Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Strengthen link" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and Methods To Improve The Efficiencies Of Immunization Registries

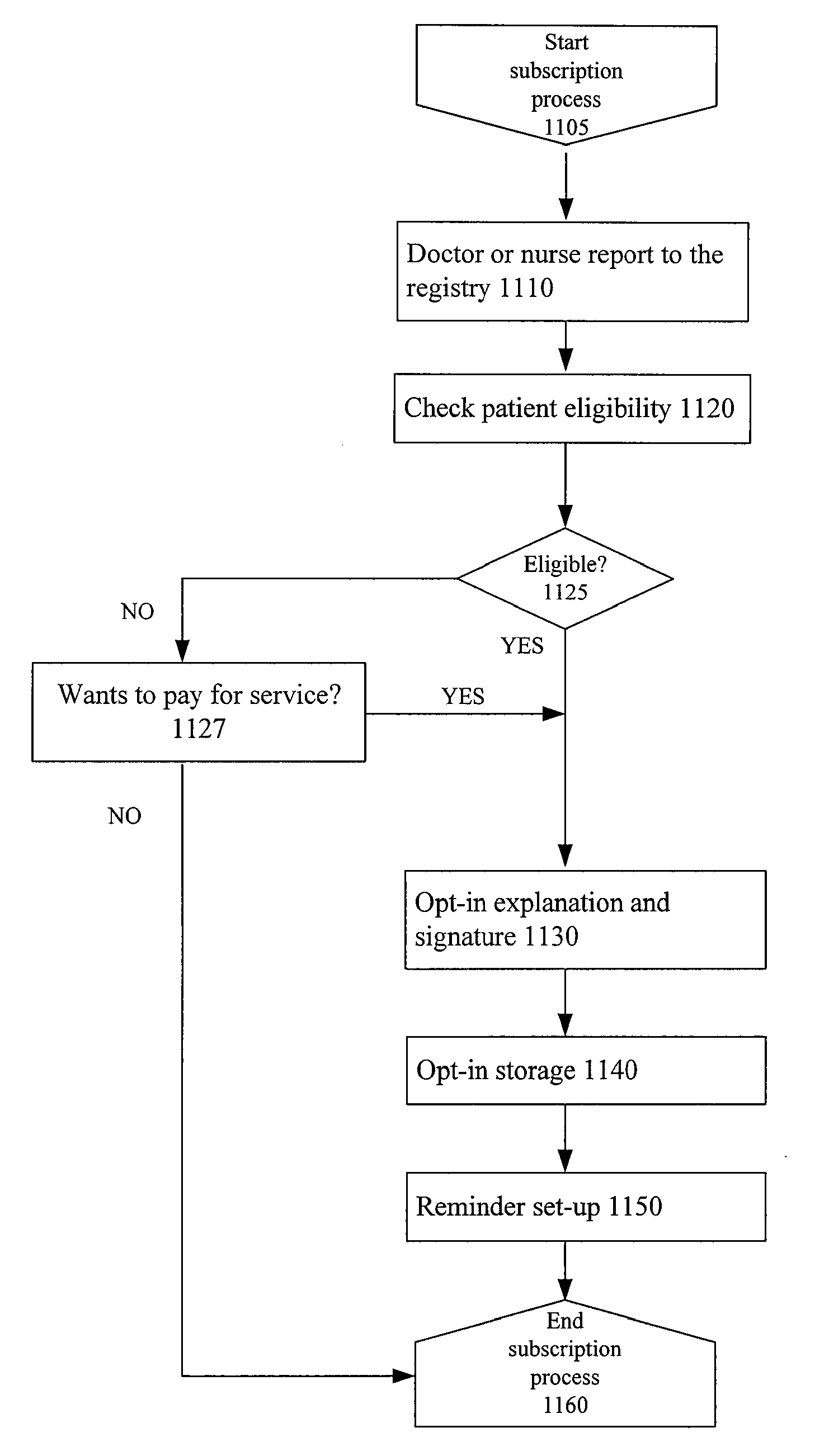

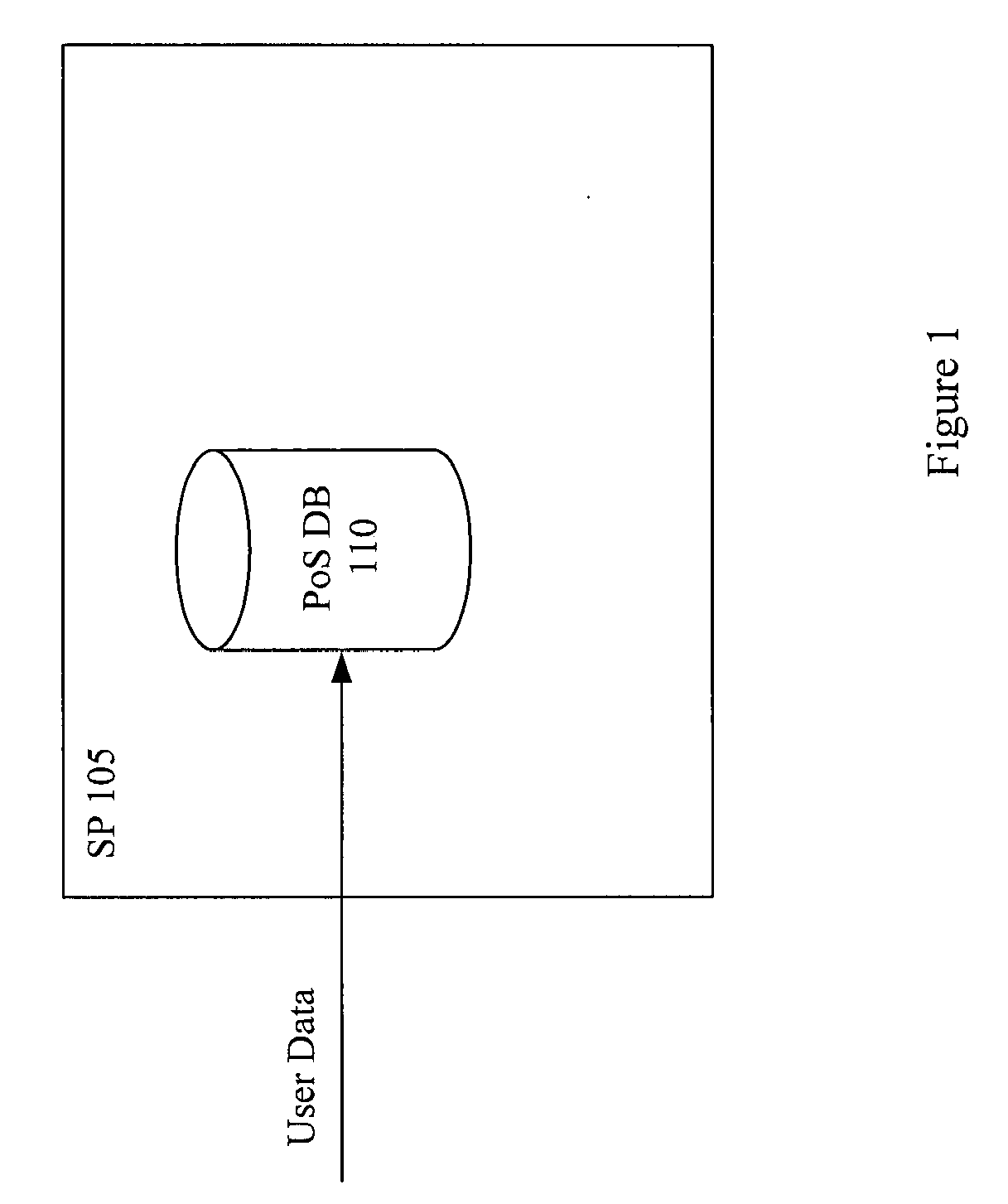

InactiveUS20080177574A1Value maximizationStrengthen linkData processing applicationsComputer-assisted medical data acquisitionPaymentCaregiver person

Systems and methods are provided for setting up and sending healthcare alerts (e.g. immunization reminders) to patients / caregivers through the use of communications devices. In an embodiment, information about a patient's / caregiver's wireless device (e.g. cell phones) is collected and reported to an immunization registry. The registry is linked to a system that uses the wireless device information to generate automatic wireless immunization reminders, recalls and educational messages that are sent to the patient / caregiver. In a preferred embodiment, opt-in information is reported to the system to ensure that the patient / caregiver has consented to the automatic wireless immunization reminders. The system may also check the eligibility of patients to receive reminders, provide incentives for patients to receive reminders, provide follow up information (e.g. performed, not performed, responses to message / s) to a healthcare provide for a particular patient or a group of patients, and / or provide billing services for payment of the reminders.

Owner:LARA GONZALEZ MARCOS +3

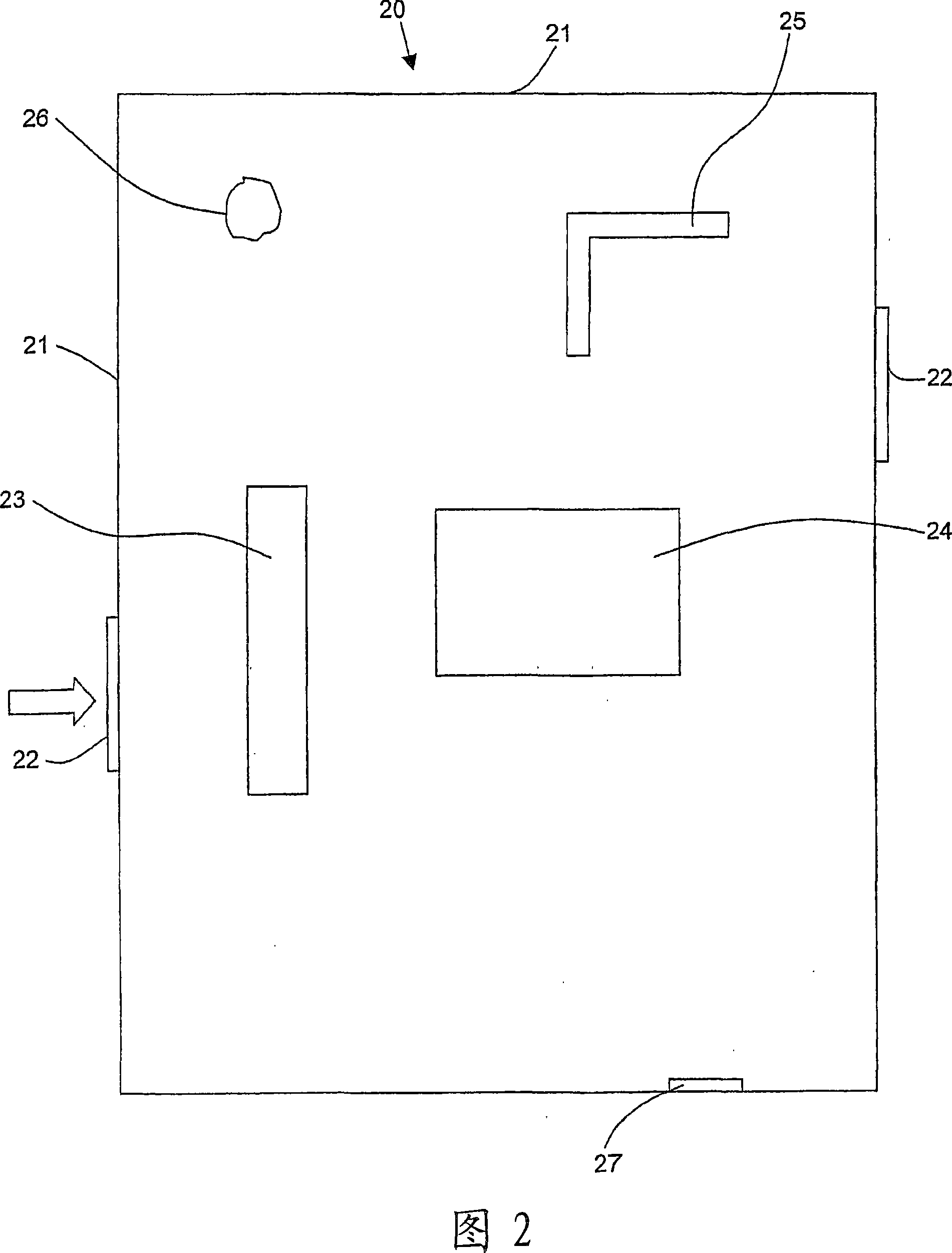

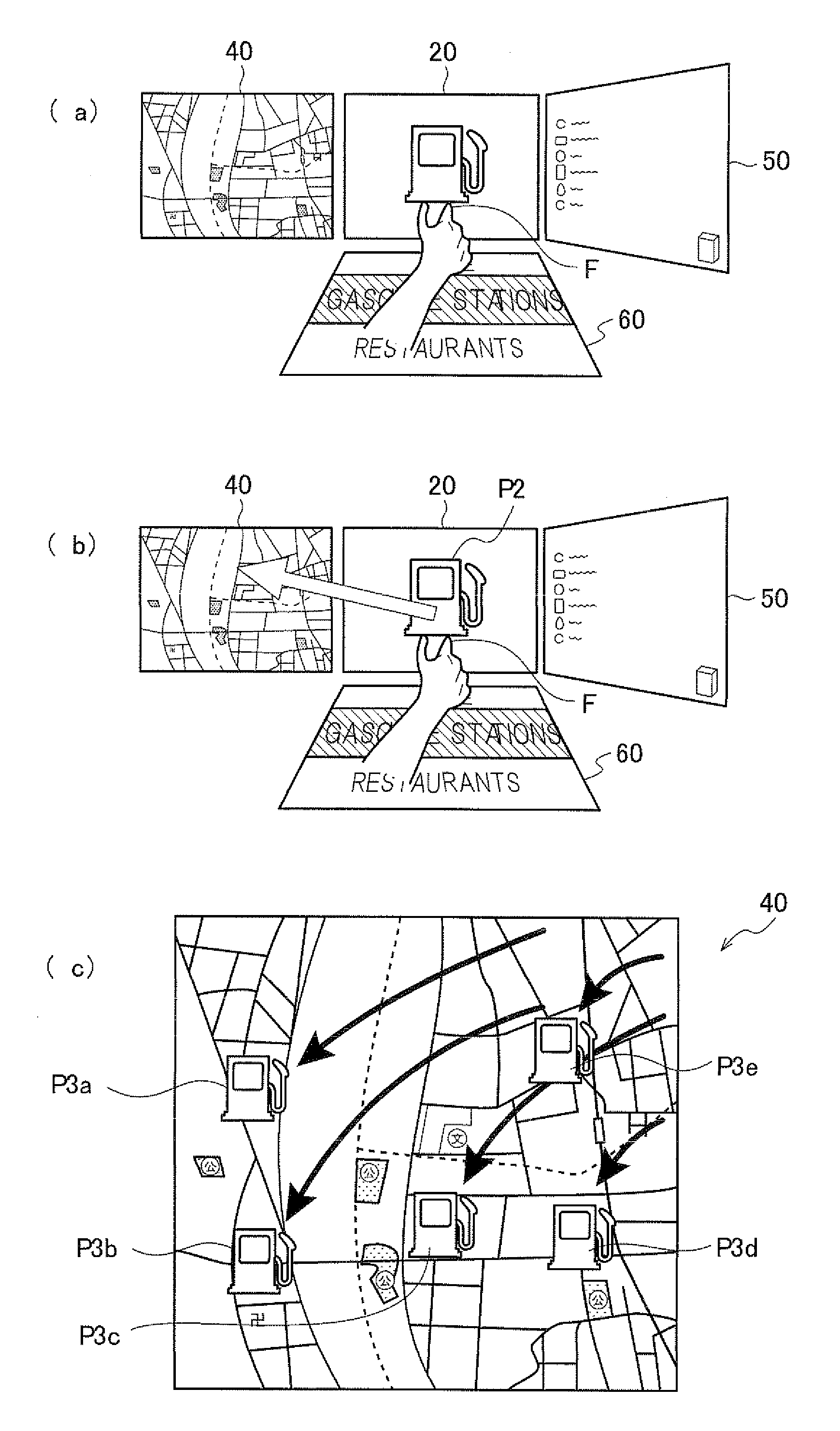

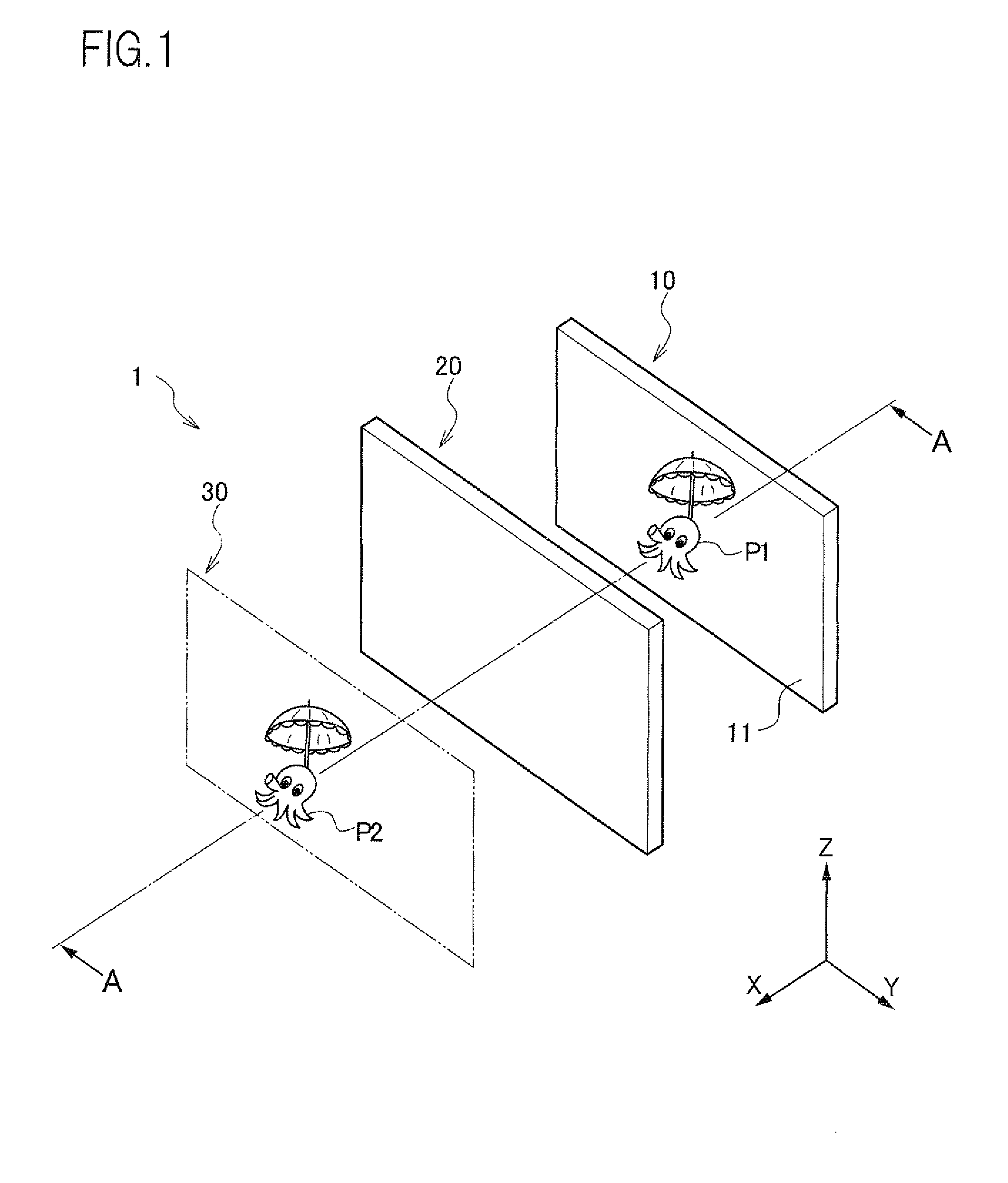

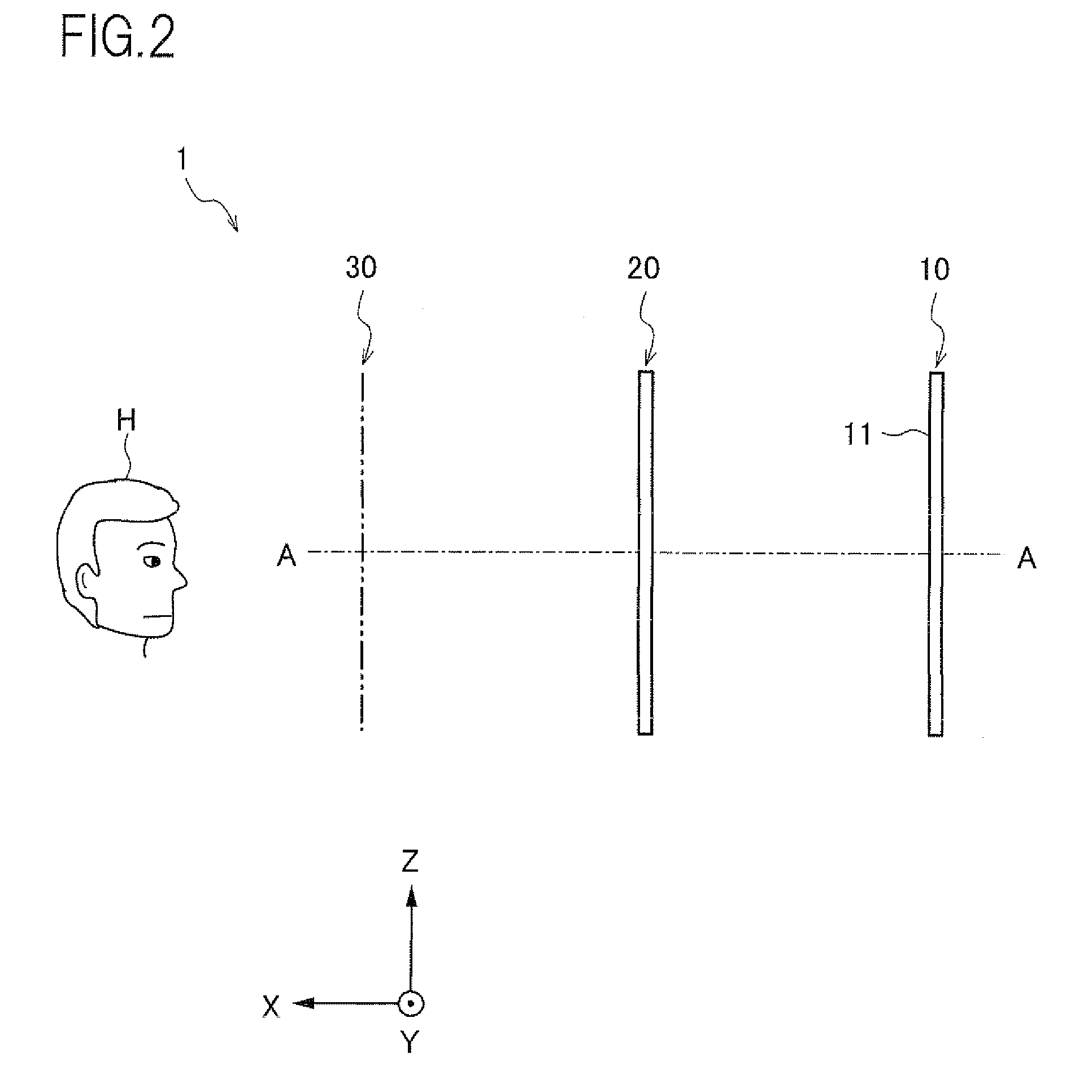

Image display device

InactiveUS20100245345A1Enhanced stereoscopic effectImprove visual effectsSteroscopic systemsInput/output processes for data processingComputer graphics (images)Image transfer

An image display device 100 includes: a display unit 10 having an image screen 11 for displaying a two-dimensional image; an image transfer panel 20 located on a path of light left from the image screen 11; a floating image display unit 1 that displays, as a floating image, the light left from the image screen 11 in a space located on one side of the image transfer panel 20 opposite to the other side thereof facing the display unit 10; a direct-view image display unit 2 provided with a display unit 40 having an image screen 41 for displaying a two-dimensional image displayed on the image screen 41 as a direct view image. The image display device carries out:floating-image control that displays the floating image P2 such that the given object displayed as the floating image P2 is shifted in a specified first direction from the displayed position of the floating image P2 to the image screen 41; anddirect-view image control that executes a process associated with the given object during or after the shift of the given object, and displays, on the image screen 41, a two-dimensional image on which the executed process is reflected.

