Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Lower surface resistance value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating forming composition used for forming transparent conductive film

InactiveUS20130251983A1Good dispersionImprove conductivityConductive layers on insulating-supportsPrinted circuit detailsMetal nanowiresHardness

To provide a material capable of obtaining a transparent conductive film having an excellent conductivity, Optical transmission, Environmental reliability, suitability for process, adhesion and hardness in a single application process, and to provide a transparent conductive film using the same and a device element using the same. A coating forming composition containing at least one kind selected from the group of metal nanowires and metal nanotubes as a first component, a polymer compound having a hydroxyl group as a second component, a compound having a group 13 element or a transition metal element as a third component, and further a solvent is prepared to obtain a transparent conductive film by the coating.

Owner:JNC CORP

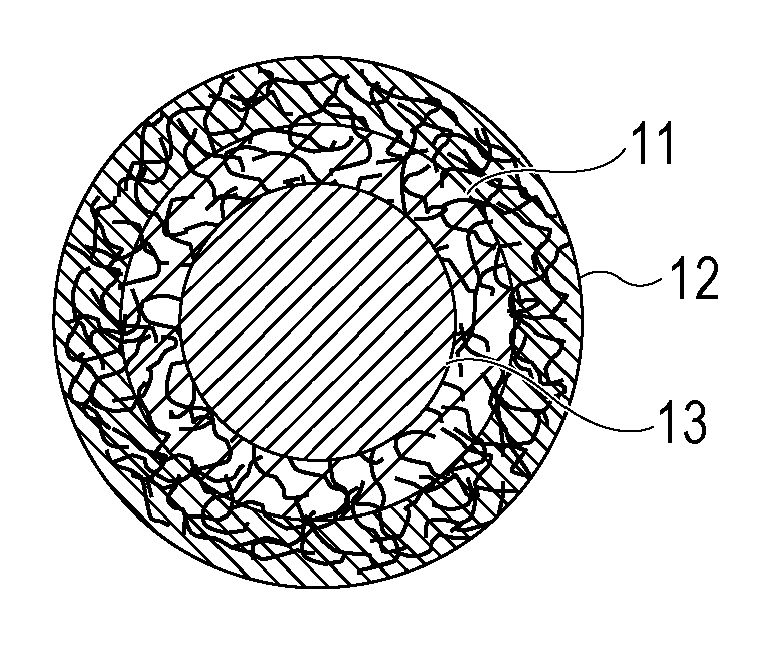

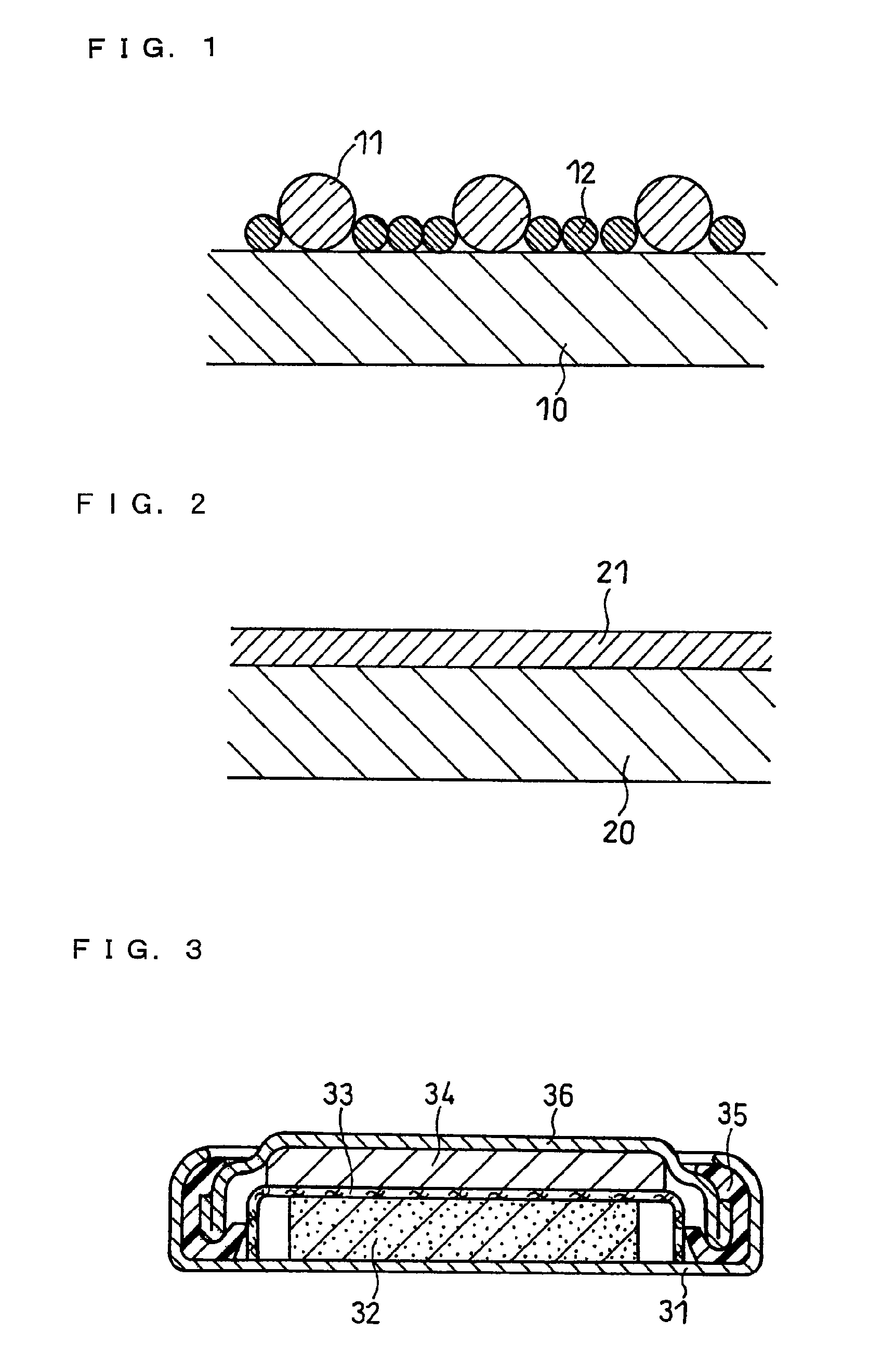

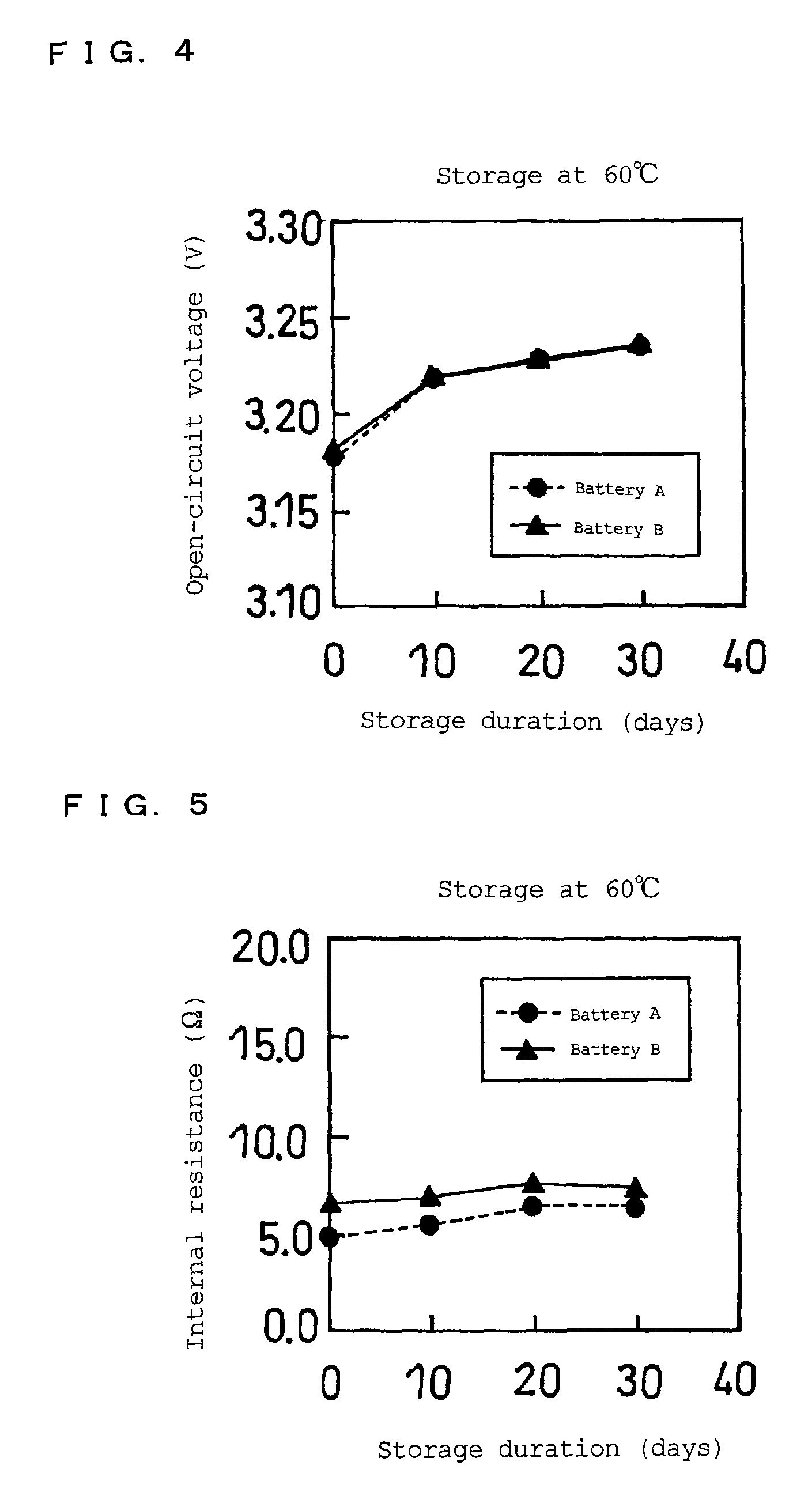

Capacitor electrode member, its manufacturing method and capacitor with same

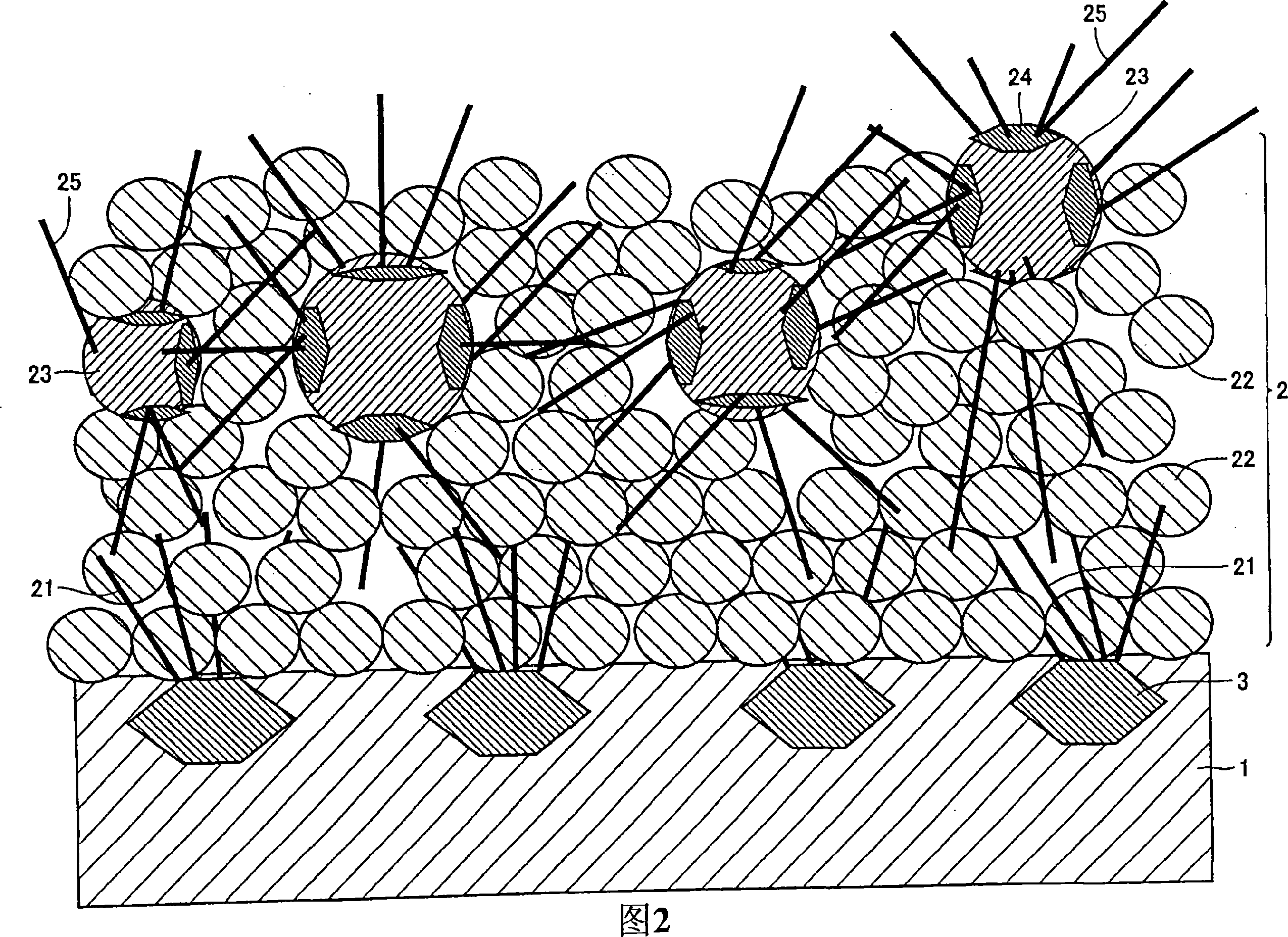

ActiveCN101027736AExcellent adhesionLarge capacityHybrid capacitor electrodesDouble layer capacitorsCarbideCarbon particle

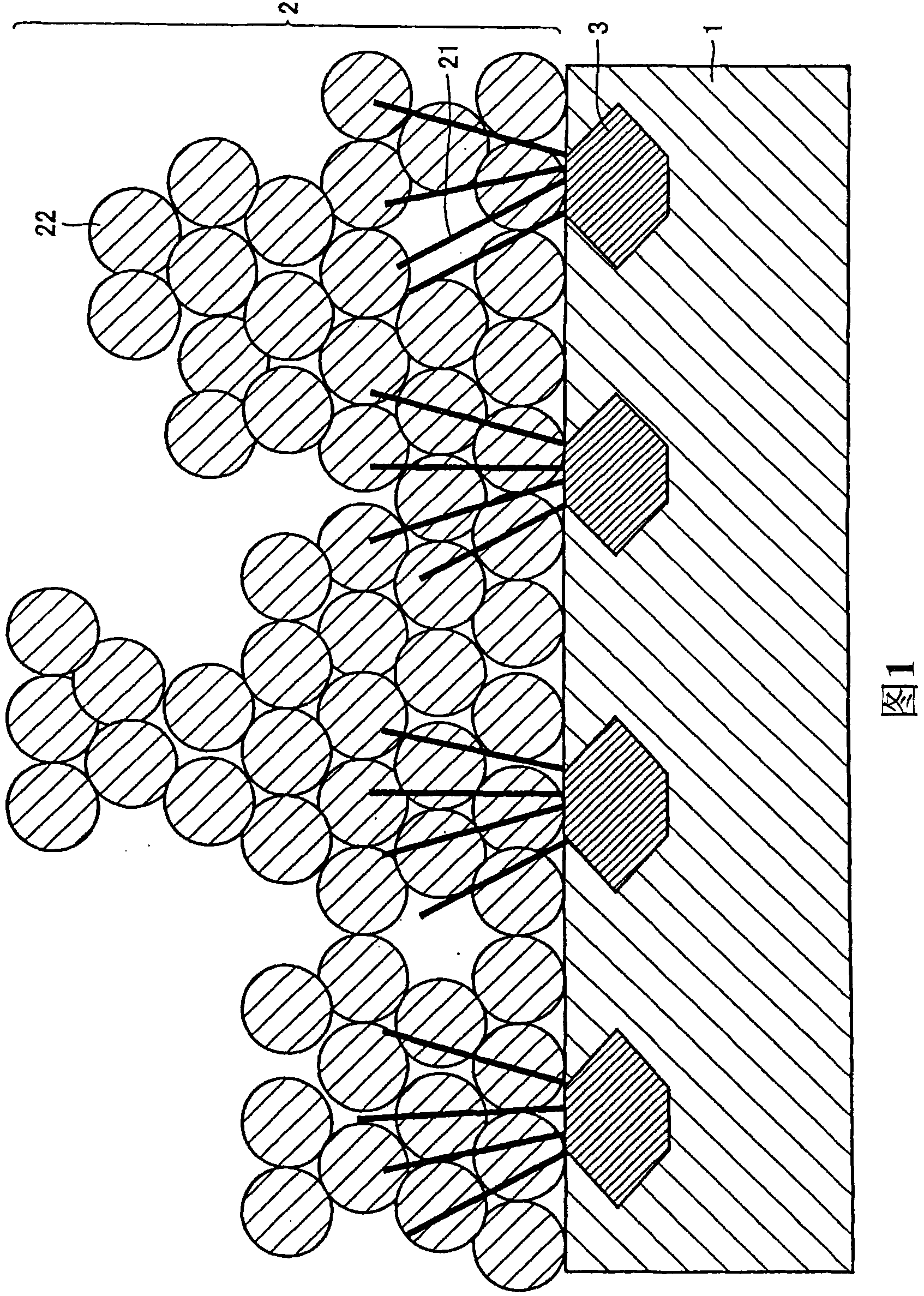

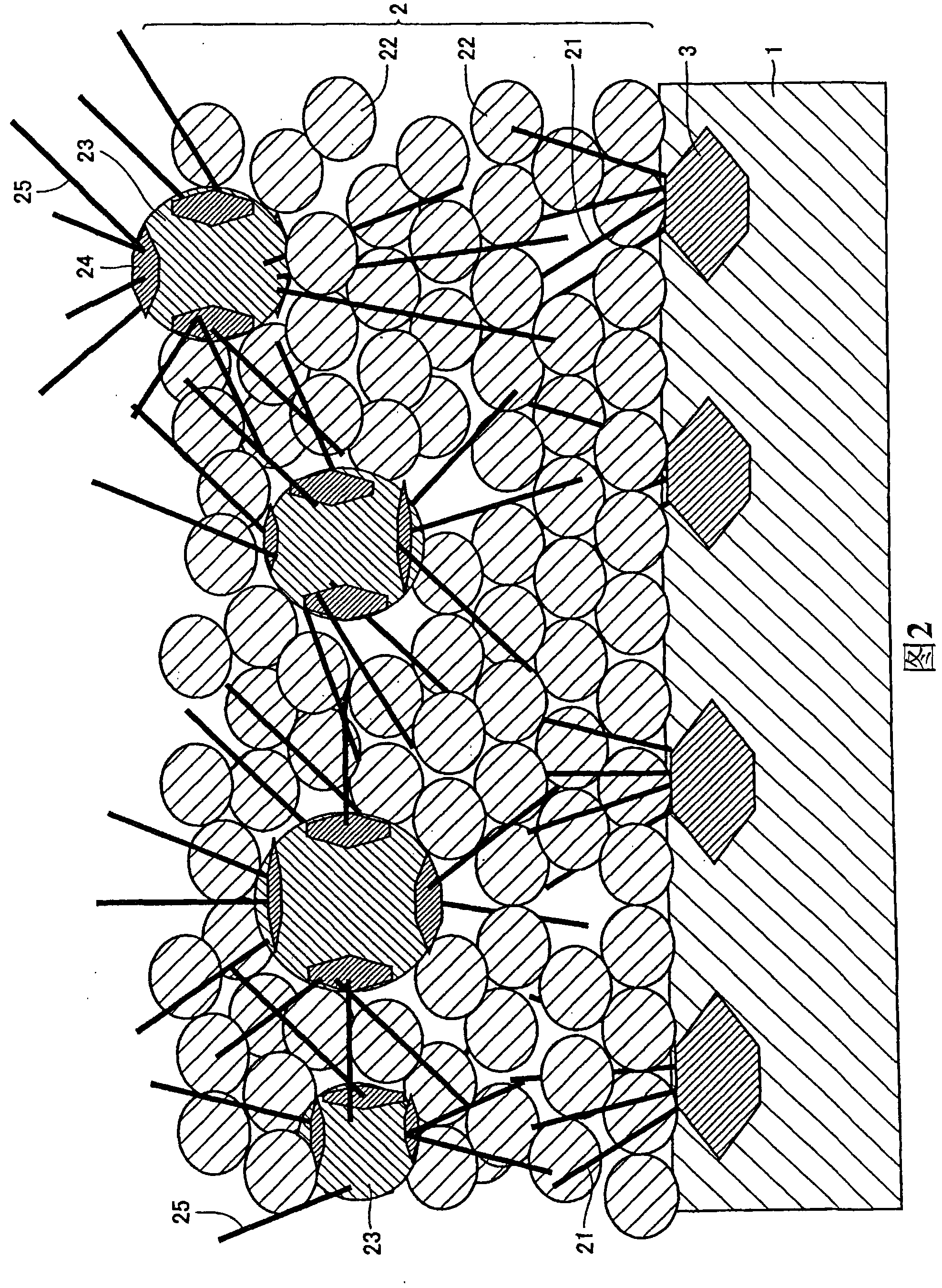

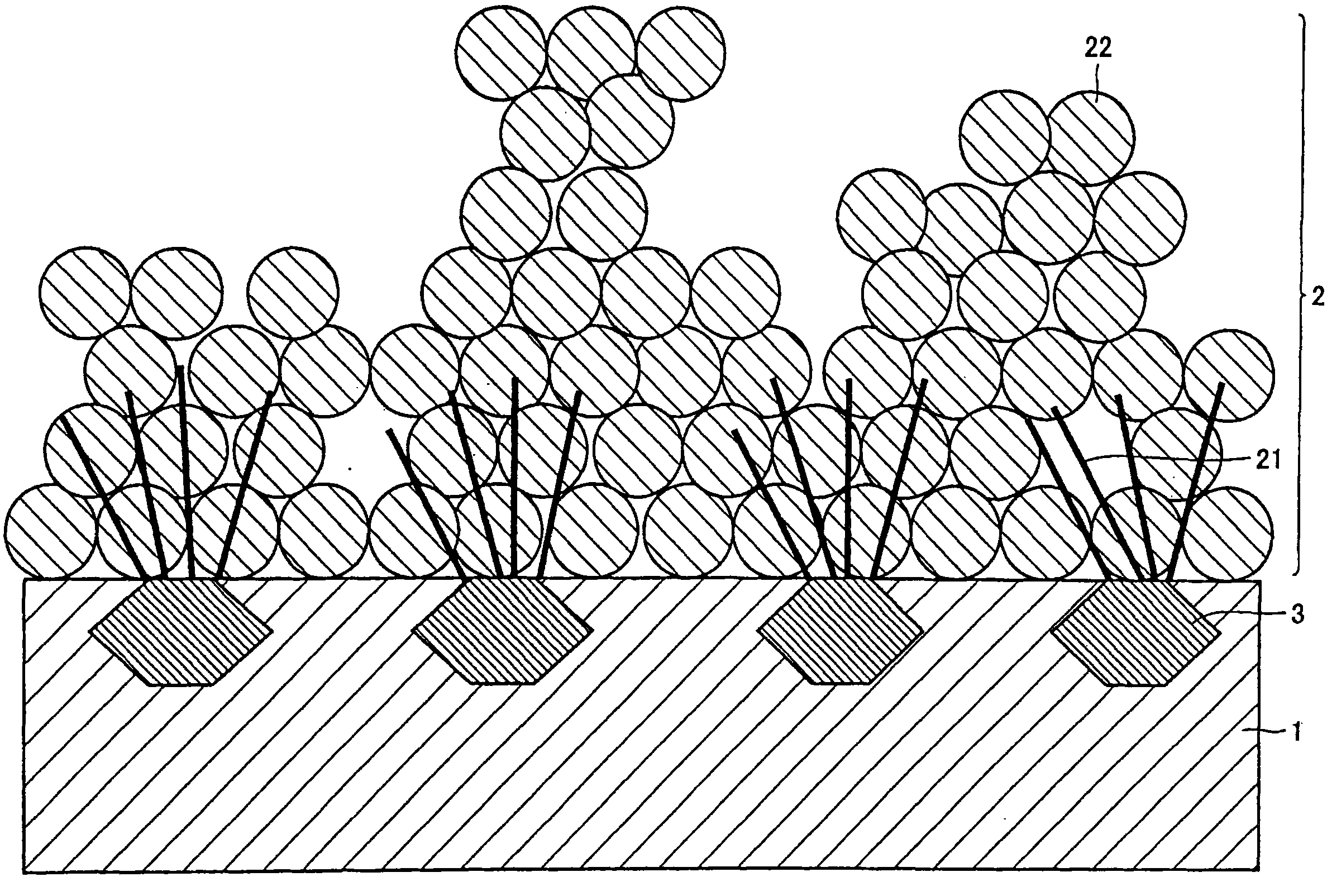

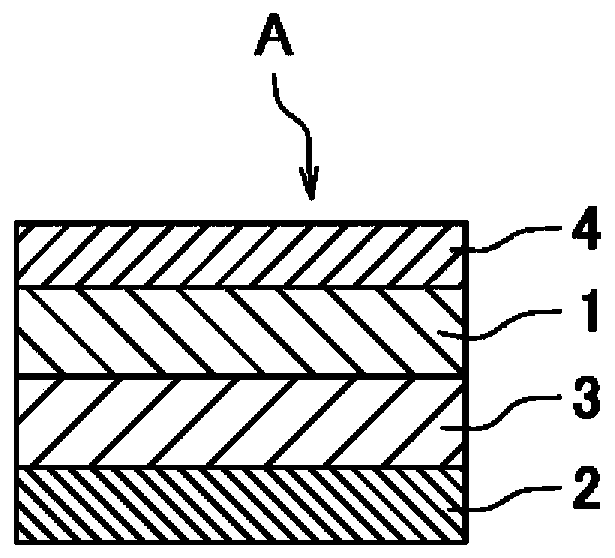

The invention provides a capacitor electrode member in which layers constituting the electrode member are highly adhesive. The capacitor electrode member comprises aluminum material (1), a carbon-containing layer (2) formed on the surface of the aluminum material (1), and further an interposition layer (3) containing an aluminum element and a carbon element, the interposition layer being formed between the aluminum material (1) and the carbon-containing layer (2). The interposition layer (3) constitutes a first surface portion which is formed on at least a part of the region of the surface of the aluminum material (1) and contains a carbide of aluminum. The carbon-containing layer (2) constitutes a second surface portion (21) formed so as to extend outward from the first surface portion (3). The carbon-containing layer (2) further contains carbon particles (22) and the second surface portion (21) is formed between the first surface portion (3) and the carbon particles (22) and contains a carbide of aluminum.

