Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "The separation effect is thorough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

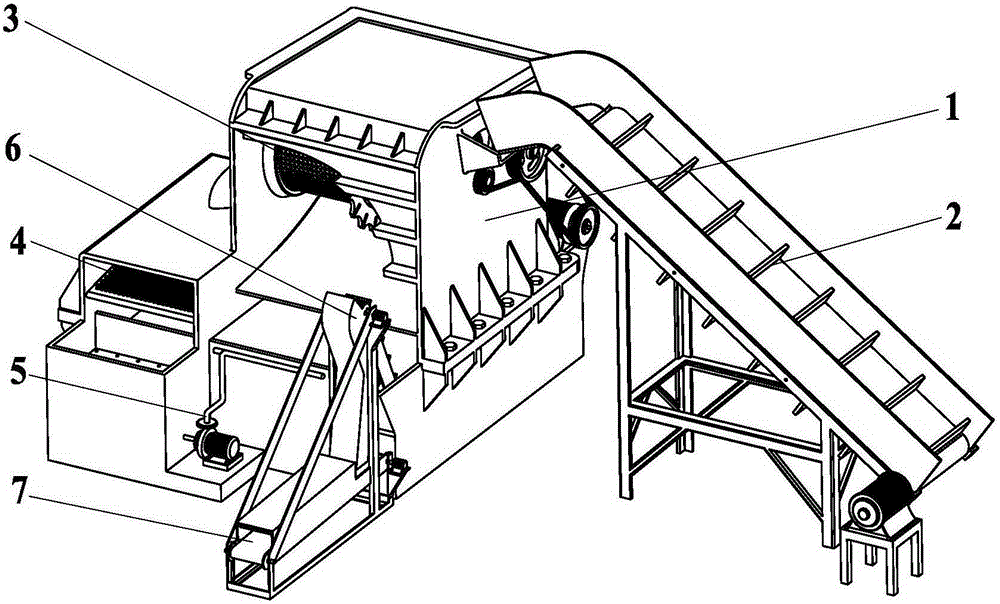

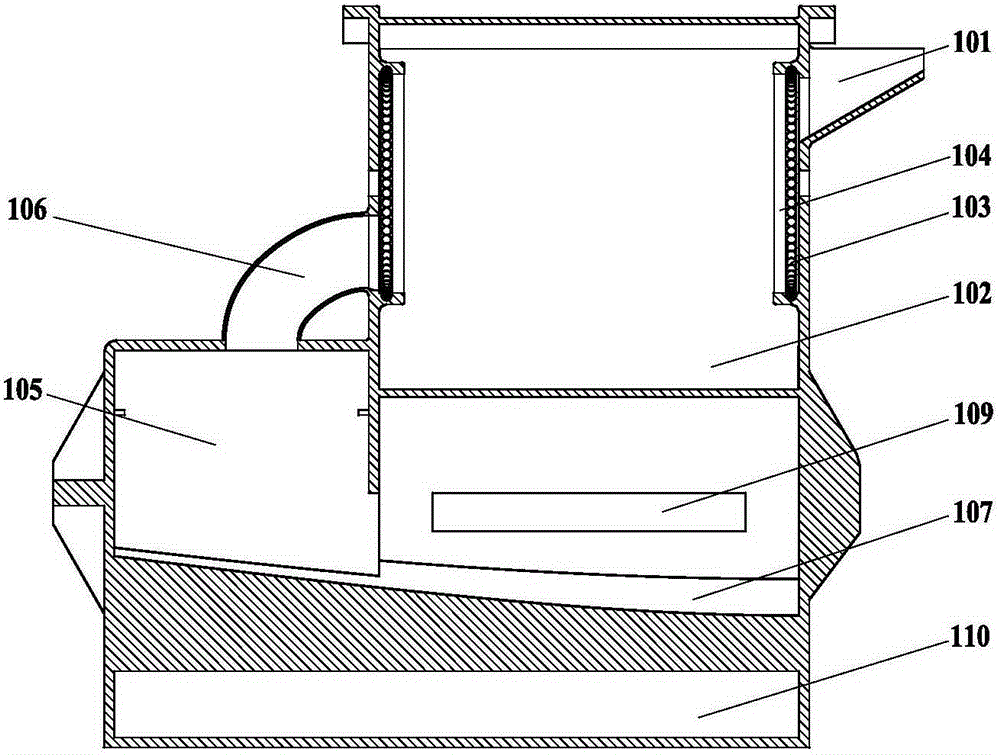

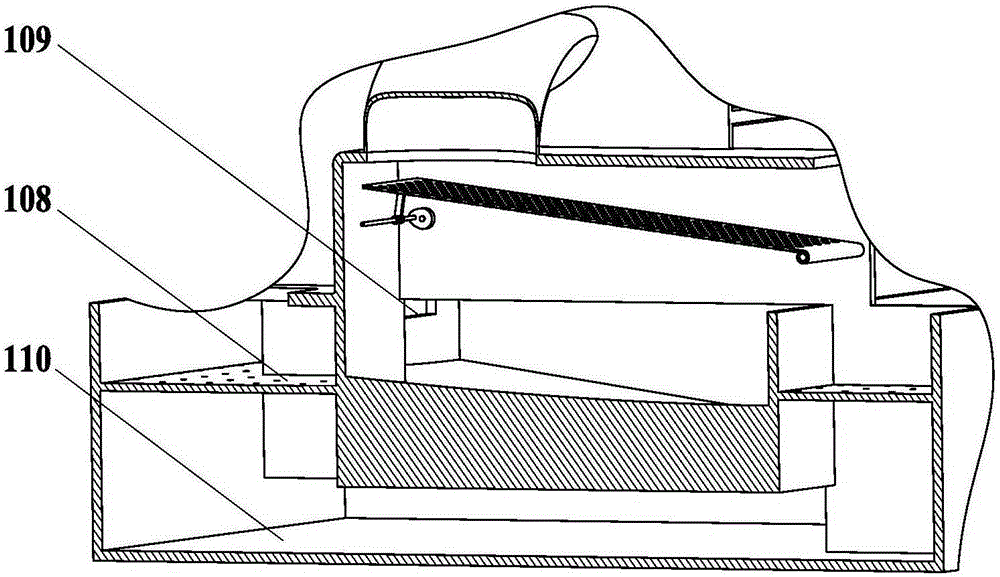

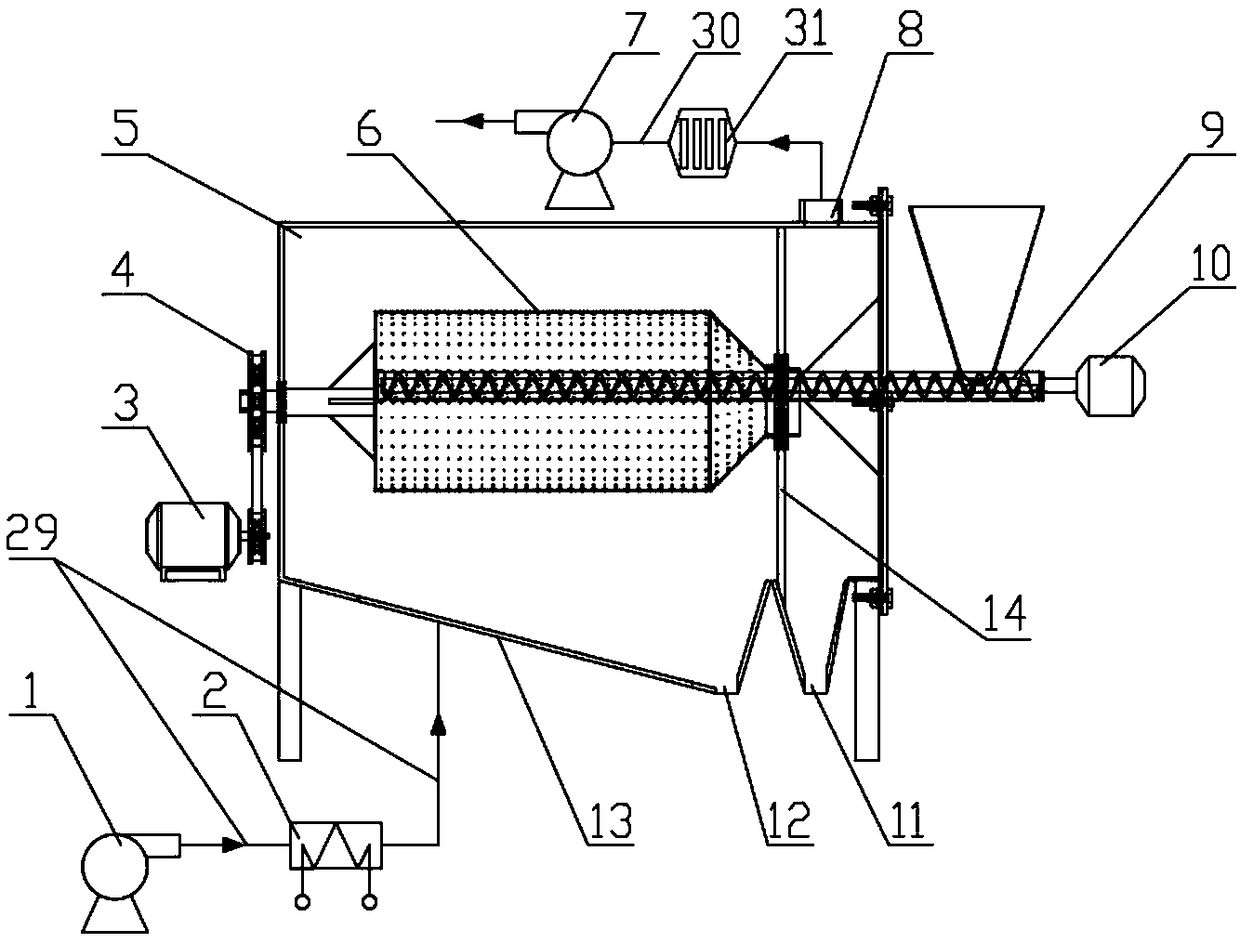

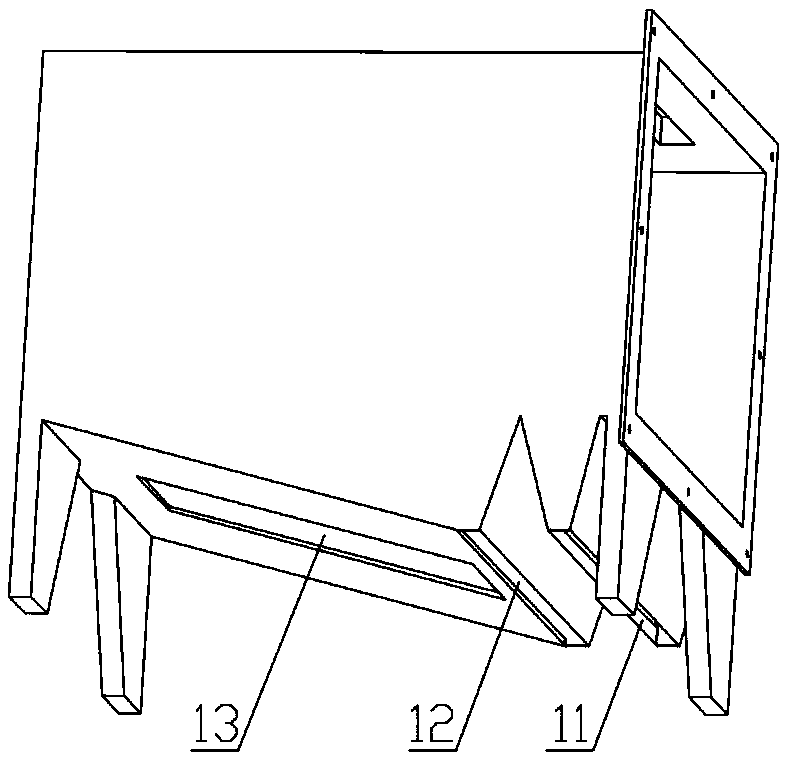

Three-time separating seed extractor for seed melons

The invention relates to the field of agricultural product processing, particularly a three-time separating seed extractor for seed melons. The seed extractor comprises a machine body, a whole seed melon transfer device, a roller separating device, a vibrating separation device, a washing device, a fishing device and a transferring and drying device, wherein the whole seed melon transfer device is positioned on the right side of the machine body for transferring the whole melon to the machine body; the roller separating device is mounted on the right side in the machine body for primarily separating the seed melon; the vibrating separating device is mounted on the left side of the roller separating device for secondarily separating the seed melon; the washing device is mounted at the front end of the machine body for separating the seed melon for the third time; the fishing device is positioned on the right side of the washing device for fishing out separated seeds; and the transferring and drying device is positioned below the front end of the fishing device for drying and transferring the seeds. The seed extractor provided by the invention can be used for separating seeds from melon pulp and melon peel for seed melons, soaking the seeds by melon juice and drying the seeds.

Owner:威海高新园区运营管理有限公司

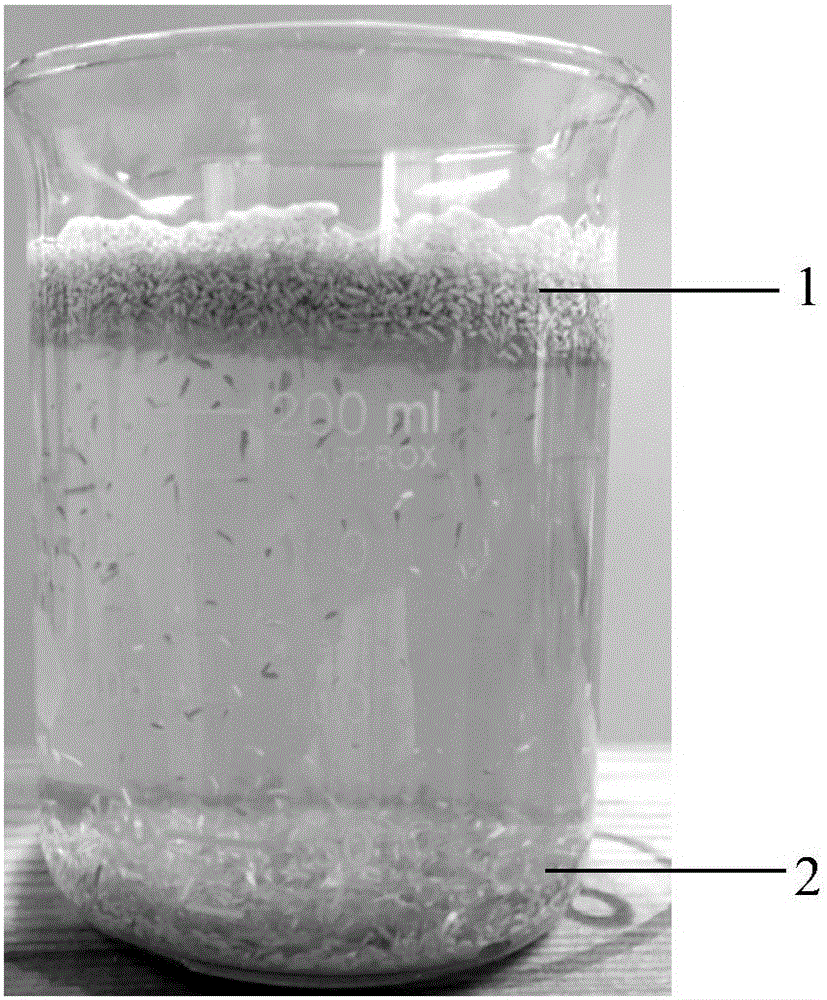

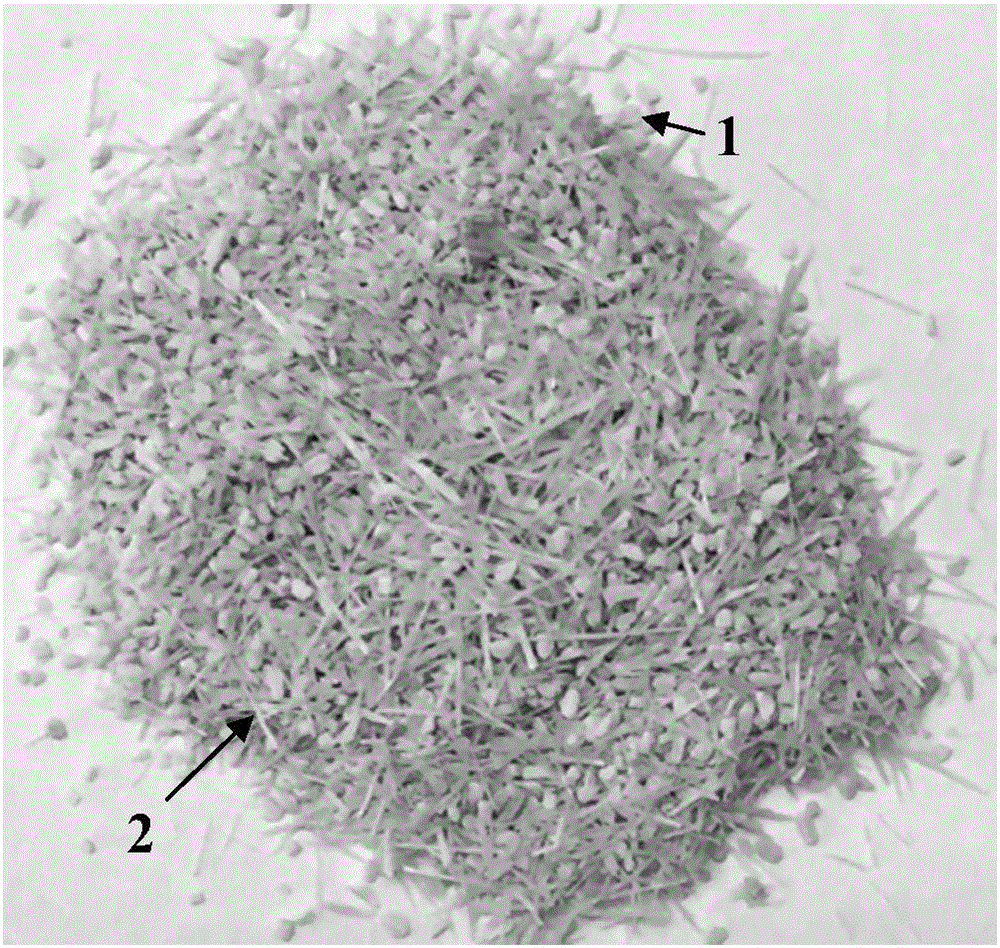

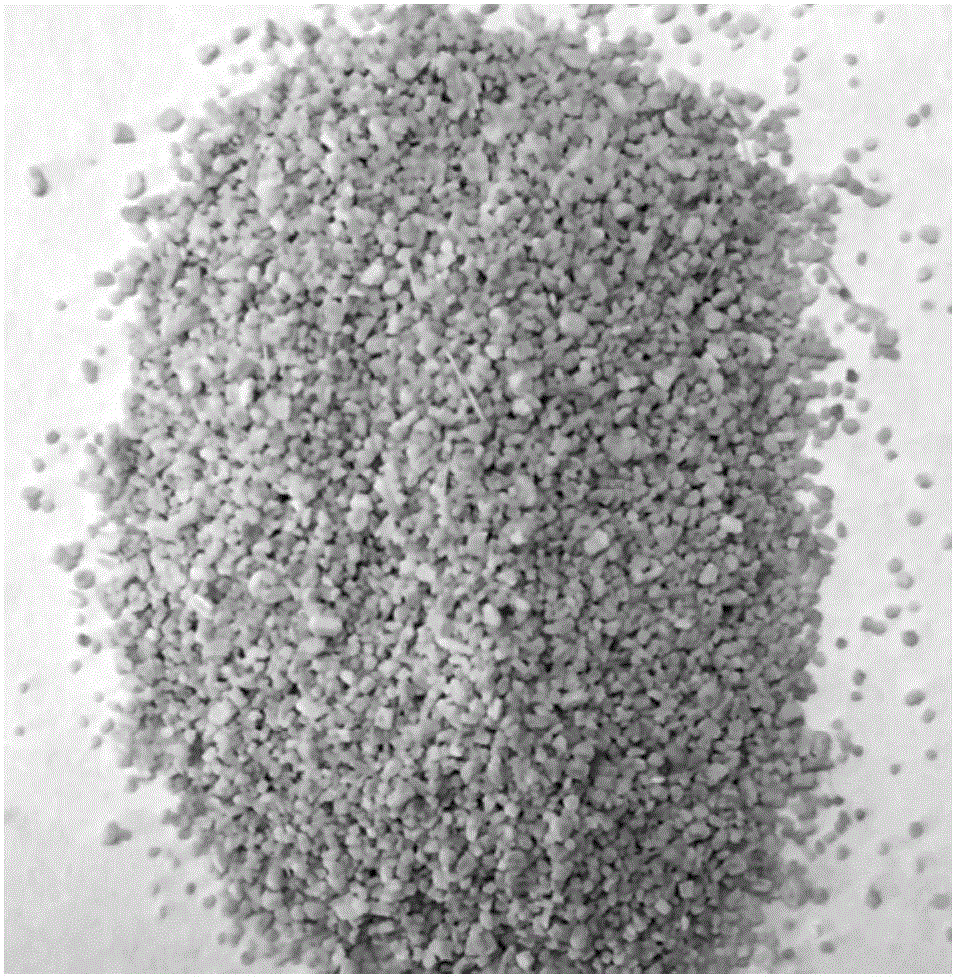

Method for separating parenchyma cells from fibers in bamboo wood

The invention belongs to the field of separation of bamboo wood, and particularly relates to a method for separating parenchyma cells from fibers in bamboo wood. Currently, in industrial utilization of the bamboo wood, bamboo fibers are mainly used, and parenchyma cells are processed as waste, not only are resources wasted, but also the environment pollution problem is caused. According to the provided physical method for quickly separating the bamboo fibers and the parenchyma cells in an environment-friendly mode, the method specifically includes the following steps of 1, smashing; 2, screening; and 3, separation. By means of the separating method, the parenchyma cell extraction rate can reach 85% or so, and the purity can reach 95%. The dispersing media adopted in the method are wide in source, low in cost and easy to obtain.

