Silver-containing nanocrystal blue light enhanced tellurite glass and preparation method thereof

A tellurate glass, silver nanotechnology, applied in the field of up-conversion luminescent materials, can solve the problems of limited practical application, limited up-conversion luminescence performance, poor stability of sulfide glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

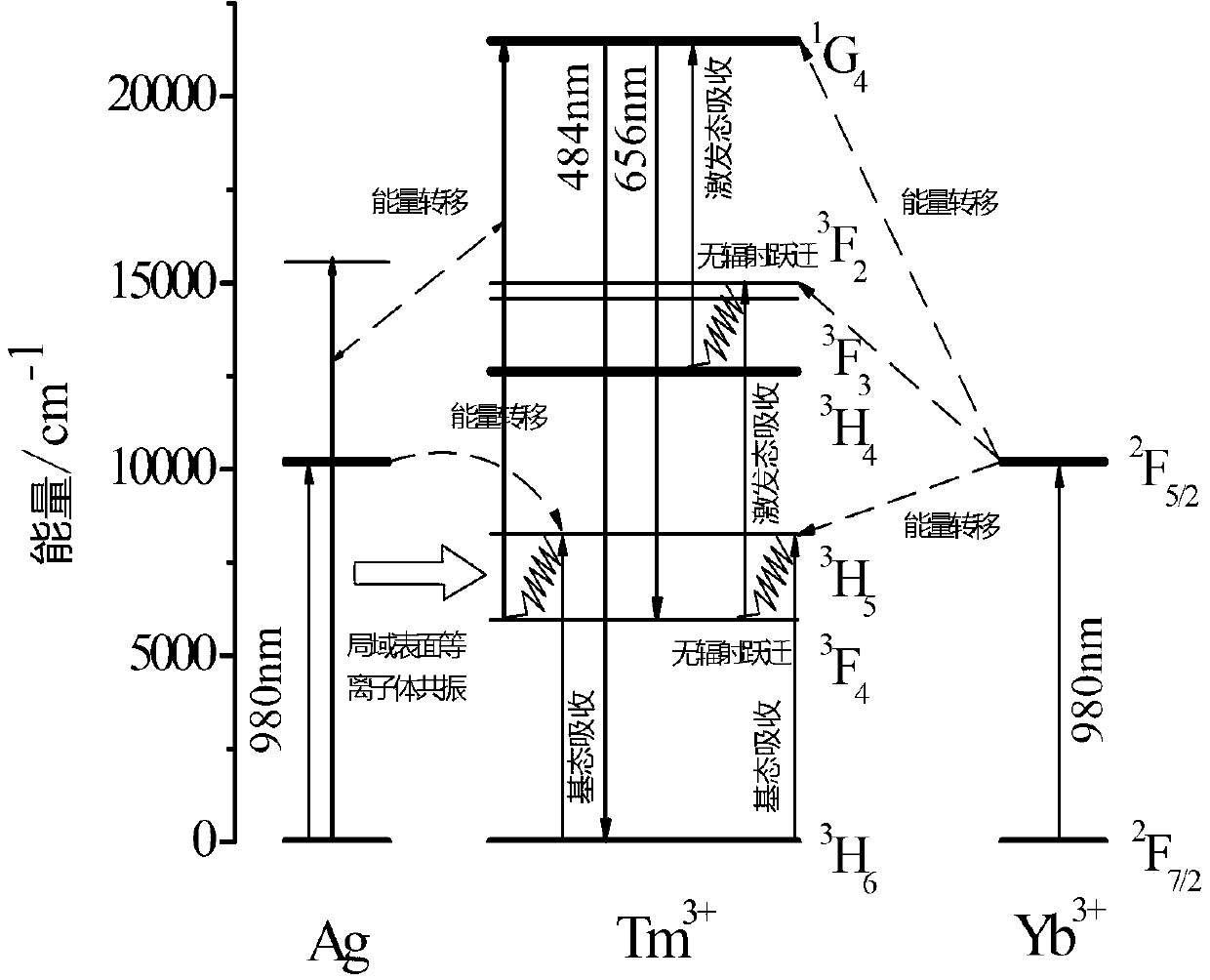

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) The composition of the glass is: TeO 2 : 80mol%, WO 3 : 5mol%, ZnO: 5mol%, ZnF 2 : 5mol%, ZnCl 2 : 5mol%, at the same time doped: Tm2 o 3 : 0.02mol%, Yb 2 o 3 : 0.1mol%, AgCl: 0.3wt%; Accurately calculate, weigh, mix according to the formula, and dry at 120°C for 10h;

[0036] (2) Put the above-mentioned batch materials into a gold crucible with a cover, and place it in a high-temperature furnace for melting, the atmosphere is air, the melting temperature is 760°C, and the melting time is 20 minutes;

[0037] (3) Pour the molten glass onto a copper plate or stainless steel mold at 250°C for molding, then anneal at 260°C for 2 hours to eliminate internal stress, and then cool with the furnace;

