Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Smooth welding surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic assembly lead-free welding paste scaling powder and preparing method thereof

ActiveCN101224528AGood printabilityGood dot formabilityWelding/cutting media/materialsSoldering mediaViscous liquidFilm-forming agent

The invention discloses an electronic mounting lead-free soldering paste flux, with the components and weight contents: 45-65% of bonding-film forming agent, 0.2-15% of activator and surfactant, 1-10% of thixotropic sink-proof slipping agent, 0.5-10% of fitting additive, and the residual quantity of solvent. The preparation method of the flux is that the solvent and the bonding film-forming agent are arranged in a container which is provided with a dispersion device according to the dosage, are heated and continuously mixed till that the material is fully dissolved; after that, other materials are once added; the heating and mixing are continued till that all materials are dissolved into bright dilute viscous liquid, and then the heating and mixing are stopped; the mouth of the container is sealed, and the invention can be obtained after static arrangement. The SnAgCuBi and AnAgCu soldering paste which is made by the flux of the invention contains no halogens, requires no cleans, has good printing performance, does not stick plates, has no bypasses or topnotch and good forming of printing point, and has no edge collapse. By reflow soldering, the welding surface and the welding spot are bright and smooth without residue or solder beadings. All technical indexes of the flux and the soldering paste achieve the JIS-3197 standard.

Owner:GUANGZHOU SOLDERWELL ADVANCED MATERIALS

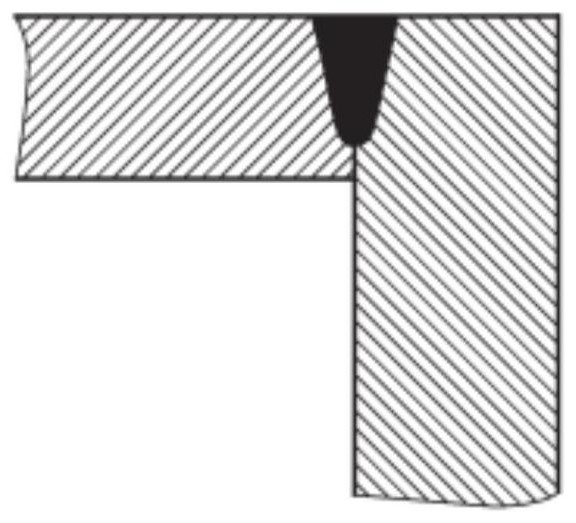

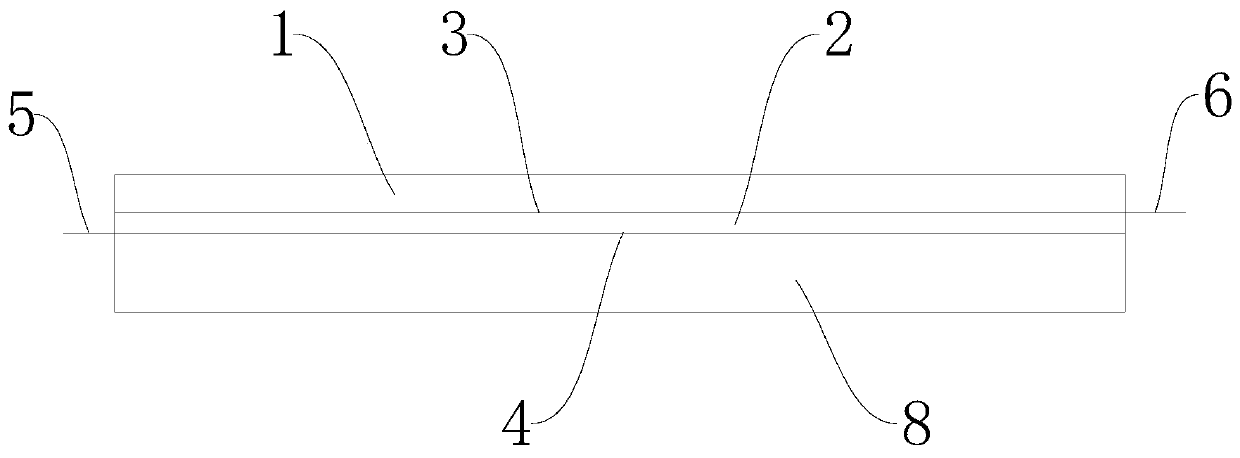

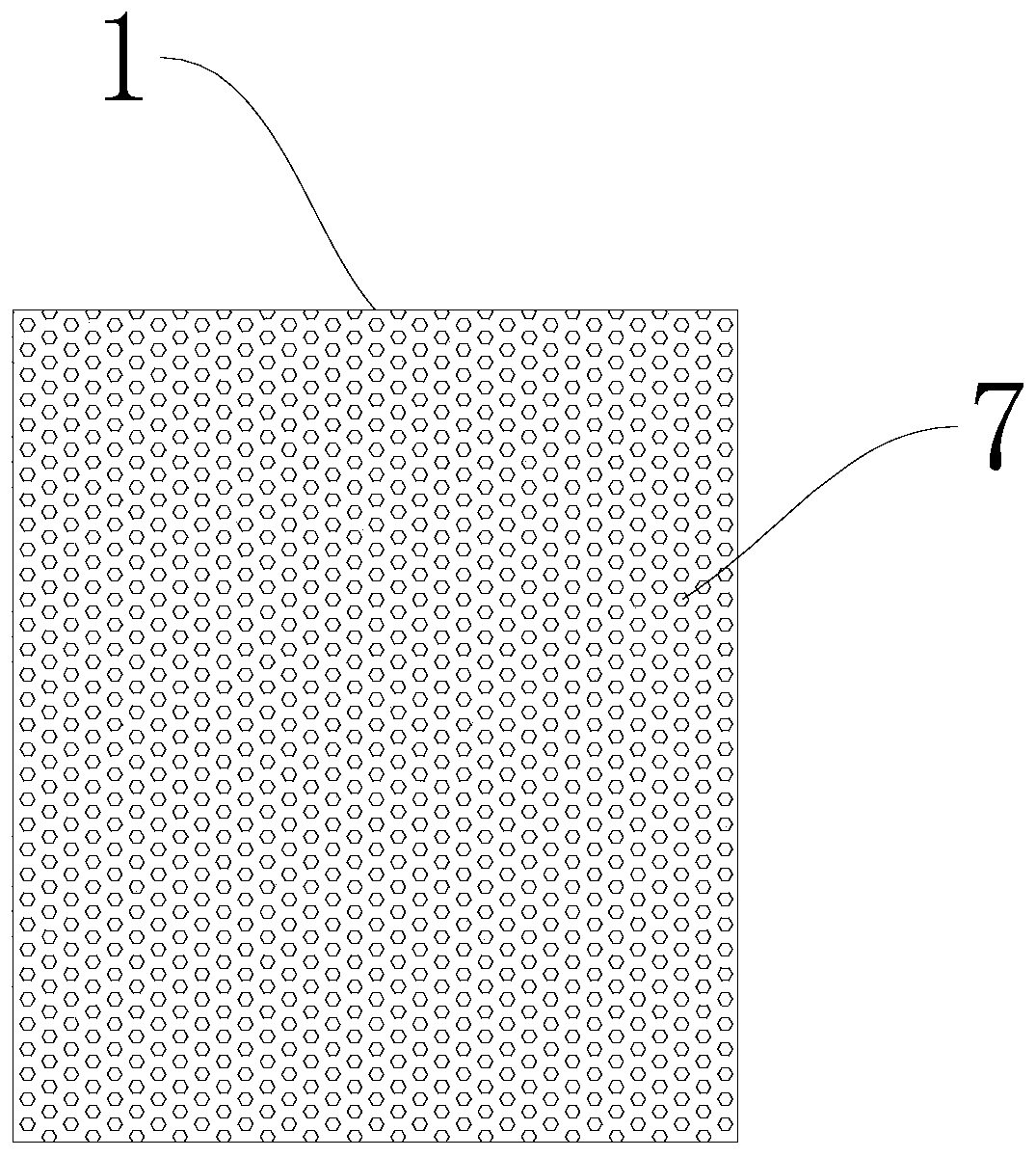

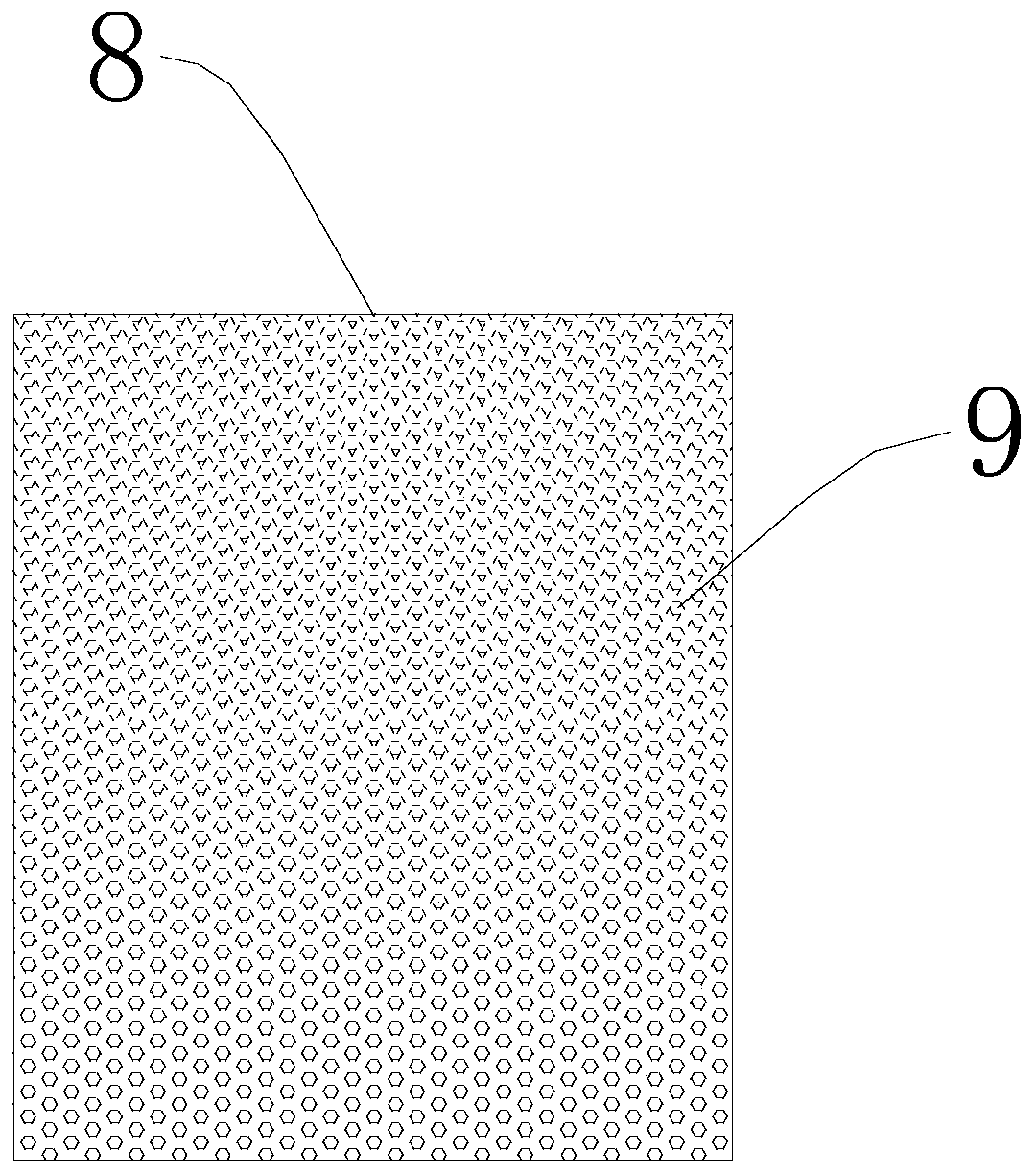

Explosive cladding welding method for titanium-steel composite board soldering joint

InactiveCN101342634AAchieving a complete weldSmooth welding surfaceWelding/soldering/cutting articlesNon-electric welding apparatusDetonatorExplosive cladding

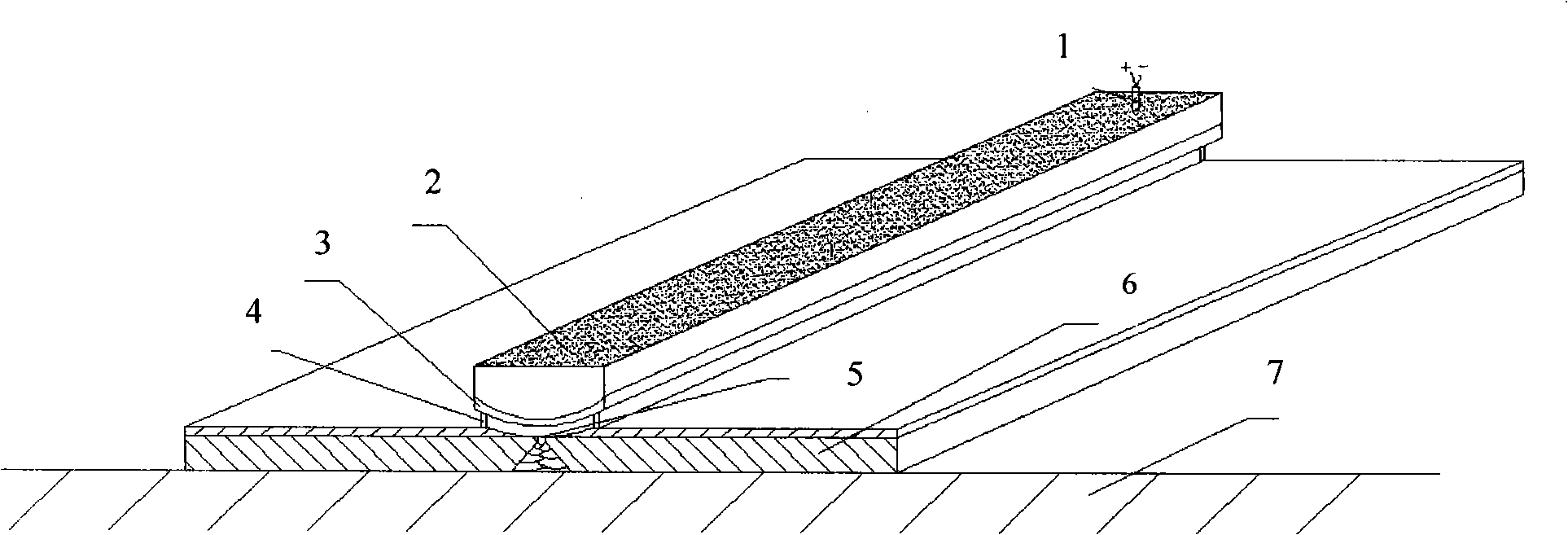

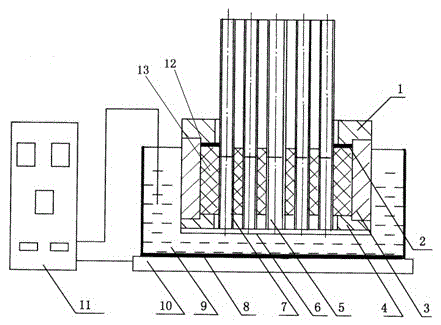

The invention discloses an explosion cladding and welding method of titanium-steel compound plate welding seams. The titanium plate used for cladding is firstly pressed into an arc-shaped titanium plate 3. The base plates of two pre-butt-jointed titanium-steel compound plates are processed into smooth arcs corresponding to the arc-shaped titanium plate 3. A groove is formed on the compound plates. The smooth arcs of the base plates, the groove of the compound plates and the arc-shaped titanium plate are grinded by abrasive paper or buffing wheel to remove the oxides on the surface of the metals and expose metallic luster. Then, the titanium-steel compound plate is arranged on a sand foundation 7, and the arc-shaped titanium plate is arranged over the smooth arcs of the base plate supported by a supporter 4. The height of the supporter is adjustable, ensuring that an arc-shaped welding seam 5 is formed between the smooth arc and the arc-shaped titanium plate. The explosive 2 is arranged on the upper surface of the arc-shaped titanium plate. Explosive charge quantity is determined by the area of explosion cladding unit. The explosive is ignited by 8# industrial electric detonator, ensuring that the arc-shaped titanium plate and the base plate are clad into an integrated body, and a complete welding titanium-steel compound plate with full penetration is gained. The welding seam has a smooth surface, is good-looking and corrosion resistance, and has a long service life.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

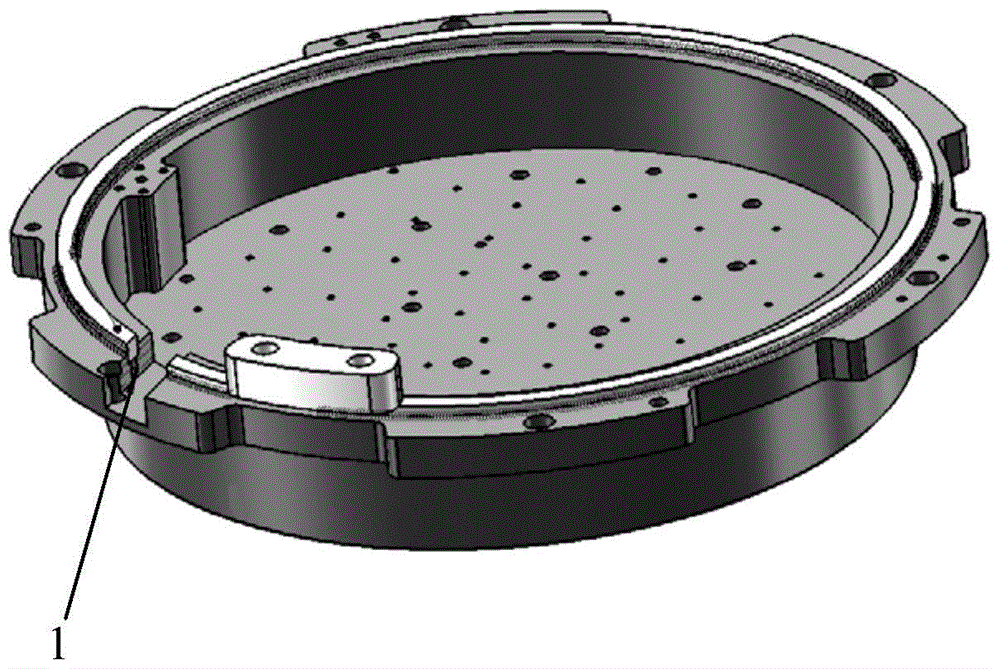

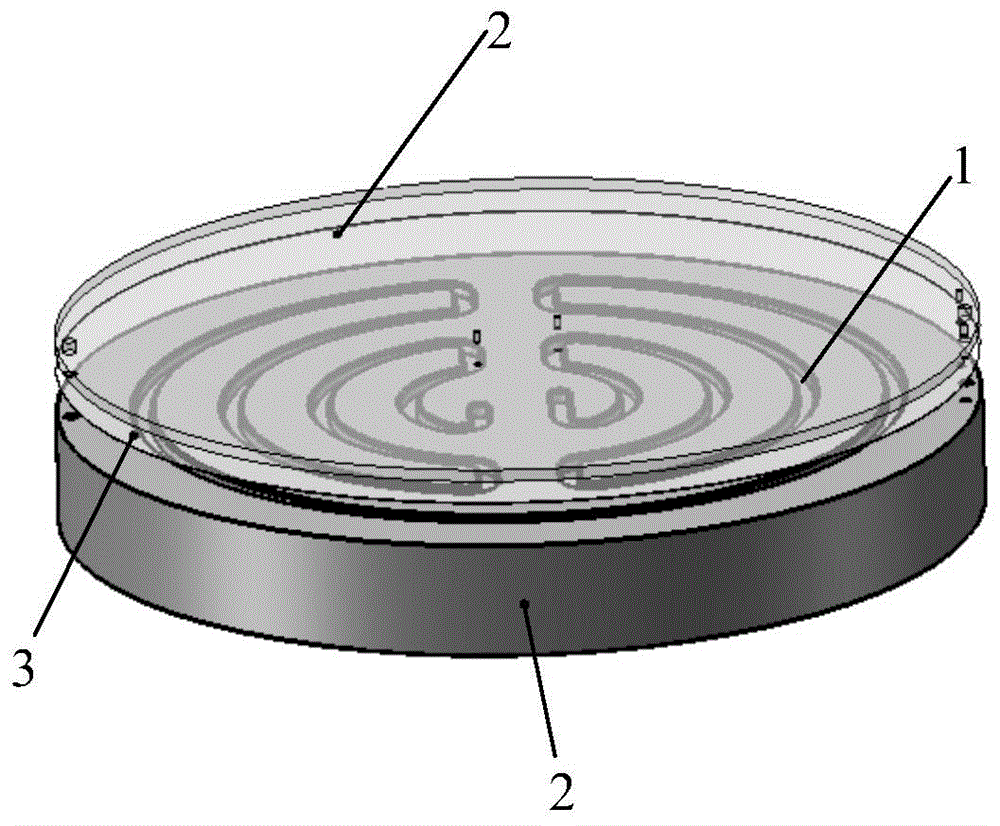

Miniature throttling refrigerator

ActiveCN104142034AEliminate thermal contact resistanceSmooth welding surfaceFluid circulation arrangementMechanical apparatusEngineeringHigh pressure

