Miniature throttling refrigerator

A refrigerator and miniature technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low yield, difficult and complex processing, achieve smooth welding surface, eliminate contact thermal resistance, and beautiful welding surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

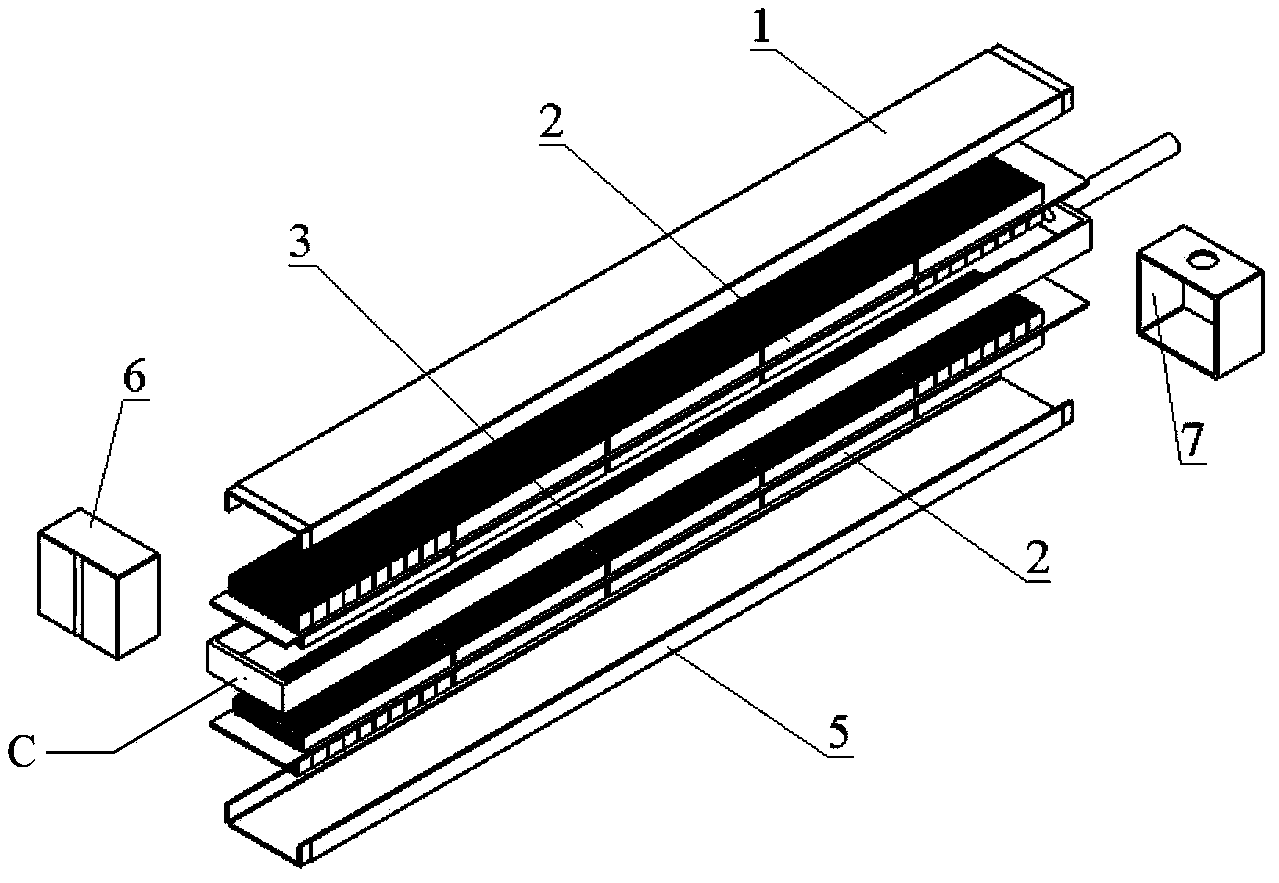

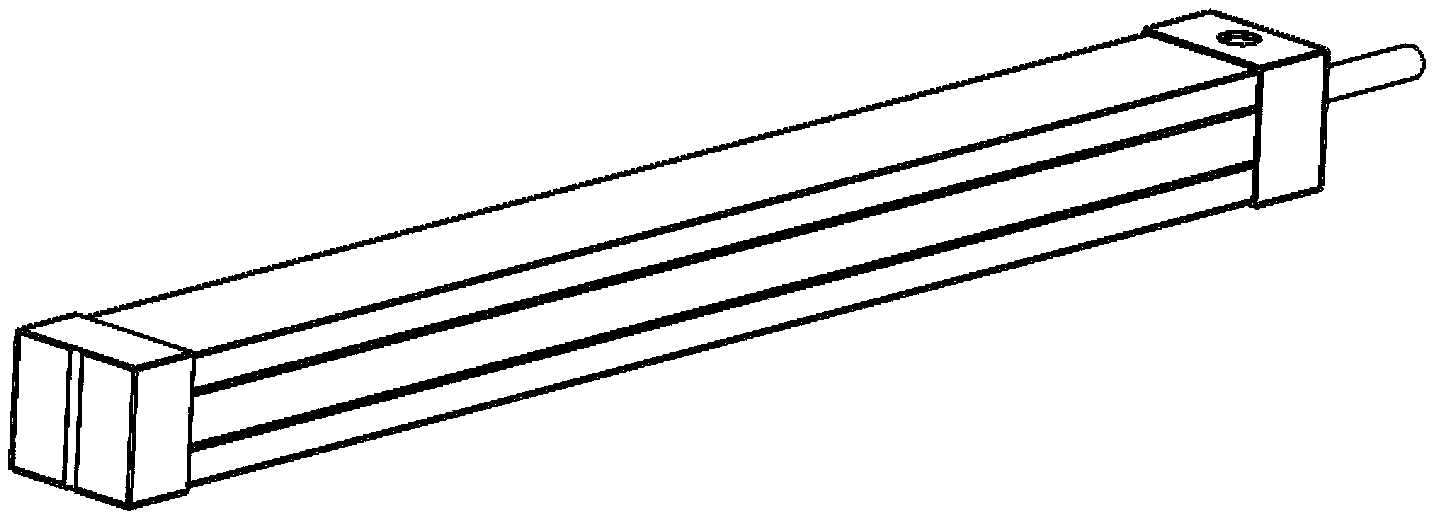

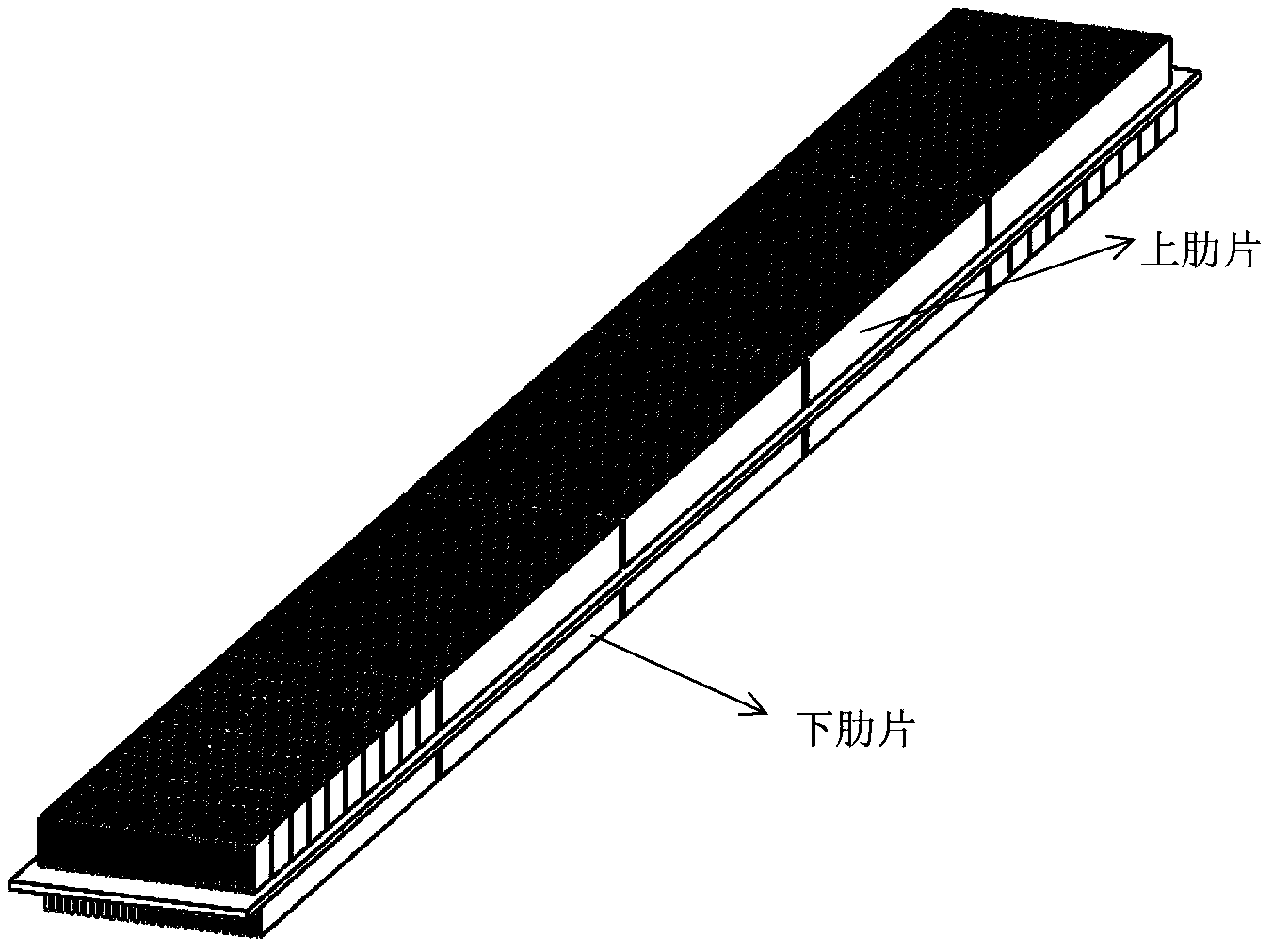

[0050] Such as figure 1 , 2 , 3, 4, 5 and 6, the micro-throttle refrigerator of the present invention is a three-channel micro-throttle refrigerator, wherein the middle flow channel is a high-pressure flow channel A, and the flow channels on both sides are the first low-pressure flow channel B 1 and the second low-pressure runner B 2 ; The miniature throttling refrigerator is composed