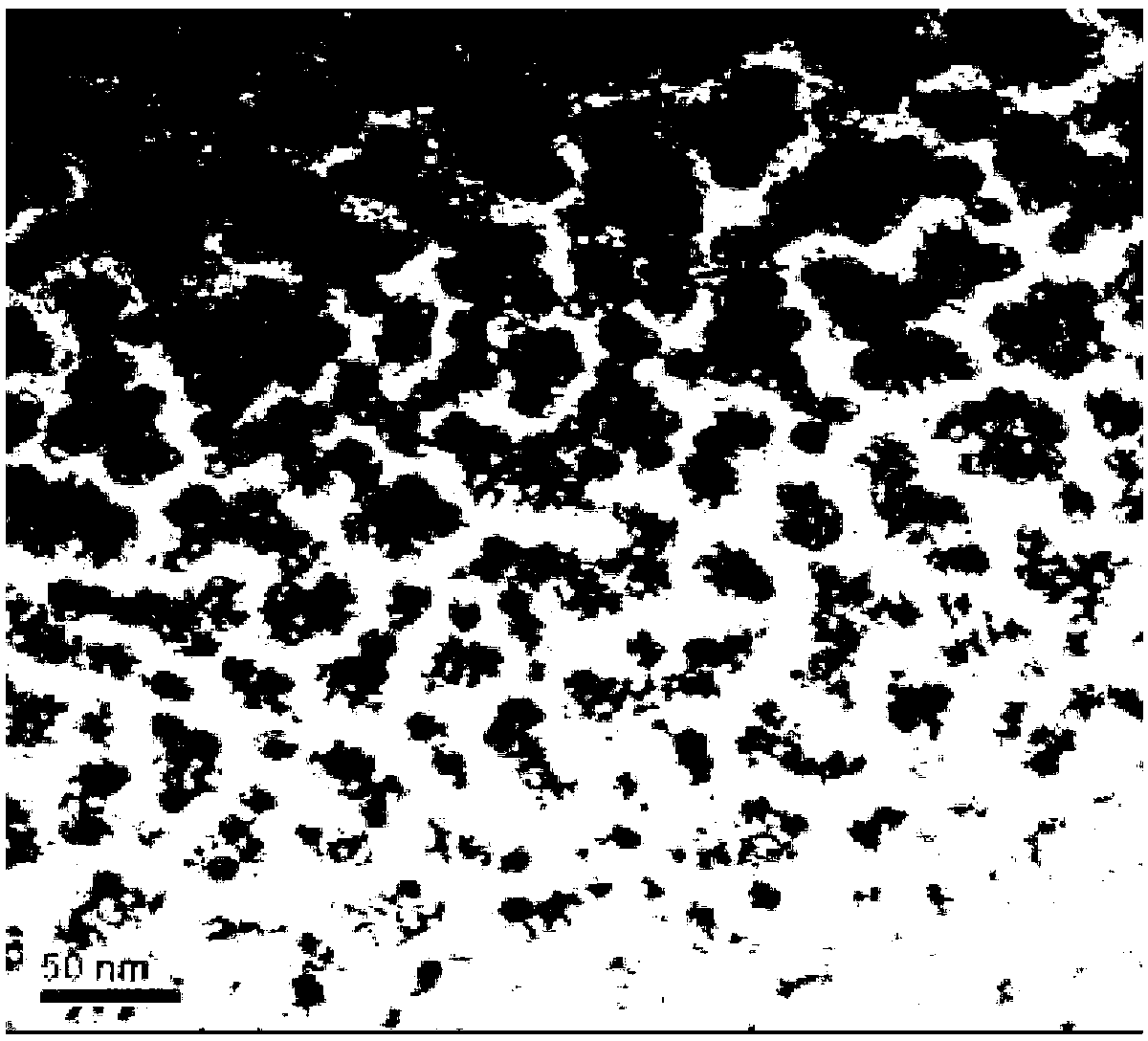

[0038] (4) The obtained glass is heat-treated at 310°C for 15 minutes and then cooled in the furnace.