Owner:INT CENT FOR BAMBOO & RATTAN

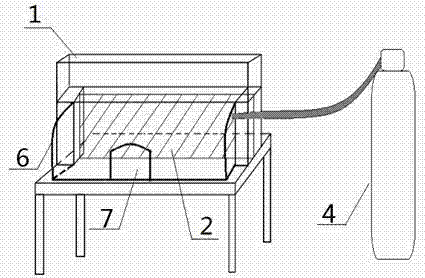

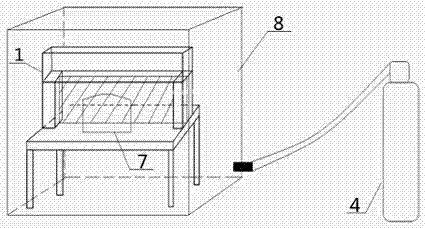

Cutting and crushing method used for flexible-package power lithium battery

ActiveCN103500862ASave Batch Processing TimeThe separation effect is thoroughWaste accumulators reclaimingBattery recyclingEngineeringMechanical engineering

The invention discloses a cutting and crushing method used for a flexible-package power lithium battery. The cutting and crushing method comprises the following steps: (1), starting a mechanical cutting device which is provided with an inert gas protective device, and ventilating an inert gas, wherein output pressure of the inert gas is 500 kPa-10000 kPa; (2), cutting off bonding positions at adjacent two sides of the flexible-package battery after outputting the inert gas for 10 minutes-30 minutes, peeling off an enclosure and getting out a battery cell; (3), cutting the battery after slowly advancing by 1 cm-5 cm in parallel along one side of the battery cell to form 1 cm-15 cm rectangular strips, keeping the original shape of the battery cell in the advancing process and keeping the rectangular strips to not scatter; and (4), integrally exchanging the battery to a position vertical to the cutting direction in the step (3), slowly advancing by 1 cm-15 cm, and cutting the battery into rectangular fragments. According to the cutting and crushing method used for the flexible-package power lithium battery, disclosed by the invention, inert gas protection is adopted, discharging pre-processing is not needed, batch processing time is saved, and therefore, the cutting and crushing method is safer.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

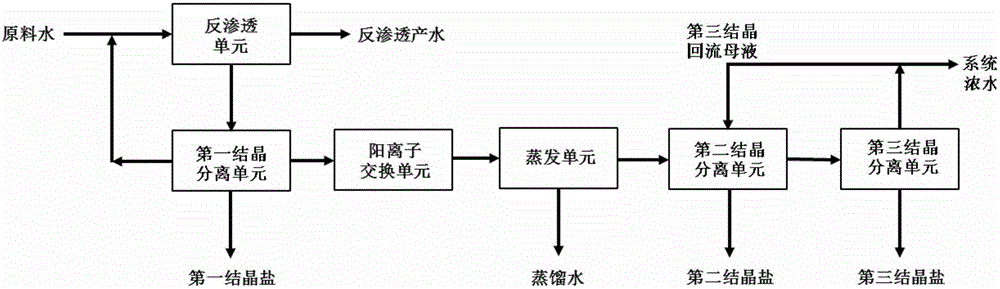

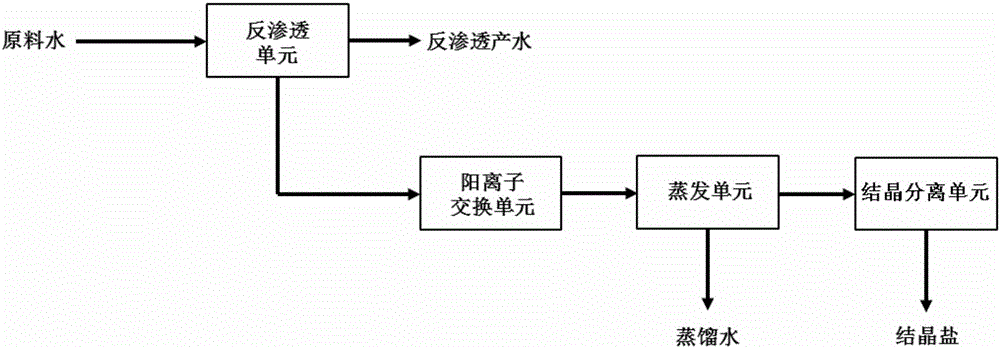

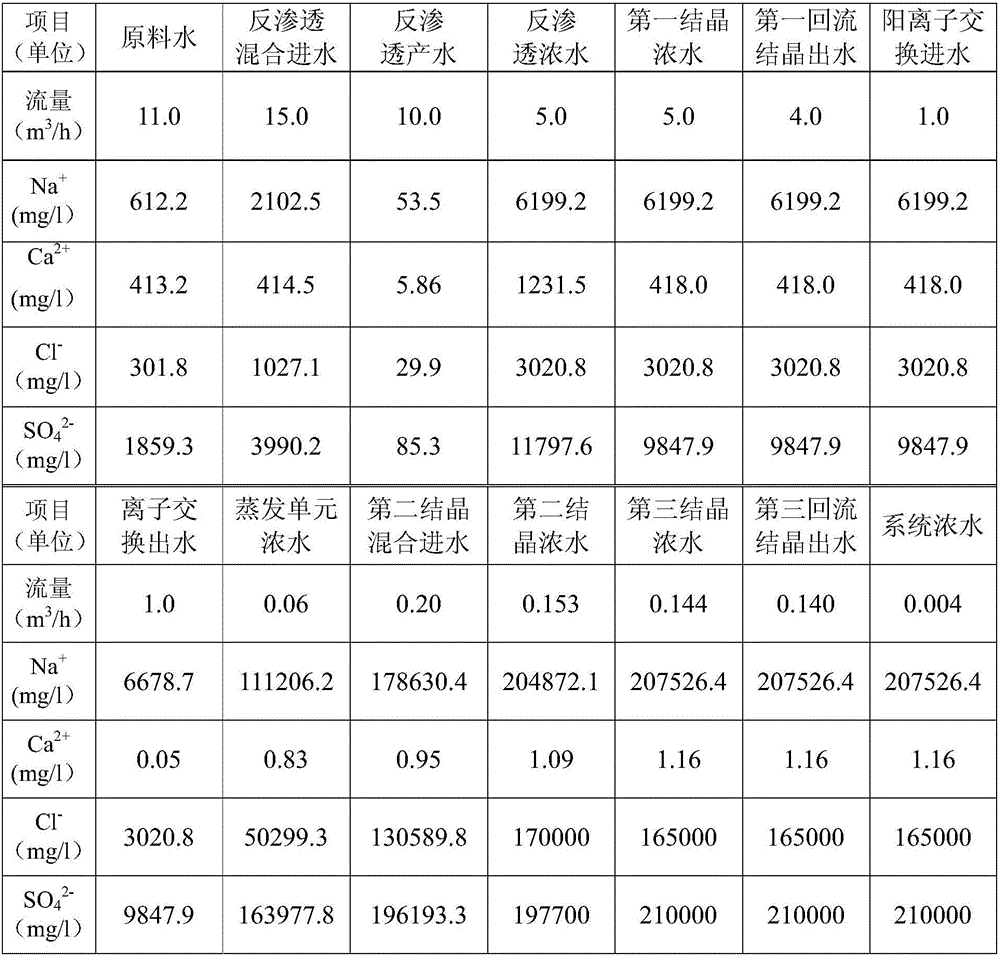

Salt production method and salt production system

ActiveCN106082275AHigh recovery rateReduce loadSpecific water treatment objectivesCalcium/strontium/barium sulfatesReverse osmosisProduced water

The invention relates to the field of water treatment, and discloses a salt production method and a salt production system. The method comprises the following steps: carrying out reverse osmosis treatment on brackish water to obtain reverse osmosis concentrate water and reverse osmosis produced water; carrying out primary crystallizing separation treatment on the reverse osmosis concentrate water to obtain primary crystal salt and primary crystal concentrate water, and dividing the primary crystal concentrate water into primary reflux crystal outlet water and cation exchange inlet water; carrying out cation exchange treatment on the cation exchange inlet water to obtain cation exchange outlet water; carrying out secondary crystallizing separation treatment on the cation exchange outlet water to obtain secondary crystal salt and secondary crystal concentrate water; and carrying out tertiary crystallizing separation treatment on the secondary crystal concentrate water to obtain tertiary crystal salt and tertiary crystal concentrate water. The method and the system are adopted to produce the highly-pure single component salt, and the method and the system have the advantages of high water recovery rate, low cation exchange load, and great reduction of the impurity salt treatment cost, the investment cost and the running cost.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

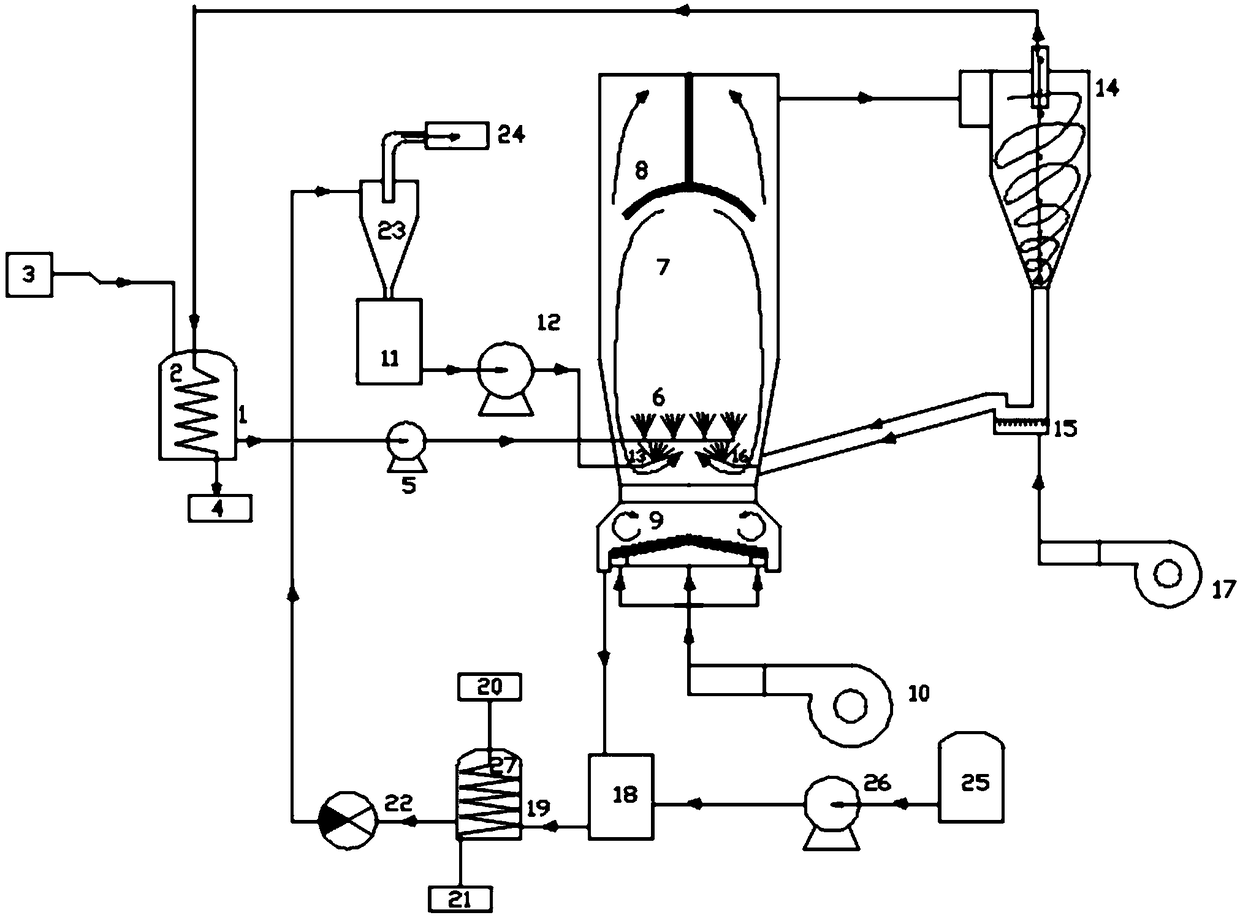

Internal circulating fluidized bed type supercritical water oxidizing system for degradation-resistant organic wastewater

ActiveCN108751384AEasy to separateIncrease usageWater treatment parameter controlWater contaminantsCycloneInorganic salts

The invention discloses an internal circulating fluidized bed type supercritical water oxidizing system for degradation-resistant organic wastewater. The internal circulating fluidized bed type supercritical water oxidizing system is characterized in that the degradation-resistant organic wastewater in a wastewater buffer tank flows into an internal circulating fluidized bed reactor via a materialpump, and generates supercritical water oxidization reaction with air which is used as an oxidant, and the reaction is promoted by a dosage pump and a catalyst which is stored into a dosage tank; onone hand, the inorganic salt, the catalyst and other residues flow into the residue storage tank after reaction, the inorganic salt is dissolved by softened water, and then separated from the catalyst, and the catalyst flows into the dosage tank again; on the other hand, the high-temperature fluid after reaction is separated by a high-temperature cyclone separator, the separated catalyst solid issent into the internal circulating fluidized bed reactor, and the high-temperature fluid flows into the wastewater storage tank to preheat the fresh material. The internal circulating fluidized bed type supercritical water oxidizing system has the advantages that the inorganic salt and the catalyst can be separated at high efficiency; the catalyst can be recycled, so that the economy of the wholesystem is improved.

Owner:XI AN JIAOTONG UNIV

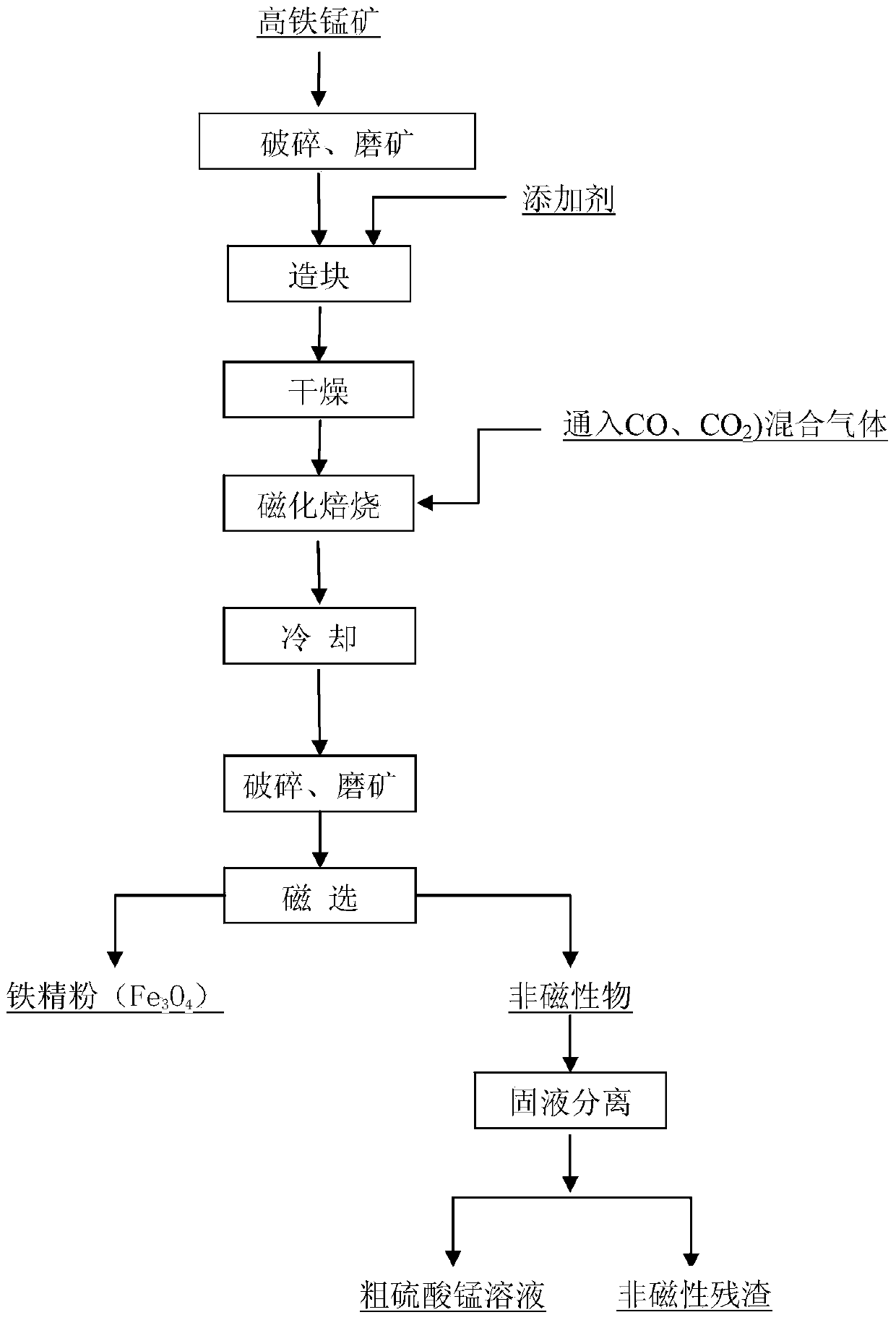

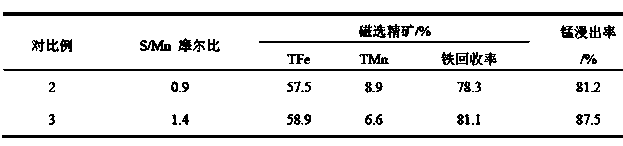

Additive and method for reinforcing separation of manganese and iron through magnetic roasting-magnetic separation of high-iron manganese oxide ore

The invention discloses an additive and a method for reinforcing separation of manganese and iron through magnetic roasting-magnetic separation of a high-iron manganese oxide ore. The additive consists of dithionic acid manganese, sodium sulfite and sodium humate by a certain mass ratio; the method comprises the following steps: after being evenly mixed with the additive, a high-iron manganese ore crushed and grinded to a certain particle size is sequentially agglomerated, dried, reduced and roasted; crushing, ore grinding, magnetic separation and solid-liquid separation are conducted on the roasted product after the roasted product is cooled; then magnetite powder, manganese sulfate-enriched filtrate and nonmagnetic residues are obtained. The additive and the method are adopted to reduce and convert iron oxide to the magnetite powder as blast furnace ironmaking raw materials; manganese oxide is reduced and converted to manganese sulfate, is introduced in the filtrate after the ore grinding, the magnetic separation and the solid-liquid separation, and can be used as raw materials for producing the manganese sulfate and electrolytic manganese after being purified and decontaminated. The additive and the method overcome the defect of incomplete separation of the manganese and iron in the conventional high-iron manganese ore treatment methods, and have such characteristics as high iron and manganese separation efficiency, simple process flow and low cost.

