Communicating type electrolytic lead smelting pot and using method thereof

A lead melting and heating furnace technology, which is applied in the field of electrolytic lead, can solve problems such as limited furnace space, heat loss, and flame penetration, and achieve the effects of high safety, enlarged space, and effective use of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

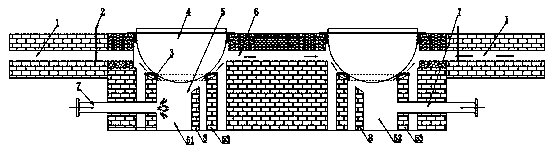

[0020] Embodiment one: by Figure 1 to Figure 2 Given, the connected electrolytic lead melting pot includes a heating furnace 5 and a lead melting pot 4 placed above the heating furnace, the heating furnace 5 is a furnace body with an upper opening, and the lead melting pot 4 is placed above the heating furnace 5 The opening of the heating furnace 5 includes a symmetrically placed first furnace body 51 and a second furnace body 52, and the first furnace body 51 and the second furnace body 52 are connected by a smoke pipe 6 Realize the interconnection between internal furnaces to form a connected boiler. The flame in the connected boiler circulates in the furnace of the first furnace body 51, the furnace connecting the smoke pipe 6 and the second furnace body 52, and each of the heating The side of the furnace 5 away from the connecting smoke pipe 6 is provided with a smoke exhaust pipe 1 for exhausting the flue gas. Since the first furnace body 51 and the second furnace body 5...

Embodiment 2

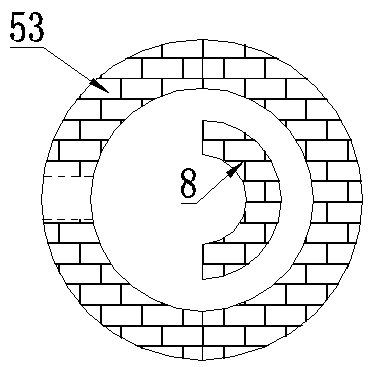

[0021] Embodiment 2: On the basis of Embodiment 1, the heating furnace 5 includes an outer furnace wall and an inner retaining wall, the outer furnace wall 53 is in the shape of a hollow cylinder, and the inner retaining wall 8 is smaller in diameter than the outer furnace wall A semi-circular arc-shaped wall with a diameter, the inner retaining wall 8 is located in the outer furnace wall to form an annular space for flue gas circulation, the combustion gun passes through the outer furnace wall, and the flame hits the annular inner retaining wall on the inner ring The curved surface is sunken inward, and returns to the direction close to the combustion gun under the action of the curved surface. The inner retaining wall 8 is lower than the outer furnace wall 53 and forms a smoke supply between the lead melting pot and the outer furnace wall. The gaps for air flow, thereby increasing the path of the flame of the combustion gun in the furnace, and fully utilizing the heat energy....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com