 32.0 (kJ / m3)1 / 2, a radical polymerizable compound (B) having an SP value of 18.0 (kJ / m3)1 / 2 or more and less than 21.0 (kJ / m3)1 / 2, and a radical polymerizable compound (C) having an SP value of 21.0 (kJ / m3)1 / 2 to 23.0 (kJ / m3)1 / 2, as curable components, and an acrylic oligomer (D) obtained by polymerizing a (meth)acrylic monomer, wherein when the total amount of the composition is 100 weight%, the radical polymerizable compound (B) is contained in an amount of 25 to 80 weight%.

Owner:NITTO DENKO CORP

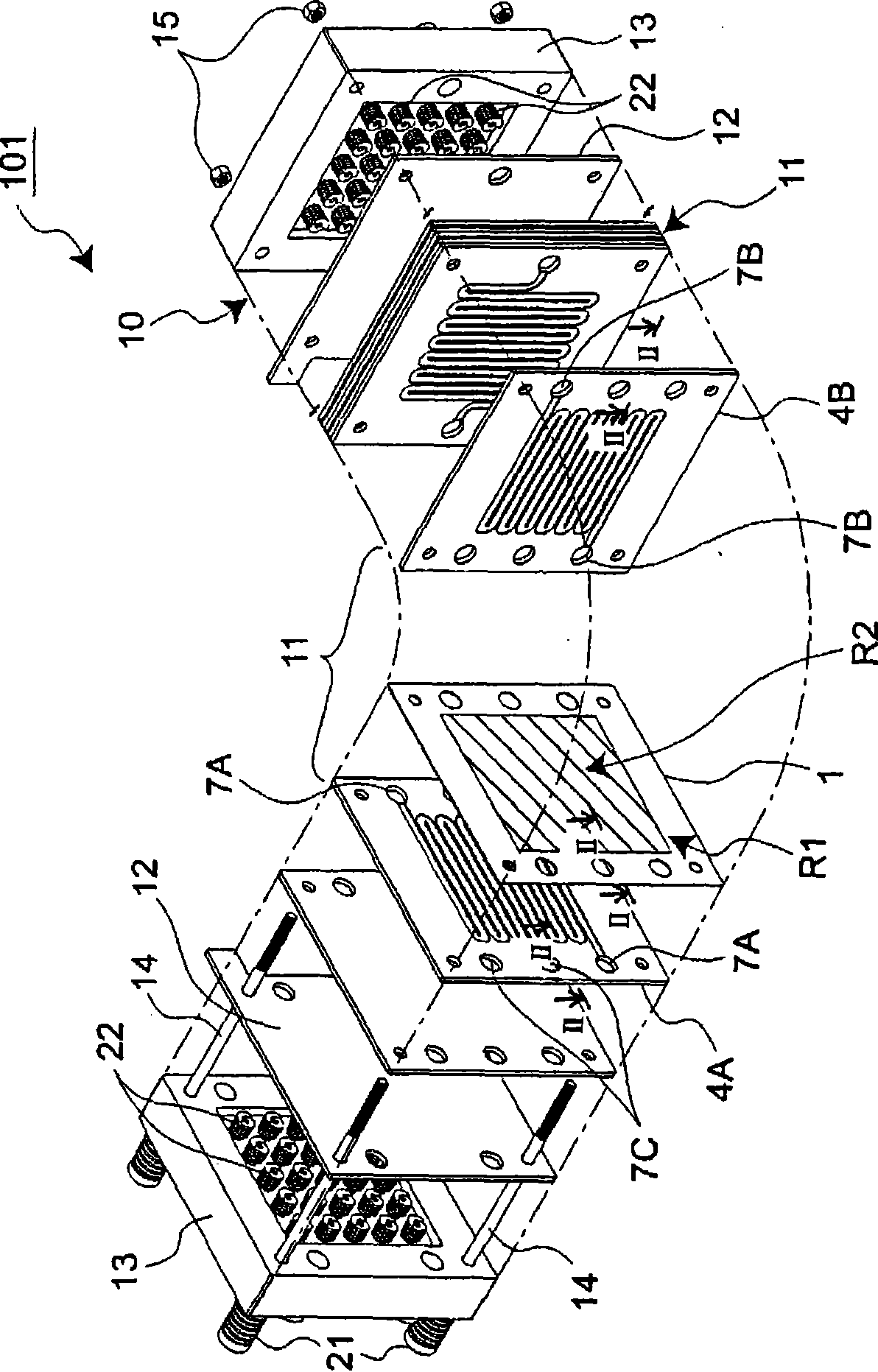

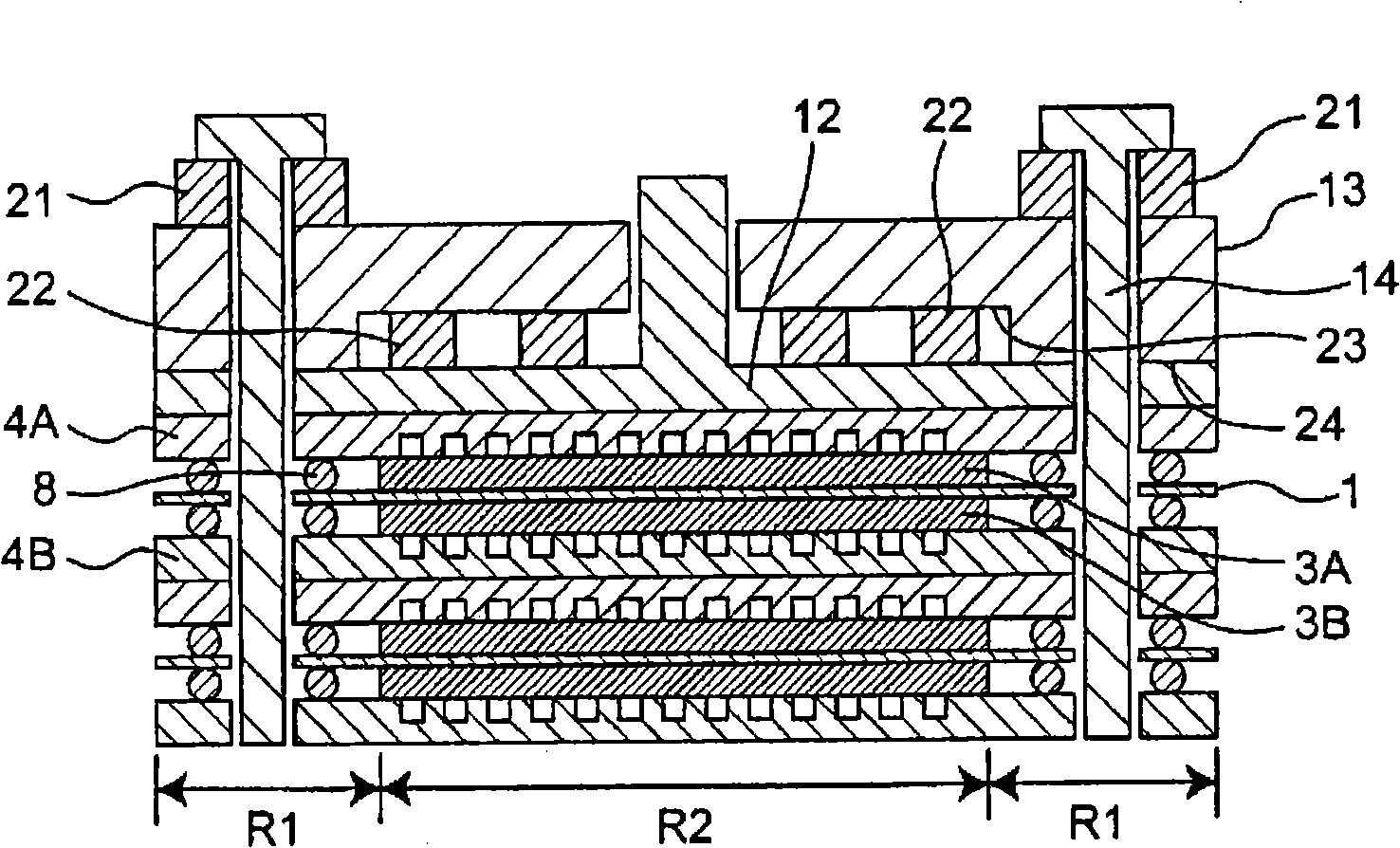

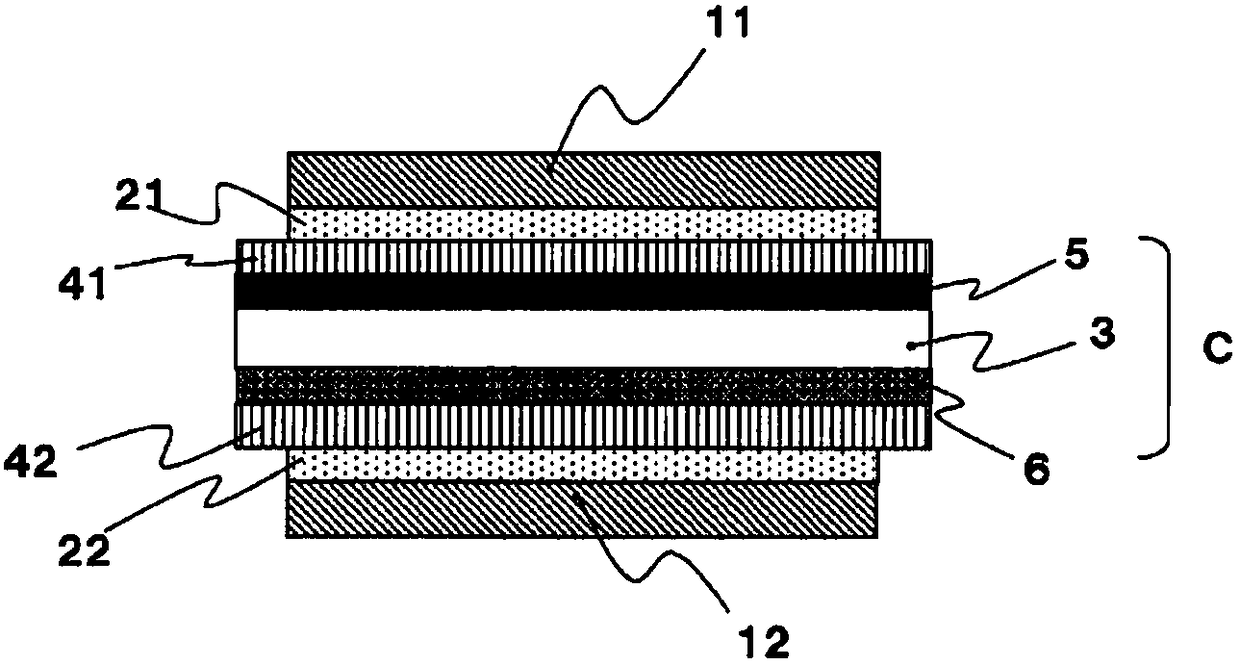

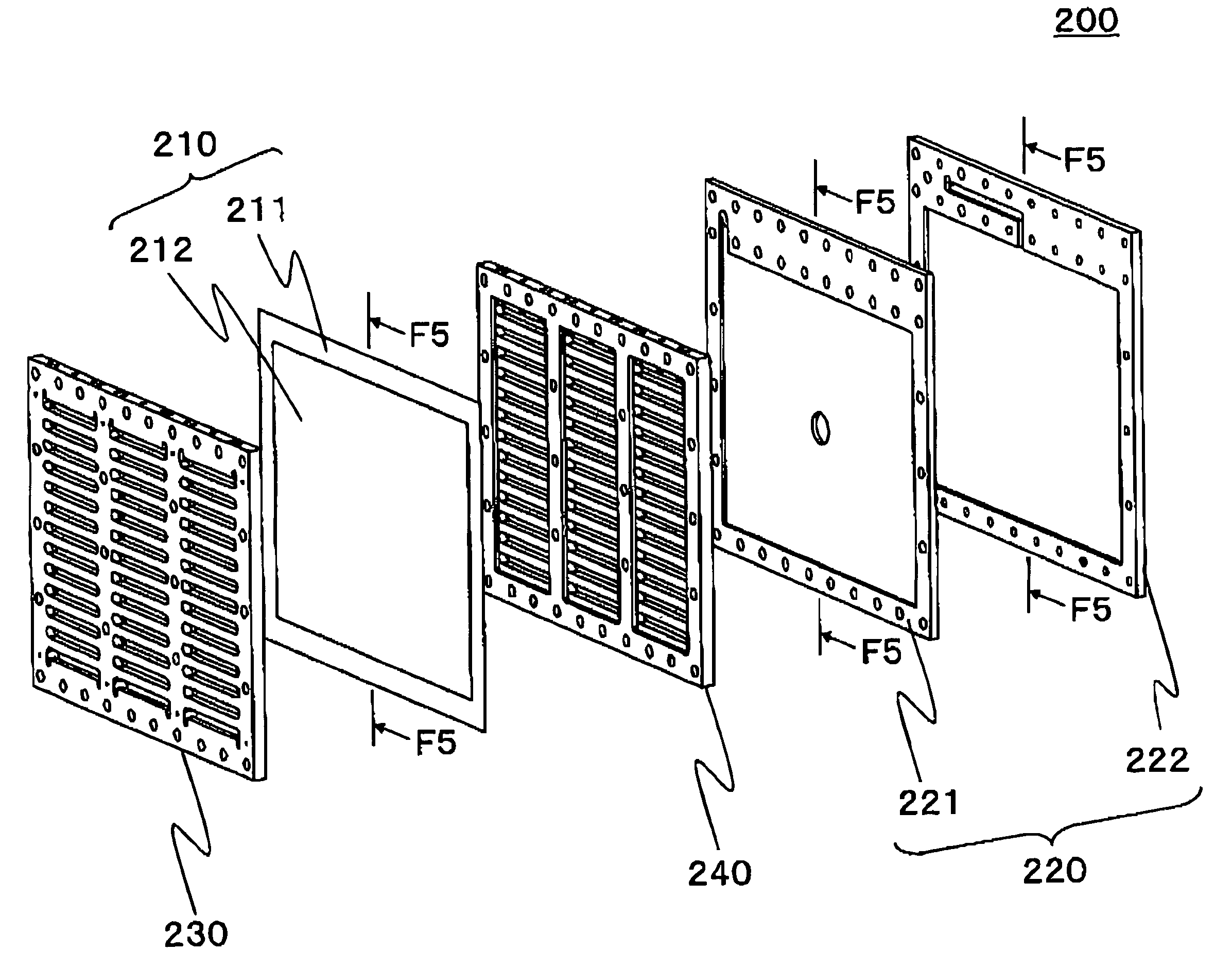

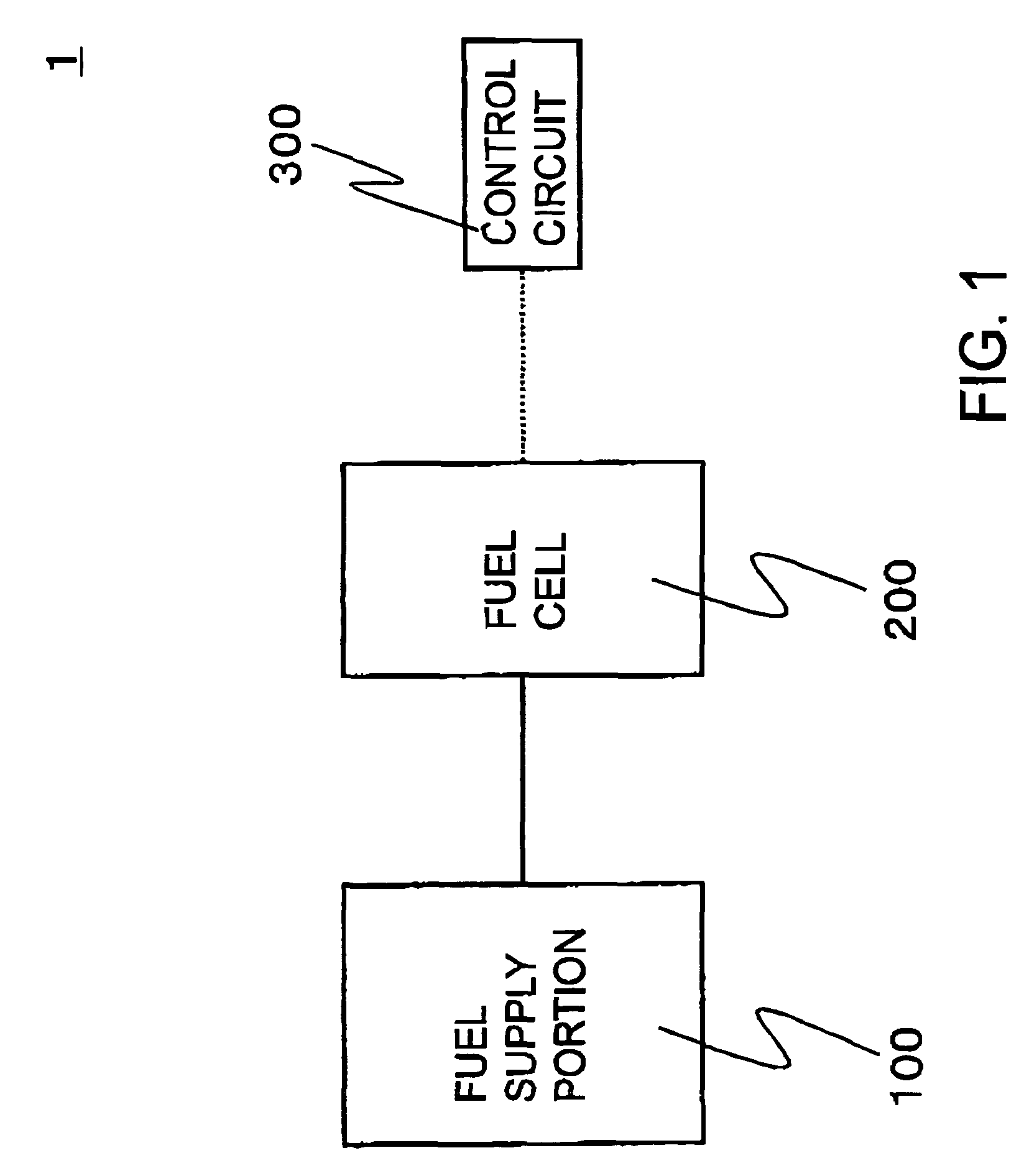

Polymer electrolyte fuel cell

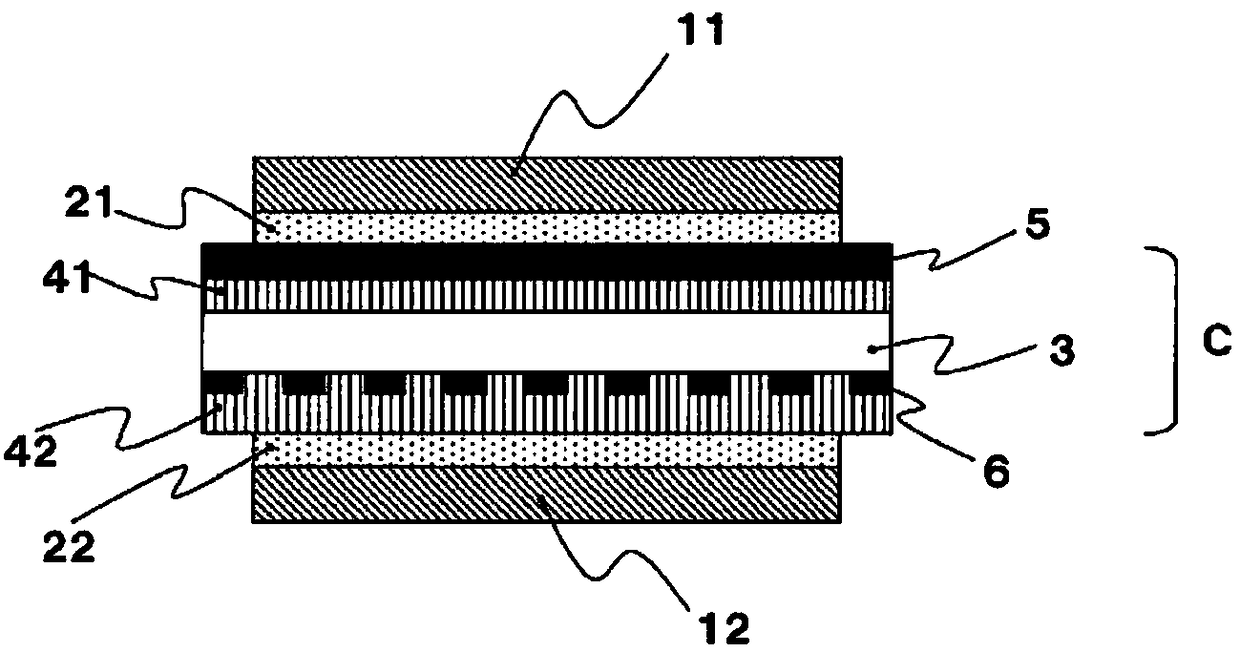

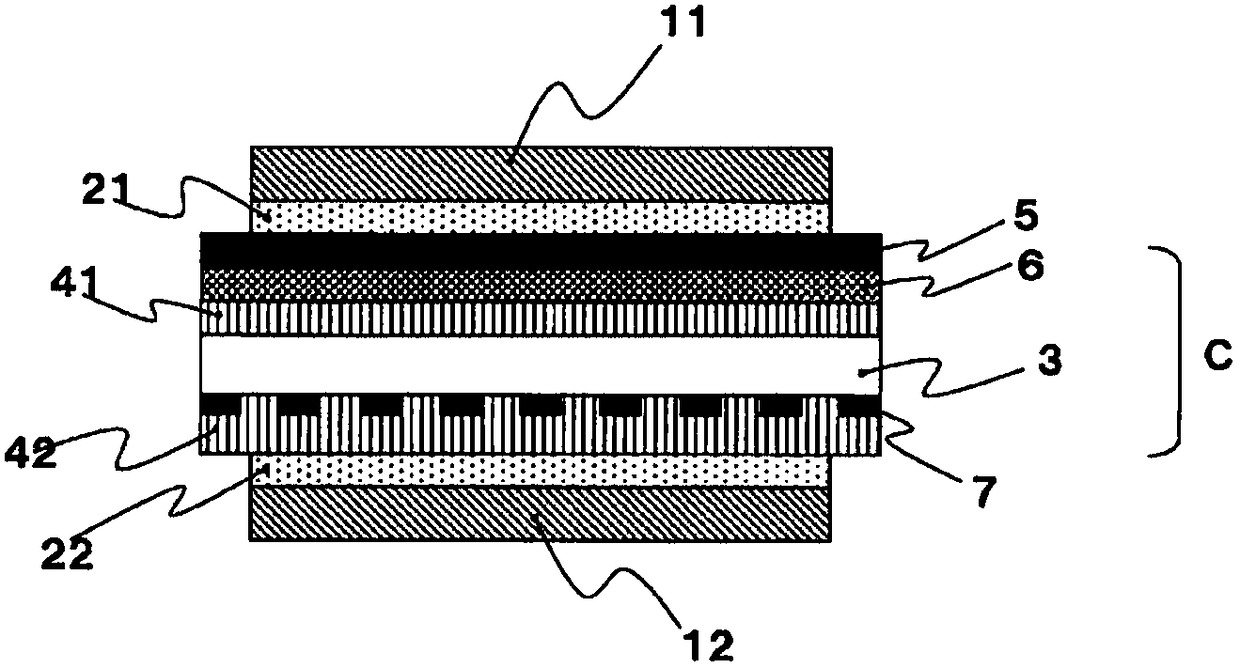