Owner:CENT SOUTH UNIV

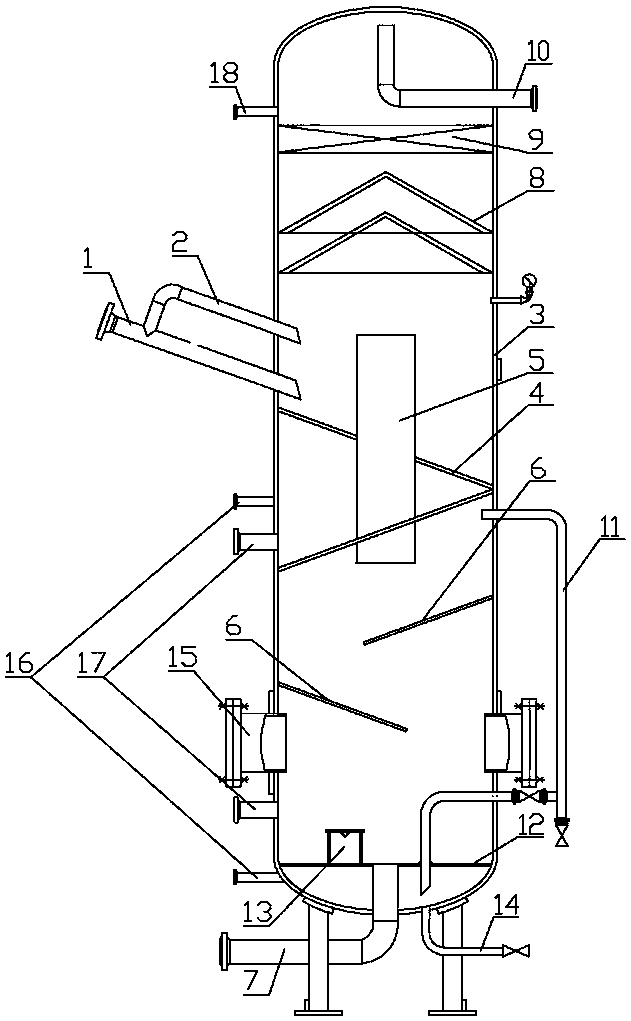

Weak vortex thick oil defoaming separator

PendingCN108295513AReasonable structureCompact structureFoam dispersion/preventionEquipment SafetyLiquid phase

The invention relates to a crude oil defoaming separating device, in particular to a weak vortex thick oil defoaming separator. The weak vortex thick oil defoaming separator comprises a liquid phase pipe and a gas phase pipe; the upper side of the liquid phase pipe communicates with the gas phase pipe; both an outlet end of the gas phase pipe and an outlet end of the liquid phase pipe are tilted downwards and a flow is guided to enter a cylinder along the tangential direction of the cylinder; a spiral vortex plate which separates the cylinder into an upper part and a lower part is fixedly mounted in the cylinder below the liquid phase pipe; a gas rising pipe which can communicate the cylinder above the vortex plate with the cylinder below the vortex plate is fixedly mounted in the centre of the vortex plate. The weak vortex thick oil defoaming separator is reasonable and compact in structure, safe and reliable in use, and high in defoaming and foam breaking efficiency; oil is separatedfrom gas thoroughly; the metering precision of a subsequent metering instrument is effectively improved; the safety of subsequent crude oil gathering and transporting pipelines and equipment is ensured effectively; the operating period of the equipment is effectively prolonged on the premise of ensuring high-efficiency operation of the equipment; the weak vortex thick oil defoaming separator is applicable to metering and separating of foamed crude oil of thick oil fire flooding development, CO2 flooding development and the like, and has a broad application prospect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

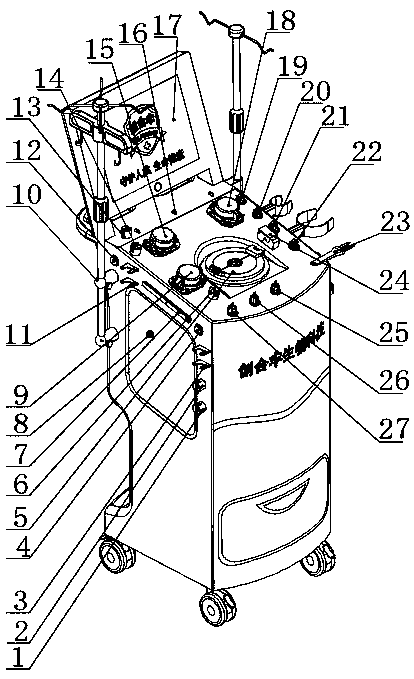

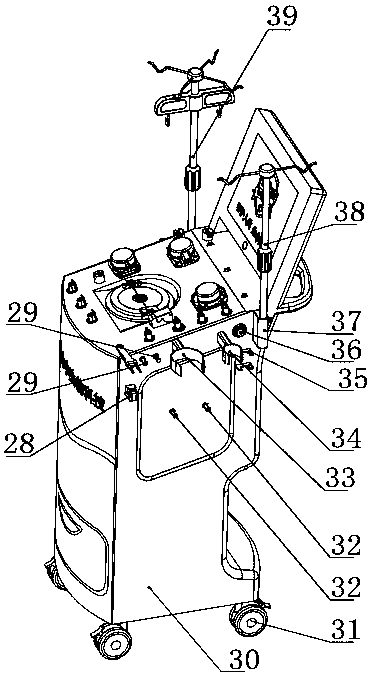

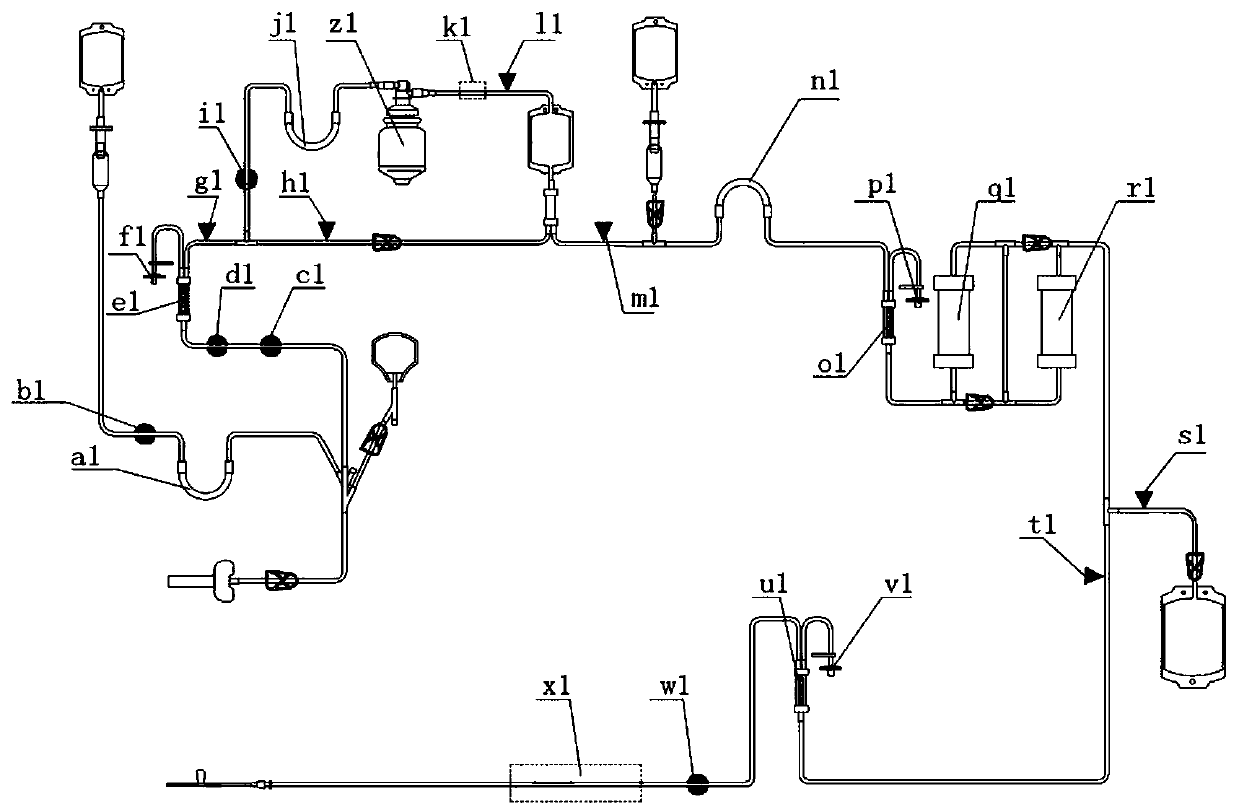

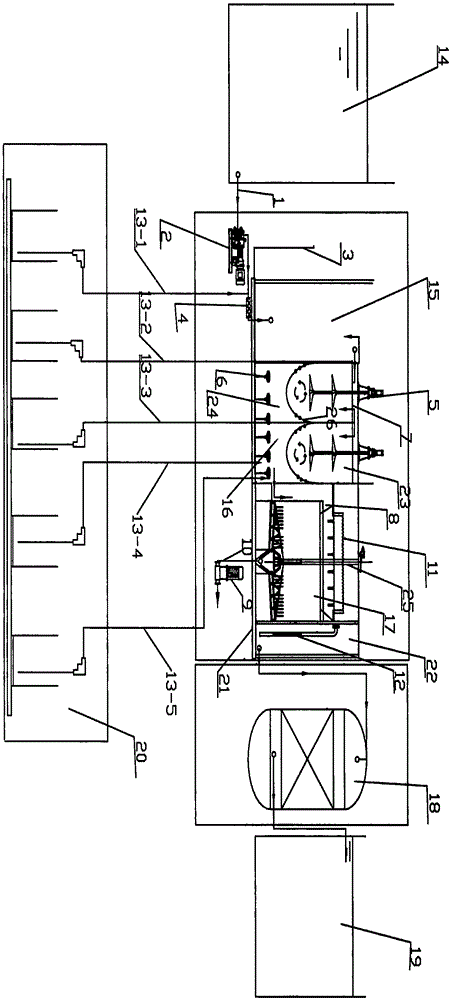

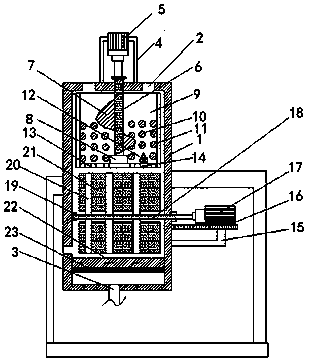

Blood separation comprehensive therapy apparatus complete machine

PendingCN109568700AThe separation effect is thoroughReduce the amount of mixingOther blood circulation devicesCentrifugationRed blood cell

The invention relates to the field of medical instruments, and discloses a blood separation comprehensive therapy apparatus complete machine. The blood separation comprehensive therapy apparatus complete machine comprises a rack, wherein the rack is provided with an anti-coagulant pump, a blood pump, a plasma pump, an anti-coagulant hanger, a normal saline hanger, a centrifugal machine, a pipelinedetector, therapeutic apparatus hoops, a plurality of pressure detectors, a plurality of ultrasonic air detectors and a plurality of pinch-off valves; the centrifugal machine is located in the central position of the rack; the blood pump and the pipe detector are arranged beside the centrifugal machine; the anti-coagulant hanger and the normal saline hanger are arranged at two sides of the rack.According to the blood separation comprehensive therapy apparatus complete machine disclosed by the invention, by utilizing the matching of the centrifugal machine and a separation cup in a purification system and adopting a centrifugation technology, blood is separated into blood cells and plasma, a membrane used for separating the blood is replaced, and the production cost is greatly reduced; functional components such as a heater, a cuff connector, an electronic scale, a heat sealing machine and the like are integrated, and medical staff can conveniently operate and use.

