Method for manufacturing liquid crystal alignment film, liquid crystal alignment film, and liquid crystal display element

A technology of liquid crystal alignment film and manufacturing method, which is applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of afterimages in liquid crystal display elements, inability to obtain sufficient liquid crystal orientation, small anisotropy, etc., and reach the limit of liquid crystal orientation High power, excellent afterimage characteristics, high anisotropy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0193] Hereinafter, the present invention will be described more specifically with reference to examples, but the present invention is not limited thereto.

[0194] The abbreviations of the compounds used in Examples and Comparative Examples and the measurement methods of each characteristic are as follows.

[0195] NMP: N-methyl-2-pyrrolidone

[0196] GBL: gamma-butyrolactone

[0197] BCS: Butyl Cellosolve

[0198] IPA: 2-propanol

[0199] PGMEA: 1-methoxy-2-propanol acetate

[0200] PG: propylene glycol

[0201] MMP: methyl 3-methoxypropionate

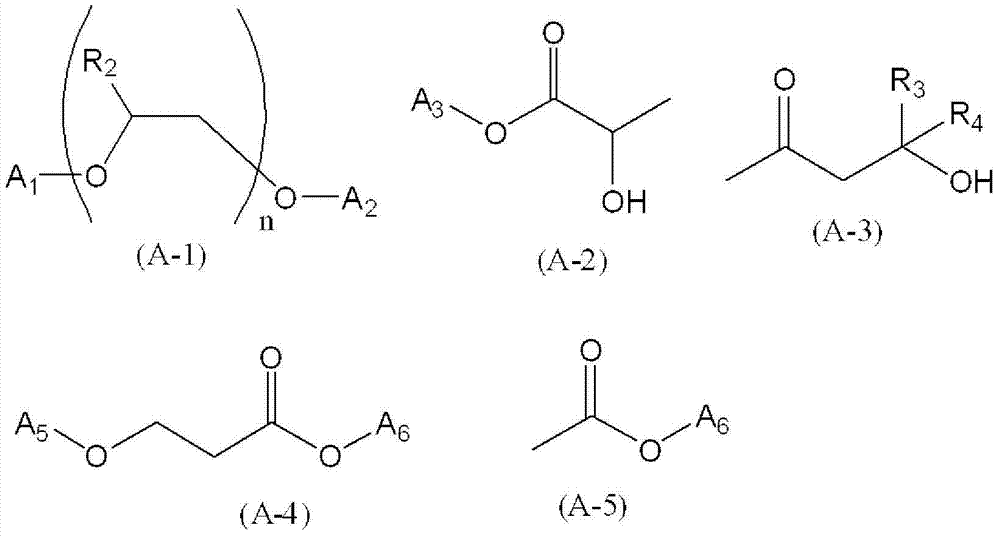

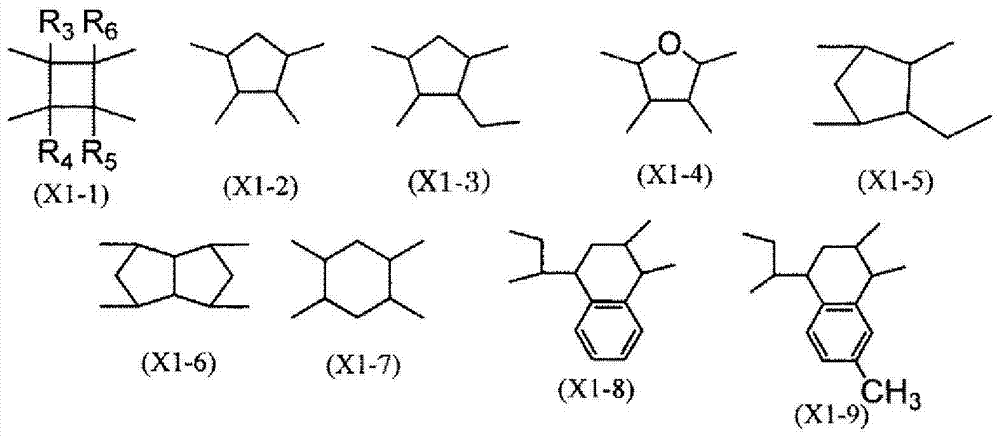

[0202] DE-1: the following formula (DE-1)

[0203] DA-1: the following formula (DA-1)

[0204] DA-2: the following formula (DA-2)

[0205] DA-3: the following formula (DA-3)

[0206] Additive A: N-α-(9-fluorenylmethoxycarbonyl)-N-τ-tert-butoxycarbonyl-L-histidine

[0207] [chem 22]

[0208]

[0209] The molecular weight, the anisotropy of an alignment film, and the evaluation method of film unevenness are shown below. ...

Synthetic example 1

[0228] Make the inside of the 500mL four-neck flask with a stirring device a nitrogen atmosphere, drop in 4.58g (42.4mmol) of p-phenylenediamine, and then drop in 1.79g (4.71mmol) of DA-1, add 84.7g of NMP, 254g of GBL and 8.40 g (106 mmol) of pyridine as a base were stirred to dissolve. Next, 14.4 g (44.2 mmol) of DE-1 was added, stirring this diamine solution, and it was made to react overnight at 15 degreeC. After stirring overnight, 1.23 g (13.6 mmol) of acryloyl chloride was added, and it was made to react at 15 degreeC for 4 hours. The obtained polyamic acid ester solution was added to 1477g of IPA while stirring, and the precipitated white precipitate was collected by filtration, then washed 5 times with 738g of IPA, and dried to obtain 17.3g of white polyamic acid ester resin powder. The yield was 96.9%. Moreover, the molecular weight of this polyamic acid ester was Mn=14288, Mw=29956.

[0229] The obtained polyamic acid ester resin powder 3.69g was taken in the 100...

Synthetic example 2

[0231] Add the polyamic acid ester solution that 5.26g obtains in the synthetic example 1 in the 20mL sampling tube that has stirring bar, add the additive A of the BCS of the GBL of 3.16g, 2.11g and 0.19g, stir 30 minutes with magnetic stirrer, Liquid crystal aligning agent A was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com