Owner:TOYO ALUMINIUM KK

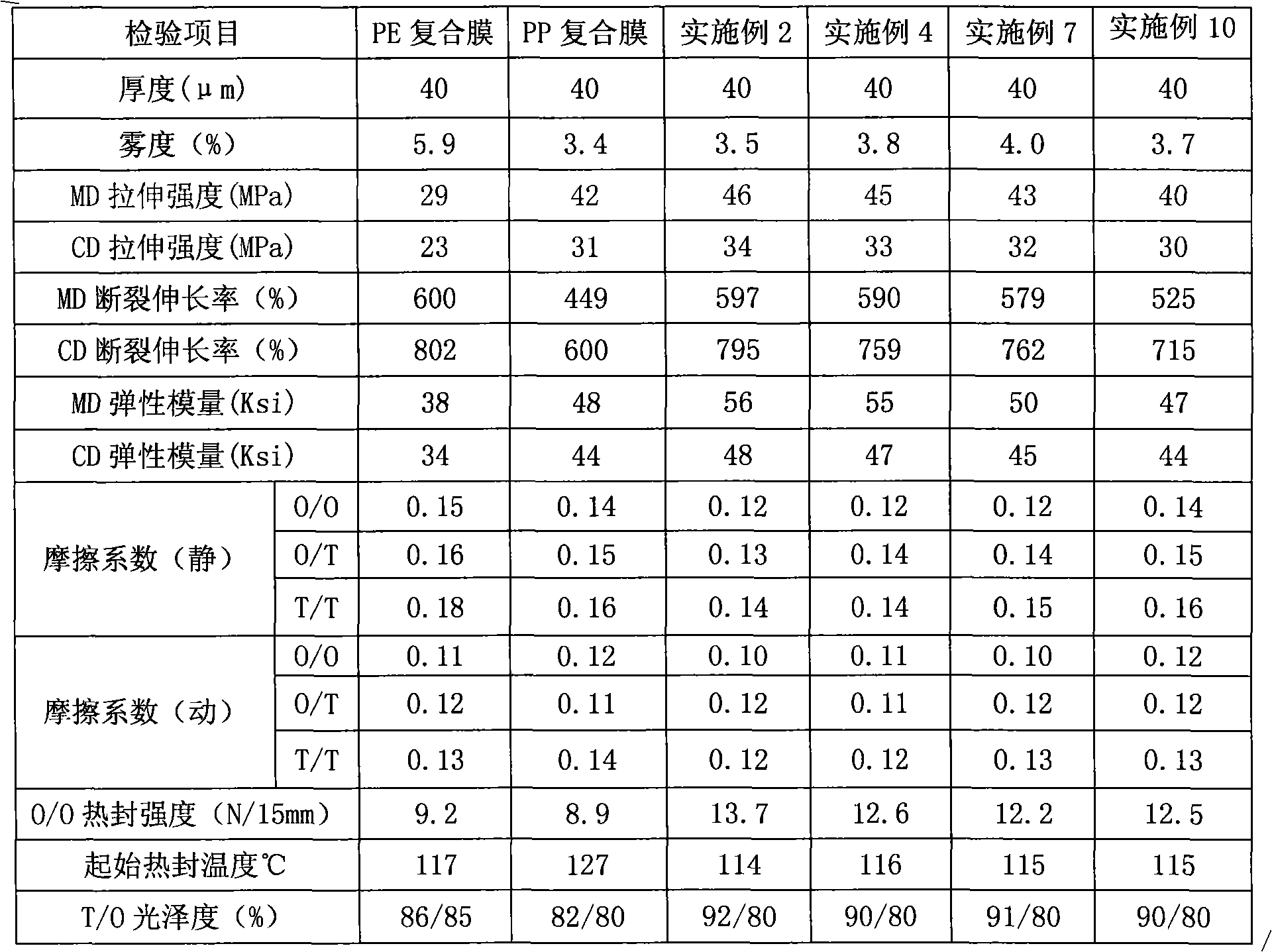

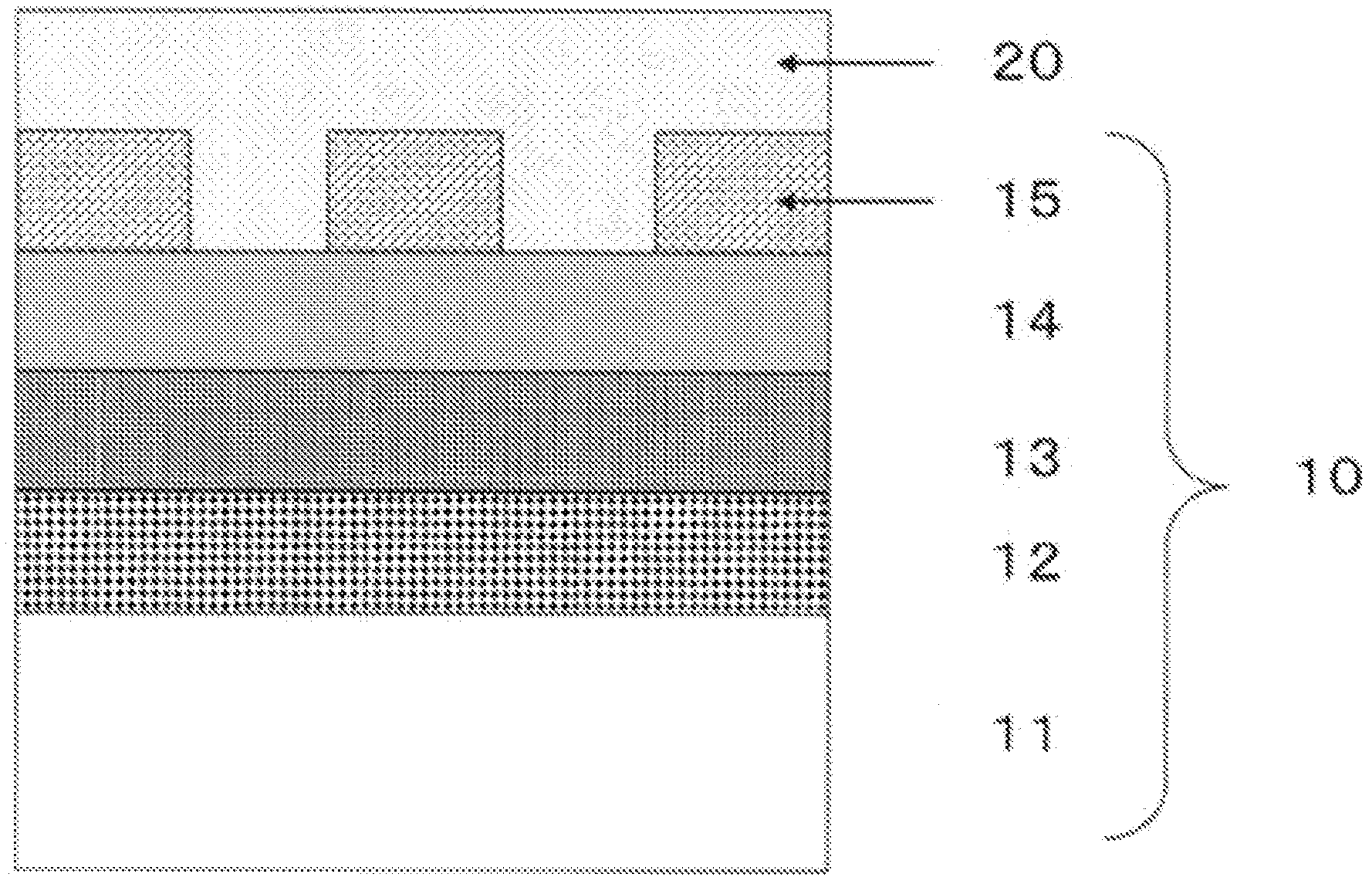

Multifunctional casting polyolefine firmness-increasing film

InactiveCN101659142ALower surface resistance valueProduce anti-static effect of plastic filmFlexible coversWrappersCompound aPolyolefin

The invention relates to a multifunctional casting polyolefine firmness-increasing film which is formed by compounding a heat sealing layer, a core layer and a corona layer. The corona layer or the heat sealing layer mainly comprises the following components in portions by weight: 100 portions of polyethylene resin, 10-60 portions of compatilizer, 0.1-0.5 portion of anti-blocking agent and 0.1-0.5portion of slipping agent; and the core layer mainly comprises the following components in portions by weight: 100 portions of polypropylene resin and 0.1-1.1 portions of nucleating agent. The multifunctional casting polyolefine firmness-increasing film has the characteristics of low temperature, favorable heat sealing performance, high firmness, high elastic modulus and the like, not only combines the advantages of polyethylene and polypropylene films, but also overcomes the defects of polyethylene or polypropylene composite films, is widely applied for packing facial tissues, foods and other products, and is particularly suitable for quick and automatic package of products.

Owner:湖北慧狮塑业股份有限公司

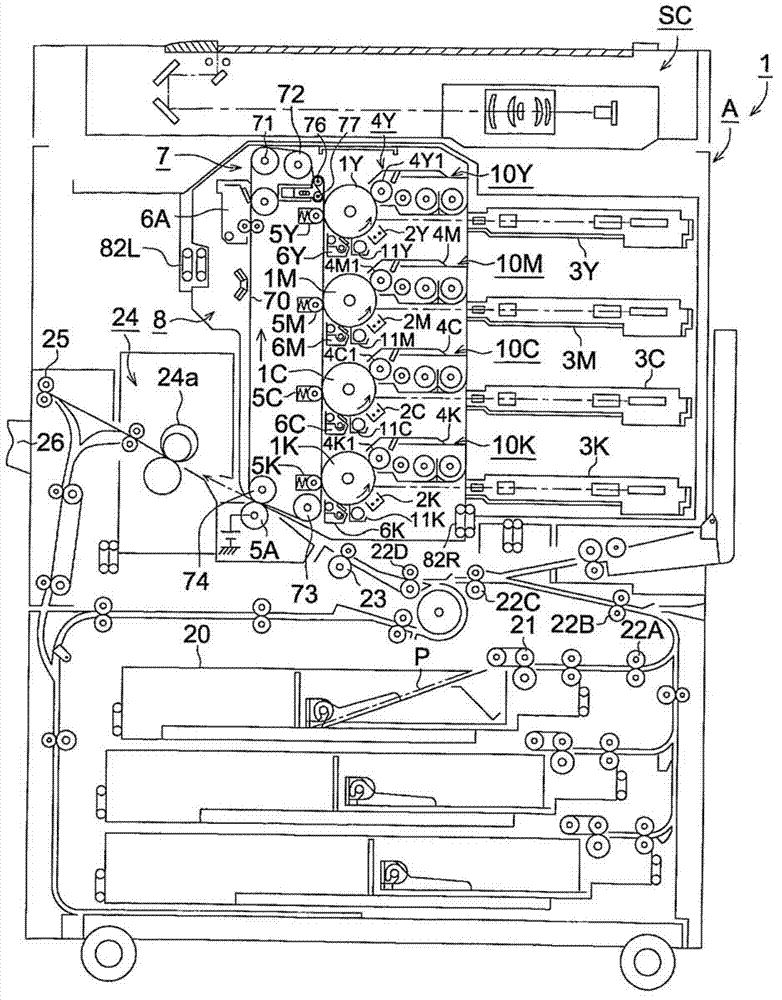

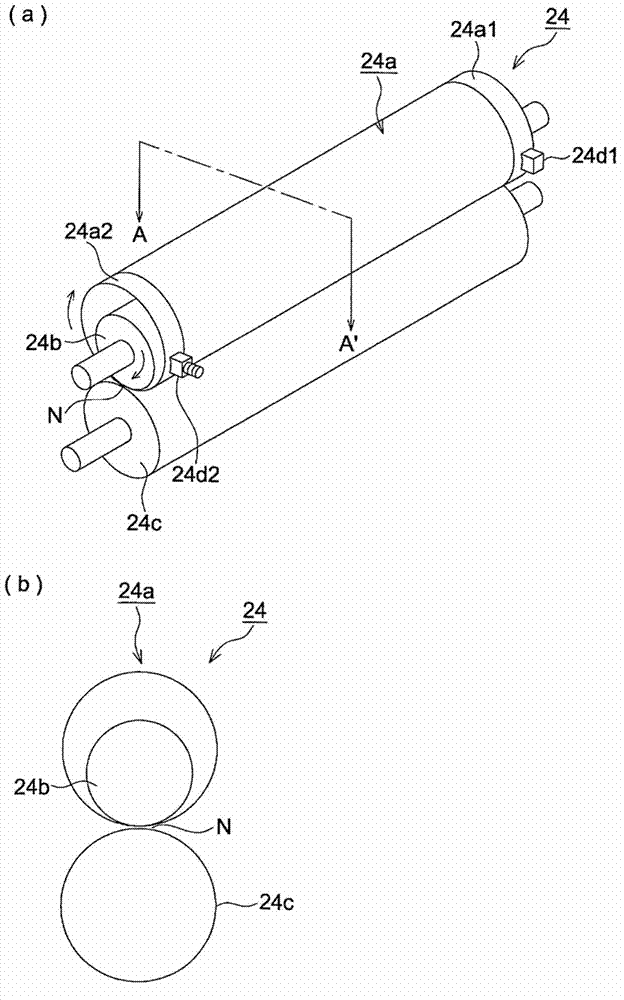

Heat-producing fixing belt and image forming apparatus using the same

ActiveCN102955409AAvoid crackingAvoid breakingOhmic-resistance heatingElectrographic process apparatusFiberCarbon fibers

Disclosed is a heat-producing fixing belt composed of a heat-producing layer, an elastic layer, and a releasing layer, wherein a pair of electrodes to supply power to the heat-producing layer making contact with the fabric containing carbon fiber are provided on both ends of the cylindrical shape.

Owner:KONICA MINOLTA BUSINESS TECH INC

Coating forming composition used for forming transparent conductive film

InactiveUS20130153829A1Lower surface resistance valueHigh light transmittanceMaterial nanotechnologyConductive layers on insulating-supportsTransparent conducting filmSolvent

A subject is to provide a material capable of obtaining a transparent conductive film that is excellent in conductivity, optical transmission, environmental reliability, suitability for process and adhesion in a single application process, and to provide the transparent conductive film and a device element using the same; a solution is to prepare a coating forming composition containing at least one kind selected from the group of metal nanowires and metal nanotubes as a first component, polysaccharides and a derivative thereof as a second component, an active methylene compound as a third component, an electrophilic compound as a fourth component and a solvent as a fifth component to obtain the transparent conductive film by using the coating.

