Automatically-assembled welding clamp with steel structure

A welding fixture and steel structure technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as cumbersome process, easy fracture of weld seam, uneven welding surface, etc., to reduce damage and increase The effect of fixed area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

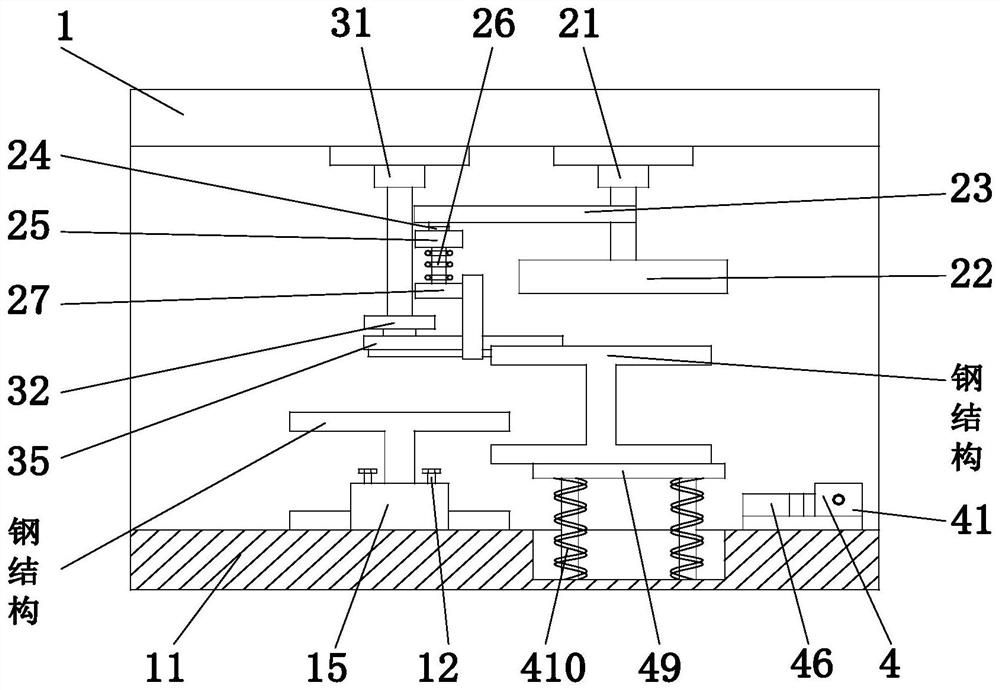

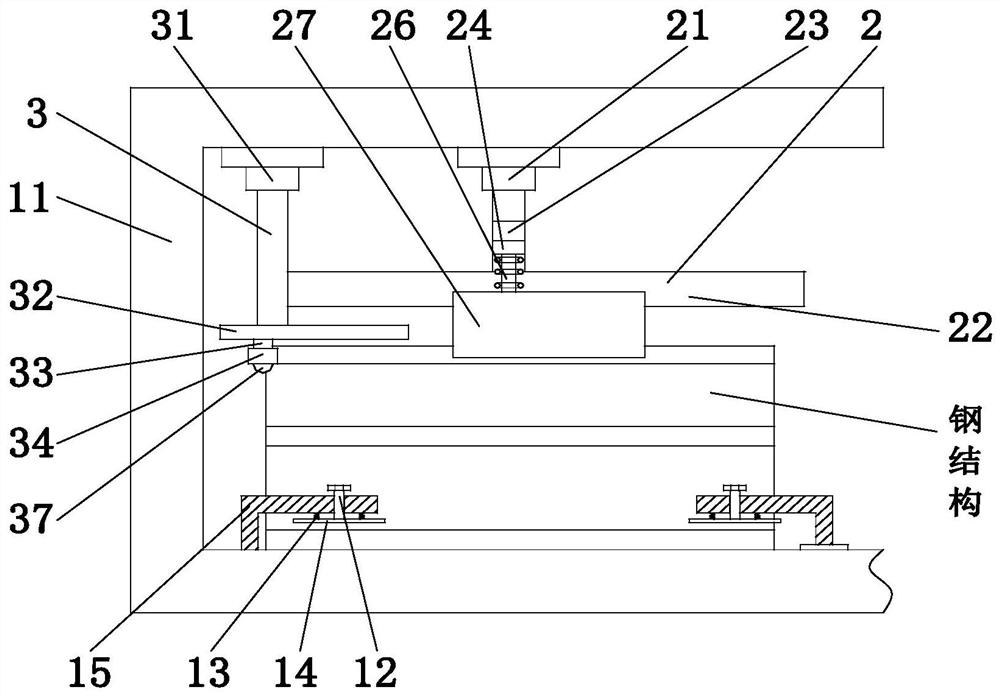

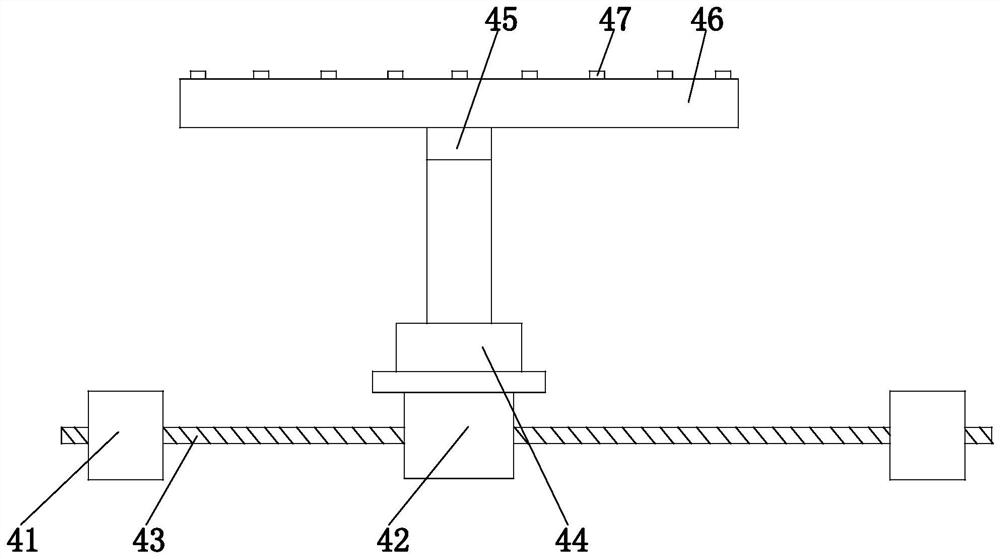

[0031] Such as Figure 1 to Figure 8 As shown, a steel structure automatic assembly welding fixture includes a welding frame 1, an alignment mechanism 2, a rolling leveling mechanism 3 and an adjustment mechanism 4. The inner upper end surface of the welding frame 1 is sequentially installed from left to right. A rolling leveling mechanism 3 and an alignment mechanism 2 , an adjustment mechanism 4 is arranged below the alignment mechanism 2 , and the adjustment mechanism 4 is installed on the welding frame 1 .

[0032] The welding frame 1 includes a bottom frame 11, a locking bolt 12, a return spring 13, a pressure plate 14, an L-shaped frame 15, and an adjustable electric slider 16, wherein the inside of the bottom frame 11 is symmetrically arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com