Pressure-sensitive adhesive optical film and image display

An optical film and adhesive type technology, applied in the direction of adhesive type, optics, optical components, etc., can solve the problems of poor appearance, adhesive deterioration, etc., and achieve the effect of improving display contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

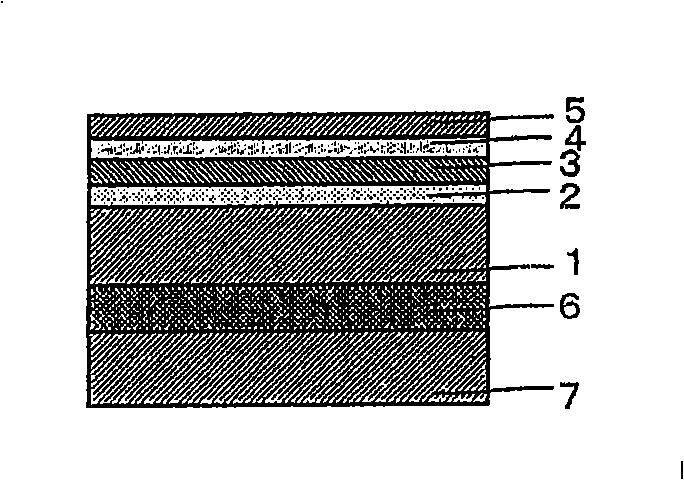

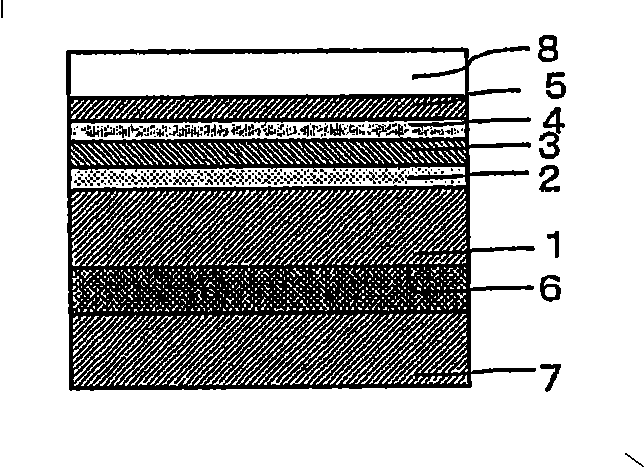

Image

Examples

Embodiment 1

[0171] ((A) Preparation of (meth)acrylic polymer)

[0172] In a 4-neck flask equipped with a stirring paddle, a thermometer, a nitrogen inlet tube, and a condenser tube, add 99 parts by weight of butyl acrylate (BA), 1 part by weight of 4-hydroxybutyl acrylate (HBA), and 0.1 parts by weight of a polymerization initiator 2,2'-Azobisisobutyronitrile and 200 parts by weight of ethyl acetate, slowly stirring and introducing nitrogen gas at the same time to carry out sufficient nitrogen replacement, and then keep the liquid temperature in the flask at around 55°C for 8 hours Polymerization reaction, preparation of acrylic polymer (1) solution. The weight average molecular weight of the acrylic polymer (1) is 1.8 million.

[0173] ((B) Preparation of (meth)acrylic oligomer)

[0174] In a 4-neck flask equipped with a stirring paddle, a thermometer, a nitrogen inlet pipe and a condenser pipe, add 99 parts by weight of butyl acrylate (BA), 2 parts by weight of acrylic acid (AA), 3 pa...

Embodiment 2~6、 comparative example 1~9

[0184] In Example 1, the type or compounding amount of the monomer components used in the preparation of the adhesive ((A) (meth)acrylic polymer and (B) (meth)acrylic oligomer) was changed to As shown in Table 1, the presence or absence of the corresponding phenolic antioxidant when preparing the primer is changed as shown in Table 1, and the type of protective film is changed as shown in Table 1. In addition, the same as that of the embodiment 1 In the same manner, an adhesive optical film was prepared.

[0185] Also, in Comparative Example 5, the undercoat layer does not contain an antioxidant, but the adhesive layer contains an antioxidant, and the content thereof is 1 part by weight (vapor) per 100 parts by weight of the adhesive polymer (acrylic polymer). Ciba Specialty Chemicals, IRGANOX1010). In Comparative Example 9, neither the undercoat layer nor the pressure-sensitive adhesive layer may contain an antioxidant.

[0186] In addition, ZEONOR (manufactured by Japan ZE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com