Owner:JNC CORP

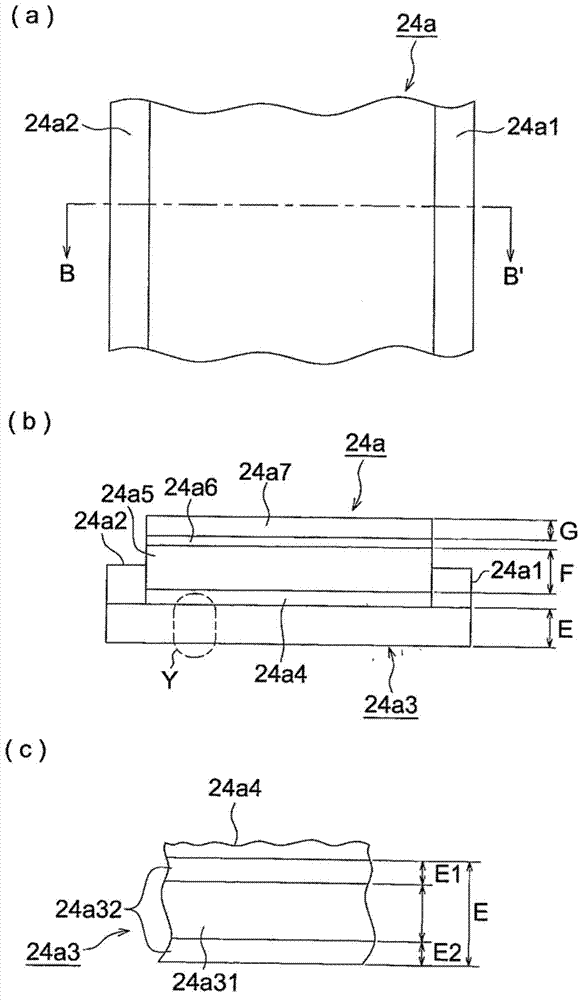

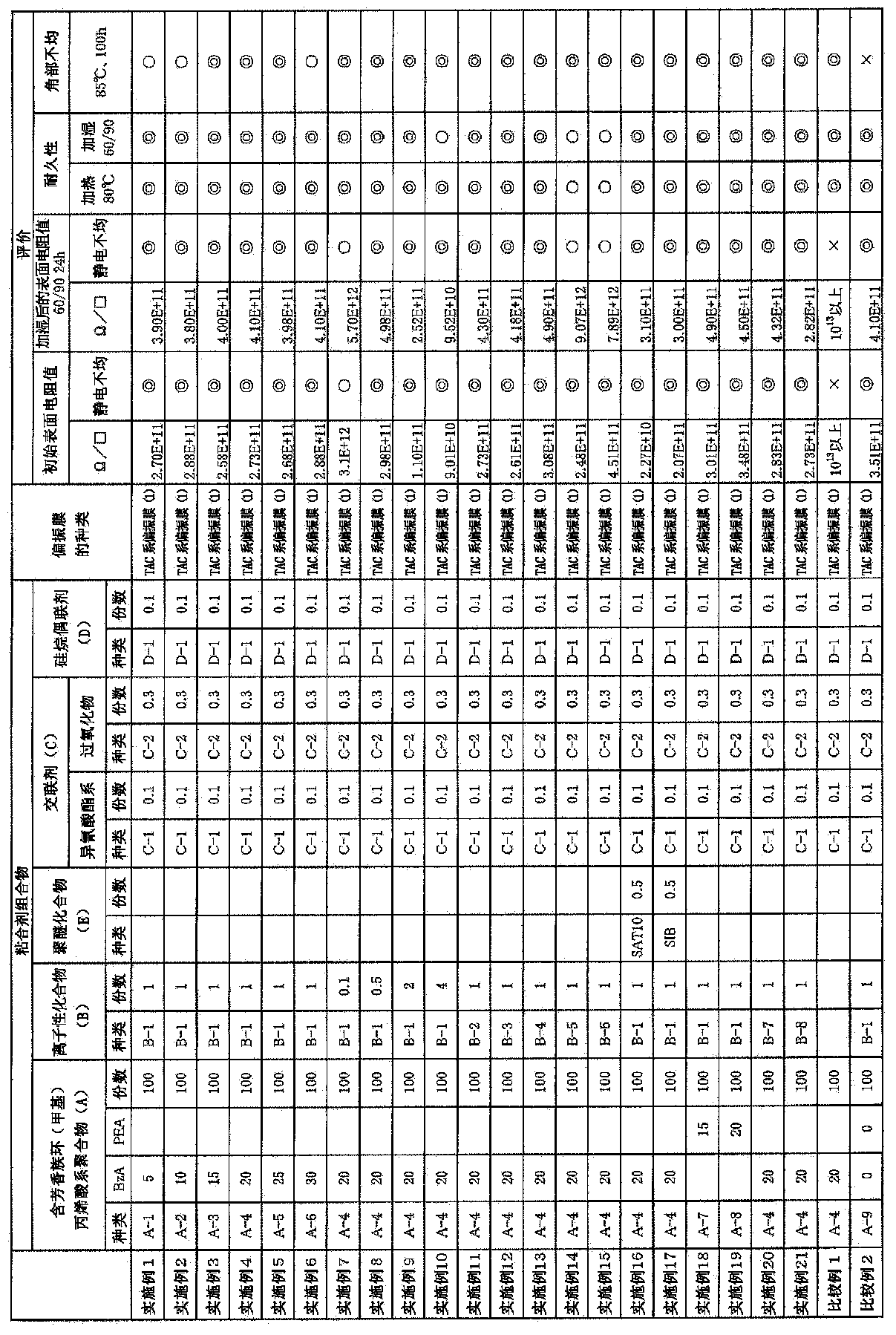

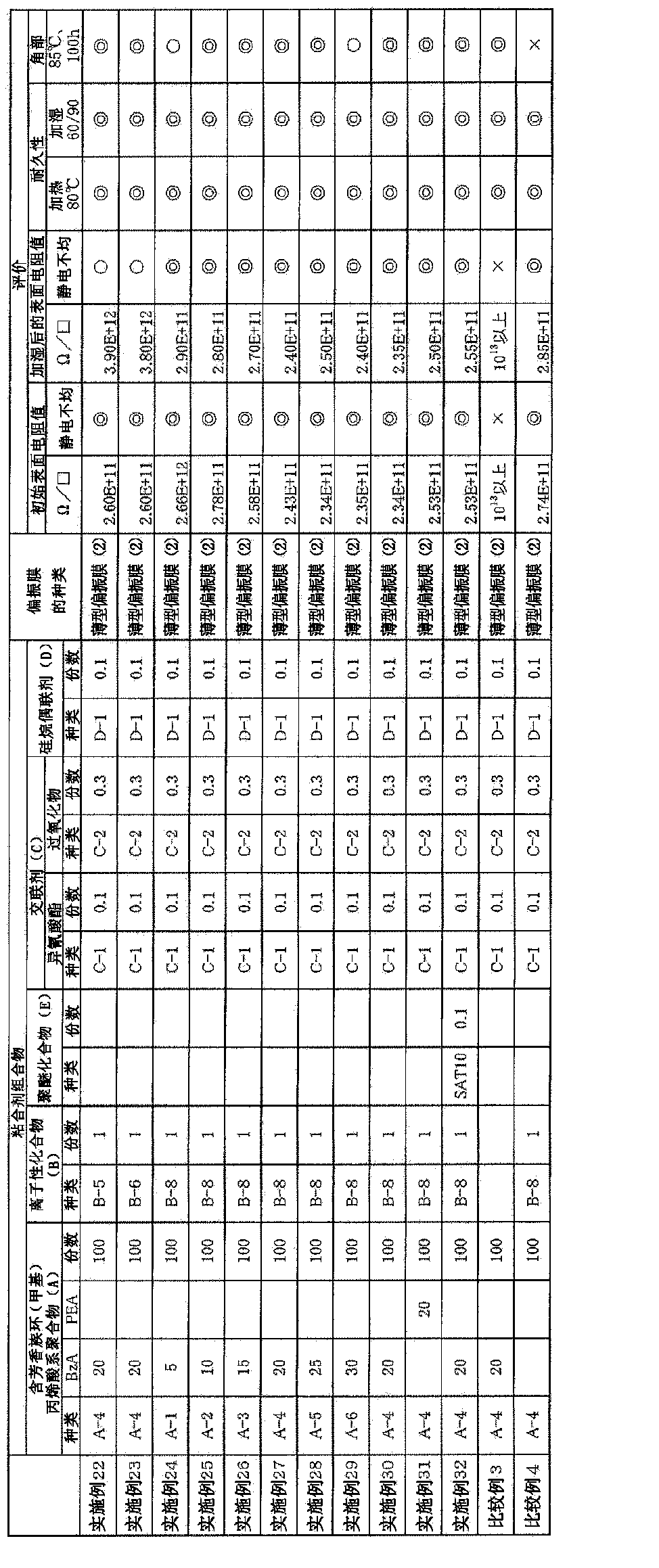

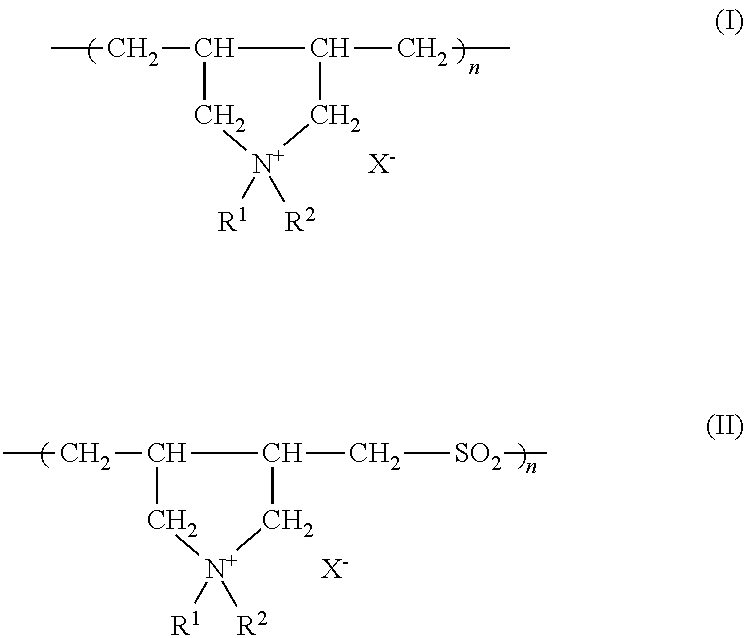

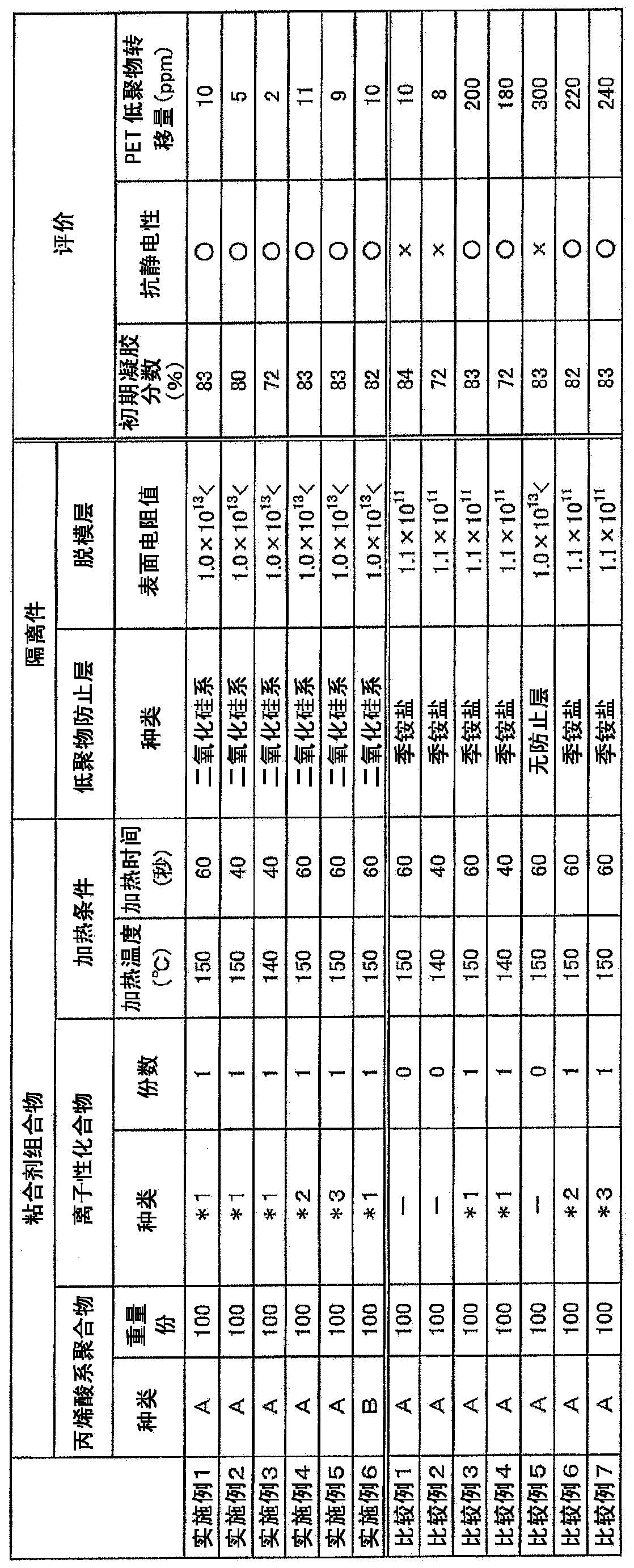

Adhesive composition, adhesive layer, polarizing film having adhesive layer, and image formation device

ActiveCN103930510AReduce adhesionGood antistatic functionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMeth-Image formation

Provided is an adhesive composition that contains (A) an aromatic ring-containing (meth)acrylic polymer that contains an aromatic ring-containing alkyl (meth)acrylate as a monomer unit, and (B) an ionic compound having an anionic moiety and a cationic moiety. The anionic moiety is preferably at least one type of anionic moiety represented by general formula (1): (CnF2n+1SO2)2N- (1)(in general formula (1), n is an integer between 1 and 10), general formula (2): CF2(CmF2mSO2)2N- (2) (in general formula (2), m is an integer between 2 and 10), or general formula (3): -O3S(CF2)l SO3 - (3) (in general formula (3), l is an integer between 3 and 10).

Owner:NITTO DENKO CORP

Optical laminated polyester film

InactiveUS20110051245A1Improve adhesionHigh transparencySynthetic resin layered productsCoatingsPolyesterDiol

The present invention provides an optical laminated polyester film which can exhibit a good adhesion to a light diffusion plate, a prism layer and a hard coat layer as well as an excellent antistatic property without deterioration in transparency. The present invention relates to an optical biaxially oriented polyester film comprising a polyester film, a coating layer comprising a cationic polymer which is formed on one surface of the polyester film, and a layer formed on the other surface of the polyester film which is obtained by applying thereonto a coating agent comprising a polyurethane comprising a diol component having a polycarbonate structure, and a heat-crosslinking agent.

Owner:MITSUBISHI PLASTICS INC

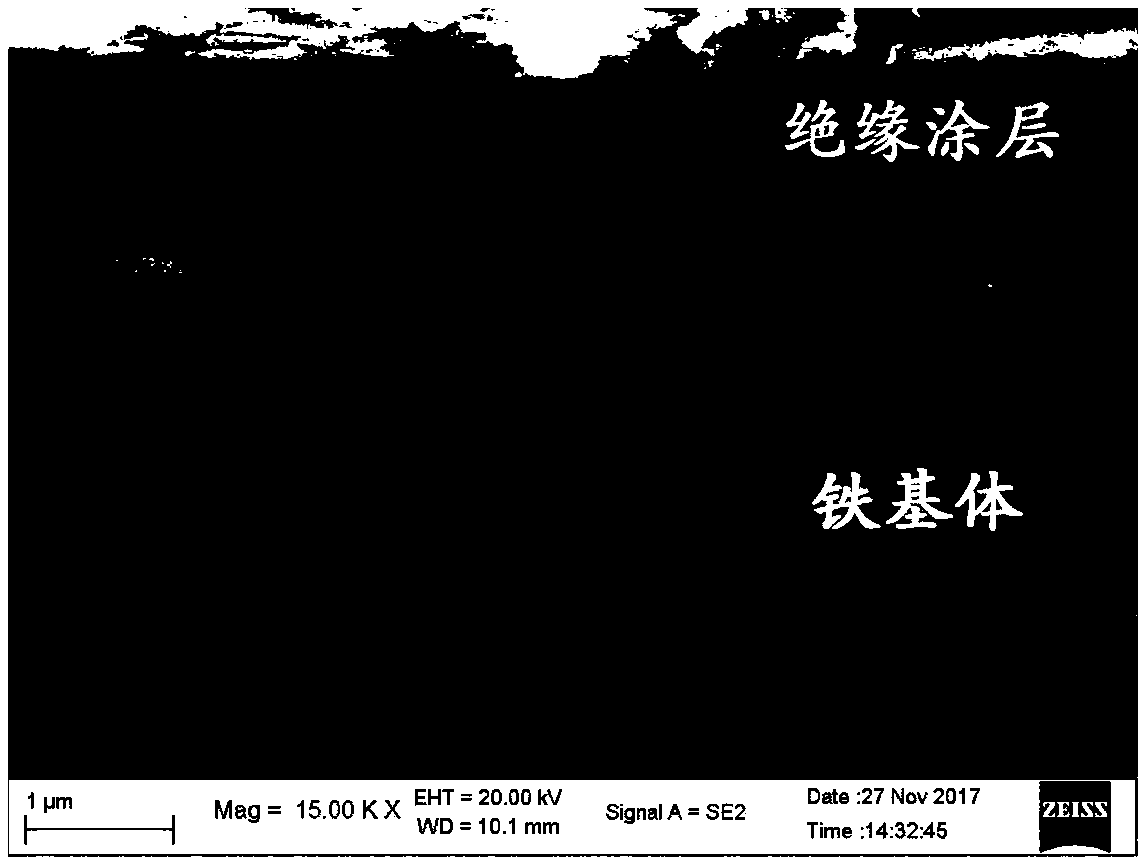

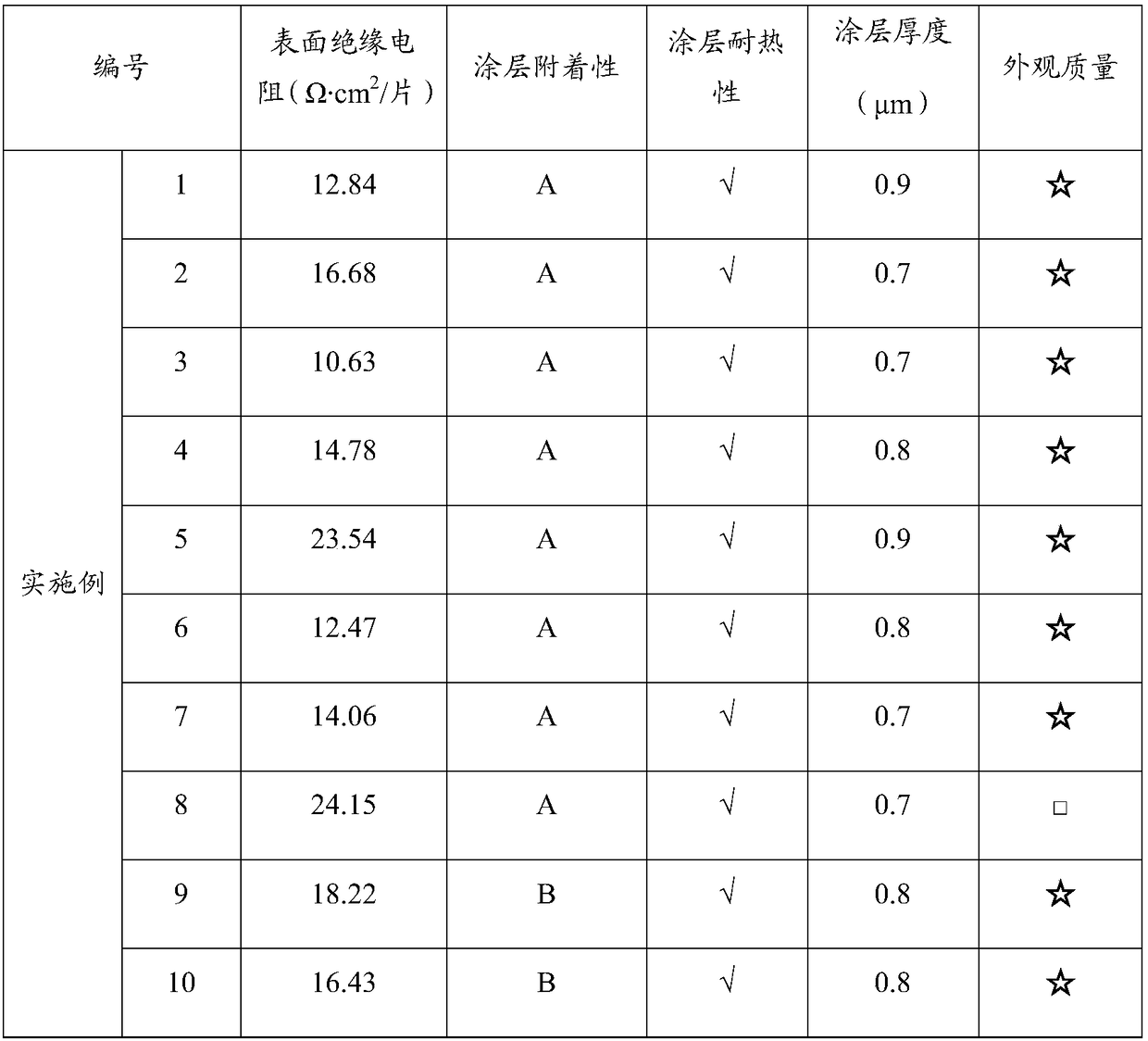

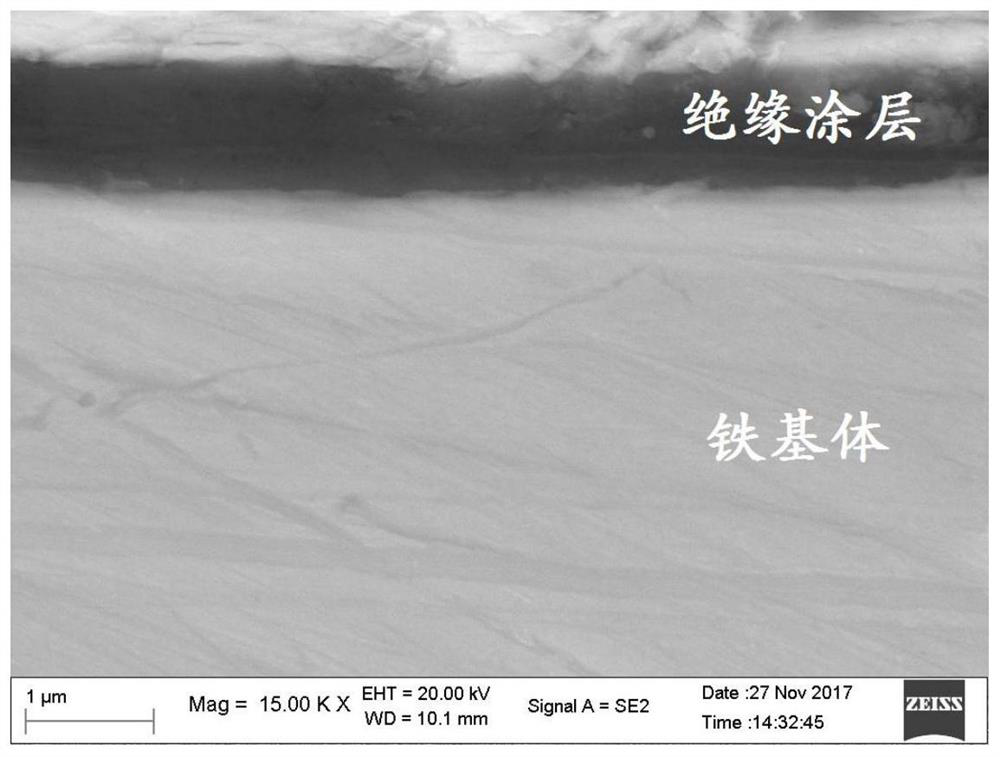

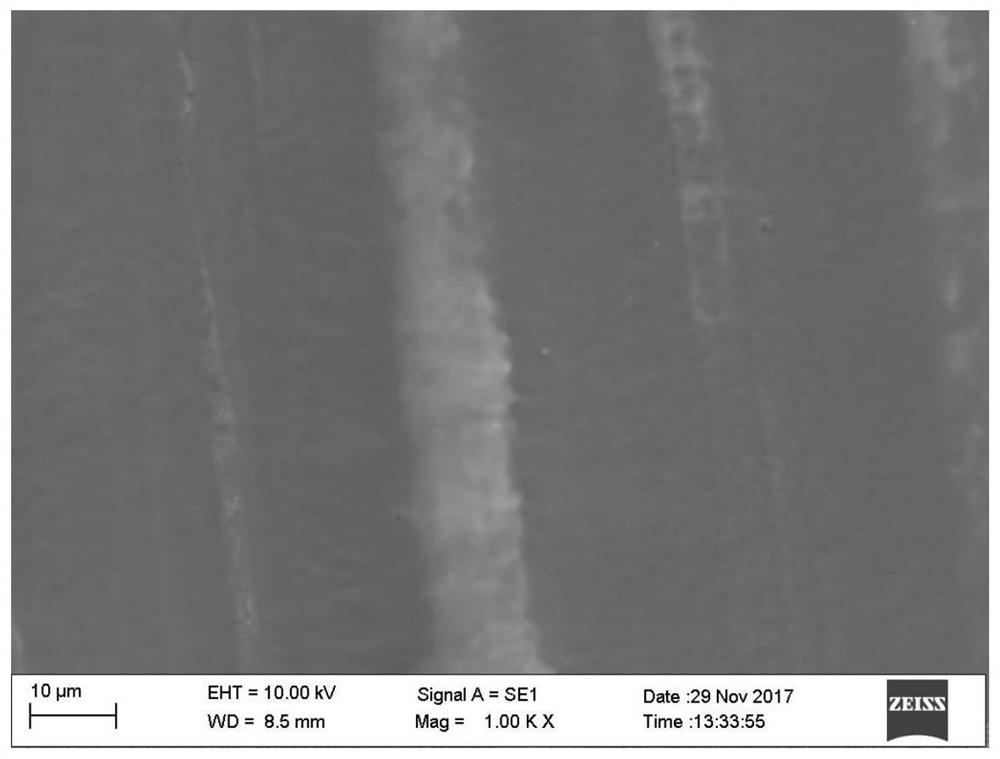

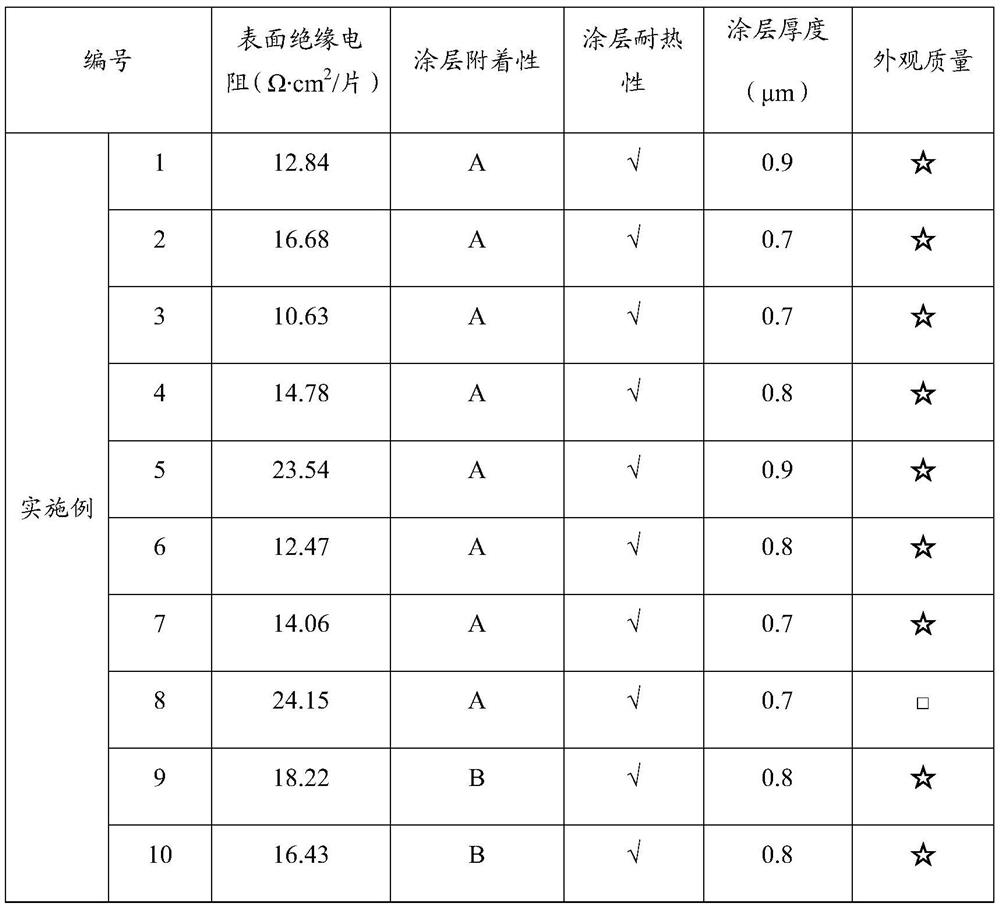

Ultra-thin silicon steel surface insulating coating and preparation method thereof

ActiveCN108659584AGood adhesionHigh insulation resistanceFireproof paintsMonomagnesium phosphatePhosphate

The invention belongs to the technical field of coating compositions, in particular to an ultra-thin silicon steel surface insulating coating and a preparation method thereof. The insulating coating provided by the invention is prepared from the following components: 65 to 85 parts of magnesium dihydrogen phosphate, 0.1 to 1.5 parts of insulating inorganic nanoparticles, 2 to 15 parts of silica sol, 2 to 4 parts of boric acid and 1 to 32.9 parts of deionized water. The coating formed by synergistic effects of all the components has excellent adhesion property to the surface of a bare steel sheet of ultra-thin silicon steel, and meanwhile, the insulation performance is ensured. The insulating coating provided by the invention is also prepared from 0.01 to 5 parts by weight of organic resin;by the addition of the organic resin, the adhesion of the ultra-thin silicon steel surface coating can be improved and subsequent high temperature sintering can be resisted, so that the ultra-thin silicon steel with the coating can be suitable for preparing a roll core of a saturation reactor, and further complex operating conditions such as strong vibration and high temperature rise of high pressure anode saturation reactors are met.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Method of forming niobium doped tin oxide coatings on glass and coated glass formed thereby

A niobium doped tin oxide coating is applied onto a glass substrate to produce a low emissivity (low E) glass. The coating can optionally be doped with both niobium and other dopant (s), such as fluorine. The low emissivity glass has properties comparable or superior to conventional low E glass with fluoring doped tin oxide coatings.