Owner:成都创合丰生物科技有限公司

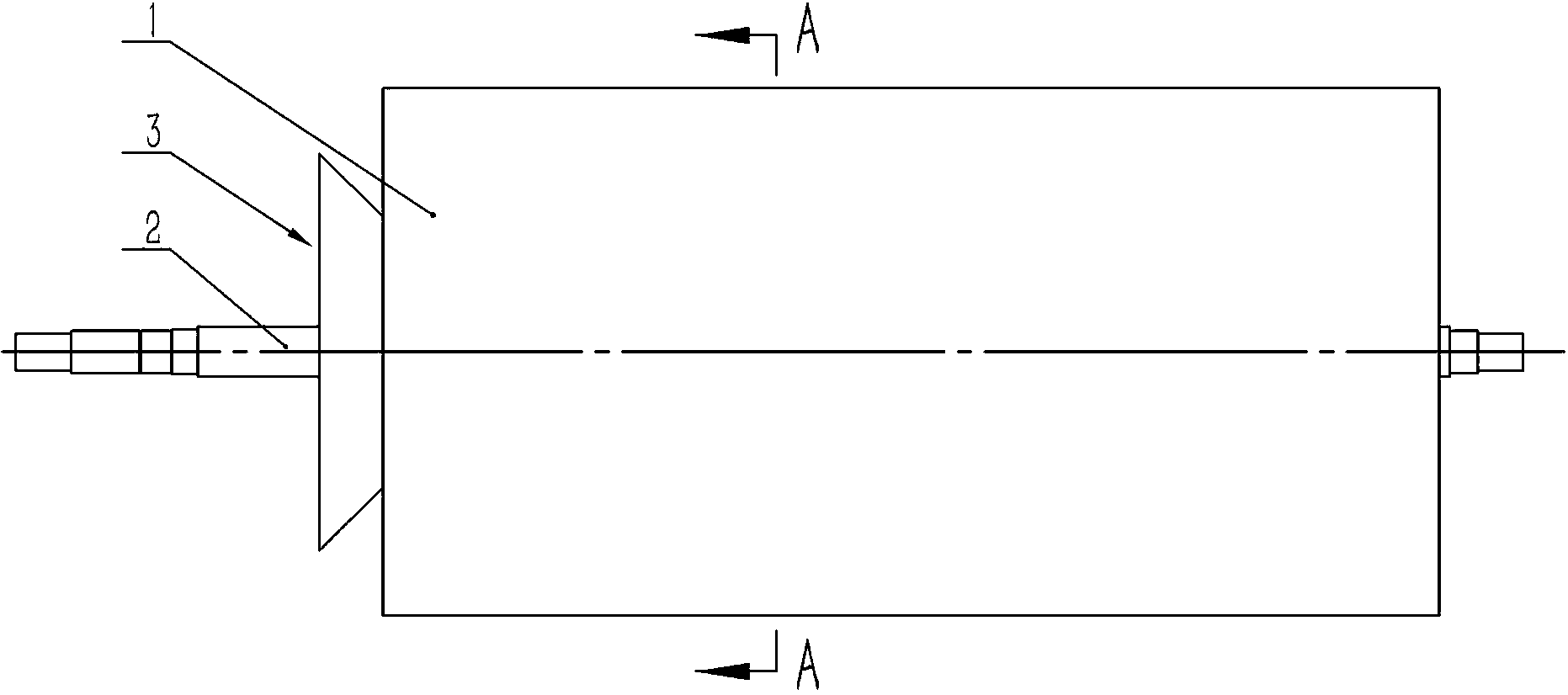

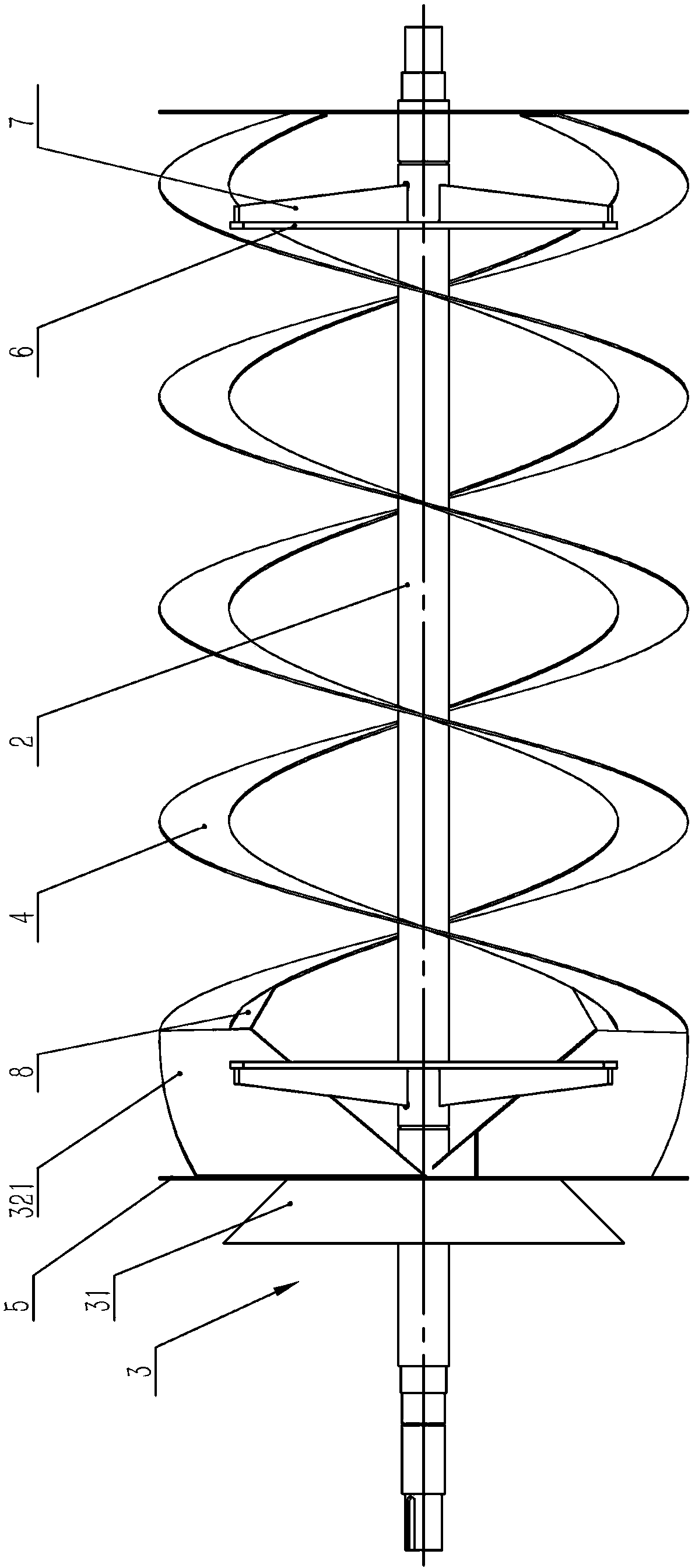

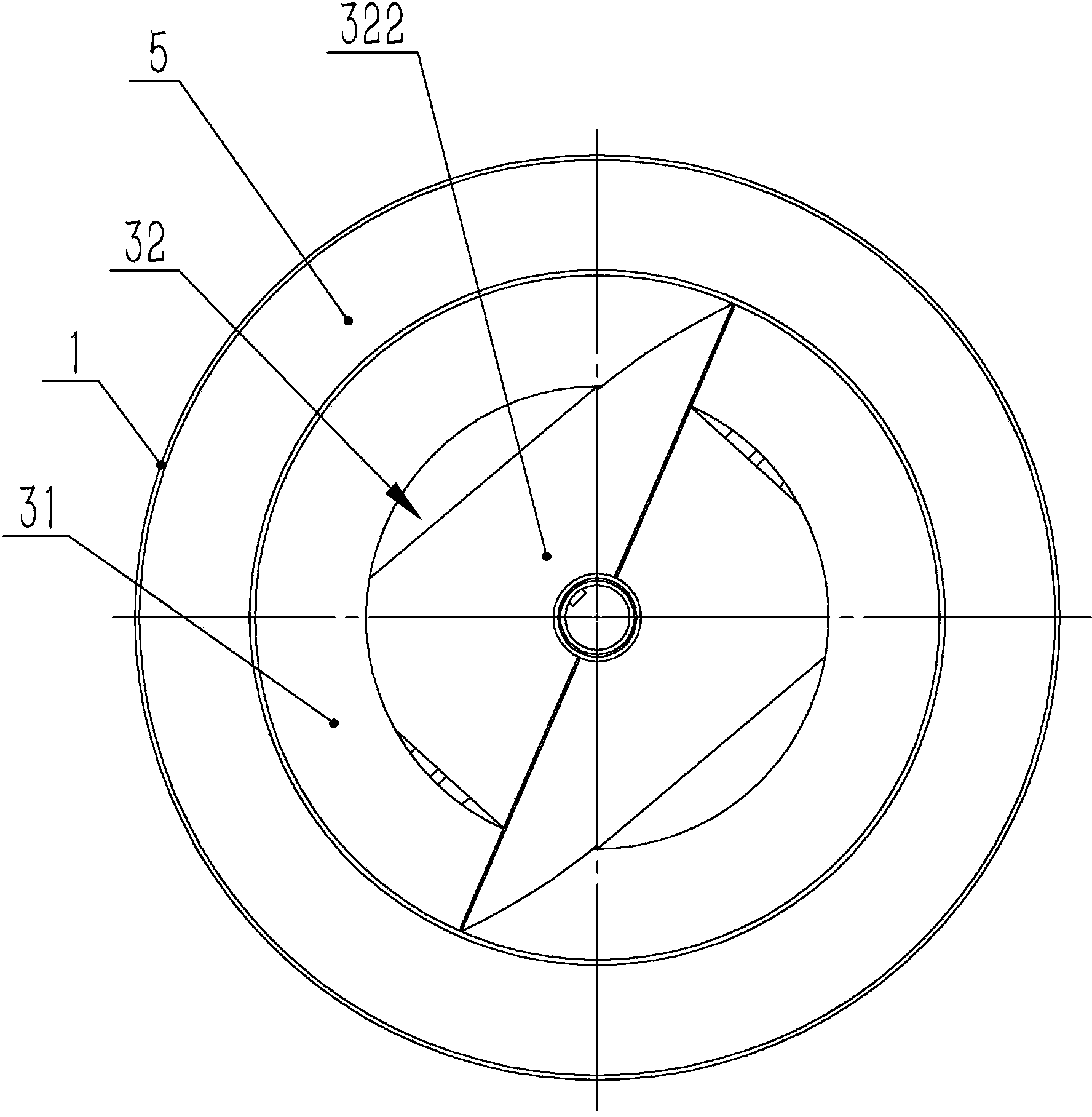

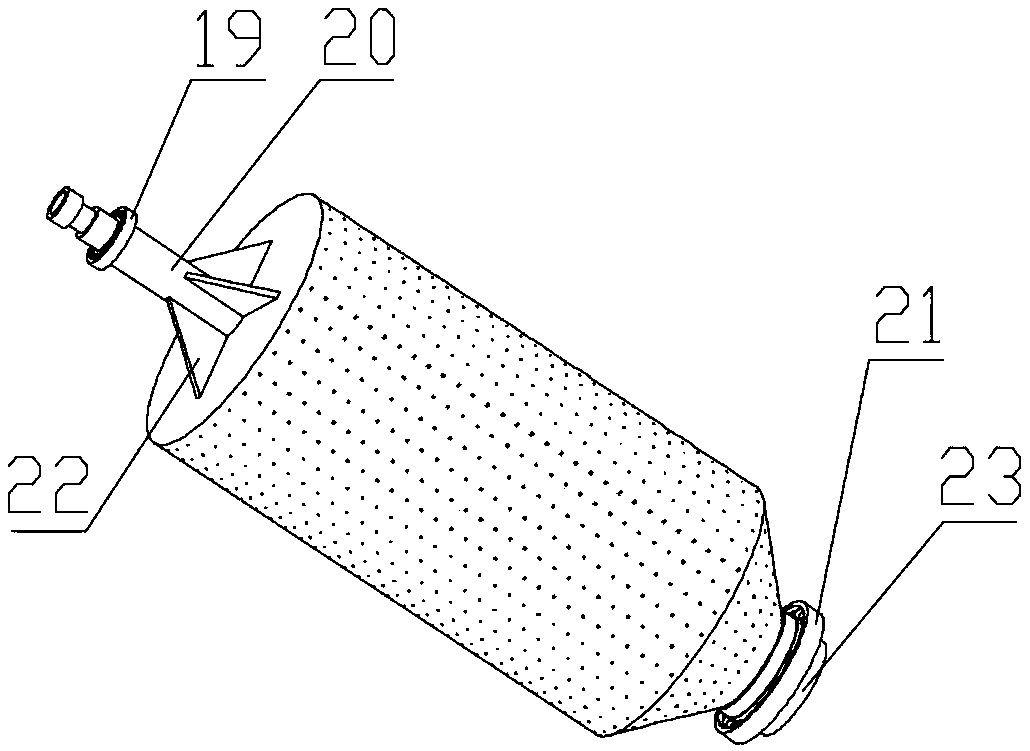

Roller used for separating sand and stone

The invention discloses a roller used for separating sand and stone. The roller comprises a cylinder body, wherein a rotating shaft is arranged in the center of the cylinder body in the axial direction, a supporting part is arranged on the rotating shaft and connected with the inner wall of the cylinder body, and a discharging device with the interior lower than the exterior is arranged at one end of the cylinder body. Spiral blades are arranged on the inner wall of the cylinder body, and the discharging device is located at the tail ends of the spiral blades and comprises two material guiding grooves which are connected with the ends of the spiral blades and an end sealing plate of the cylinder body and symmetrical about the center. The cylinder body is driven to rotate by the rotating shaft, the spiral blades on the inner wall of the cylinder body rotate along with the rotating shaft so that materials are driven to move to the discharging device, sand in the sand and stone mixed material falls off from holes of a screen of the roller, stone material moves to the high end of the cylinder body along the spiral blades and finally is guided out of the discharging device, the process for separating the sand and the stone is prolonged, wash water is reduced, the sand and stone separating utilization rate is improved, and environmental protection and energy conservation are achieved. In use, the roller is obliquely installed with the end of the discharging device high, the mixed material enters from the low end of the roller, and a driving device is connected to the end, close to the discharging device, of the rotating shaft.

Owner:CHANGSHA SUNHON MACHINERY

Novel integral softening and treating device for industrial wastewater with high salt content

InactiveCN105621741AIncrease solid contentThe separation effect is thoroughTreatment involving filtrationWater softeningIndustrial waste waterSludge

The invention discloses a novel integral softening and treating device for industrial wastewater with a high salt content, and belongs to the field of water treatment. A reaction tank, a flocculate collecting tank and a sedimentation tank are arranged on a tank base of the novel integral softening and treating device side by side, and a flocculate mixing tank and a flocculation tank are vertically arranged in the flocculate collecting tank; the reaction tank is communicated with the flocculate mixing tank via a water distributing channel of the reaction tank, the flocculate mixing tank is communicated with the flocculation tank via a water outlet hole in a tank bottom, the flocculation tank is communicated with the sedimentation tank via an overflow zone, the sedimentation tank is communicated with a mixing tank via outlet water of a water outlet weir, the mixing tank is communicated with a quartz sand filter, and chemical tanks are arranged in a chemical dosing device side by side and are respectively communicated with the front end of a pipeline mixer, the reaction tank, the flocculate mixing tank and the flocculation tank via chemical dosing pipes. The novel integral softening and treating device has the advantages that the occupied area and the investment can be effectively reduced; sediments can be prevented in the flocculate collecting tank; the novel integral softening and treating device is high in hardness removal rate; chemical dosing quantities can be reduced; thorough sludge and water separation effects can be realized; sludge is high in solid content and can be directly dehydrated and treated; the novel integral softening and treating device is simple in structural design and simple and reasonable in arrangement.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Special cleaning machine for PE films

PendingCN107856225ALow energy consumptionReduce water consumptionPlastic recyclingCleaning using liquidsPlastic filmEngineering

The invention discloses a special cleaning machine for PE films, and belongs to the field of resource recycling. The special cleaning machine for PE films mainly comprises a belt pulley, a support, afeeding opening, a water inlet, a rotor, a screen, an inner cover, an outer cover, a water outlet, a discharge opening and a motor. The special cleaning machine for PE films is fully closed, plastic films which contain silt can be thoroughly cleaned and separated under the effects of mechanical power and hydraulic power by the special cleaning machine for PE films, energy consumption is reduced, meanwhile, 50% of water consumption is reduced, degree of purity is greatly improved, the capacity is 2-3 times that of a cleaning tank, secondary cleaning is not required, and thus, the labor intensity is relieved.

Owner:SHANDONG JIA LAN ENVIRONMENTAL PROTECTION TECH CO LTD +1

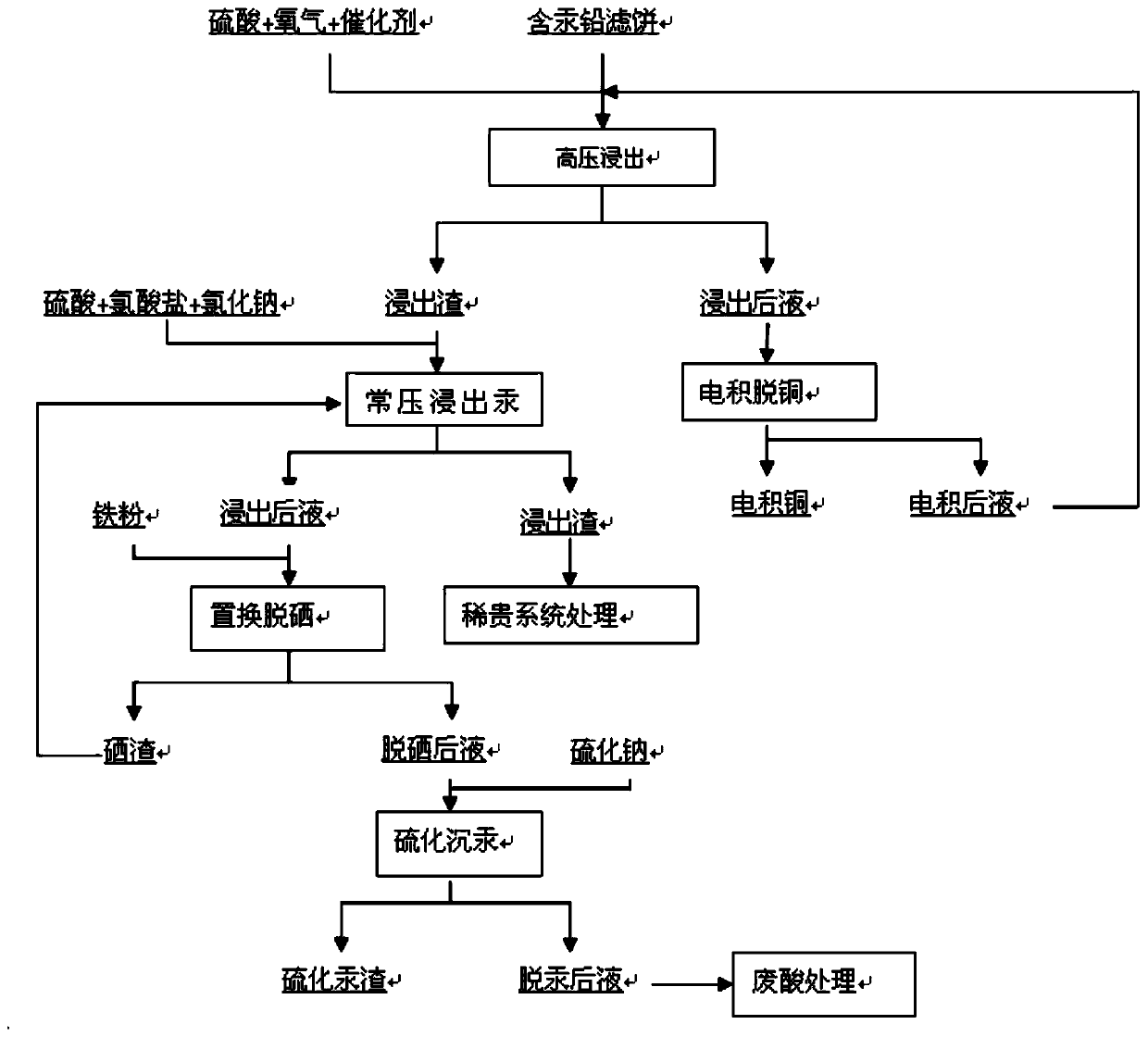

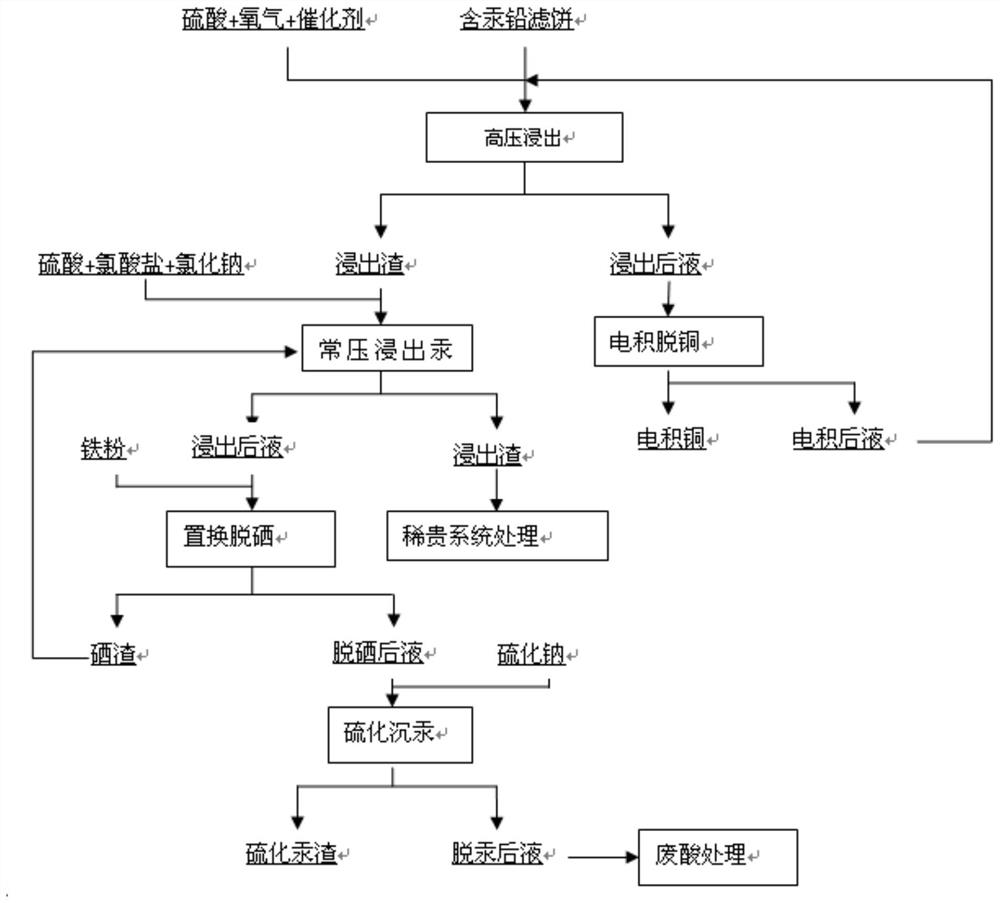

Treatment process of copper, mercury, selenium, lead, gold and silver in copper smelting lead filter cake

ActiveCN109971962AImprove leaching effectImprove overall recoveryPhotography auxillary processesProcess efficiency improvementVulcanizationSlag

The invention provides a treatment process of copper, mercury, selenium, lead, gold and silver in a copper smelting lead filter cake. The process mainly comprises following steps of low-temperature high-pressure oxidizing leaching of copper, normal-pressure oxidizing leaching and removal of mercury, replacement of selenium and vulcanization mercury sediment and further comprises rare precious system treatment and electrodeposition copper removal treatment. The treatment process is thorough in copper, mercury, selenium, lead, gold and silver separating effect, the gold, silver and selenium arebasically and completely enriched in the slag phase, the copper recycling rate is about 96%, the leaching rate of mercury is above 90%, and the aim of comprehensively treating valuable elements is achieved.

Owner:YANGGU XIANGGUANG COPPER

Process method for separating glucose from ionic liquid

ActiveCN102559943BAccelerate the process of industrializationReduce consumptionGlucose productionAnti solventSpins

The invention provides a process method for crystallizing and separating glucose from ionic liquid by an anti-solvent method to obtain a pure product. The process method for separating the glucose from the ionic liquid by the anti-solvent method comprises the following process that firstly, dissolving the glucose into the ionic liquid at a certain temperature; and then adding an anti-solvent into the homogeneous mixed solution to crystallize and separate the glucose. The solid glucose obtained by crystallization is separated out from the solvent by filtering and then the anti-solvent in the residual solution is removed in a spin steaming mode to obtain the mixed solution of the ionic liquid and a trace amount of glucose, so that the aim of repeatedly using is fulfilled.

Owner:BEIJING UNIV OF CHEM TECH

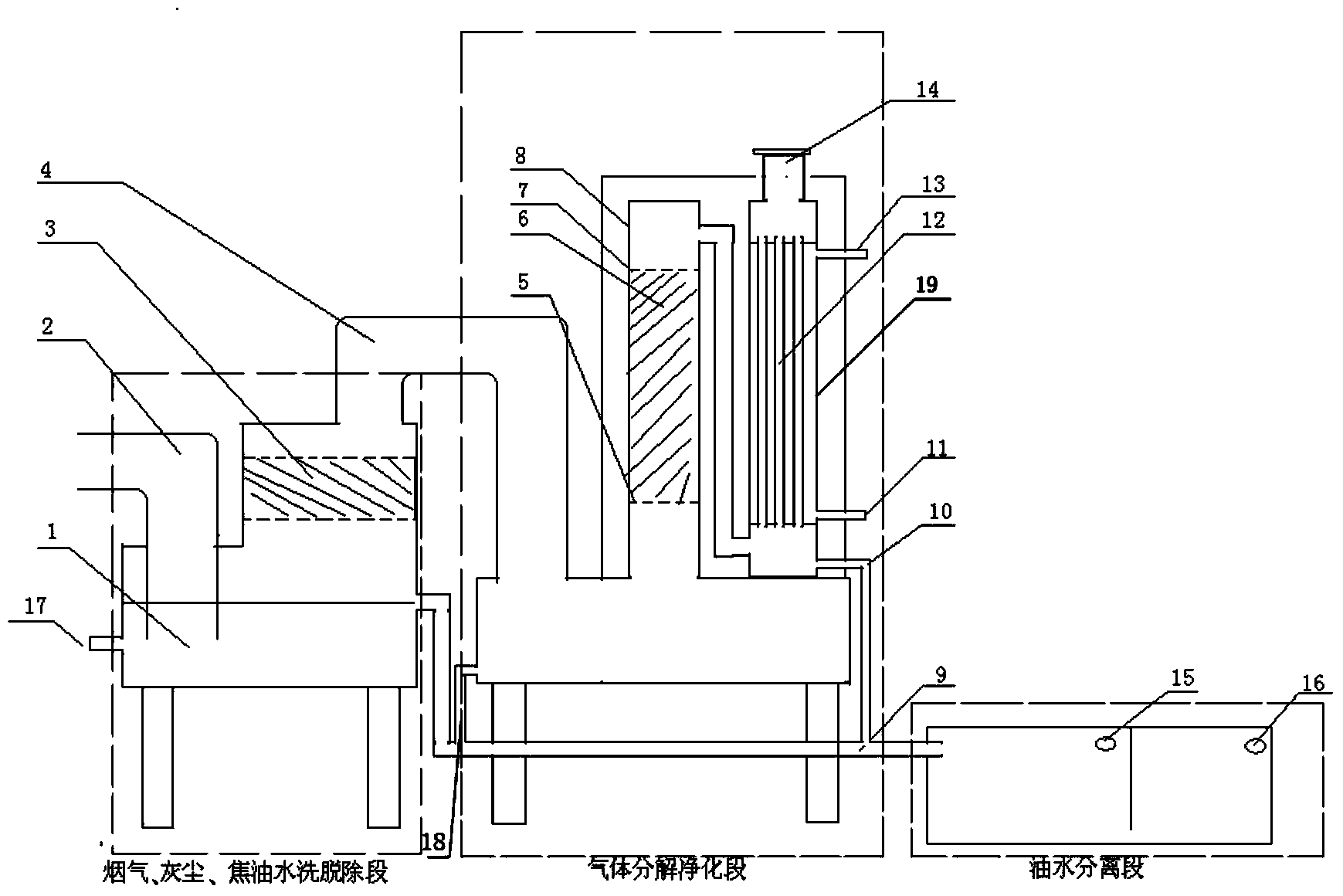

Efficient plastic melting cracking flue gas desorption separation purification system

InactiveCN103657322ASolve the pollution of the environmentSimple structureCombination devicesUsing liquid separation agentDesorptionFlue gas

The present invention discloses an efficient plastic melting cracking flue gas desorption separation purification system, which comprises a flue gas, dust and tar water-washing removal section, a gas decomposition purification section, an oil-water separation section capable of collecting and separating oil-water debris, and an oil-water debris discharge pipeline, wherein the left end and the right end of the oil-water debris discharge pipeline are respectively connected with the flue gas, dust and tar water-washing removal section and the oil-water separation section, and the upper portion of the flue gas, dust and tar water-washing removal section is connected with the gas decomposition purification section through a flue gas pipeline. With the efficient plastic melting cracking flue gas desorption separation purification system, the problem that the existing waste plastic recovery process can produce harmful gas so as to pollute the environment can be solved. The efficient plastic melting cracking flue gas desorption separation purification system has characteristics of simple structure, low energy consumption, complete separation effect, low discharged flue gas temperature, no harmful gas production, and environmental protection.

