Seal for a toner cartridge assembly

a toner cartridge and assembly technology, applied in the field of sealing for toner cartridge assemblies, can solve the problems of extending into the passage of toner, film is also partly torn out, and the slot can be damaged, so as to prevent the loss or leakage of toner, prevent the loss of toner, and reduce the tearing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

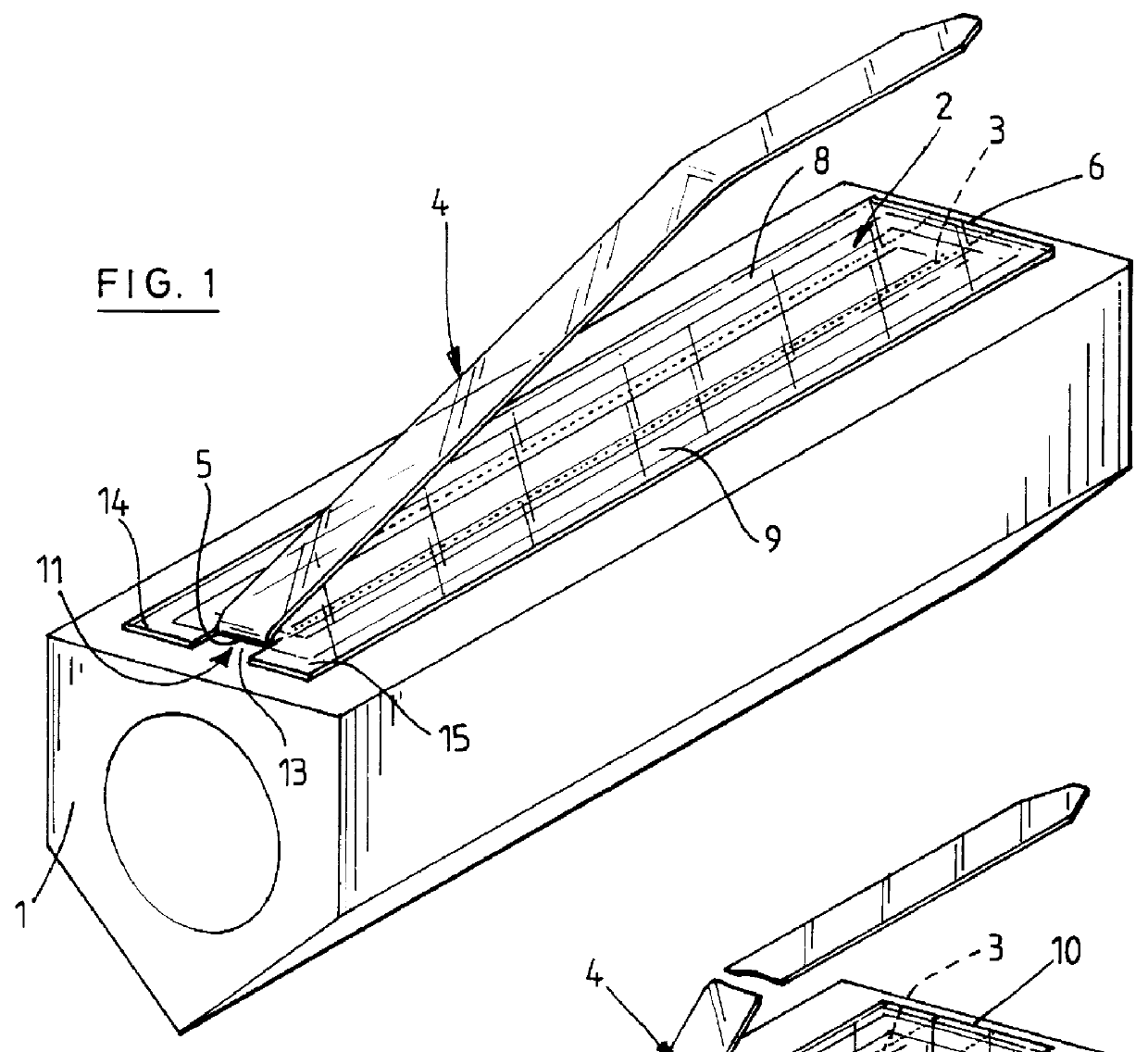

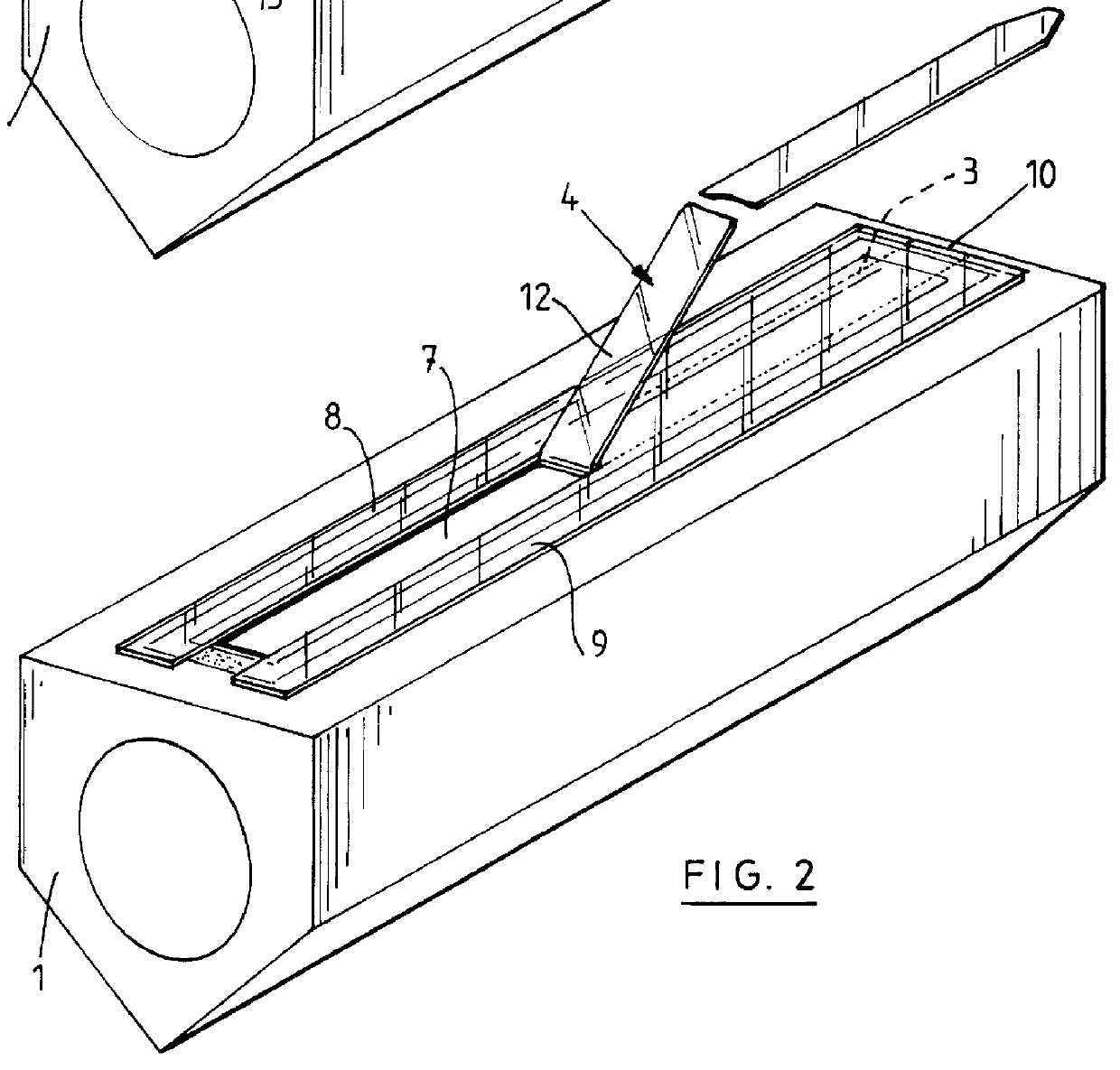

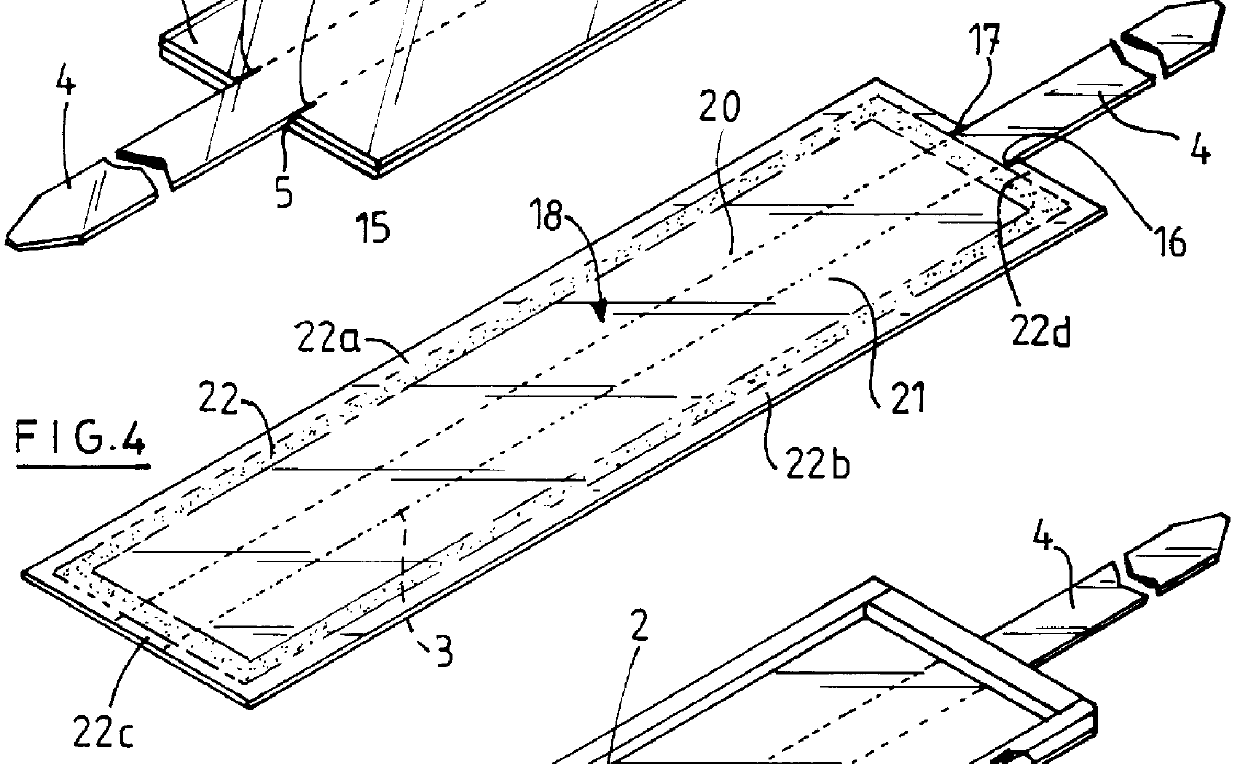

FIGS. 1 and 2 show a toner cartridge 1 provided with a seal 2. Said seal 2 is for example an unperforated film comprising fibers extending in a direction along which a central strip 3 has to be torn. Said central strip 3 can be torn by pulling a tongue 4 from a first end part 5 up to a second end part 6. When the first end part 5 is not torn, the strip closes an opening 7 through which the toner can pass and therefore prevents the loss or leakage of toner. When the central strip 3 is torn up to the second end 6 and is therefore removed, the opening 7 is formed. In the embodiment shown, the width of the opening 7 is defined by the width of the central strip 3 to be torn.

Lateral strips or parts 8,9 of the seal, i.e. along its lateral edges, are glued on the cartridge. Between the glue lines of the lateral strips 8,9, two cross glue lines extend, a first acting as means for attaching the first end part 5 to the cartridge, while the other acting as means for attaching a lateral edge 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com