Owner:PILKINGTON NORTH AMERICA INC +1

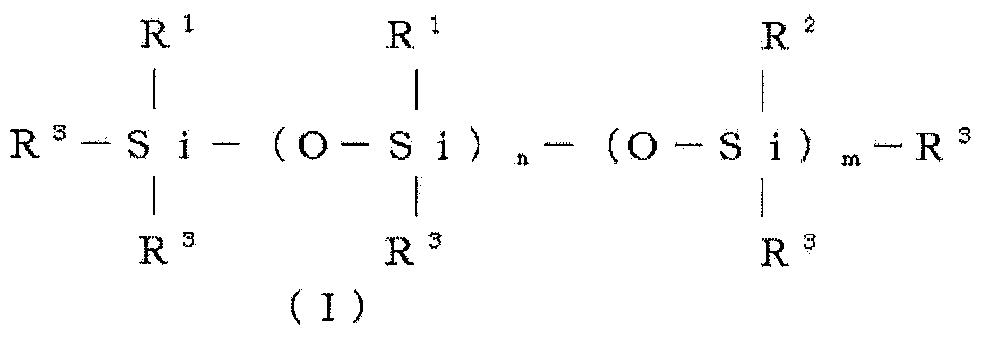

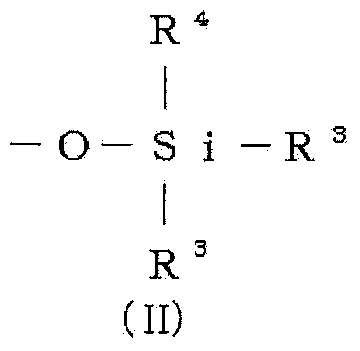

Separator-attached adhesive layer, method for producing the same and adhesive layer-attached optical film with separator

ActiveCN104231959ALower surface resistance valueWith antistatic functionNon-macromolecular adhesive additivesLayered productsPolymer scienceOligomer

The object of the invention is to provide a separator-attached adhesive layer capable of inhibiting an oligomer contained in the base film used for a separator from migrating into the pressure-sensitive adhesive layer, even an adhesive layer containing ionic compositions are formed on the separator. A separator-attached adhesive layer of the present invention including an adhesive layer on a separator, wherein the separator includes a base film and an oligomer prevention layer, and a release layer provided in this order on the base film, and the release layer has a surface resistance value of 1.0*1013[Omega] / - or more, and the adhesive layer is formed from an adhesive composition including a base polymer and an ionic compound and is provided on the release layer of the separator.

Owner:NITTO DENKO CORP

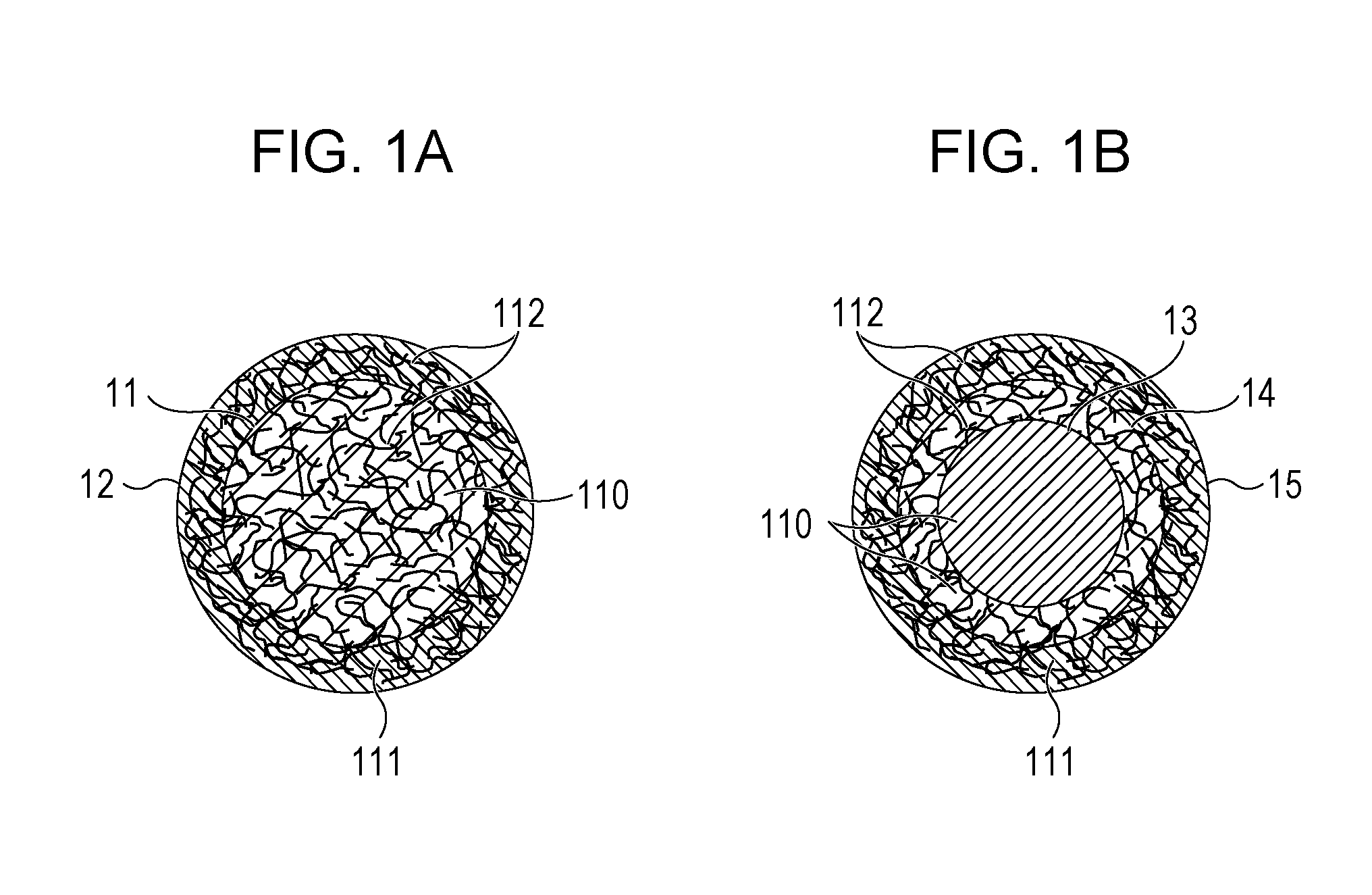

Antistatic polyester resin molded body

InactiveUS20130156992A1Lower surface resistance valueStable continuous antistaticityMaterial nanotechnologyElectroconductive/antistatic filament manufactureCarbon nanotubePolyester resin

A molded body has a base material, a first region covering the base material, and a second region covering the first region, in which the first region has the base material and carbon nanotubes and the second region has carbon nanotubes and an ionic liquid.

Owner:CANON KK

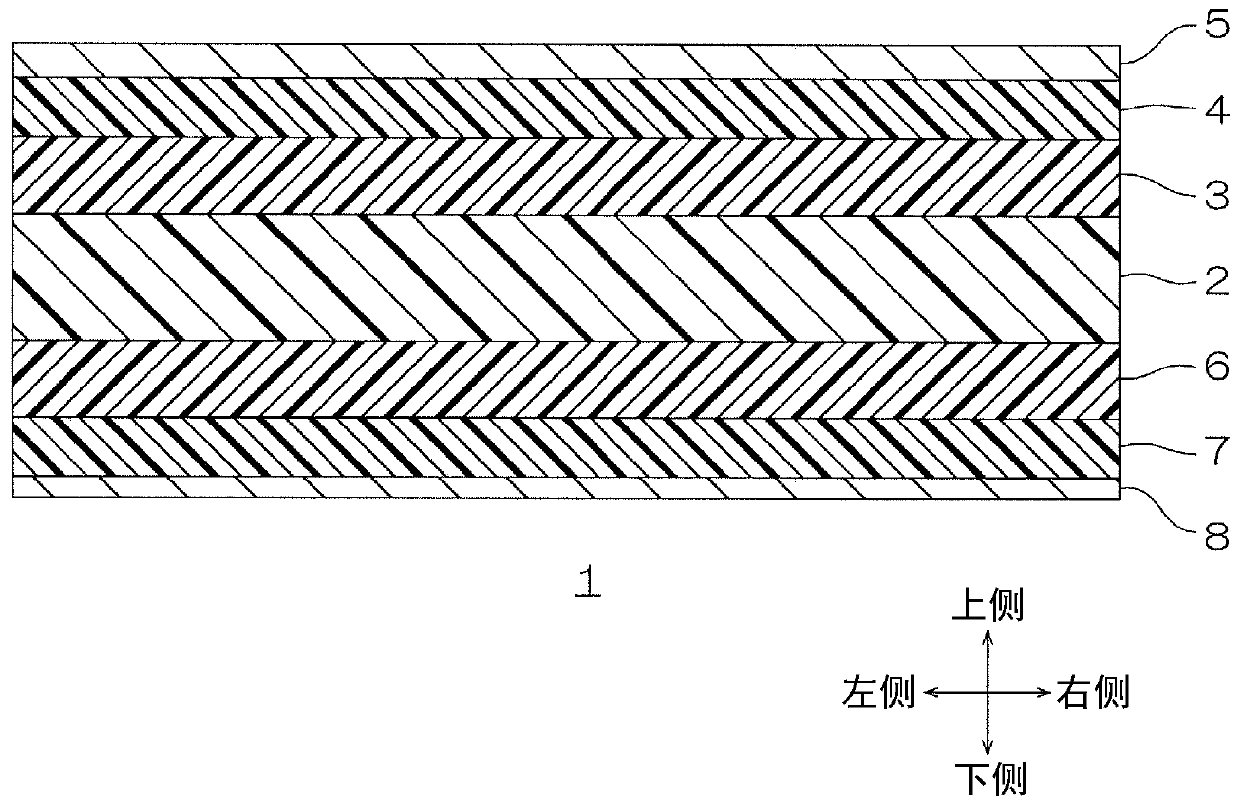

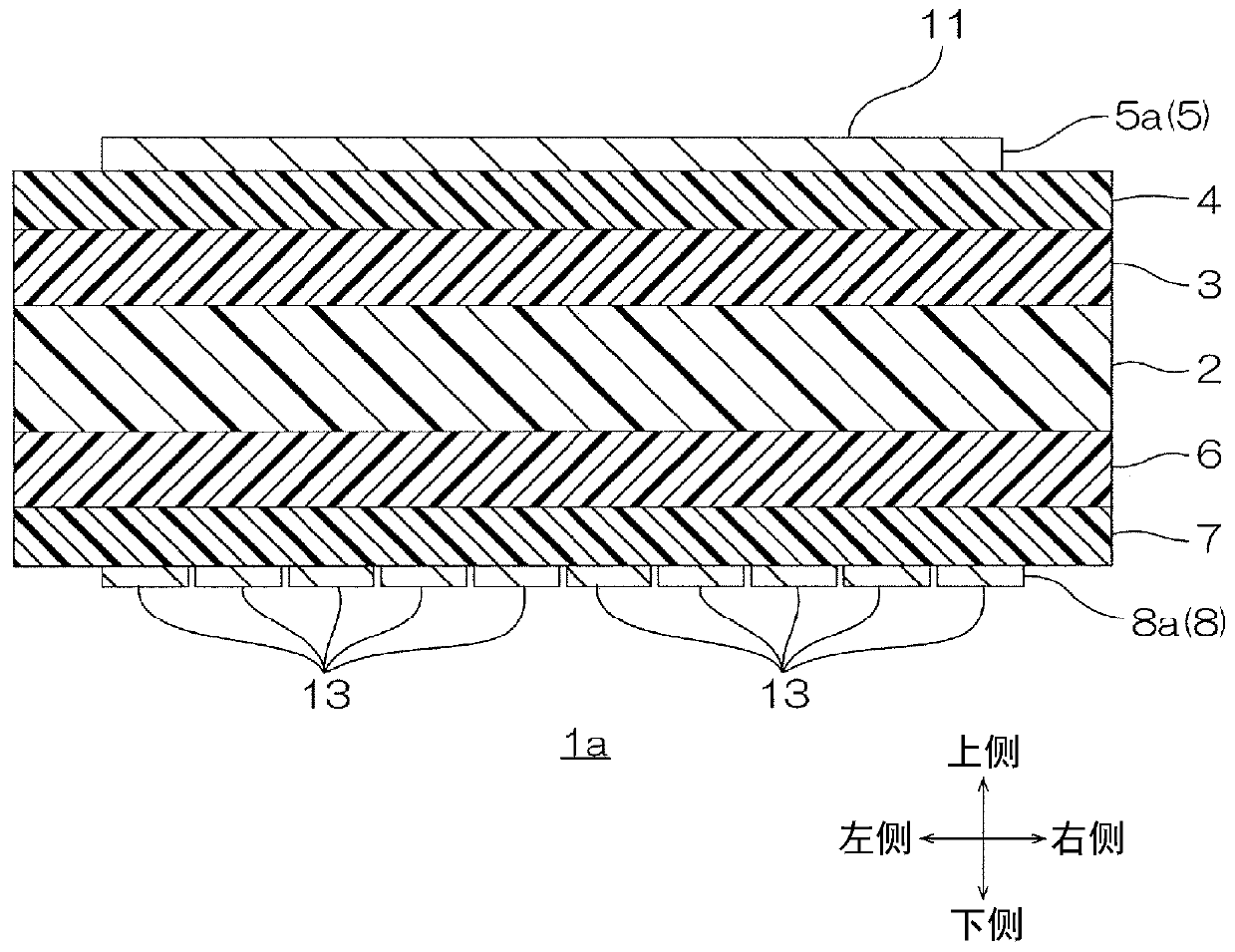

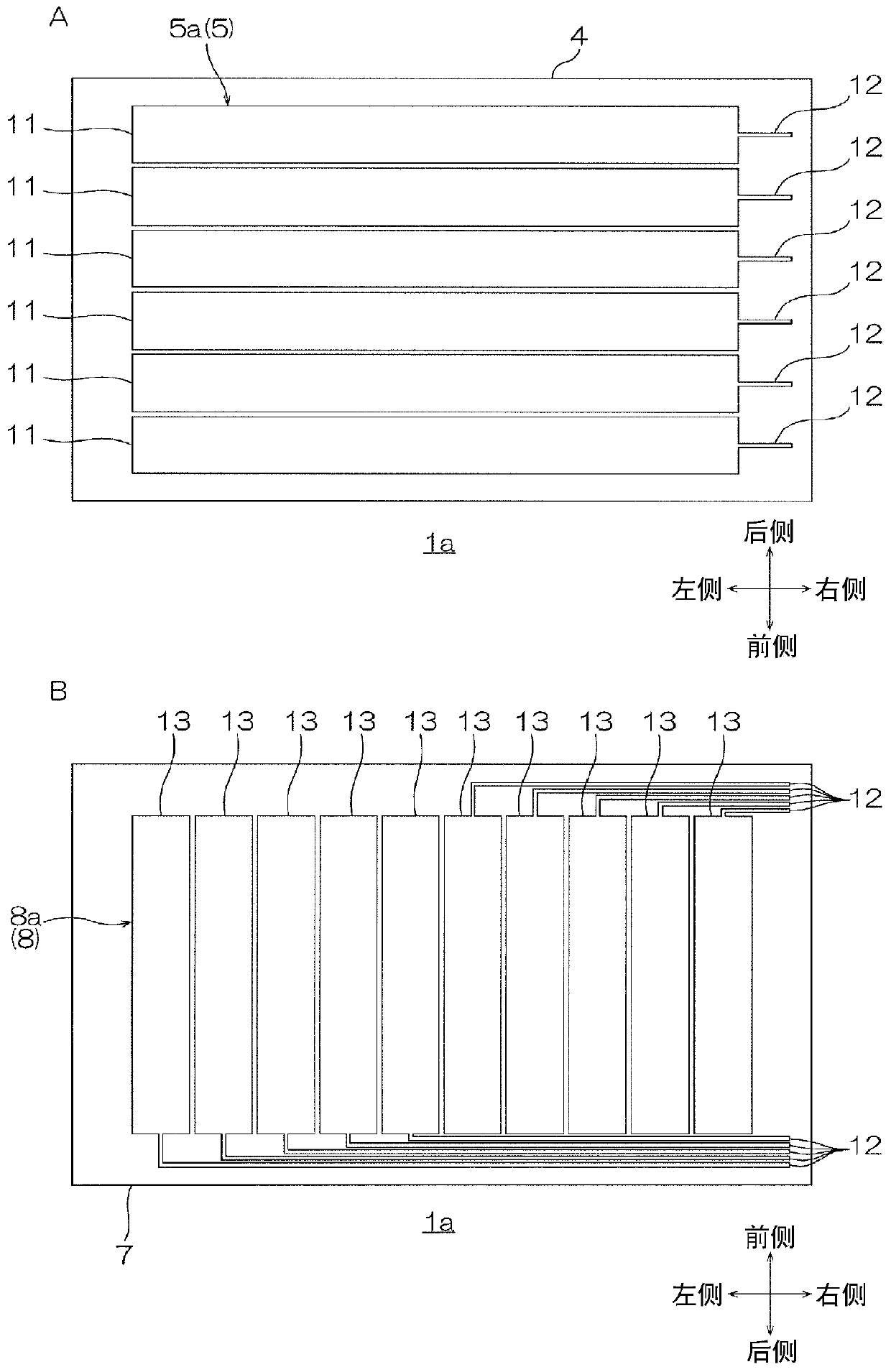

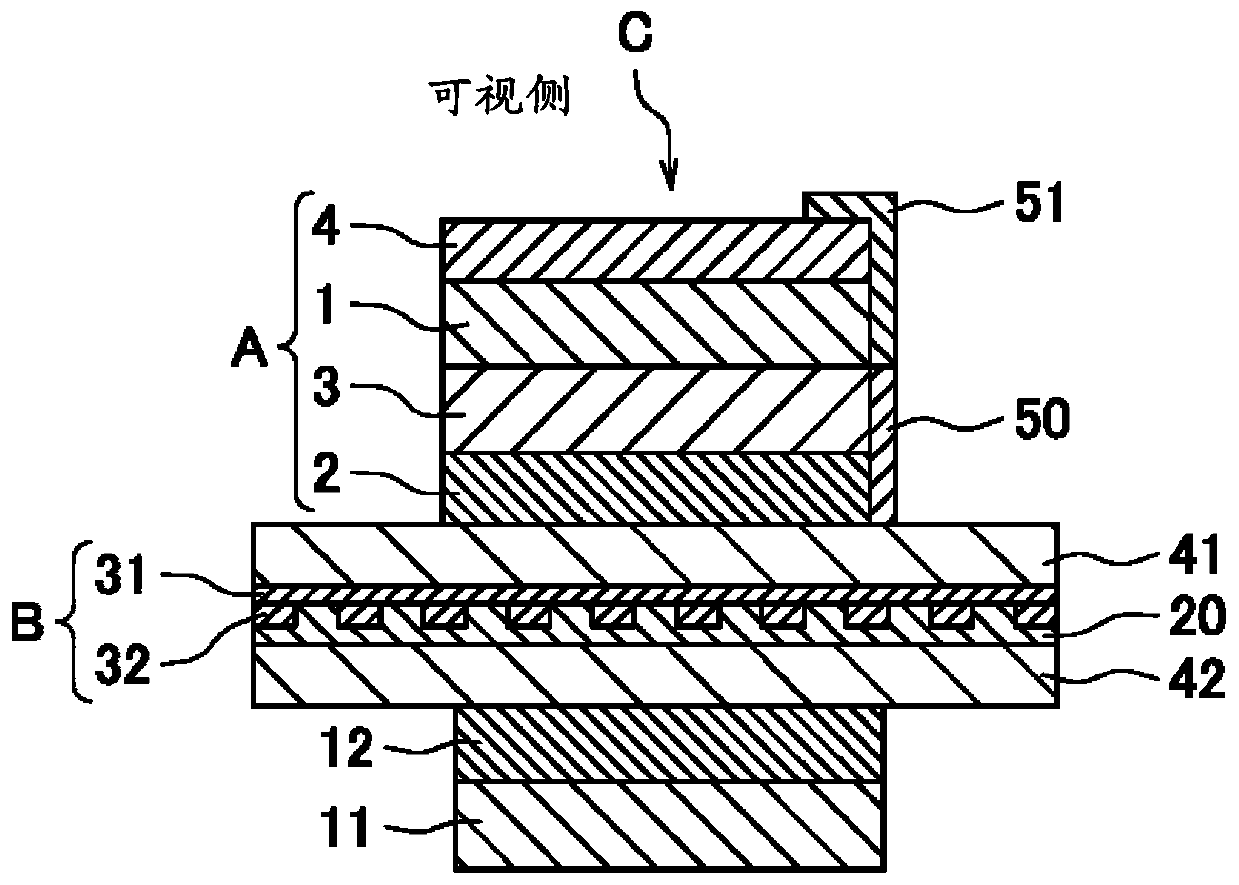

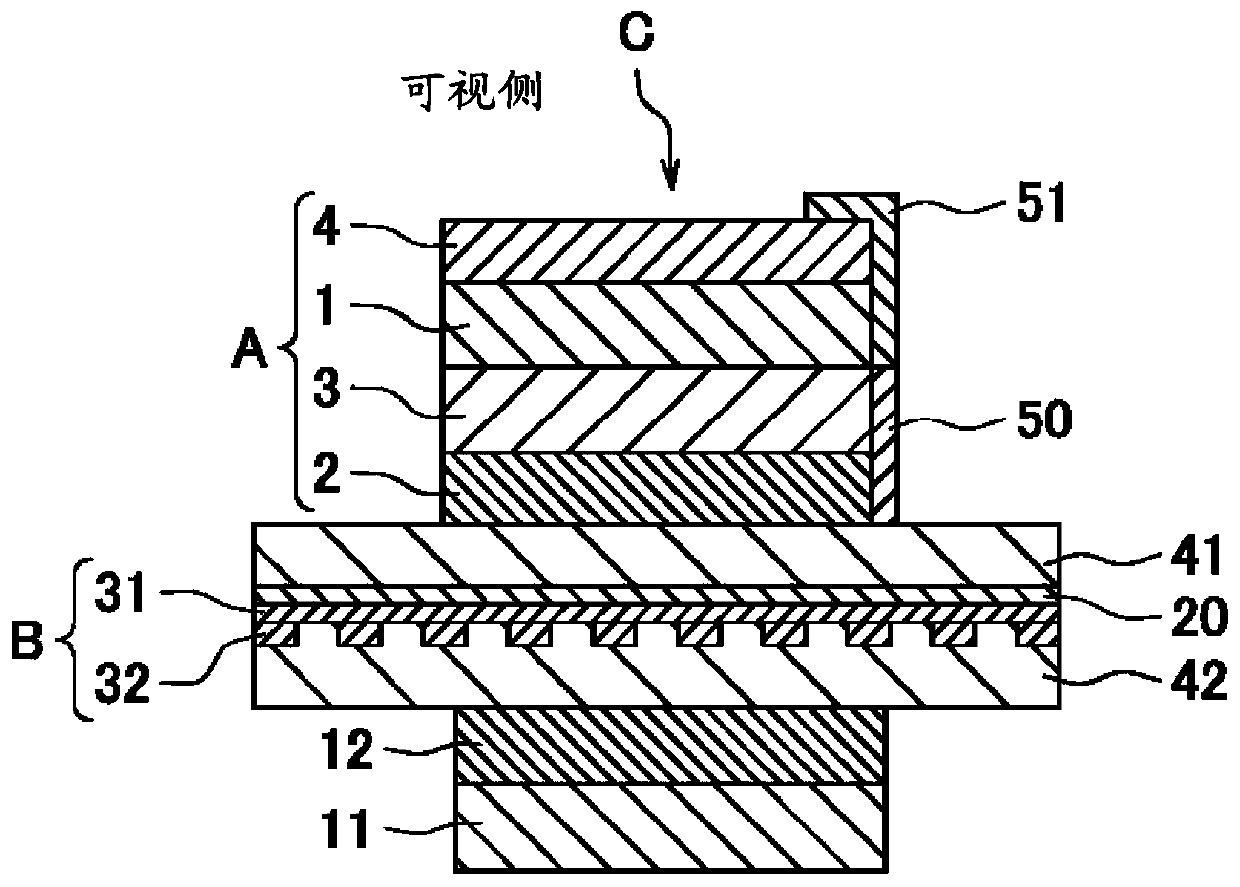

Liquid crystal panel with touch sensing function and liquid crystal display device

ActiveCN108139625ALower surface resistance valueInhibit static electricity generationSynthetic resin layered productsPolarising elementsMeth-Touch Senses