ActiveCN101542815AControl loadUneven suppressionFuel cells groupingSolid electrolyte fuel cellsPolymer electrolytesFuel cells

A polymer electrolyte fuel cell is formed by a fuel cell stack assembled by cramping a plurality of layered single cell modules via a pair of end plates by a plurality of cramping members. The polymer electrolyte fuel cell includes: a plurality of first elastic members each arranged between the cramping member and the end plate; and a plurality of second elastic members each arranged between the end plate and the fuel cell stack end portion. The respective second elastic members are arranged on the end plate surface equivalent to an electrode portion of a film electrode assembly in the respective single cell modules while the respective first elastic members are arranged on the end plate surface equivalent to an arrangement region of a seal member arranged between the rim portion of the film electrode assembly and a pair of separator plates.

Owner:PANASONIC CORP

Liquid crystal panel with touch sensing function and liquid crystal display device

ActiveCN108139625ALower surface resistance valueInhibit static electricity generationSynthetic resin layered productsPolarising elementsMeth-Touch Senses

Owner:NITTO DENKO CORP

Color filter ink, color filter ink set, color filter, image display, and electronic apparatus

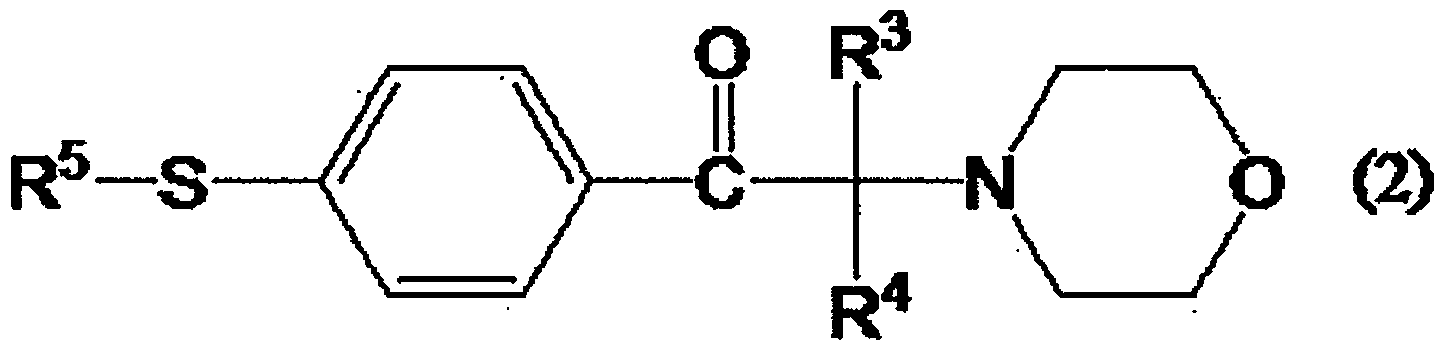

InactiveUS20090152516A1Improve long-term stabilityImprove discharge stabilityInksOptical elementsHydrogen atomDisplay device

A color filter ink, which is used to produce a color filter by using an inkjet method, includes: C. I. pigment yellow 150; and a sulfonated pigment derivative represented by following chemical formula 1:where n represents an integer of 1 to 5, and X1 to X8 each independently represent a hydrogen atom or a halogen atom.