Owner:ASUKANET

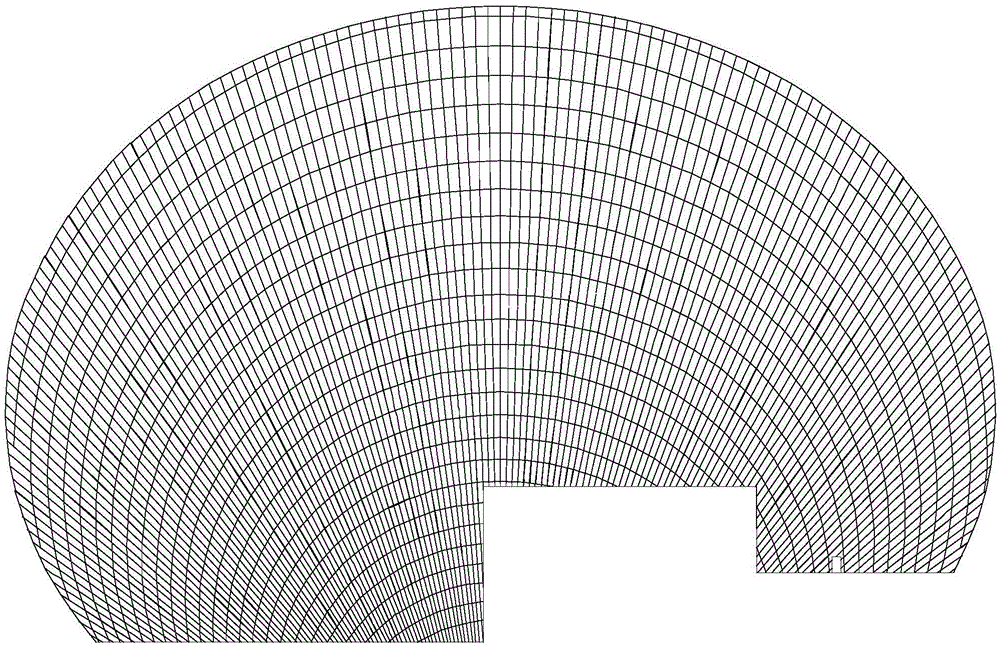

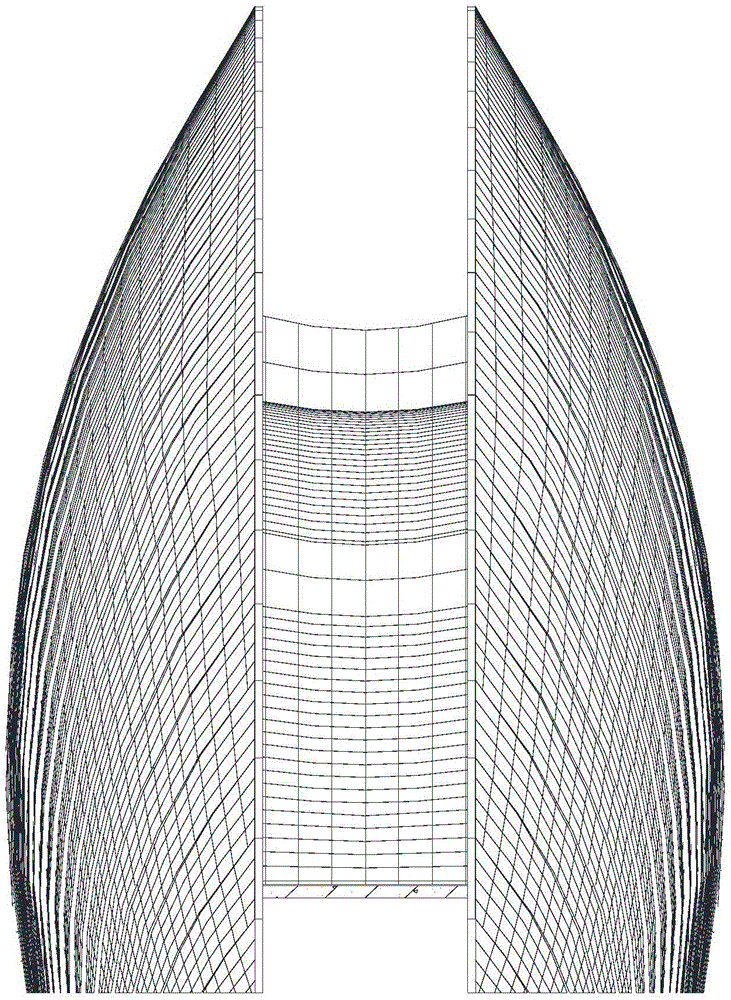

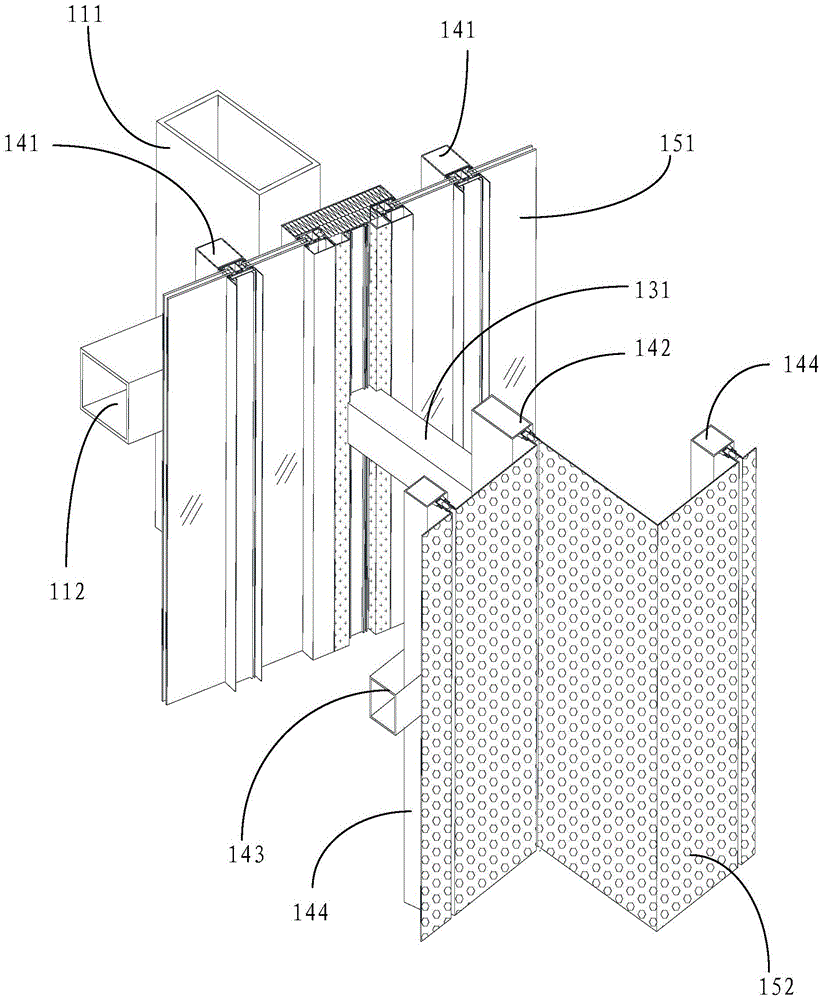

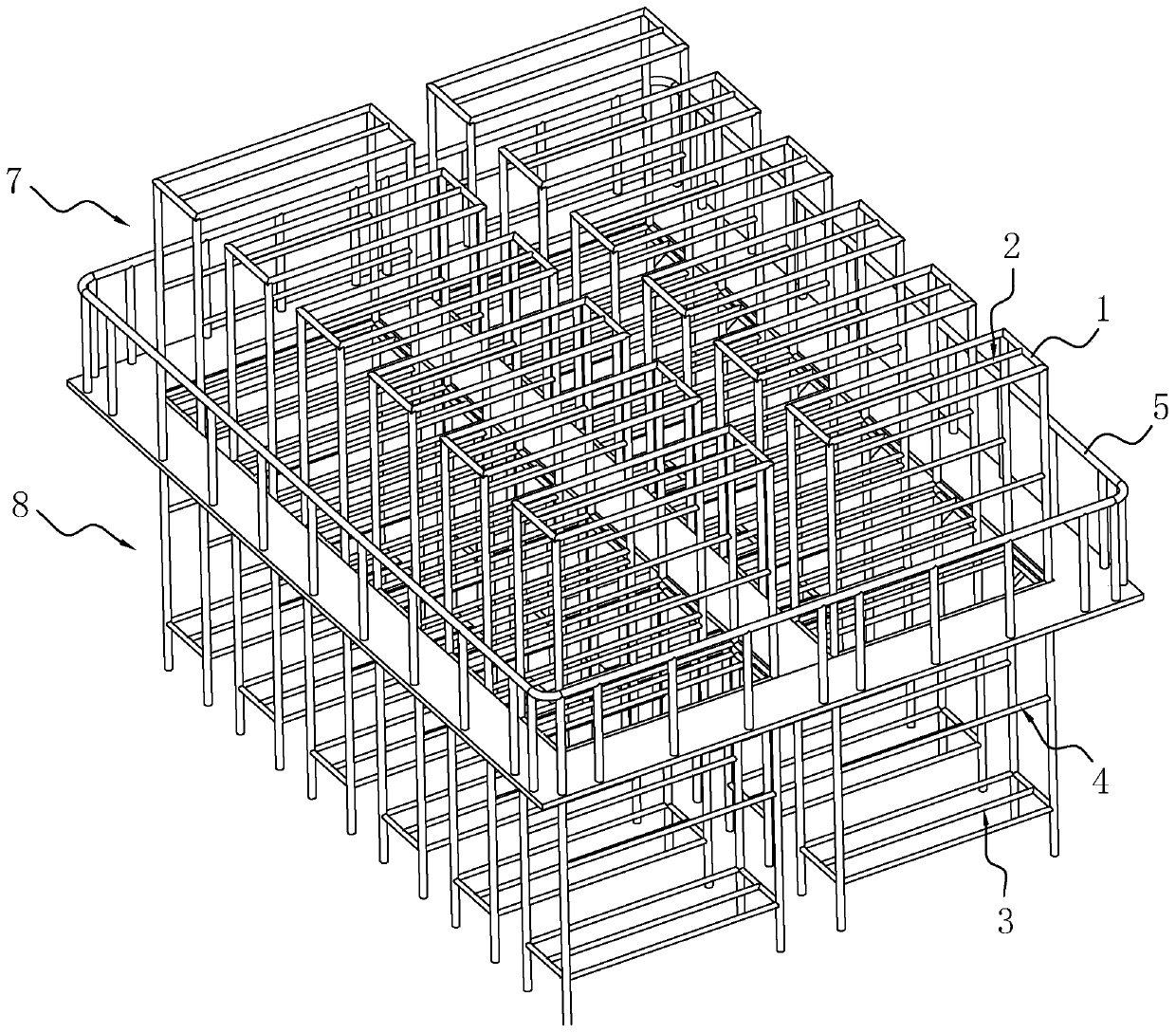

Construction method of large conchoidal hyperbolic curtain wall

The invention discloses a construction method of a large conchoidal hyperbolic curtain wall. The construction method comprises the following steps of mounting a scaffold support and a wall connecting piece on a conchoidal hyperbolic main structure; mounting a scaffold on the scaffold support and the wall connecting piece; mounting a bracket structure on the conchoidal hyperbolic main structure; mounting a first cambered keel frame on one side, which is close to the conchoidal hyperbolic main structure, of the bracket structure; mounting a second cambered keel frame on the other side, which is far away from the conchoidal hyperbolic main structure, of the bracket structure; mounting a first cambered curtain wall on the first cambered keel frame; and mounting a second cambered curtain wall on the second cambered keel frame. The scaffold is mounted by the scaffold support arranged on the conchoidal hyperbolic main structure, and can be supported by the conchoidal hyperbolic main structure, and connection between the scaffold and the conchoidal hyperbolic main structure is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

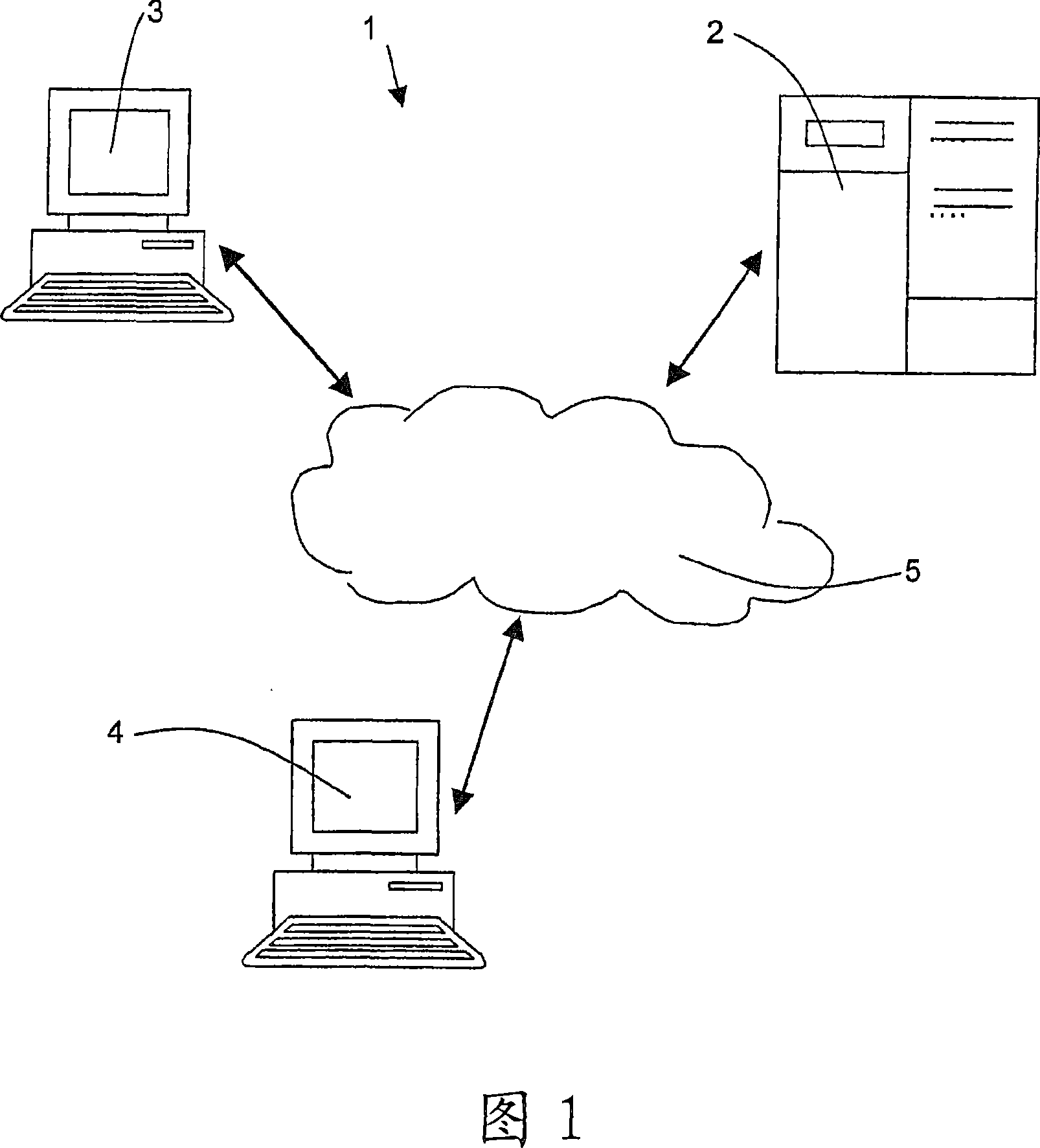

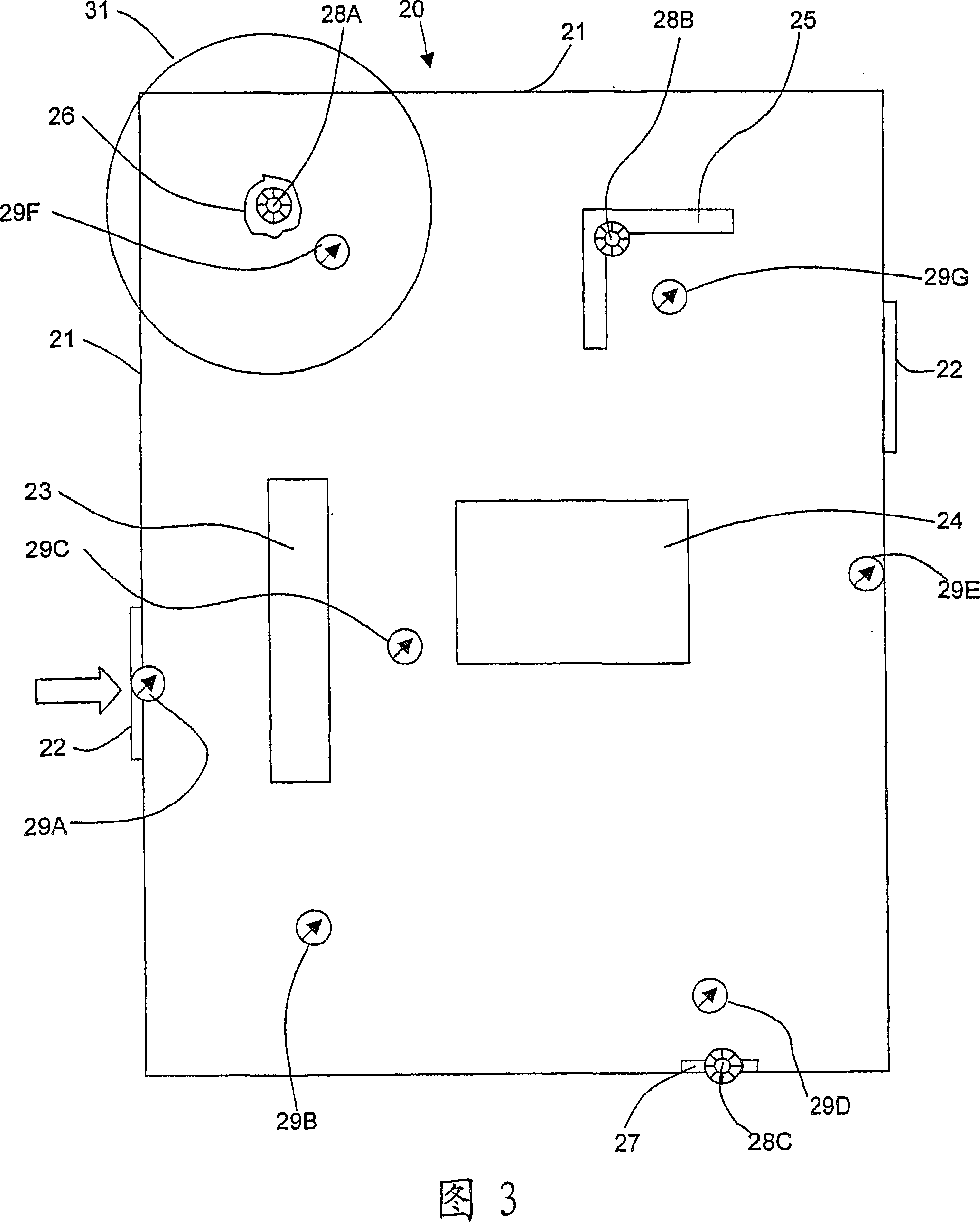

Pathfinding system

InactiveCN1938562AAuto increment quantityStrengthen linkInstruments for road network navigationReservationsDistributed computing

A method of generating a new path to a destination node (29G) in a virtual environment comprising a plurality of nodes (29A-G). The method comprises nodal information identifying one or more nodes associated with a previously created path to said destination node, dynamically reconfiguring the topology of the virtual environment to define a start node (29A) for said new path, and processing said stored nodal information to determine the new path to said destination (29G) by including at least one node of said previously created path.

Owner:BRITISH TELECOMM PLC

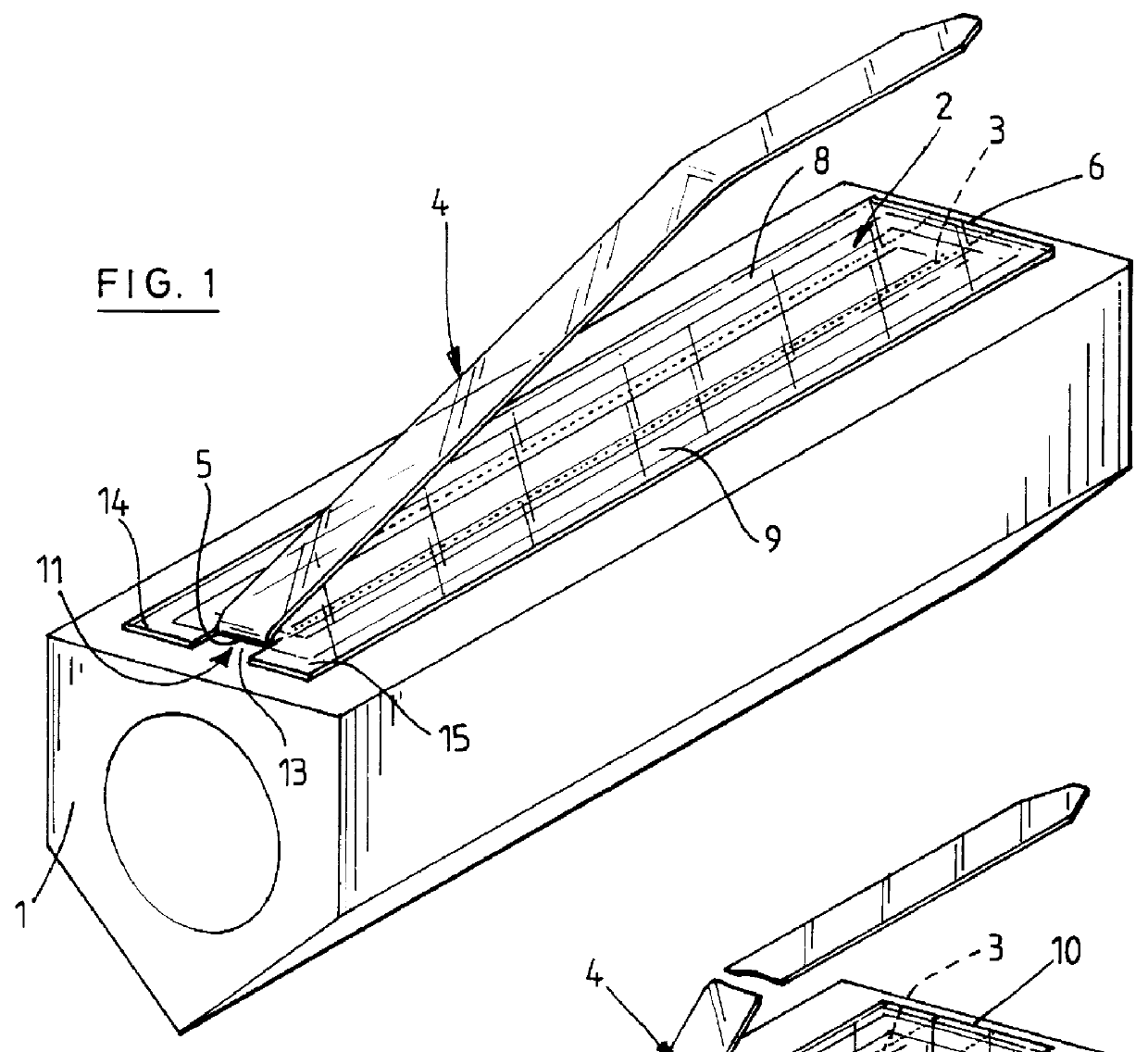

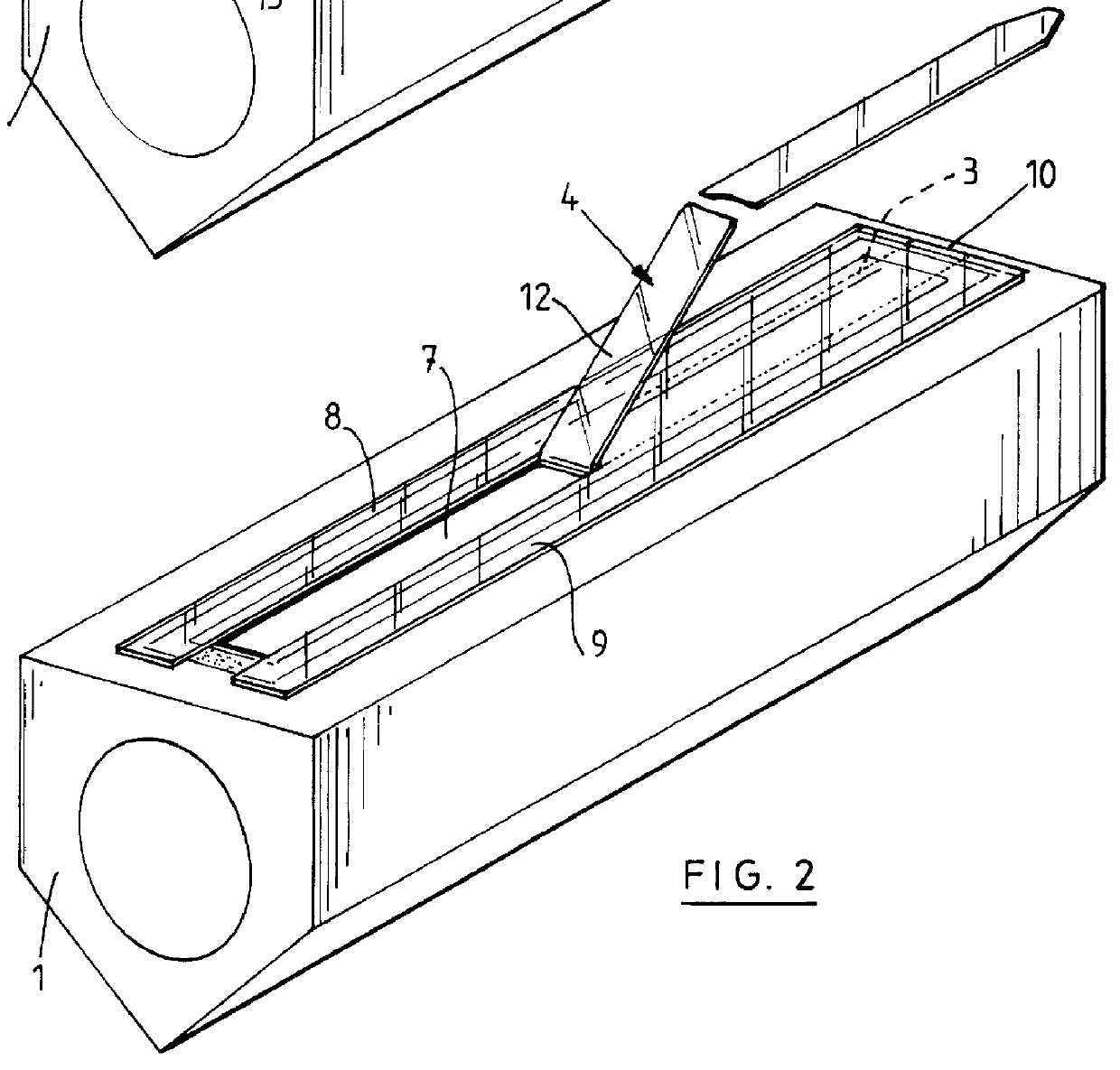

Seal for a toner cartridge assembly

InactiveUSRE36920E1Avoid lostAvoid lossElectrographic process apparatusEngineeringMechanical engineering

A seal for a toner cartridge assembly used in printers, copy machines and facsimile machines. The seal is a strip which can be torn out so as to define an opening for the passage of toner. The strip has a structure which lowers the tearing force required when starting to tear the strip with respect to the tearing force required for other parts of the seal, or the seal has a structure which increases the binding of parts of the seal adjacent to the strip on the cartridge.

