Processing cassette, image forming method and apparatus

A technology for processing cartridges and images, which is applied in the direction of electric recording process applying charge pattern, electric recording process applying electric charge pattern, electric recording technique, etc. problem, to achieve the effect of stable coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

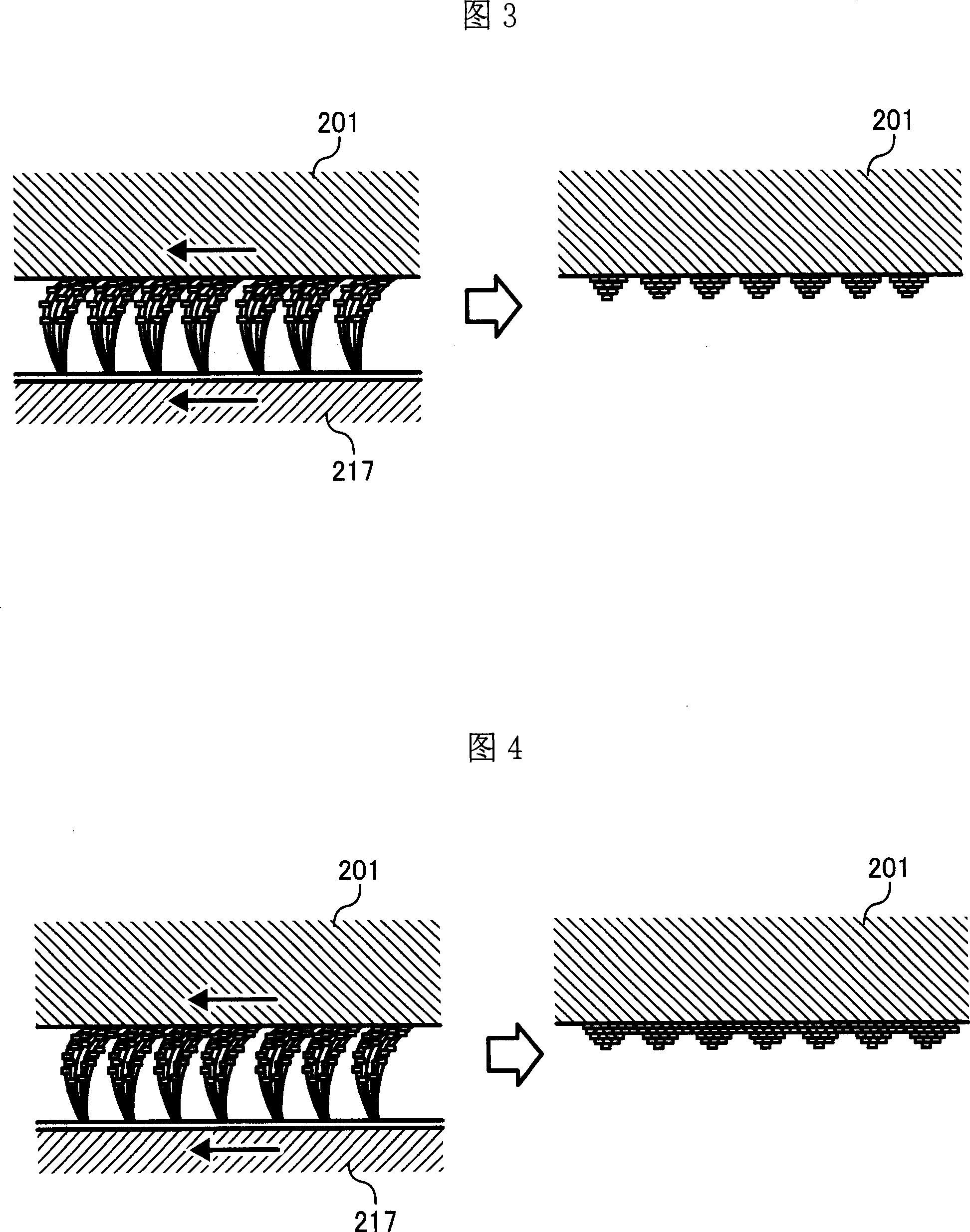

[0093] The lubricant application brush roll 17a was composed of acrylic fibers, and solid zinc stearate was used as a lubricant, and was pressed against the lubricant application brush roll 17a with an initial contact force of 500 mN. Lubricant coating brush roll 17a diameter is 12mm, like carrier 1 diameter 30mm, lubricant coating brush roll 17a bites 1mm relative to image carrier 1, therefore, at the part that contacts with like carrier 1, lubricates The substantial diameter of the lubricant application brush roller 17 a was 10 mm, and the linear velocity of the lubricant application brush roller 17 a was set to 1.1 times the linear velocity of the image carrier 1 .

Embodiment 2

[0095] The lubricant application brush roll 17a was composed of acrylic fibers, and solid zinc stearate was used as a lubricant, and was pressed against the lubricant application brush roll 17a with an initial contact force of 1000 mN. Lubricant coating brush roll 17a diameter is 12mm, like carrier 1 diameter 30mm, lubricant coating brush roll 17a bites 1mm relative to image carrier 1, therefore, at the part that contacts with like carrier 1, lubricates The substantial diameter of the lubricant application brush roller 17 a was 10 mm, and the linear velocity of the lubricant application brush roller 17 a was set to 1.1 times the linear velocity of the image carrier 1 .

Embodiment 3

[0097] The lubricant application brush roll 17a was composed of acrylic fibers, and solid zinc stearate was used as a lubricant, and was pressed against the lubricant application brush roll 17a with an initial contact force of 1000 mN. Lubricant coating brush roll 17a diameter is 12mm, like carrier 1 diameter 30mm, lubricant coating brush roll 17a bites 1mm relative to image carrier 1, therefore, at the part that contacts with like carrier 1, lubricates The substantial diameter of the lubricant application brush roller 17 a was 10 mm, and the linear velocity of the lubricant application brush roller 17 a was set to be 1.3 times the linear velocity of the image carrier 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com