Tool for performing exposed type back wiring on pipe body

A post-wiring and cutting tool technology, which is applied in the direction of cutting tools used in lathes, manufacturing tools, tool holder accessories, etc., can solve the problems that the plastic oxide layer cannot be eliminated, the resistance wire pipe is ejected, and the hidden danger of welding is increased to achieve superior welding. Compatibility and stability, uniform burial depth and spacing, and the effect of meeting the needs of emergency repair construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

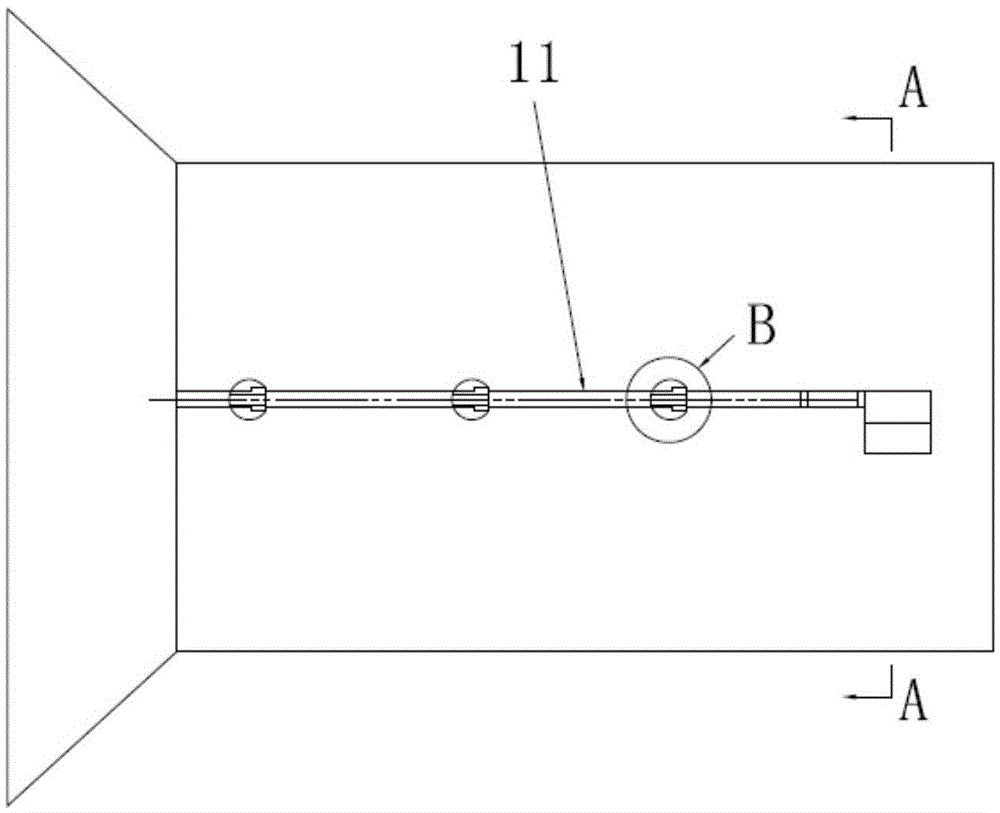

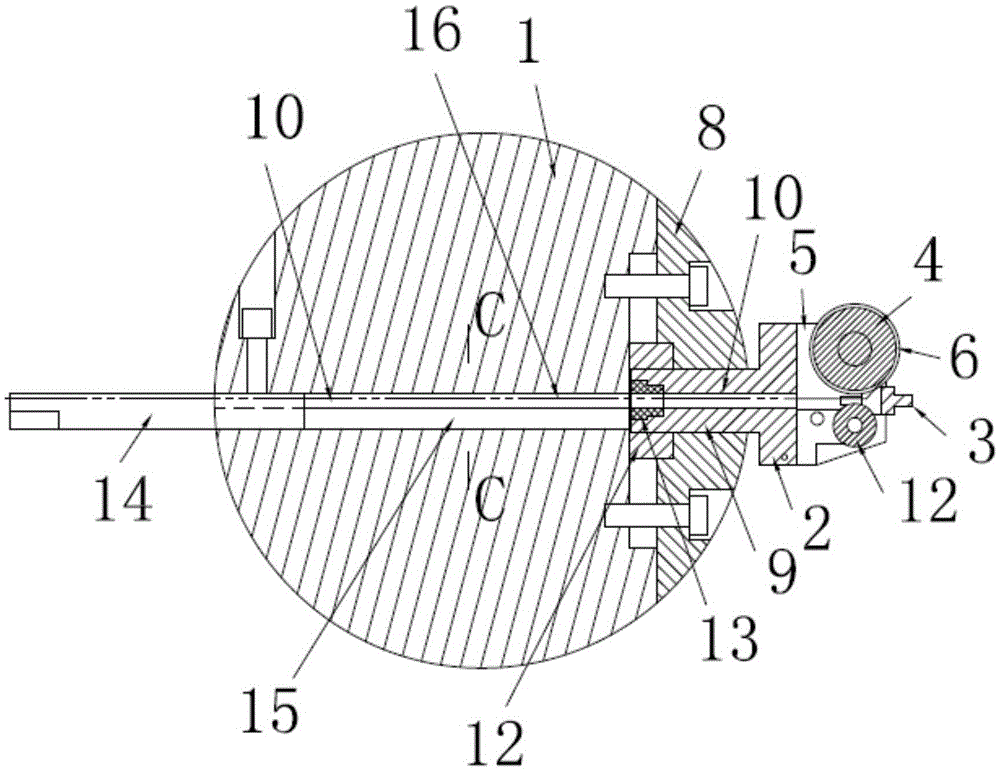

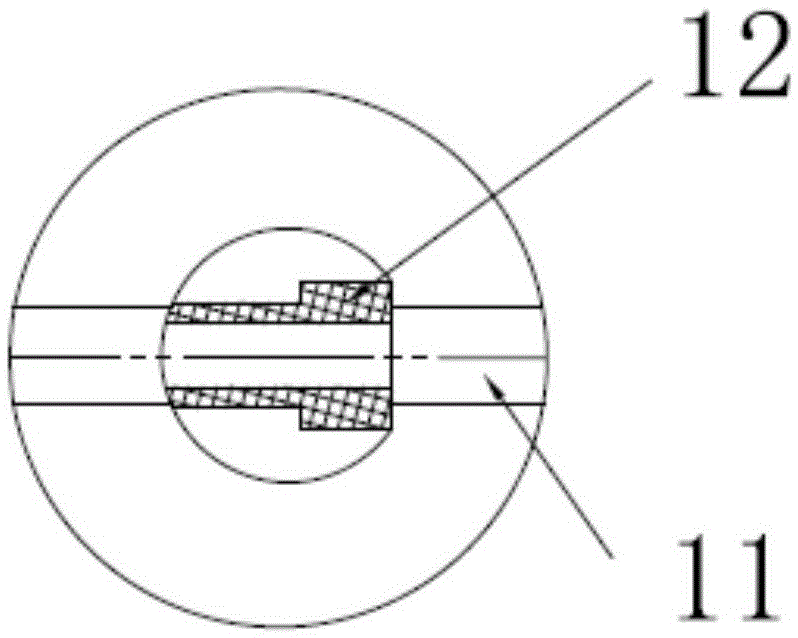

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0030] Such as Figure 1-Figure 6 Shown is a tool for exposing the pipe body after wiring, including a knife holder 1, a knife holder 2, an inner hole knife 14, a cutting knife 3 and a roller 4; the bottom of the knife holder 2 is connected to the knife holder 1; The top of the knife seat 2 is provided with a gap 5, and the cutter 2 is installed on the knife seat 2 for cutting the embedded groove for laying the resistance wire 16 in the pipe body, and the outer circular surface of the roller 4 is provided with a ring And it is used to place the placement groove 6 of the resistance wire. The roller 4 is located in the gap 5 and can rotate, and the outer circular surface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com