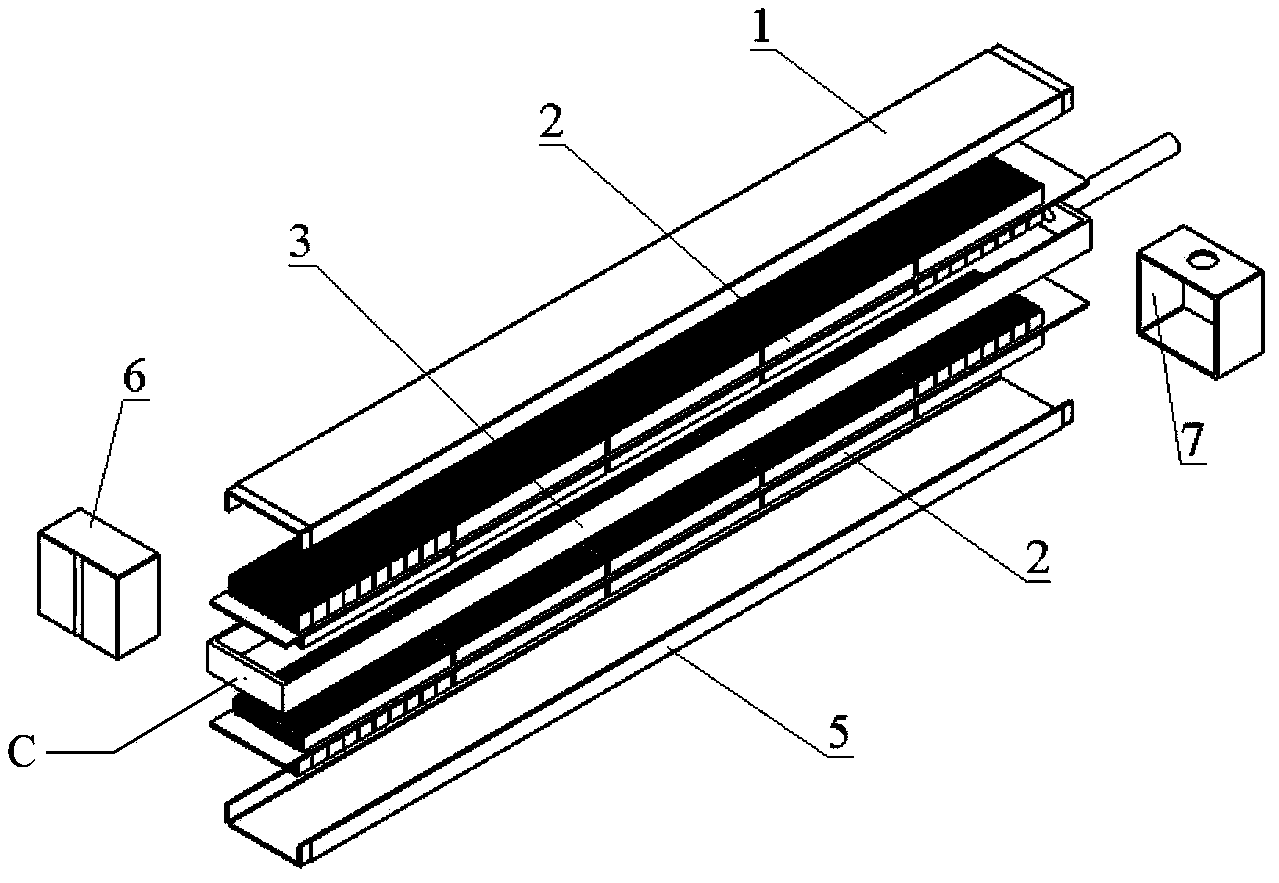

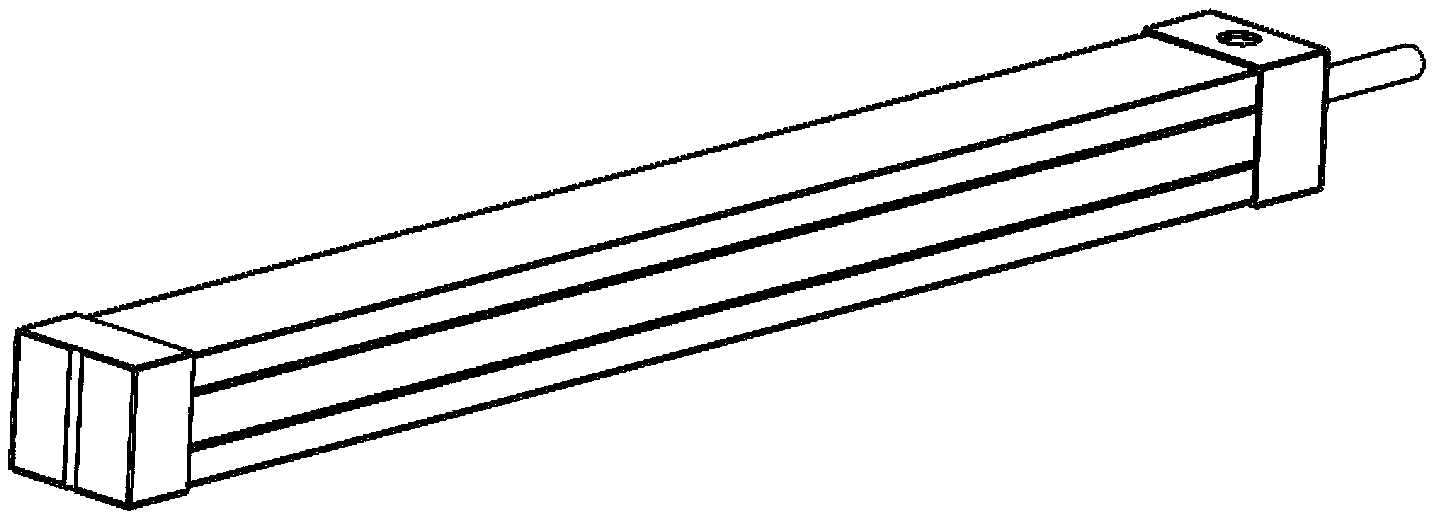

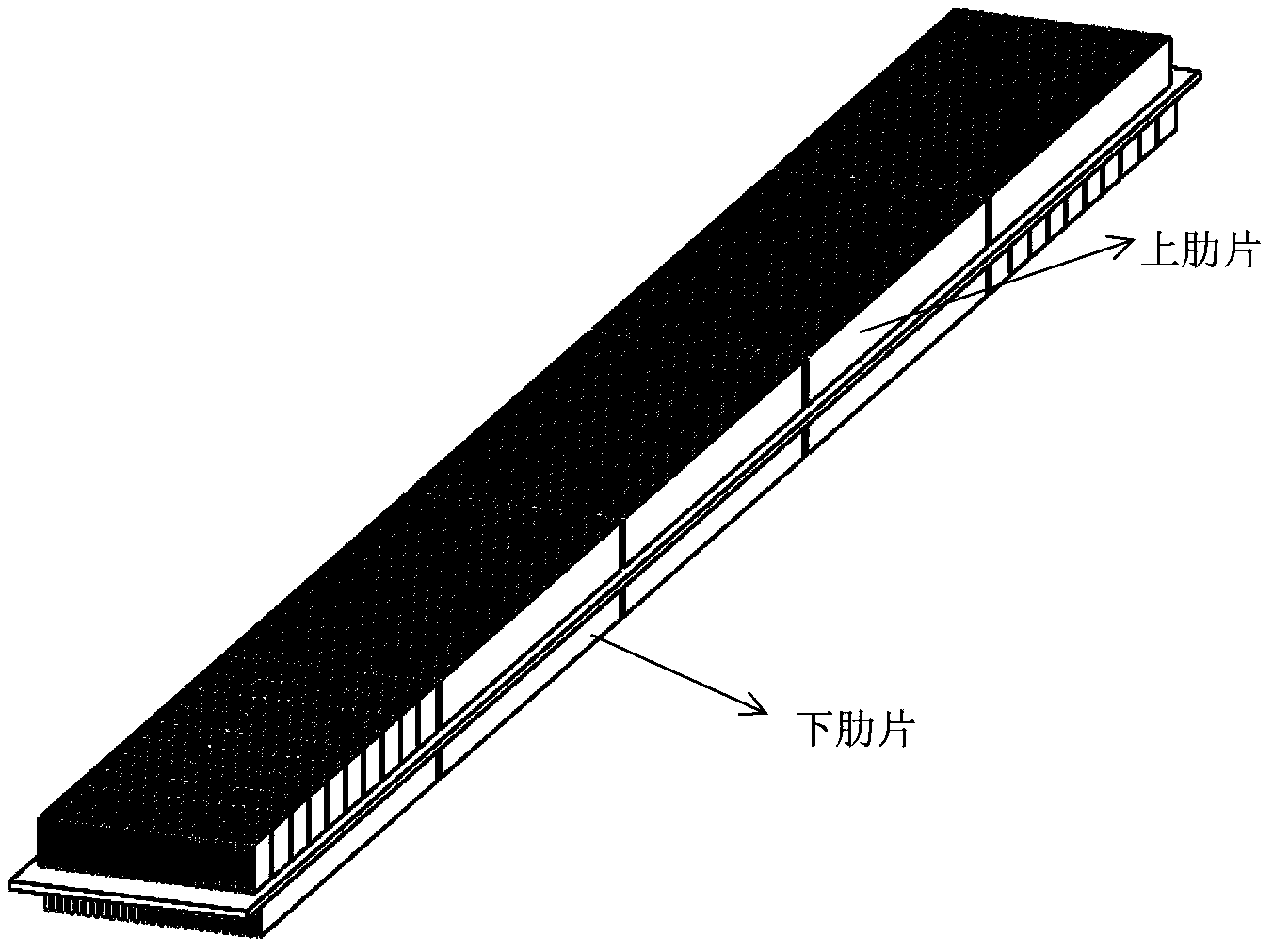

The invention discloses a miniature throttling refrigerator which is composed of an upper cover plate, a lower cover plate, a heat-exchange core body and a cold-end seal head. An upper rib sheet and a lower rib sheet are fixed on the two sides of a panel base of the heat-exchange core body; channels which are in disjunction distribution and vertical to the long side edges of the panel base are formed in the length direction of both the upper and lower rib sheets; the upper rib sheet is located in a lower groove of the upper cover plate; the lower rib sheet is located in an upper groove of the lower cover plate; a through hole and an air inlet are formed in the top part of one end of the upper cover plate while the other end is unsealed and provided with a throttling hole; a through hole and an air outlet are formed in the top part of one end of the lower cover plate while a throttling hole is formed in the other end thereof; the upper cover plate, the lower cover plate and the heat-exchange core body compose a throttling refrigeration body; the cold-end seal head is arranged on one end, at which the throttling hole is, of the throttling refrigeration body in a sleeved manner; a low-pressure passageway is formed between the upper cover plate and the upper rib sheet; a high-pressure passageway is formed between the lower cover plate and the lower rib sheet; a high-temperature and high-pressure fluid enters into the high-pressure passageway from the air inlet, is changed into a low-temperature and low-pressure fluid after passing through the throttling hole, then enters into the low-pressure passageway, and finally flows out of the air outlet. The miniature throttling refrigerator has big specific surface area and high heat exchange efficiency, can bear high-pressure operation and is easy for large-scale production.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

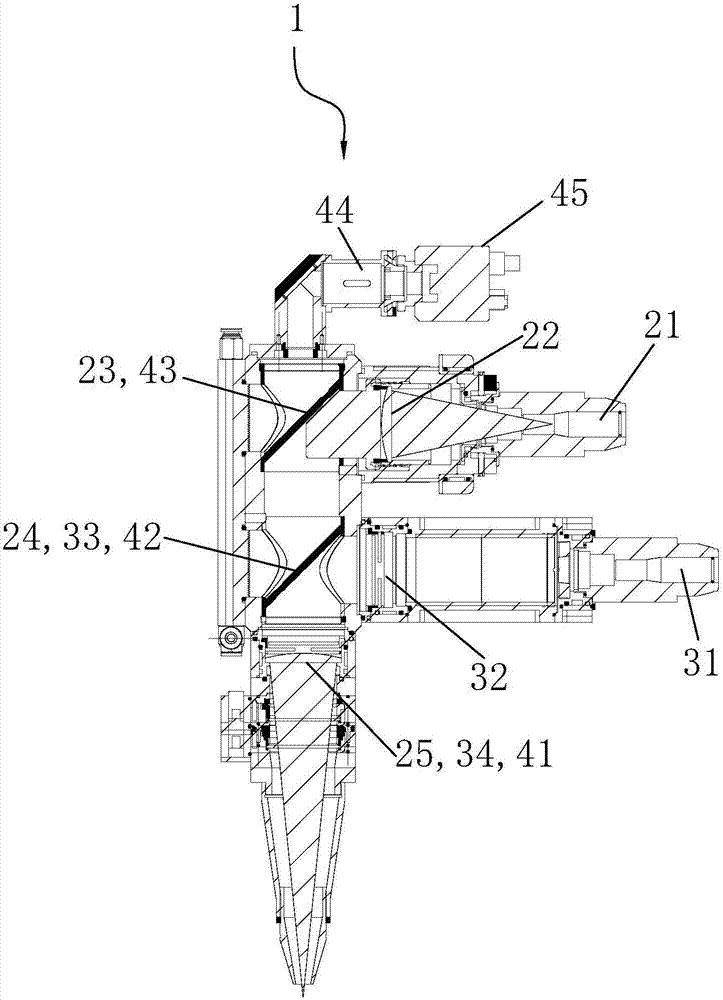

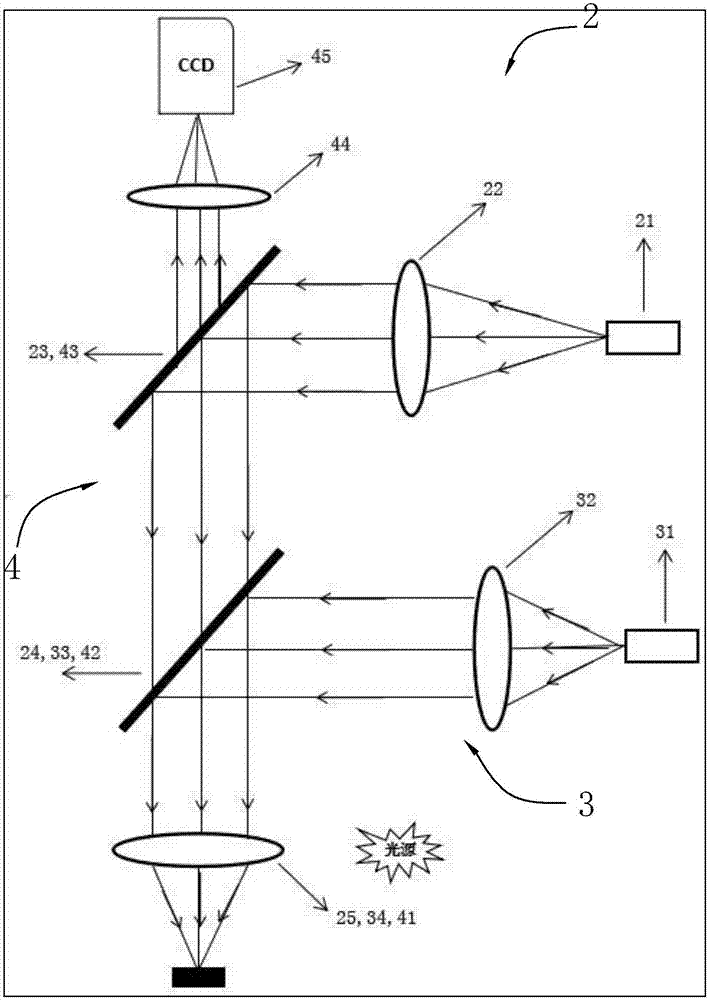

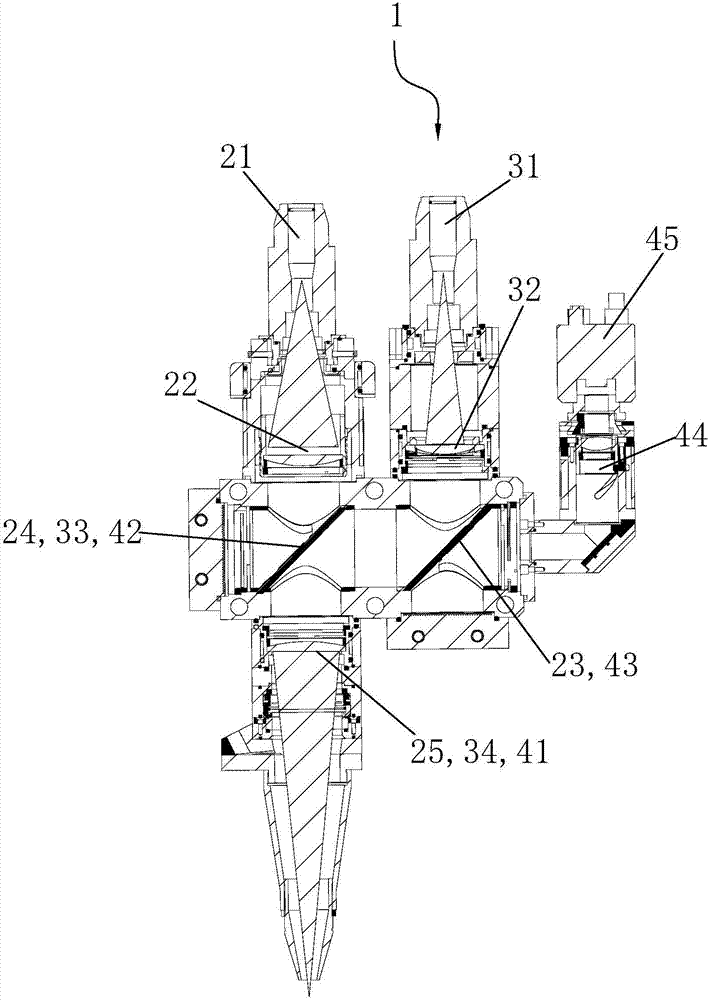

Exiting device for laser hybrid welding

ActiveCN107052580AImprove energy utilizationKeyhole stableLaser beam welding apparatusLaser-hybrid weldingLaser light

The invention discloses an exiting device for laser hybrid welding. The exiting device for laser hybrid welding comprises a laser welding head, a semiconductor laser device and an optical fiber laser device, wherein the semiconductor laser device and the optical fiber laser device are respectively connected with the laser welding head; the semiconductor laser device transmits semiconductor laser; the optical fiber laser device transmits optical fiber laser; a light path of the laser welding head comprises a semiconductor light path, an optical fiber light path and a coaxial monitoring light path; a laser light beam of the semiconductor light path and a laser light beam of the optical fiber light path are superposed into a light beam for welding at a focus point of the laser welding head; a welding position is illuminated through an external light source; and light reflected by the welding position is displayed by a monitor after the welding position is imaged a coaxial monitoring light path. The technical problems that traditional welding pores are abundant, hot crack tendency is high, welding spatter is severe, welding joints are large and the like are solved. The exiting device for laser hybrid welding has the characteristics that energy utilization rate is increased, key holes are stable, the device is suitable for high-speed welding, solidification speed is reduced, the pores are also reduced, hot crack tendency is decreased, welding spatter is reduced, forming of welding joints is improved, so that a welding surface is smooth and the like.