Owner:BMT LIMITED

Flexible display device

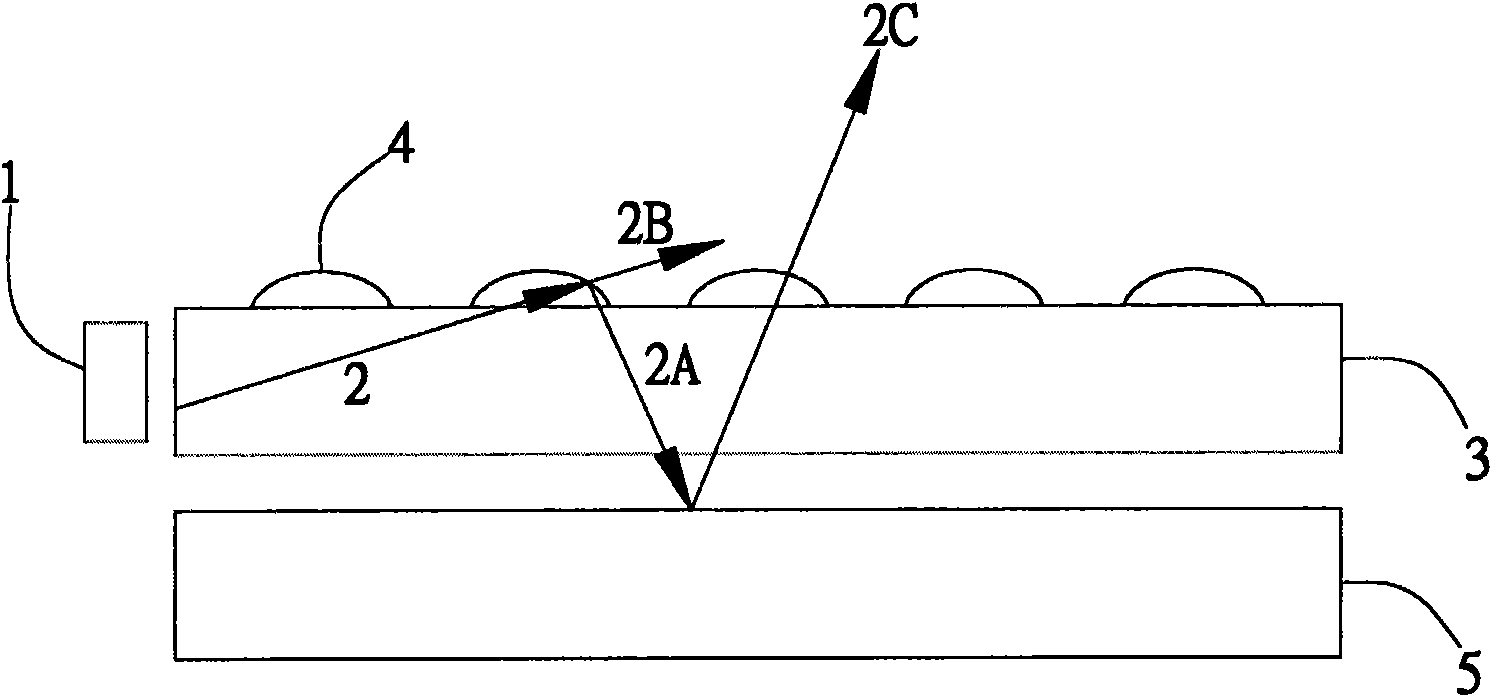

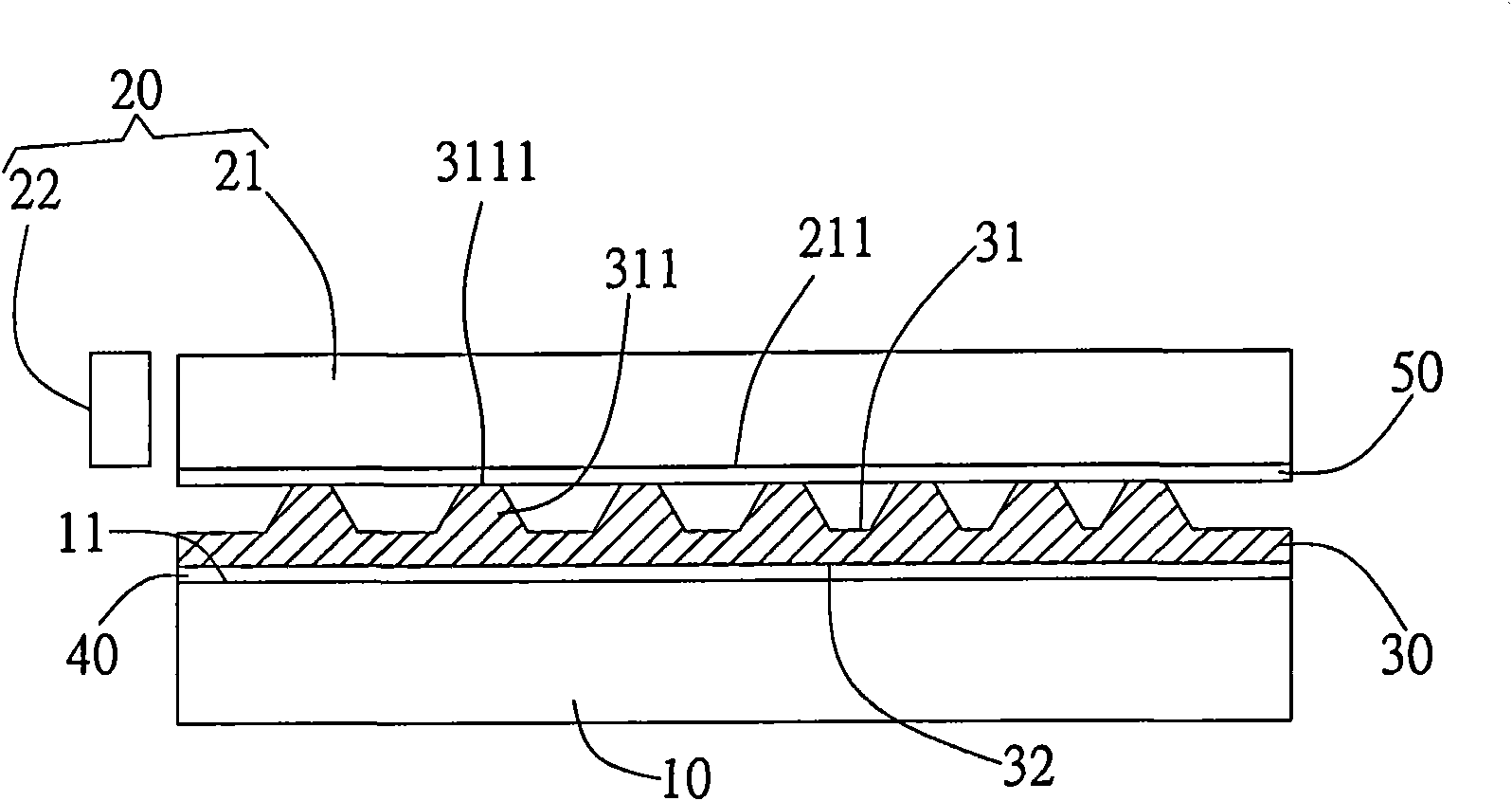

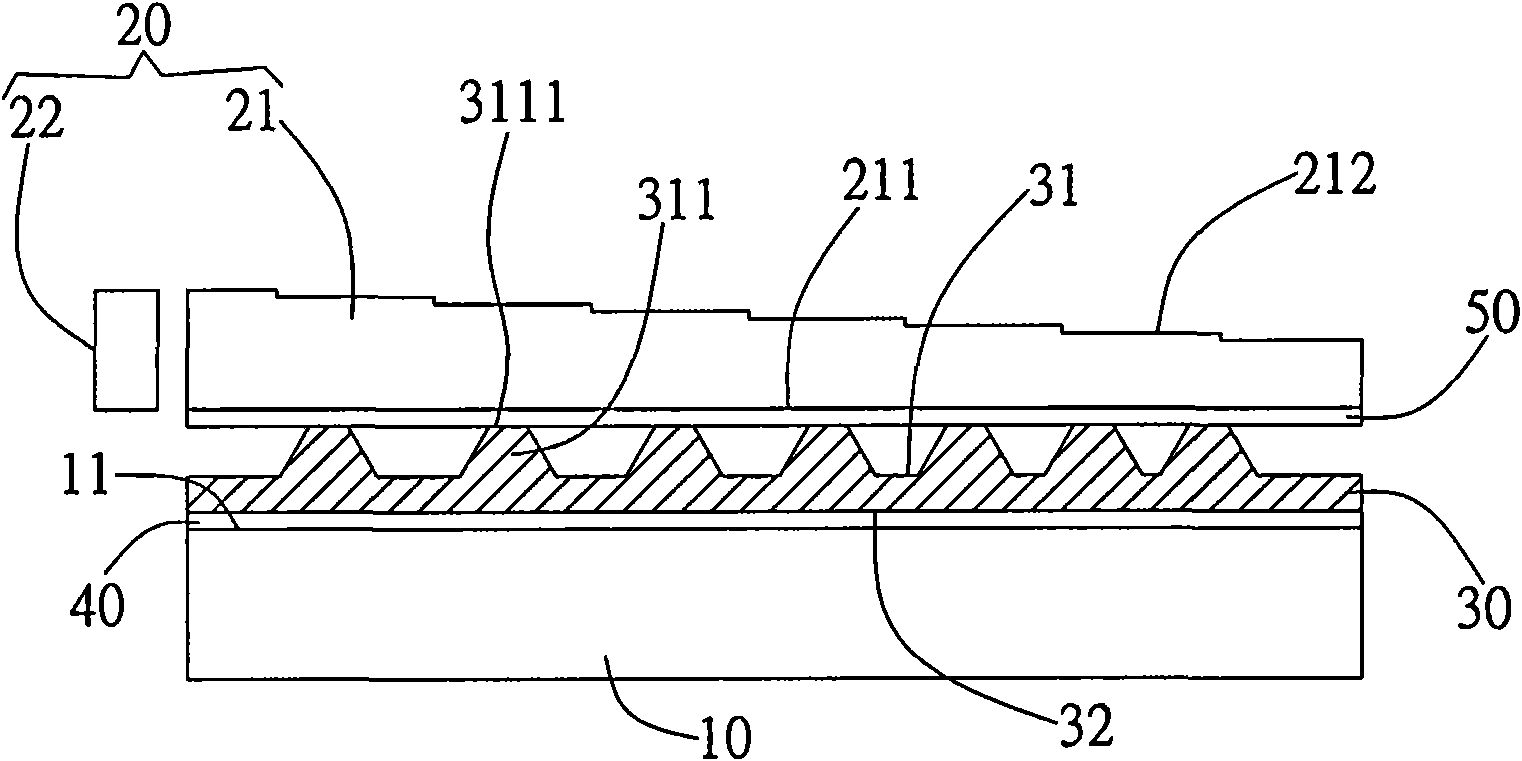

ActiveCN101598865AImprove flexibilityStrengthen linkMechanical apparatusStatic indicating devicesLight energyLight guide

The invention provides a flexible display device. The flexible display device comprises a display panel, a light source module and an optical structure film, wherein the display panel is provided with a light entering surface; the light source module and the display panel are parallelly arranged, and the light source module comprises a light guide plate with an light emitting surface; the light emitting surface faces the light entering surface, and light rays generated by the light source module are projected to the light entering surface from the light emitting surface; the optical structure film is arranged between the display panel and the light source module and is provided with a first surface and a second surface opposite to the first surface; a plurality of platform-shaped optical structures with platform top surfaces are formed on the first surface; and a first translucent glue layer and a second translucent glue layer are formed on the light entering surface and the light emitting surface respectively, the platform top surfaces are glued with one translucent glue, and the second surface is glued with the other translucent glue layer. The structure strengthens the joint between the display panel and the light source module, ensures the excellent flexibility of the whole display device, removes air gaps between the display panel and the light source module and improves the light energy utilization rate.