of an upper cover plate 1 and a lower cover plate 5, two heat exchange cores 2, a high-pressure flow channel side wall 3, a cold end head 6 and a hot end head 7; The core body 2 is an upper heat exchange core body and a lower heat exchange core body respectively, both of which are composed of a long flat plate base and upper fins and lower fins on the lower surface vertically fixed on the upper surface of the long flat plate base respectively. Composition; the upper ribs and the lower ribs are flaky fins or needle-like fins with the same height and uniform distribution; the flaky ribs are paral...

Embodiment 2

[0054] Such as Figure 7 , 8 , 9 and 10, the miniature throttling refrigerator of this embodiment 2 is a miniature throttling refrigerator of two flow channels, wherein one channel is a high-pressure flow channel, and the other flow channel is a low-pressure flow channel; The upper cover plate 1, the lower cover plate 5, the heat exchange core 2 and the cold end head 6; the heat exchange core 2 has a length of 150 mm and a width of 14.7 mm, and the upper fin 21 has a height of 3.0 mm and a width of 0.3 mm , the height of the lower fin is 2.5mm, the width is 0.3mm, the base thickness of the upper and lower fins is 0.5mm, and a depth of 30mm is processed on the upper and lower fins, which is the value of the height of the fin or is lower than the height of the fin. 10% to 20%, groove 8 with a width of 0.2mm, in which a longitudinal groove 8 with a depth of fin height and a width of 0.2mm is processed every 3mm within the distance of 30mm in front of the air inlet of the high an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com