A column valve for continuous chromatographic separation and purification apparatus and its application method

A technology of separation and purification and continuous chromatography, which is applied in the field of column valves of continuous chromatography separation and purification instruments, can solve the problems of complex composition of continuous chromatography separation and purification equipment, ineffective improvement of production efficiency, and low efficiency of packing utilization. The principle is clear, batch processing time is saved, and the effect of sample penetration is avoided

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

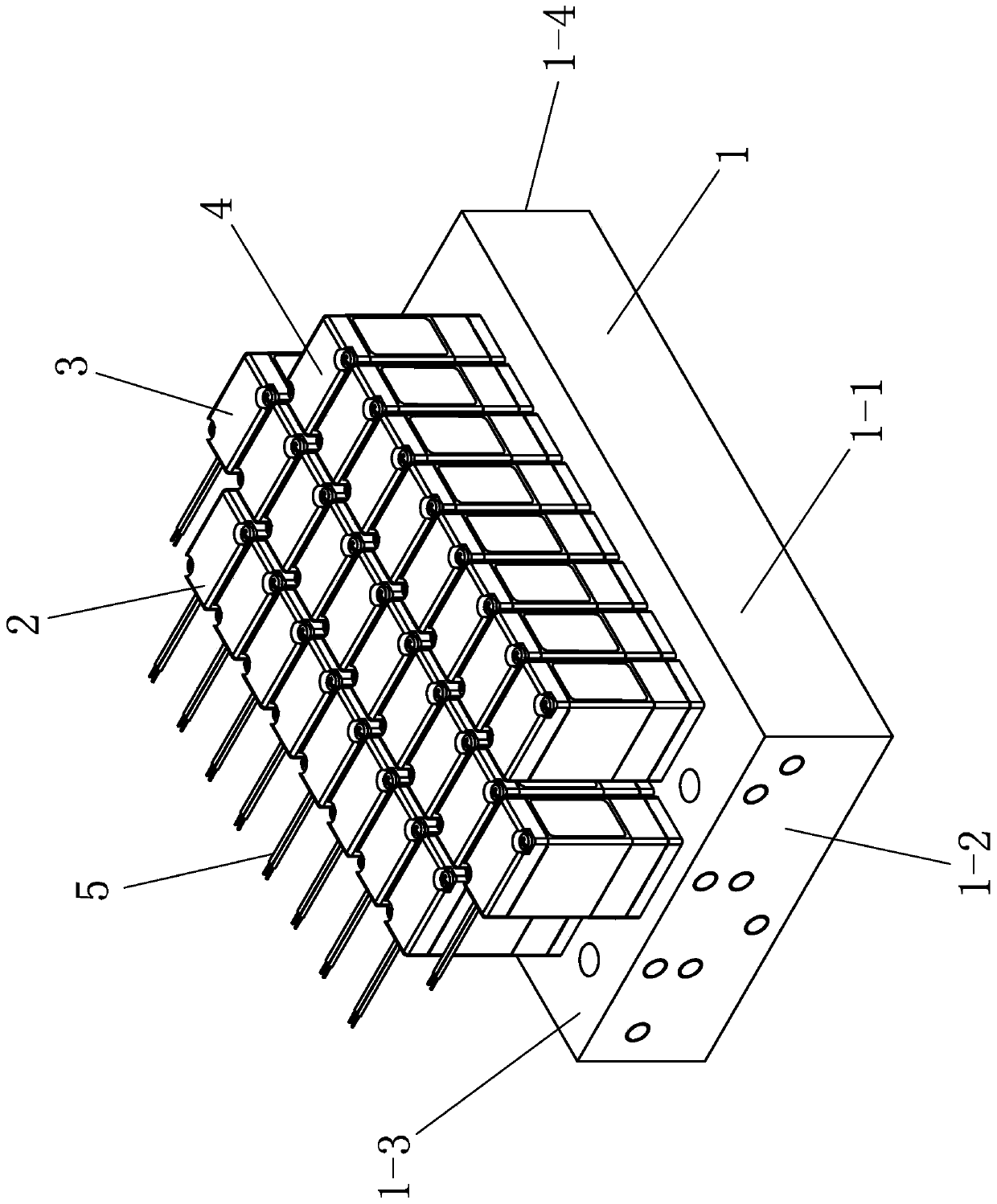

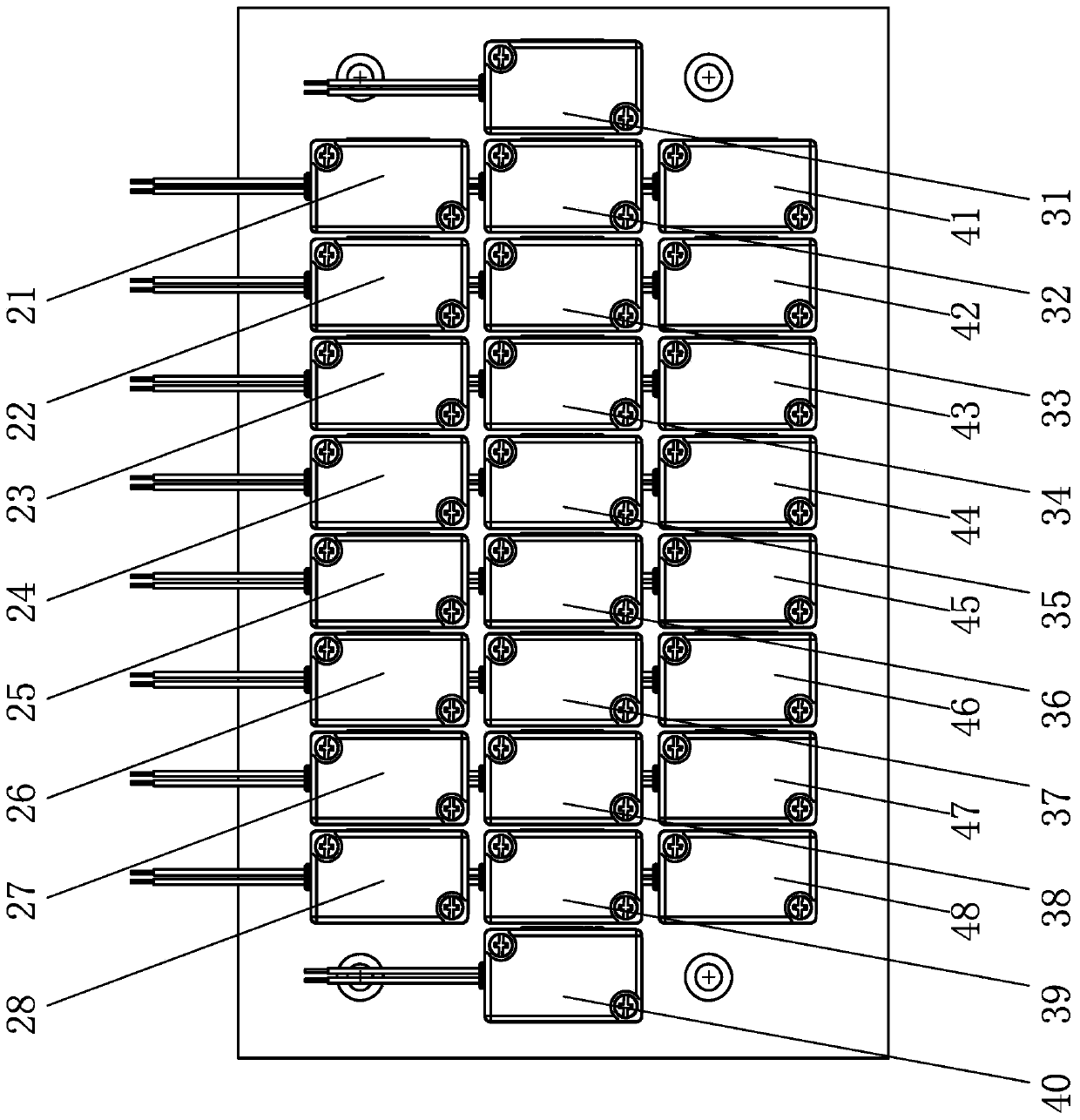

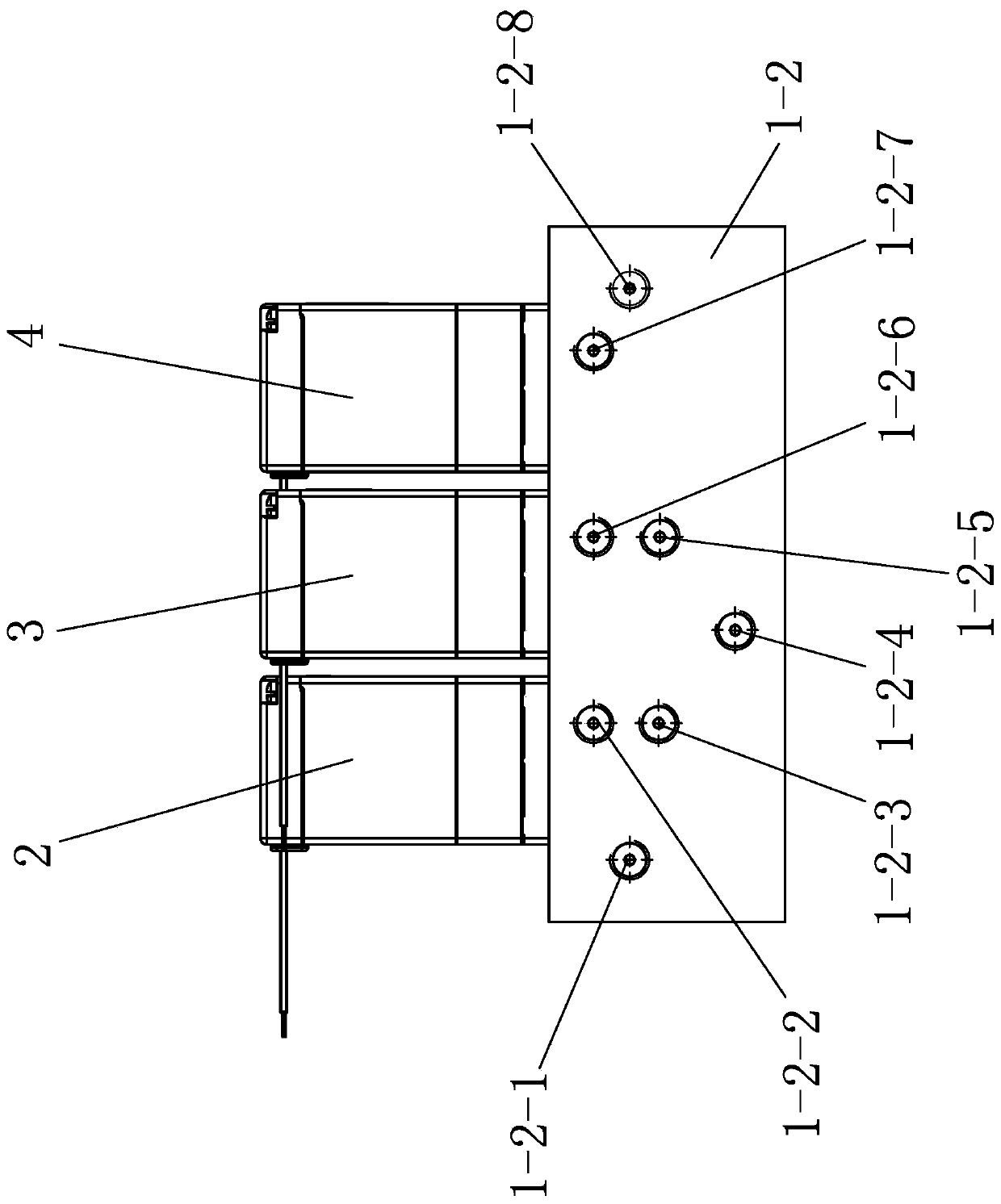

[0062] The present invention will be further described below in conjunction with accompanying drawing:

[0063] Such as Figure 1-4 As shown, a column valve for a continuous chromatographic separation and purification instrument includes a valve plate base 1, and a sampling pump, an elution pump, a chromatography column 1, a chromatography column 2, and Chromatography column 3 and chromatography column 4; 26 two-position two-way solenoid valves with the same structure are arranged on the top valve plate 1-3 of the valve plate base 1, and 26 two-position two-way solenoid valves constitute the front row solenoid valve group 2. The middle solenoid valve group 3 and the rear solenoid valve group 4; the front solenoid valve group 2 consists of solenoid valve V5-1, solenoid valve V5-2, solenoid valve V5-3, solenoid valve V5-4, solenoid valve V3- 1. Solenoid valve V3-2, solenoid valve V3-3 and solenoid valve V3-4 are composed; the middle solenoid valve group is composed of solenoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com