Owner:AU OPTRONICS CORP

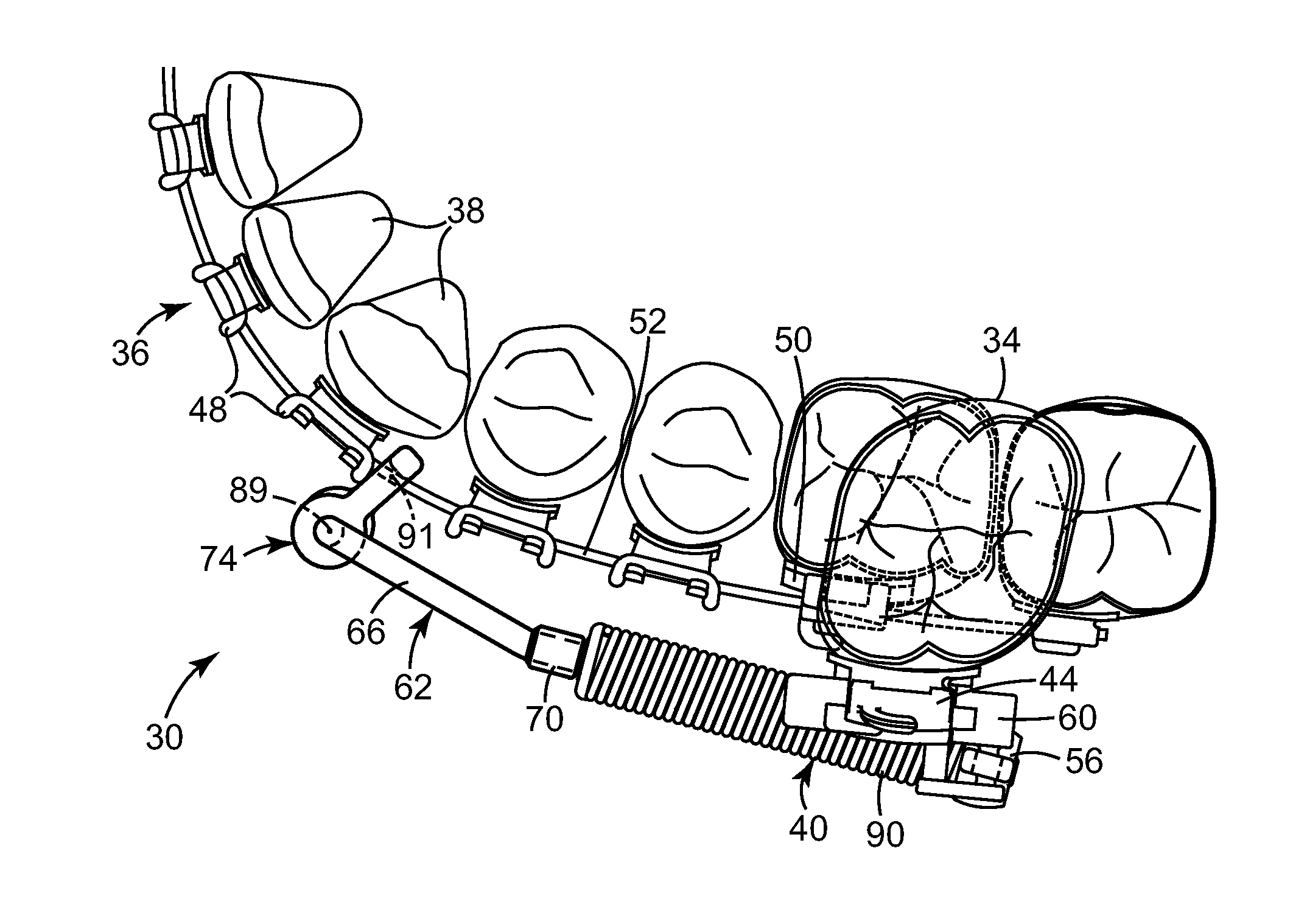

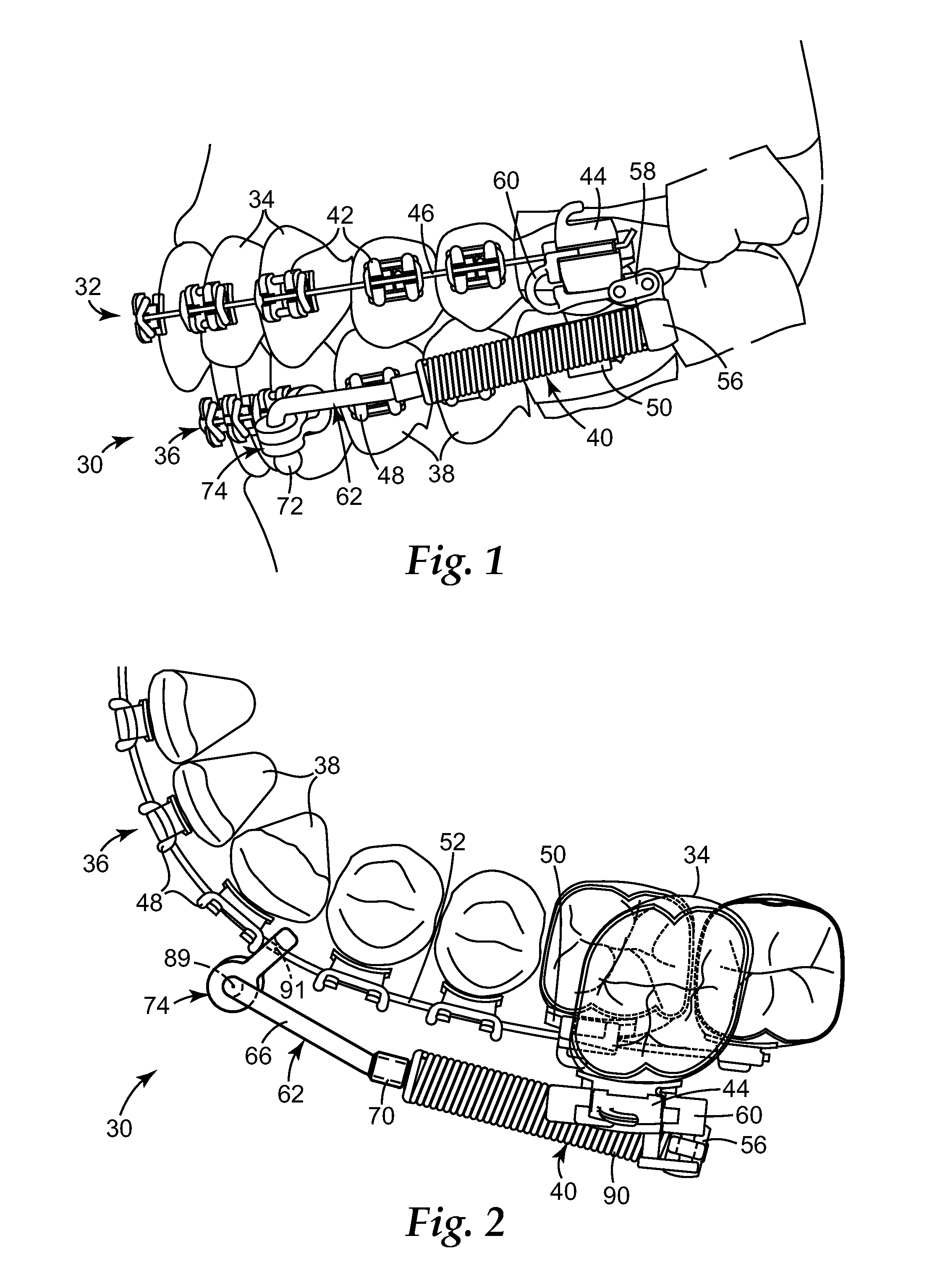

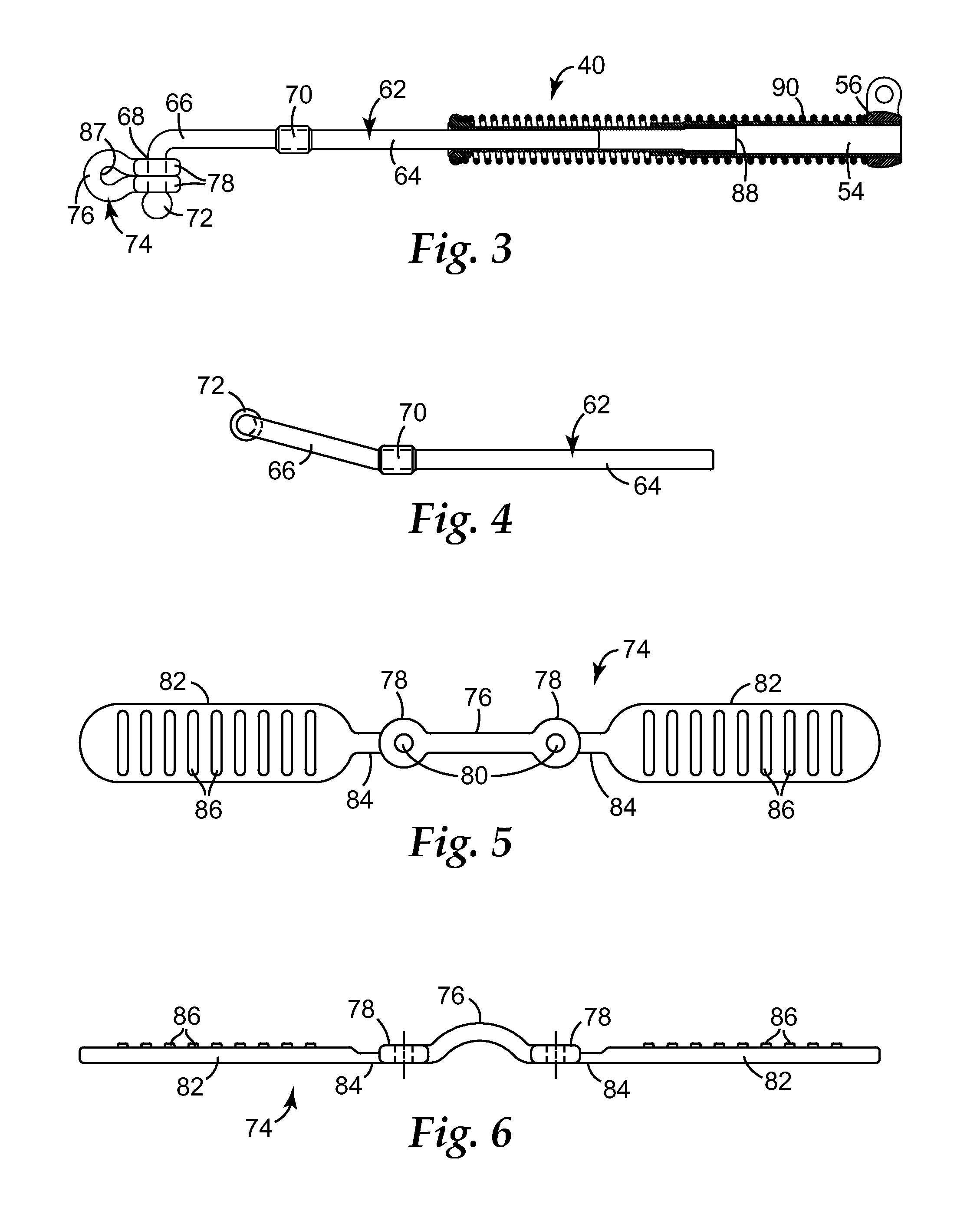

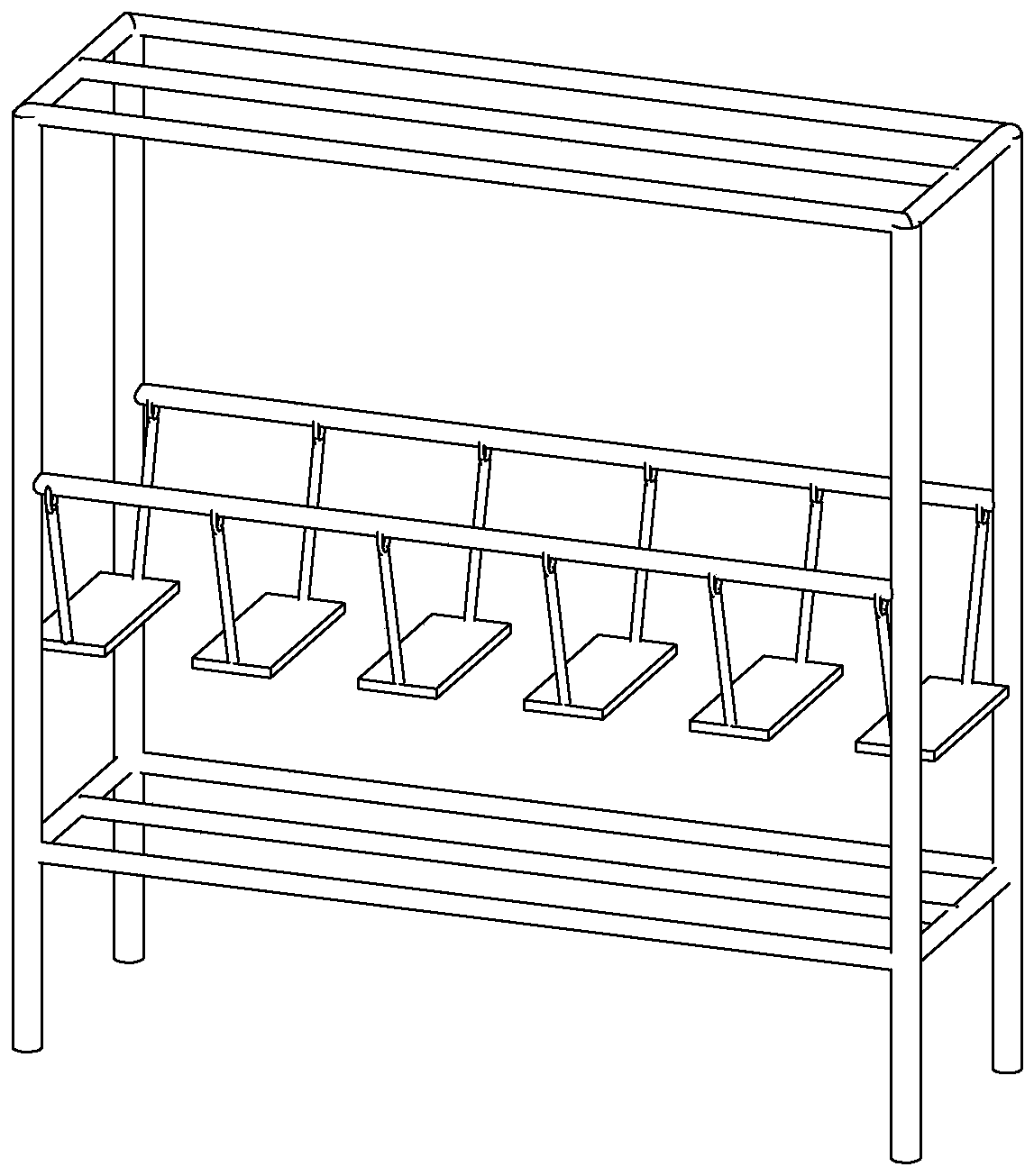

Interarch force module with link for orthodontic treatment

Owner:3M INNOVATIVE PROPERTIES CO

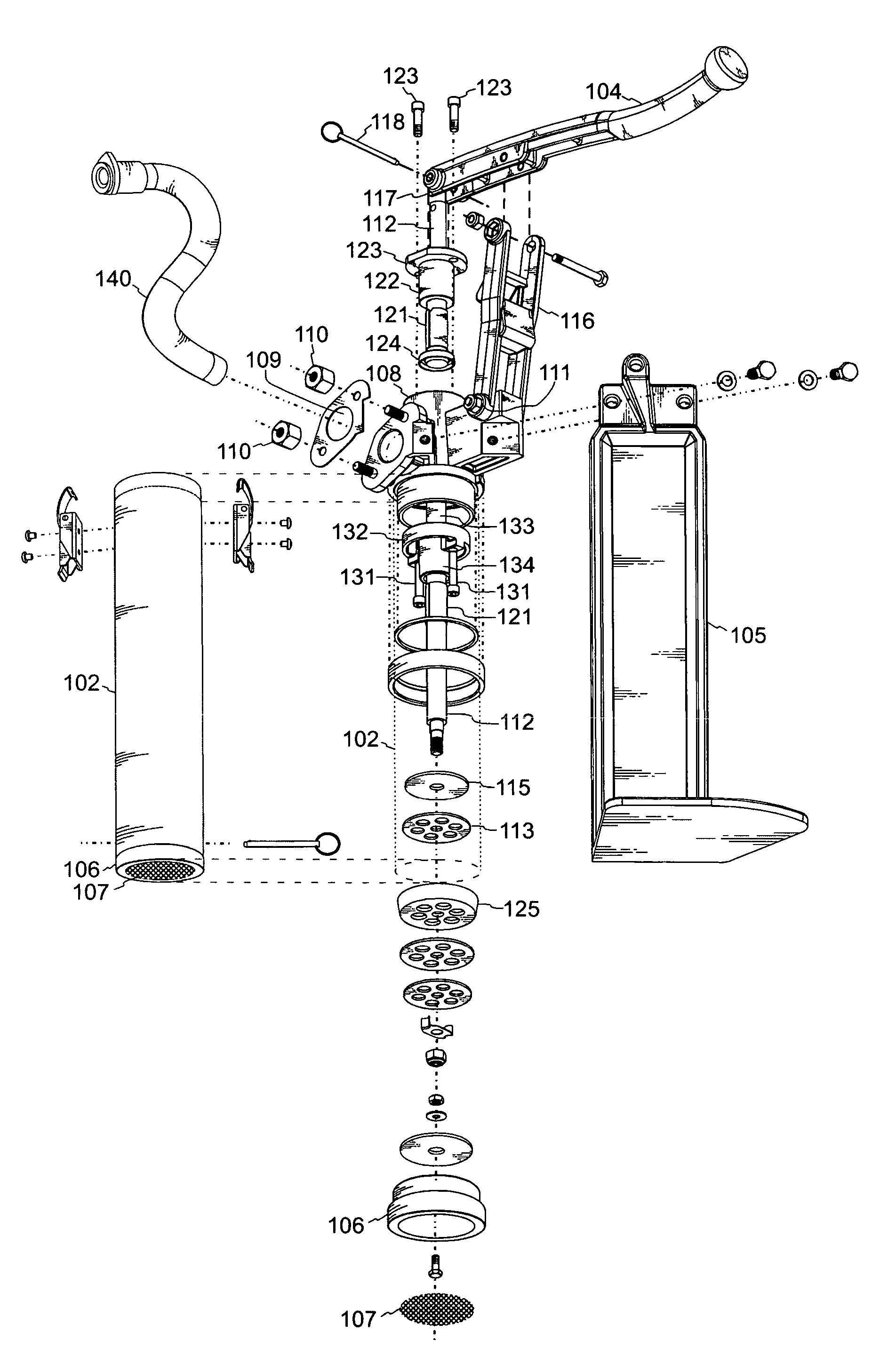

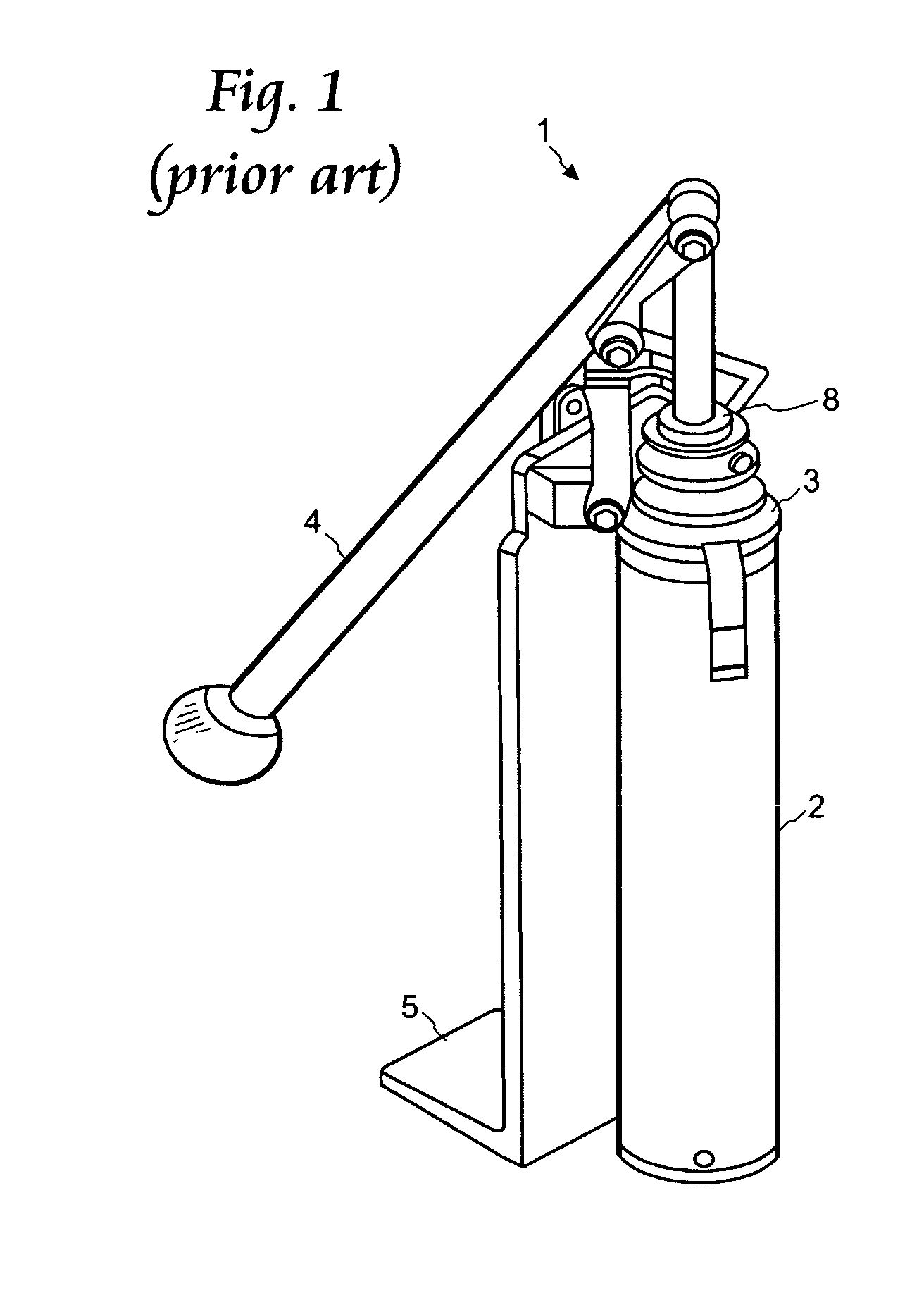

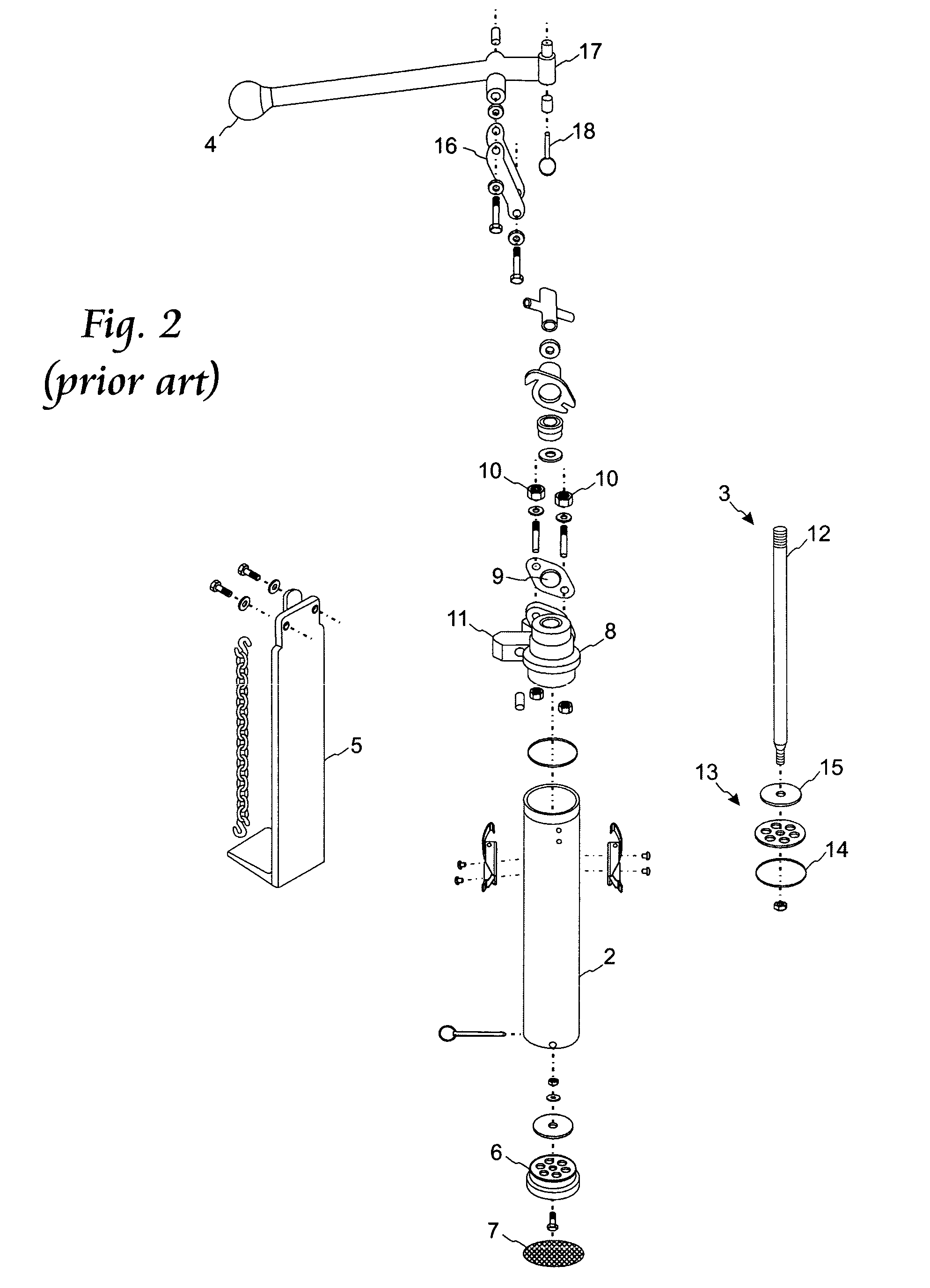

Drywall mud pump

InactiveUS20070122301A1Increase capacityExcessive transferPositive displacement pump componentsPiston pumpsEngineeringRisk stroke

An improved capacity mud pump is achieved by lengthening the link between the piston and the pump handle in such a way that each stroke of the handle moves the piston farther, thus transferring more mud per stroke. Reconfiguration of the output aperture of the pump by attaching a high filler allows the user to hold the empty tool in a position that affords better leverage in working the pump handle and shaft guides improve the application of vertical force to the piston.

Owner:CINTA TOOLS

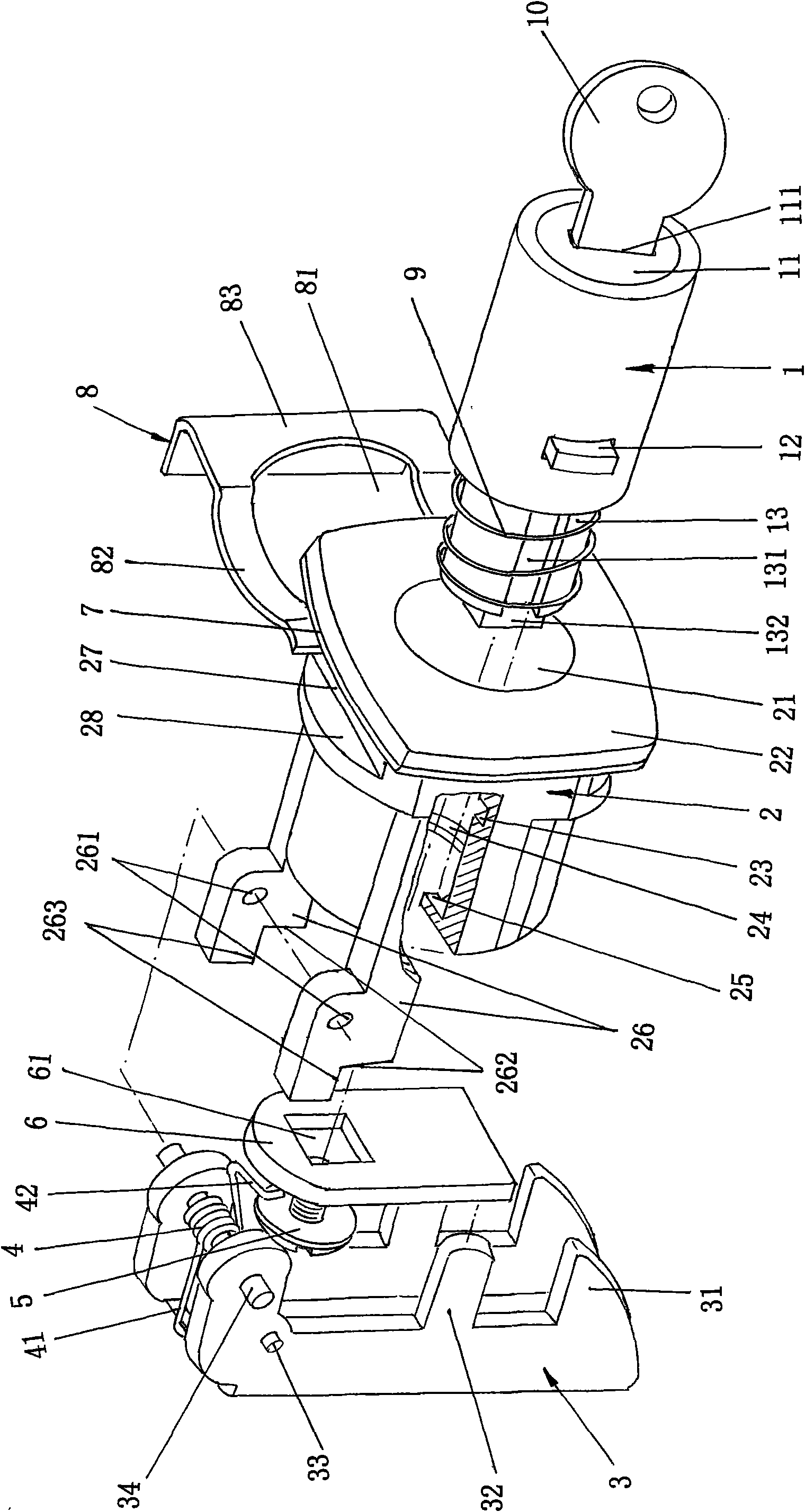

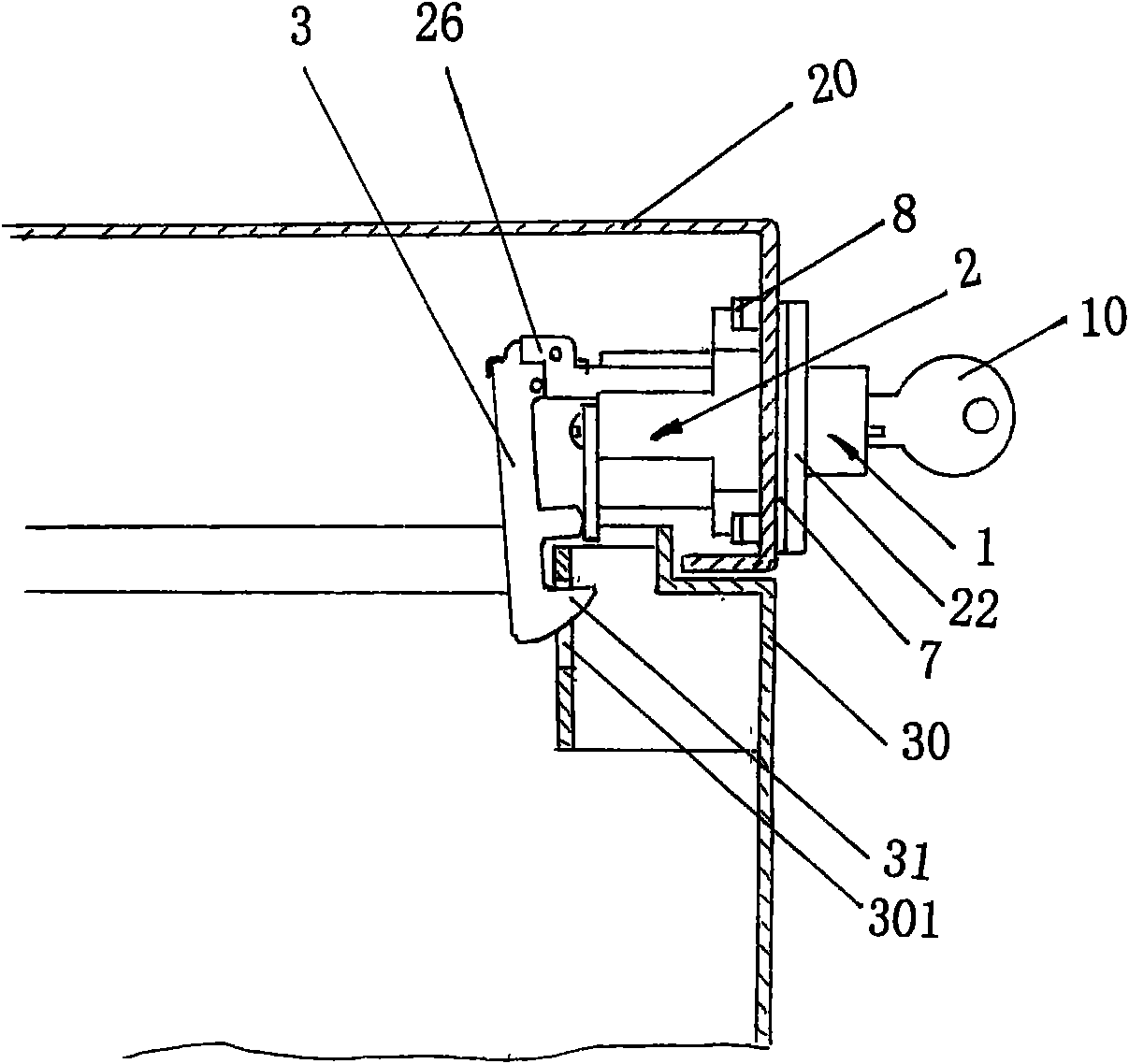

Lockset for tool case

InactiveCN101672133AImprove the bonding firmnessStrengthen linkBuilding locksEngineeringSelf locking

A lockset for tool case belongs to the technical field of hardware manufacture and comprises a lock shell, a lock cylinder body, a spring, a push plate, a lock hook plate and a torsion spring, whereinthe middle of the lock shell is provided with a lock cylinder hole, the front end thereof a panel and the back end thereof a lock hook plate bracket, the hole wall of the lock cylinder hole is provided with a lock tongue slot, and the bottom of the lock cylinder hole is provided with a supporting seat and a lock cylinder positioning lug; the lock cylinder body is arranged in the lock cylinder hole, the middle of the front end of the lock cylinder body is provided with a lock cylinder and a lock tongue and the back end thereof is provided with a spring seat, a slide slot is arranged on the spring seat, and the tail of the spring seat is provided with a square head; the spring is sheathed at the spring seat of the lock cylinder body and is contacted and matched with the supporting seat; thepush plate is fixed on the square head; the lock hook plate is pivoted on the lock hook plate bracket and provided with a push pin and a lock hook pin; and the torsion spring is mounted on a pin shaft, a first torsion spring pin of the torsion spring is fixed with the lock hook plate and the second first torsion spring pin thereof is fixed with the lock hook plate bracket. The invention has the advantages of good concealment, outstanding anti-pry and anti-theft performance, good self-locking function, long service life, labor-saving and convenient operation, simple structure and good closeness effect.

Owner:常熟中诚工具箱柜有限公司

Al2O3-C refractory fired by nitridation and preparation method for Al2O3-C refractory

The invention relates to an Al2O3-C refractory fired by nitridation and a preparation method for the Al2O3-C refractory. According to the technical scheme, the preparation method comprises the following steps of: mixing 55 to 94 weight percent of corundum, 5 to 20 weight percent of crystalline flake graphite, 1 to 30 weight percent of metal Si fine powder which serve as raw materials, adding a bonding agent in an amount which is 3.5 to 8 percent of the weight of the raw materials, and mixing and grinding for 10 to 30 minutes; and pressing the mixed and ground mixture to form a raw blank of the required Al2O3-C refractory, baking the pressed raw blank at the temperature of between 180 and 220 DEG C, putting into a high-temperature kiln, and keeping the temperature at the temperature of between 1,350 and 1,700 DEG C under the atmosphere of N2 for 1 to 8 hours to obtain the Al2O3-C refractory fired by the nitridation. The Al2O3-C refractory fired by the nitridation comprises a case-hardened Al2O3-C refractory brick, an Al2O3-C protective tube for the continuous casting of molten steel, an Al2O3-C sliding plate for the pouring of the molten steel and a nozzle brick. The Al2O3-C refractory has the characteristics of high strength, oxidation resistance, long service life and high performance of resisting the washing and erosion of high-temperature melts.

Owner:WUHAN UNIV OF SCI & TECH

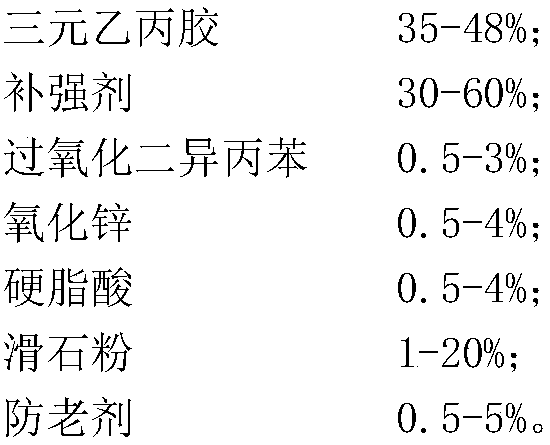

Ethylene propylene rubber and preparation method thereof

ActiveCN107815028AGood physical and mechanical propertiesImprove vulcanization efficiencyPolymer science2-mercaptobenzimidazole

The invention discloses ethylene propylene rubber and a preparation method thereof, and belongs to the rubber field. The ethylene propylene rubber includes the following raw material components by mass: 35 to 48% of EPDM rubber, 30 to 60% of a reinforcing agent, 0.5-3% of dicumyl peroxide, 0.5-4% of zinc oxide, 0.5-4% of stearic acid, 1-20% of talcum powder and 0.5-5% of an anti-aging agent. The anti-aging agent includes one or more of 2,2,4-trimethyl-1,2-dihydroquinoline polymer and 2-mercaptobenzimidazole, and the ethylene-propylene rubber includes 1-3% by mass of vinyl guanamine. The ethylene propylene rubber has the following beneficial effects: through addition of the anti-aging agent in the EPDM rubber, the oxidation of the EPDM rubber can be inhibited, the stearic acid as a surfactant can improve the uniformity of the dispersion of the anti-aging agent in the EPDM rubber and improve the connection of the anti-aging agent and the EPDM rubber, and the ethylene propylene rubber hasa better anti-aging effect.

Owner:玉环市鑫庄电子股份有限公司

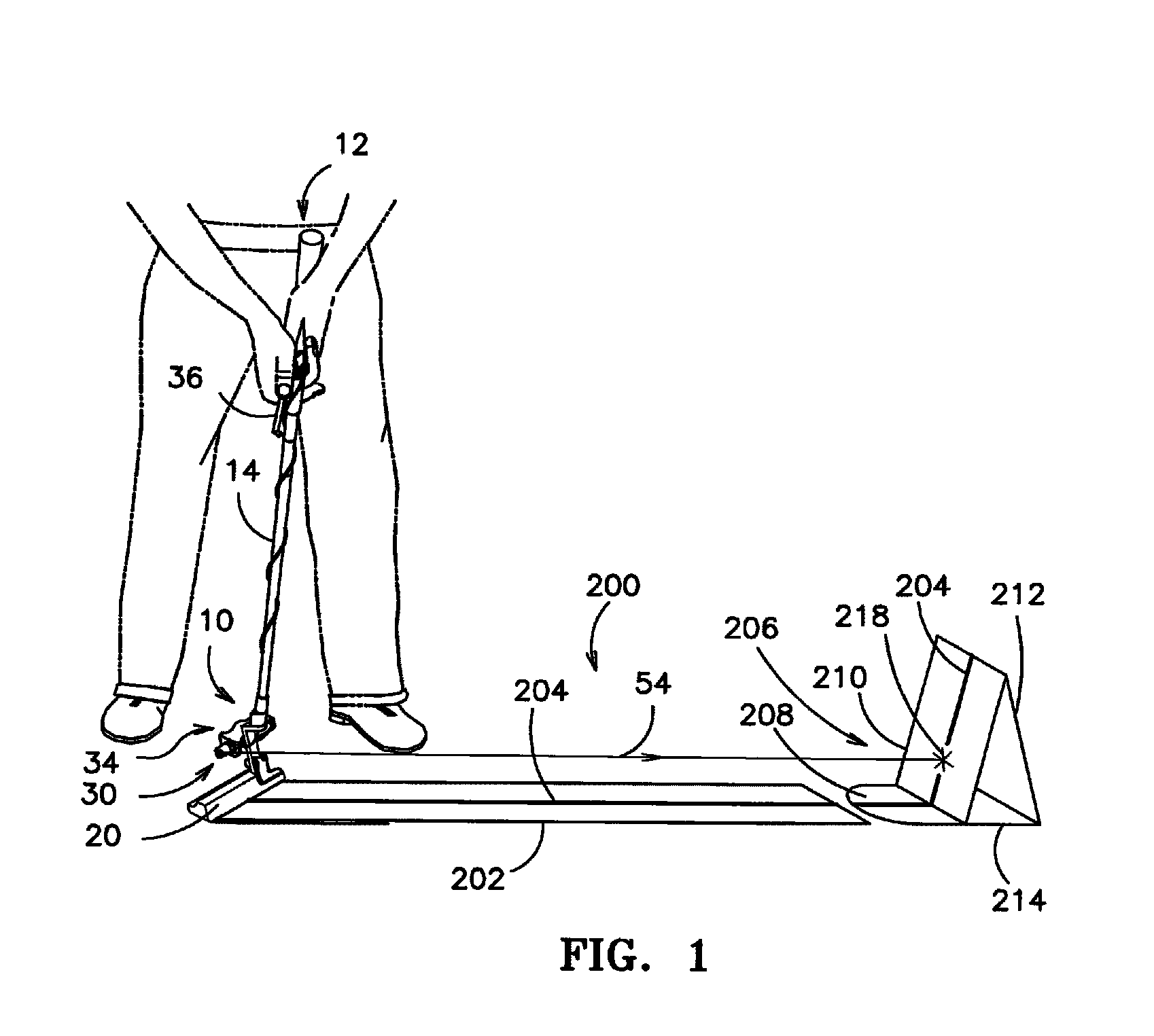

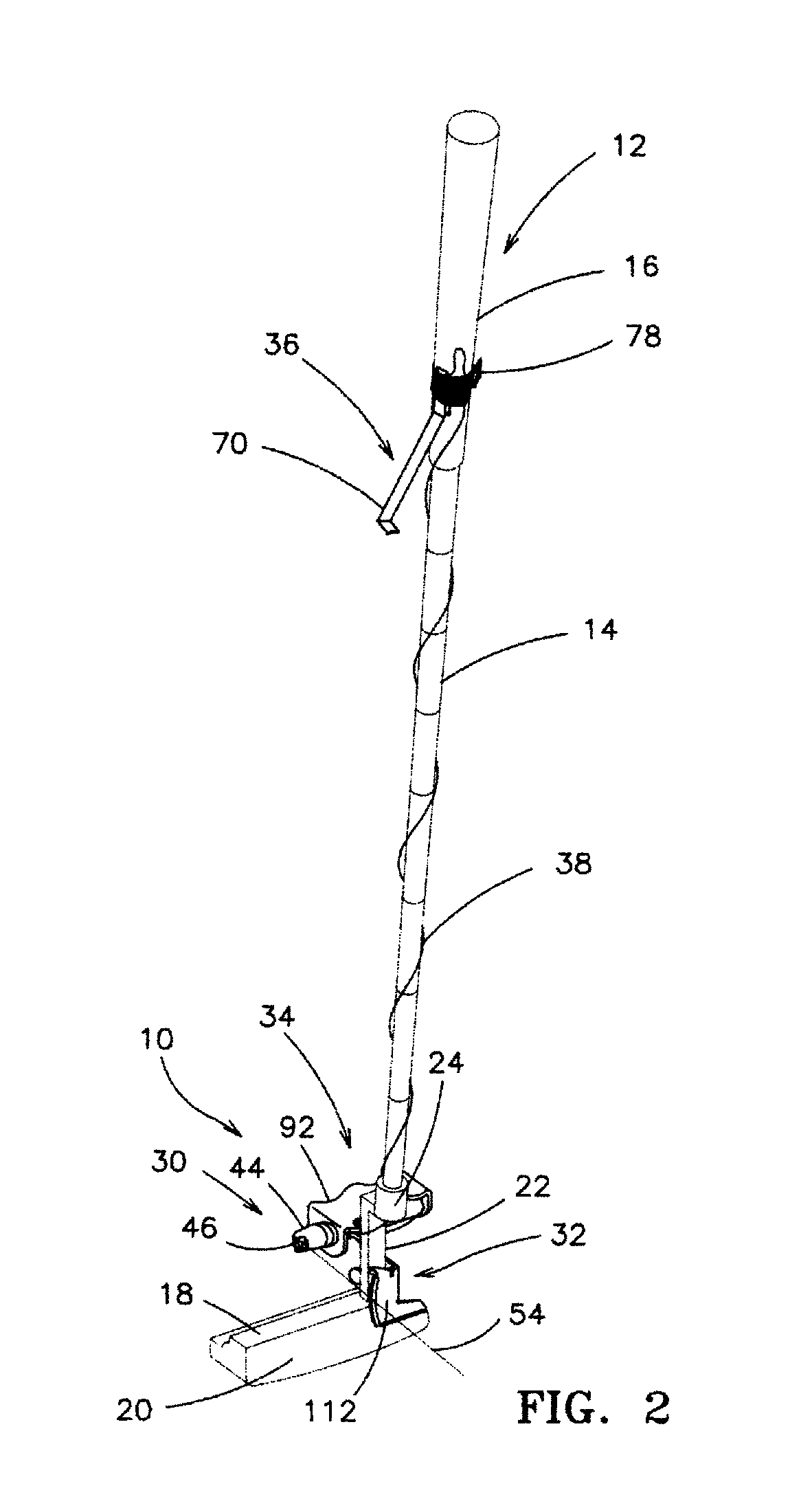

Laser putting device

InactiveUS8109837B1Easy to installStrengthen linkSpace saving gamesGolfing accessoriesEngineeringGolf Ball

A laser putting device for a golf putter includes a guiding unit for generating a laser beam, a frame for supporting the guiding unit disposed in the frame, an activator connected to the golf putter and communicated with the guiding unit for turning the guiding unit between on and off positions thereby generating the laser beam. A bracket of the laser guiding device is adaptable to receive a tubular member of the guiding unit that has a mirror and a diode emitting the laser beam and guiding the laser beam into the mirror angled in the fashion to form the laser beam having 90 degrees thereby allowing the golfer to point the laser beam at the target point, such as a hole in a golf green. The laser guiding device help the golfer to learn how to improve a strike and place the golf ball into a hole within short period of time and without necessity of using outdoor facility.

