A suction type pneumatic conveying equipment

A pneumatic conveying and equipment technology, which is applied in the field of suction pneumatic conveying equipment, can solve the problems such as inability to separate materials, achieve fast separation speed, complete separation effect, and increase separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

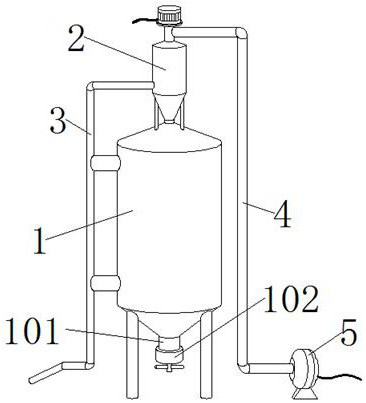

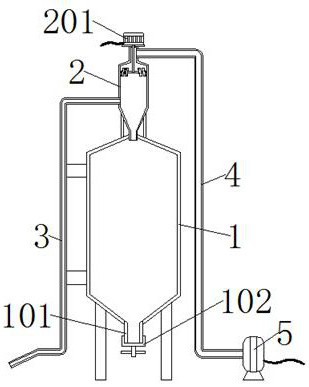

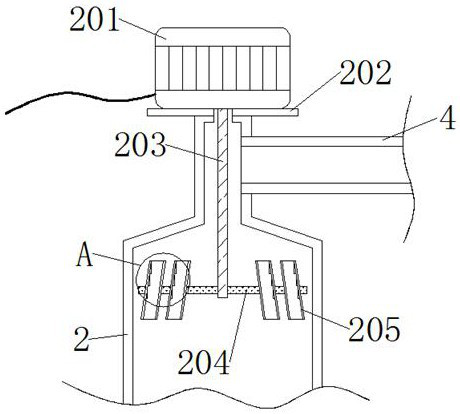

[0027] see Figures 1 to 8 Among them, in the embodiment of the present invention, a suction-type pneumatic conveying equipment includes a storage cylinder 1, a conveying pipe 3, an air pipe 4, a fan 5 and a separation cylinder 2. The top of the storage cylinder 1 is embedded with a separation cylinder 2, and the separation cylinder One side of the 2 is embedded and welded with a conveying pipe 3, and the other side of the conveying pipe 3 is embedded and welded with an air pipe 4. One end of the air pipe 4 is embedded and welded in the fan 5, and the bottom of the storage cylinder 1 is embedded and welded with a discharge pipe 101. The bottom of the pipe 101 is threaded with a threaded cover 102, and one side of the delivery pipe 3 is welded with the storage cylinder 1 through a pole; Strut 2010, bearing 2011, rotating bolt 2012, fixed rod 2013, curved surface playing plate 2014, bump 2015, curved plate 208 and rubber strip 209, the top welding of separating cylinder 2 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com