Owner:SEIKO EPSON CORP

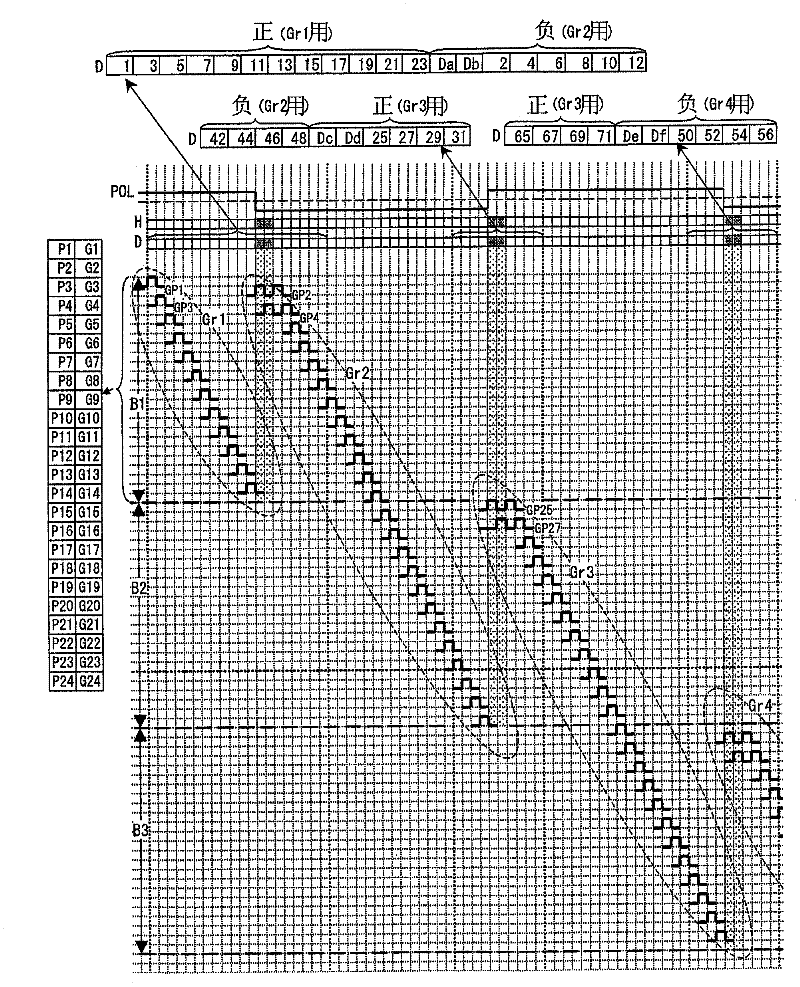

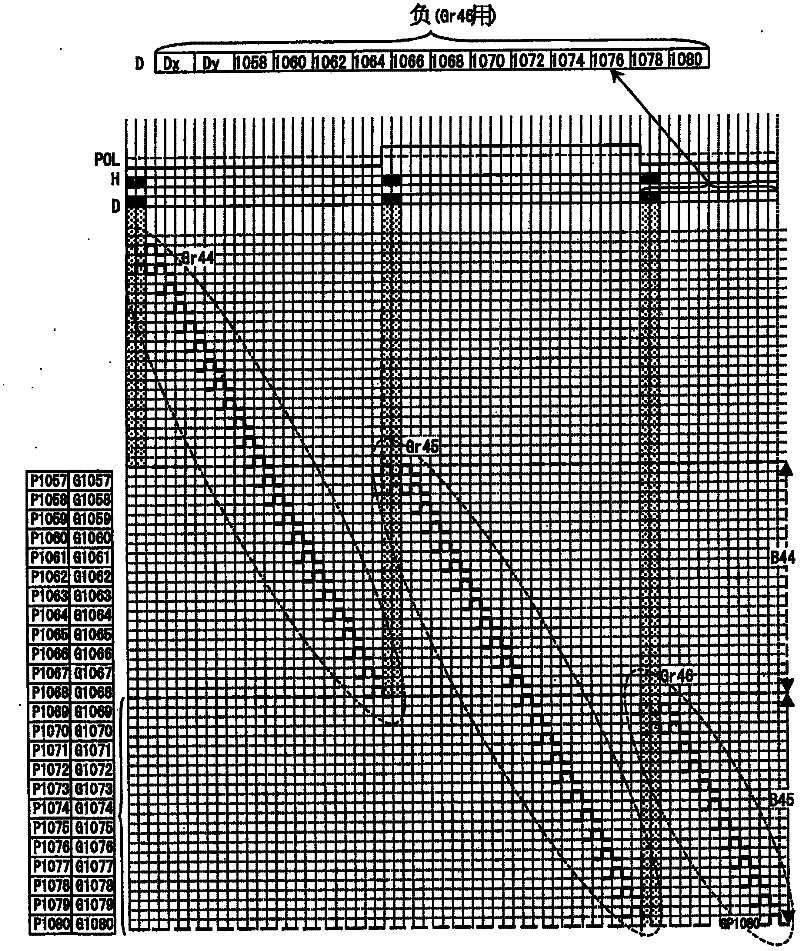

Liquid crystal display device, liquid crystal display device drive method, and television receiver

InactiveCN102224538AReduce the difference in charge rateUneven suppressionStatic indicating devicesTelevision receiversLiquid-crystal display

Provided is a liquid crystal display device including a display unit having scan signal lines divided into a plurality of groups (Gr1, Gr2, ...) which are successively selected. While the scan signal lines belonging to the selected group are successively scanned horizontally, signal potentials of the same polarity are successively supplied to a data signal line. The polarity of the signal potential is reversed between a preceding group and a subsequent group which are selected continuously. A plurality (n) of dummy scan periods (periods Da, Db, ...) are inserted between the horizontal scan period corresponding to the last horizontal scan in the preceding group and the horizontal scan period corresponding to the first horizontal scan in the subsequent group. In each of the dummy scan periods, one of the scan signal lines which belong to the group selected after the preceding group is subjected to a dummy scan so that the scan signal line is maintained in an active state for a predetermined period and then deactivated so as to align the load state of a scan signal line drive circuit. This can reduce irregularities of the horizontal stripes when the data signal line is subjected to the block reverse drive.

Owner:SHARP KK

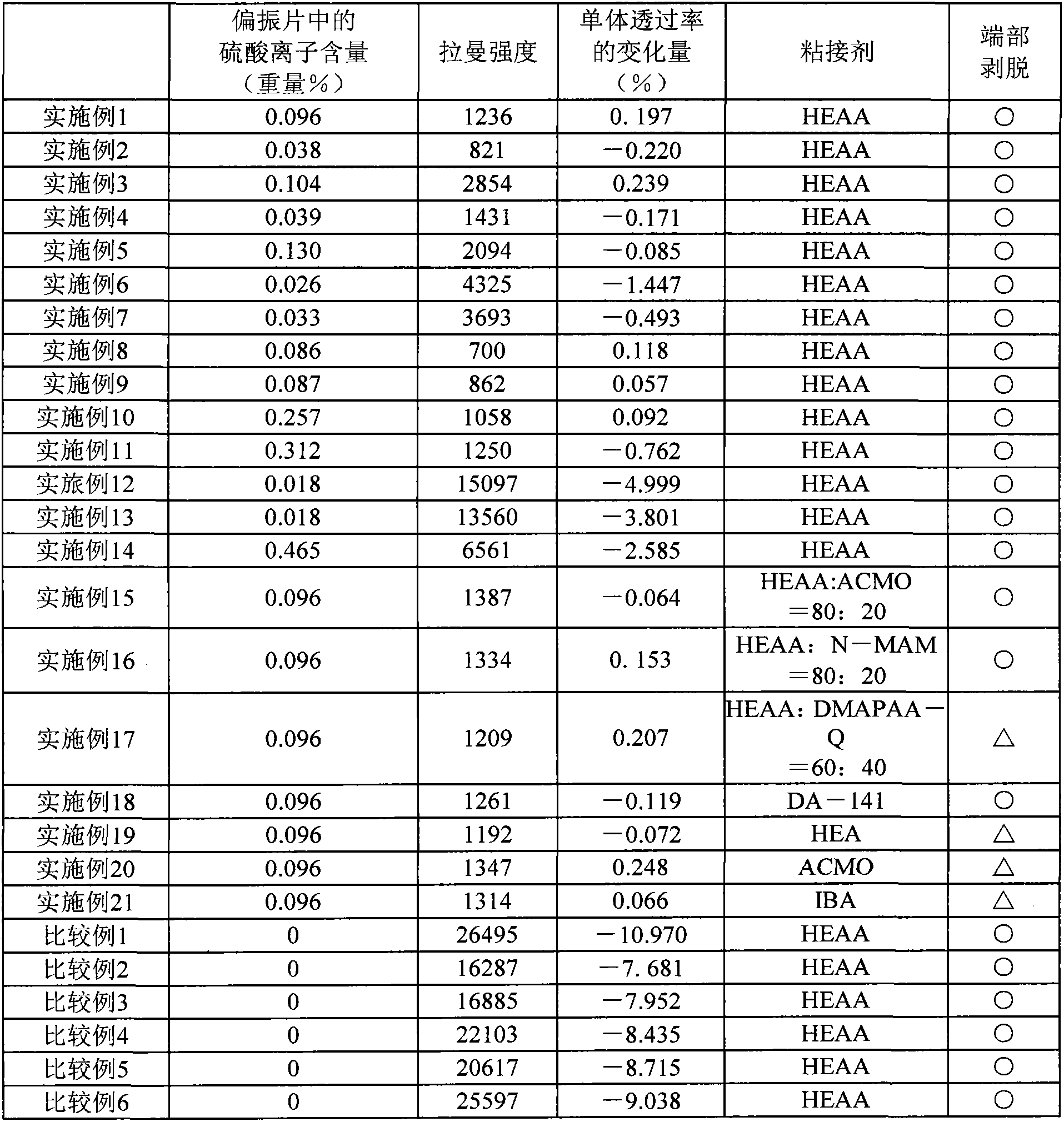

Polarizing plate, method of manufacturing the same, optical film and image display apparatus

ActiveCN102193133AMeet the durabilityGood dimensional stabilitySynthetic resin layered productsLaminationPolyvinyl alcoholAdhesive

The invention provides a polarizing plate including a polarizer and a transparent protective film bonded together with an active energy ray-curable adhesive and having durability at high temperature. The polarizing plate is a polarizing plate that the transparent protective film is placed on at least one side of a polarizer and an adhesive layer interposed between the polarizer, which is characterized in that the polarizer is a stretched polyvinyl alcohol film dyed with a dichroic material and containing a sulfate ion, and the adhesive layer is formed with an active energy ray-curable adhesive containing at least one curable component.