Owner:UNITED WINNERS LASER CO LTD

Method and device for welding thin-wall micropipes of fluoroplastic heat exchanger

ActiveCN102744879AFast thermal conductionUniform and easy to control temperatureHeat exchange apparatusMolten stateHeat carrier

The invention discloses a method for welding thin-wall micropipes of a fluoroplastic heat exchanger, which is characterized in that the fluoroplastic thin-wall micropipes are heated by metal bath as a heat carrier; a welding mold is placed in the metal bath; row tubes are placed in the welding mold to enable thermal expansion of a fluoroplastic end plate in the welding mold to be hindered in order to generate radial pressure; and the radial pressure is superposed with the pressure from the thermal expansion of an expansion core that is inserted in the fluorplastic heat exchanger, so that under molten state, the fluoroplastic end plate and the row tubes composed of the fluoroplastic thin-wall micropipes are molten together, and the welding purpose is achieved.

Owner:ZHUZHOU HONGDA POLYMER MATERIALS

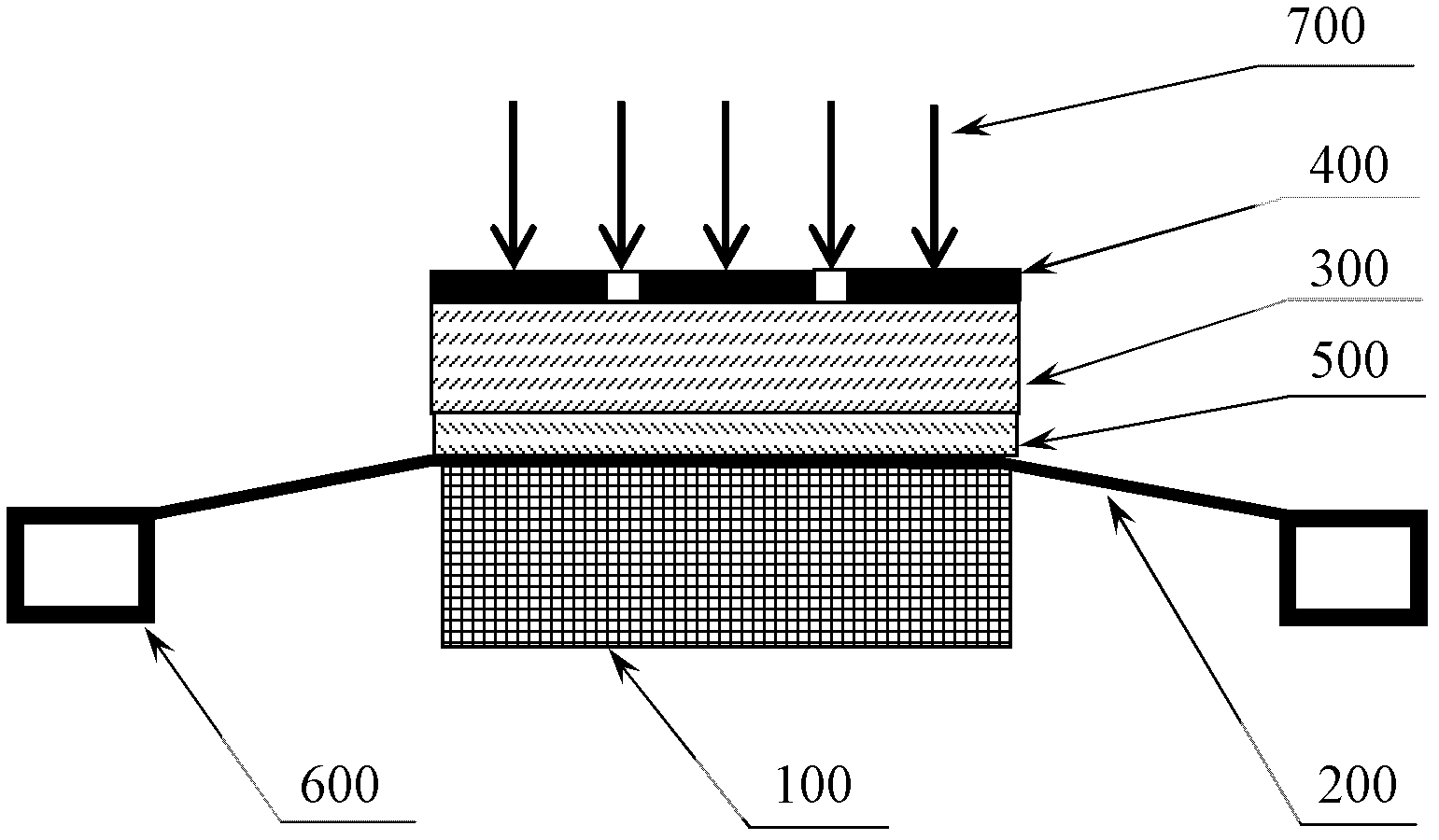

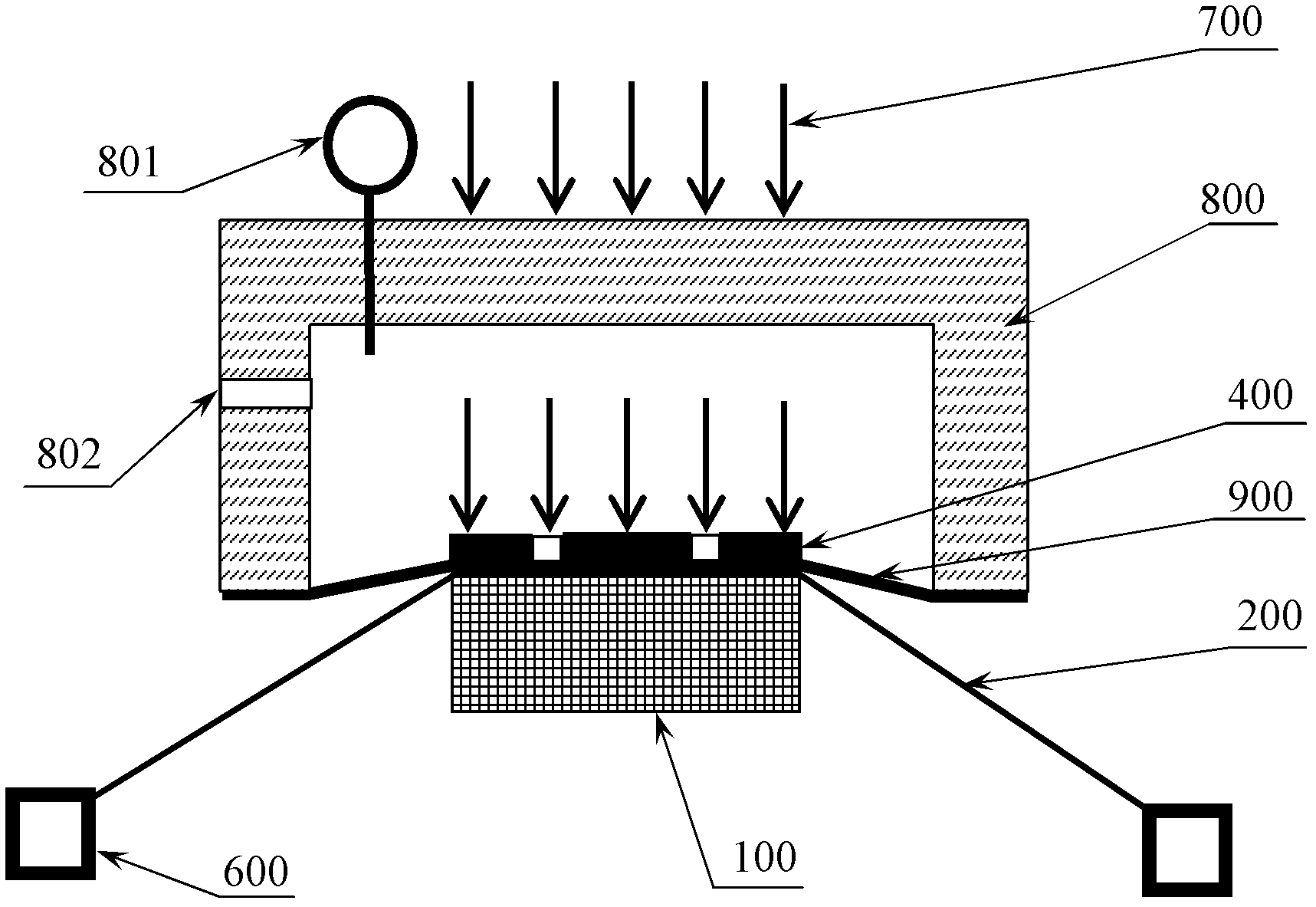

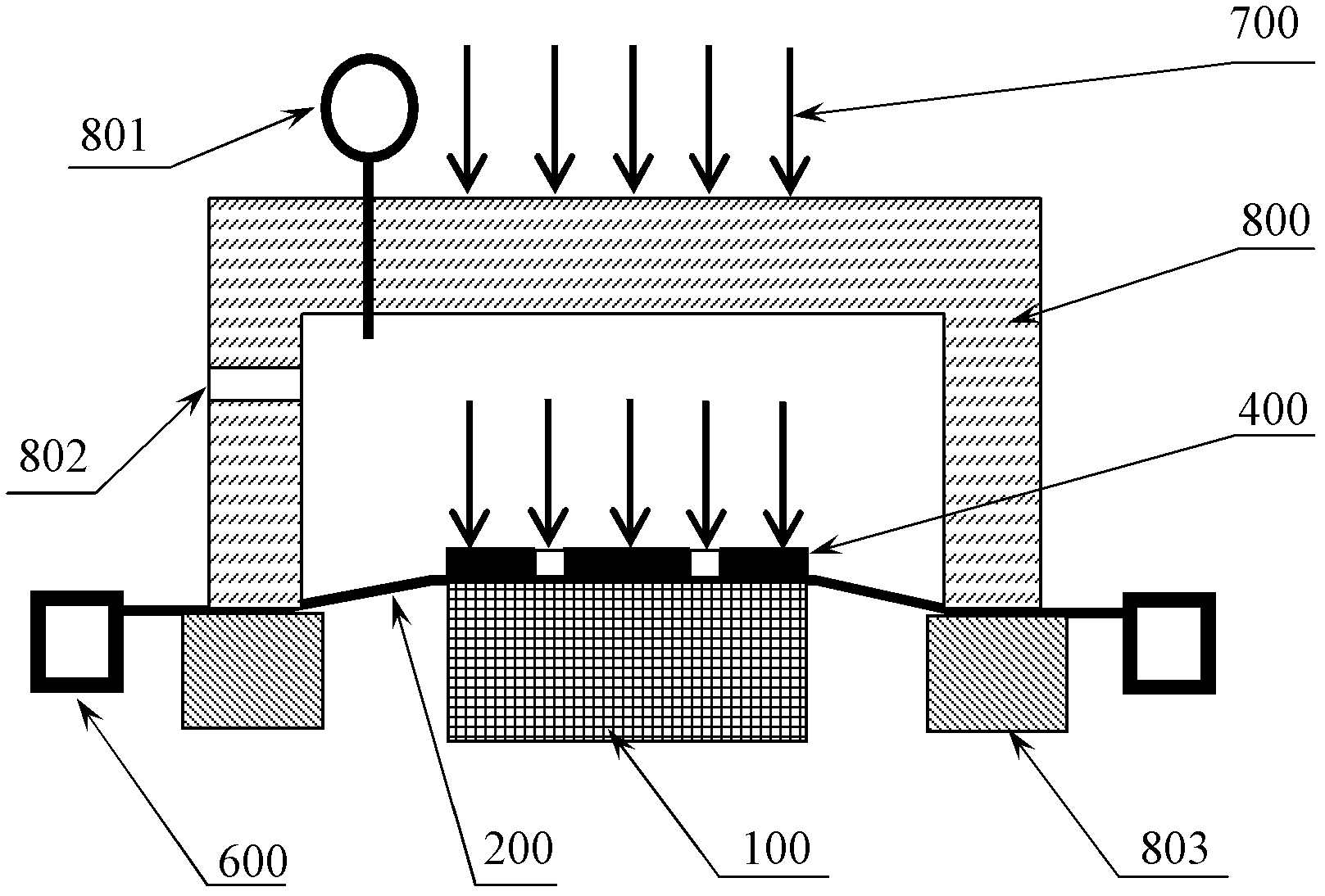

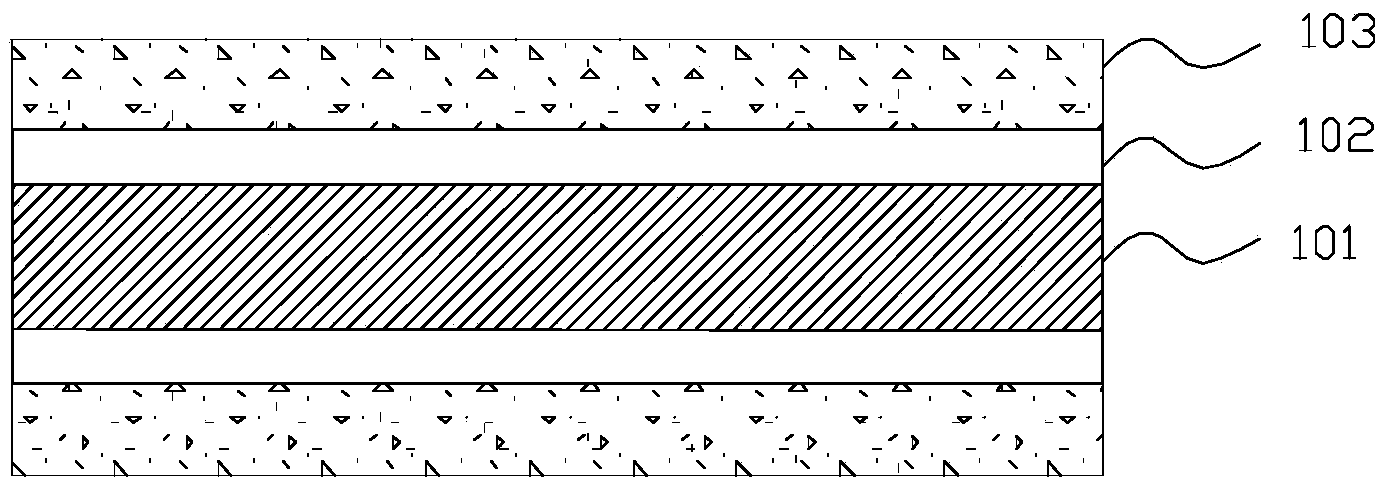

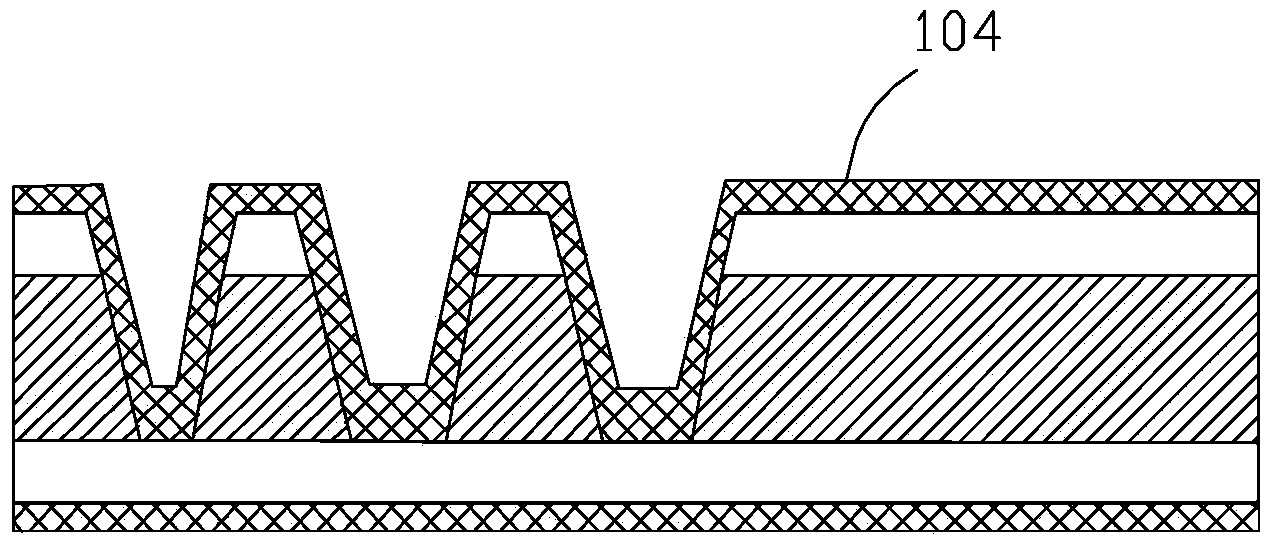

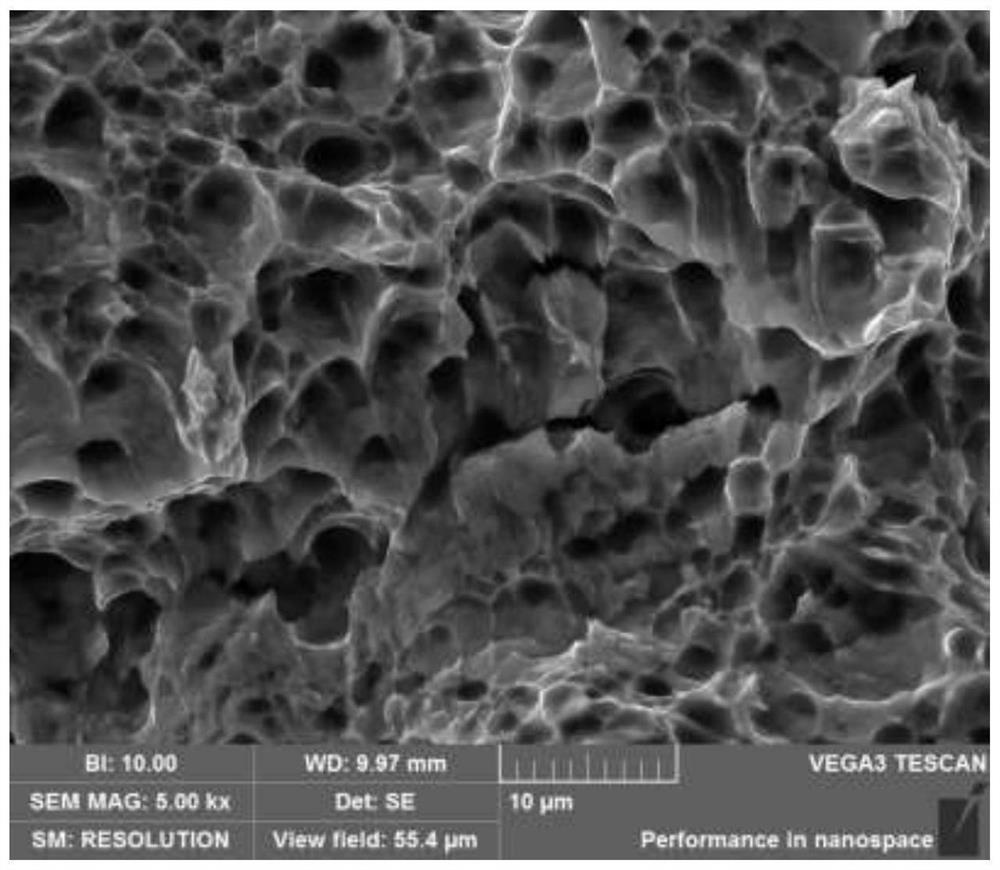

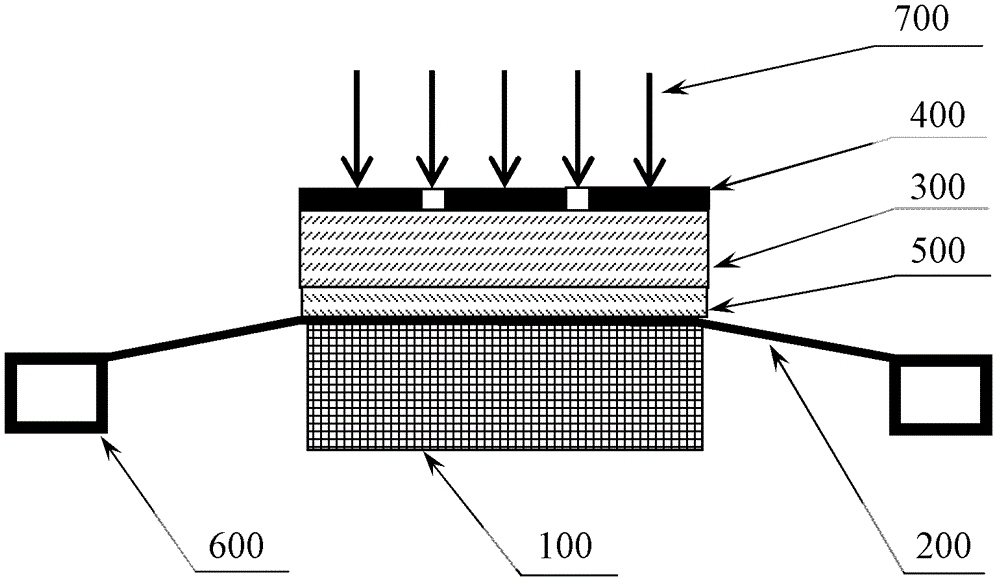

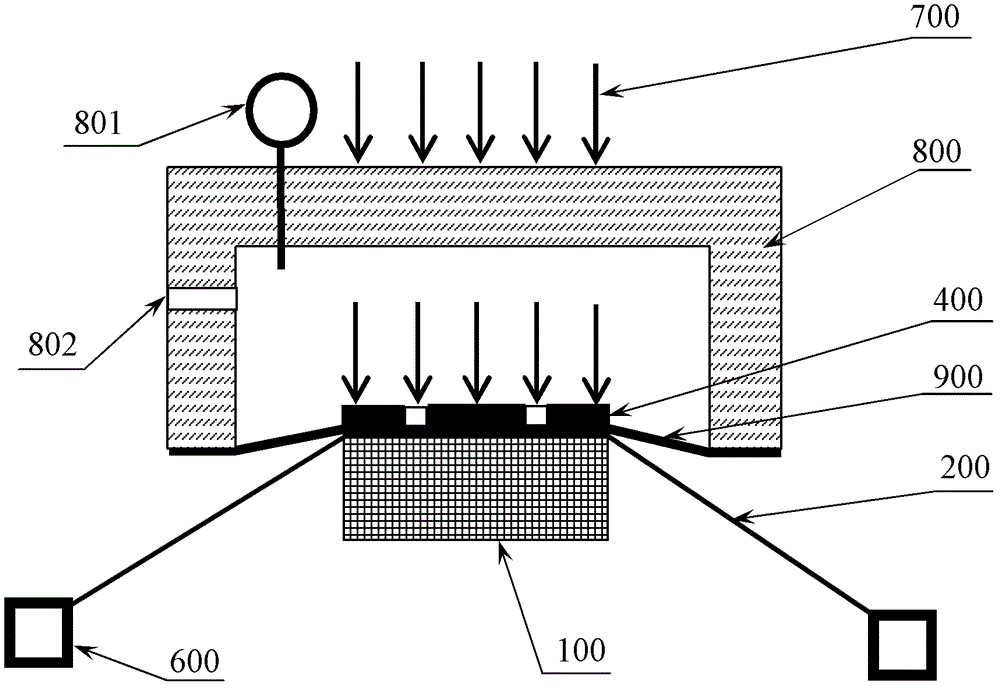

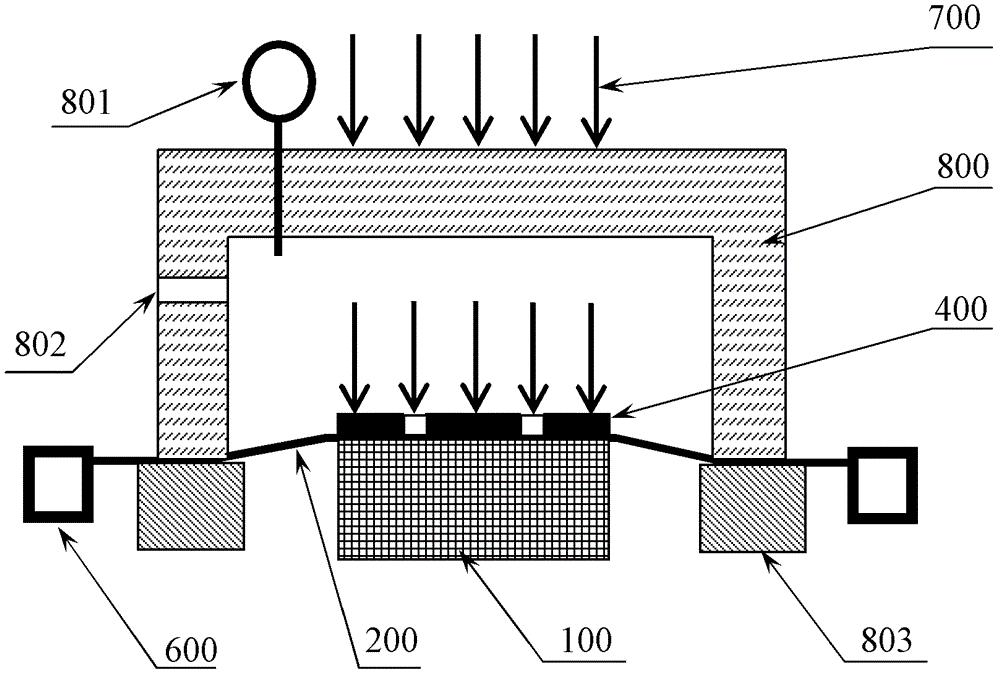

Method for welding substrate and diaphragm of diaphragm-moving polymer microfluidic chip

ActiveCN102319956AWeld firmlySmooth welding surfaceLaboratory glasswaresForming microstructural systemsEngineeringPolymer

The invention discloses a method for welding a substrate and a diaphragm of a diaphragm-moving polymer microfluidic chip, which relates to the technical field of diaphragm-moving polymer microfluidic chip production. The method includes the steps that: before welding, the substrate is fixed, the diaphragm is spread flat to cover the surface of the