Owner:HEILONGJIANG SIDATE VETERINARY DRUG

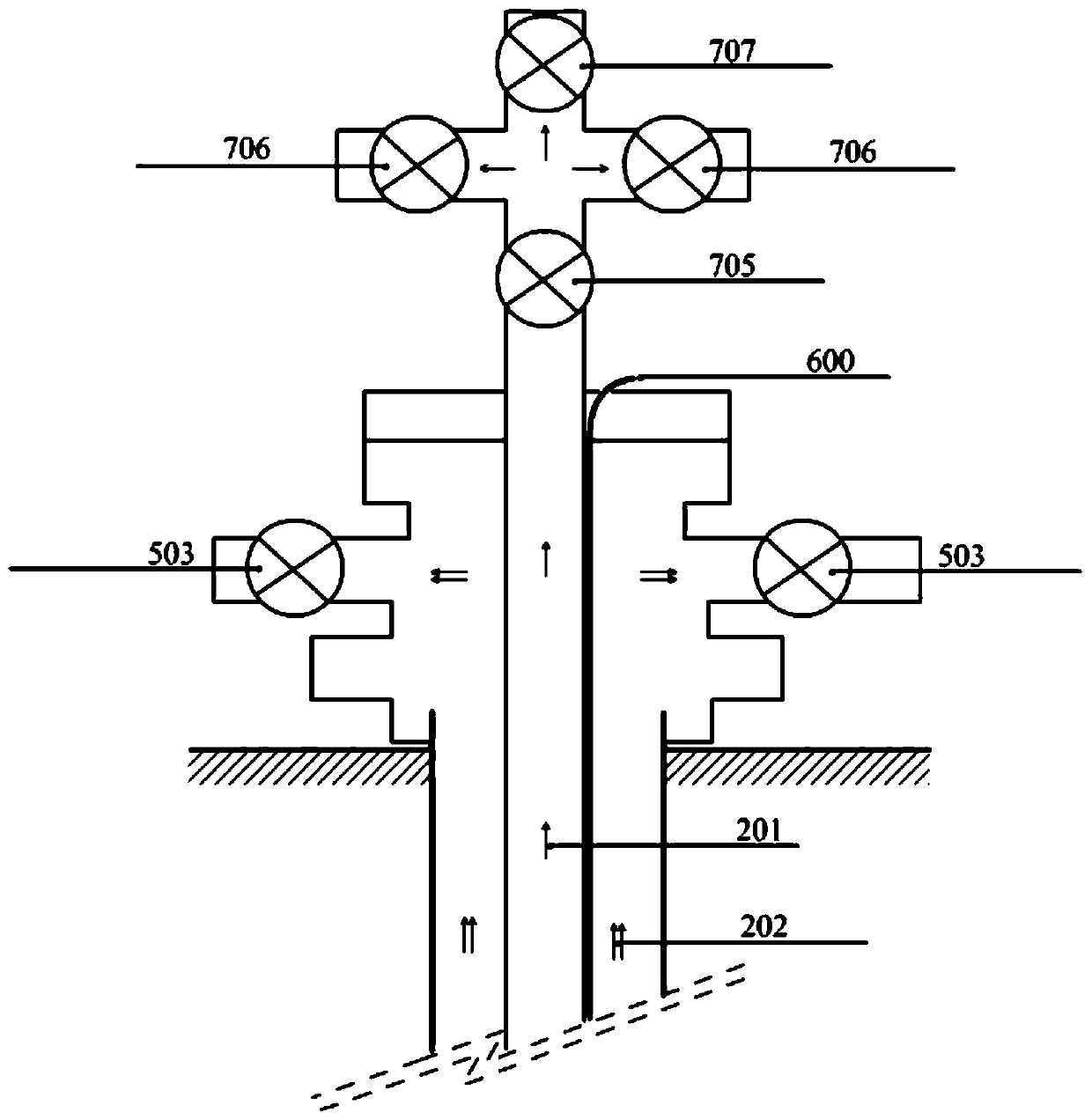

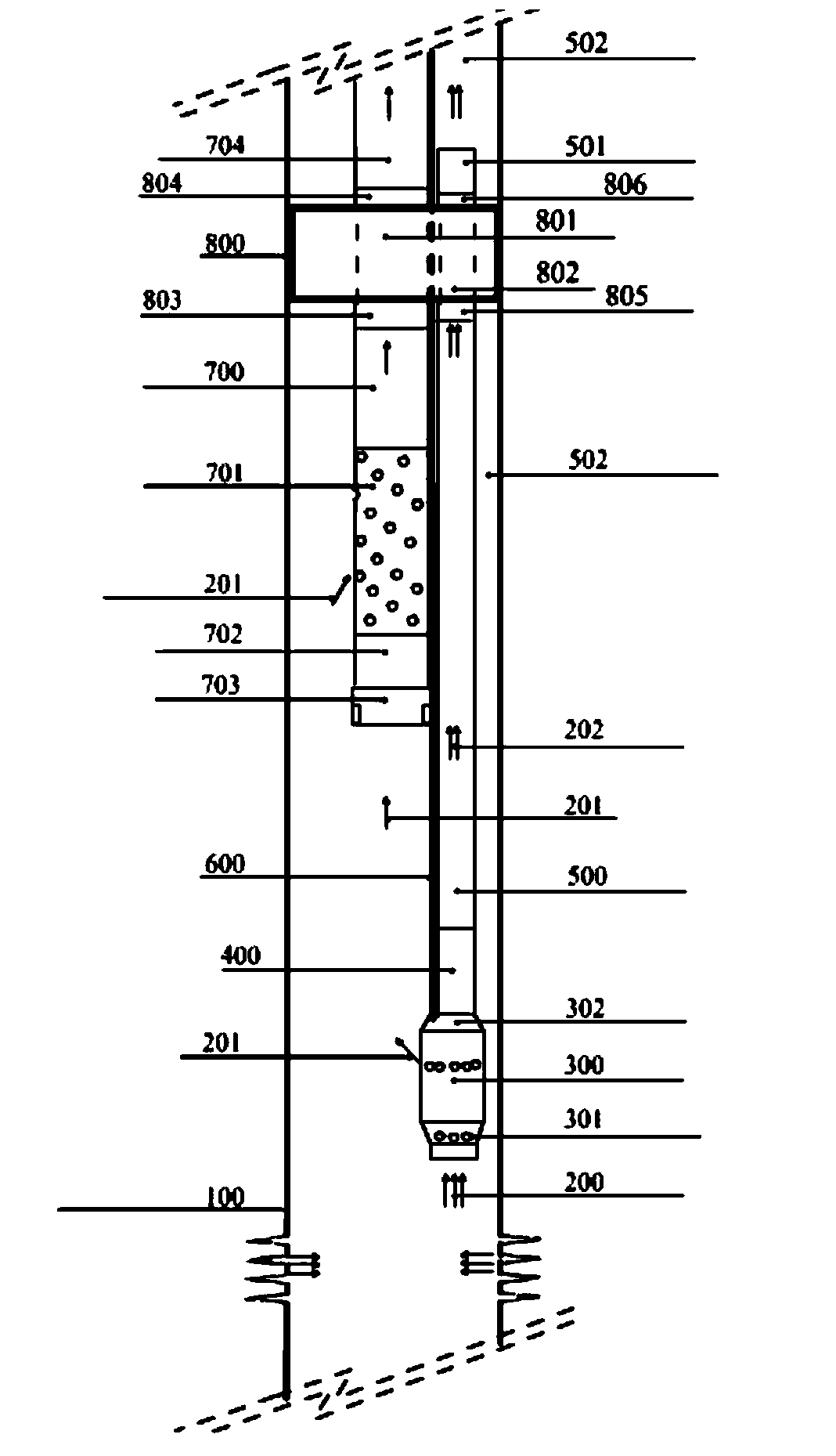

Gas well gas-liquid separating producing well completion pipe string

InactiveCN110593846AAvoid flow disturbanceEfficiency improvement of liquid drainage and gas recoveryDrilling rodsFluid removalMain channelProduct gas

The invention provides a gas-liquid separating producing pipe string for offshore gas well liquid discharging gas production. A shaft, an immersion pump, a gas production oil pipe and a liquid discharging oil pipe are included, wherein the immersion pump is arranged at the bottom of the shaft, and the gas production oil pipe and the liquid discharging oil pipe are vertically placed in the shaft. Abottom inlet of the liquid discharging oil pipe is connected with a discharging port of the immersion pump. The position of a bottom air inlet of the gas production oil pipe is higher than and away from a liquid inlet of the immersion pump. A double-pipe packer for blocking the shaft is further arranged in the shaft. The gas production oil pipe and the liquid discharging oil pipe communicate witha main channel and an auxiliary channel of the double-pipe packer correspondingly. The character that the specific gravity of liquid is larger than the specific gravity of gas is utilized, the liquidinlet is arranged below a gas inlet, the immersion pump gas-liquid separation function is matched, and the purpose of deep and thorough gas-liquid separation can be achieved. The well completion pipestring is simple in structure and good in effect and has very high usage benefits.

Owner:闫波

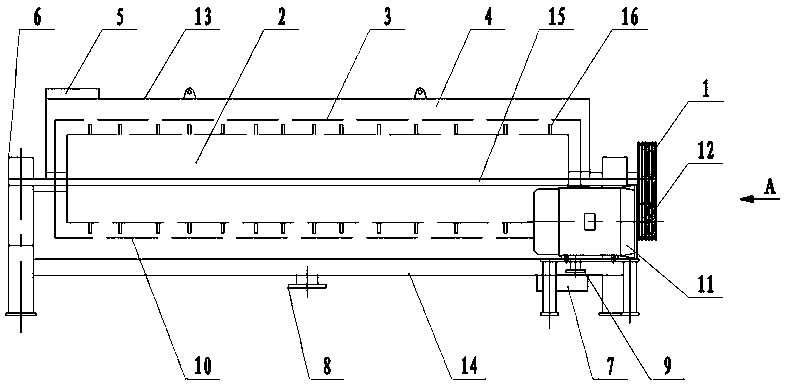

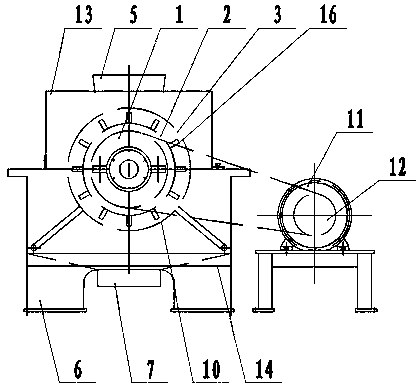

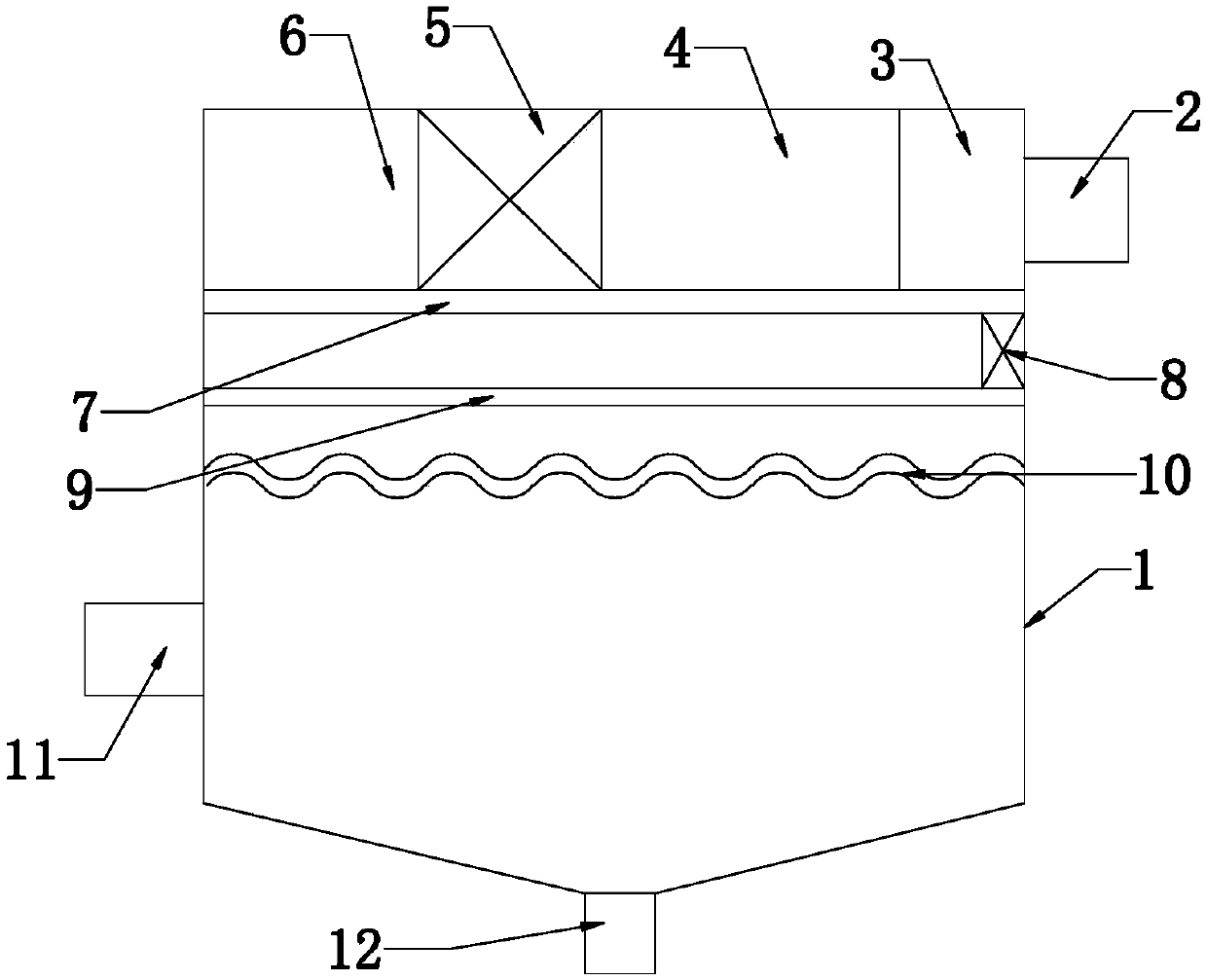

Fluidized bed drying equipment

InactiveCN109028766AUniform temperature distributionImprove heat transfer performanceDrying solid materials with heatDrying gas arrangementsFluidized bed dryingAutomatic control

The invention discloses fluidized bed drying equipment. The equipment integrally designs a material drying system, a separation system and a collection system based on the fluidizing drying technologyand the centrifugal principle, and materials have the advantages that heating is uniform, the time in a drying roller can be adjusted, the drying speed is high, products obtained after material drying are separated thoroughly, multiple dried articles can be collected at the same time, and the automation degree is high. A box body is composed of an inner heat conduction layer, a middle heating layer and an outer heat preservation layer, the heat energy utilization rate is high, a temperature controller and a timer are arranged, and therefore automatic control is achieved; temperature distribution in a fluidized bed is uniform, and the heat transfer effect is good; and the temperature and the air speed can be automatically controlled at the same time, the phenomenon of non-uniform partial heating of the materials is avoided, and the fluidized bed drying equipment is especially suitable for drying thermosensitive materials. The reliability of a screw feeding mechanism is high; a dust removal device can reduce the amount of dust in waste gas and is beneficial to environment protection; and the equipment structure is simple, and the fluidized bed drying equipment is suitable for beingused and popularized in drying and separating of crop and chemical products.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

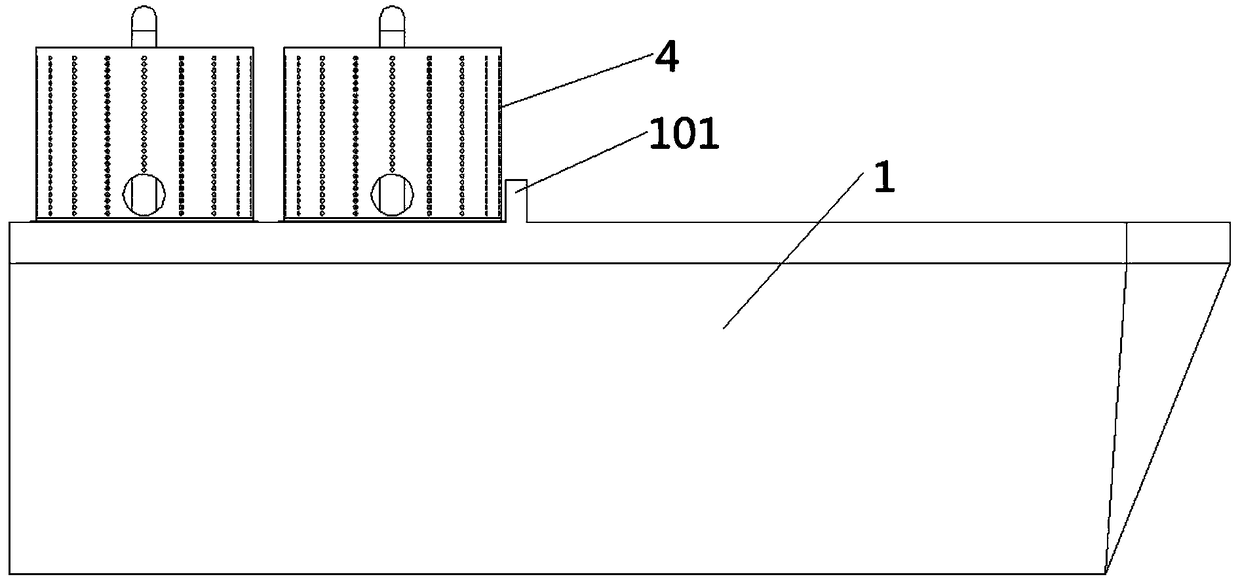

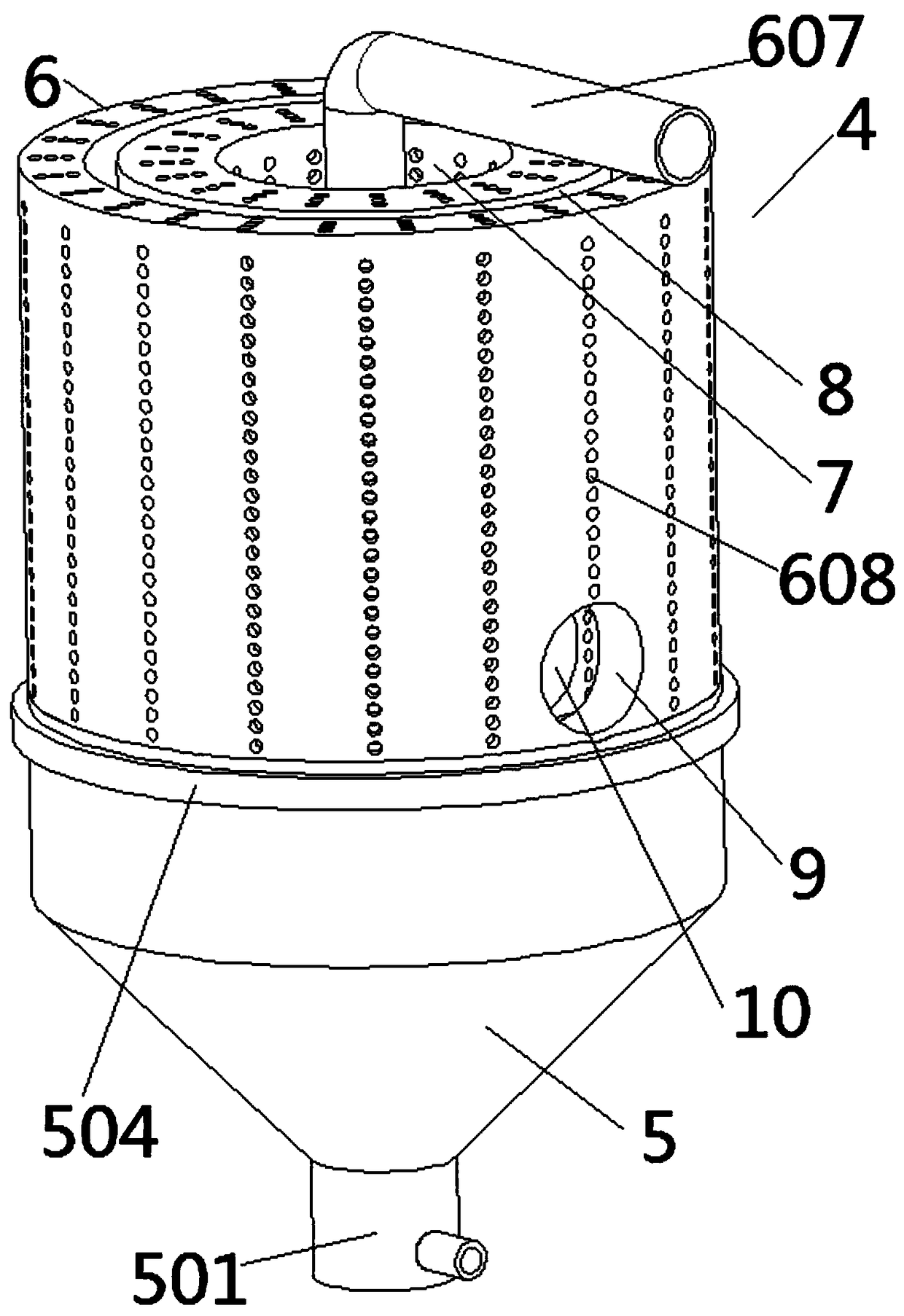

River and lake dredger with efficient silt-water separation function

ActiveCN108797671AThe separation effect is thoroughSave energySludge treatment by de-watering/drying/thickeningMechanical machines/dredgersPipeflowEngineering

