UV-cured self-repairing antistatic coating

A self-healing and antistatic technology, applied in conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as general stability and durability, poor heat resistance, poor water resistance, and increased surface resistance, so as to avoid antistatic Functional attenuation or failure, permanent antistatic effect, wide application effect

Active Publication Date: 2020-04-28

湖南宏泰新材料有限公司

View PDF14 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing UV-curable coatings generally do not have antistatic properties themselves, and antistatic components need to be added to make them have antistatic functions.

[0004] One of the commonly used methods for existing UV antistatic coatings is to add conductive fillers such as graphite, carbon nanotubes, nano-metals and their oxides to UV coatings. The conductive fillers can be evenly dispersed in the paint film to obtain antistatic The electrostatic effect is stable and long-lasting, but the addition of conductive fillers will affect the transparency and color of the coating; one is to add ionic antistatic resins or antistatic agents such as acrylate modified quaternary ammonium salts, quaternary phosphonium salts, alkyl Sulfonate, alkyl phosphate, etc., this method is to use the hydrophilic group of antistatic resin or antistatic agent to absorb water molecules in the air on the surface of the paint film to form a layer of water film to make the surface of the paint film antistatic, but Quaternary ammonium salts and quaternary phosphorus salts have poor heat resistance and water resistance, and the antistatic effect of UV antistatic coatings made of ionic antistatic substances is greatly affected by ambient humidity and temperature. Abrasion and washing in water will also lead to an increase in surface resistance; patent CN 104356927 A obtains a UV curable coating with better antistatic performance by using a quaternary ammonium salt that can participate in photocuring acrylate, and can resist ethanol wiping, but it is not resistant to it. Research on water washing and wear resistance

[0005] High molecular polymers with conductive functions, such as polyaniline and polythiophene, have stable chemical properties. They are added to UV coatings as film-forming substances or antistatic agents. They have excellent antistatic effects and are not affected by temperature and humidity, but non-reactive polymers Thiophene or polyaniline polymer molecules cannot form a cross-linked network structure, and many of its resistances such as wear resistance, solvent resistance, water resistance, and durability are not as good as reactive types (heat curing, light curing, etc.)

Patent CN 104263229 A mentions a method of dispersing polythiophene polymers into UV coatings. The prepared paint film initially has good antistatic performance, but its antistatic effect cannot be kept stable for a long time; patent CN 107418422 A It is mentioned that polythiophene is added to the UV coating system, and the antistatic MS board prepared by it has good antistatic performance and scrub resistance, but its solvent resistance and resistance to scratching by sharp and hard objects cannot meet the actual requirements

In short, the existing method of making UV coatings antistatic by adding polythiophene, although the initial antistatic performance is excellent, but the stability and durability are average; although the obtained product has high hardness and wear resistance, it still cannot achieve Resistant to scratches by sharp objects without scratches, and poor flexibility, easy to crack when bent, only suitable for hard substrates, not suitable for soft films

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

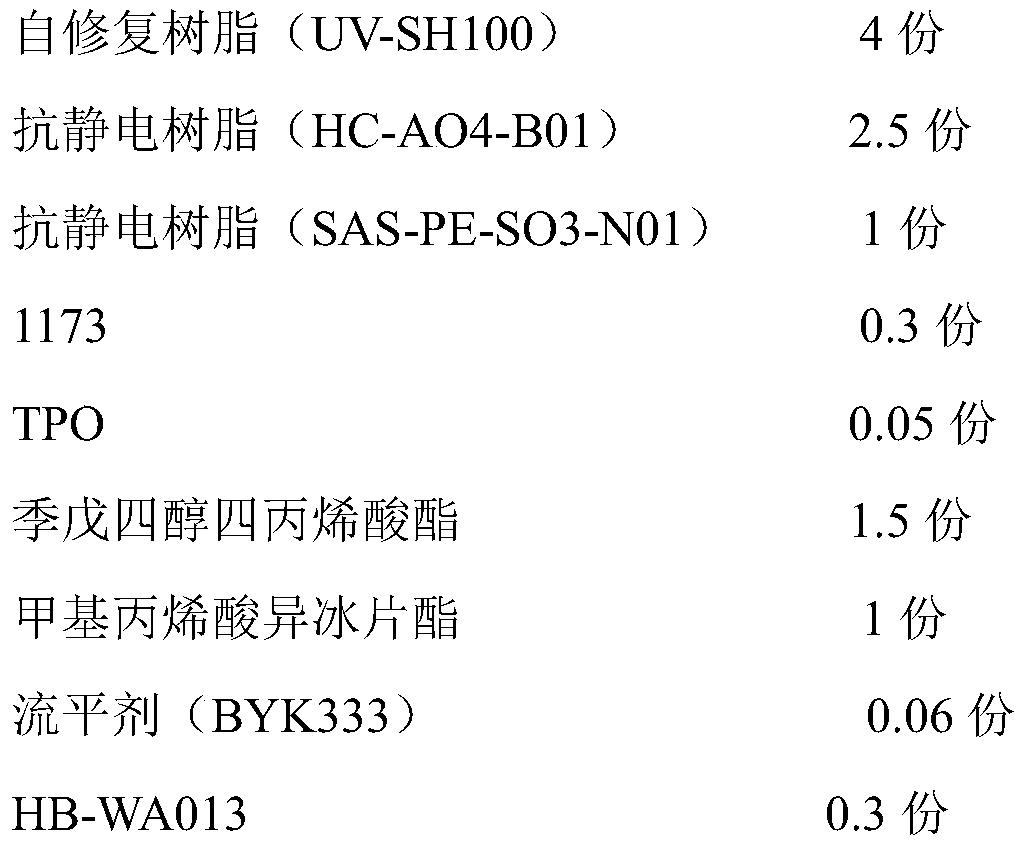

Embodiment 1

[0034] A UV curing self-repairing antistatic coating, comprising the following parts by mass:

[0035]

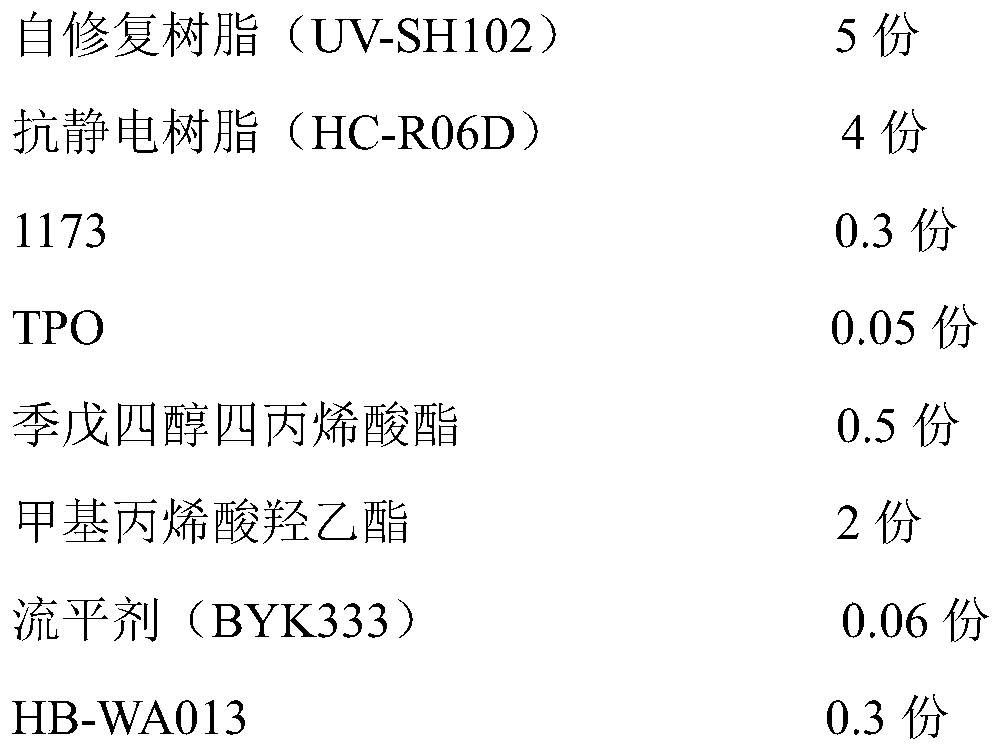

Embodiment 2

[0037] A UV curing self-repairing antistatic coating, comprising the following parts by mass:

[0038]

Embodiment 3

[0040] A UV curing self-repairing antistatic coating, comprising the following parts by mass:

[0041]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides UV curing self-repairing antistatic coating. The coating comprises, by mass, 40 to 55 parts of UV curing self-repairing resin, 2 to 10 parts of a photoinitiator, 30 to 50 partsof antistatic resin, 5 to 30 parts of a photopolymerization monomer, 0.1 to 1 part of a leveling aid and 0.1 to 5 parts of an antistatic aid. The antistatic resin adopted is modified polythiophene, has good intermiscibility with each component in the system, is stable in storage, and can form a cross-linked structure with other photopolymerization components during curing; a coating layer has highlight transmittance and lasting and stable antistatic effect; and because of the addition of the self-repairing resin, the prepared coating has excellent sharp article scratch resistance. The coatingcan be used for surface coating of optical devices, sensitive electronic components and functional films.

Description

technical field [0001] The invention relates to the field of ultraviolet curing coatings, in particular to a UV curing self-repairing antistatic coating. [0002] technical background [0003] Coatings can be seen everywhere in people's lives, including mobile phones, computers, cars, houses, etc., all need to use coatings, and coatings have a protective and decorative effect. UV-curable coating is a kind of high-efficiency, energy-saving, and environmental-friendly coating, which is used in various aspects such as wood, plastic, glass, and metal. Materials used for optical instruments, electronic product components or functional protective films of electronic appliances, etc. Static electricity may cause damage to sensitive electronic components, and it is easy to accumulate dust. Coating a layer of UV antistatic coating on the surface of these materials can It eliminates static electricity very well, and can also improve its wear-resistant and anti-scratch functions withou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D175/14C09D133/04C09D165/00C09D5/24

CPCC08K2201/017C08L2201/04C08L2205/025C08L2205/03C08L2205/035C09D5/24C09D133/04C09D175/14C08L65/00C08K3/042C08L75/14

Inventor 陈朝岚周瑜杨科吴玉民曾宇

Owner 湖南宏泰新材料有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com