Owner:NITTO DENKO CORP

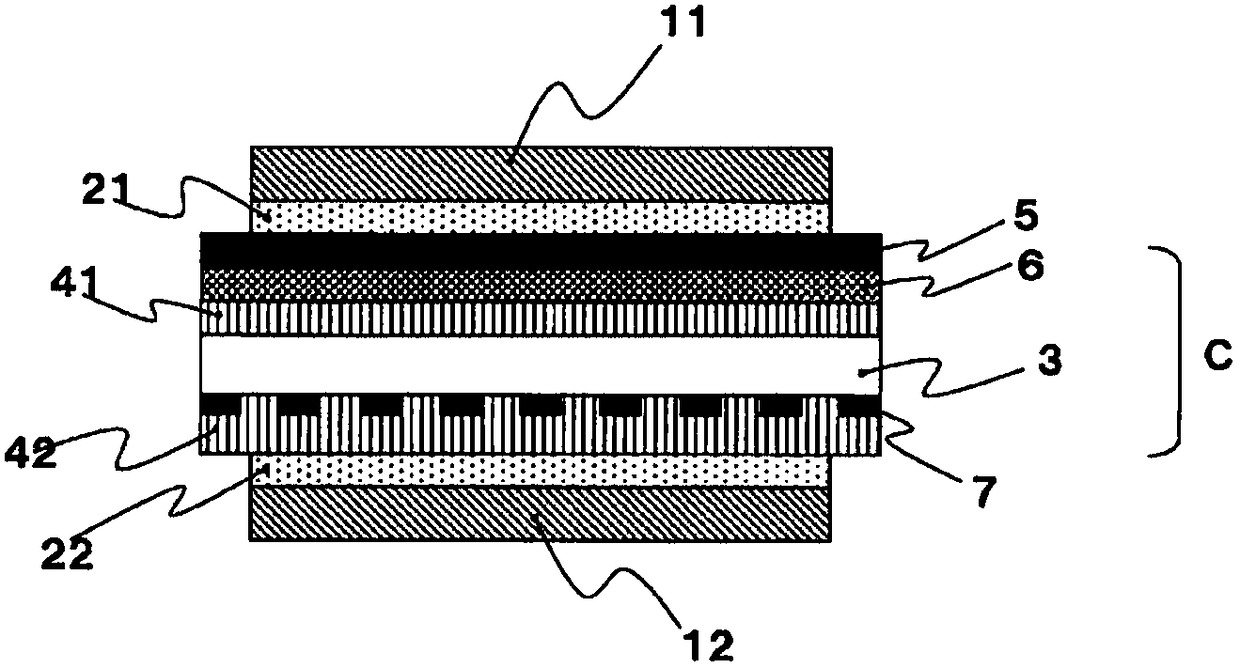

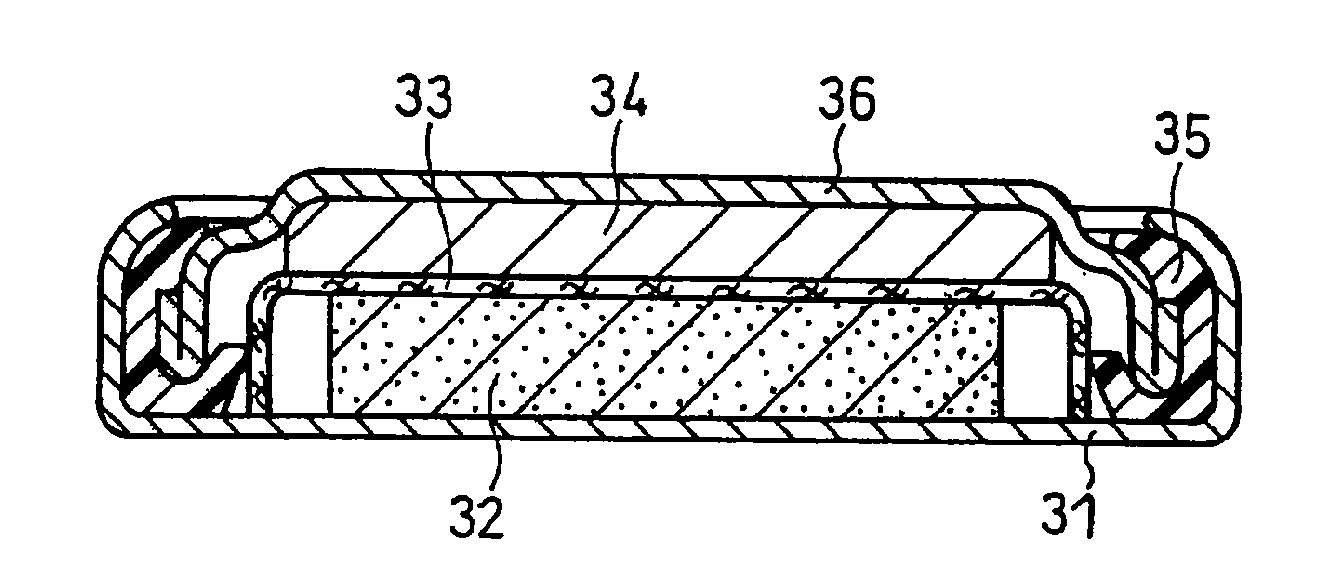

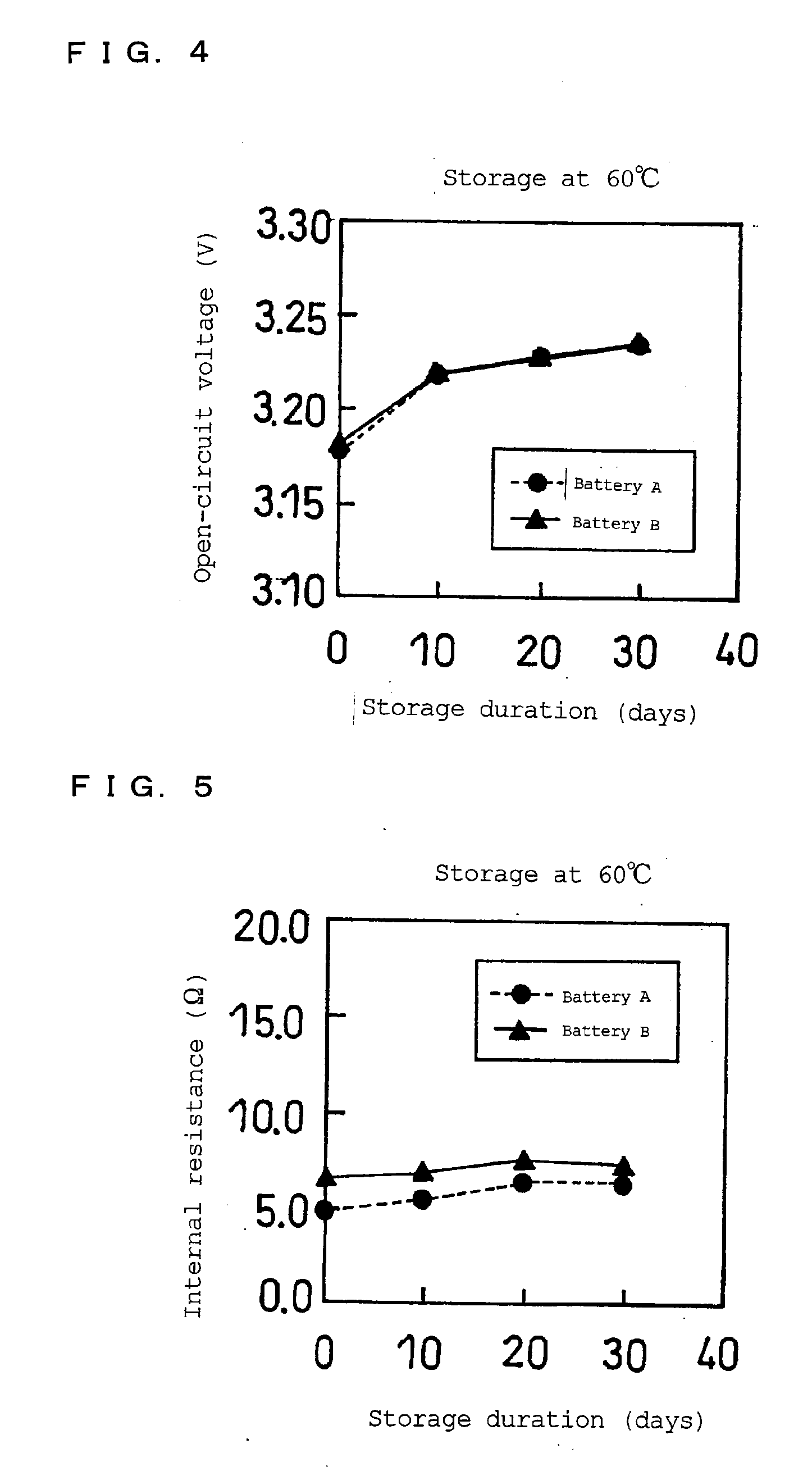

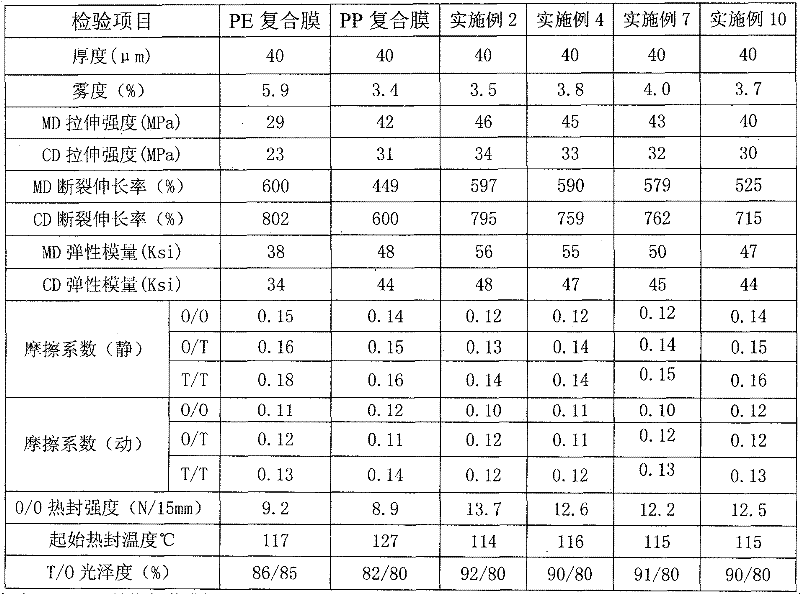

Material for contact components or battery components, and battery using the same

InactiveUS20090325073A1Lower surface resistance valueIncrease valueOrganic electrolyte cellsJackets/cases materialsSurface layerElectrical battery

A material for contact components or battery components, which includes a metal sheet having a surface layer portion containing a first metal element, the metal sheet including a Cr-containing steel plate or a surface-treated steel plate, and at least a part of the first metal element on an outermost surface of the surface layer portion being substituted by a second metal element having a nobler standard electrode potential than the first metal element, the second metal element being deposited on the outermost surface in a state of a particulate metal, oxide, or hydroxide.

Owner:PANASONIC CORP +1

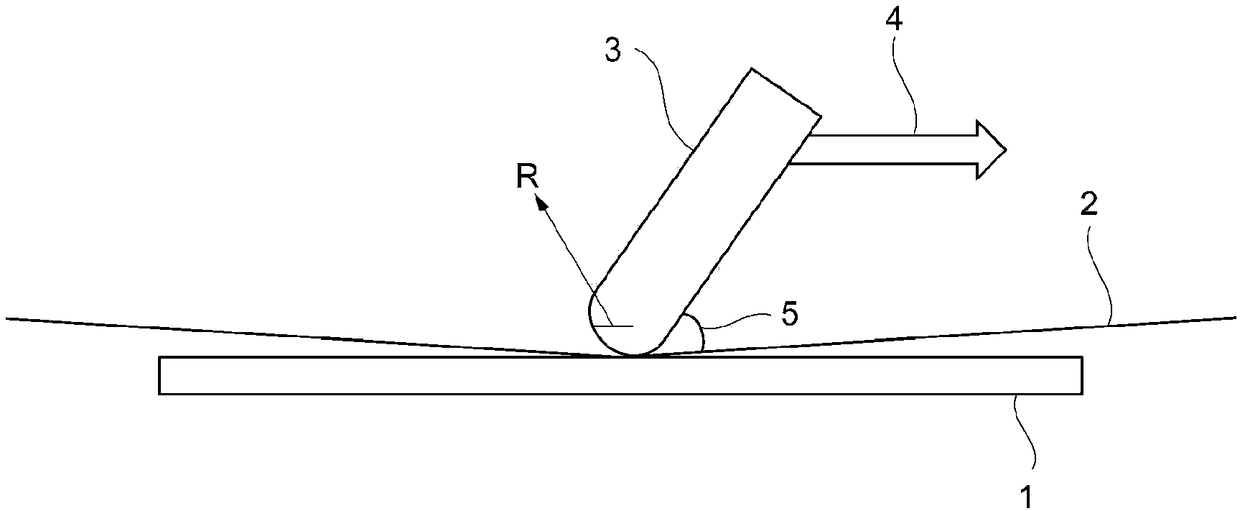

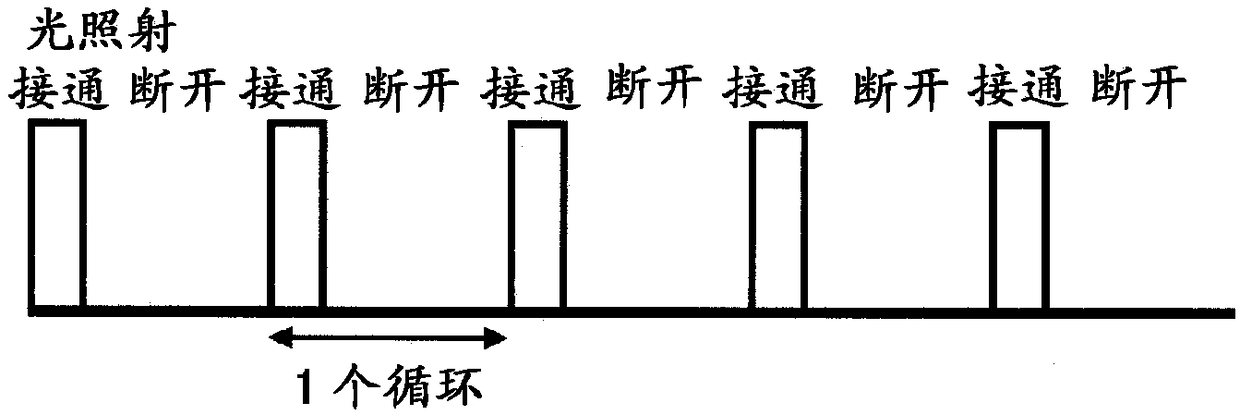

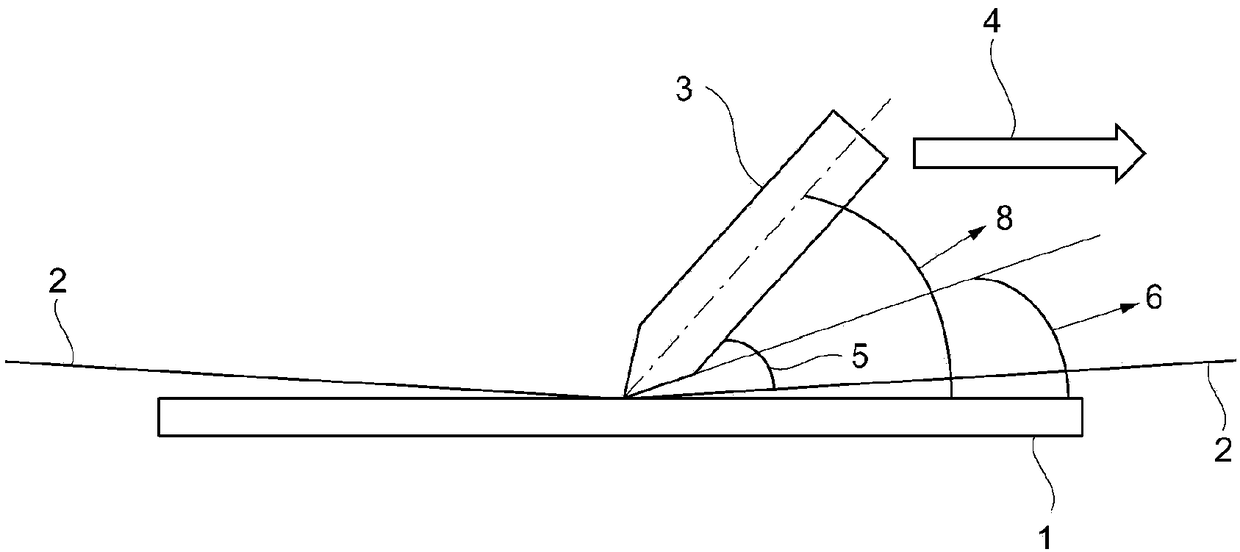

Method for forming transparent conductive pattern

ActiveCN109074919AReduce damageLower surface resistance valueConductive materialInksMetal nanowireElectrically conductive

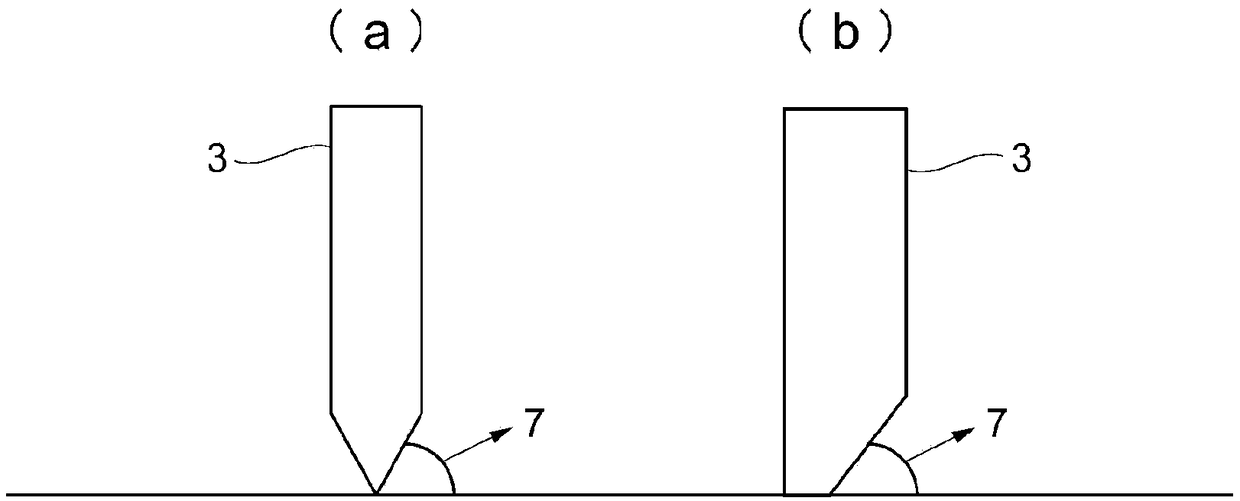

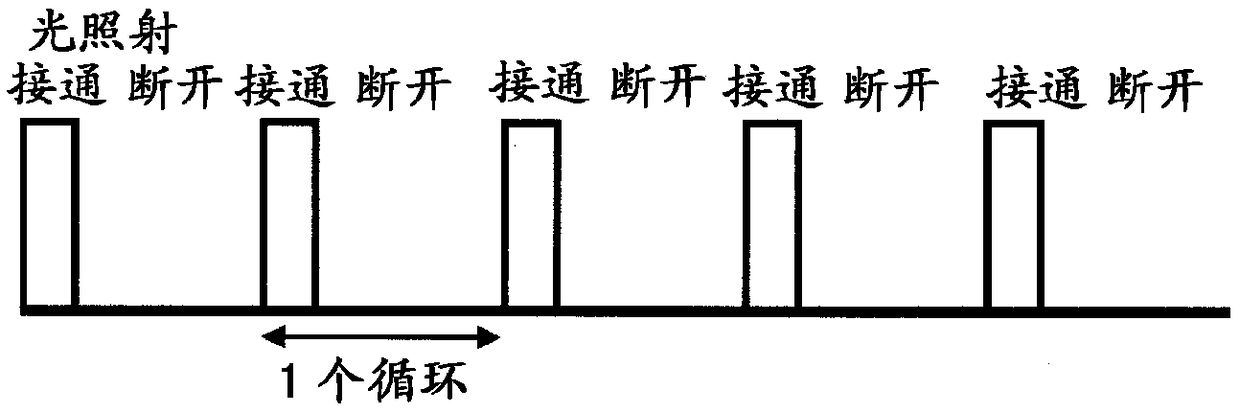

To provide a method for forming a transparent conductive pattern that reduces damage to metal nanowires and / or metal nanotubes during screen printing using a transparent conductive ink containing metal nanowires and / or metal nanotubes as a conductive component and thereby makes it possible to form a transparent conductive pattern via a simple production process while minimizing production costs and environmental impact. [Solution] A round squeegee 3 in which a tip section that is brought into contact with a screen mask 2 has a curved surface shape is used to screen print with a transparent conductive ink 5 containing a dispersion medium and at least one of metal nanowires and metal nanotubes.