The invention discloses a river and lake dredger with an efficient silt-water separation function, and relates to the technical field of river and lake dredgers. The river and lake dredger with the efficient silt-water separation function comprises a silt-water separation device. The silt-water separation device comprises a silt storage base and a separation net layer, wherein a silt outlet pipe is arranged at the bottom of the silt storage base, and a water outlet pipe is arranged on the peripheral side of the silt outlet pipe; the separation net layer comprises an outer separation net and aninner separation net; a fixing ring A is arranged between the inner edge of the outer separation net and the outer edge of the inner separation net, and a fixing ring B is arranged on the inner edgeof the inner separation net; a through hole is formed in one surface of the fixing ring B, and a silt inlet pipe is fixed to the inner surface of the through hole; the upper surface of the silt storage base is fixedly connected with the lower surface of the outer separation net; the silt inlet pipe communicates with a silt suction pipe; and the silt outlet pipe stretches into the silt storage box.Under the effect of the silt-water separation device, the river and lake dredger has the advantages that the dredger is not limited by the distance or pipelines, an efficient and complete silt-waterseparation effect is achieved, energy is saved, the production cost is low, and the economical benefits are high.

Owner:ANHUI JIAMING ENVIRONMENTAL PROTECTION TECHCO

Process method for separating glucose from ionic liquid

ActiveCN102559943AAccelerate the process of industrializationReduce consumptionGlucose productionAnti solventSpins

The invention provides a process method for crystallizing and separating glucose from ionic liquid by an anti-solvent method to obtain a pure product. The process method for separating the glucose from the ionic liquid by the anti-solvent method comprises the following process that firstly, dissolving the glucose into the ionic liquid at a certain temperature; and then adding an anti-solvent into the homogeneous mixed solution to crystallize and separate the glucose. The solid glucose obtained by crystallization is separated out from the solvent by filtering and then the anti-solvent in the residual solution is removed in a spin steaming mode to obtain the mixed solution of the ionic liquid and a trace amount of glucose, so that the aim of repeatedly using is fulfilled.

Owner:BEIJING UNIV OF CHEM TECH

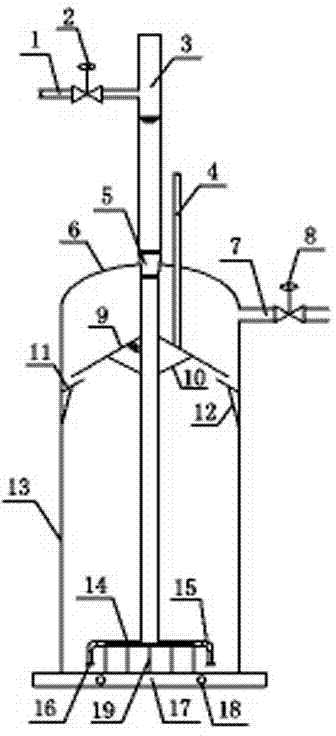

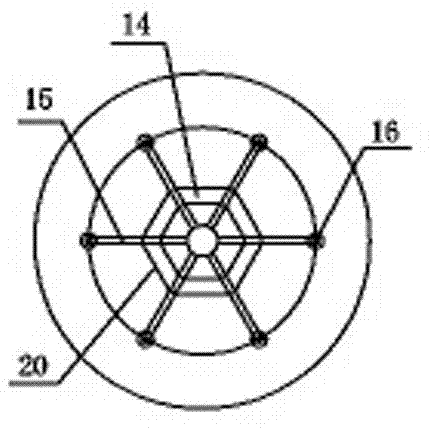

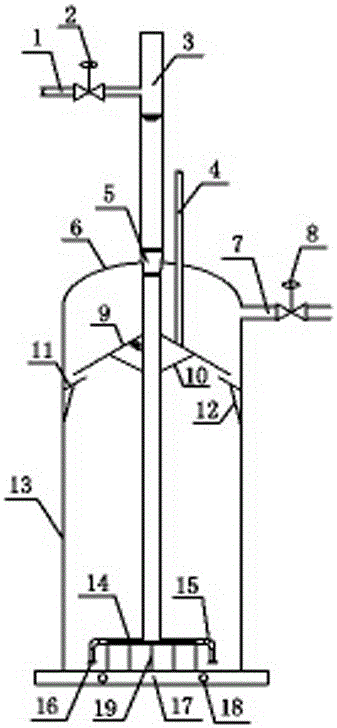

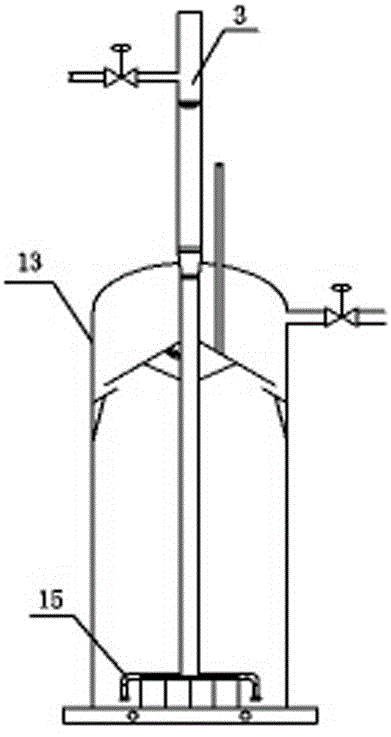

Efficient anaerobic reaction tank for large-scale raising of livestock

ActiveCN104761053AFully Anaerobic Fermentation ReactionEfficient separationWaste water treatment from animal husbandryBiological treatment apparatusEngineeringHeight difference

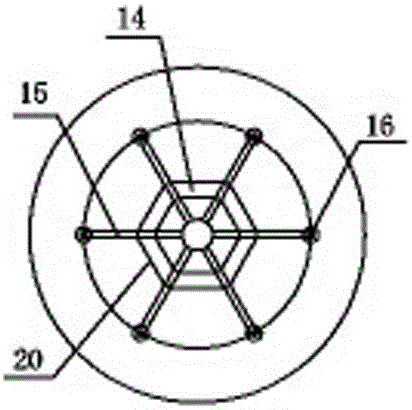

The invention discloses an efficient anaerobic reaction tank for large-scale raising of livestock. A central pipeline is arranged at the center of a tank body of the anaerobic reaction tank; a water distribution pipeline is fixedly arranged at the bottom of the central pipeline through a fixed support and is composed of six branch water distribution pipelines; a reflecting cone is arranged below the end part of each branch water distribution pipeline; a reducing pipe is arranged on a position where the central pipeline is in contact with the top of the anaerobic reaction tank; a water inlet pipeline is arranged at the side of the upper end of the central pipeline and is communicated with the six branch water distribution pipelines through the central pipeline; the tank body of the anaerobic reaction tank is provided with an exhaust pipeline at the top end and a drainage pipeline at the side; the top end of the exhaust pipeline is lower than the water inlet pipeline; and the top end of the drainage pipeline is lower than the top end of the exhaust pipeline. According to the efficient anaerobic reaction tank, waste sewage can be sufficiently subjected to anaerobic fermentation reaction by virtue of the water pressure obtained after the reducing pipe is reduced, the self gravity of the waste sewage and the height difference of the central pipeline, so that gas and sewage are effectively separated, and the yield of biogas is increased.

Owner:MUYUAN FOODS CO LTD

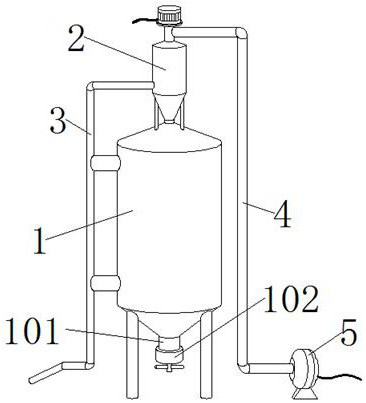

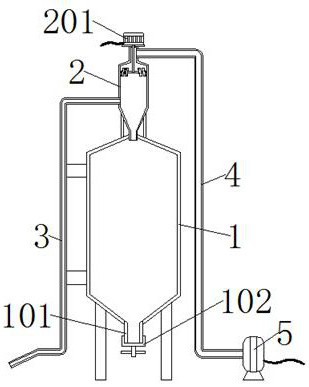

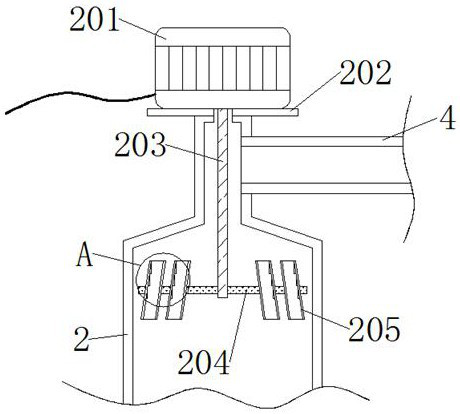

A suction type pneumatic conveying equipment

The invention provides suction type pneumatic conveying equipment. The suction type pneumatic conveying equipment comprises a storage cylinder, a conveying pipe, a gas pipe, a fan and a separating cylinder; the separating cylinder is embedded and welded in the top of the storage cylinder; the conveying pipe is embedded and welded in one side of the separating cylinder; the gas pipe is embedded andwelded in the other side of the conveying pipe; one end of the gas pipe is embedded and welded in the fan; a discharge pipe is embedded and welded in the bottom of the storage cylinder; the bottom ofthe discharge pipe is sleeved with a screw cap in a threaded mode; one side of the conveying pipe is welded to the storage cylinder through a support rod; a carrier plate is welded to the top of theseparating cylinder; and a motor is welded to the top of the carrier plate. A separating pipe is driven by a disc to rotate at a high speed, in the movement process of the separating pipe, due to rotation of the separating pipe, the separating pipe can lay down materials in the separating pipe before the materials fall off from the separating pipe, so that the materials fall into the separating cylinder, the materials are completely separated from airflow, and thus the materials can be completely separated from airflow just through one time of separating.

Owner:江苏道金智能制造科技股份有限公司

Industrial waste water and waste residue separating and filtering device with good separation effect

InactiveCN108031183AThe separation effect is thoroughThe effect of thorough separation and treatment of wastewaterFiltration circuitsChemical industryIndustrial waste water

The invention relates to the technical field of chemical industry, and discloses an industrial waste water and waste residue separating and filtering device with a good separation effect. The device comprises a box body, a water inlet is opened at the top of the box body, and a water outlet pipe is fixedly installed at the bottom of the box body, a fixing bracket is fixedly installed at the top ofthe box body, a first motor is fixedly mounted on the upper end of the fixing bracket, a rotating shaft is fixedly connected to an output shaft of the first motor, stirring blades are fixedly connected to the surface of the rotating shaft, a fixing block is fixedly connected to the bottom of the rotating shaft, a rotating drum is fixedly connected to the bottom of the fixing block, through holesare opened on the surface of the rotating drum, and a first filter net is fixedly connected to the inner wall of each through hole, and a control switch is fixedly installed on the inner wall of the rotating drum. The industrial waste water and waste residue separating and filtering device with a good separation effect has a more remarkable treatment effect on industrial waste water, can effectively separate waste water and waste residue, and is convenient for users to use.