Owner:NITTO DENKO CORP

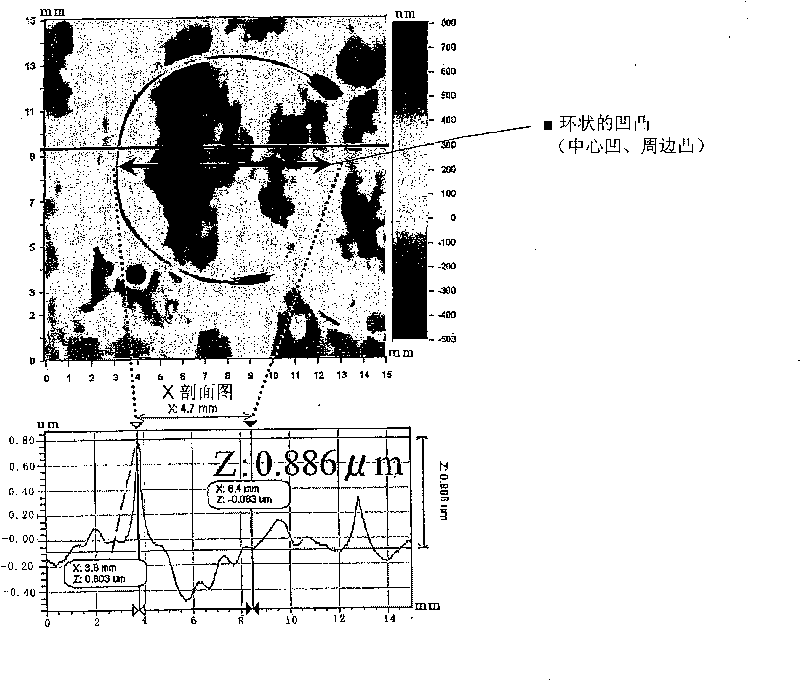

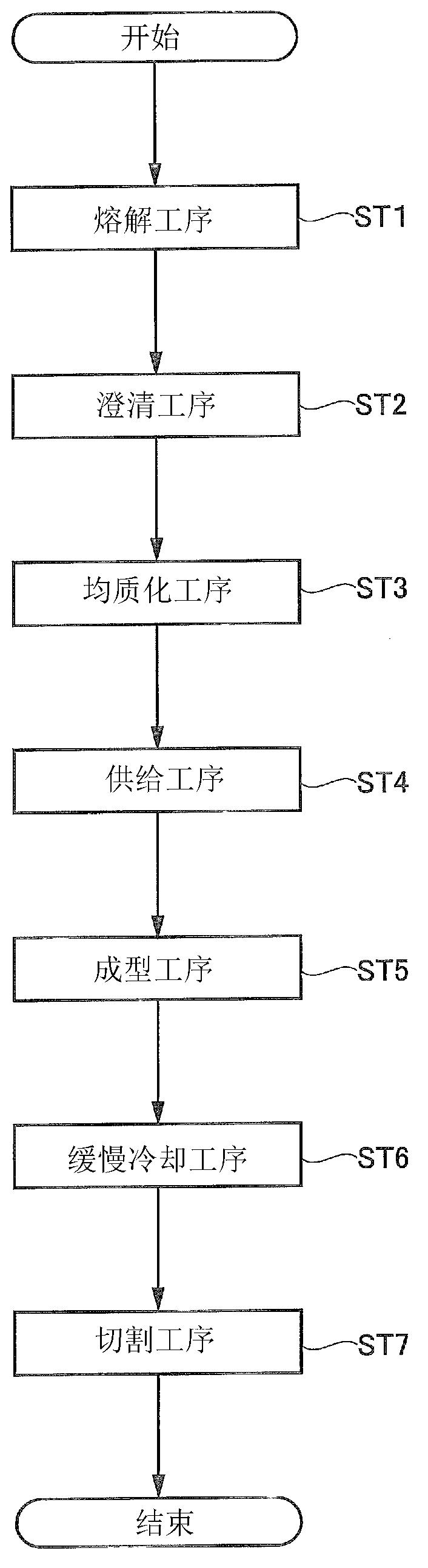

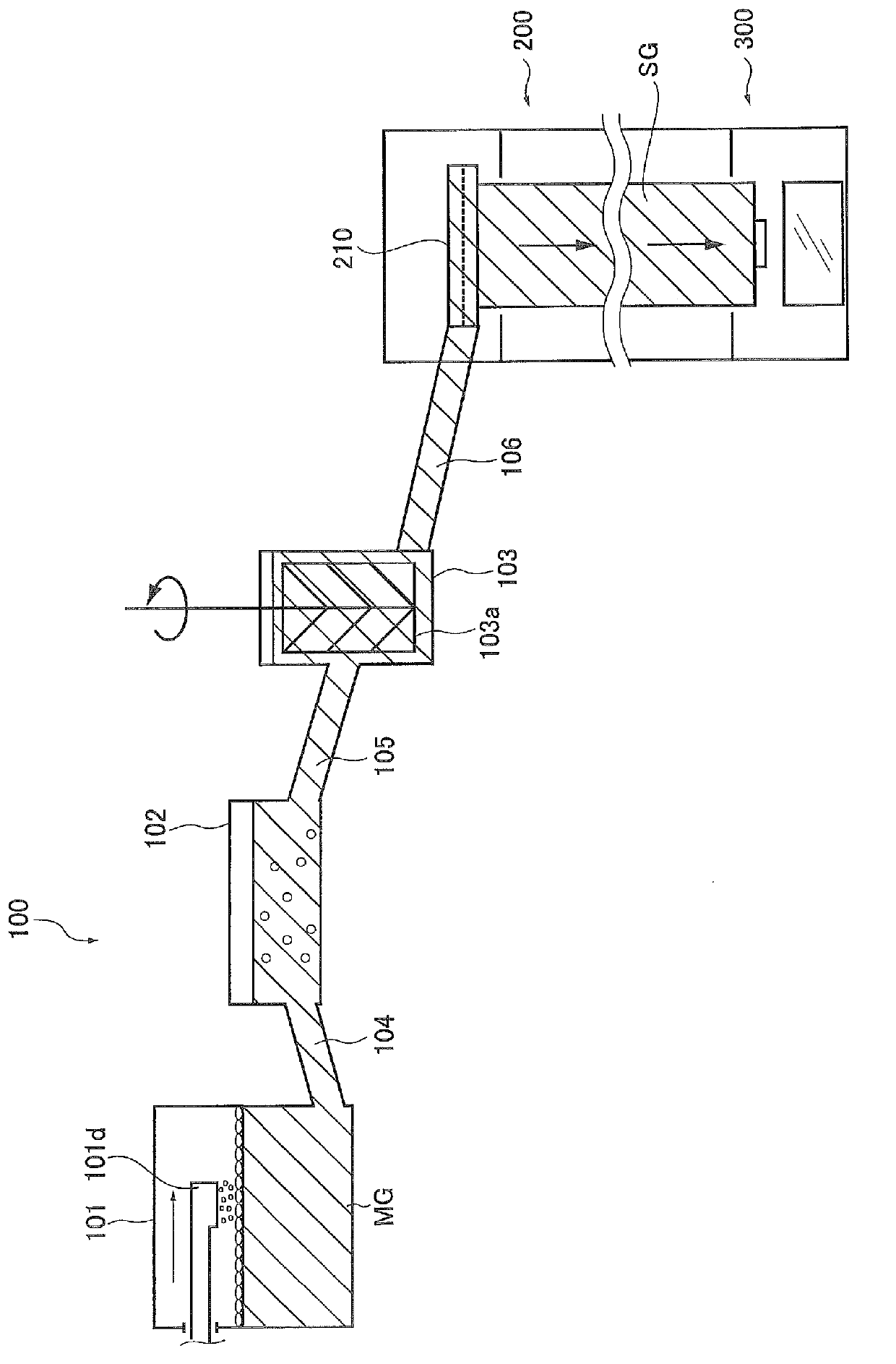

Glass substrate production method

ActiveCN103124700AUneven suppressionCharging furnaceGlass furnace apparatusMelting tankSurface layer