Owner:KHANANAYEV VLADIMIR +1

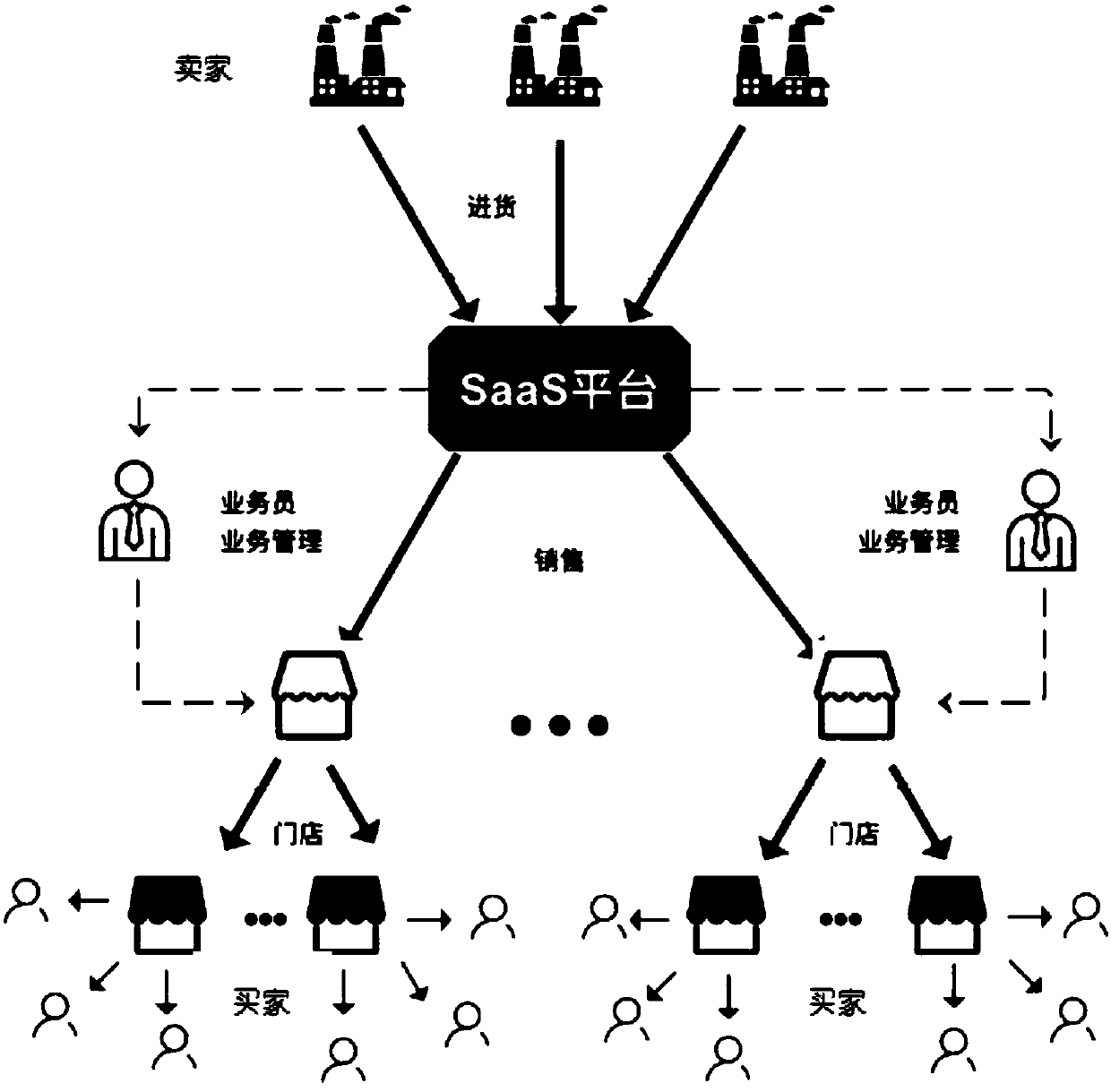

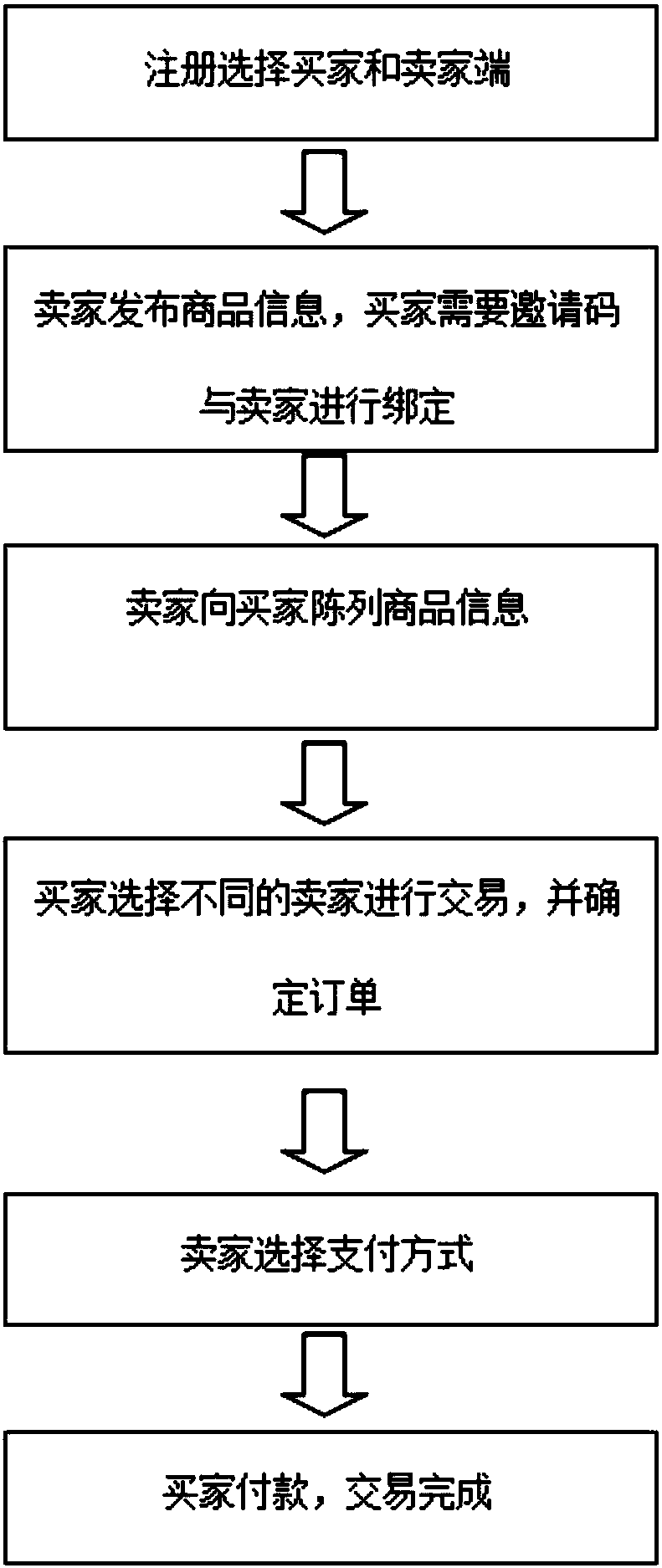

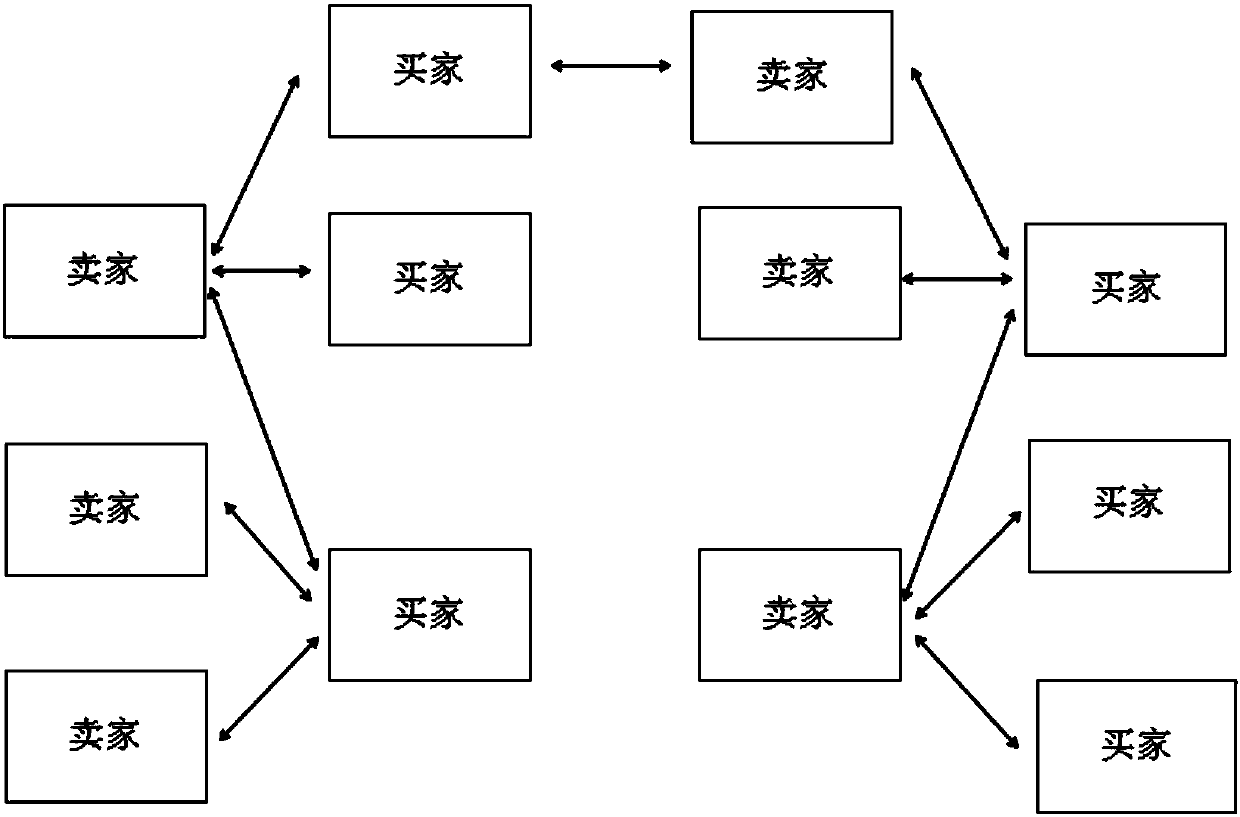

Agricultural material management platform based on Internet SaaS (Software as a Service) mode

InactiveCN107909434AImprove business efficiencyImprove service capability and qualityCredit schemesBuying/selling/leasing transactionsSoftware as a serviceBusiness-to-business

The invention discloses an agricultural material management platform based on an Internet SaaS (Software as a Service) mode, and relates to the field of agricultural material management. The platformcomprises a SaaS platform, a B2B (Business to Business) subsystem and a B2C (Business to Customer) subsystem, wherein the SaaS platform comprises a salesman, a store, a buyer and a seller; the store,the buyer and the seller can enter the SaaS platform after registering an account; the buyer provides a commodity which needs to be sold on the SaaS platform, can carry out selling or removal operations on the commodity and simultaneously can revise price; the buyer needs to input a correct invitation code sent from the buyer to bind with the seller, and can check the commodities sold by the seller after binding; the buyer can provide different pieces of goods selling information for different buyers; and the salesman maintains the SaaS platform and manages sellers and buyers. Through the Internet tool, i.e., the SaaS platform, the online design of traditional agricultural material selling and buying business and channel relationships can be realized, and goods ordering efficiency and selling agricultural material management efficiency can be improved.

Owner:安徽阡陌网络科技有限公司

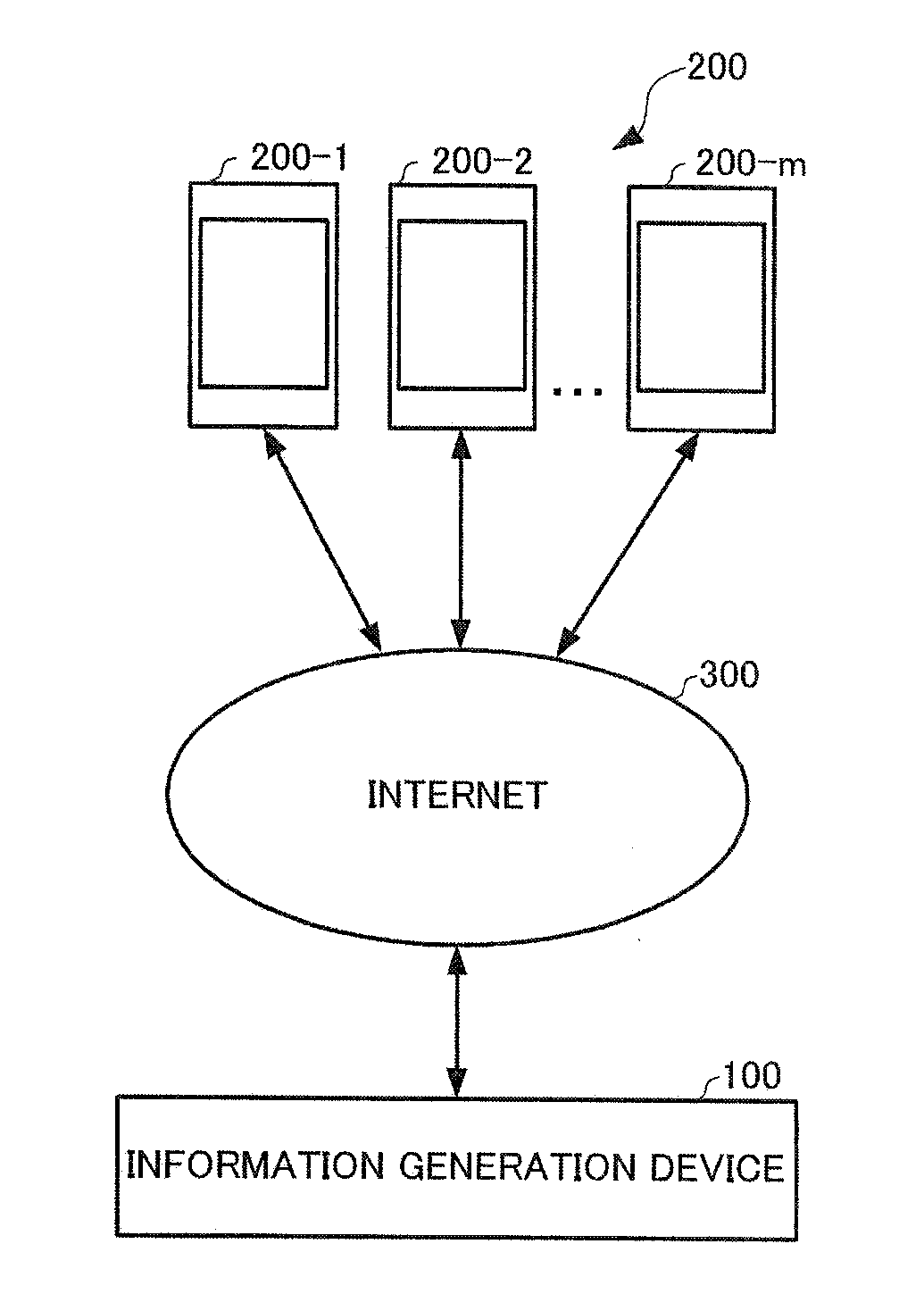

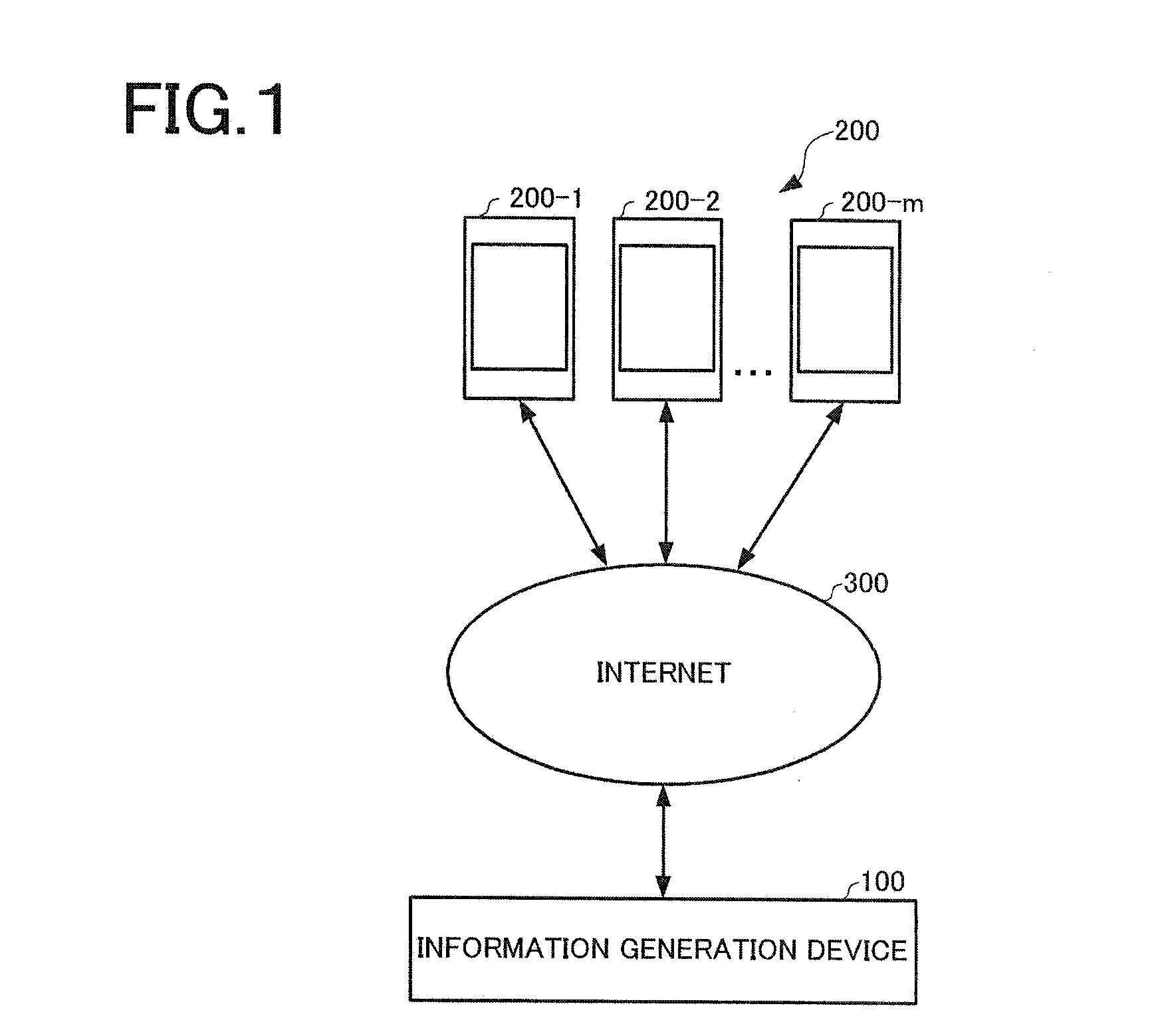

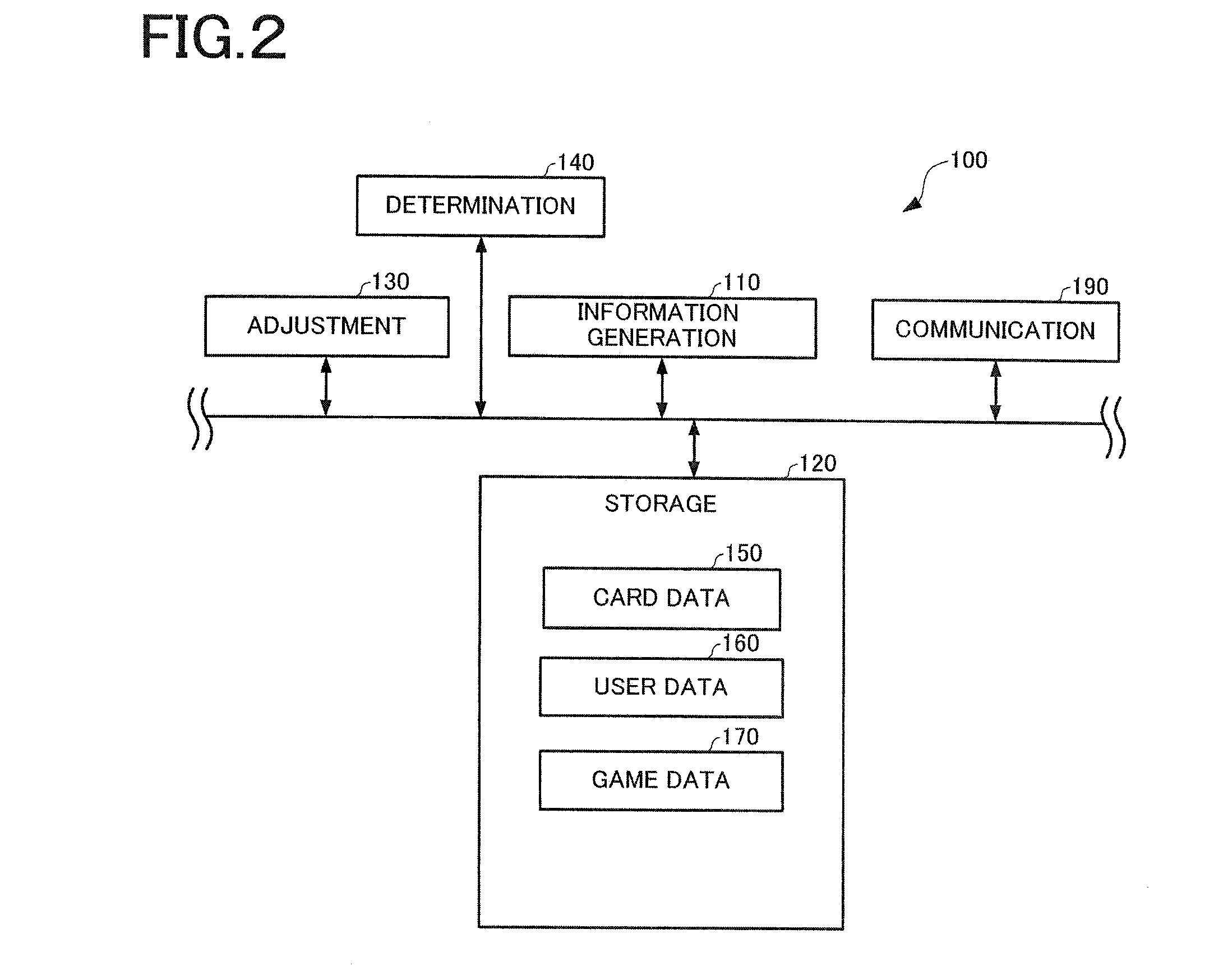

Information generation device, information provision system, and information storage medium

ActiveUS20130252689A1Strengthen linkApparatus for meter-controlled dispensingVideo gamesOperations researchData science

Owner:BANDAI NAMCO ENTERTAINMENT INC

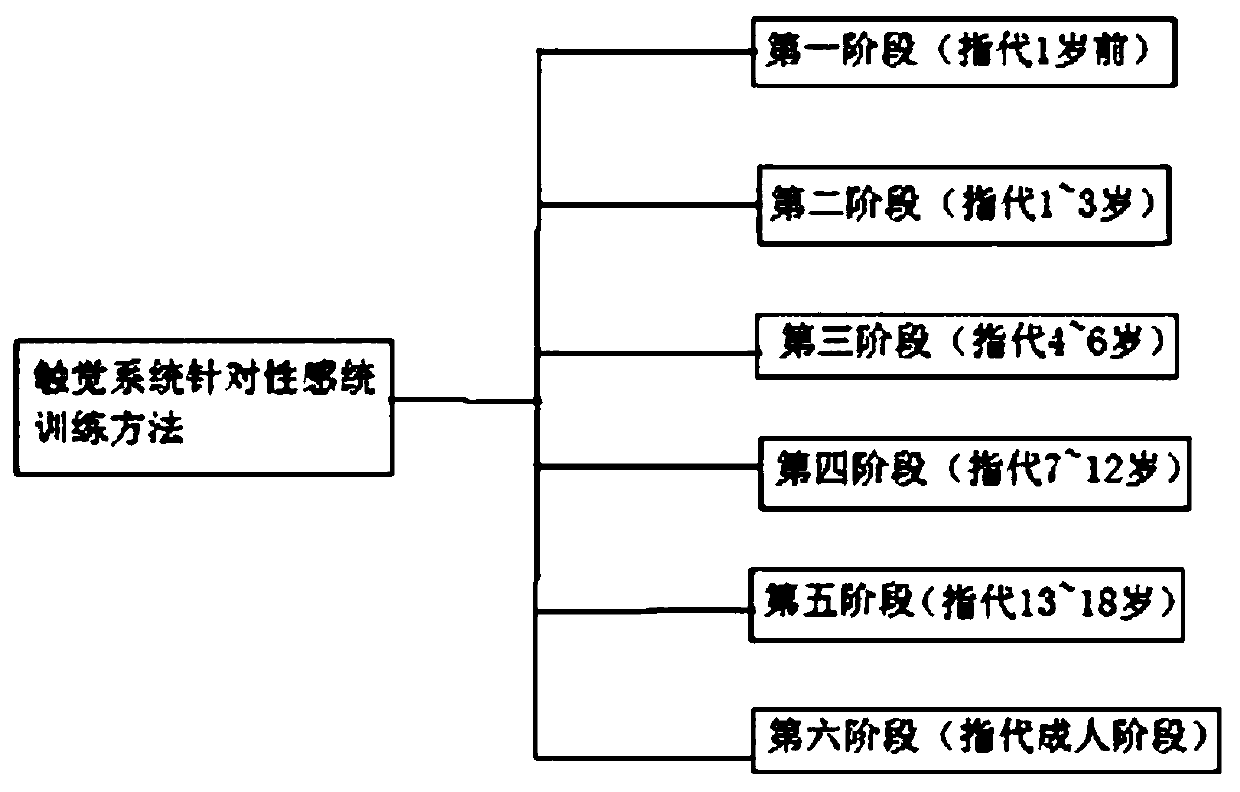

Targeted sensory integration training system for haptic system

InactiveCN110585649ARelieve nervous tensionImprove sensory acuityGymnastic climbingSpring boardsAdult stageTouch Perception

The invention discloses a targeted sensory integration training system for a haptic system; and a method particularly aimed at six stages comprises the following steps: a first stage (referring to theage before 1 year old) of a haptic system targeted sensory integration training method, a second stage (referring to the 1 -3 year old) of the haptic system targeted sensory integration training method, a third stage (referring to the 4 -6 year old) of the haptic system targeted sensory integration training method, a fourth stage (referring to the 7 -12 year old) of the haptic system targeted sensory integration training method, a fifth stage (referring to the 13 -18 year old) of the haptic system targeted sensory integration training method, and a sixth stage (referring to the adult stage) of the haptic system targeted sensory integration training method. According to the targeted sensory integration training system for the haptic system in the invention, the actual sensory integration development condition of a tested person is obtained through an evaluation system, a specific targeted training and evaluation method is given, the haptic sensory ability of a trainee is improved, andthe overall feeling and sensory ability of the trainee is enhanced.