Owner:SHOWA DENKO KK

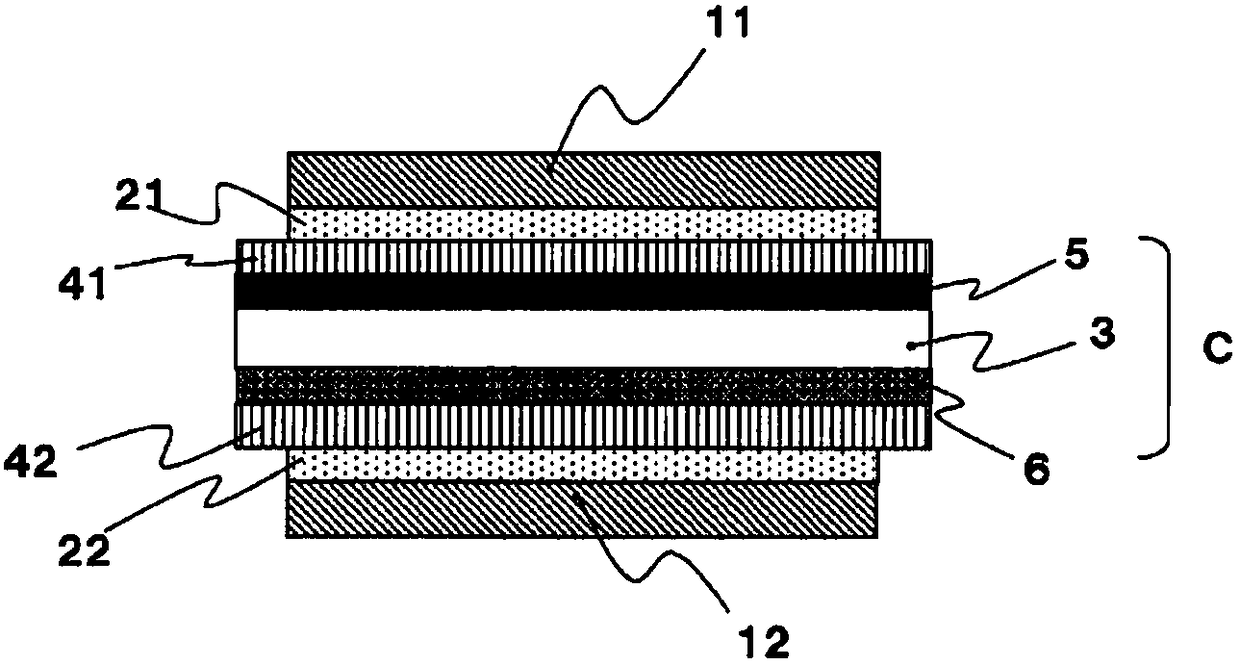

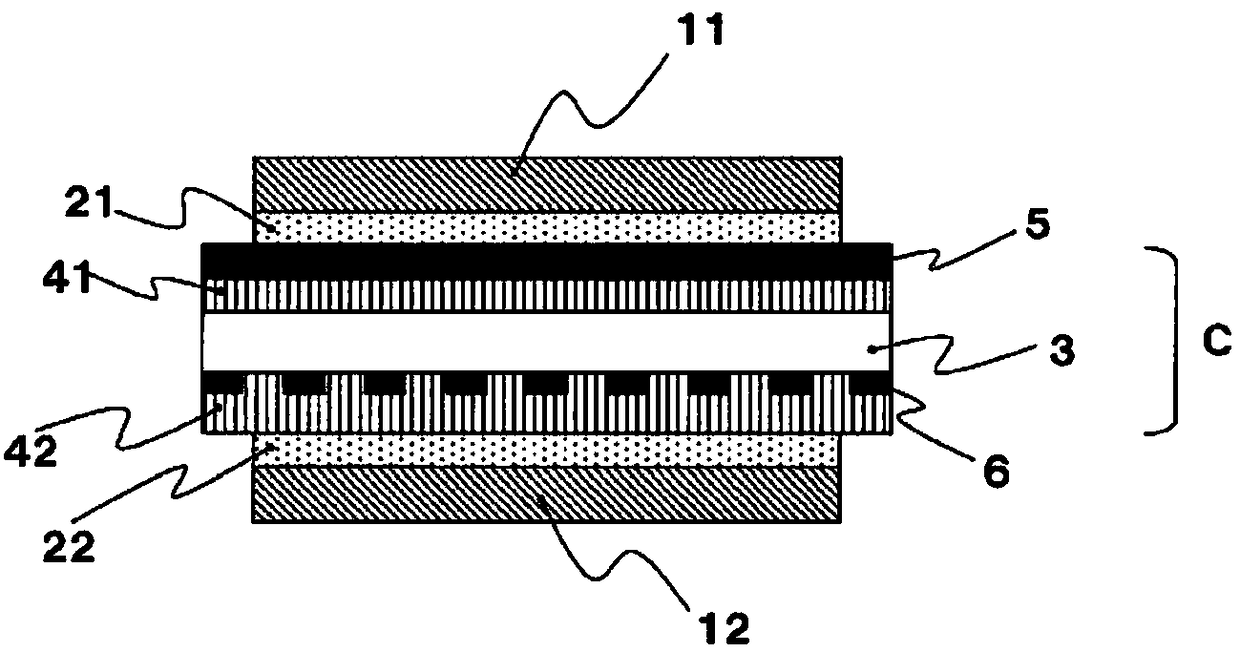

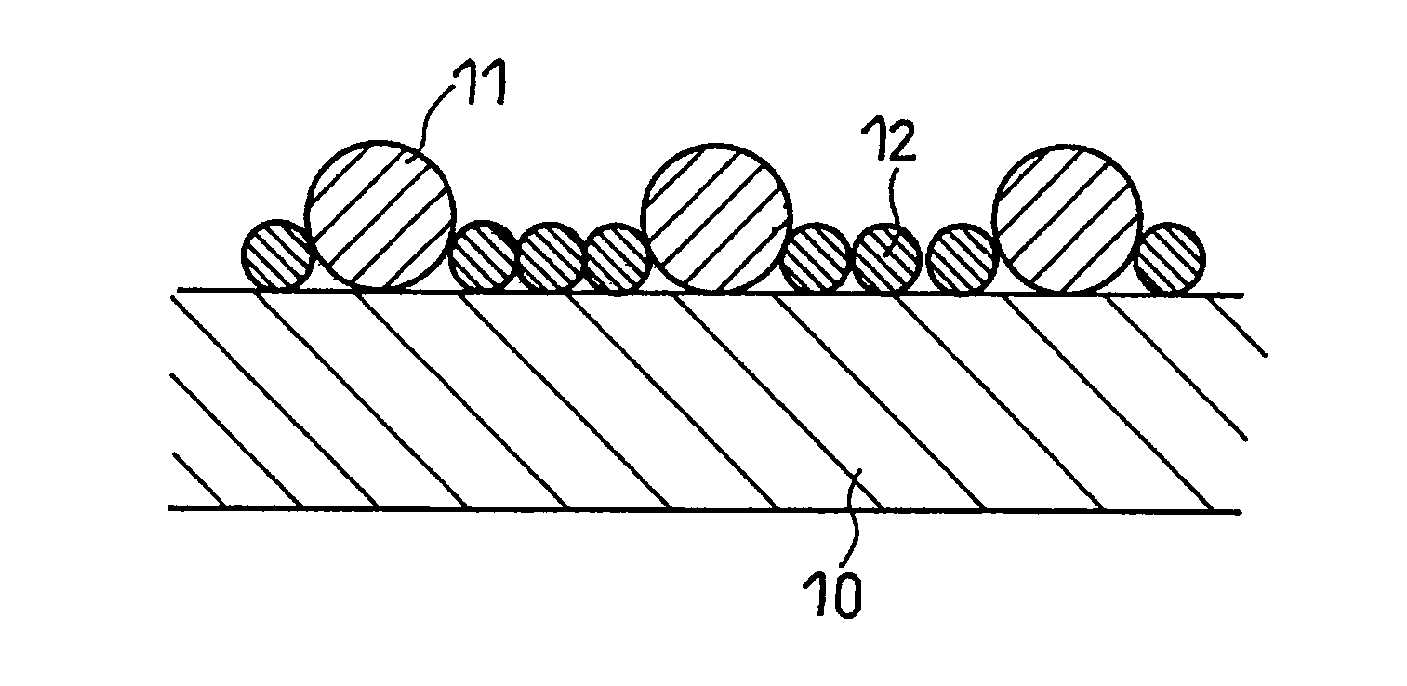

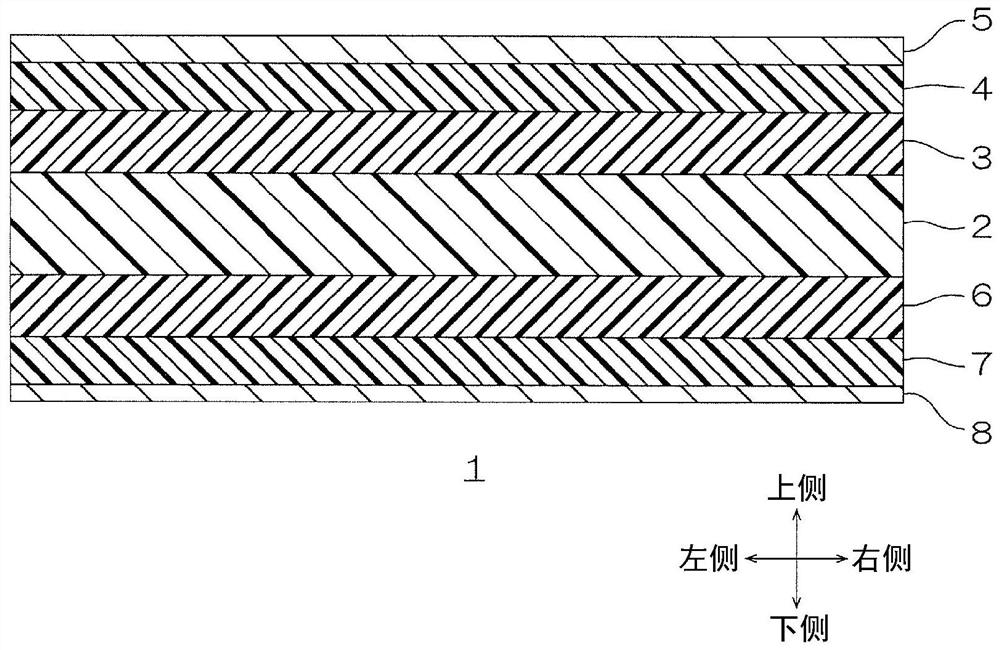

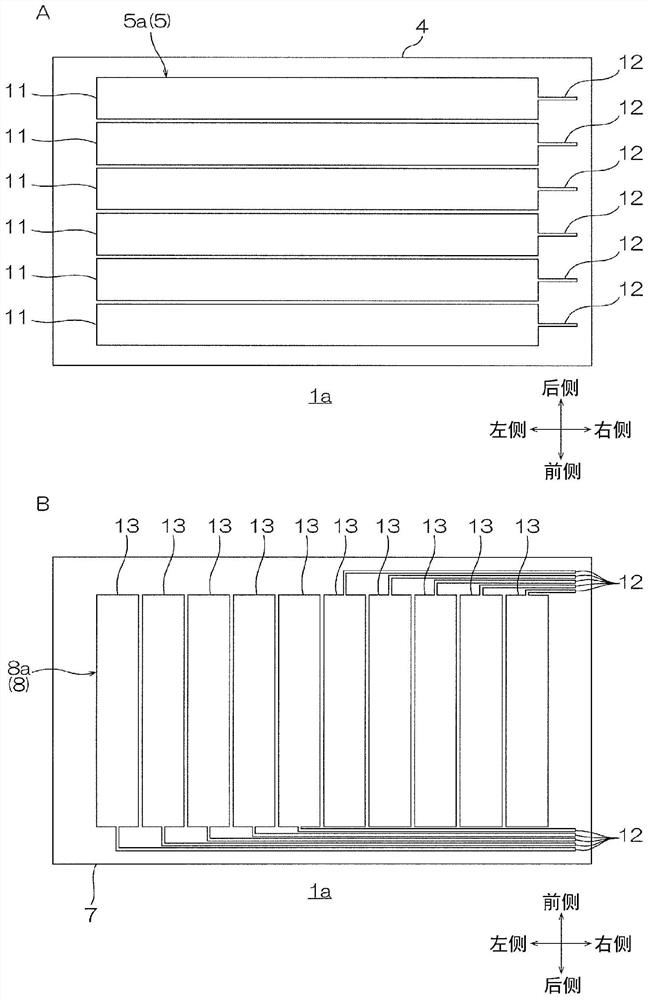

Electroconductive film, touch panel, and image display device

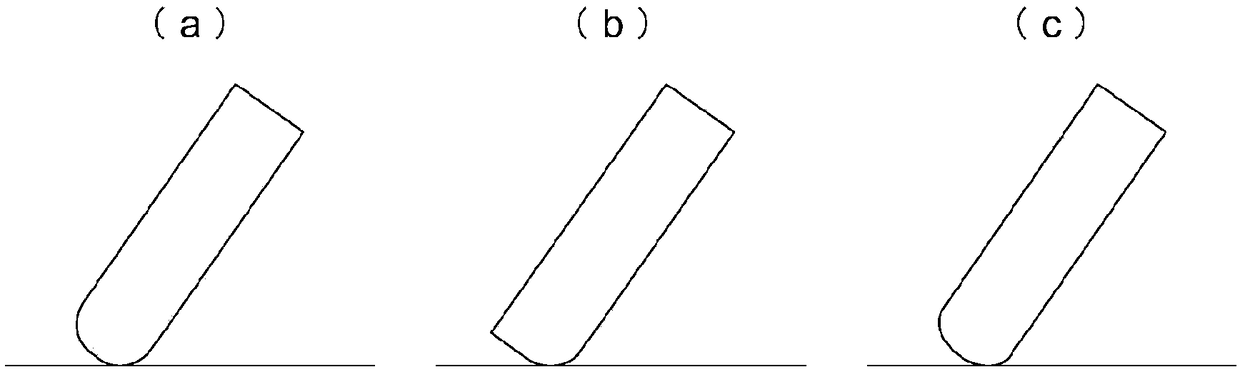

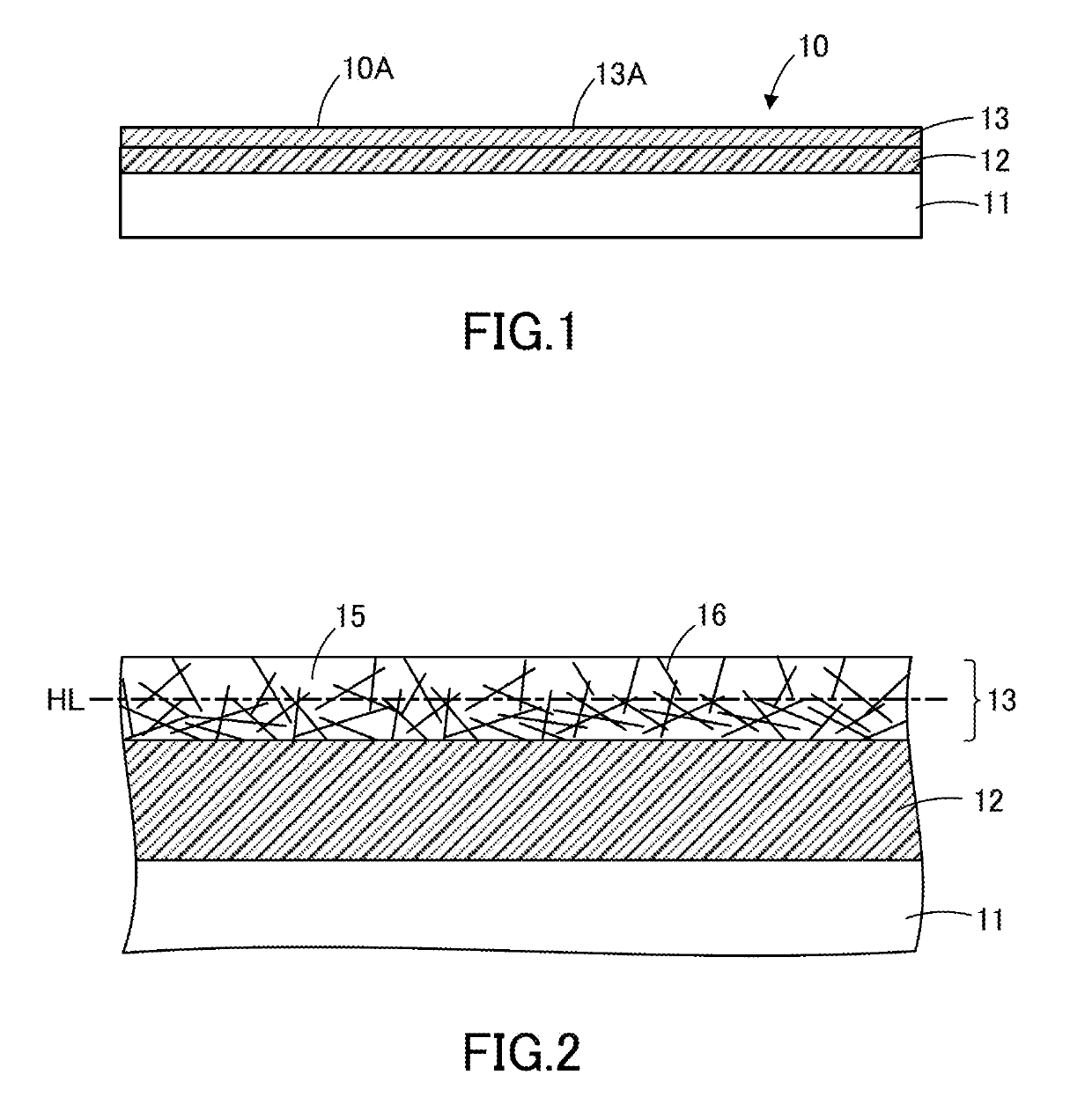

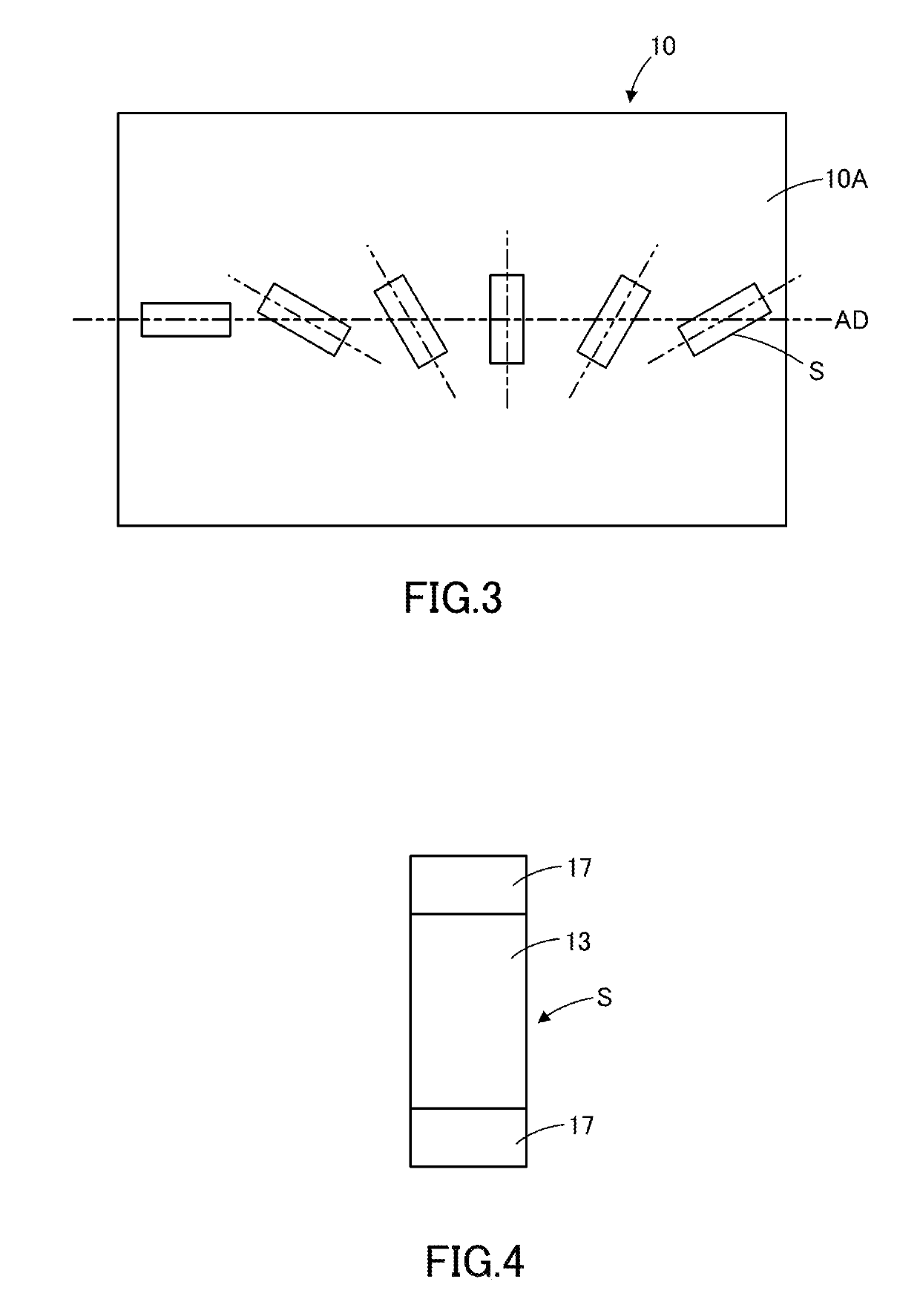

ActiveUS20190302925A1Lower surface resistance valueReduce conductivityConductive layers on insulating-supportsSynthetic resin layered productsFiberTouch panel