Owner:AVANSTRATE INC +1

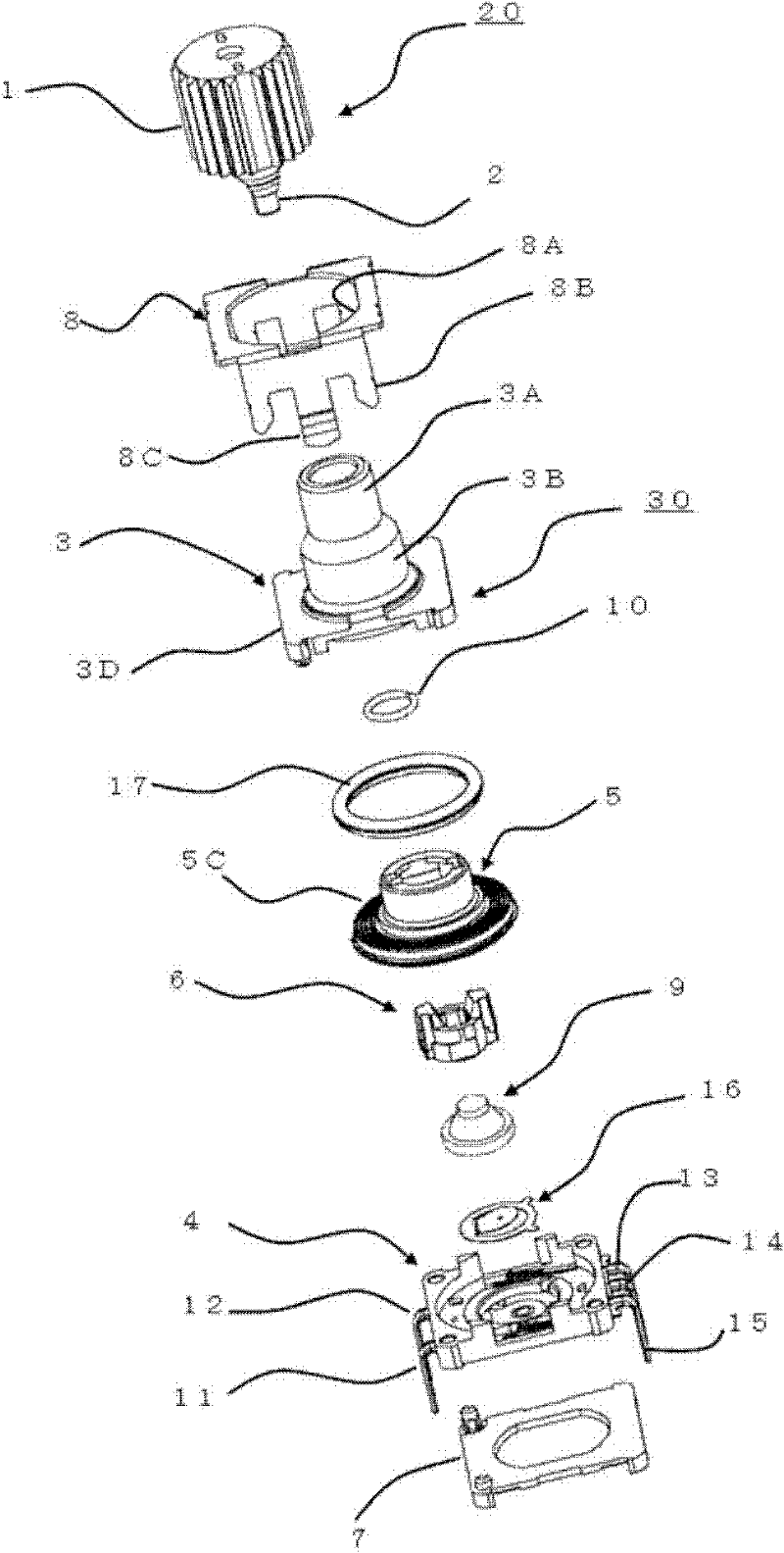

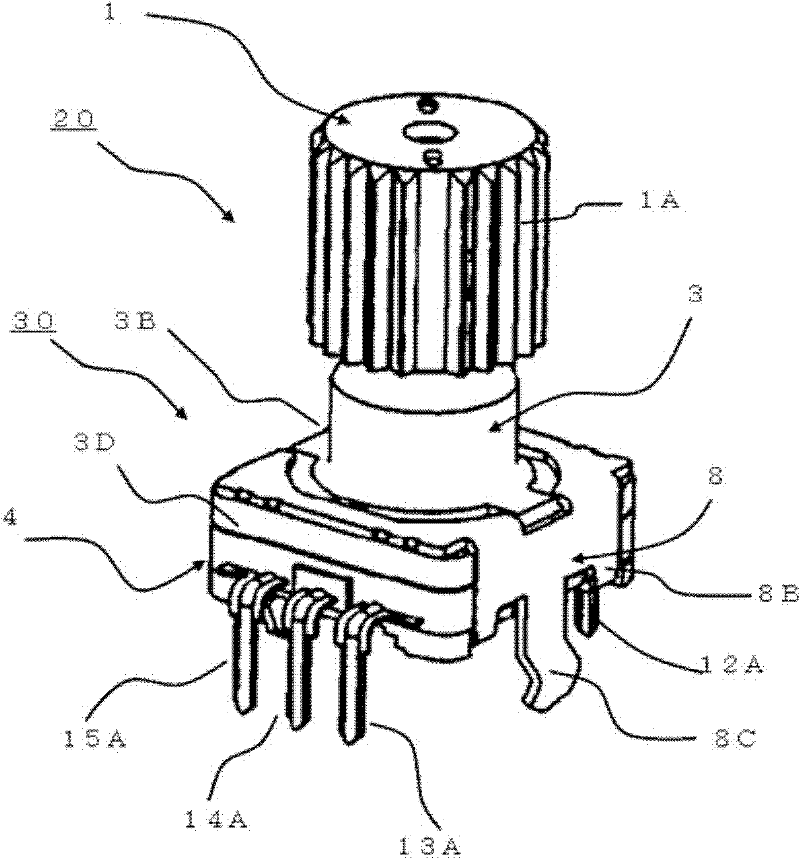

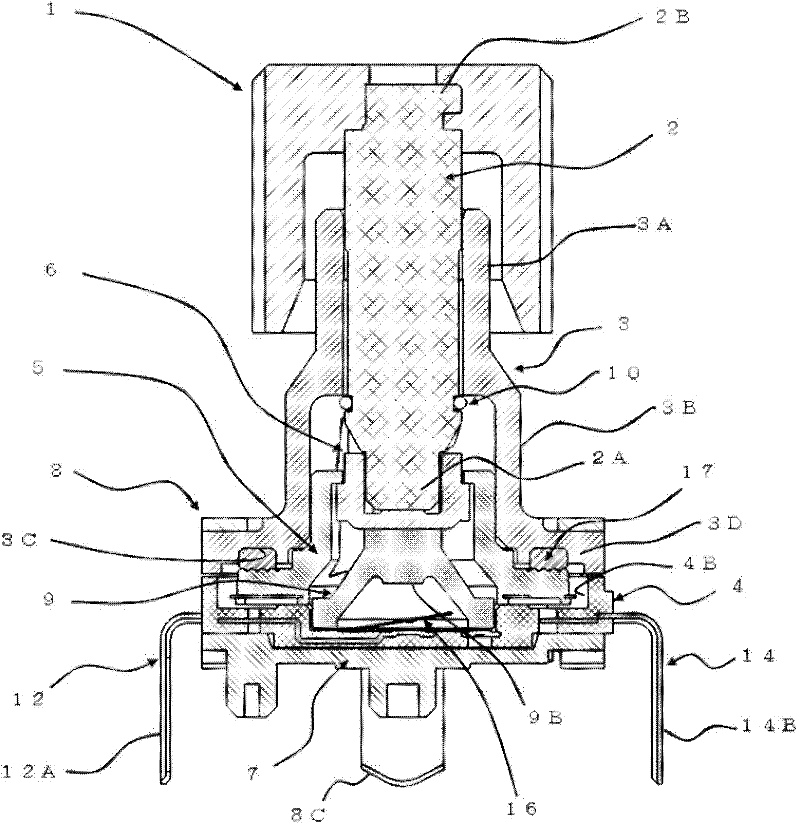

Rotating type electric component

ActiveCN102208299AIncrease frictional resistanceUneven suppressionElectric switchesSolid of revolution