Owner:上海必问企业管理咨询有限公司

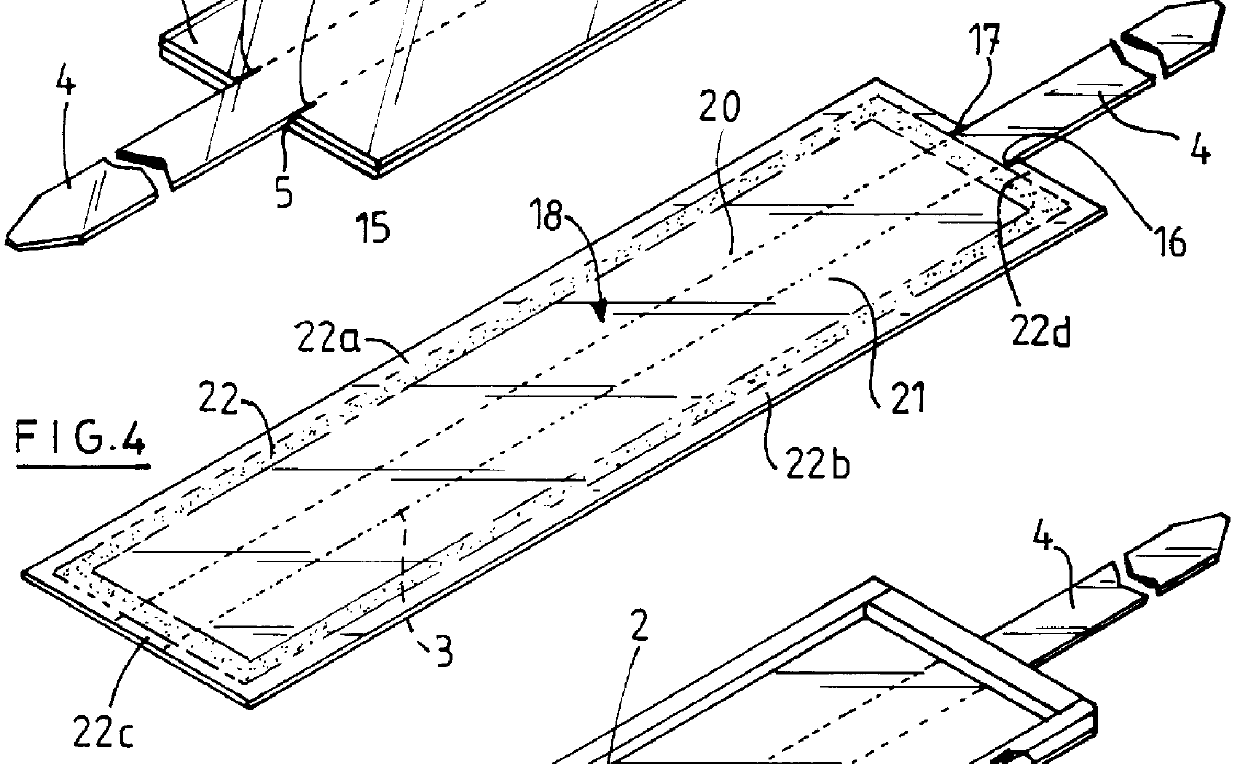

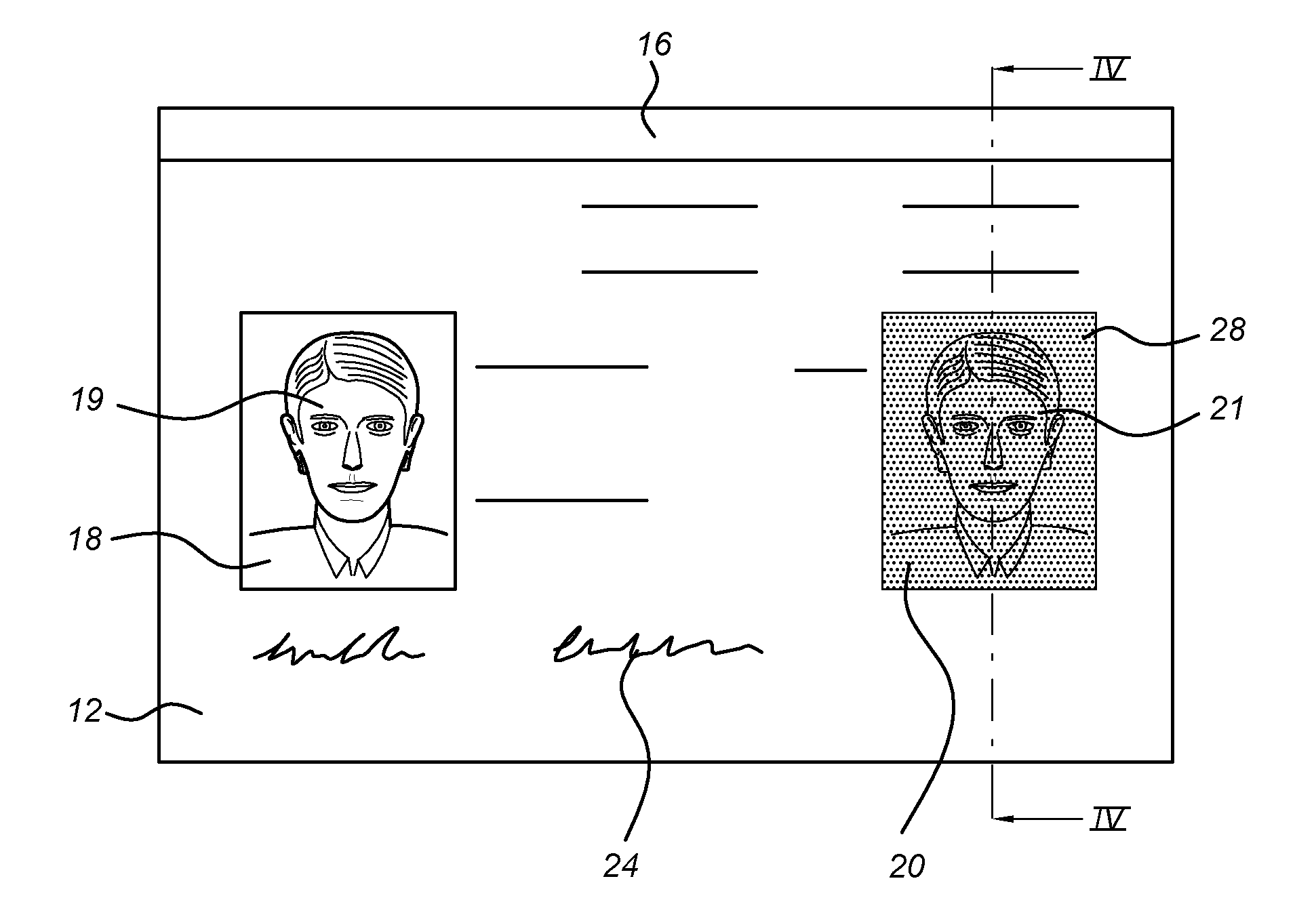

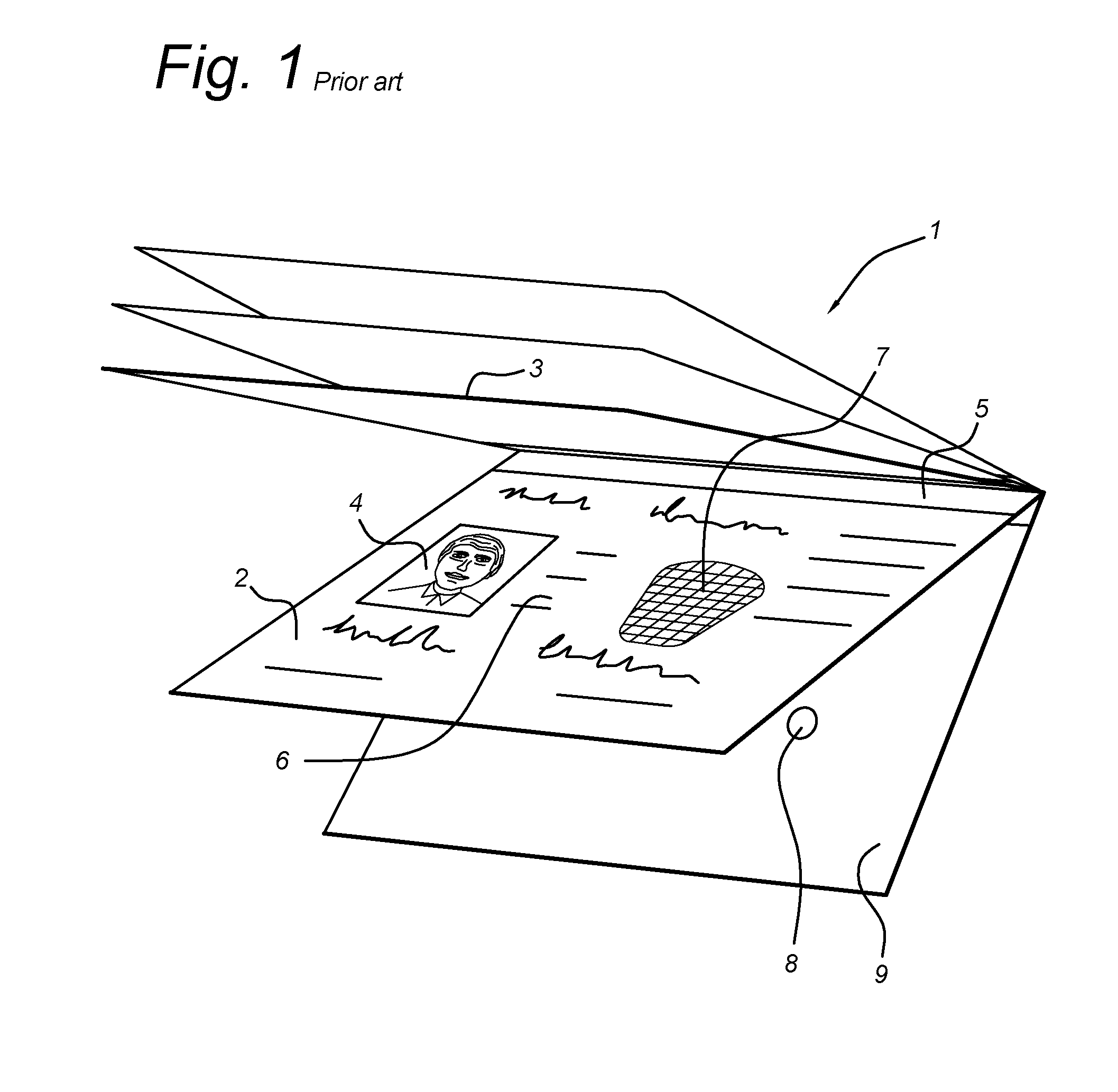

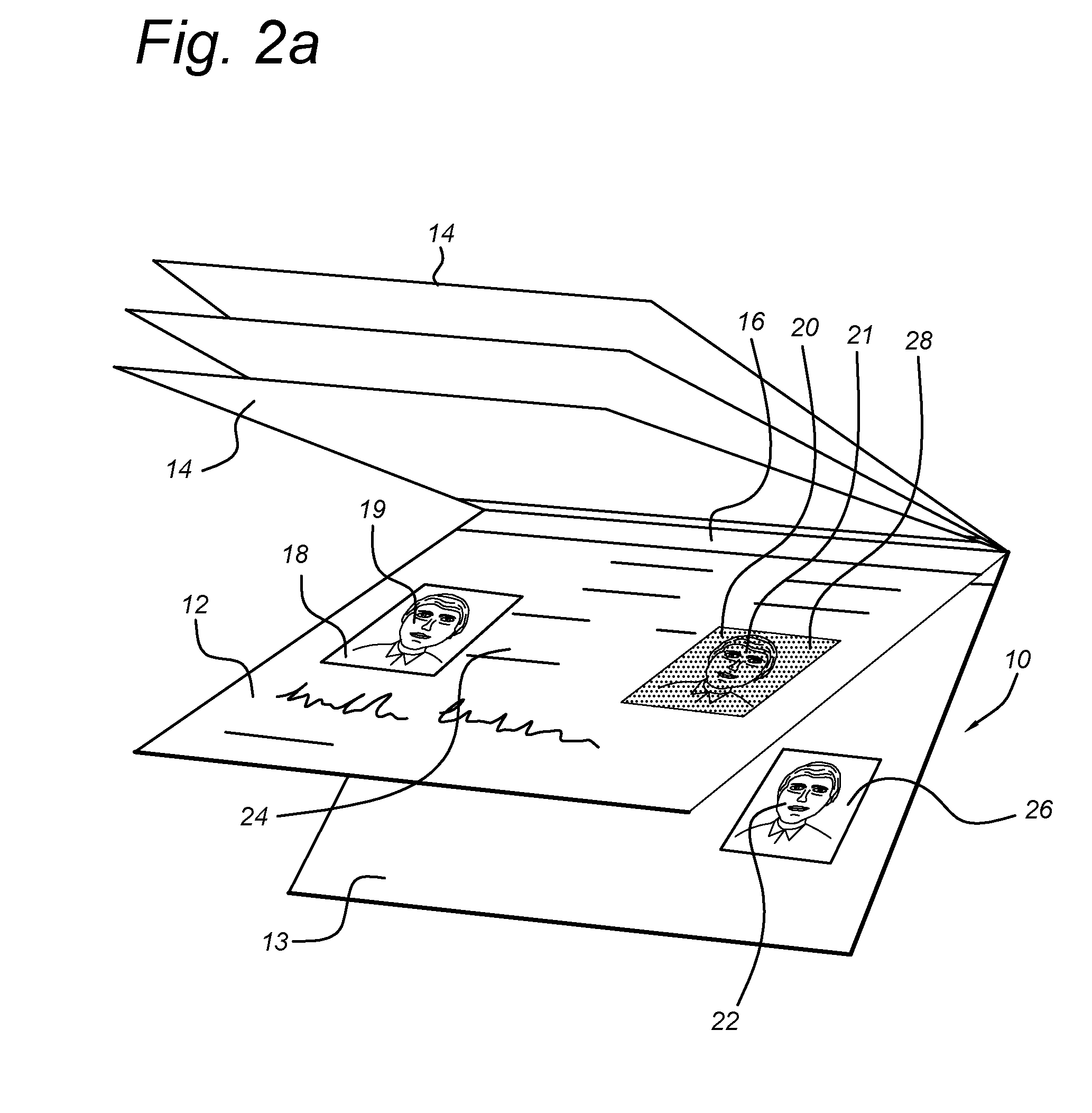

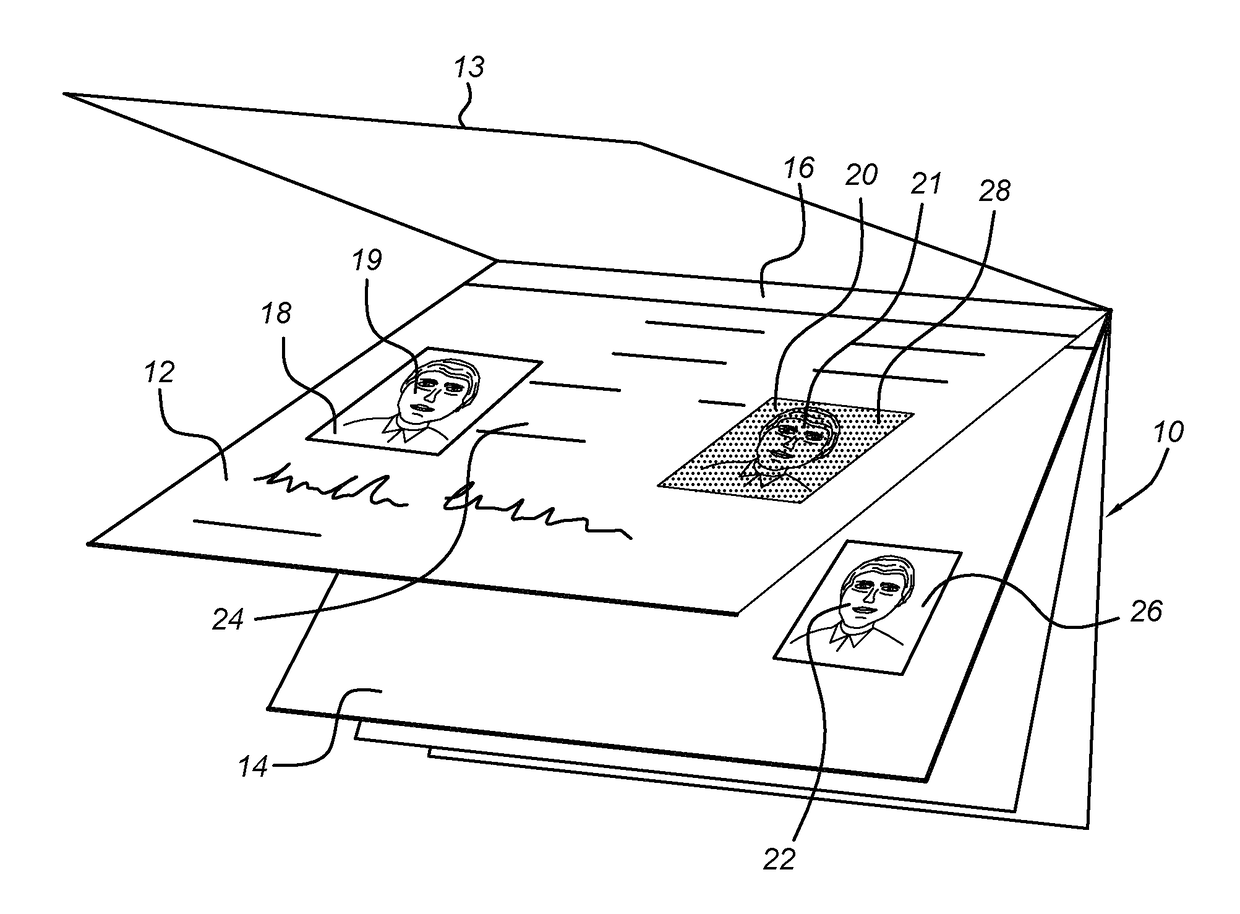

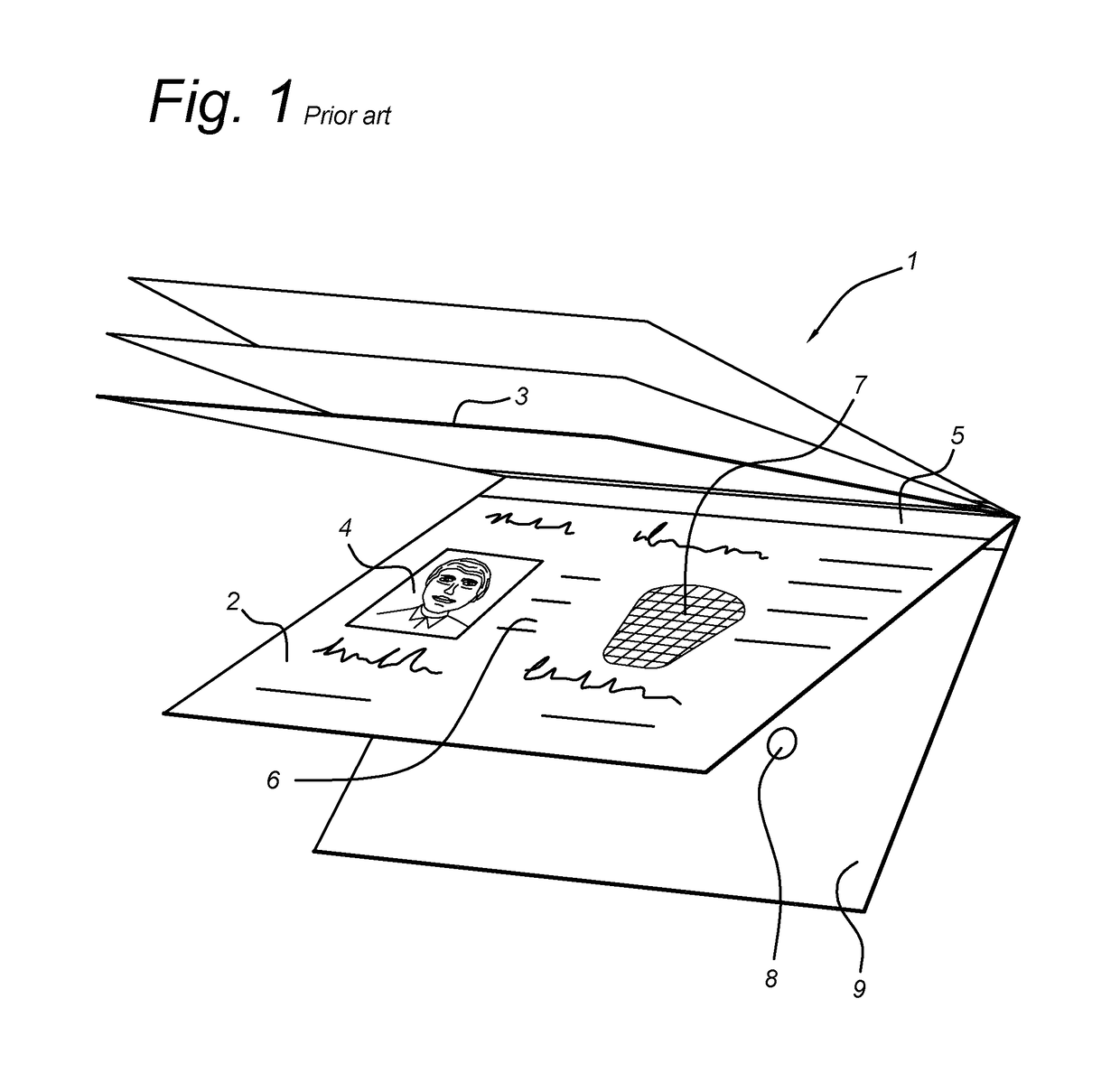

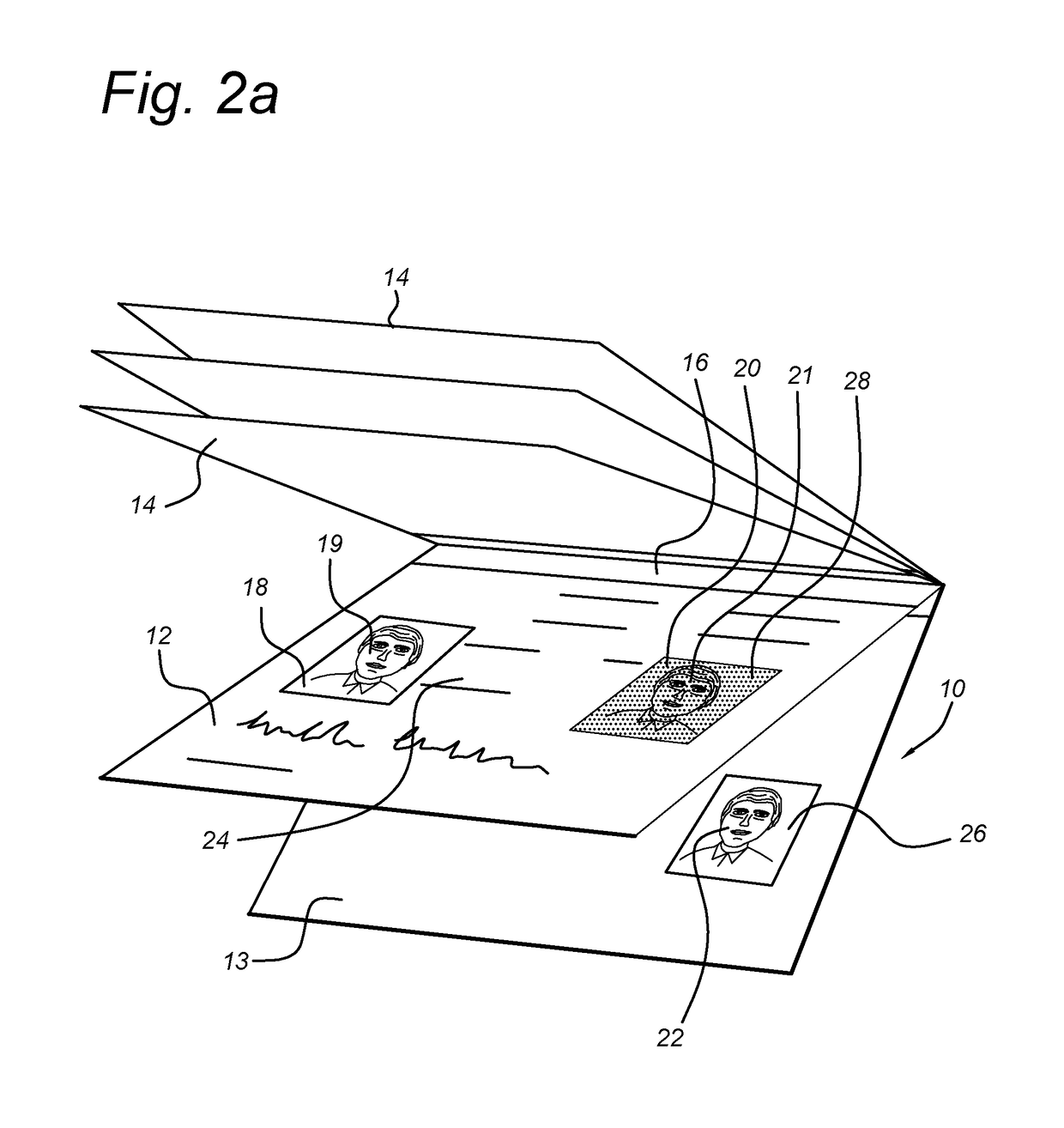

Identification assembly for an identity document

ActiveUS20160176219A1Definition of image is declinedEasy visual inspectionOther printing matterCoding/ciphering apparatusPaper documentDocument preparation

An identification assembly for an identity document (10) includes a substrate (12) with a substantially planar configuration, and an adjacent surface (13, 14) hingeably attached to the substrate (12) and provided adjacent to the substrate (12). The substrate (12) includes at least two image areas (18, 20), a first image area (18) having a first image (19), and wherein the substrate includes a second image area (20) including a second laser produced image (21), and a third image (22) corresponding to the second image (21) is provided through the second image area (20) onto the adjacent surface (13, 14), the third image (22) being visible for a user by hinging the substrate away from the adjacent surface (14).

