Adhesive for polarizing plate, polarizing plate, manufacturing method therefor, optical film and image display

一种偏振板、胶粘剂的技术,应用在光学、光学元件、光学元件等方向,能够解决偏振板不均等问题,达到抑制不均、满足密合性、提高成品率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] (polarizer)

[0133] A polyvinyl alcohol film having an average degree of polymerization of 2400 and a degree of saponification of 99.9 mol % was immersed in warm water at 30° C. to swell with a thickness of 75 μm. Next, immerse in an aqueous solution with a concentration of 0.3% of iodine / potassium iodide (weight ratio = 0.5 / 8), stretch it to 3.5 times, and dye the film at the same time, and then, in a borate aqueous solution at 65°C, perform Stretch so that the total draw ratio becomes 6 times. After stretching, it was dried in a 40° C. oven for 3 minutes to obtain a polarizing plate.

[0134] (transparent protective film)

[0135] A cellulose triacetate film with a thickness of 40 μm was used as a transparent protective film 1 . As another transparent protective film 2 , a biaxially stretched norbornene-based film (manufactured by Nippon Zeon Co., Ltd., Zeonoa) having a thickness of 70 μm was used.

[0136] (preparation of adhesive)

[0137] With respect to 100 ...

Embodiment 2~4、 comparative example 1~5

[0141] In the preparation of the adhesive in Example 1, the adhesive was prepared in the same manner as in Example 1, except that the types and usage ratios of the components shown in Table 1 were changed. Moreover, using the obtained adhesive agent, it carried out similarly to Example 1, and produced the polarizing plate.

Embodiment 5

[0143] In Example 2, in addition to being the transparent protective film 2, a polymethyl methacrylate resin (manufactured by Mitsubishi Rayon Co., Ltd. Except VH), it carried out similarly to Example 1, and produced the polarizing plate.

[0144] (Evaluation)

[0145] The following evaluations were performed on the polarizing plates obtained in Examples and Comparative Examples.

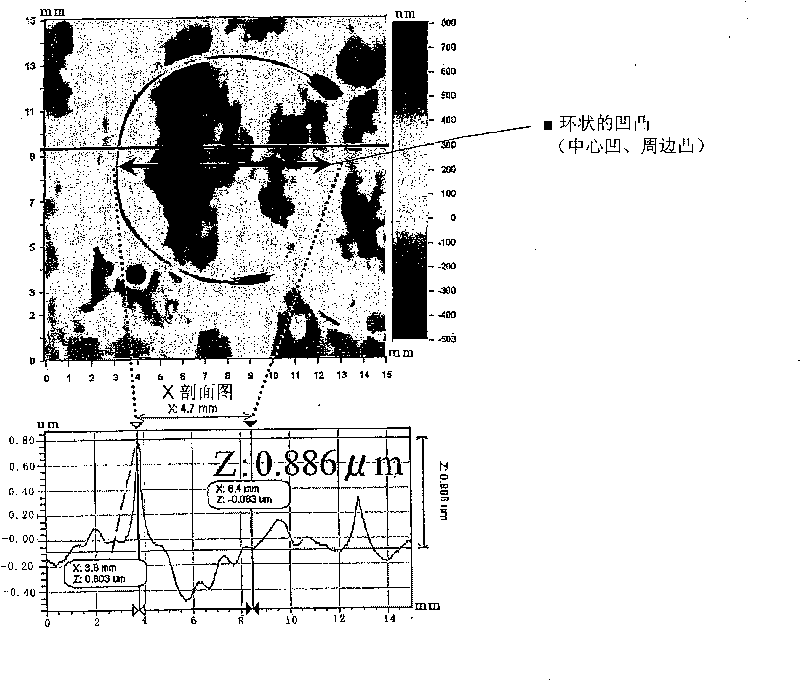

[0146] (unevenness of polarizing plate)

[0147] In each example, about the obtained polarizing plate, the presence or absence of visible unevenness in the state was visually confirmed by the following criteria.

[0148] ⊚: In the obtained polarizing plate, unevenness was not observed even in a dark room, and there was no image display failure.

[0149] ◯: In the obtained polarizing plate, unevenness was confirmed in a dark room, but there was no image display failure.

[0150] ×: In the obtained polarizing plate, unevenness was confirmed, which had an influence on image display.

[0151] It shou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com