Owner:孝感正茂建材有限公司

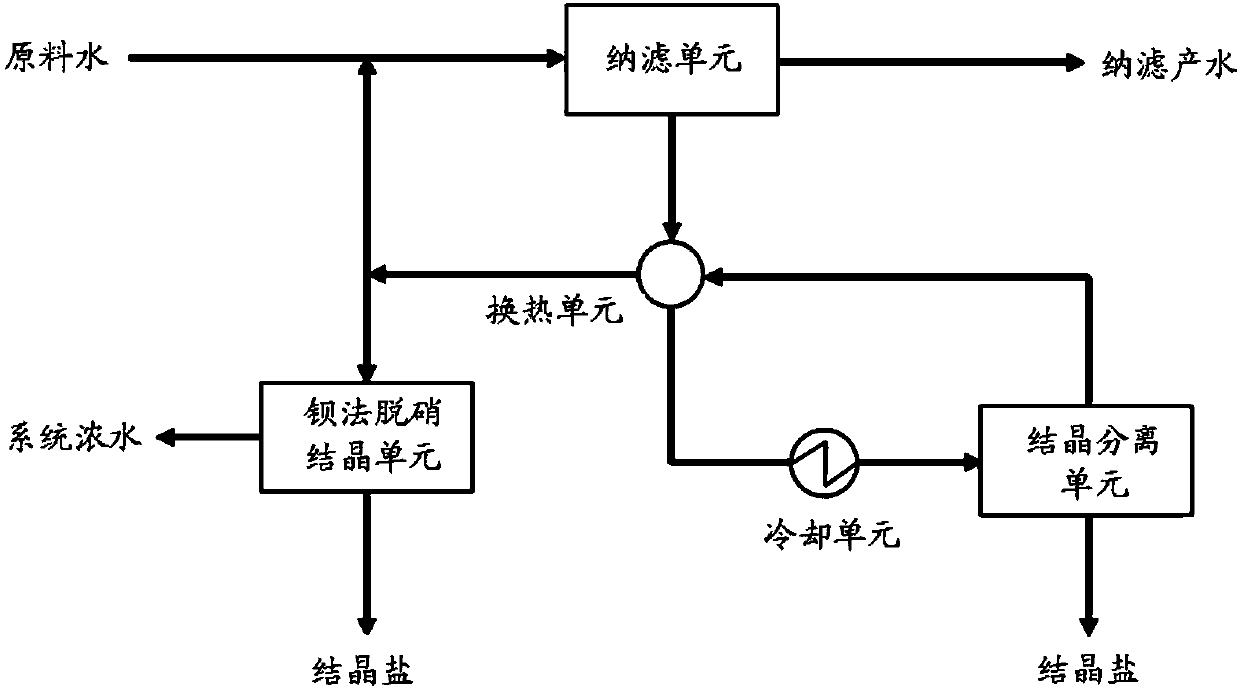

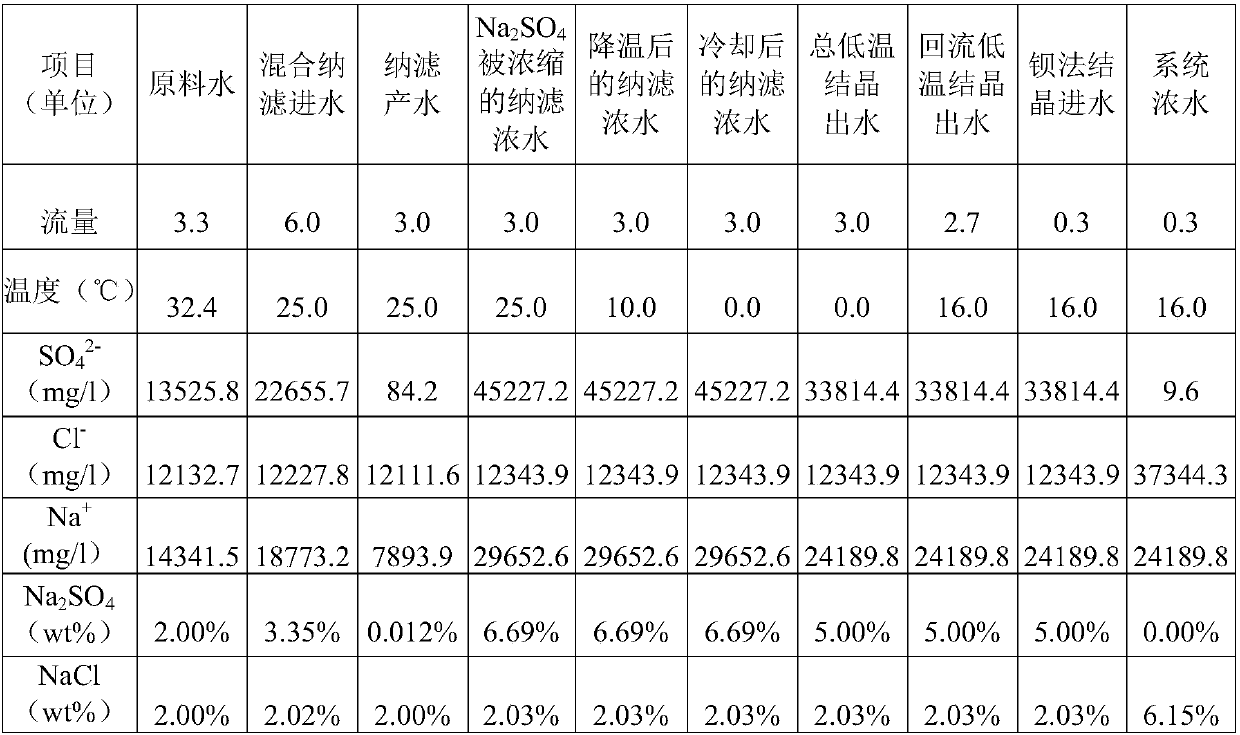

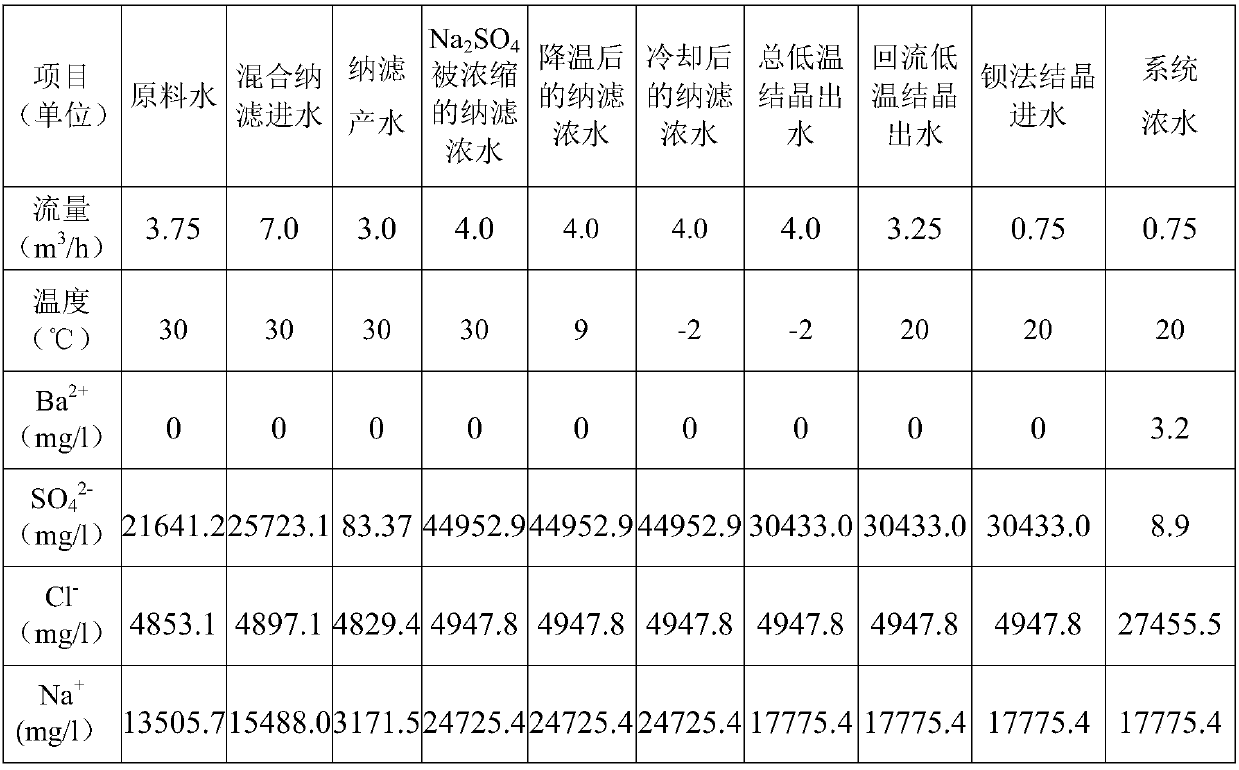

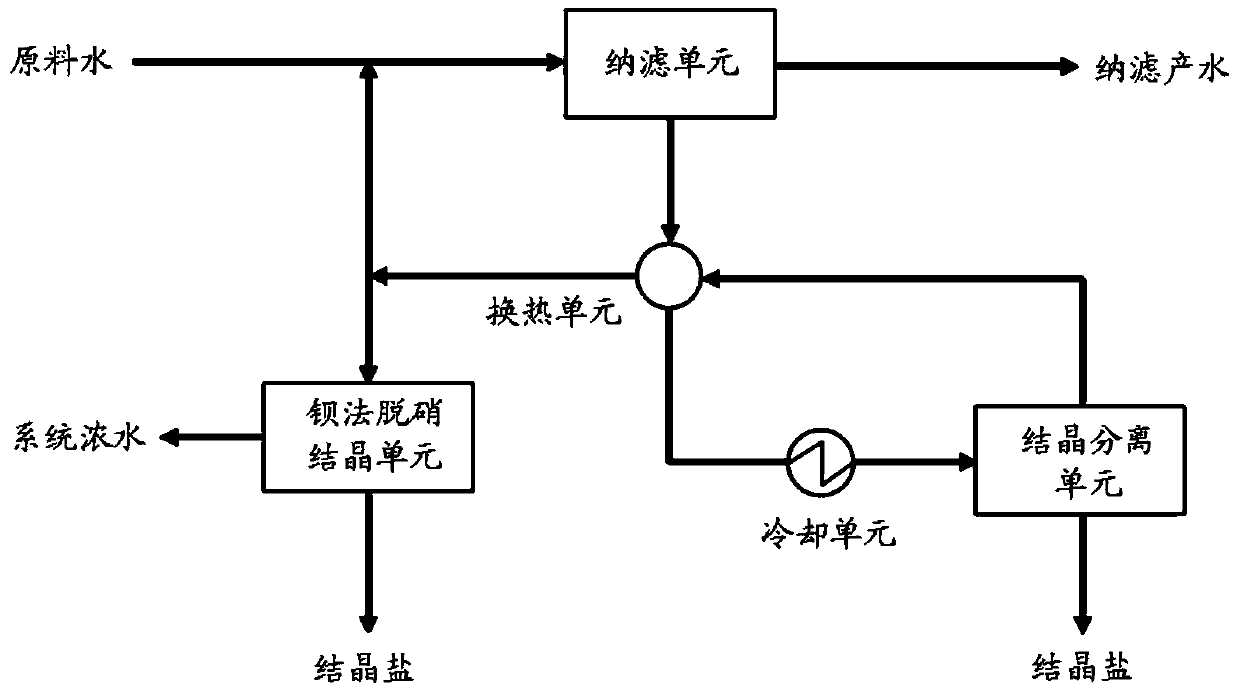

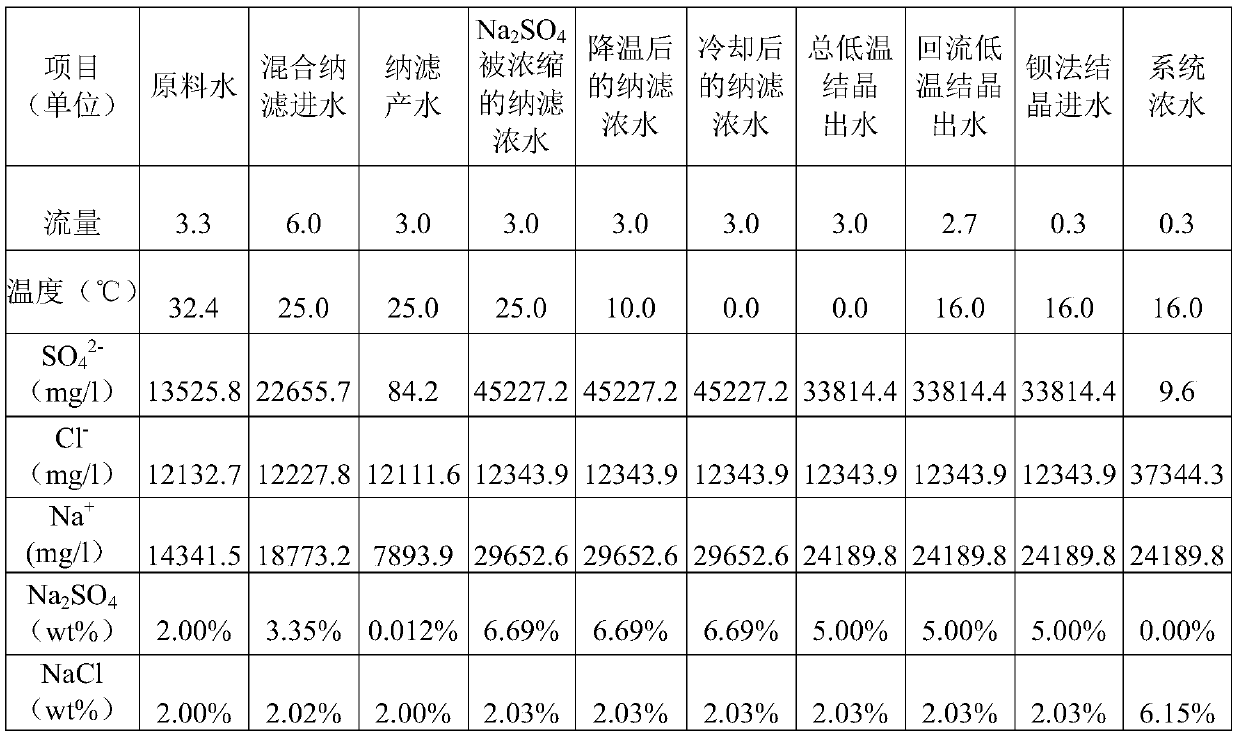

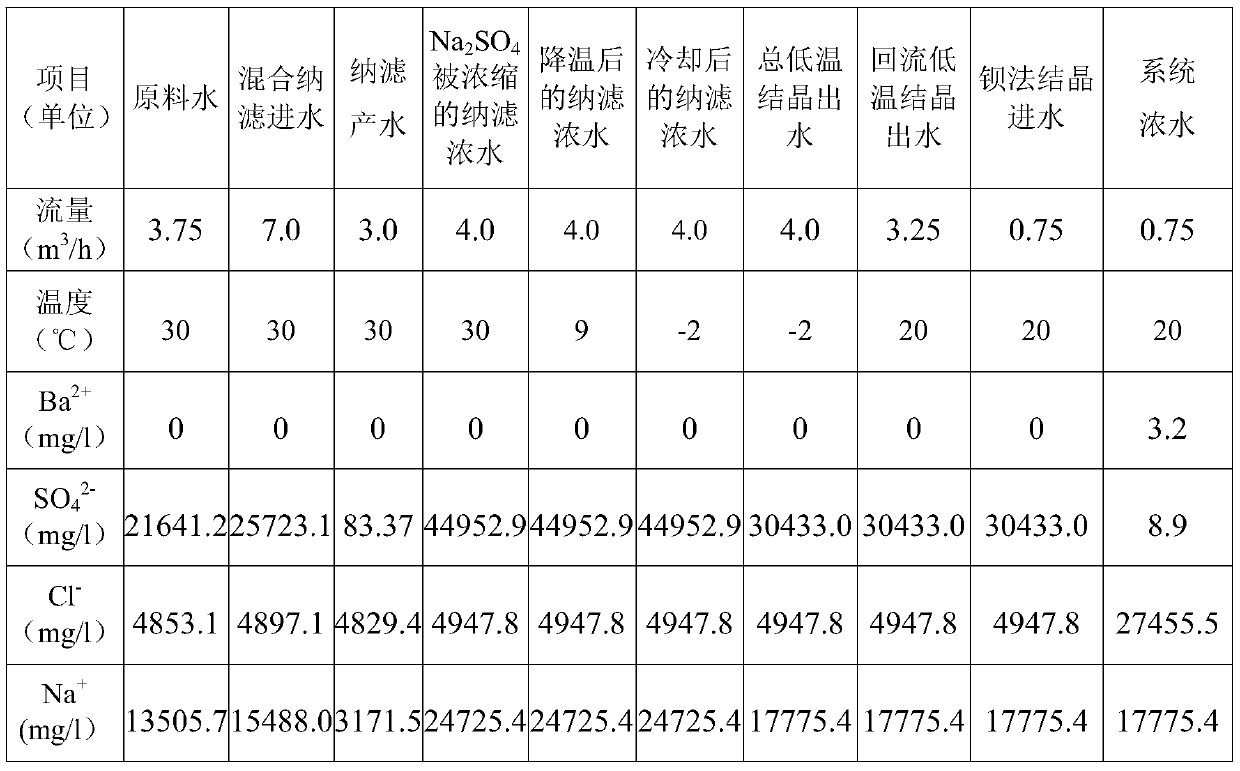

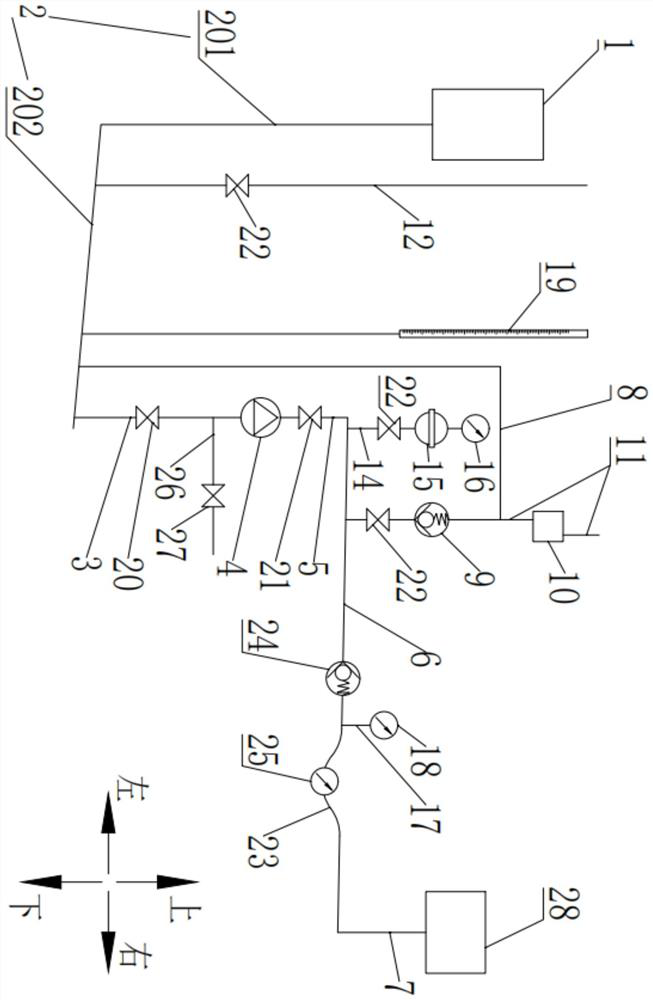

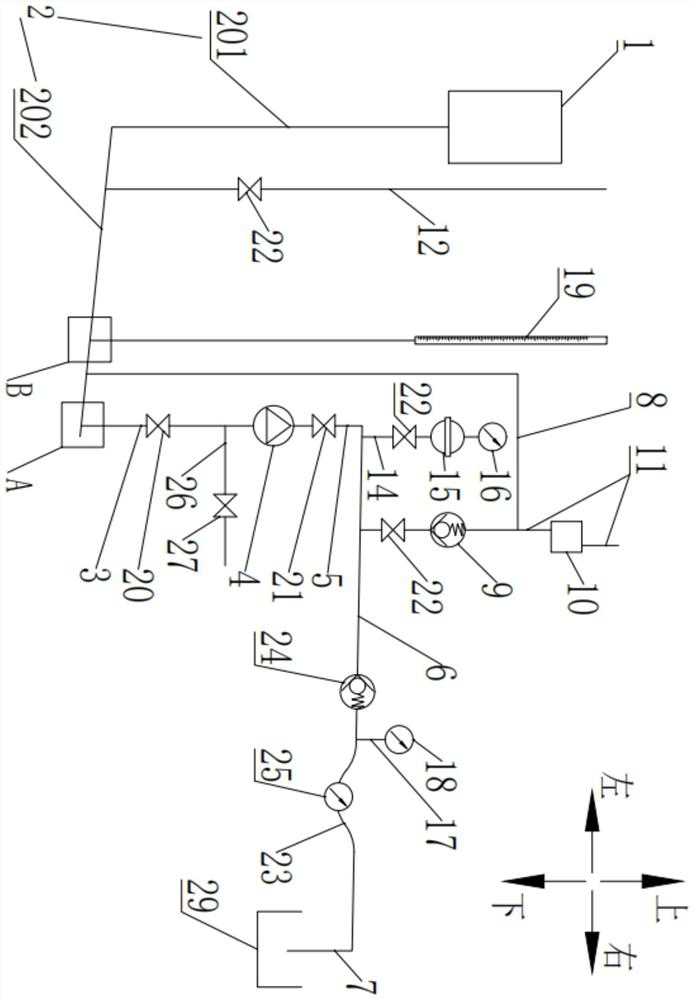

Continuous salt production method and system

ActiveCN107619057AHigh recovery rateHigh purityCalcium/strontium/barium sulfatesAlkali metal sulfite/sulfate purificationFlow ratioWater of crystallization

The invention relates to the field of water treatment, and discloses a continuous salt production method and system. The method comprises: (1) performing nanofiltration separation to salt-containing water to obtain nano-filtered product water and nano-filtered concentrated water; (2) performing heat transfer between the nano-filtered concentrated water and low-temperature crystallization product water obtained from the step (4) to obtain cooled nano-filtered concentrated water and warmed crystallization product water, and dividing the warmed crystallization product water into reflux crystallization product water and low temperature crystallization water product water concentrated water; (3) cooling the nano-filtered concentrated water; (4) performing low temperature crystallization separation to the cooled nano-filtered concentrated water to obtain crystallization product water and crystallization salt, and when the content X% of divalent anion salt in raw water is less than 5wt%, allowing R1<X / (5-X) to be satisfied, wherein R1 is the volume flow ratio of the low temperature crystallization water product water concentrated water to the nano-filtered product water; and (5) performing denitration crystallization to the low temperature crystallization water product water concentrated water through a barium method. The salt-containing water contains raw water and reflux crystallization product water. The method allows high-purity single-component salt to be continuously produced and is low in energy consumption and cost.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

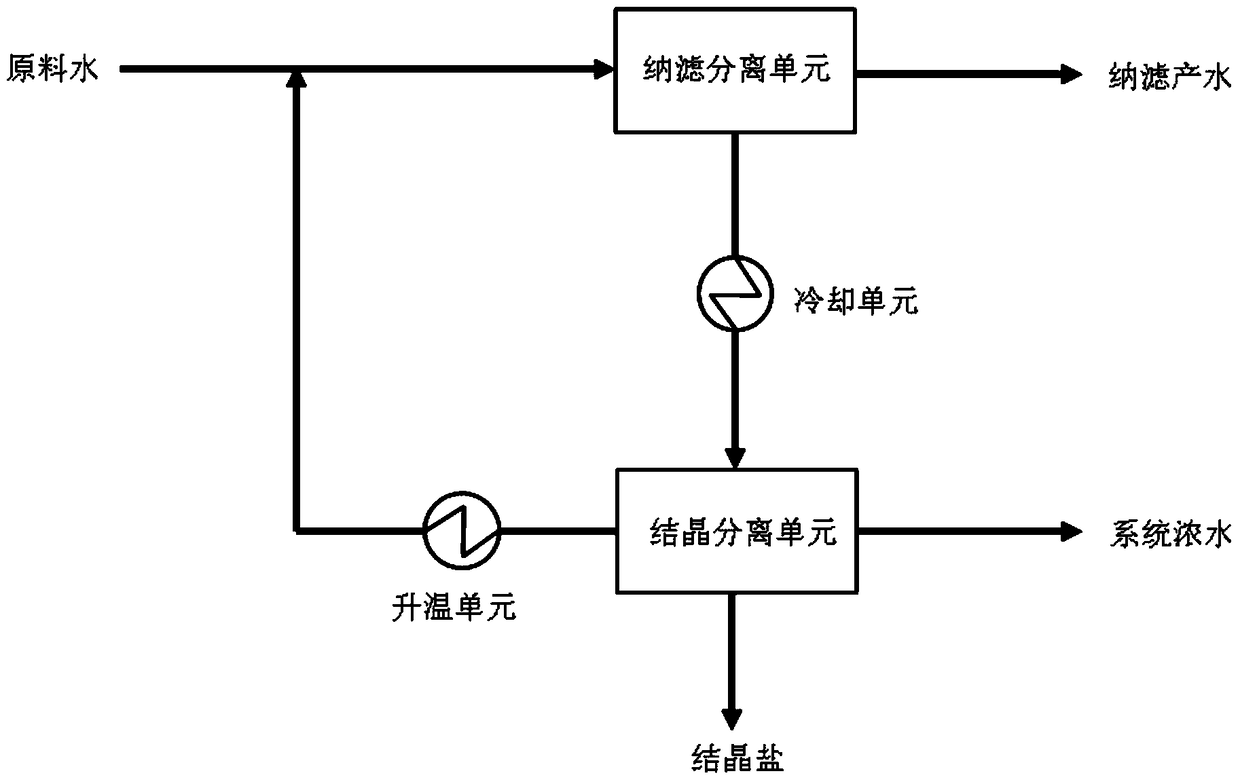

A kind of continuous salt production method and continuous salt production system

ActiveCN107010644BThe separation effect is thoroughCrystallized thoroughlyAlkali metal sulfite/sulfate purificationAlkali metal halide purificationFlow ratioProduced water

The invention relates to the field of water treatment and discloses a continuous salt making method and a continuous salt making system. The continuous salt making method comprises the following steps: (1) carrying out nanofiltration separation on salt-containing water containing a bivalent anionic salt and a monovalent anionic salt to obtain nanofiltration producing water and nanofiltration concentrated water; (2) cooling the nanofiltration concentrated water obtained in the step (1) to obtain cooled nanofiltration concentrated water; and (3) carrying out crystallization separation on the cooled nanofiltration concentrated water to obtain crystallization producing water and a crystalline salt, dividing the crystallization producing water into two flows which serve as backflow crystallization producing water to backflow to nanofiltration separation and as system concentrated water respectively, wherein the salt-containing water is prepared from raw material water and the backflow crystallization producing water in the step (3), a relationship that R1 is smaller than X / (5-X) is satisfied when the mass percentage X% of the bivalent anionic salt in the raw material water is smaller than 5 percent, and R1 is a volume flow ratio of the system concentrated water to the nanofiltration producing water. By adopting the method and the system provided by the invention, a high-purity single component salt can be continuously produced, and the energy consumption and the investment cost can be greatly lowered.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