Owner:ALPS ALPINE CO LTD

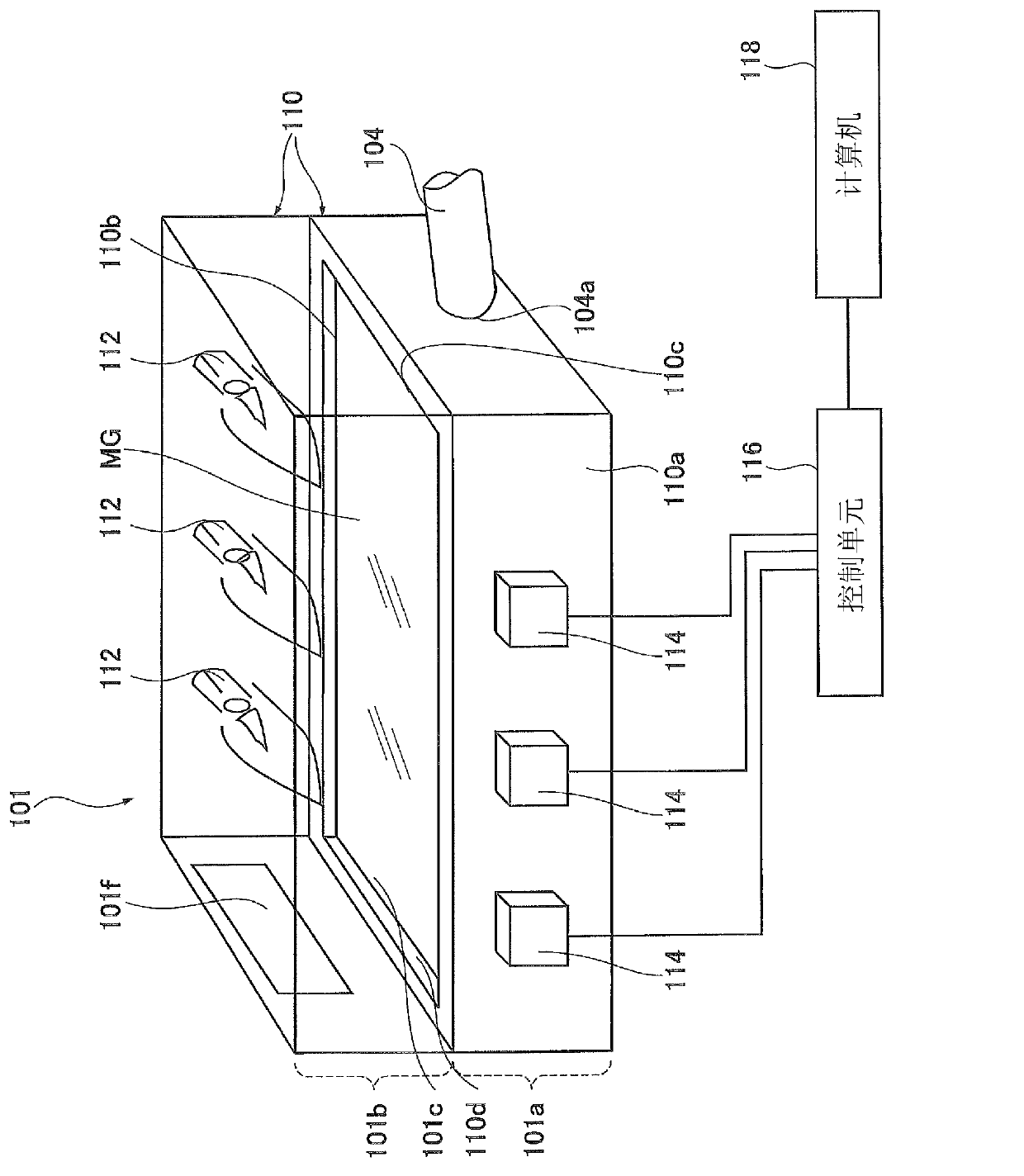

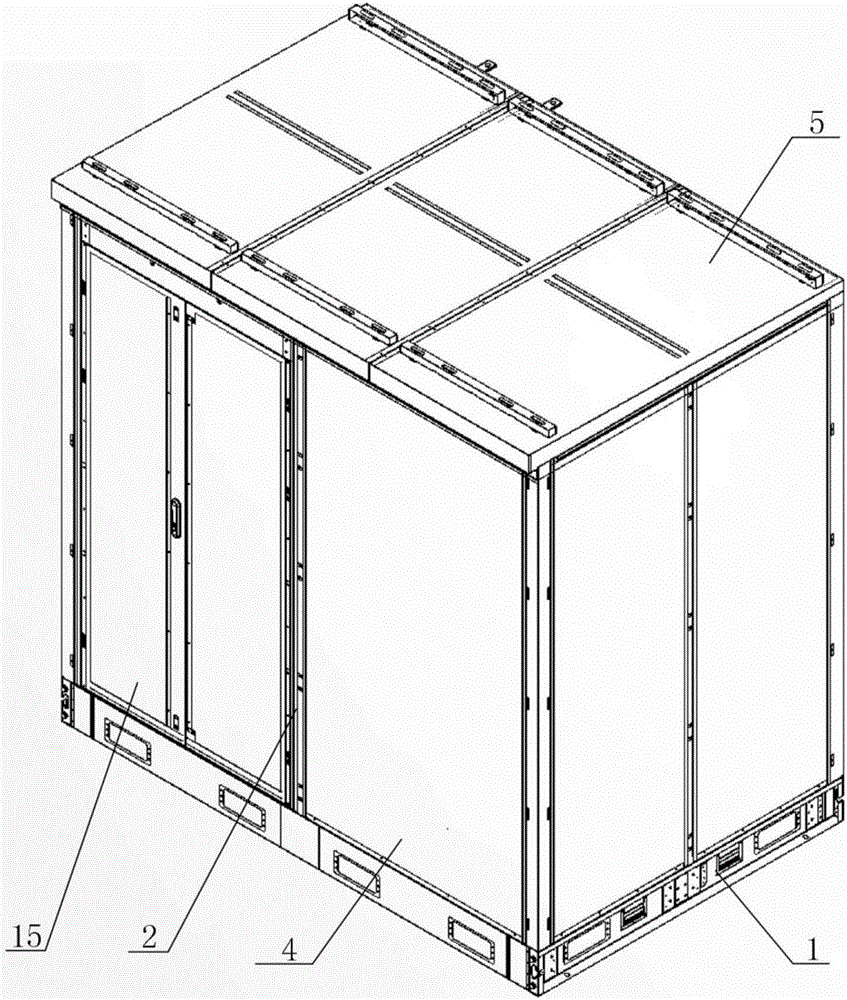

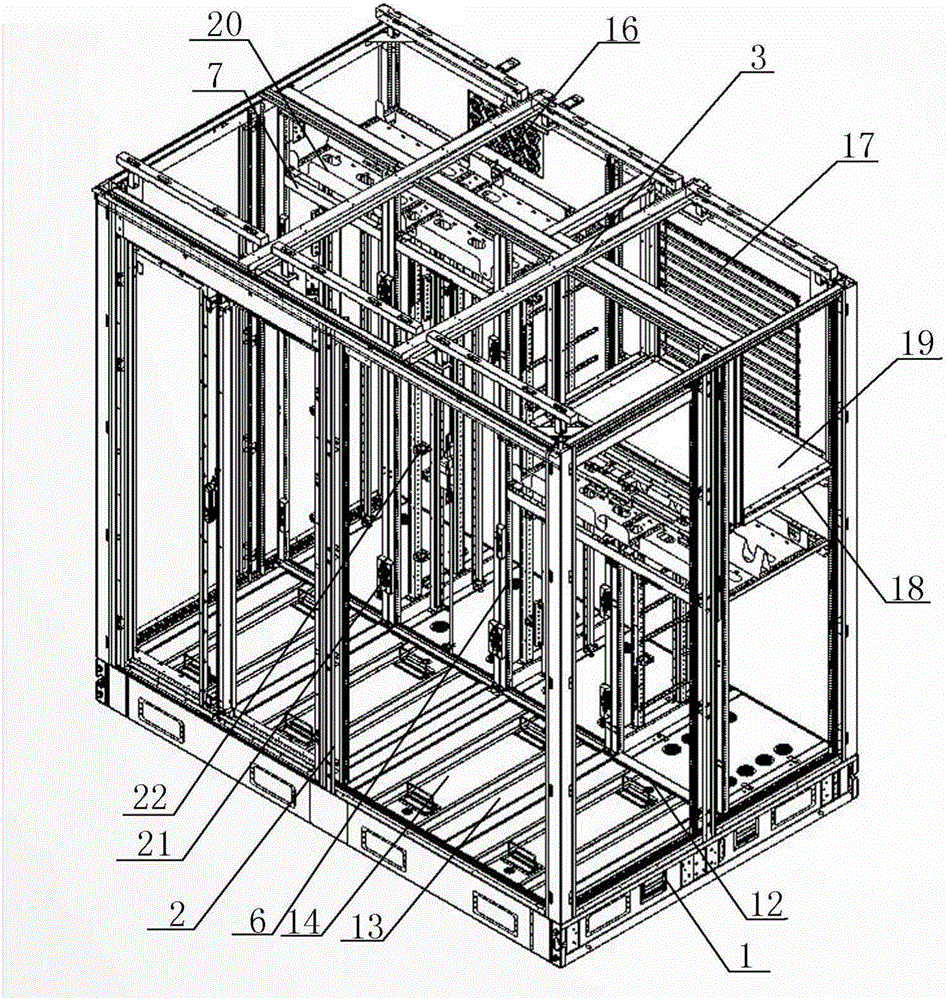

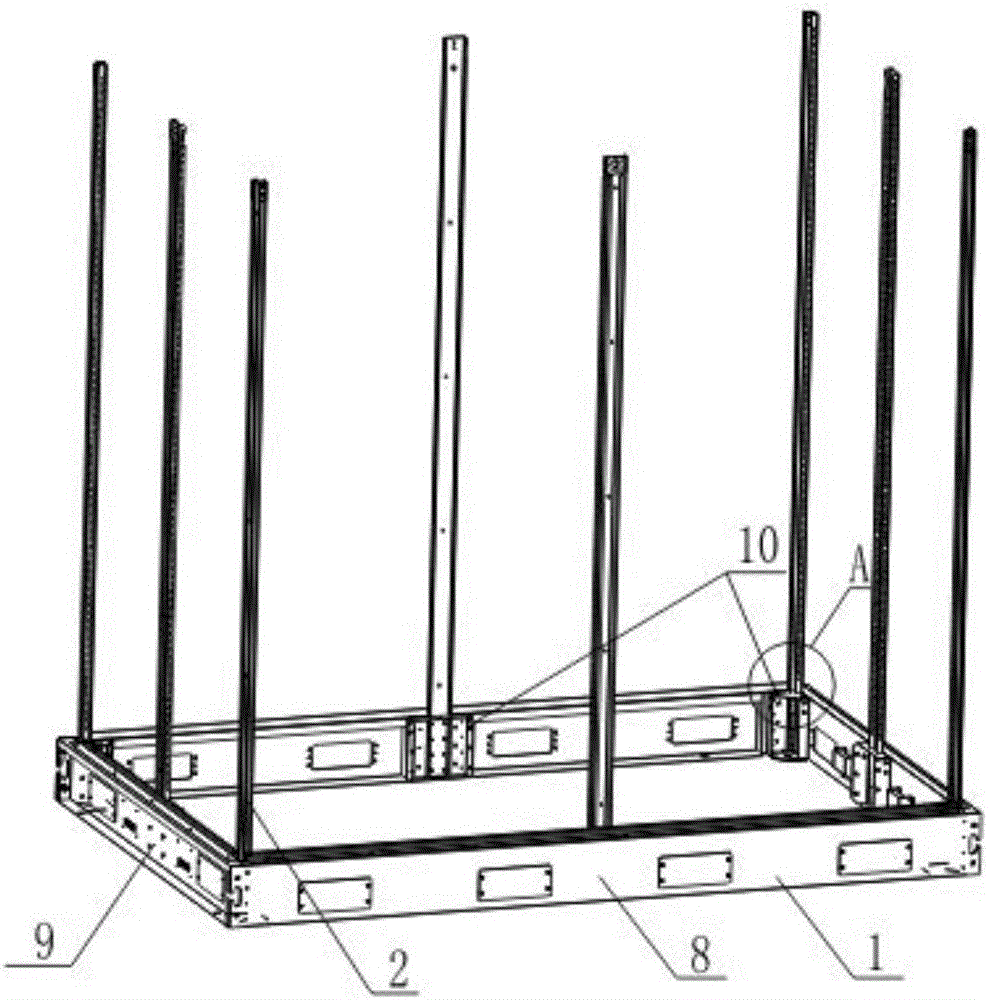

Integrated machine room

InactiveCN106639380AReduce the difficulty of transportationReduce shipping costsSpecial buildingBuilding insulationsComputer moduleEngineering

The invention provides an integrated machine room. The integrated machine room comprises a base, wherein the base is provided with a plurality of outer stand columns A; the upper ends of the outer stand columns A are connected with a top frame; a wall board is clamped between the adjacent outer stand columns A; a top cover is arranged on the top frame; a plurality of inner stand columns B are further arranged on the base; a mounting frame for separating the machine room into cabin bodies is arranged between the adjacent inner stand columns B; and the outer stand columns A and the base, the outer stand columns A and the top frame, the outer stand columns A and the wall board, the top frame and the top cover, and the base and the inner stand columns B are detachably connected. According to the integrated machine room provided by the invention, the whole machine room is divided into a plurality of small unit modules and the small unit modules only need to be simply assembled on site, so that the construction period is greatly shortened and pollution to the environment by building garbage is also reduced. In the transportation process, only all the unit modules need to be transported, so that the transportation difficulty and transportation cost of the machine room are greatly reduced, and influences on construction of the machine room, caused by a region environment, are also reduced.

