A cold-resistant flame-retardant antistatic polyvinyl chloride sheath material for coal mine cables

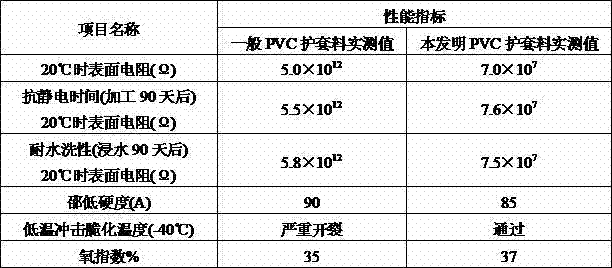

A polyvinyl chloride sheath, flame retardant and antistatic technology, applied to insulated cables, cables, circuits, etc. Good antistatic synergistic effect, not easy to precipitate and volatilize, short antistatic action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A cold-resistant, flame-retardant and antistatic polyvinyl chloride sheath material for coal mine cables, which is composed of the following raw materials in parts by weight (kg):

[0030] PVC resin SG3 100

[0031] Tris(2-chloroethyl)phosphate 10

[0032] Antistatic agent 3

[0033] Dioctyl sebacate 25

[0034] Dioctyl phthalate 10

[0035] Tricresyl Phosphate 5

[0037] Zinc borate 10

[0038] Tribasic lead sulfate 6

[0039] Dibasic lead phosphite 5

[0040] Light calcium carbonate 10

[0041] Bisphenol A 1

[0042] 2-thiolbenzimidazole 2

[0043] Vinyl tris(β-methoxyethoxy)silane 0.8

[0044] Accelerator TMTD 0.8

[0045] Modified asbestos powder 4

[0046] The preparation method of the modified asbestos powder is: mix asbestos powder with 5% by mass of ferrocene, 6% by mass of styrene, and 1% by mass of N-2-(aminoethyl)-3-ammonia Propyltrimethoxysilane is mixed, stirred at a high speed of 1500 r / min, dried and pulverized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com