Owner:IDEMIA THE NETHERLANDS BV

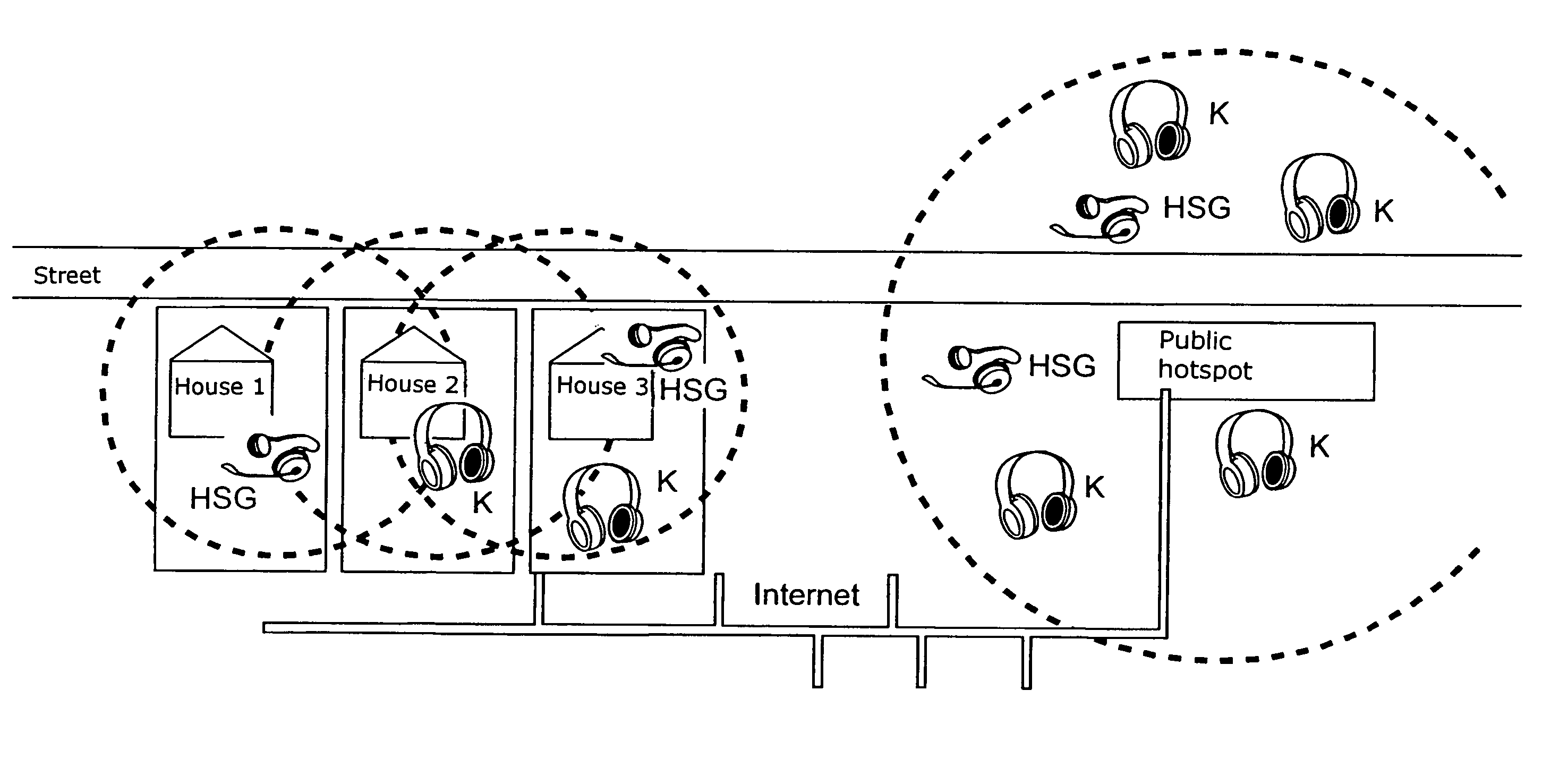

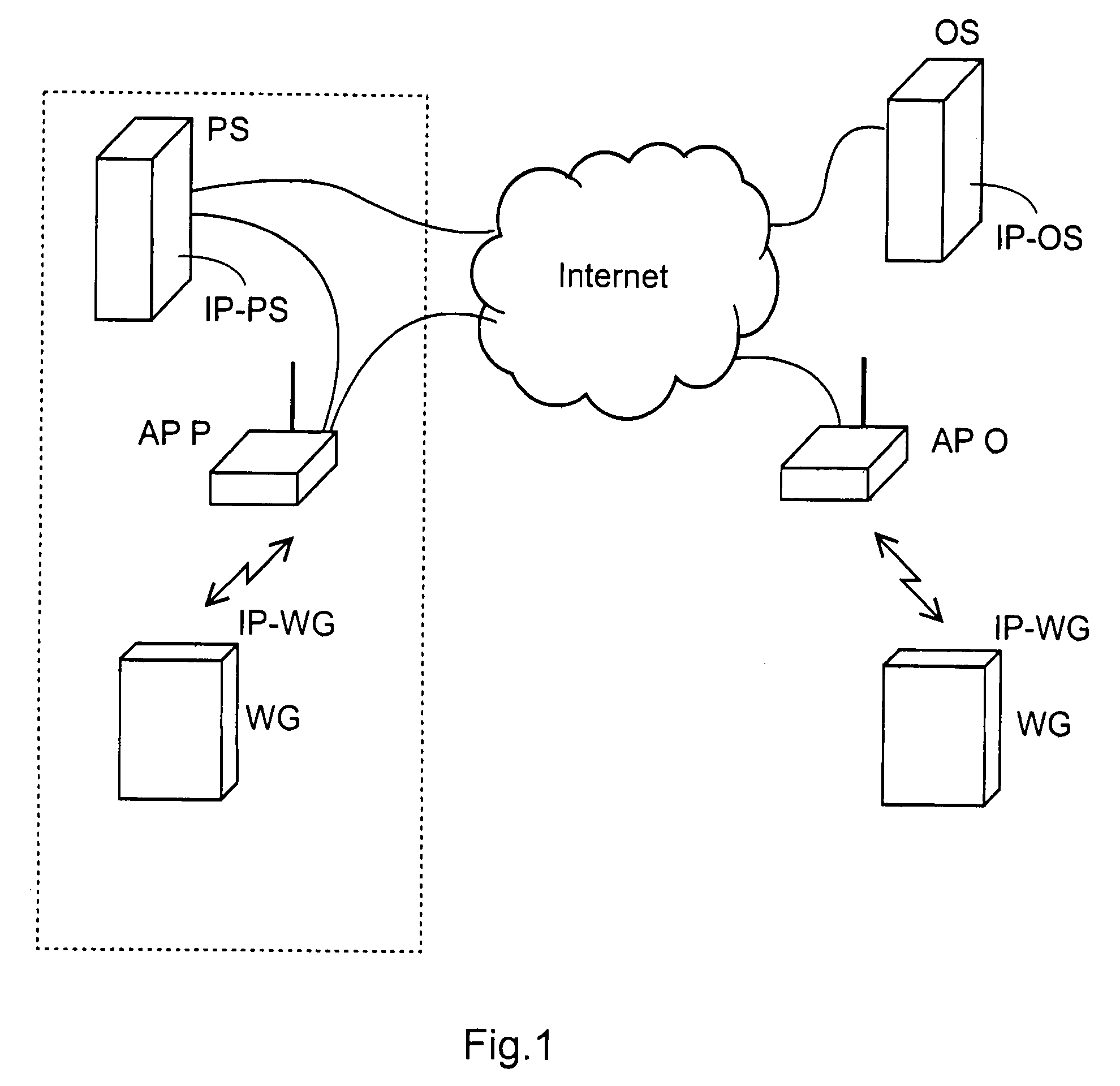

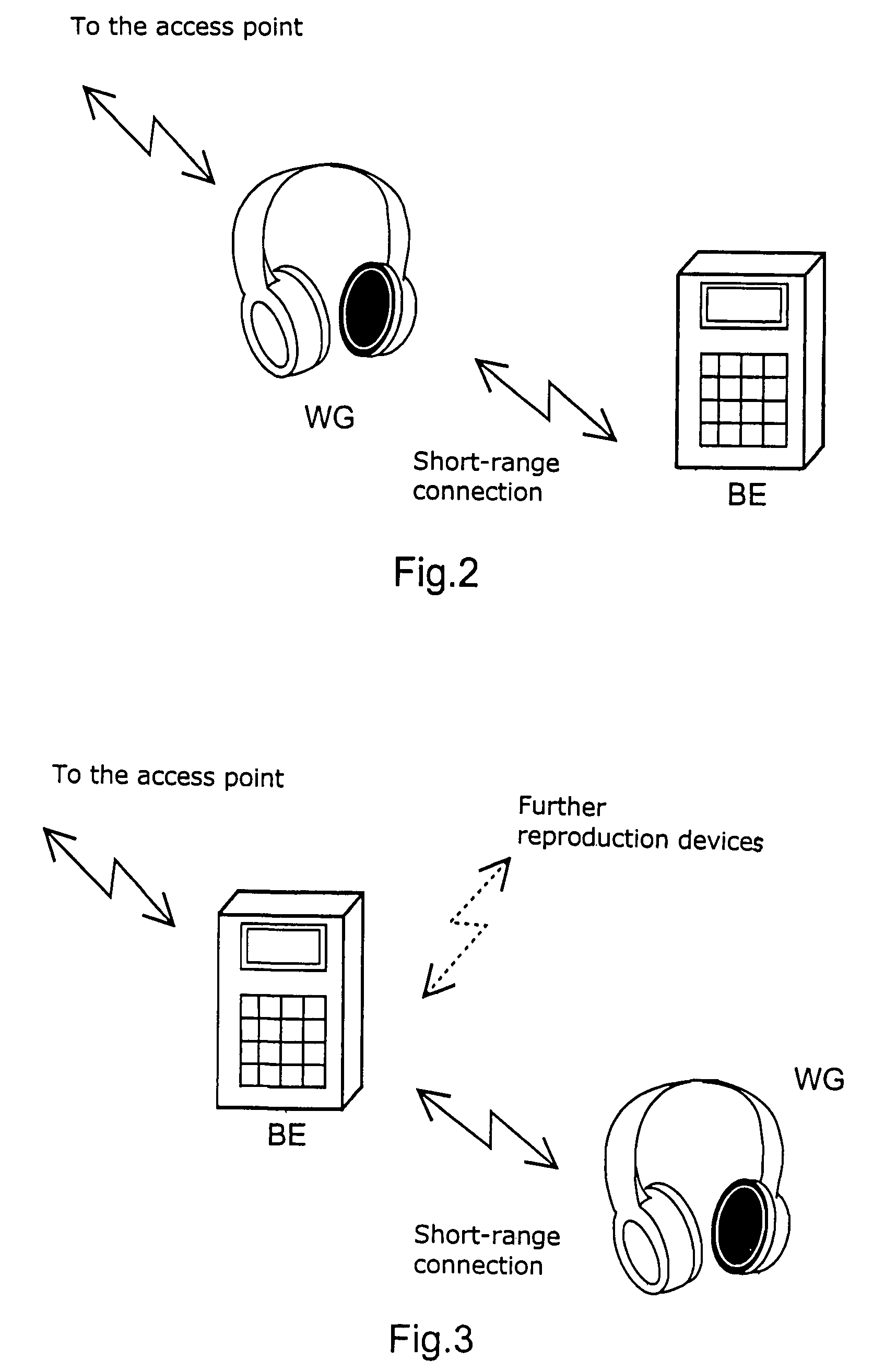

Wireless headphones and data transmission method

ActiveUS8897841B2Strengthen linkBroadcast specific applicationsSubstation equipmentTransducerHeadphones

There is provided a wireless headphone unit having at least one electroacoustic transducer and a transmitting / receiving unit for wirelessly receiving first signals which contain audio signals to be reproduced on the electroacoustic transducer and a network identification unit for storing the network identification of the wireless headphone unit, wherein the transmitting / receiving unit is adapted for wirelessly transmitting the network identification of the headphone unit.

Owner:SENNHEISER ELECTRONICS GMBH & CO KG

Image display device

InactiveUS8416268B2Improve visual effectsSuperfluous imageCathode-ray tube indicatorsSteroscopic systemsComputer graphics (images)Display device

Owner:ASUKANET

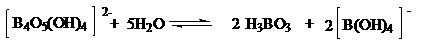

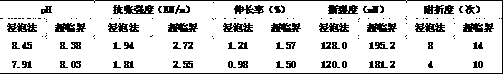

Method for deacidifying through utilizing soluble tetraborate in supercritical CO2 state

ActiveCN102828443ALow viscosityIncrease the diffusion coefficientOld paper after-treatmentPaper sheetAqueous solution

The invention discloses a method for deacidifying through utilizing a soluble tetraborate in a supercritical CO2 state. The method comprises the following steps: putting paper, especially aged and acidified paper in a supercritical CO2 processing apparatus, and processing with an alcohol-water solution containing the soluble tetraborate. The method enables the pH of the paper to be controlled in an optimum range and the deacidifying agent application amount to be reduced. Compared with other methods, the method disclosed in the invention has the advantages of obvious improvement of the paper strength because of the soluble tetraborate in the supercritical CO2 state, and great increase of various mechanical strengths.

Owner:GUANGDONG UNIV OF TECH

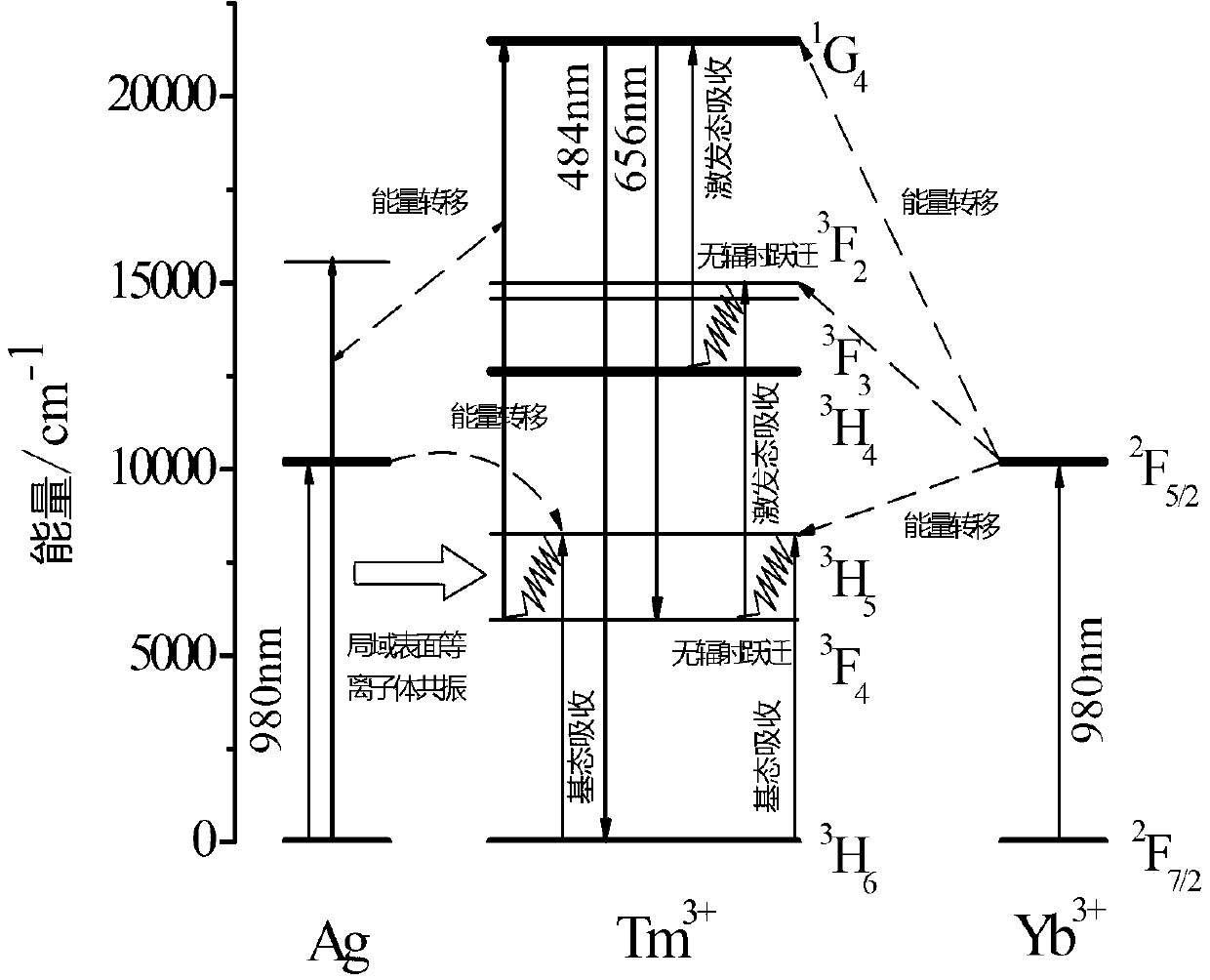

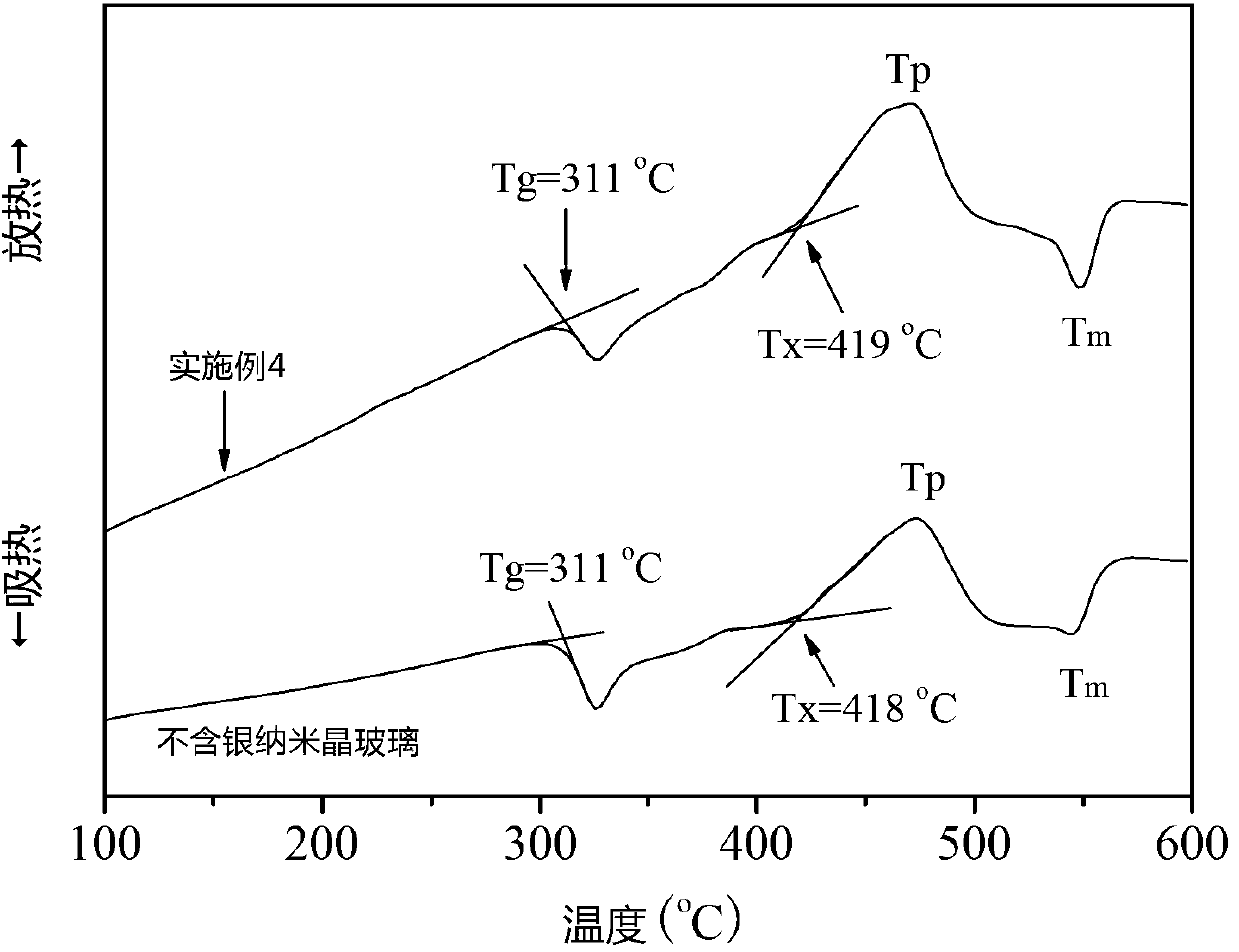

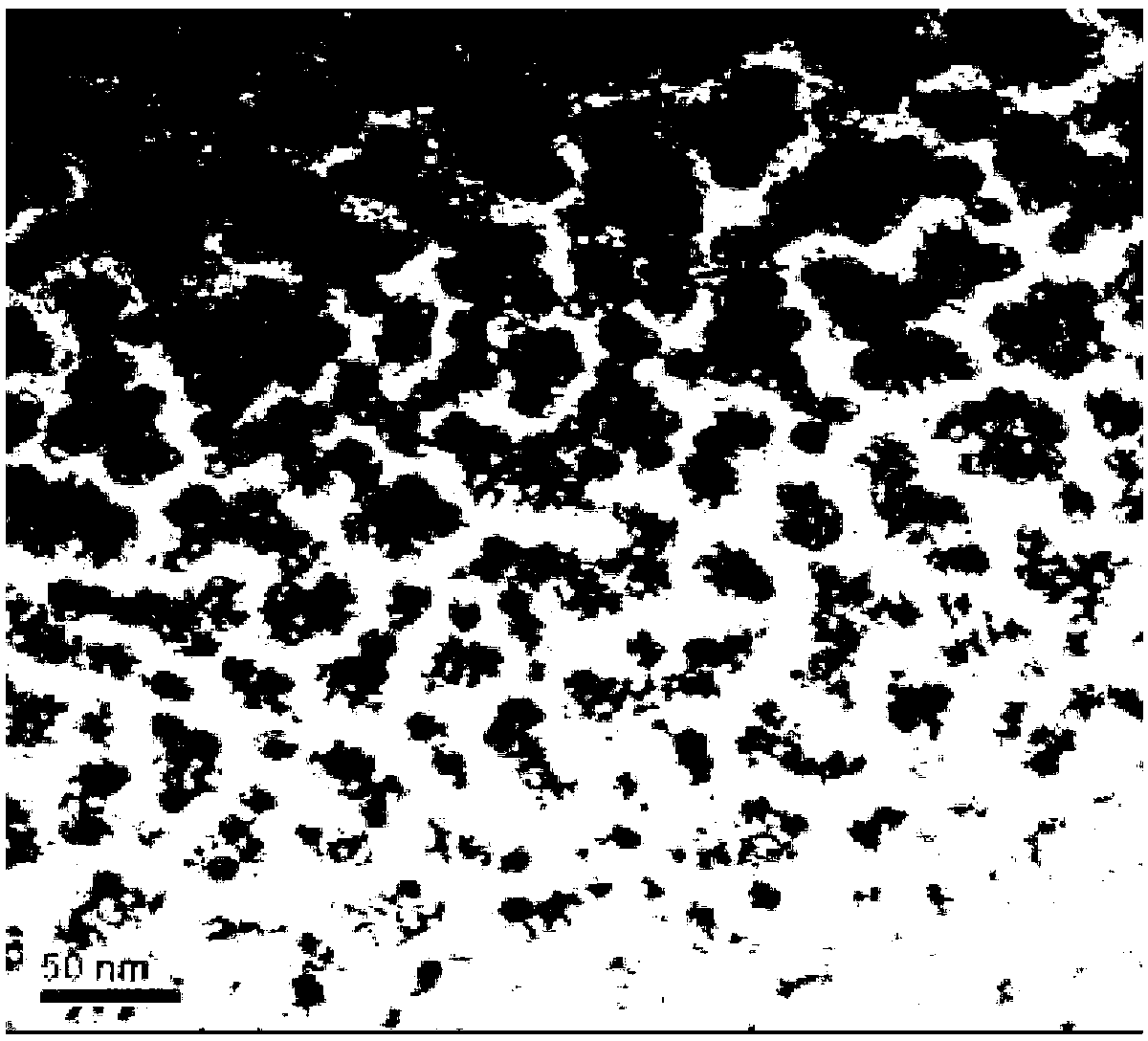

Silver-containing nanocrystal blue light enhanced tellurite glass and preparation method thereof

InactiveCN103342464AImprove structural stabilityPromote formationUpconversion luminescenceRare earth

The invention belongs to the technical field of conversion luminescence materials and relates to a silver-containing nanocrystal blue light enhanced tellurite glass and a preparation method of the tellurite glass. The glass comprises glass phase components, externally doped rear earth oxides and silver salts and is prepared by virtue of melting and thermal treatment, wherein the glass phase components include the following substances in percentages by mol: 60-80% of TeO2, 5-10% of WO3, 0-5% of La2O3, 0-5% of GeO2, 5-10% of ZnO, and 5-20% of ZnF2+ZnCl2; the externally doped rear earth oxides include the following ingredients in percentages by mol based on the molar contents of the above glass phase components: 0.02-0.1% of Tm2O3 and 0.1-1% of Yb2O3; and the silver salts include the following ingredients in percentages by mass based on the mass contents of the above glass phase components: 0.3-0.7% of AgCl+AgF. The silver-containing nanocrystal blue light enhanced tellurite glass disclosed by the invention can be widely applied to the manufacturing of a blue light emission laser device.

Owner:TONGJI UNIV

Cattle-sheep dung recycling processing method

InactiveCN105016875ASimple manufacturing processLow costBio-organic fraction processingOrganic fertiliser preparationFecesResource utilization

The invention relates to the livestock resource utilization field, and provides a cattle-sheep dung recycling processing method including the following steps: drying cattle-sheep dung in the sun, preparing a culture material, carrying out high temperature heap-curing, and carrying out farmland fermentation. The culture material comprises the components in parts by mass: 50 parts of dried cattle-sheep dung, 10 parts of rice straw, 10 parts of straw, 5 parts of plant ash, 3 parts of calcium superphosphate, and 2 parts of lime. The cattle-sheep dung production process is simple and effective, especially adapts to fungi breeding and breeding seedling of other plants, can significantly improve the activity of seeds, and improves the survival rate. At the same time, a large amount of dung generated from large cattle and sheep breeding is also effectively solved, local related industry links are promoted, the costs of animal breeding and plant planting are reduced in a double-sided mode, and supplement with each other is achieved.

Owner:JIANGXI JUSHENG ANIMAL HUSBANDRY CO LTD

Organic-inorganic composite electrolyte membrane as well as preparation method and application thereof

ActiveCN108134036AThere will be no problem of large self-dischargeSolve self-dischargeCell component detailsElectrolyte accumulators manufactureComposite electrolyteInorganic particle

The application discloses an organic-inorganic composite electrolyte membrane. The electrolyte membrane is a porous polymer membrane prepared from a porous organic-inorganic composite particle, wherein the porous organic-inorganic composite particle is prepared from a porous inorganic matter and thermosetting resin. The electrolyte membrane has abundant pore structures and high porosity while maintaining the low crystallinity of a polymer; thus, the ionic conductivity of the electrolyte membrane can be greatly improved, wherein the porous inorganic particle can be also used for forming abundant ion channels inside besides being capable of improving the liquid preservation capacity of the electrolyte membrane and prolonging the cycle service of a battery core; the ionic conductivity and anelectrochemical stability window of the electrolyte membrane are further improved, and the requirement of the application to a high-voltage system can be met.