substrate; pressure is applied to press the diaphragm on the surface of the substrate; during welding, laser is utilized to irradiate the welding area on the substrate via the diaphragm, and after the welding area is heated to be molten, the substrate and the diaphragm are welded together. The method realizes the welding of the diaphragm and the substrate of the diaphragm-moving polymer microfluidic chip, moreover, welding is firm, and the face of weld is smooth and even.

Owner:BEIJING BOHUI INNOVATION TECH

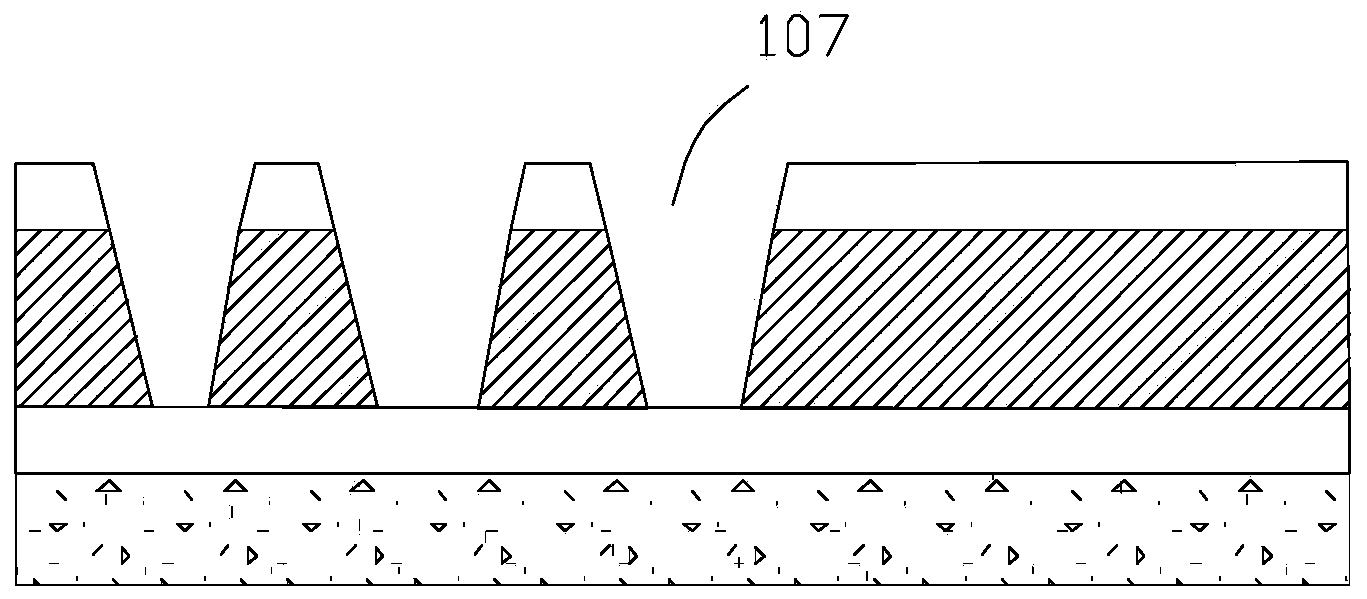

High-density package substrate on-hole disk product and preparation method thereof

ActiveCN104270888AImproved dimensional stabilityOptimizing the Laser Processing ProcessPrinted circuit aspectsElectrical connection printed elementsCopper foilEtching

The invention discloses a high-density package substrate on-hole disk product and a preparation method of the high-density package substrate on-hole disk product. The preparation method comprises the following steps of drying a substrate, manufacturing locating holes, conducting laser drilling, conducting micro-etching, conducting copper plating, conducting pattern transfer, conducting electroplating for hole filling and conducting film stripping and etching, and then the high-density package substrate on-hole disk product is obtained. According to the method, under the effect of protective film layers of the thin copper substrate, the problem that copper foil at the bottom is cut through in the thin copper processing process in the past is solved, and a complete half-through hole structure is made on the thin copper substrate; meanwhile, the direct laser processing technology is adopted, the thickness of the copper foil can not be influenced, and through good matching between the direct laser processing technology and the MSAP process, a high-density Flip-chip product with the high-flatness on-hole disk structure can be manufactured.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