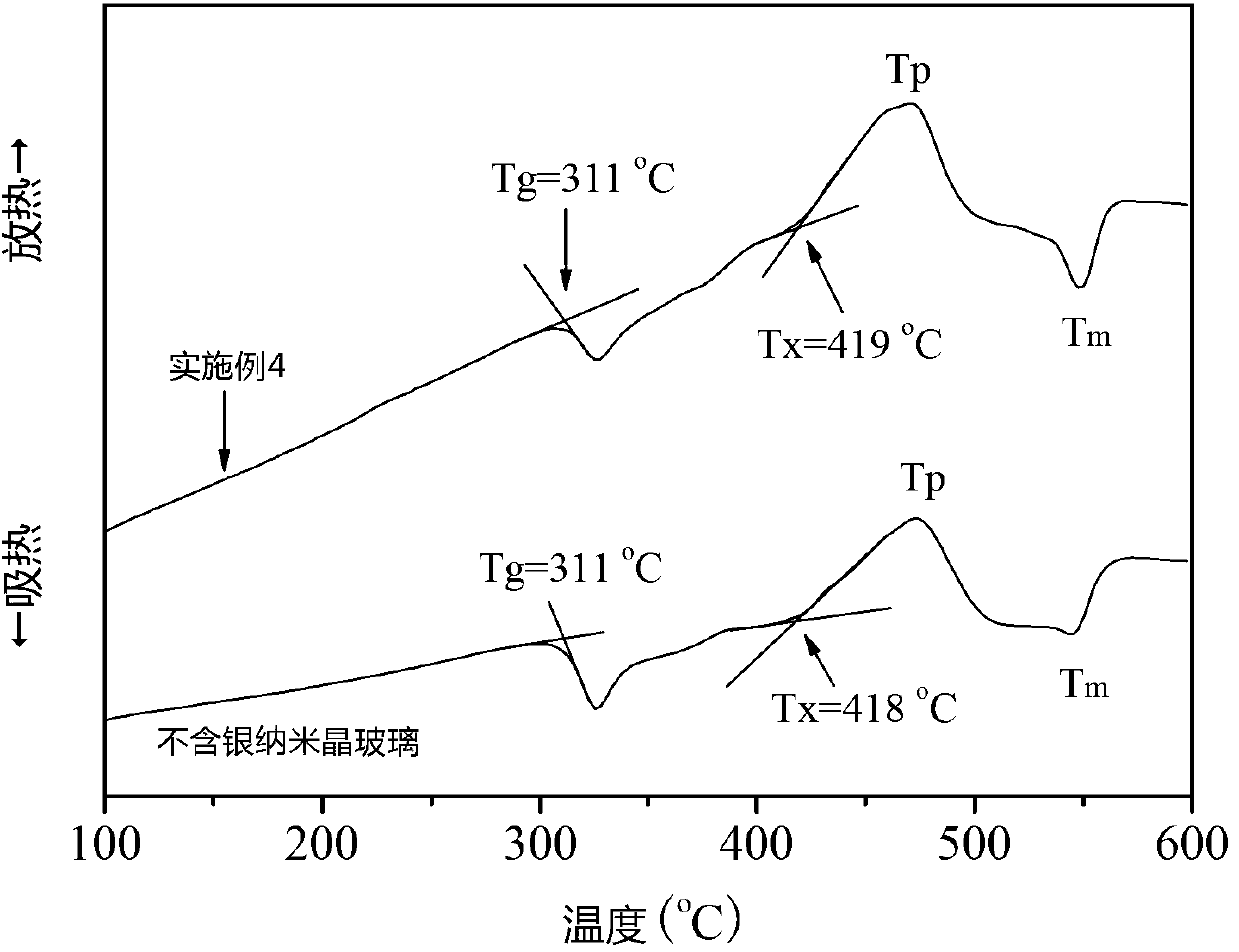

[0039] The thermal stability parameter ΔT(°C) of the glass prepared in this example reaches 102°C, the glass has good glass-forming properties, and the fluorescence ...

Embodiment 2

[0041] (1) The composition of the glass is: TeO 2 : 75mol%, WO 3 : 8mol%, La 2 o 3 : 2%, ZnO: 5mol%, ZnF 2 : 5mol%, ZnCl 2 : 5mol%, at the same time doped: Tm 2 o 3 : 0.02mol%, Yb 2 o 3 : 0.1mol%, AgCl: 0.5wt%, AgF: 0.1wt%. Accurately calculate, weigh and mix according to the formula, and dry at 120°C for 8 hours;

[0042] (2) Put the above-mentioned batch materials into a covered gold crucible, and place it in a high-temperature furnace for melting, the atmosphere is air, the melting temperature is 780°C, and the melting time is 18 minutes;

[0043] (3) Pour the molten glass onto a copper plate or stainless steel mold at 260°C for molding, then anneal at 260°C for 2 hours to eliminate internal stress, and then cool with the furnace;

[0044] (4) The obtained glass is heat-treated at 330°C for 30 minutes and then cooled in the furnace. The thermal stability parameter ΔT(°C) of the prepared glass reaches 105°C, the glass has good glass-forming performance, and the fl...

Embodiment 3

[0046] (1) The composition of the glass is: TeO 2 : 70mol%, WO 3 : 8mol%, GeO 2 : 2mol%, ZnO: 5mol%, ZnF 2 : 10mol%, ZnCl 2 : 5mol%, at the same time doped: Tm 2 o 3 : 0.06mol%, Yb 2 o 3 : 0.3mol%, AgCl: 0.5wt%. Accurately calculate, weigh and mix according to the formula, and dry at 130°C for 8 hours;

[0047] (2) Put the above-mentioned batch materials into a gold crucible with a cover, and place it in a high-temperature furnace for melting, the atmosphere is air, the melting temperature is 800°C, and the melting time is 18 minutes;

[0048] (3) Pour the molten glass onto a copper plate or stainless steel mold at 270°C for molding, then anneal at 260°C for 2 hours to eliminate internal stress, and then cool with the furnace;

[0049] (4) The obtained glass is heat-treated at 330°C for 30 minutes and then cooled in the furnace.

[0050] The thermal stability parameter ΔT(°C) of the glass prepared in this example reaches 110°C, the glass has good glass-forming proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com