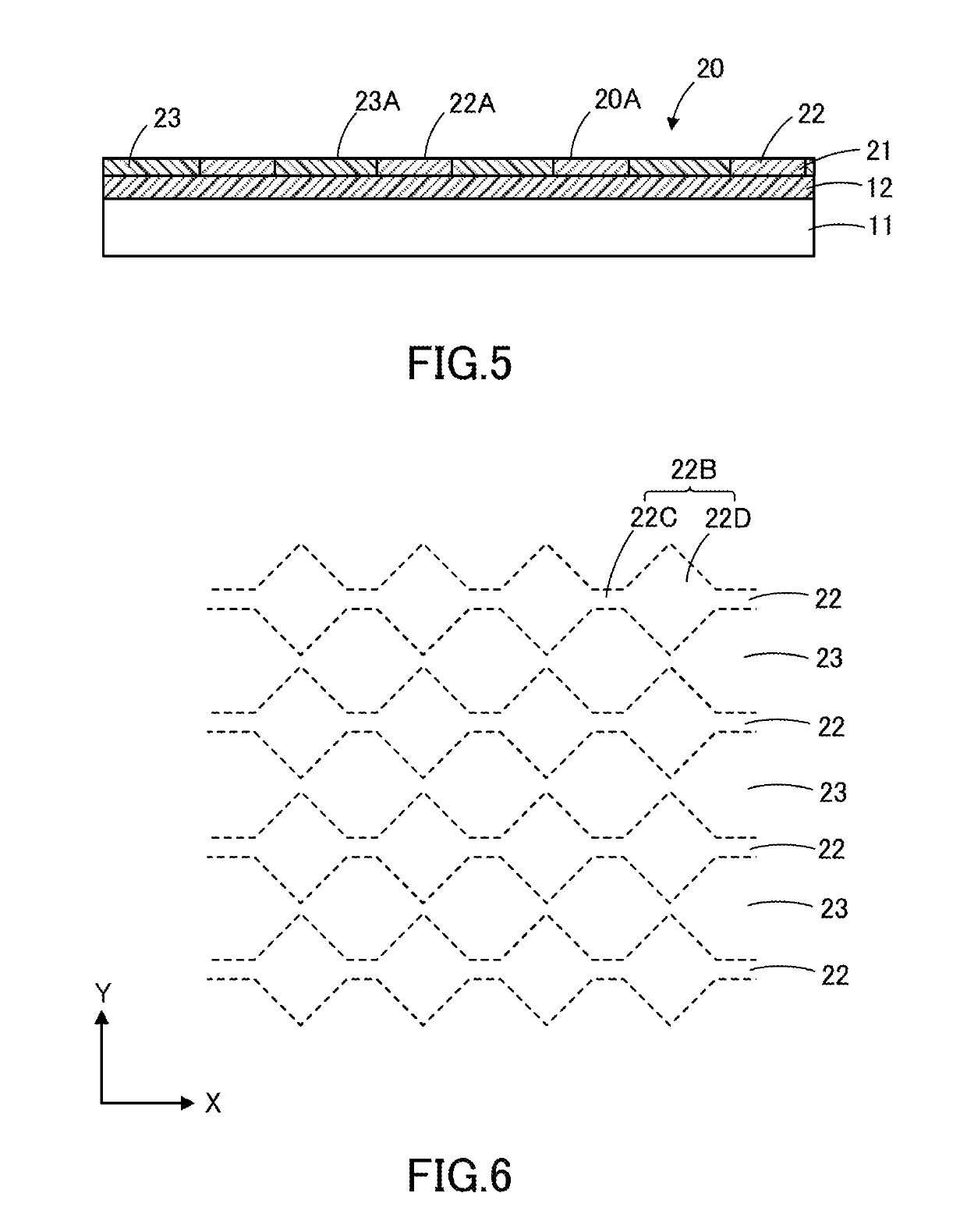

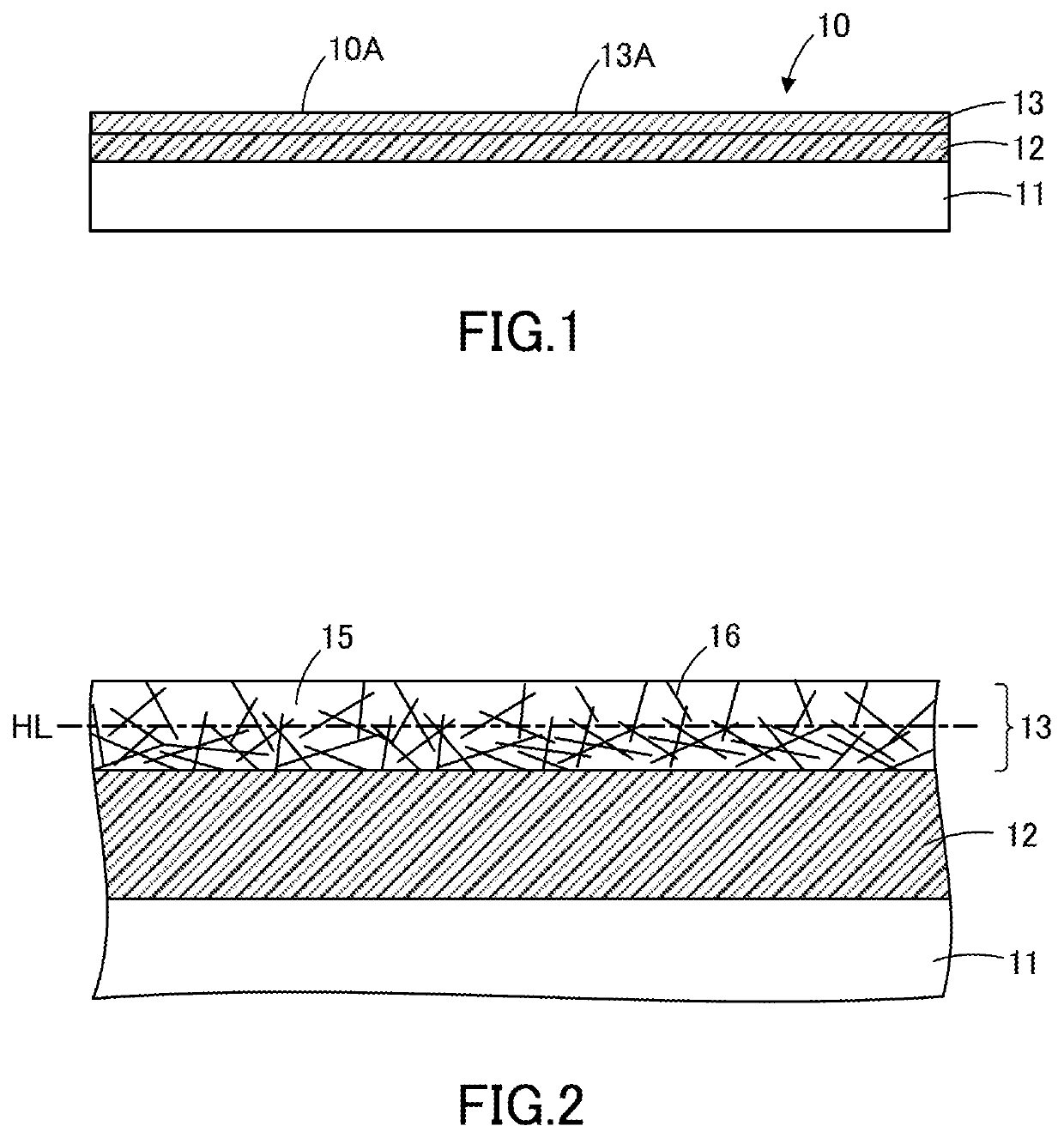

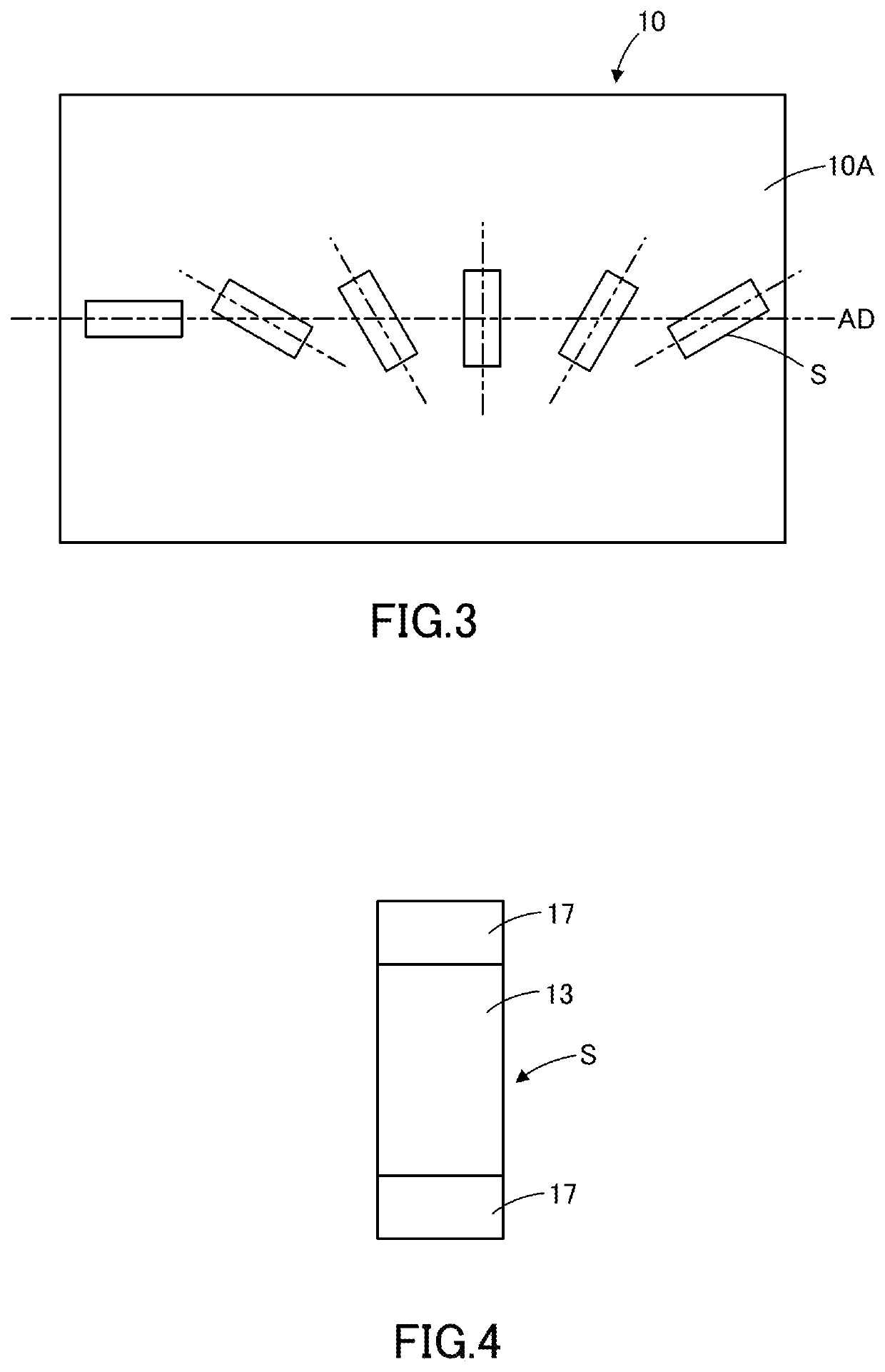

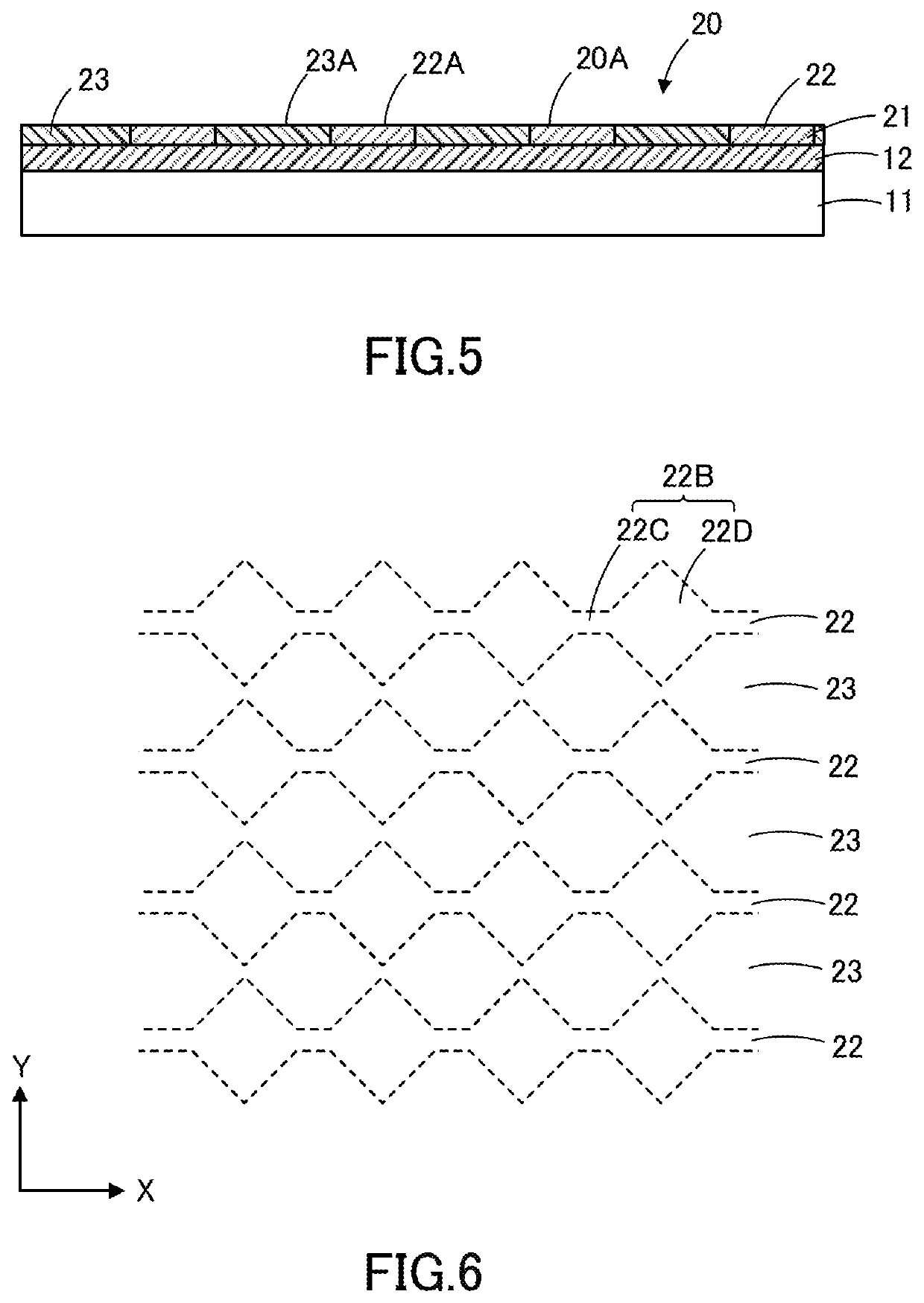

One aspect of the present invention provides a light-transmitting electroconductive film 10 comprising a light-transmitting base material 11 and an electroconductive part 13 provided on one surface of the light-transmitting base material 11, wherein the electroconductive part 13 includes a light-transmitting resin 15 and plural electroconductive fibers 16 incorporated in the light-transmitting resin 15, and the electroconductive part 13 can conduct electricity from the surface 13A of the electroconductive part 13, and the electroconductive fibers 16 as a whole are unevenly distributed on the light-transmitting base material side than the position HL, which is located at half the film thickness of the electroconductive part 13 in the electroconductive part 13, and the electroconductive part 13 has a surface resistance value of 200 Ω / □ or less, and the electroconductive film 10 has a haze value of 5% or less.

Owner:DAI NIPPON PRINTING CO LTD

Electroconductive film, touch panel, and image display device

ActiveUS10831327B2Lower surface resistance valueReduce conductivityConductive layers on insulating-supportsSynthetic resin layered productsFiberEngineering

One aspect of the present invention provides a light-transmitting electroconductive film 10 comprising a light-transmitting base material 11 and an electroconductive part 13 provided on one surface of the light-transmitting base material 11, wherein the electroconductive part 13 includes a light-transmitting resin 15 and plural electroconductive fibers 16 incorporated in the light-transmitting resin 15, and the electroconductive part 13 can conduct electricity from the surface 13A of the electroconductive part 13, and the electroconductive fibers 16 as a whole are unevenly distributed on the light-transmitting base material side than the position HL, which is located at half the film thickness of the electroconductive part 13 in the electroconductive part 13, and the electroconductive part 13 has a surface resistance value of 200 Ω / □ or less, and the electroconductive film 10 has a haze value of 5% or less.

Owner:DAI NIPPON PRINTING CO LTD

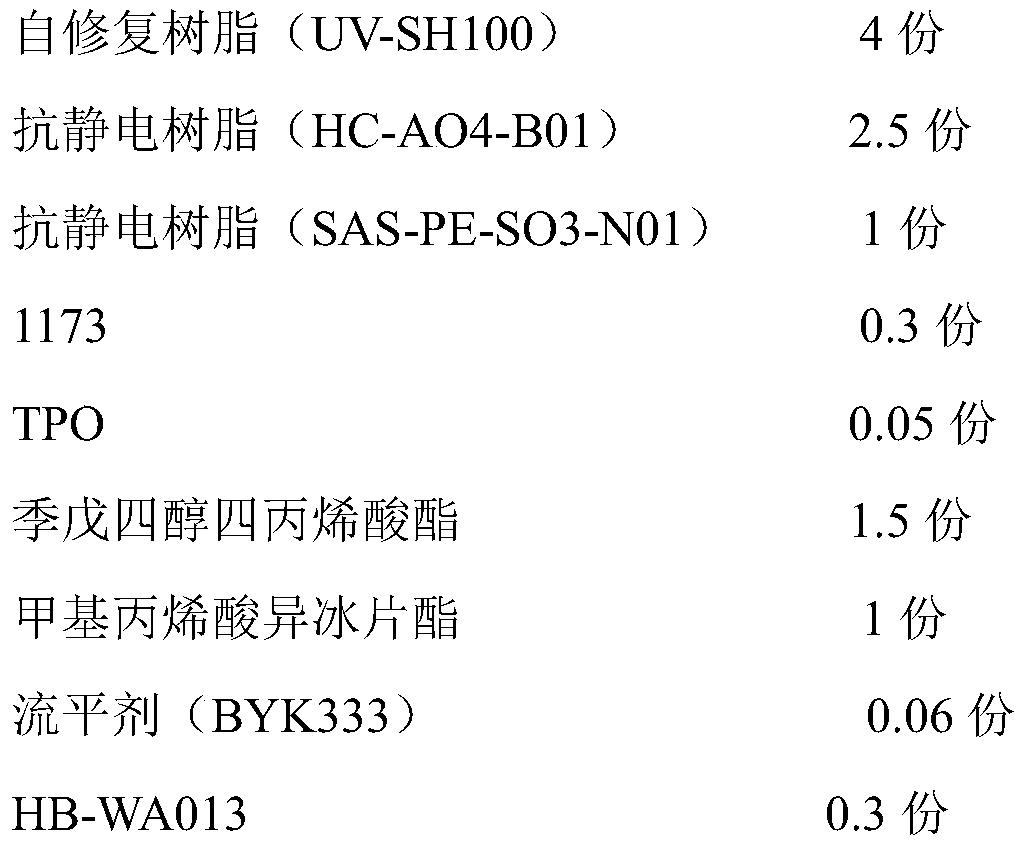

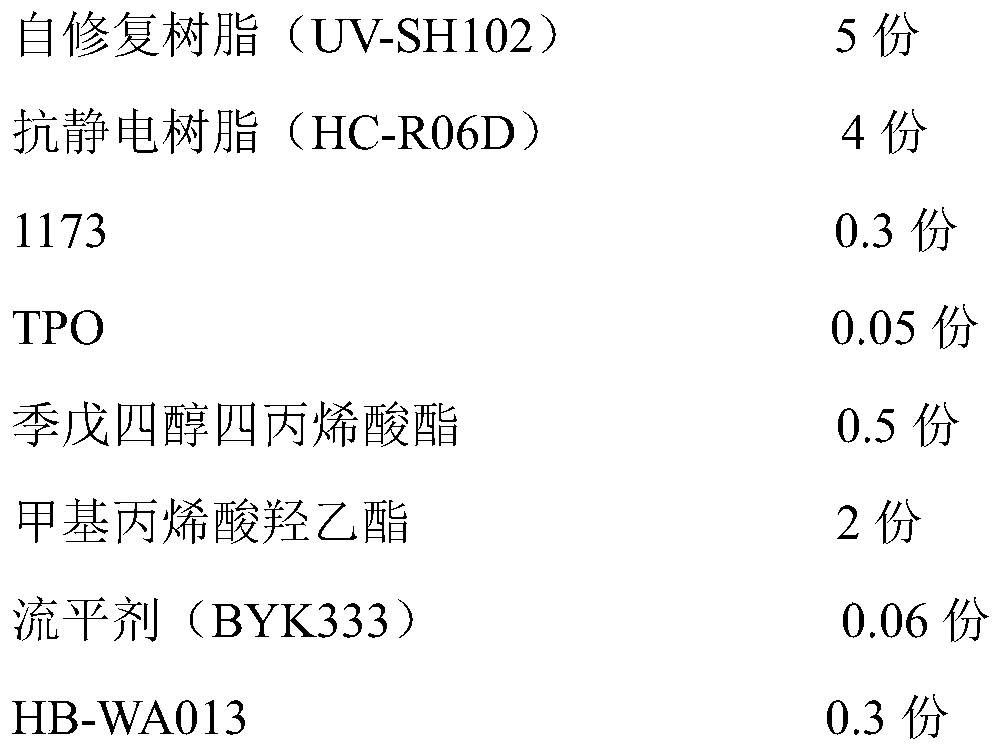

UV-cured self-repairing antistatic coating

ActiveCN111073498AHigh light transmittanceGood flexibilityPolyurea/polyurethane coatingsElectrically-conductive paintsPolymer scienceUV curing

The invention provides UV curing self-repairing antistatic coating. The coating comprises, by mass, 40 to 55 parts of UV curing self-repairing resin, 2 to 10 parts of a photoinitiator, 30 to 50 partsof antistatic resin, 5 to 30 parts of a photopolymerization monomer, 0.1 to 1 part of a leveling aid and 0.1 to 5 parts of an antistatic aid. The antistatic resin adopted is modified polythiophene, has good intermiscibility with each component in the system, is stable in storage, and can form a cross-linked structure with other photopolymerization components during curing; a coating layer has highlight transmittance and lasting and stable antistatic effect; and because of the addition of the self-repairing resin, the prepared coating has excellent sharp article scratch resistance. The coatingcan be used for surface coating of optical devices, sensitive electronic components and functional films.

Owner:湖南宏泰新材料有限公司

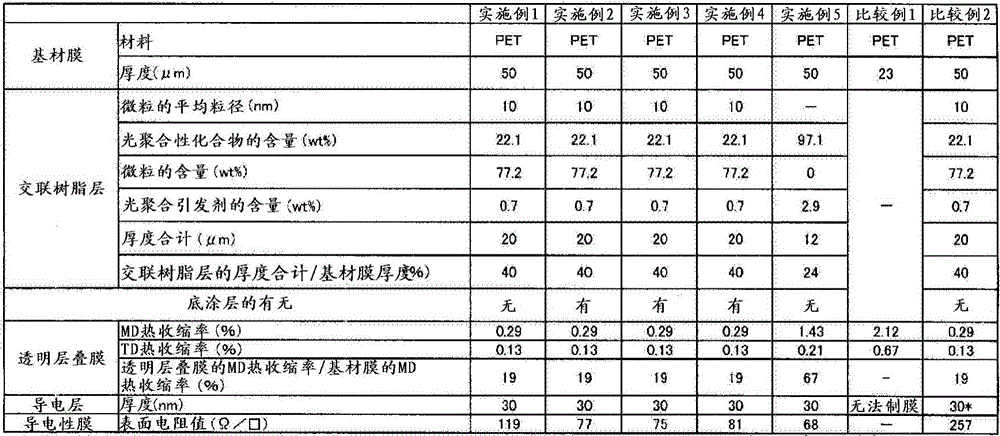

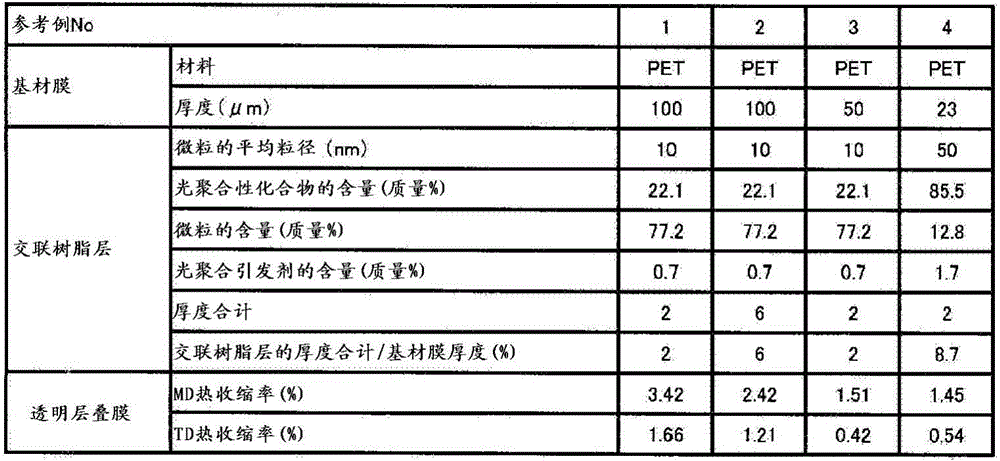

Transparent laminated film, transparent conductive film, and gas barrier laminated film

ActiveCN104969305BLower surface resistance valueHigh crystallinityConductive layers on insulating-supportsSynthetic resin layered productsOptoelectronicsGas barrier

Provided is a new transparent conductive film having superior transparency and thermal dimensional stability at a high temperature (for example, 200°C), and having a low surface resistance value. Further provided is a new transparent stacked film and a new gas barrier stacked film that can be used as a base material film for the transparent conductive film and in other types of transparent substrates. Provided is a transparent conductive film in which a transparent conductive layer is formed directly or through an undercoat comprising a resin material onto one side or both sides of a cross-linked resin layer of a transparent stacked film having the cross-linked resin layer on at least one surface of a base material film, the transparent conductive film being firstly characterized in that the transparent stacked film has a thermal shrinkage in the vertical direction and in the horizontal direction when heated for 10 minutes at a temperature of 200°C of 1.5% or less, and secondly characterized in that the surface resistance value of the transparent conductive film is 150 &OHgr; / □ or less.

Owner:MITSUBISHI CHEM CORP

Conductive structure and electronic device comprising same

ActiveUS20180037004A1High light transmittanceLower surface resistance valueConductive layers on insulating-supportsLayered product treatmentEngineeringElectron

Owner:LG CHEM LTD

Material for contact components or battery components, and battery using the same

InactiveUS8568917B2Lower surface resistance valueIncrease valueCell electrodesOrganic electrolyte cellsSurface layerSheet steel

A material for contact components or battery components, which includes a metal sheet having a surface layer portion containing a first metal element, the metal sheet including a Cr-containing steel plate or a surface-treated steel plate, and at least a part of the first metal element on an outermost surface of the surface layer portion being substituted by a second metal element having a nobler standard electrode potential than the first metal element, the second metal element being deposited on the outermost surface in a state of a particulate metal, oxide, or hydroxide.

Owner:PANASONIC CORP +1

Multifunctional casting polyolefine firmness-increasing film

InactiveCN101659142BLower surface resistance valueProduce anti-static effect of plastic filmFlexible coversWrappersCompound aPolymer science

The invention relates to a multifunctional casting polyolefine firmness-increasing film which is formed by compounding a heat sealing layer, a core layer and a corona layer. The corona layer or the heat sealing layer mainly comprises the following components in portions by weight: 100 portions of polyethylene resin, 10-60 portions of compatilizer, 0.1-0.5 portion of anti-blocking agent and 0.1-0.5 portion of slipping agent; and the core layer mainly comprises the following components in portions by weight: 100 portions of polypropylene resin and 0.1-1.1 portions of nucleating agent. The multifunctional casting polyolefine firmness-increasing film has the characteristics of low temperature, favorable heat sealing performance, high firmness, high elastic modulus and the like, not only combines the advantages of polyethylene and polypropylene films, but also overcomes the defects of polyethylene or polypropylene composite films, is widely applied for packing facial tissues, foods and other products, and is particularly suitable for quick and automatic package of products.