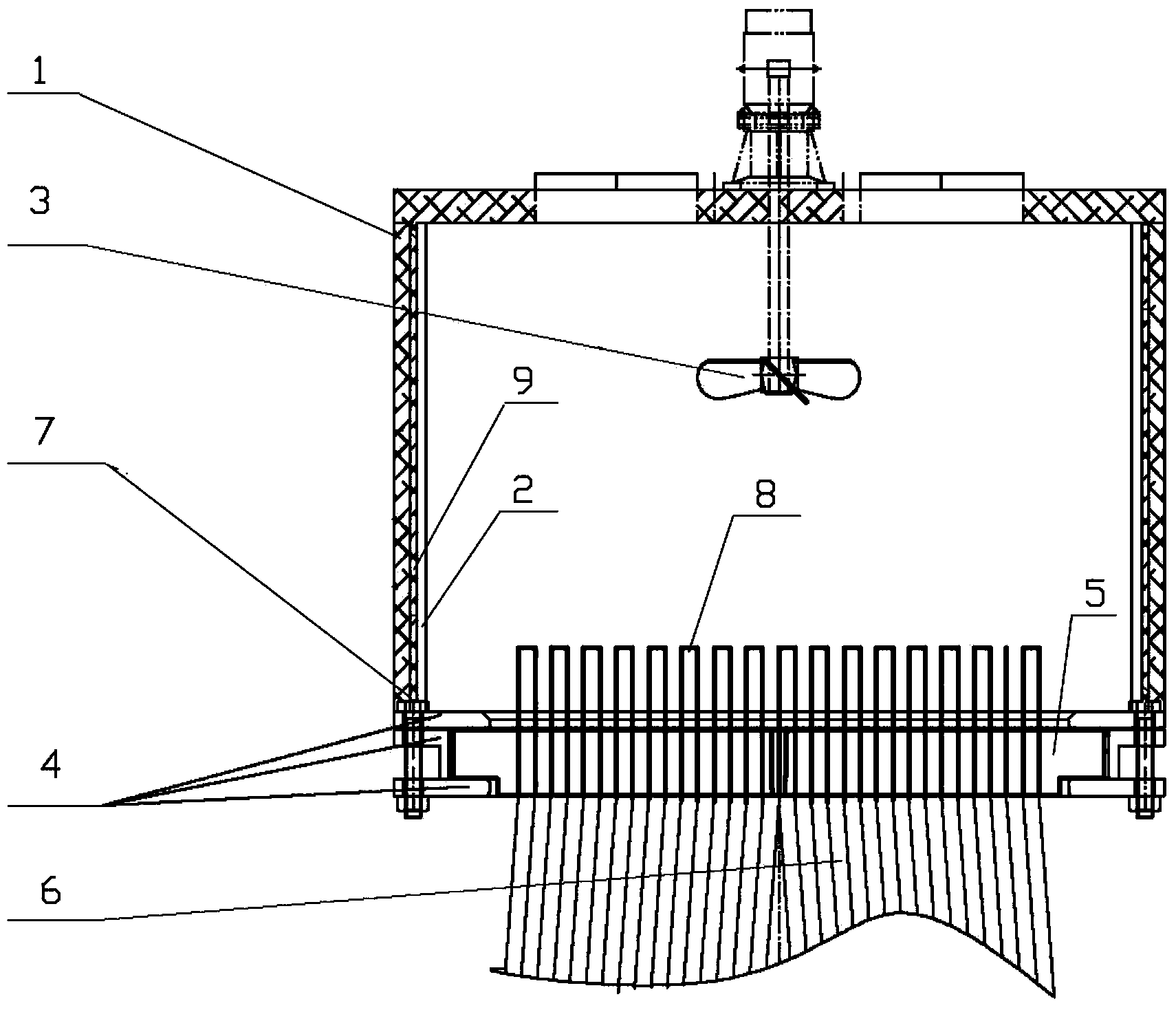

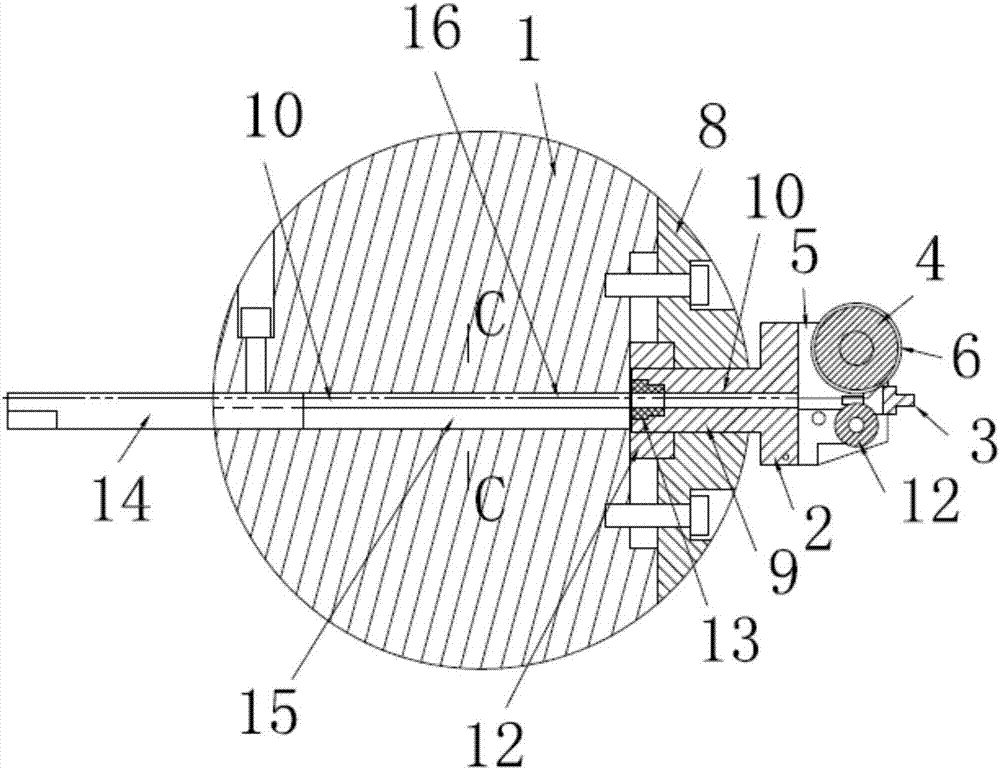

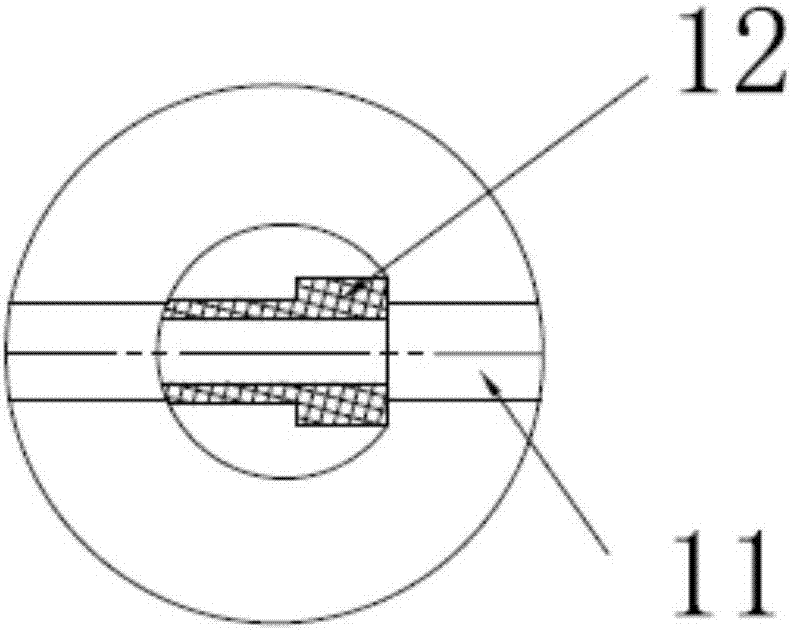

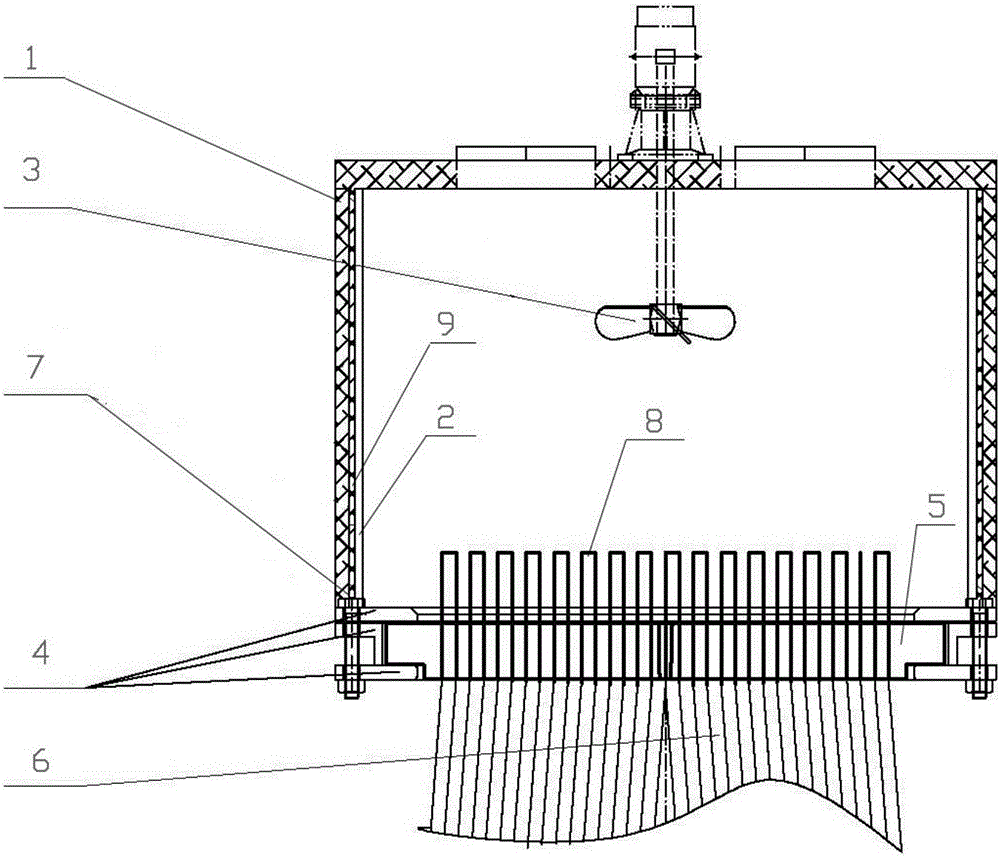

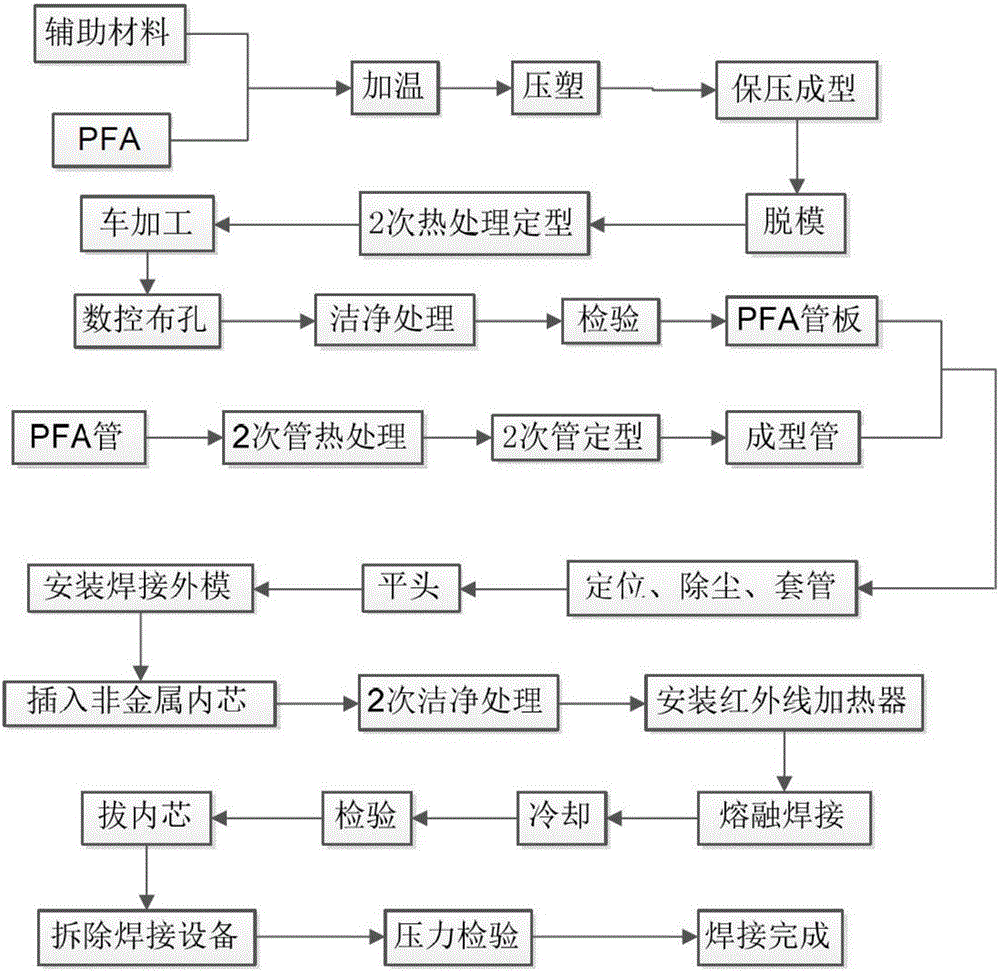

Fluoroplastic condenser welding equipment and welding process thereof

The invention provides fluoroplastic condenser welding equipment, comprising an outer shell, an infrared heater disposed at the inner side of the outer shell, a fan disposed at the upper part of the outer shell, a fixing mold disposed at the lower end of the outer shell, a tube plate disposed below the outer shell through the fixing mold, a tube bundle connected to the tube plate through the fixing mold and a temperature sensor connected to the fixing mold. The tube bundle is provided with a modified PTFE inner core. Besides, the invention also provides a process for welding by using the equipment. The fluoroplastic condenser welding equipment prepared by the welding process provided by the invention is expected to achieve the following technical indexes: (1) a welding depth is larger than 8 mm; a welding surface is flat; and the fluoroplastic condenser welding equipment has no bubble; (2) pressure tests after shaping show that the fluoroplastic condenser welding equipment has no bubble after being kept for 30 minutes at a temperature of 25 DEG C and gas tightness of 0.45 MPa; and hydrostatic test show that the fluoroplastic condenser welding equipment has no leakage after being kept for 30 minutes at a pressure of 0.6 MPa.

Owner:ZHEJIANG JINFULONG CHEM EQUIP

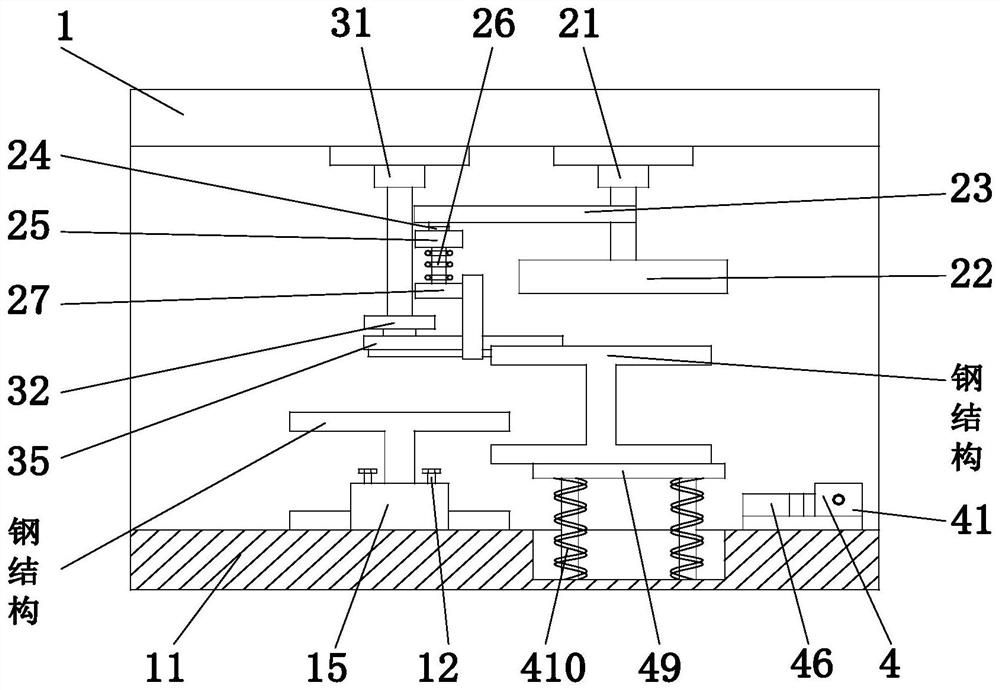

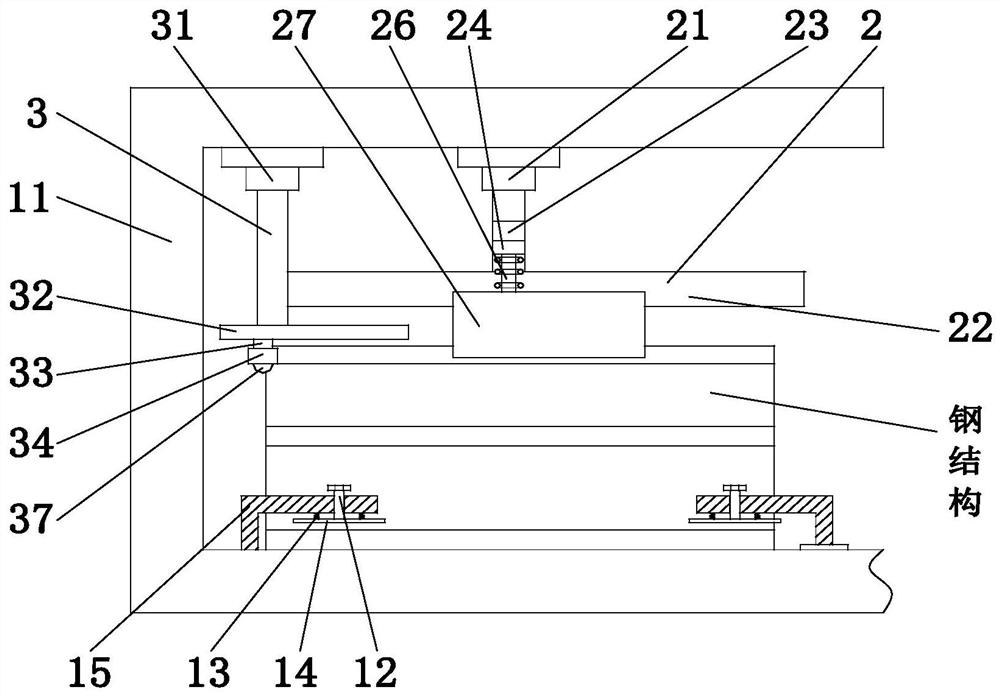

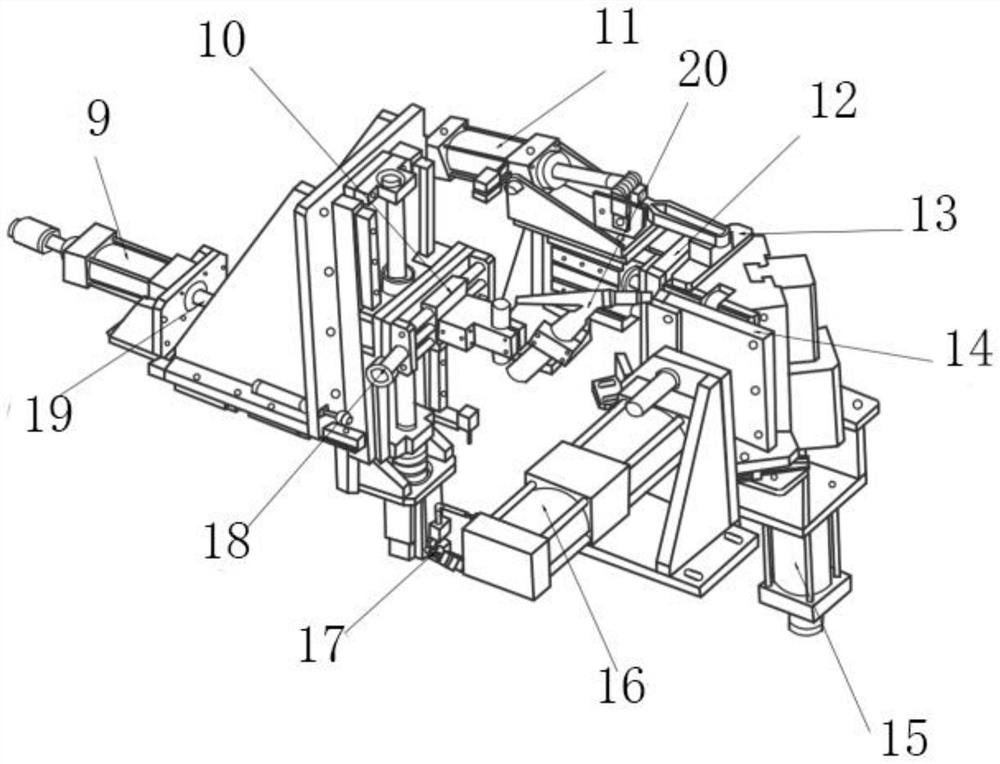

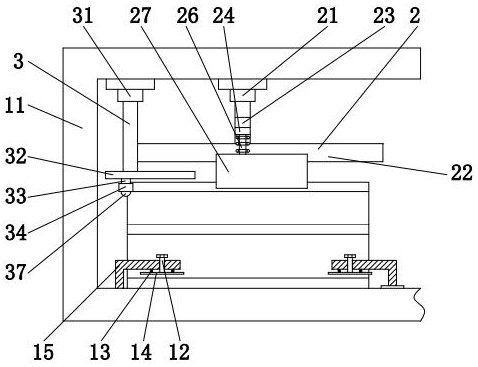

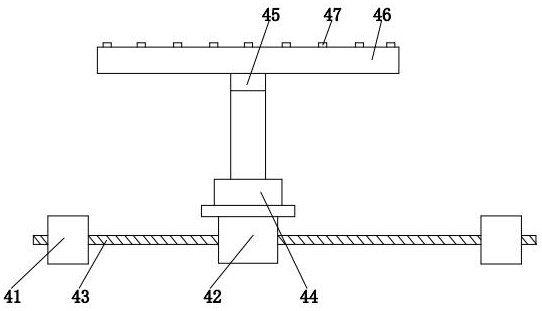

Automatically-assembled welding clamp with steel structure

ActiveCN111644797AAvoid damageIncrease the fixed areaWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringWelding process

The invention relates to an automatically-assembled welding clamp with a steel structure. The automatically-assembled welding clamp comprises a welding rack, an aligning mechanism, a rolling levelingmechanism and an adjusting mechanism. The problems in the welding process of the steel structure can be solved and are as follows: a, in the traditional welding process, the clamping specification forthe steel structure is fixed, the clamp of one specification can only respond to one steel structure, as for steel structures of different specifications in practical production, in the welding process, clamps need to be frequently replaced, a process is tedious, and the production cost is high; b, in the traditional welding process, the problems that weldments are aligned incompletely, and weldsurfaces are not uniform probably exist, and using of steel structures after welding is influenced; and c, in the traditional welding process, the weldments are only attached together, after welding is completed, the problem that weld joints are prone to being broken probably exists, and the welding effect is poor.

Owner:江苏恒智重工制造有限公司

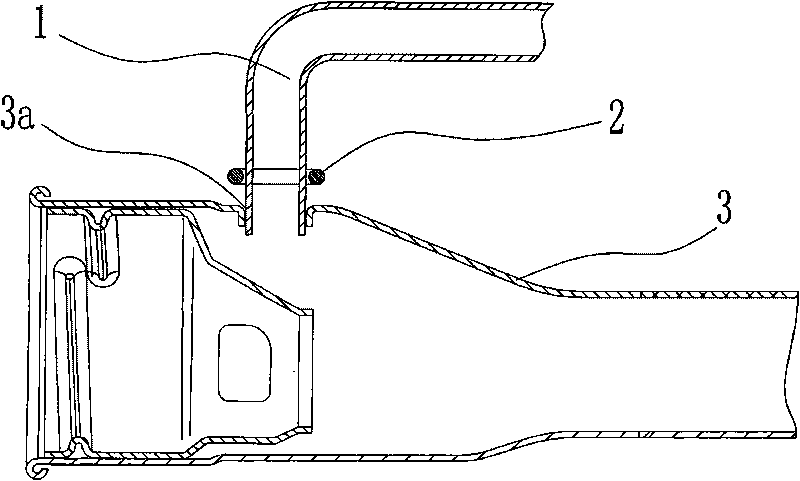

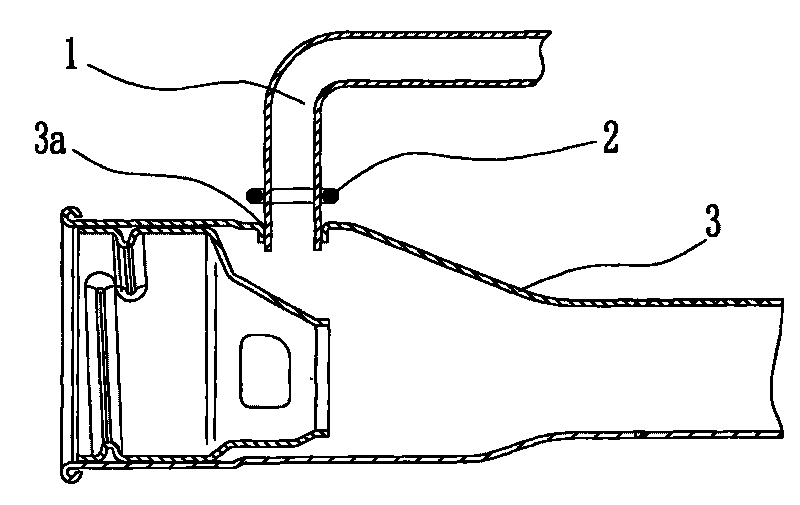

Welding method for welding vent pipe on oil filling pipe

InactiveCN101745733ALow soldering temperatureReduce usageHigh frequency current welding apparatusWeld seamUltimate tensile strength

The invention discloses a welding method for welding a vent pipe on an oil filling pipe, which comprises the following steps: selecting a metal welding ring to be sheathed on the periphery of the weld of the vent pipe; placing the oil filling pipe on a stand fixture of a high-frequency welding machine; arranging the vent pipe into a connecting hole of the oil filling pipe, leading the connecting part of the vent pipe and the oil filling pipe to be vertical to the connecting hole; fixing the vent pipe, and leading the metal welding ring to be covered above the connecting hole; circling a high-frequency welding head of the high-frequency welding machine on the periphery of the vent pie and leading the high-frequency welding head to correspond to the welding part of the oil filling pipe and the vent pipe, and simultaneously positioning the metal welding ring at a heating part; starting the high-frequency welding machine, melting the metal welding ring and leading the molten metal welding ring to permeate into a weld seam till completely filling the weld seam; and taking out the oil filling pipe and the vent pipe and finishing welding. Compared with the prior art, the welding method has the advantages of simple operation, welding material conservation, smooth welding surface, high welding quality, good welding strength, better sealing property, low welding temperature, safety and the like.