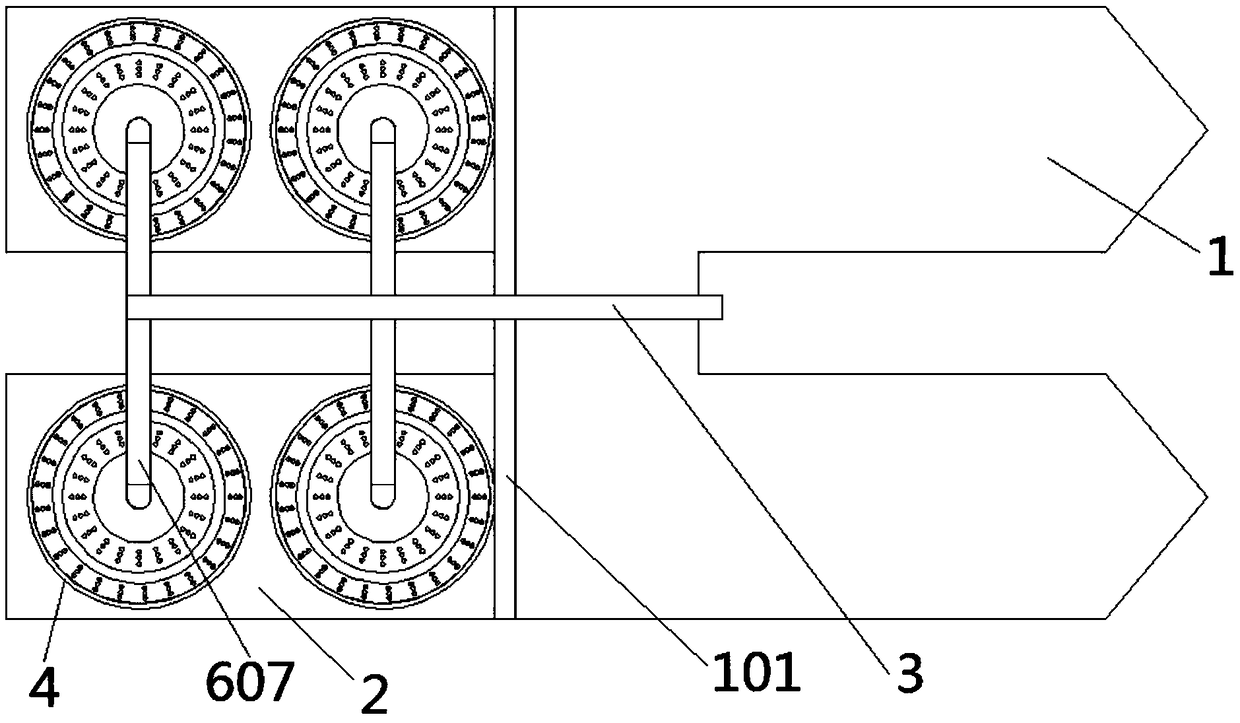

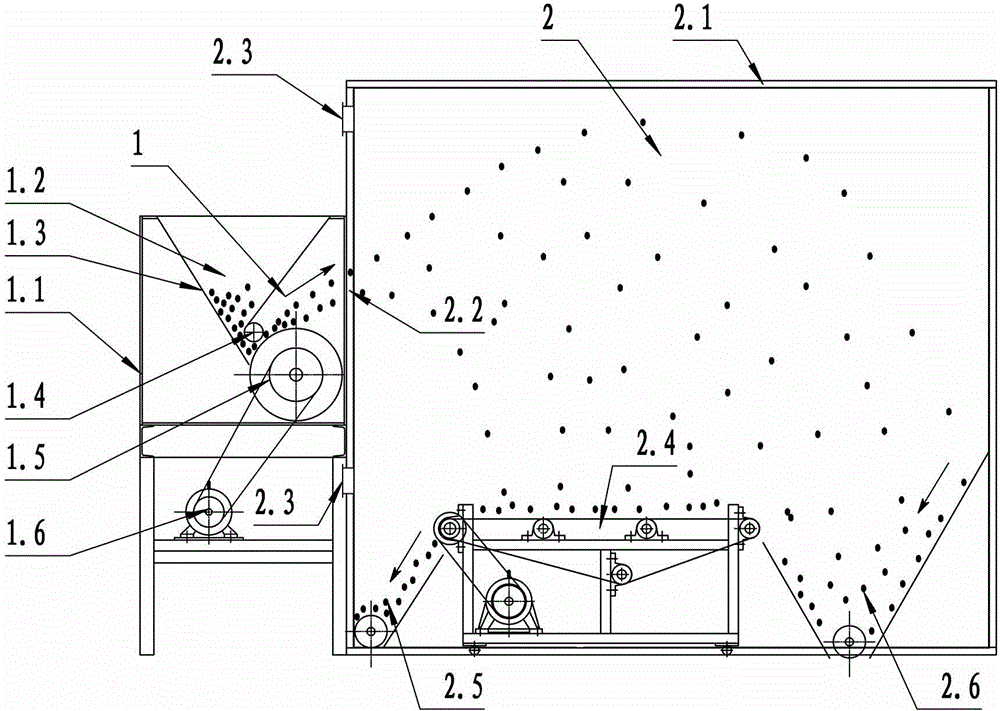

Device for separating cotton seed kernel and cotton seed hull of cotton seed

The invention provides a device for separating cotton seed kernels and cotton seed hulls of cotton seeds. The device for separating cotton seed kernels and cotton seed hulls of cotton seeds comprises a material throwing device and a material separation chamber, wherein the material throwing device comprises a housing I, a feed hopper, flow guide plate, a roller, a motor and a transmission device, wherein the feed hopper, the flow guide plate, the roller, the motor and the transmission device are installed on the housing I, and the roller is driven by the motor and the transmission device to throw materials into the material separation chamber; the material separation chamber comprises a housing II, wherein a material inlet and an air guide port are formed in the housing II, and a cotton seed hull conveyer, a cotton seed hull collection and conveying device and a cotton seed kernel collection and conveying device are arranged on a bottom surface of the housing II. The device for separating cotton seed kernels and cotton seed hulls of cotton seeds has the beneficial effects that the device is simple, the manufacturing cost is low, the power consumption is less, the occupied area is small, the operation and maintenance are simple to conduct and the separation effect is greatly improved.

Owner:北京中唐瑞德生物科技有限公司 +1

A kind of continuous salt production method and continuous salt production system

ActiveCN107619057BHigh recovery rateHigh purityCalcium/strontium/barium sulfatesAlkali metal sulfite/sulfate purificationSalt waterNanofiltration

The invention relates to the field of water treatment, and discloses a continuous salt production method and system. The method comprises: (1) performing nanofiltration separation to salt-containing water to obtain nano-filtered product water and nano-filtered concentrated water; (2) performing heat transfer between the nano-filtered concentrated water and low-temperature crystallization product water obtained from the step (4) to obtain cooled nano-filtered concentrated water and warmed crystallization product water, and dividing the warmed crystallization product water into reflux crystallization product water and low temperature crystallization water product water concentrated water; (3) cooling the nano-filtered concentrated water; (4) performing low temperature crystallization separation to the cooled nano-filtered concentrated water to obtain crystallization product water and crystallization salt, and when the content X% of divalent anion salt in raw water is less than 5wt%, allowing R1<X / (5-X) to be satisfied, wherein R1 is the volume flow ratio of the low temperature crystallization water product water concentrated water to the nano-filtered product water; and (5) performing denitration crystallization to the low temperature crystallization water product water concentrated water through a barium method. The salt-containing water contains raw water and reflux crystallization product water. The method allows high-purity single-component salt to be continuously produced and is low in energy consumption and cost.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Liquid medicine treatment equipment capable of eliminating gas interference

PendingCN113880177AEasy to transportReduced entry into the suction pipeWater/sewage treatment by degassingWater/sewage treatment apparatusExhaust valveEngineering

The invention relates to the field of water treatment equipment, in particular to liquid medicine treatment equipment for eliminating gas interference. The equipment comprises a liquid medicine tank and a main pipeline, and further comprises a suction pipe, a metering pump and a discharge pipe which are vertically connected. The discharge pipe communicates with a transverse conveying pipe, and the conveying pipe is connected with a feeding pipe. The upper surface of the conveying pipe communicates with a safety pipe, the safety pipe communicates with the main pipeline, the safety pipe is provided with an exhaust valve and a first exhaust pipe, the middle of the first exhaust pipe communicates with a gas-liquid separation chamber, and the upper surface of the main pipeline communicates with a second exhaust pipe. The top of the gas-liquid separation chamber and the top of the second exhaust pipe are higher than the top of the liquid medicine tank. The tail end of the main pipeline is closed, the suction pipe extends into the main pipeline from top to bottom, the end of the suction pipe is close to or makes contact with the inner wall of the bottom of the main pipeline, an inclined port is formed in the end of the suction pipe, and the inclined port faces the liquid inlet direction. The problem that the working efficiency and the service life of equipment are affected by gas residues is solved.

Owner:浙江义乌市自来水有限公司

A process for treating copper, mercury, selenium, lead and gold and silver in lead filter cake of copper smelting

ActiveCN109971962BImprove leaching effectImprove overall recoveryPhotography auxillary processesProcess efficiency improvementSlagMercury (element)

The invention provides a treatment process of copper, mercury, selenium, lead, gold and silver in a copper smelting lead filter cake. The process mainly comprises following steps of low-temperature high-pressure oxidizing leaching of copper, normal-pressure oxidizing leaching and removal of mercury, replacement of selenium and vulcanization mercury sediment and further comprises rare precious system treatment and electrodeposition copper removal treatment. The treatment process is thorough in copper, mercury, selenium, lead, gold and silver separating effect, the gold, silver and selenium arebasically and completely enriched in the slag phase, the copper recycling rate is about 96%, the leaching rate of mercury is above 90%, and the aim of comprehensively treating valuable elements is achieved.

Owner:YANGGU XIANGGUANG COPPER

Circulating oil gas separation method

InactiveCN110860174AImprove filtering effectThe separation effect is thoroughGas treatmentDispersed particle filtrationThermodynamicsFiltration

The invention discloses a circulating oil gas separation method. The method comprises the following steps: A, primarily condensing oil gas and then feeding the condensed oil gas into a shell; B, filtering the condensed oil gas through a filter and adsorbing the filtered oil gas through an adsorption cavity, then feeding the adsorbed oil gas into a heating cavity for heating, and sending the heatedoil gas into a gas delivery pipeline; C, condensing the heated oil gas in a condenser again, feeding the condensed oil gas into a condensing pipeline, and discharging the condensed oil gas from an exhaust hole; and D, dispersing the oil gas discharged from the exhaust hole by blocking through an oil blocking plate below the exhaust hole. After the method is adopted, layer-by-layer filtration canbe carried out through each layer of structures, and multi-layer oil dropping by condensation can be realized through a specific measure of high-temperature heating and direct low-temperature condensation to the maximum degree in the filtration process, so that gas has a very good filtration effect. In addition, the whole oil gas separation process has a plurality of treatment measures, so that oil gas can be thoroughly separated and collected in a pure manner, the separation effect is good, energy consumption is very low, and thus treatment cost is greatly reduced.

Owner:江苏中远环保科技有限公司

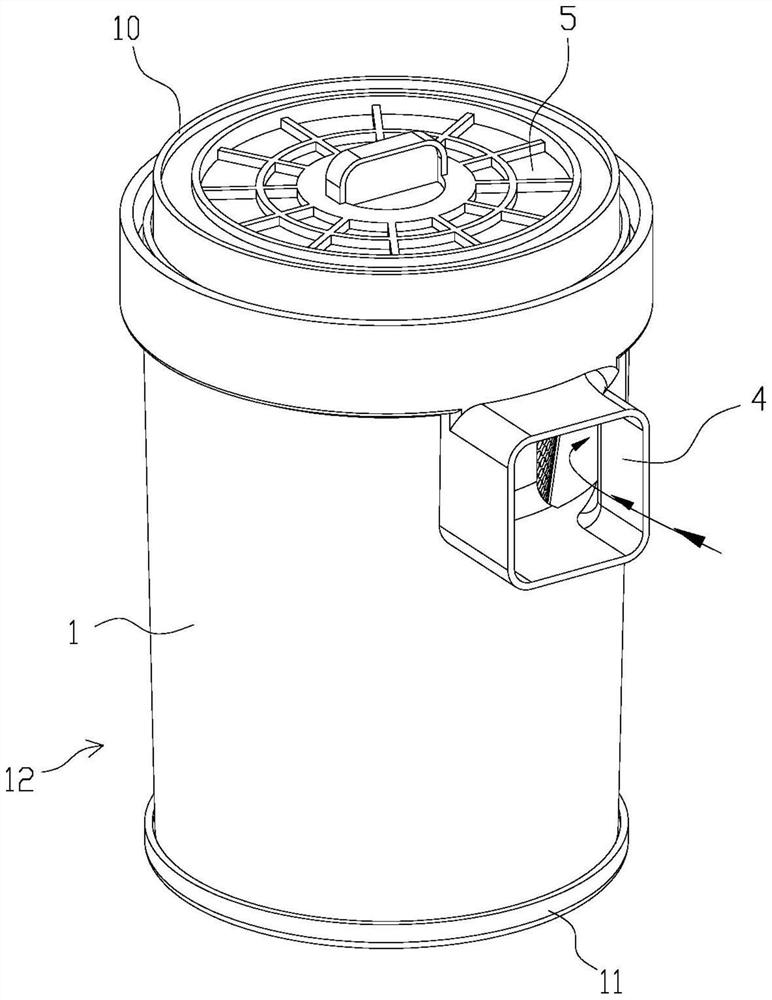

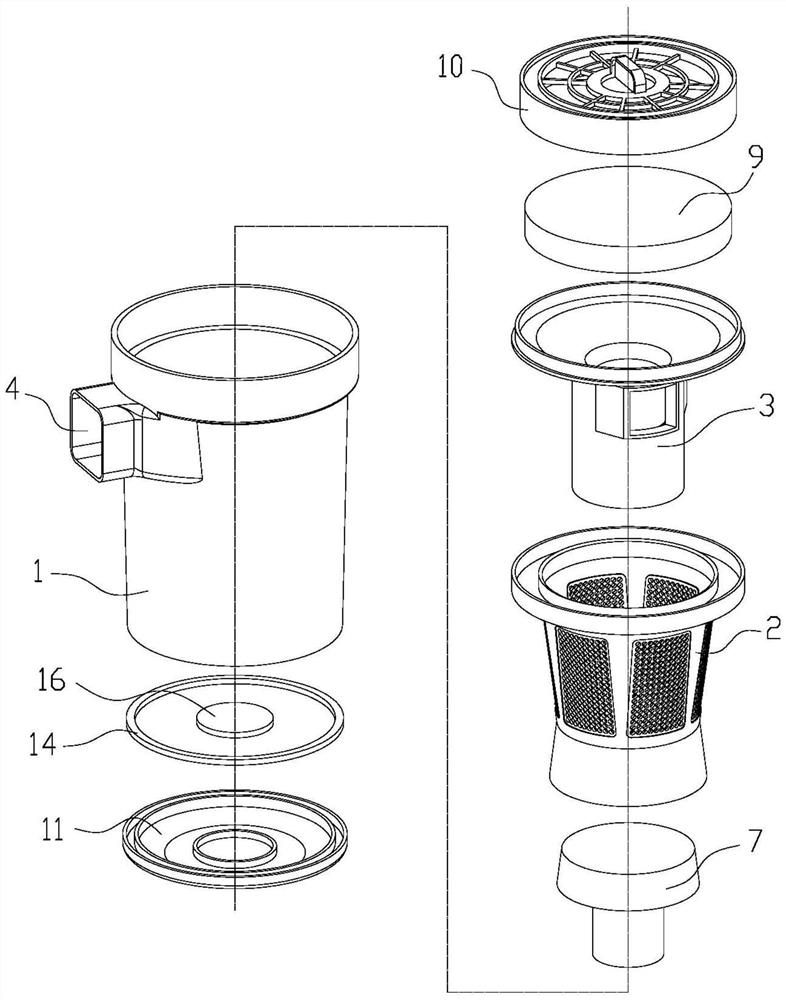

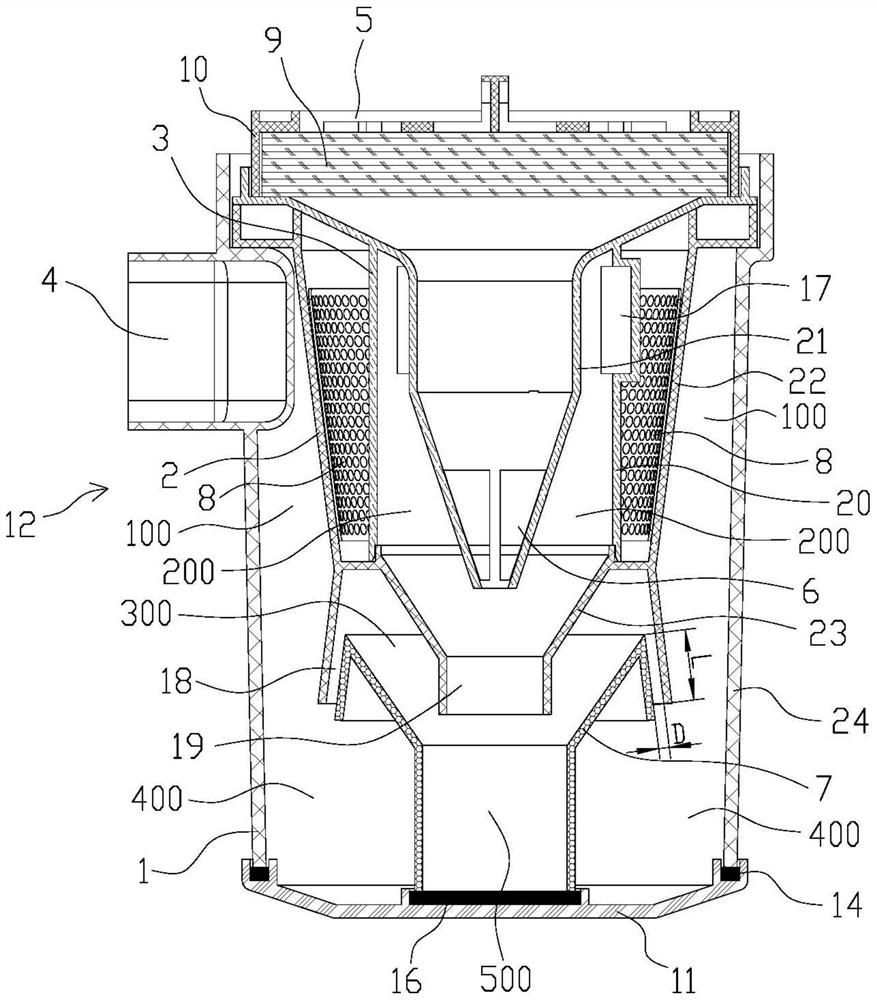

A multi-stage cyclone separation dust collection device and vacuum cleaner

ActiveCN110811421BIncrease the lengthAvoid Situations That Impair SeparationSuction filtersCyclonic separationEngineering

The invention discloses a multistage cyclone separation dust collection device which comprises a dust collection cup; a first-stage cyclone channel and a second-stage cyclone channel are arranged in the dust collection cup, the first-stage cyclone channel and the second-stage cyclone channel communicate through a second-stage separation inlet, and the second-stage cyclone channel and a clean air outlet communicate through a second-stage separation outlet; a third-stage cyclone channel is further arranged in the dust collection cup, the first-stage cyclone channel and the third-stage cyclone channel communicate through a third-stage separation inlet, and the third-stage cyclone channel and the second-stage cyclone channel communicate through a third-stage separation outlet; and air in the first-stage cyclone channel is subjected to three times of direction change in the process of entering the second-stage cyclone channel through the three-stage separation inlet, the third-stage cyclonechannel and the third-stage separation outlet. A new separation path is added on the basis of an original separation path; and on one hand, the situation that the separation effect is weakened due toblockage of the original separation path is avoided, and on the other hand, the separation path length in the whole separation process is increased by the new separation path, so that the separationprocess is completer.

Owner:SUMEC HARDWARE & TOOLS

Large-scale livestock breeding anaerobic reaction tank

ActiveCN104761053BFully Anaerobic Fermentation ReactionEfficient separationBiological treatment apparatusWaste water treatment from animal husbandryEngineeringHeight difference

Owner:MUYUAN FOODS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com