Owner:湖北慧狮塑业股份有限公司

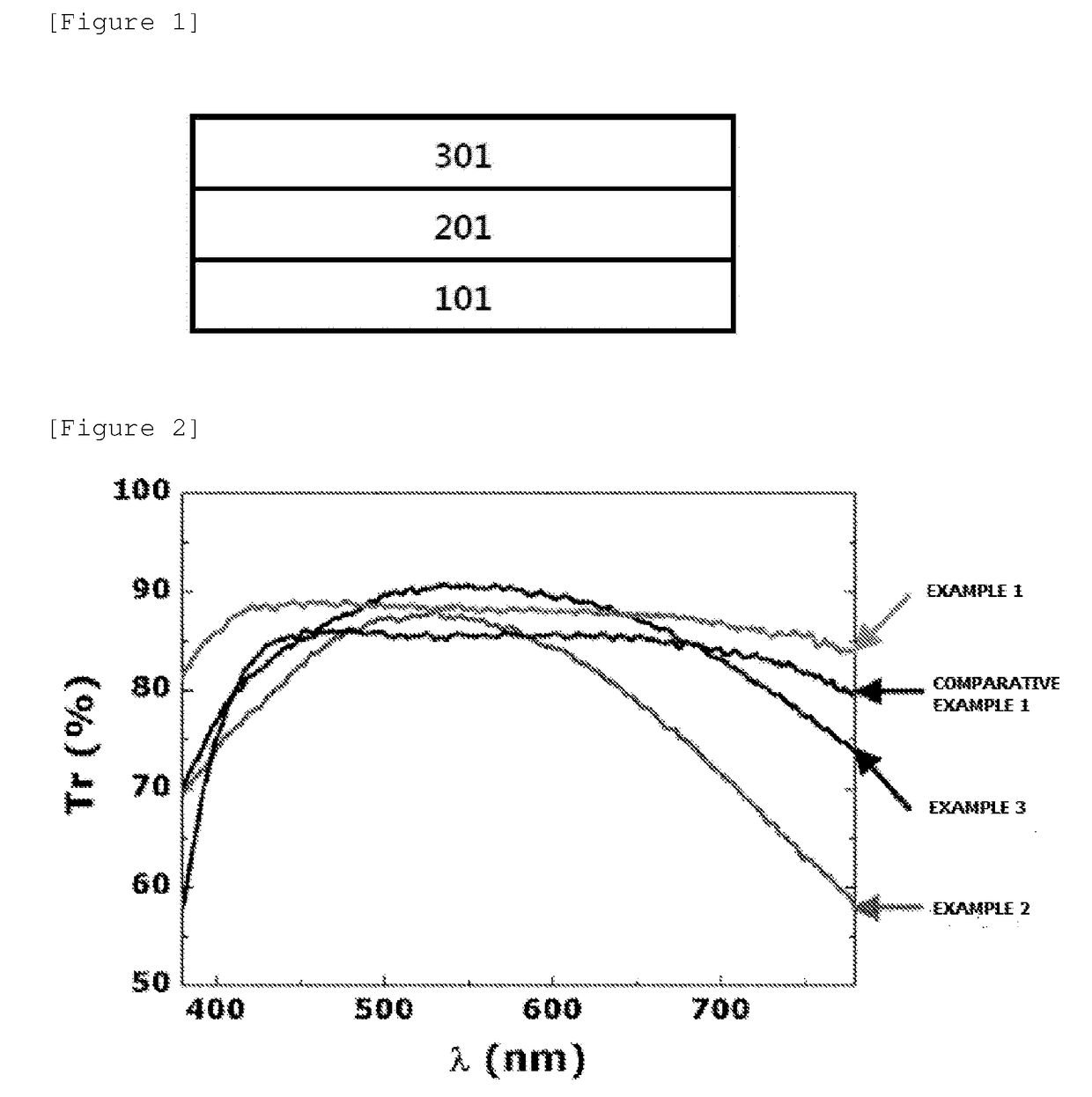

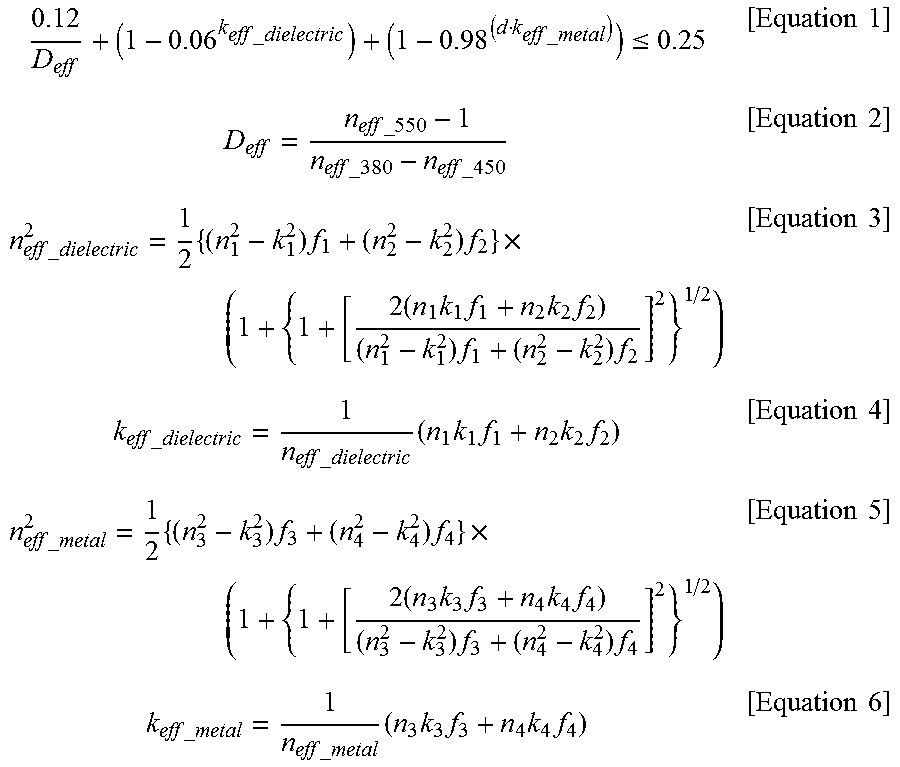

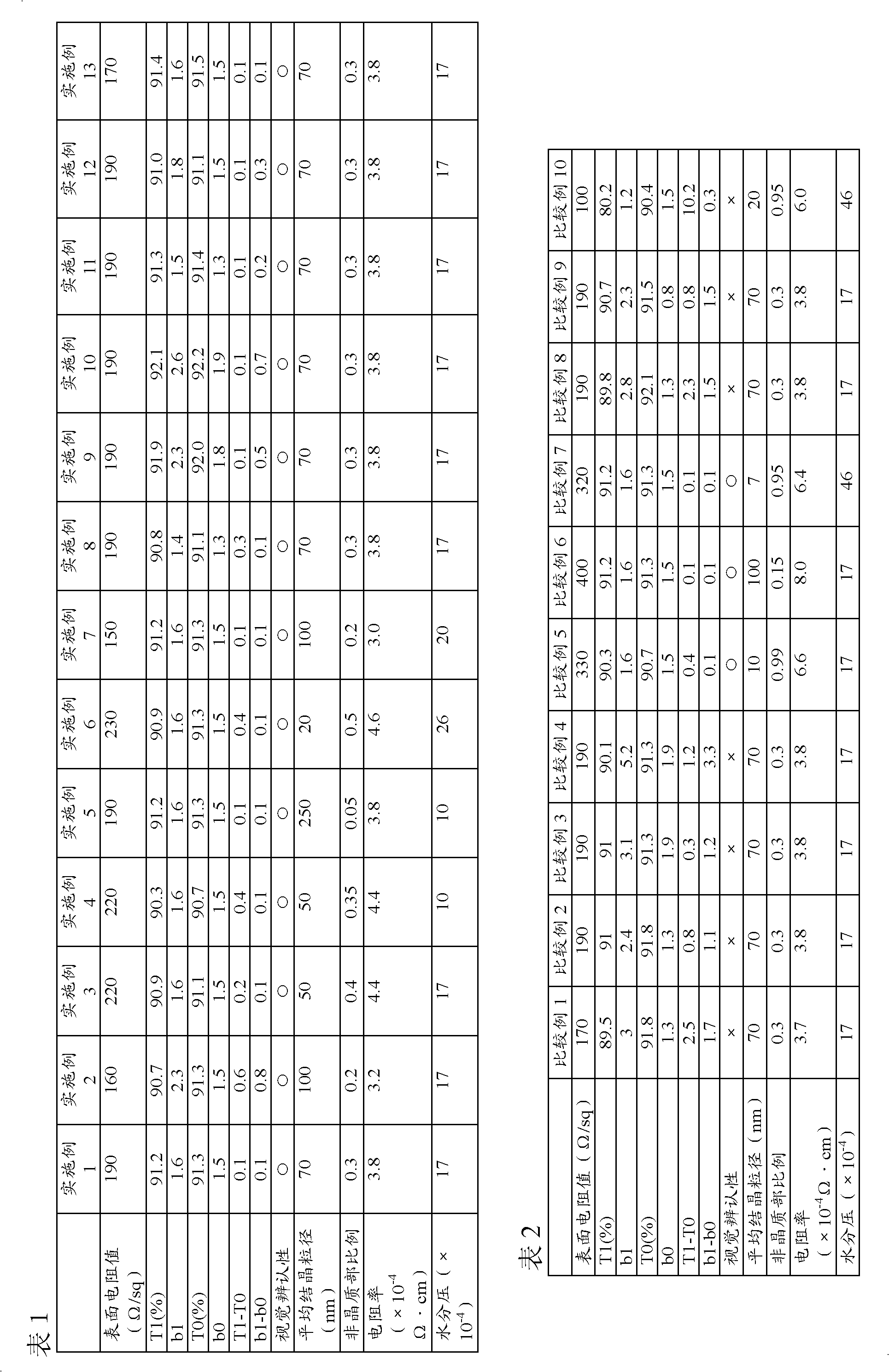

Transparent Conductive Laminated Film

ActiveCN102448717BImprove visual effectsSmall difference in optical propertiesConductive layers on insulating-supportsSynthetic resin layered productsRefractive indexPlastic film

Disclosed is a transparent conductive multilayer film for an electrode film that is used in a capacitive touch panel or the like, and has a low surface resistance. When a transparent conductive thin film is patterned in the transparent conductive multilayer film, the pattern is not highly visible since the difference in the optical characteristics is small between the portion with the transparent conductive thin film and the portion without the transparent conductive thin film. Specifically disclosed is a transparent conductive multilayer film which has a structure wherein a high refractive index layer, a low refractive index layer and a transparent conductive thin film layer are arranged in this order on a base that is composed of a transparent plastic film. The transparent conductive multilayer film is characterized in that the high refractive index layer has a refractive index of 1.70-2.50 and a film thickness of 4-20 nm, the low refractive index layer has a refractive index of 1.30-1.60 and a film thickness of 20-50 nm, and the transparent conductive thin film layer has a specific resistance of 1.0-4.6 × 10-4 O·cm and a film thickness of 10-28 nm.

Owner:TOYOBO CO LTD

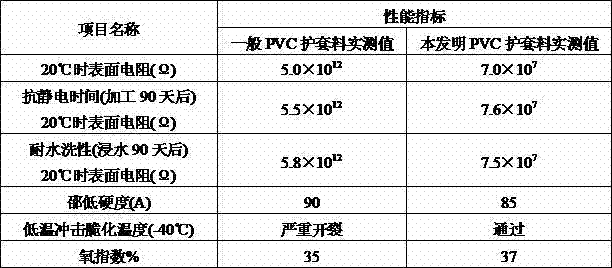

A cold-resistant flame-retardant antistatic polyvinyl chloride sheath material for coal mine cables

ActiveCN103113692BLower surface resistance valueImprove antistatic performanceInsulated cablesInsulated conductorsPhosphatePolyvinyl chloride

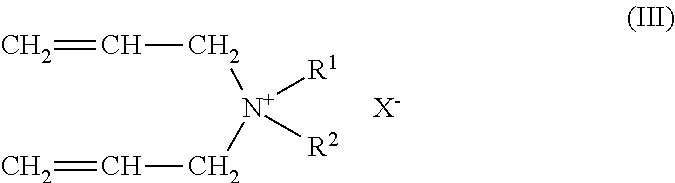

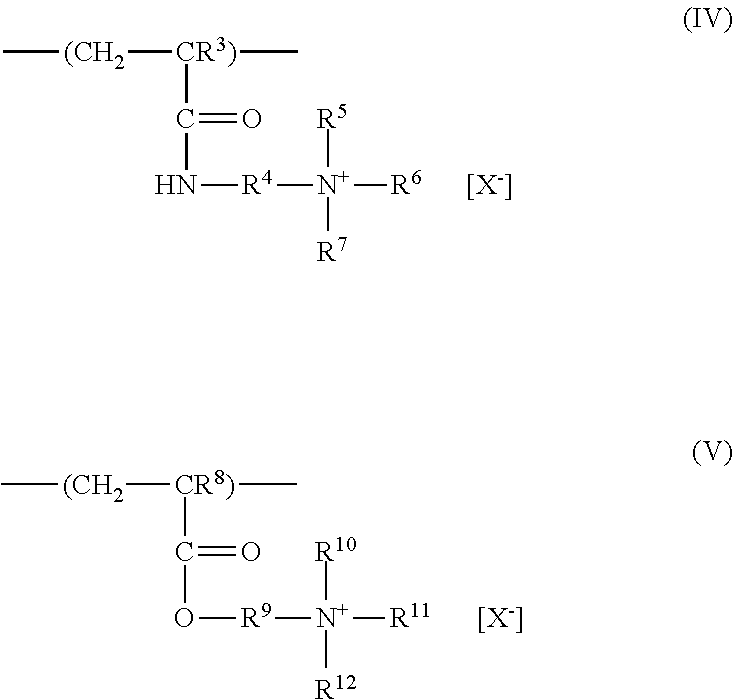

The invention discloses a cold-resistance flame-retardant anti-static polyvinyl chloride sheathing material for coal mine cable; the sheathing material is characterized by consisting of the following raw materials: polyvinyl chloride resin SG3, tri(2-chloroethyl) phosphate, an anti-static agent, dioctyl sebacate, dioctyl phthalate, tricresyl phosphate, antimonous oxide, zinc borate, tribasic lead sulfate, bibasic lead sulfate, light calcium carbonate, bisphenol A, 2-mercapto benzimidazole, vinyl tri(beta-methoxyl ethyoxyl) silane, accelerant TMTD and modified asbestos powder; the polyvinyl chloride sheathing cable material provided by the invention has the following characteristics of being low in surface resistance value and high in anti-static property; by adopting the compound high-concentration anti-static agent consisting of TCEP (trichloroethyl phosphate), quaternary ammonium salt cationic surface active agent and nonionic surface active agent, the excellent anti-static synergistic effect can be brought; the surface resistance value of the sheathing material is no higher than 108ohms, and thus the sheathing material has excellent anti-static property.

Owner:安徽龙庵电缆集团有限公司

Transparent conductive film and image display device

ActiveCN110636943BInhibition recognitionLower surface resistance valueConductive layers on insulating-supportsSynthetic resin layered productsRefractive indexThin membrane

The transparent conductive film includes a first transparent conductive layer, a first optical adjustment layer, a transparent substrate, a second optical adjustment layer, and a second transparent conductive layer in this order. The surface resistance value of the second transparent conductive layer is larger than the surface resistance value of the first transparent conductive layer, the surface resistance value of the first transparent conductive layer is not less than 10Ω / □ and not more than 70Ω / □, and the surface resistance value of the second transparent conductive layer is 50Ω / □ to 150Ω / □, the refractive index of the second optical adjustment layer is lower than the refractive index of the first optical adjustment layer.

Owner:NITTO DENKO CORP

Transparent conductive film and image display device

ActiveCN110636943AInhibition recognitionGood light transmissionConductive layers on insulating-supportsSynthetic resin layered productsThin membraneElectrically conductive

This transparent conductive film is sequentially provided with a first transparent conductive layer, a first optical adjustment layer, a transparent substrate, a second optical adjustment layer and asecond transparent conductive layer. The surface resistivity of the second transparent conductive layer is higher than the surface resistivity of the first transparent conductive layer; the surface resistivity of the first transparent conductive layer is from 10 [Omega] / [] to 70 [Omega] / [] (inclusive); the surface resistivity of the second transparent conductive layer is from 50 [Omega] / [] to 150[Omega] / [] (inclusive); and the refractive index of the second optical adjustment layer is lower than the refractive index of the first optical adjustment layer.

Owner:NITTO DENKO CORP

Method for forming transparent conductive pattern

ActiveCN109074917AAvoid damageEfficient preparationConductive materialInksScreen printingMetallic nanotubes

The subject of the invention provides a method for forming a transparent conductive pattern that reduces damage to metal nanowires and / or metal nanotubes during screen printing using a transparent conductive ink containing metal nanowires and / or metal nanotubes as a conductive component and thereby makes it possible to form a transparent conductive pattern via a simple production process while minimizing production costs and environmental impact. The attack angle of a squeegee tip section that is brought into contact with a screen mask (2) is set in the range of 1-30 degrees when screen printing with a transparent conductive ink (5) containing a dispersion medium and at least one of metal nanowires and metal nanotubes.

Owner:RESONAC CORP

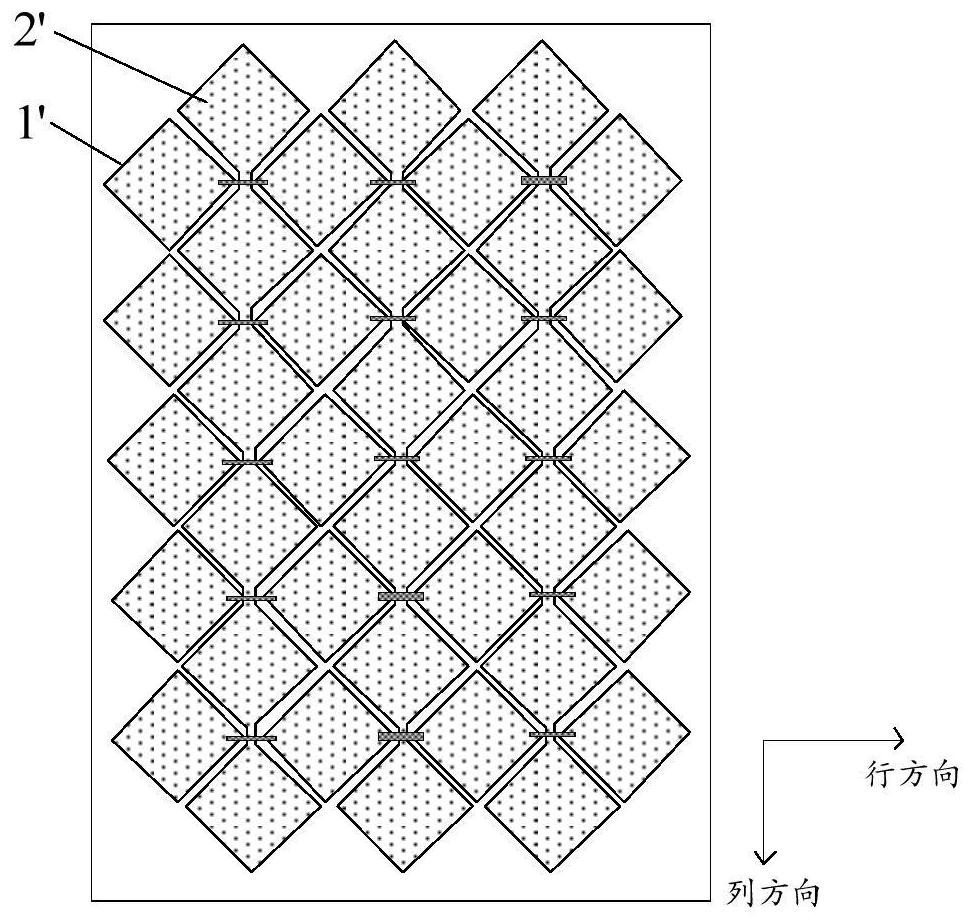

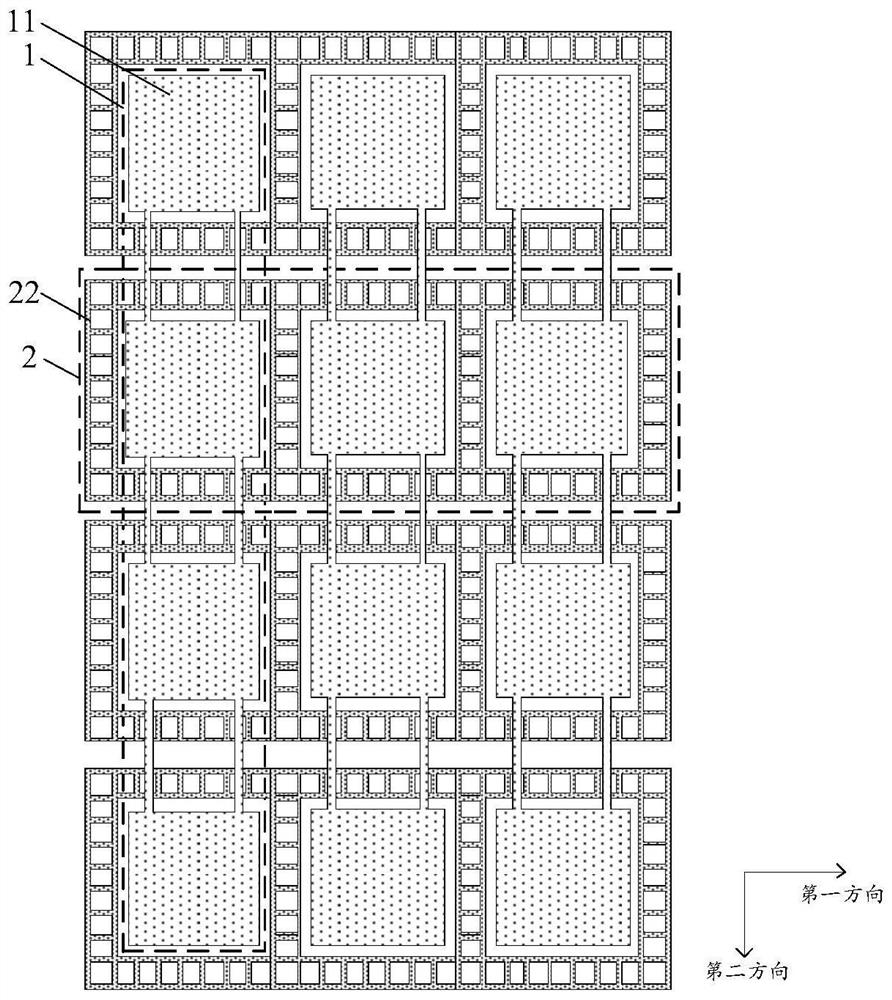

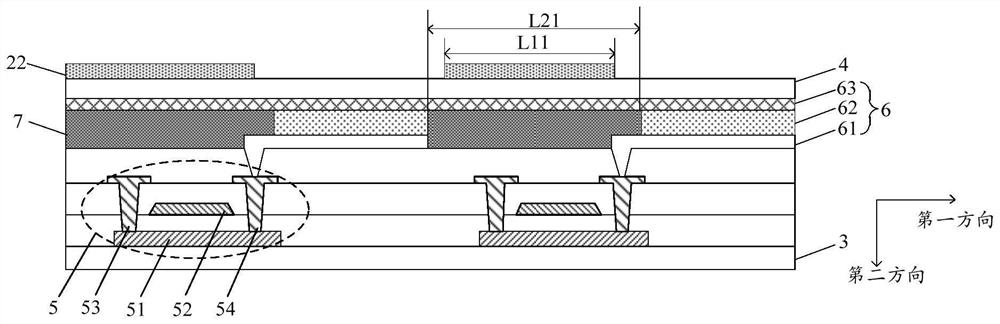

A touch display panel and a touch display device

ActiveCN108089759BLower surface resistance valueReduce loadInput/output processes for data processingMetallic electrodeDisplay device

Embodiments of the present invention provide a touch display panel and a touch display device, which relate to the field of display technology and are used to reduce power consumption generated during touch control. The touch display panel includes a plurality of transparent touch electrodes and a plurality of metal touch electrodes, wherein the transparent touch electrodes are arranged along the first direction and extend along the second direction; the metal touch electrodes are arranged along the second direction and extend along the first direction. The transparent touch electrode includes a plurality of transparent electrode blocks arranged along the second direction, and two adjacent transparent electrode blocks are connected; the metal touch electrode includes a plurality of metal electrode blocks arranged along the first direction, adjacent to each other. Two metal electrode blocks are connected. The above-mentioned touch display panel is used to realize the touch function.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

A kind of insulating coating on the surface of ultra-thin silicon steel and its preparation method

ActiveCN108659584BGood adhesionHigh insulation resistanceFireproof paintsMonomagnesium phosphatePhosphoric acid

The invention belongs to the technical field of coating compositions, in particular to an ultra-thin silicon steel surface insulating coating and a preparation method thereof. The insulating coating provided by the invention is prepared from the following components: 65 to 85 parts of magnesium dihydrogen phosphate, 0.1 to 1.5 parts of insulating inorganic nanoparticles, 2 to 15 parts of silica sol, 2 to 4 parts of boric acid and 1 to 32.9 parts of deionized water. The coating formed by synergistic effects of all the components has excellent adhesion property to the surface of a bare steel sheet of ultra-thin silicon steel, and meanwhile, the insulation performance is ensured. The insulating coating provided by the invention is also prepared from 0.01 to 5 parts by weight of organic resin;by the addition of the organic resin, the adhesion of the ultra-thin silicon steel surface coating can be improved and subsequent high temperature sintering can be resisted, so that the ultra-thin silicon steel with the coating can be suitable for preparing a roll core of a saturation reactor, and further complex operating conditions such as strong vibration and high temperature rise of high pressure anode saturation reactors are met.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Capacitor electrode member, its manufacturing method and capacitor with same

ActiveCN101027736BExcellent adhesionLarge capacityHybrid capacitor electrodesDouble layer capacitorsCarbideCapacitor

Owner:TOYO ALUMINIUM KK

In-cell liquid crystal panel and liquid crystal display device

PendingCN110462499AEnsure continuitySuppresses static unevennessPolarising elementsCoatingsAntistatic agentConductive polymer

The present invention provides an in-cell liquid crystal panel having: an in-cell liquid crystal cell that is provided with a liquid crystal layer comprising liquid crystal molecules which are homogeneously oriented when no electric field is present, a first transparent substrate and a second transparent substrate sandwiching the liquid crystal layer on both sides, and a touch sensing electrode portion related to touch sensor and touch-driven functions between the first transparent substrate and the second transparent substrate; and a polarizing film with added adhesive layer that is disposed,via a first adhesive layer and without interposing a conductive layer, to the first transparent substrate side on the viewing side of the in-cell liquid crystal cell. The polarizing film with added adhesive layer is provided with a surface treatment layer, a first polarizing film, and the first adhesive layer in this order. The surface treatment layer includes at least one of any antistatic agentselected from ionic surfactants, conductive microparticles, and conductive polymers. In the in-cell liquid crystal panel, the antistatic function is satisfactory and it is possible to satisfy touch sensor sensitivity as well as conduction reliability and durability in humid environments.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com