Owner:NINGBO SHUNJIANG AUTO PARTS MFG

Lead-free paste welding material and preparation method thereof

InactiveCN106475703AReduce contact resistanceImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaMass ratioPositive pressure

The invention proposes a lead-free paste welding material and a preparation method thereof. The lead-free paste welding material is prepared by mixing lead-free solder alloy powder with a flux according to a mass ratio of 10-11: 0.9-1.2; the lead-free solder alloy powder is prepared by the following raw materials: 5-10 wt% of Zn, 0.1-0.2 wt% of Ti, 0.6-2.4 wt% of graphene, and the balance of Sn; and the flux has the following components: 40-50 wt% of adhesive film forming agent, 3-12 wt% of activating agent, 2-8 wt% of thixotropy anti-sinking slipping agent, and the balance of solvent. The preparation method comprises the following steps: the lead-free solder alloy powder and the flux are mixed according to the mass ratio of 10-11: 0.9-1.2; the flux is firstly put in a synthesizer; then, solder powder of the lead-free solder alloy powder is added; the synthesizer is sealed; then, a vacuum system is started for vacuumizing to fill nitrogen to reach positive pressure; a stirring system is started for stirring; the stirring is stopped; and the discharge is performed to obtain the lead-free paste welding material. The lead-free paste welding material is excellent in welding point combination strength; and meanwhile, the flux is better in oxidation resistance without needing to add antioxidant.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

Tool for performing exposed type back wiring on pipe body

ActiveCN105642926AEvenly spacedSmooth insideTurning toolsElectrical resistance and conductanceEngineering

The invention discloses a tool for performing exposed type back wiring on a pipe body. The tool comprises a tool rack, a tool seat, a cutter and a roller, wherein the bottom of the tool seat is connected with the tool rack; a gap is formed in the top of the tool seat; the cutter is mounted on the tool seat, and is used for cutting an embedding slot for paving a resistance wire in the pipe body; the roller is positioned in the gap and can rotate, and the resistance wire is arranged on the outer circular face and is conveyed into the cut slot in the pipe body through rotation; the outer circular face of the roller presses the inner wall of the pipe body to embed the resistance wire on the outer circular face of the roller into the embedding slot of the pipe body. The tool for performing exposed type back wiring on the pipe body is stable in wire laying, controllable in precision and perfect in performance.

Owner:NINGBO HENGYUAN PRECISION VALVES TECH

Method and device for welding thin-wall micropipes of fluoroplastic heat exchanger

ActiveCN102744879BFast thermal conductionUniform and easy to control temperatureHeat exchange apparatusMolten stateHeat carrier

Owner:ZHUZHOU HONGDA POLYMER MATERIALS

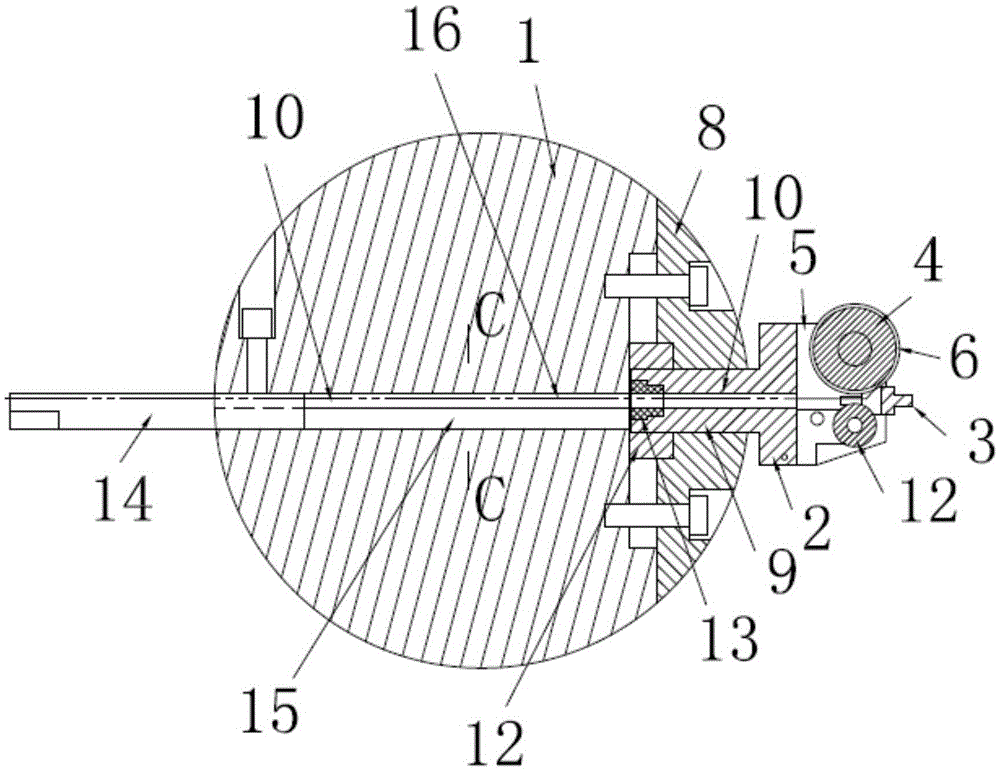

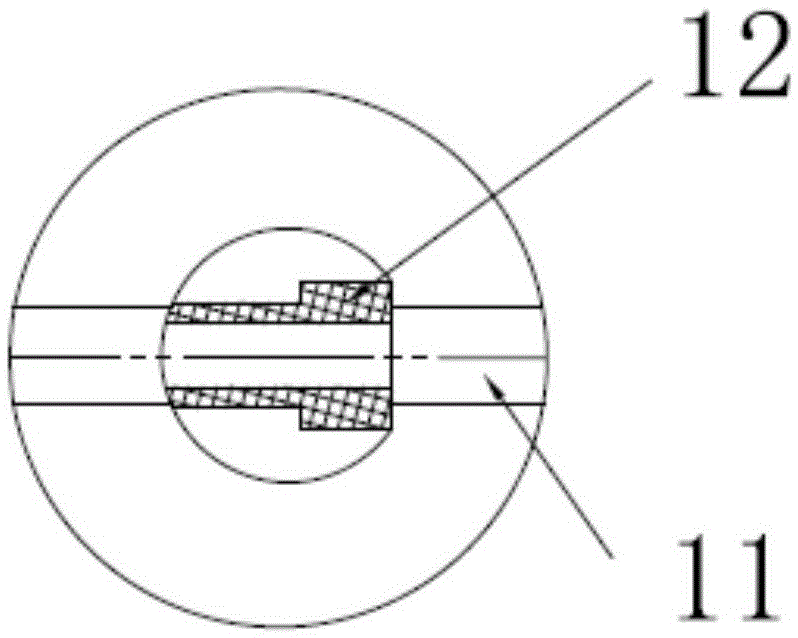

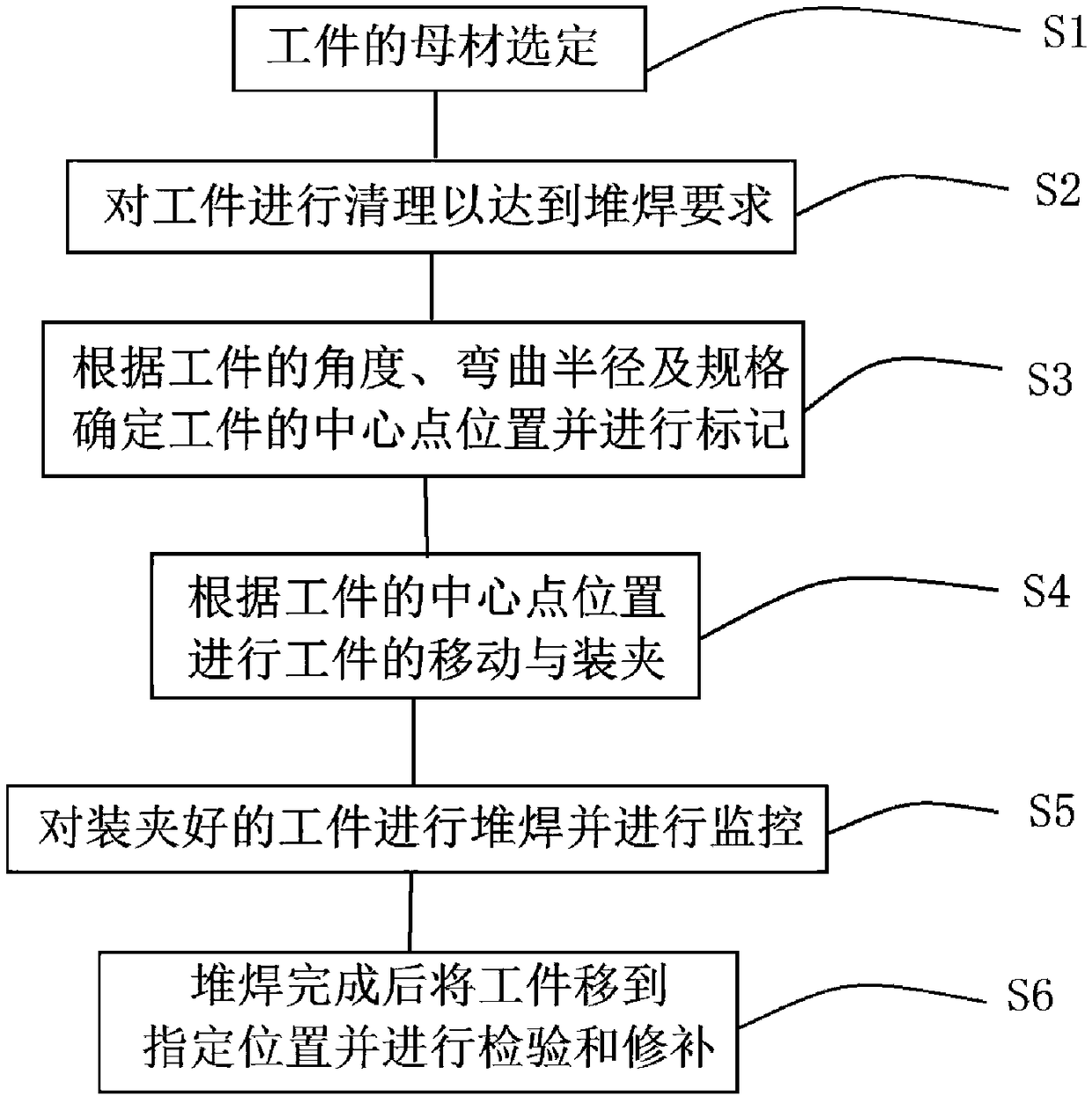

All-position open-arc surfacing method for inner wall of large-diameter bend

The invention discloses an all-position open-arc surfacing method for the inner wall of a large-diameter bend. The method has the advantages that a workpiece is cleaned so as to meet the surfacing requirement; the central point position of the workpiece is determined and marked according to the angle, the bending radius and the specification of the workpiece; the workpiece is moved and clamped according to the central point position of the workpiece; surfacing and monitoring are carried out on the clamped workpiece; and after surfacing is completed, the workpiece is moved to a designated position and is inspected and repaired. The method has the advantages that according to a bend adopting annular open-arc surfacing, the combination degree is higher, the surface of a surfacing layer is smoother, fluid can conveniently pass through the bend, the friction between a wear-resistant layer and the fluid is reduced, and the using efficiency is improved; and the operation is simple and convenient, the safety coefficient is higher, manual semi-automatic operation is not needed, the uncertainty caused by manual work is reduced, the production efficiency is improved, all the motion shaft speed can be subjected to stepless adjustment the welding quality is improved, the welding combination degree is high, and a weld joint is attractive.

Owner:艾锑威(上海)材料科技有限公司

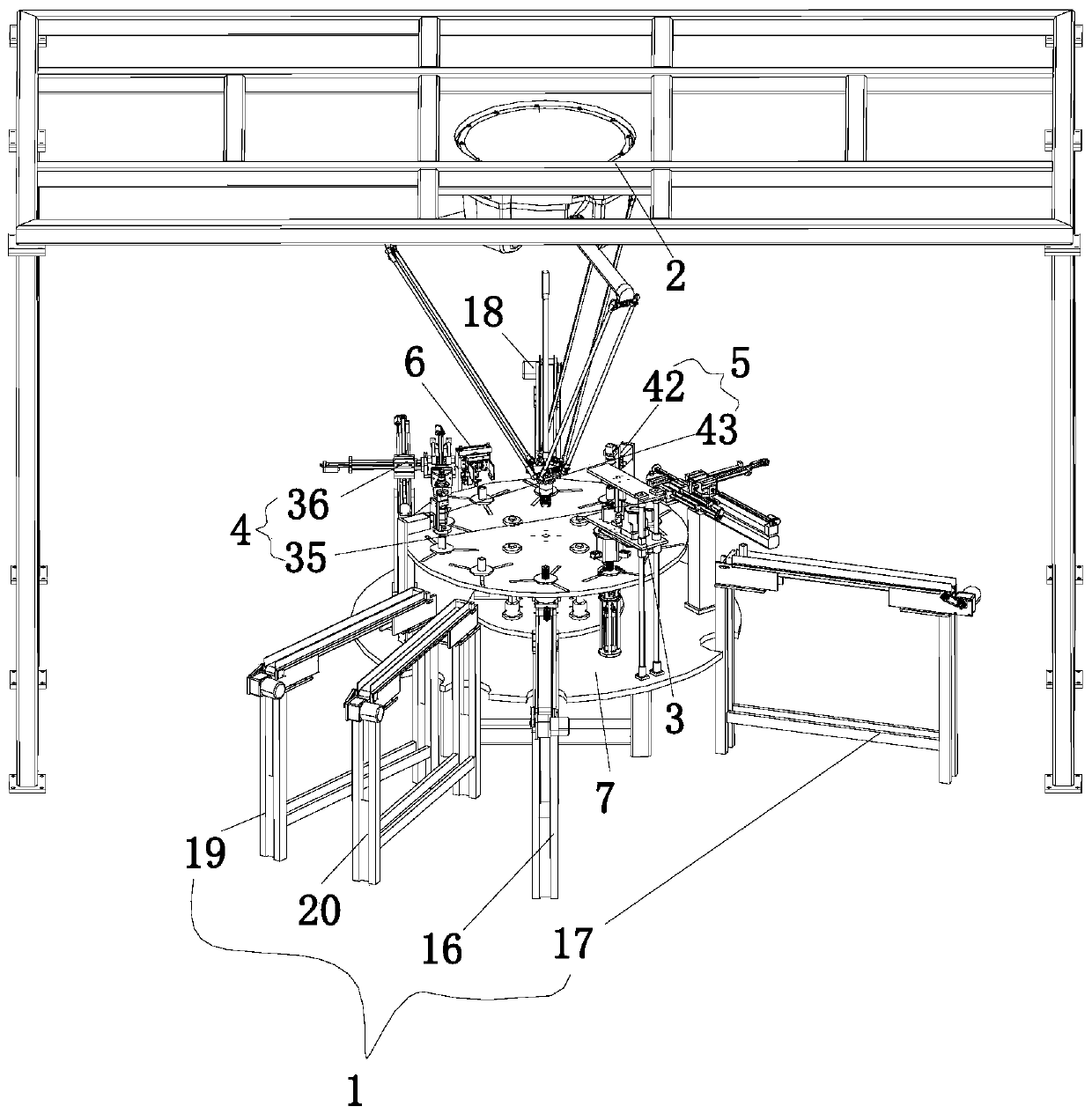

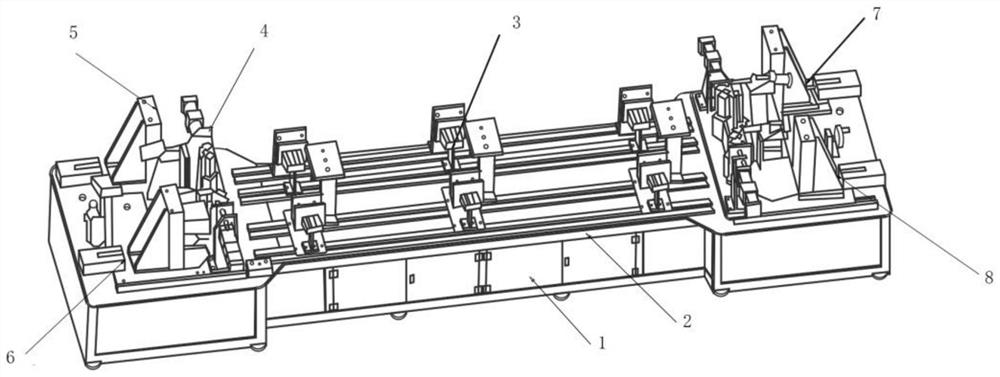

Automatic production line for connector terminals, and process thereof

ActiveCN111403984APrecision weldingSmooth welding surfaceContact member manufacturingSortingManipulatorEngineering

The invention discloses an automatic production line for connector terminals. The invention belongs to the technical field of connectors, the automatic production line comprises a narrow-distance conveying belt, a spider man manipulator, a twisting and pulling mechanism, a welding mechanism, a detection mechanism, a turnover mechanism and a platform, the narrow-distance conveying belt is arrangedon the periphery of the platform. The spider man manipulator is arranged on the upper portion of the platform and can work on the narrow-distance conveying belt, the twisting and pulling mechanism, the welding mechanism, the detection mechanism, the turnover mechanism and the platform. The twisting and pulling mechanism, the welding mechanism and the overturning mechanism are sequentially arrangedat the fixed position of the upper edge of the lifting type rotary disc. All the structures are matched and connected in sequence, so that all procedures in the whole production can be integrated ina more matched mode, a complete assembly line is formed, the space is saved, operation is convenient, meanwhile, the production efficiency is greatly improved, and the labor cost is saved.

