Cutting and crushing method used for flexible-package power lithium battery

A crushing method, lithium battery technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve problems not specifically related to shearing and crushing methods, so as to save batch processing time, reduce dissolution, and improve extraction purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Such as figure 1 , The mechanical cutting equipment 1 is a manual all stainless steel knife mechanical cutting equipment, the blade 2 is about 1 meter long, close to both sides of the knife wall, four air guide pipes 3 are arranged on each side, and the inert gas is output by the gas supply device 4 . The battery is crushed according to the following steps: ① Manually rotate the turntable 5 to lift the blade, start the gas supply device 4, introduce inert gas nitrogen, and the gas output pressure is controlled at 500kPa; ②After 10 minutes of nitrogen output, manually rotate the turntable 5 to drop the blade, cut A soft-packed ternary power lithium battery is bonded on both sides, peel off the shell, and take out the battery core; ③ Manually rotate the turntable 5 to lift the blade 2, and slowly push it in parallel for 1 cm along one side of the battery cell, and manually rotate the turntable 5 Drop the blade, cut, and cut the battery into 1cm-wide rectangular strips. Co...

Embodiment 2

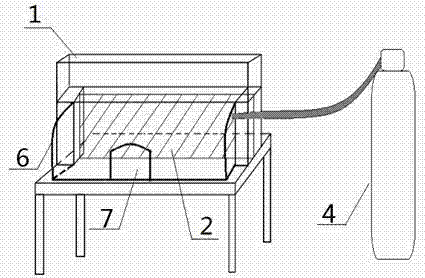

[0022] Such as figure 2 , the mechanical cutting equipment 1 is an automatic mechanical cutting equipment, equipped with a blade 2, the blade 2 is an inlaid alloy steel knife, and the protective cover 6 is set on both sides of the blade 2, and three lithium iron phosphate soft pack batteries are put in through the opening 7, neatly stack. Break the battery according to the following steps: ①Start the automatic mechanical cutting equipment and gas supply device 4, introduce inert gas argon, and control the gas output pressure at 5000kPa; At the bonding place, peel off the outer shell separately, take out the battery core, and stack them neatly again; ③The three battery cores are neatly stacked, and slowly advance in parallel along one side of the battery core, and cut each time 8cm, and cut the battery into 8cm wide Rectangular strips, keep the original shape of the battery core during the advancing process, and the rectangular strips will not be scattered; ④ Replace the batt...

Embodiment 3

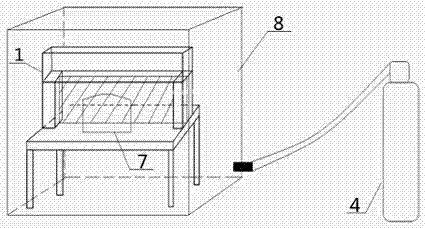

[0024] Such as image 3 , the mechanical cutting equipment 1 is an automatic mechanical cutting equipment, the automatic mechanical cutting equipment is put into the isolation room 8 as a whole, and the inert gas is supplied to the isolation room 8 by the gas supply device 4 . The battery is crushed according to the following steps: ①Start the mechanical cutting equipment 1 and the gas supply device 4, introduce the inert gas helium, and control the gas output pressure at 10000kPa; , put it through the opening 7, stack it neatly, start to cut off the joints on the adjacent two sides of the six lithium manganese oxide soft pack batteries, peel off the shells respectively, take out the battery cores, and stack them neatly again; ③ Along one side of the battery cores, Slowly advance in parallel, and cut the battery into 15cm-wide rectangular strips every 15cm. During the advancing process, keep the original shape of the battery core and the strips will not be scattered; ④ Replace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com