Capacitor electrode member, its manufacturing method and capacitor with same

A manufacturing method and capacitor technology, which are applied in the manufacture of hybrid capacitor electrodes, hybrid capacitor current collectors, and hybrid/electrical double-layer capacitors, can solve the problems of electric double-layer capacitors' charge-discharge characteristics, life reduction, etc., and reduce the surface resistance value. , The effect of reducing surface resistance value and low ESR

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0113] An aluminum rigid foil (JIS A1050-H18) having a thickness of 30 μm was heated at a temperature of 300° C. in air for 12 hours to obtain an electrode member for a solid electrolytic capacitor. The standard purity of the aluminum foil is 99.55% by mass, and the mass analysis values of the composition are silicon: 2250 ppm and iron: 3800 ppm.

[0114]

[0115]Aluminum soft foil (JIS A1080-0) with a thickness of 50 μm is placed in an electrolyte solution containing 15% hydrochloric acid and 0.5% sulfuric acid at a temperature of 50°C and a current density of 0.5A / cm 2 Under the above conditions, an alternating current etching treatment was performed for 50 seconds, and then the etched aluminum foil was washed with water and dried to obtain an electrode member for a solid electrolytic capacitor.

Embodiment 1~10

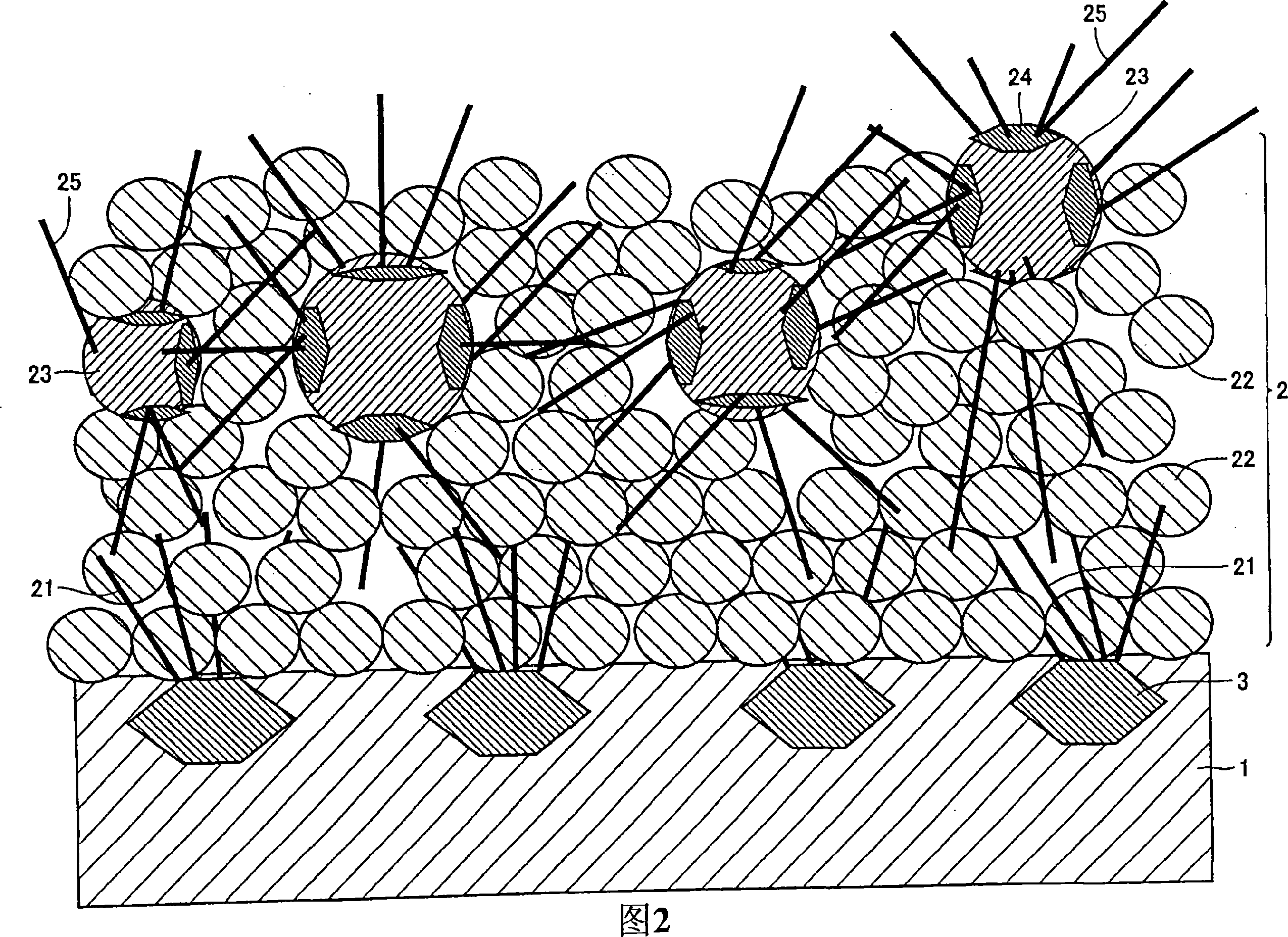

[0117] A carbonaceous substance was coated on both sides of an aluminum hard foil (JIS A1050-H18) with a thickness of 30 μm, and dried at a temperature of 100° C. for 10 minutes to adhere. The composition of the carbonaceous material is relative to 1 weight part of carbon black with an average particle diameter of 0.05 μm, by adding 1 weight part of acrylic resin with an average molecular weight of 3000 and aluminum powder with an average particle diameter of 1 μm according to the weight parts shown in Table 1, And dispersed in toluene, it will form a solid content of 30%. Regarding the adhesion of carbonaceous substances, the thickness after drying was the value shown in Table 1 on one side of the aluminum foil.

[0118] Then, the aluminum foil to which the carbonaceous substance was adhered was heated for 12 hours according to the environment and temperature conditions shown in Table 1, and an electrode member for a solid electrolytic capacitor was produced.

[0119] (refer...

Embodiment 11~14

[0126] A carbonaceous substance was coated on both sides of an aluminum hard foil (JIS A1050-H18) with a thickness of 30 μm, and was adhered by drying at a temperature of 100° C. for 10 minutes. The composition of hydrocarbon carbonaceous substances is as shown in Table 2 by adding 1 part by weight of acrylic resin with an average molecular weight of 3000 and aluminum powder with an average particle size of 1 μm relative to 1 part by weight of carbon black with an average particle size of 0.05 μm. parts by weight and dispersed in toluene to form a solid content of 50%. Regarding the adhesion of carbonaceous substances, the thickness after drying was the value shown in Table 2 on one side of the aluminum foil.

[0127] Then, after heating the aluminum foil with the carbonaceous substance attached thereto for 12 hours under the environment and temperature conditions shown in Table 2, it was converted to 3V in a 150 g / L ammonium adipate aqueous solution at 60°C. The converted al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com