Owner:SICHUAN ANNENG ENERGY TECH CO LTD

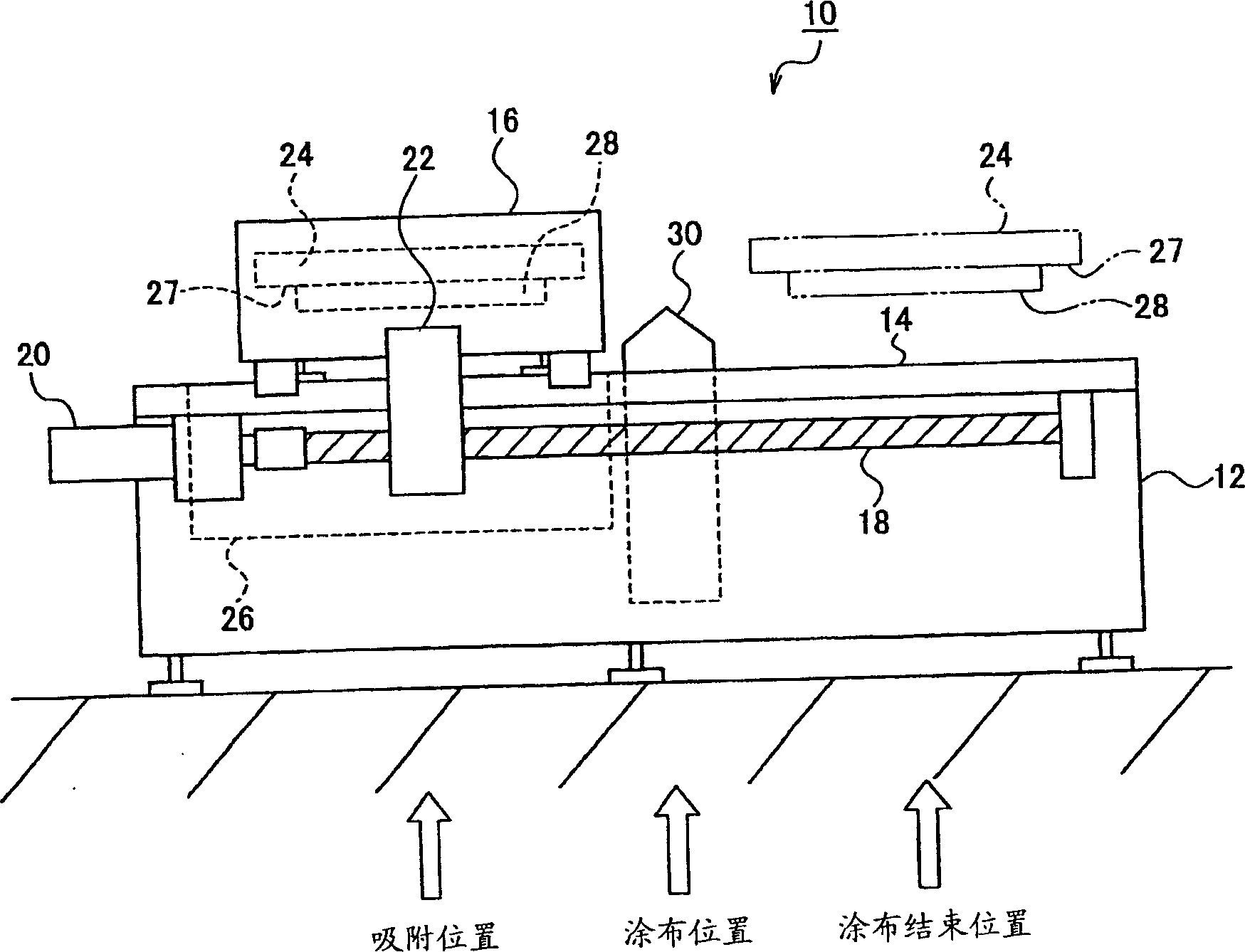

Coating device

InactiveCN1843637ASuppress uneven coatingAvoid skewLiquid surface applicatorsSpraying apparatusSpray nozzleMoving frame

The present invention provides a coating device capable of suppressing uneven coating of the coating liquid when the coating liquid is coated on a surface to be coated with a nozzle. The coating device includes: a nozzle having a capillary gap communicated with the top opening and allowing the coating liquid to guide the top opening through the capillary gap; The cloth surface is approached or separated, and the coating liquid that has reached the above-mentioned tip opening can be in liquid contact with the surface to be coated; The coating liquid in the above-mentioned tip opening can be coated on the surface to be coated. The lifting mechanism part has a nozzle support shaft for supporting the nozzle, a pedestal is fixed on the top end of the nozzle support shaft, and a coil is wound around the nozzle support shaft, and the nozzle is held by the magnetic force of the electromagnet generated by energizing the coil. Mounted on the pedestal above.

Owner:HOYA CORP

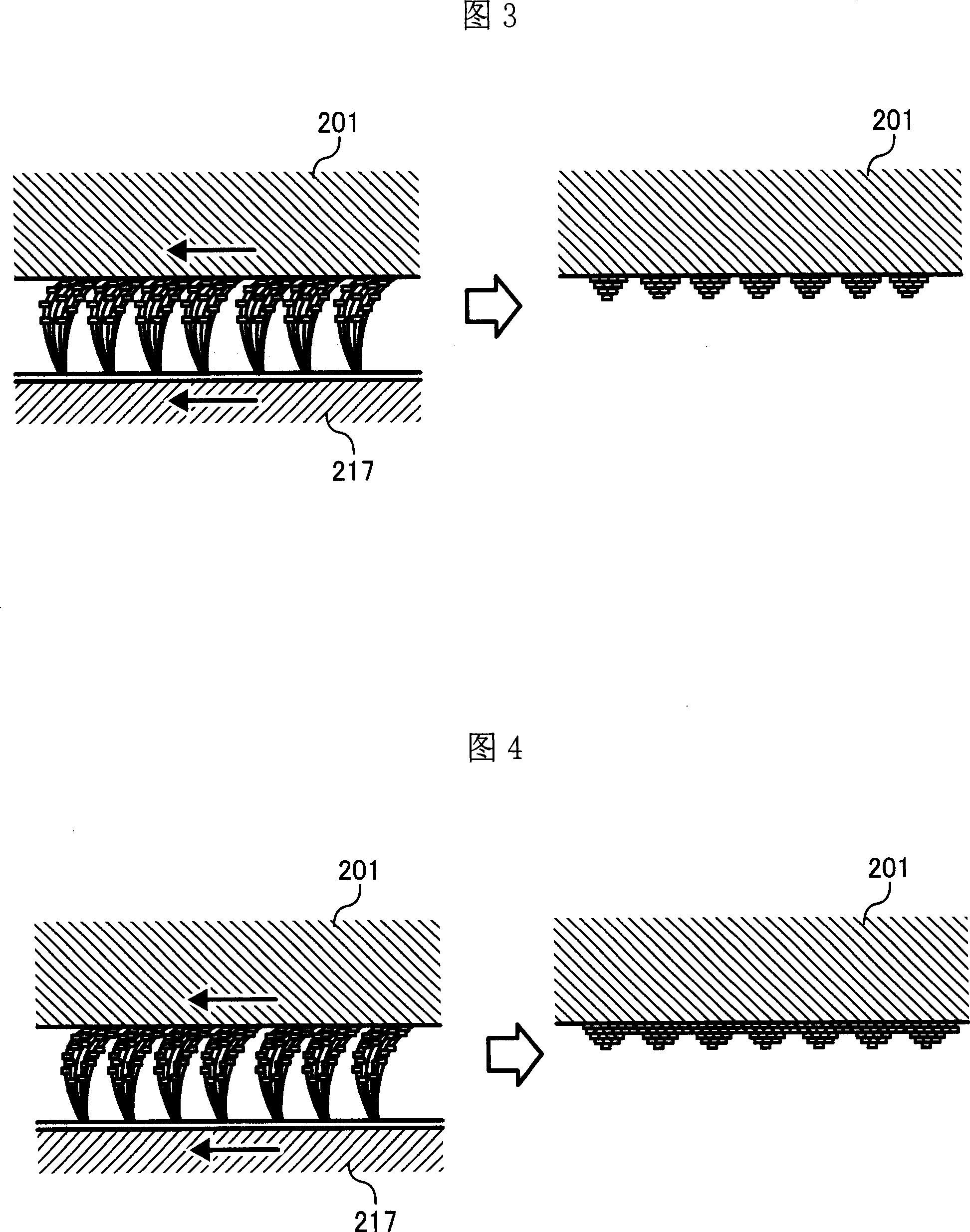

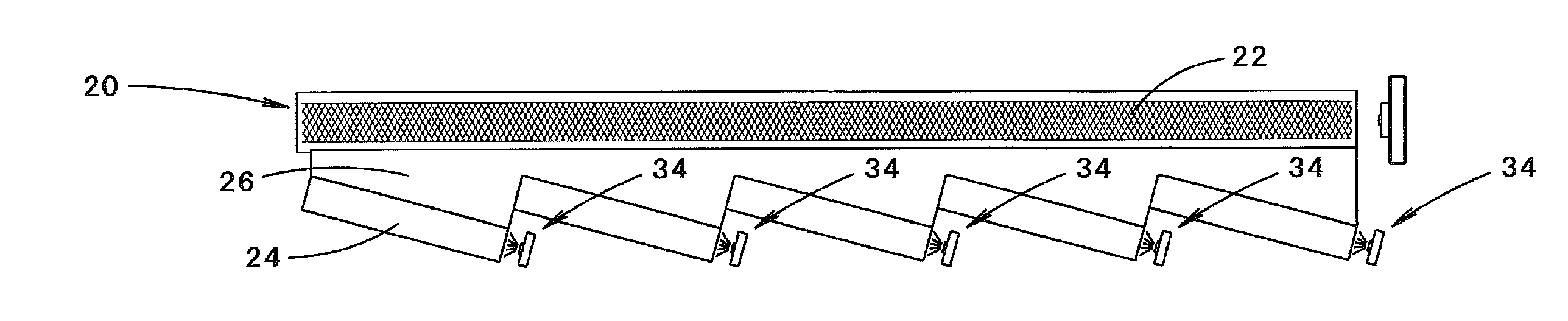

Recording head maintenance device and inkjet recording apparatus therewith

ActiveCN111660672AStable supportUneven suppressionPower drive mechanismsStructural engineeringMechanical engineering

A maintenance device has a maintenance unit. The maintenance unit has a blade unit to which a plurality of wiping blades are fixed, a wiper carriage to which the blade unit is attached, and a supportframe that supports the wiper carriage. The wiper carriage has a stationary portion with a sliding roller, a movable portion with a positioning roller, and an elastic member. The elastic member elastically supports the movable portion relative to the stationary portion, and elastically contracts, when the maintenance unit is pressed against a plurality of recording heads by a unit ascent-descent mechanism with an excessive pressing force stronger than a predetermined pressing force, by receiving the reaction force of the excessive pressing force.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Fuel cell exhibiting enhanced hydrogen distribution density

InactiveUS8129066B2Uneven suppressionIncrease the output voltageFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

Owner:SEIKO INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com