Owner:浙江新力达电力金具有限公司

A tool for exposing and post-wiring a pipe body

The invention discloses a tool for performing exposed type back wiring on a pipe body. The tool comprises a tool rack, a tool seat, a cutter and a roller, wherein the bottom of the tool seat is connected with the tool rack; a gap is formed in the top of the tool seat; the cutter is mounted on the tool seat, and is used for cutting an embedding slot for paving a resistance wire in the pipe body; the roller is positioned in the gap and can rotate, and the resistance wire is arranged on the outer circular face and is conveyed into the cut slot in the pipe body through rotation; the outer circular face of the roller presses the inner wall of the pipe body to embed the resistance wire on the outer circular face of the roller into the embedding slot of the pipe body. The tool for performing exposed type back wiring on the pipe body is stable in wire laying, controllable in precision and perfect in performance.

Owner:NINGBO HENGYUAN PRECISION VALVES TECH

A kind of fluoroplastic condenser welding equipment and its welding process

The invention provides fluoroplastic condenser welding equipment, comprising an outer shell, an infrared heater disposed at the inner side of the outer shell, a fan disposed at the upper part of the outer shell, a fixing mold disposed at the lower end of the outer shell, a tube plate disposed below the outer shell through the fixing mold, a tube bundle connected to the tube plate through the fixing mold and a temperature sensor connected to the fixing mold. The tube bundle is provided with a modified PTFE inner core. Besides, the invention also provides a process for welding by using the equipment. The fluoroplastic condenser welding equipment prepared by the welding process provided by the invention is expected to achieve the following technical indexes: (1) a welding depth is larger than 8 mm; a welding surface is flat; and the fluoroplastic condenser welding equipment has no bubble; (2) pressure tests after shaping show that the fluoroplastic condenser welding equipment has no bubble after being kept for 30 minutes at a temperature of 25 DEG C and gas tightness of 0.45 MPa; and hydrostatic test show that the fluoroplastic condenser welding equipment has no leakage after being kept for 30 minutes at a pressure of 0.6 MPa.

Owner:ZHEJIANG JINFULONG CHEM EQUIP

Electronic assembly lead-free welding paste scaling powder and preparing method thereof

ActiveCN101224528BGood printabilityGood dot formabilityWelding/cutting media/materialsSoldering mediaViscous liquidFilm-forming agent

The invention discloses an electronic mounting lead-free soldering paste flux, with the components and weight contents: 45-65% of bonding-film forming agent, 0.2-15% of activator and surfactant, 1-10% of thixotropic sink-proof slipping agent, 0.5-10% of fitting additive, and the residual quantity of solvent. The preparation method of the flux is that the solvent and the bonding film-forming agentare arranged in a container which is provided with a dispersion device according to the dosage, are heated and continuously mixed till that the material is fully dissolved; after that, other materials are once added; the heating and mixing are continued till that all materials are dissolved into bright dilute viscous liquid, and then the heating and mixing are stopped; the mouth of the container is sealed, and the invention can be obtained after static arrangement. The SnAgCuBi and AnAgCu soldering paste which is made by the flux of the invention contains no halogens, requires no cleans, has good printing performance, does not stick plates, has no bypasses or topnotch and good forming of printing point, and has no edge collapse. By reflow soldering, the welding surface and the welding spot are bright and smooth without residue or solder beadings. All technical indexes of the flux and the soldering paste achieve the JIS-3197 standard.

Owner:GUANGZHOU SOLDERWELL ADVANCED MATERIALS

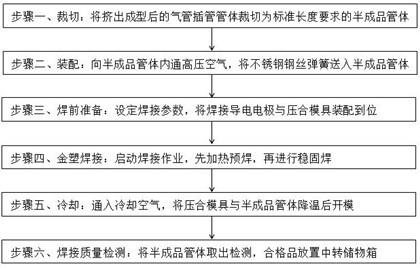

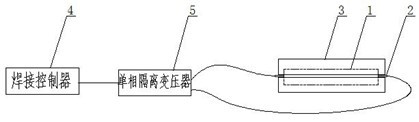

A manufacturing process of gold-plastic welded steel wire reinforced endotracheal intubation tube

The invention discloses a manufacturing process of a metal-plastic welded steel wire reinforced tracheal intubation tube. The manufacturing process is as follows: Step 1, cutting a semi-finished tube body; Step 2, passing a stainless steel wire spring to the semi-finished tube body Inside; step 3, set the welding parameters of the welding equipment, contact the welding conductive electrode with the ends of the stainless steel wire spring at both ends, and install the semi-finished pipe body equipped with the stainless steel wire spring in the pressing mold; step 4, start welding Equipment, first perform heating pre-welding, and then perform stable welding. After completion, turn off the welding equipment; step five, cooling: after the welding operation is completed, use compressed cold air to cool the semi-finished pipe body and the pressing mold; step six, welding quality inspection . Through the manufacturing process disclosed by the present invention, the stainless steel wire spring and the tube body of the trachea intubation can be quickly welded together, and the cost is significantly reduced compared with the traditional inner dipping process, and it has the advantages of high pass rate, low energy consumption, clean and environment-friendly.

Owner:HENAN TUOREN MEDICAL DEVICE GRP

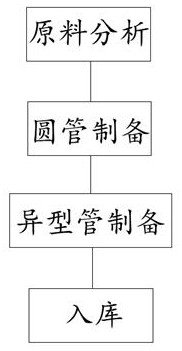

Manufacturing method of thin-wall chilled special-shaped pipe

The invention discloses a manufacturing method of a thin-wall chilled special-shaped pipe. The manufacturing method comprises the following steps of: adjusting and changing parameters of raw materials entering a forming mold according to the hardness and the thickness of the raw materials; increasing the thickness of a formed closed hole type guide sheet; and controlling the size of an opening angle of a small guide and properly widening the width of the raw materials. With the adoption of the manner, the special-shaped pipe manufactured by the manufacturing method of the thin-wall chilled special-shaped pipe solves the problem that four corners of a welding line are easy to crack, so that the surface of the welding line of the special-shaped pipe is relatively flat and the yield is greatly improved.

Owner:常熟市盈博钢管有限公司

Welding machine special for four-gun automatic argon arc welding

PendingCN112809127ASmooth welding surfaceShorten production timeWelding accessoriesEngineeringFully automated

The invention discloses a welding machine special for four-gun automatic argon arc welding. The welding machine special for four-gun automatic argon arc welding comprises an outer shell and a workbench arranged on the outer shell, wherein the workbench comprises a middle mold clamping mechanism arranged on the outer shell and welding gun mechanisms arranged at the two ends of the outer shell; each welding gun mechanism is composed of a first welding gun device, a second welding gun device, a third welding gun device and a fourth welding gun device; and the first welding gun devices, the second welding gun devices, the third welding gun devices and the fourth welding gun devices are symmetrical in pairs. Manual argon arc welding is replaced by a full-automatic welding technology, so that welding can be executed by manually starting a button; through full-automatic welding, production time can be greatly saved, production efficiency is improved, and welding quality is ensured; and the automatic argon arc welding machine has the advantages of being smooth in weld joint surface forming, free of undercut, weld beading, abrupt-change cross section and the like.

Owner:北青(江苏)环境装备有限公司

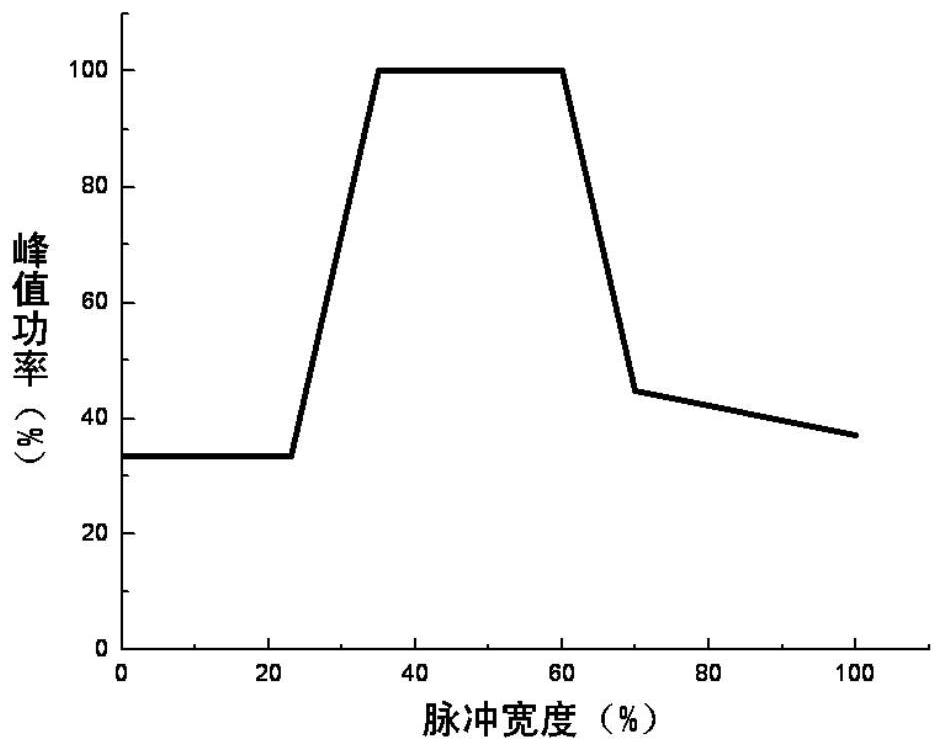

Laser seal welding method for oxygen-free copper shell and oxygen-free copper cover plate

PendingCN113059268AStable solder joint diameterThe appearance of the weld seam is beautifulWelding/soldering/cutting articlesLaser beam welding apparatusLaser lightNitrogen gas

The invention discloses a laser seal welding method for an oxygen-free copper shell and a cover plate. Green laser with the wavelength of 515nm is adopted to conduct laser seal welding on the oxygen-free copper shell and the cover plate adopting a lock bottom self-centering joint in a glove box filled with high-purity nitrogen in an output mode of pulse or continuous laser light emission. The technological parameters of pulse mode laser seal welding are as follows: the laser pulse peak power ranges from 1200 W to 1400 W, the pulse waveform is a rectangular wave, the pulse width ranges from 5 ms to 7 ms, the pulse repetition frequency ranges from 5 Hz to 10 Hz, the welding speed ranges from 18 mm / min to 36 mm / min, and the defocusing amount ranges from 0 mm to 2 mm. The technological parameters of the continuous mode laser seal welding are as follows: the laser power ranges from 700W to 900W, and the welding speed ranges from 6000 mm / min to 8000 mm / min. According to the pulse or continuous laser seal welding method for the oxygen-free copper shell, the stable welding process can be obtained, splashing and holes in the laser welding seam of the oxygen-free copper shell are effectively eliminated, and the packaged microwave assembly oxygen-free copper shell has the advantages of being attractive in appearance of the welding seam, high in air tightness, high in reliability and the like.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

A kind of steel structure automatic assembly welding fixture

ActiveCN111644797BAvoid damageIncrease the fixed areaWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringWelding process

The invention relates to a steel structure automatic assembly welding fixture, which comprises a welding frame, an alignment mechanism, a rolling leveling mechanism and an adjustment mechanism. The present invention can solve the following problems in the welding process of steel structures: a. In the traditional welding process, the clamping specifications for steel structures are fixed, and one type of clamp can only correspond to one type of steel structure. For steel structures of different specifications, fixtures need to be replaced frequently during the welding process, the process is cumbersome, and the production cost is high. bIn the traditional welding process, there may be problems such as incomplete alignment between weldments and uneven welding surfaces. It affects the use of the steel structure after welding. In the traditional welding process, the weldments are only close together. After the welding is completed, there may be problems such as the weld is easy to break, and the welding effect is not good.