Owner:DONGGUAN AMPEREX TECH

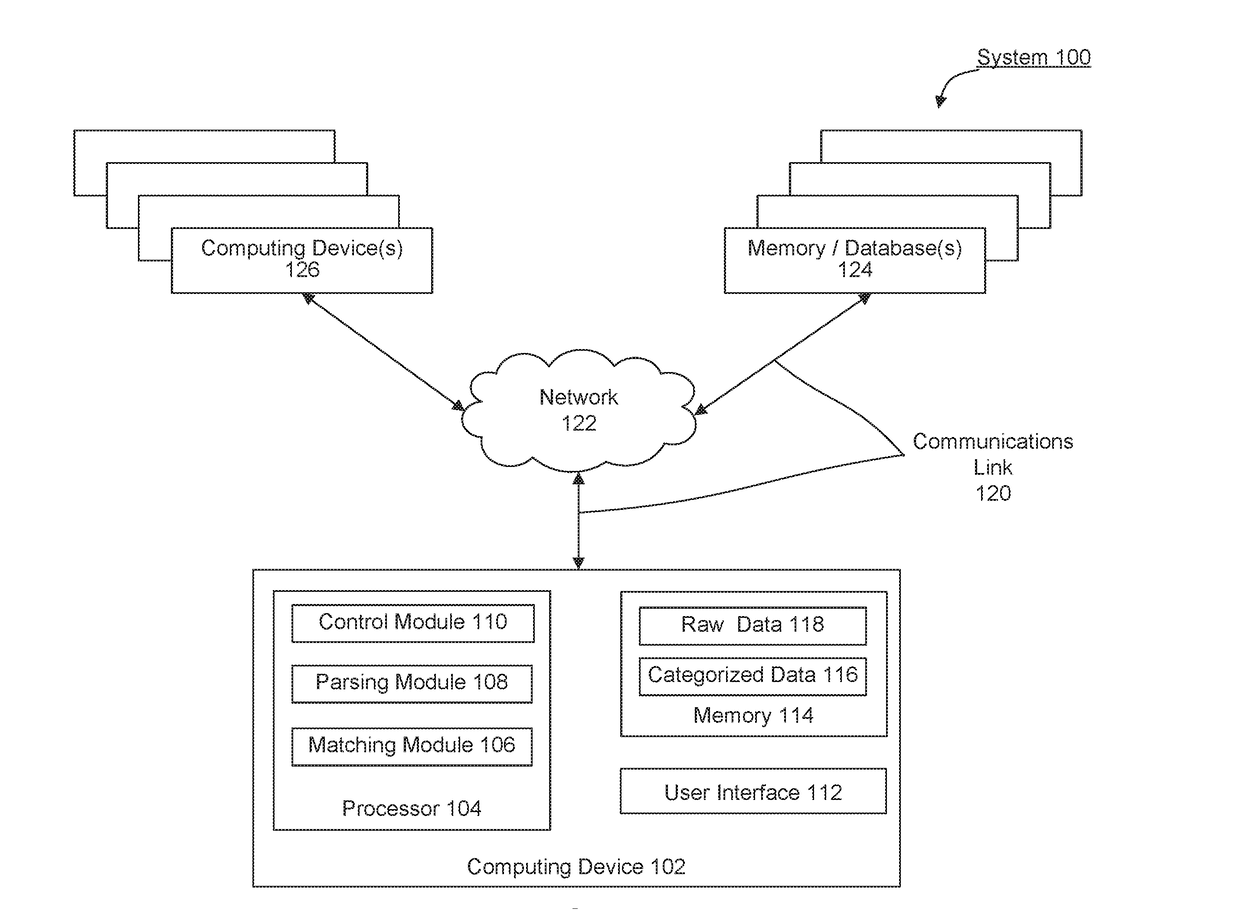

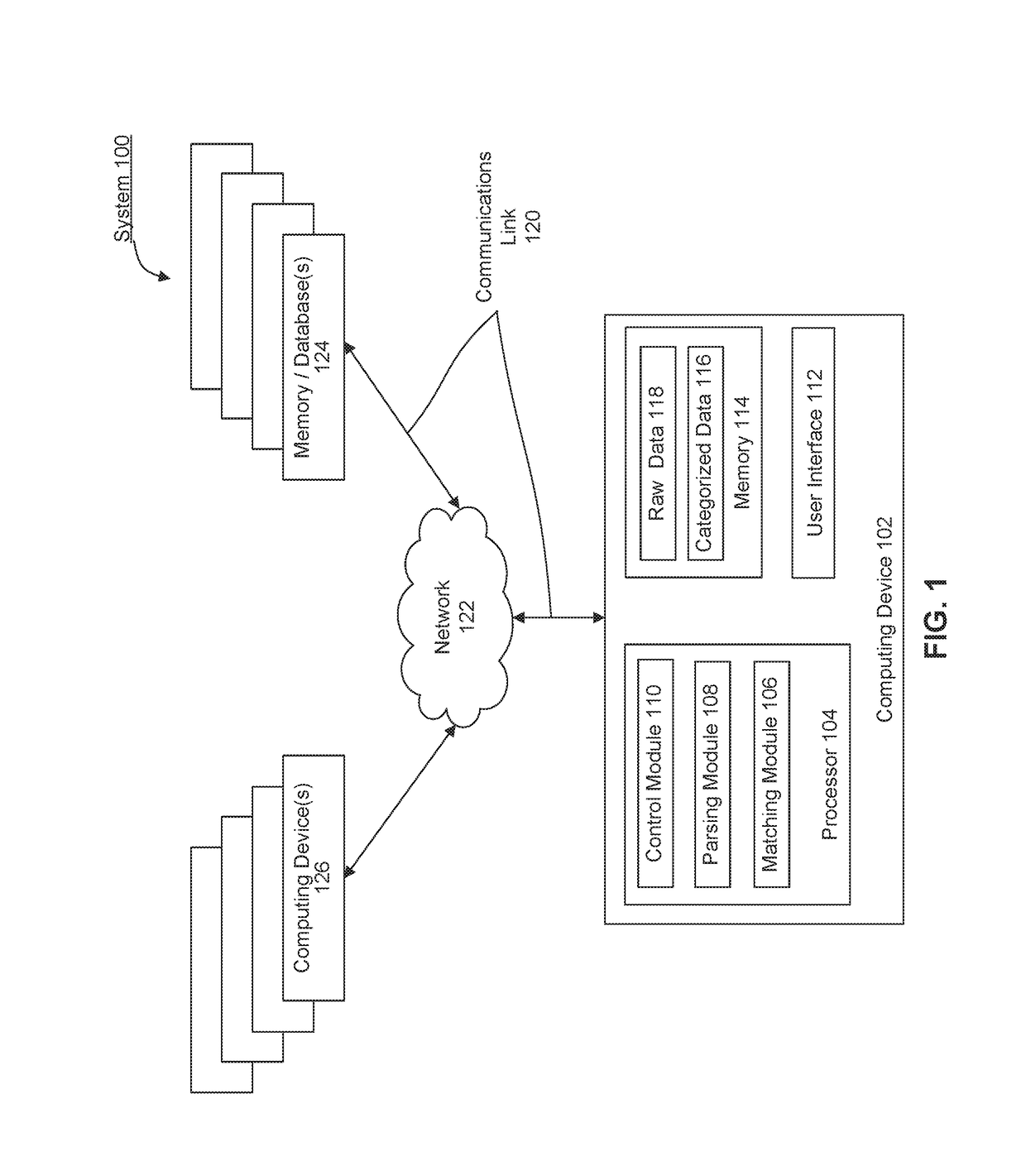

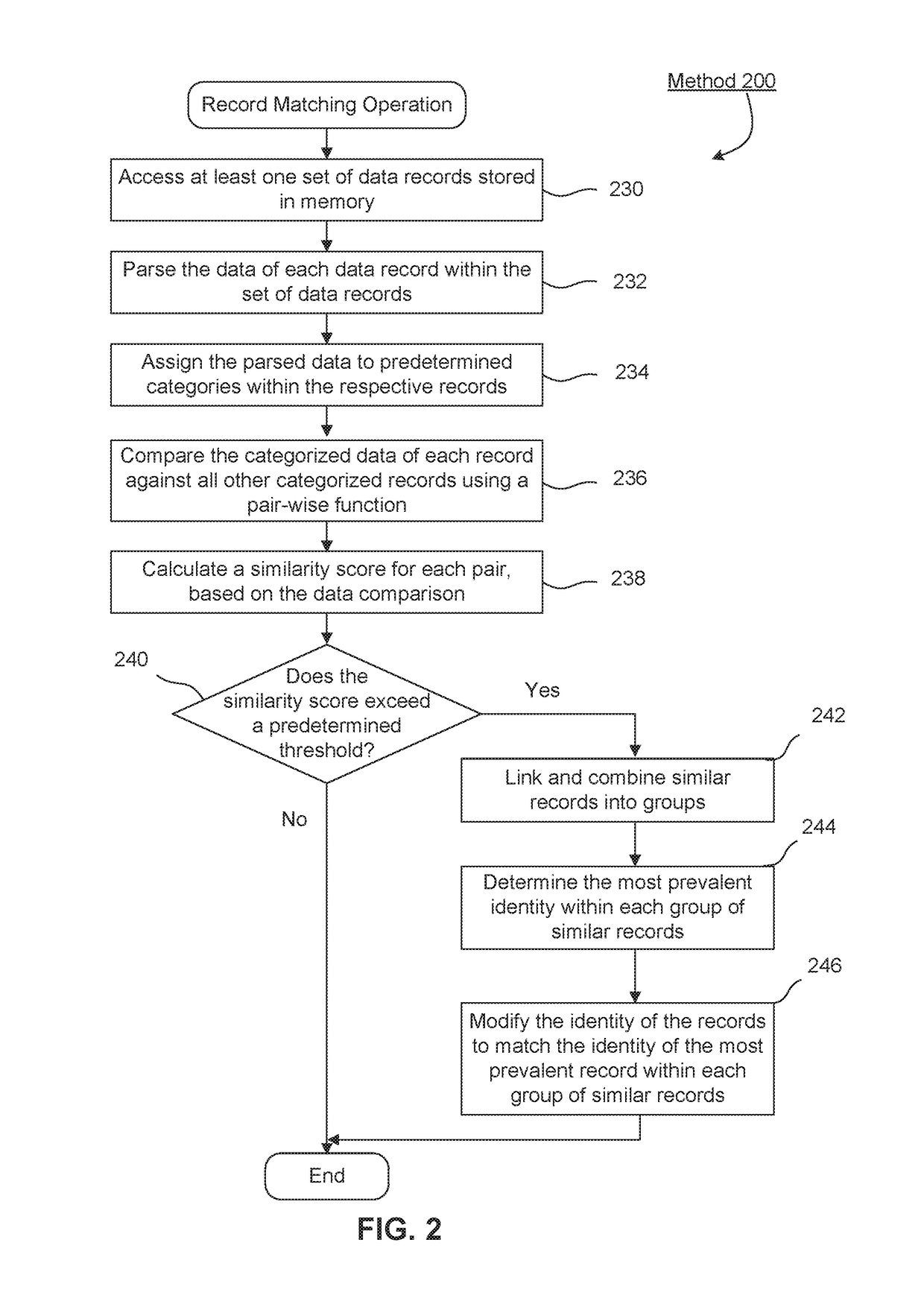

Linking incongruous personal data records, and applications thereof

ActiveUS20170270181A1Strengthen linkRelational databasesNatural language data processingData recordingLinked data

Disclosed herein are system, method, and computer program product embodiments for linking data records in memory. The system, method, and computer program product includes accessing a first record stored in memory, the first record holding information describing a first person and accessing at least one additional record stored in memory, the additional records holding information describing additional persons. The method continues by parsing the information of the first record and additional record and assigning the parsed information to predefined categories within the respective records. After assigning the information into categories, a similarity score between categorical information in the first record and categorical information of additional records is determined. A category of an additional record is then modified based on the similarity score, so the additional record is associated with the first person.

Owner:VEDA DATA SOLUTIONS INC

Identification assembly for an identity document

ActiveUS9944109B2Easy to checkSimple and reliable processInformation cardsPaper documentDocument preparation

An identification assembly for an identity document (10) includes a substrate (12) with a substantially planar configuration, and an adjacent surface (13, 14) hingeably attached to the substrate (12) and provided adjacent to the substrate (12). The substrate (12) includes at least two image areas (18, 20), a first image area (18) having a first image (19), and wherein the substrate includes a second image area (20) including a second laser produced image (21), and a third image (22) corresponding to the second image (21) is provided through the second image area (20) onto the adjacent surface (13, 14), the third image (22) being visible for a user by hinging the substrate away from the adjacent surface (14).

Owner:IDEMIA THE NETHERLANDS BV

Selenium nutrition medium, preparation method, morchella selenium-rich culture method and application

InactiveCN113647294AIncrease profitGood selenium enrichment effectCultivating equipmentsMushroom cultivationBiotechnologyNutrition

The invention provides a selenium nutrition medium, a preparation method, a morchella selenium-rich culture method and application, and belongs to the technical field of agriculture. The selenium nutrition medium provided by the invention is prepared from the following raw materials in parts by mass: 50 to 60 parts of selenium nutrition, 6 to 15 parts of organic silicon, 68000 parts of water and 1000000 parts of wheat grains. According to the invention, the selenium nutrition is absorbed into the wheat grains under the assistance of permeability of organic silicon, capture failure of other elements in the culture medium on selenium is avoided, the decomposition and utilization rate of morchella hyphae on the wheat grains is high, the absorption and utilization rate of selenium is increased, and the selenium content of morchella products is increased.

Owner:恩施土家族苗族自治州中心医院

Repair regeneration material for curbstone and bonding method of repair regeneration material

The invention relates to a repair regeneration material for curbstone and a bonding method of the repair regeneration material. The repair regeneration material is prepared via the following steps ofpulverization of waste ore-moldability activation of a regeneration material-preparation of an accessory material-ultra low temperature treatment of the accessory material-curbstone processing. curbstone under repair and originally damaged curbstone are connected by a binding agent, the inner layer of the binding agent is connected with stone and glue, outer-layer glue is bonded with inner-layer glue, outer-layer particles are integrated into repair curbstone at high temperature, interlinkage is strengthened, demolding time is reduced, strength is enhanced, meanwhile, metal powder at a seam and inner-layer magnetofluid are adsorbed, the magnetofluid is used for driving the glue to flow to the periphery, the metal powder enters the seam, bonding is completed at the seam finally, the seam can be effectively filled, the abradability at the seam is enhanced, and the aging rate is reduced.

Owner:FENGYANG FENGCHENG JIANAN PREFABTED FACTORY

Collagen/hydroxyapatite composite coating joint prosthesis implant and preparation method thereof

The invention discloses a collagen / hydroxyapatite composite coating joint prosthesis implant and a preparation method thereof. The surface of a joint prosthesis material is coated with collagen and hydroxyapatite composite sequentially, wherein the thickness of the collagen coating is 10-20 mu m, the porosity of the collagen coating is 90-95 percent, the thickness of the hydroxyapatite coating is 20-50 mu m, and the porosity of the hydroxyapatite coating is 5-15 percent, so that the surface of the joint prosthesis contains a natural bone extracellular matrix ingredient, so that the function of inducing osteogenesis is enhanced, and thus the linkage of bone and an implanted titanium plate is promoted, the joint prosthesis is physiologically fixed, and the difficulty that the joint prosthesis is easy to loosen after being implanted inside in the prior art is effectively solved.

Owner:ZHEJIANG UNIV

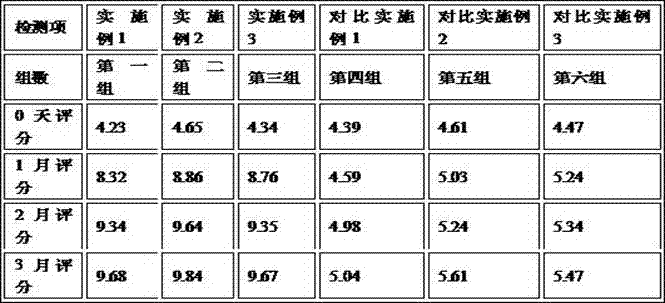

Hair conditioner and preparation method thereof

PendingCN107485593AStrengthen linkIncrease contactCosmetic preparationsHair cosmeticsLicorice rootsGlyceryl monostearate

The invention relates to a hair conditioner and a preparation method thereof. The hair conditioner of the present invention is composed of polyquaternium-7, a conditioning agent, a repairing agent, an emulsifier, and deionized water. The conditioning agent is composed of Polygonum multiflorum, Chinese yam, cinnamon, Composed of Eucommia ulmoides, Angelica dahurica, Astragalus, Gastrodia elata, and licorice, the repairing agent is composed of polydimethylsiloxane, lanolin, and glyceryl monostearate; the conditioning agent is mainly to enhance the body's kidney function and activate the activity of hair follicles. The hair quality becomes healthier, and the repairing agent directly fills the scales on the surface of the hair, making the hair smooth and shiny. The hair conditioner obtained by the invention has remarkable effects in improving the hair quality, smoothness and brightness of the hair.

Owner:卓小玲

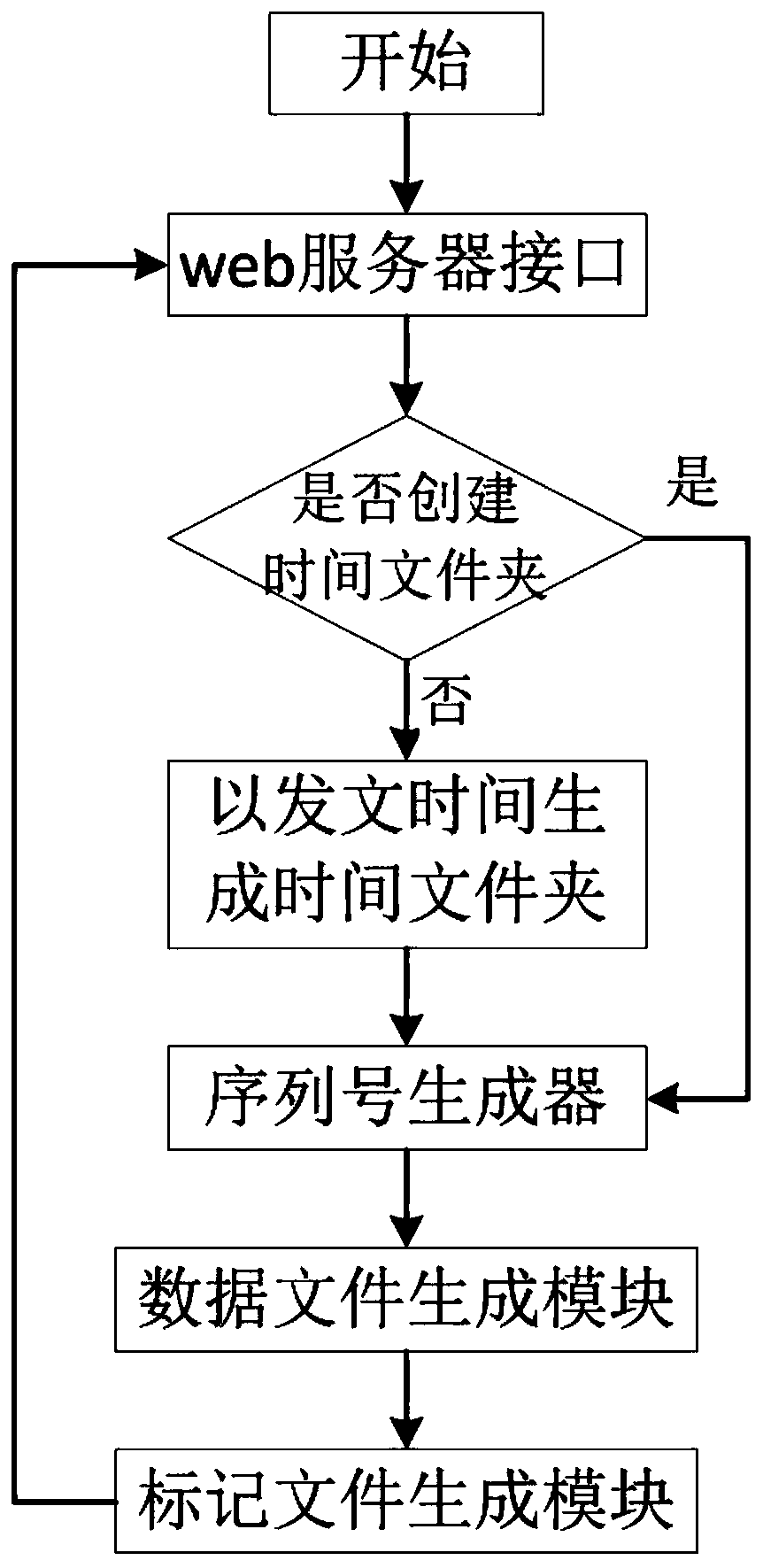

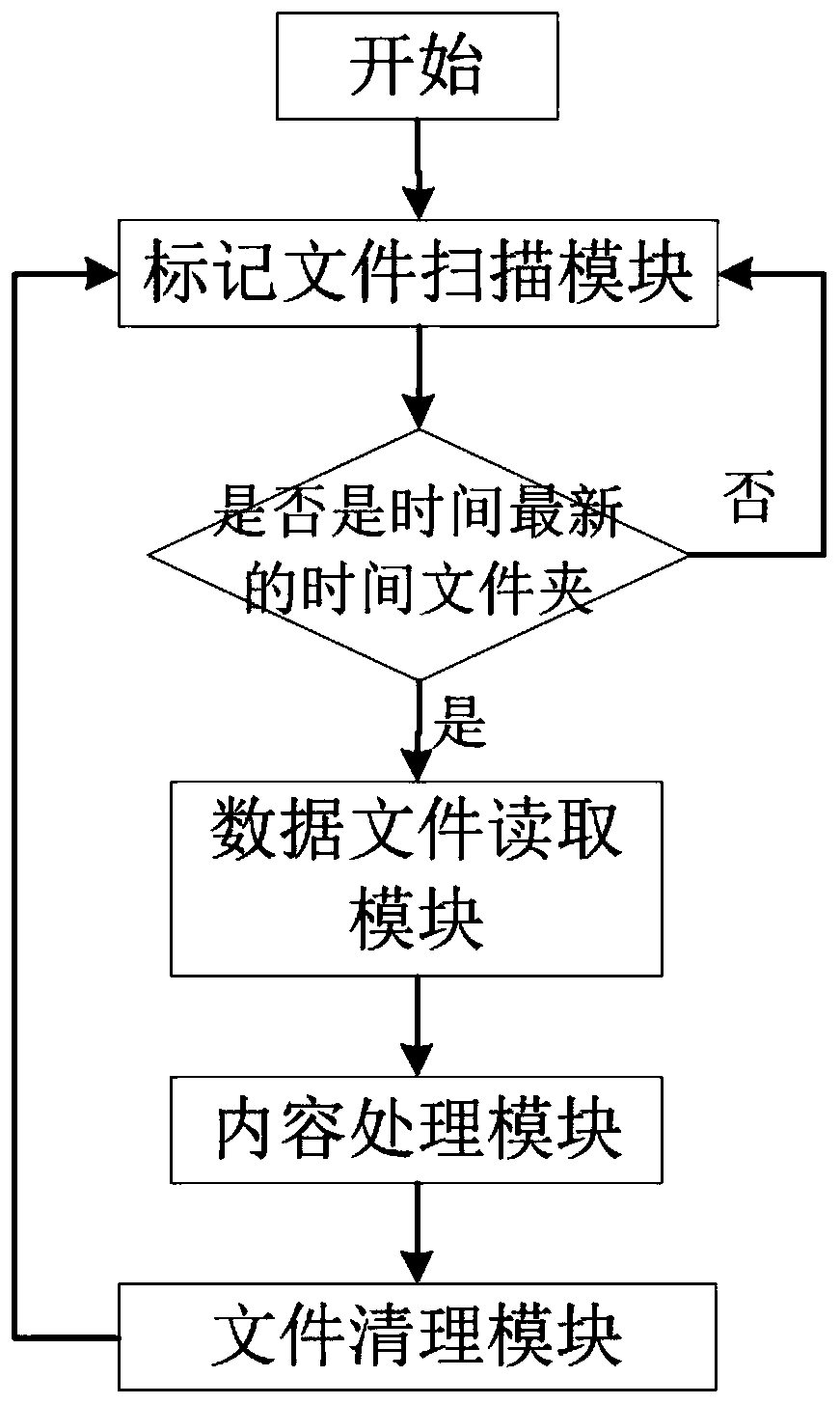

Recent message sending priority processing method and system based on crawler texts

PendingCN110727845AReduce wasteStrengthen linkMulti-dimensional databasesFile/folder operationsLogic complexityData file

The invention discloses a recent message sending priority processing method and system based on a crawler text. The recent message sending priority processing method comprises the steps: a producer process stores all crawled data files in time folders with the message sending time of the producer process as a file name, and generates a mark file correlated with the data files in each time folder;and the consumer process extracts a time folder with the latest current time, regularizes the corresponding data file according to the mark file under the time folder, and moves the regularized data file to a historical folder. The recent message sending priority processing adopts a double-file control method, so that a producer and a consumer can be prevented from operating one file at the same time without using a system lock, and the accuracy of data is ensured, and the logic complexity of the system is reduced, and the maintainability of the system is improved.

Owner:DATAGRAND TECH INC

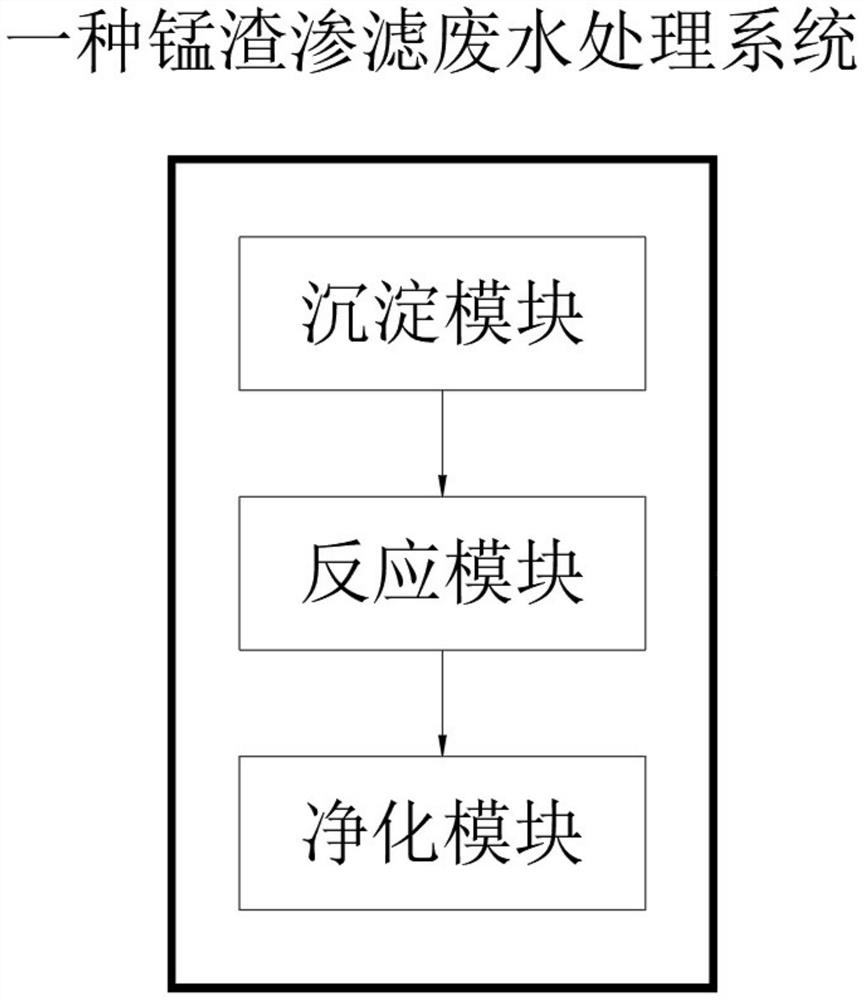

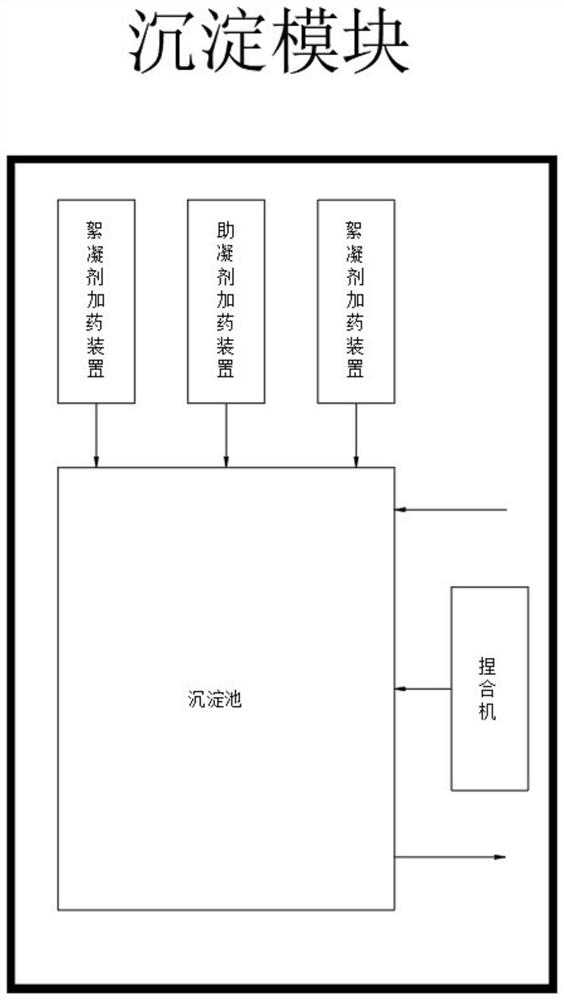

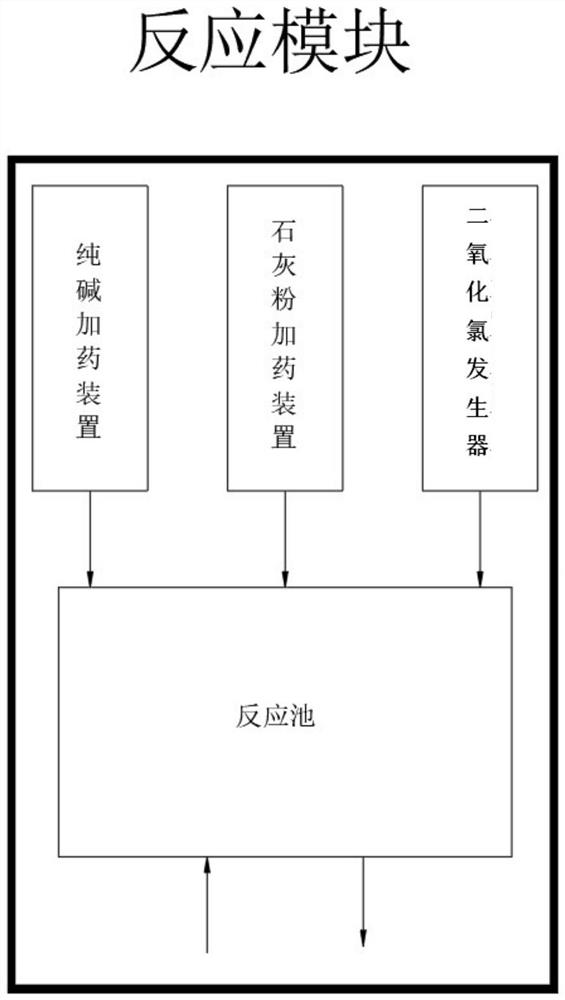

Manganese slag percolation wastewater treatment system

PendingCN114314952AEasy to separate and precipitateEasy to recycleWater contaminantsMultistage water/sewage treatmentAmmoniacal nitrogenWater treatment system

The invention discloses a manganese residue percolation wastewater treatment system, and relates to the field of wastewater treatment, the manganese residue percolation wastewater treatment system comprises a precipitation module, a reaction module and a purification module, the precipitation module comprises a precipitation tank, a coagulant aid dosing device, a kneading machine and two flocculant dosing devices, the reaction module comprises a sodium carbonate dosing device, a lime powder dosing device, a chlorine dioxide generator and a reaction tank, and the purification module comprises a purification tank, an ammonia nitrogen membrane separator, an electric adsorption device, an adjusting tank, an alkali liquor dosing device and a dilute acid dosing device. By adding the flocculating agent and the coagulant aid, large-particle pollutants easy to precipitate in the wastewater can be separated and precipitated, subsequent recycling or innocent treatment of the precipitates is facilitated, and meanwhile, the inorganic flocculating agent can separate out and precipitate color development substances in the wastewater, so that the cost of subsequent decolorization treatment is reduced; the waste water treatment efficiency is high, the cost is low, the discharge standard is met, and meanwhile impurities in the waste water can be conveniently recycled and reused.

Owner:靖西市大西南锰业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com