Owner:江苏恒智重工制造有限公司

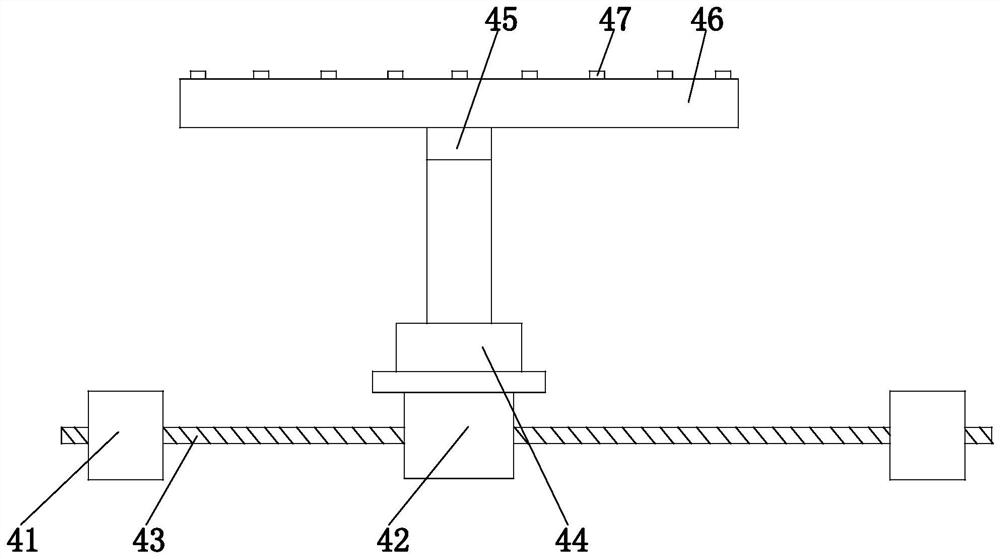

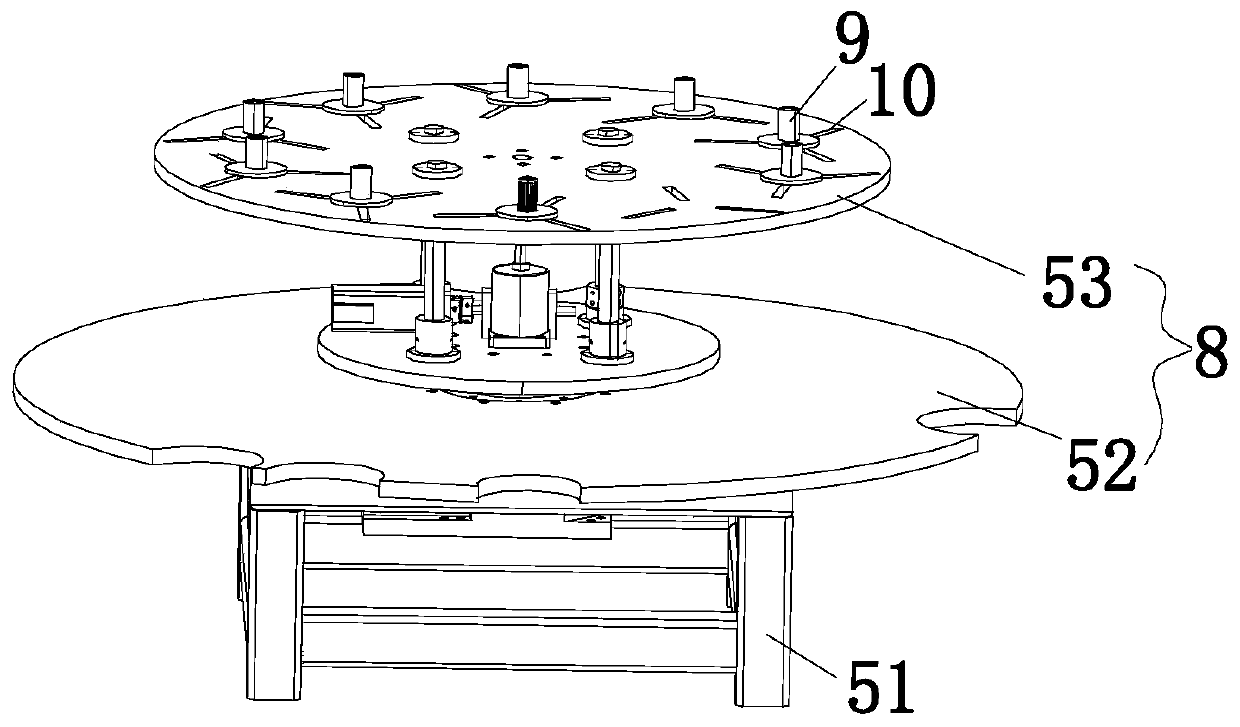

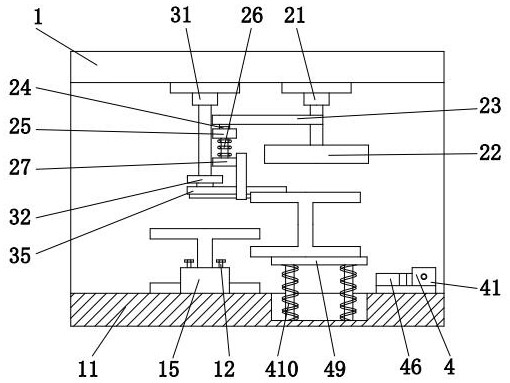

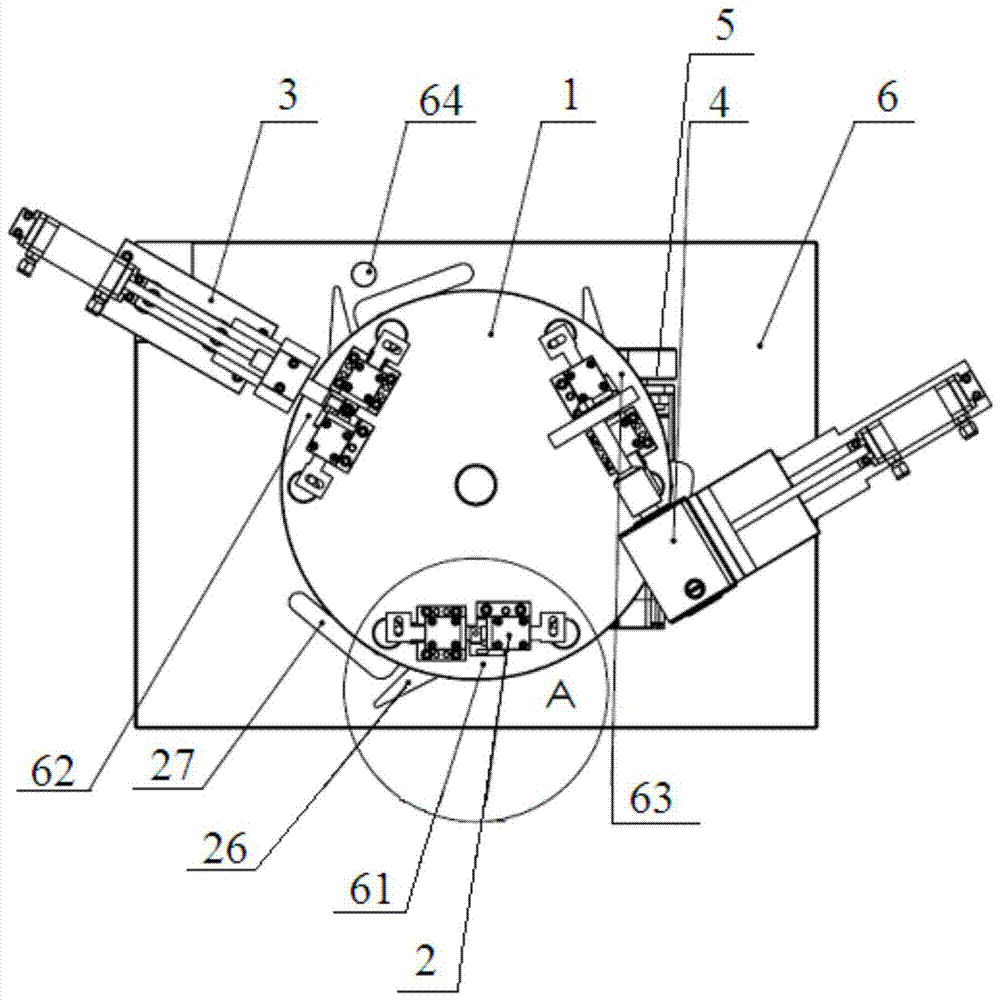

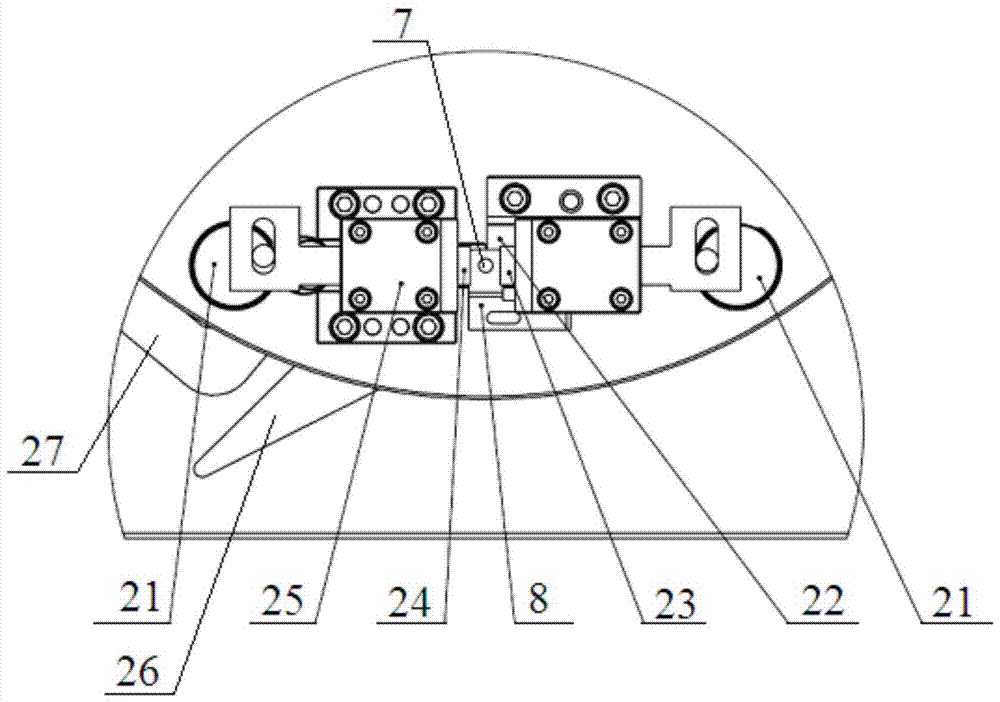

A precision pulley bracket welding assembly machine

ActiveCN105436671BUniform welding arcAccurate trackingWelding/cutting auxillary devicesArc welding apparatusEngineeringAssembly machine

The invention relates to a precision pulley bracket welding and assembling machine. The precision pulley bracket welding and assembling machine comprises a rack, a clamping workbench, a workbench driving assembly, a workpiece fixture assembly, an argon arc welding assembly and a polishing assembly. The rack comprises a feeding and discharging station, an argon arc welding station and a polishing station. The clamping workbench is arranged on the rack and makes contact with the feeding and discharging station, the argon arc welding station and the polishing station at the same time. The workbench driving assembly is arranged below the clamping workbench and drives the clamping workbench to rotate horizontally. The workpiece fixture assembly is arranged on the clamping workbench and used for installing and fixing a pulley shaft and a pulley bracket which need to be welded and assembled. The argon arc welding assembly is arranged in the argon arc welding station, and argon arc welding is conducted on the pulley shaft and the pulley bracket on the workpiece fixture assembly. The polishing assembly is arranged in the polishing station, and the welding position of the pulley shaft and the pulley bracket is polished. Compared with the prior art, the assembling process, the welding process and the polishing process can be effectively completed automatically, the production efficiency is high, and the surface quality is good.

Owner:上海英祺精密零件制造有限公司

Gas shielded metal type flux-cored welding wire for X100 pipeline steel and preparation method thereof

ActiveCN112917041BImprove welding productivityLess welding productivityWelding/cutting media/materialsSoldering mediaArc stabilityMetal

The gas-shielded metal-type flux-cored welding wire for X100 pipeline steel disclosed in the present invention comprises a flux core and a welding skin, wherein the flux core is composed of the following components by mass percentage: C≤0.08%, Si: 0.10-0.30%, Mn: 0.5 ‑1.5%, P≤0.003%, S≤0.003%, Ni: 3.5‑5.0%, Cr: 0.05‑0.10%, Cu≤0.02%, Nb≤0.02%, V: 0.005‑0.01%, Ti: 0.01‑0.08 %, Al: 0.05-0.08%, B: 0.010-0.020%, and the rest are Fe, and the sum of the mass percentages of the above components is 100%. It can be used for welding X100 pipeline steel. The metal type flux-cored welding wire is welded under gas protection, with good arc stability, less spatter, and the joint performance meets the standard requirements. Also provided is a preparation method of the welding wire.

Owner:XIAN UNIV OF TECH

Brazing Processing Method of Inner Channel of Aluminum Parts

ActiveCN104128687BSimple processing technologyFirmly connectedSoldering apparatusWelding/soldering/cutting articlesMetal machiningMachining process

The invention relates to an aluminum part internal channel brazing method and belongs to the technical field of metal machining. The aluminum part internal channel brazing method comprises the steps that firstly, aluminum parts and composite brazing filler metal are machined and cleaned, so that the welding surfaces of the aluminum parts are flat, oxide layers and dirt of the aluminum parts and the composite brazing filler metal are removed so that good connection between the aluminum parts subjected to brazing can be guaranteed, and then the sealing performance of internal channels in the aluminum parts is ensured; next, the aluminum parts and the composite brazing filler metal are assembled, fixed and placed into a vacuum brazing furnace, the temperature is raised to the melting point of the composite brazing filler metal by means of controlling the temperature of the vacuum brazing furnace and detecting the temperature of the aluminum parts through a workpiece coupler, and then brazing is completed. Meanwhile, by the adoption of the aluminum part internal channel brazing method, the machining process is simple, the cost is low, and the application range is rather wide.

Owner:TORRANCE SEMICON EQUIP QIDONG CO LTD

Method for welding substrate and diaphragm of diaphragm-moving polymer microfluidic chip

ActiveCN102319956BWeld firmlySmooth welding surfaceLaboratory glasswaresForming microstructural systemsManufacturing technologyEngineering

The present invention discloses a welding method for substrate and membrane of membrane mobile polymer microfluidic chip, which relates to the manufacturing technology of membrane mobile polymer microfluidic chip and comprises the following steps: before the welding, the substrate is fixed, the surface of the substrate is covered with the membrane; the membrane is pressed against the surface of the substrate, and in the course of welding, the laser irradiates the welding area on the substrate through the membrane, and the welding area fuses and then welds the substrate and membrane together. The present invention realizes the firm welding between membrane and substrate of membrane mobile polymer microfluidic chip, and ensures that the weld face is flat and uniform.

Owner:BEIJING BOHUI INNOVATION TECH

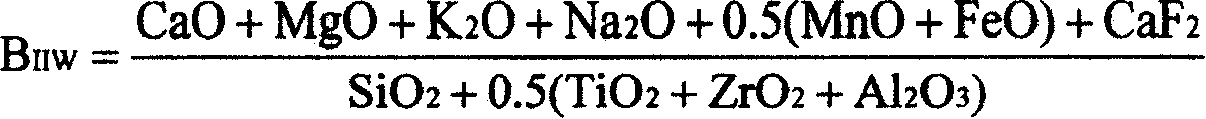

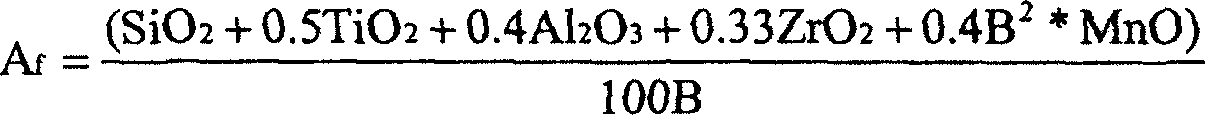

High alkalinity, low activity, superlow hydrogen sintering type solder

InactiveCN100374238CReduced activityHigh particle strengthWelding/cutting media/materialsSoldering mediaLow activityAlkalinity

The sintered welding flux with high alkalinity, low activity and ultralow hydrogen content consists of MgO 28-33 wt%, CaF2 12-20 wt%, Al2O3 16-22 wt%, SiO2 8-15 wt%, CaCO3 5-10 wt%, BaCO3 5-10 wt%, Na2O 2-4 wt%, Li2CO31-4 wt% and ReF 2-6 wt%. It has high grain strength, moisture absorbing resistance and S and P content meeting the requirement of relevant national standard, diffusion hydrogen content lower than 5 ml / 100 g. It is fitted with 10NiCrMoTi welding wire and 05Ni3Mn2MoTi welding wire for low temperature no-preheating welding in ship yard and can result in excellent joint mechanical performance. It has excellent technological performance, smooth weld seam, good spreading, smooth transition to the base material and good slag eliminating performance.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

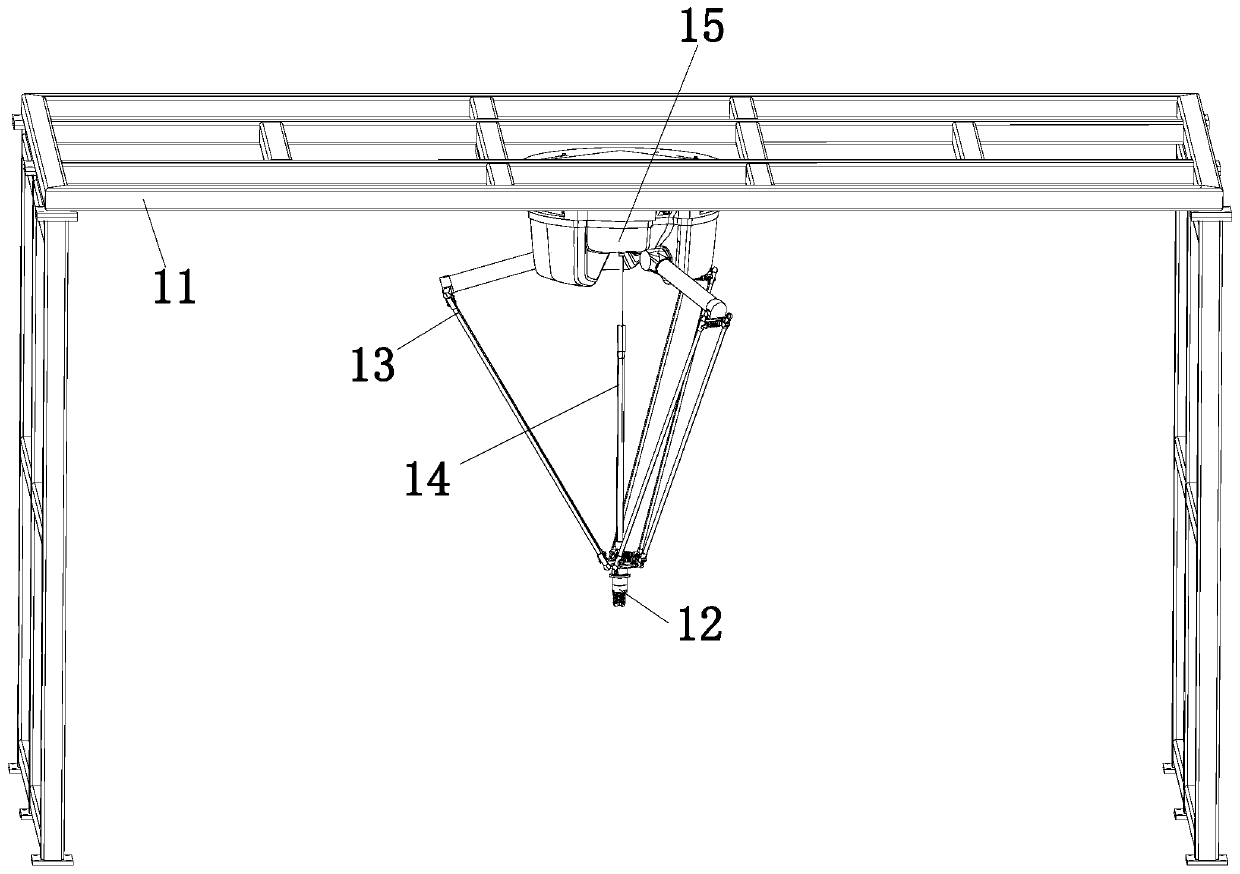

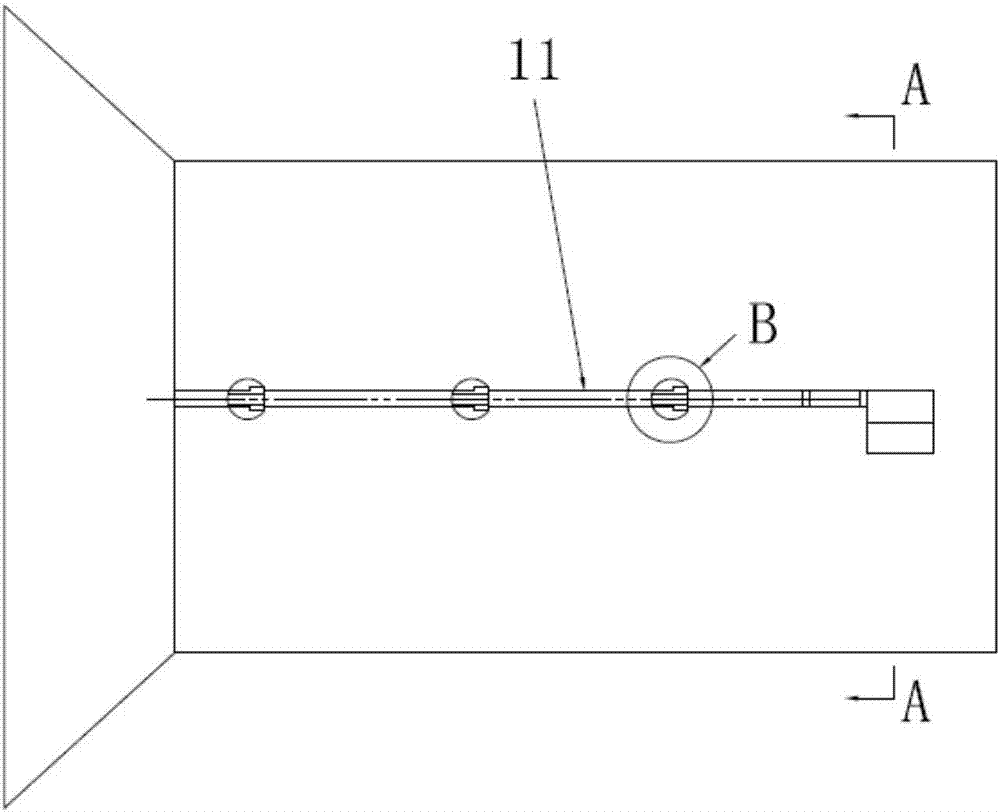

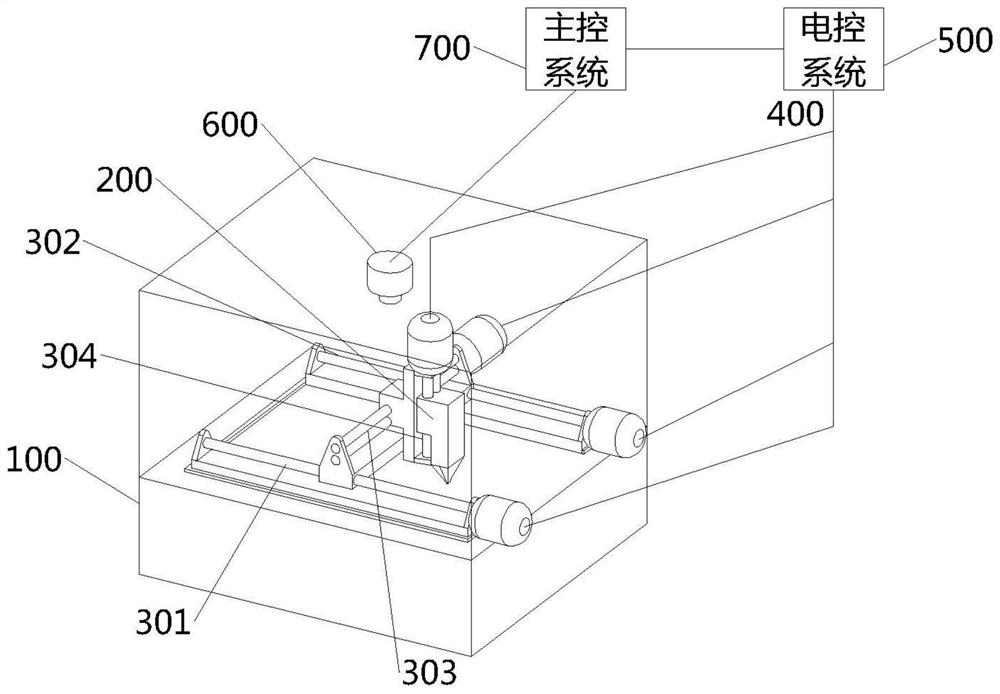

Argon arc welding automatic welding special machine

PendingCN112171017APrecision weldingImprove work efficiencyMetal working apparatusWelding accessoriesControl systemControl engineering

The invention discloses an argon arc welding automatic welding special machine.The argon arc welding automatic welding special machine comprises a gantry welding machine frame, a welding gun, a lead screw transmission system, a servo motor system, an electric control system, a vision system and a main control system, wherein the input end and the output end of the vision system are connected withthe first output end and the first input end of the main control system correspondingly; the input end of the electric control system is connected with the second output end of the main control system, the output end of the electric control system is connected with the input end of the servo motor system, and the lead screw transmission system is driven by the servo motor system and arranged on the gantry welding machine frame; and the welding gun is arranged on the lead screw transmission system. Accurate and rapid welding can be achieved, the working efficiency is improved, and the labor cost is reduced. The welding surface is flat, smooth and burr-free, and the product quality is improved. In addition, harm to human bodies is reduced in the welding process.

Owner:江苏卡邦电气科技股份有限公司

Double-layer panel welding method

The invention discloses a double-layer panel welding method. The welding method comprises the following steps: 1) welded surfaces of first panels are grooved to form multiple first grooves; 2) first electric heating nets are paved on the welded surfaces of the first panels; 3) hot melting plates are paved on the first electric heating nets; 4) the first electric heating nets are heated, so that the sides, facing the first panels, of the hot melting plates are molten, and molten liquid flows into the first grooves; 5) welded surfaces of second panels are upwards arranged and grooved to form multiple second grooves; 6) second electric heating nets are paved on the welded surfaces of the second panels; 7) one sides of the hot melting plates of semi-finished welded parts in the step 4) cover the second electric heating nets; and 8) the second electric heating nets are heated, so that the sides, facing the second panels, of the hot melting plates are molten, and molten liquid flows into thesecond grooves. The double-layer panel welding method enables the welded surfaces to be smoother and the twisting resistance to be better.

Owner:马鞍山楚锐科技信息咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com