Fluoroplastic condenser welding equipment and welding process thereof

A welding equipment and welding process technology, applied in the field of fluoroplastic condenser welding equipment and its welding process, can solve problems such as increased manufacturing cost, unbalanced welding section, chemical burns, etc., and achieve improved mechanical properties, excellent heating performance, Chemically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

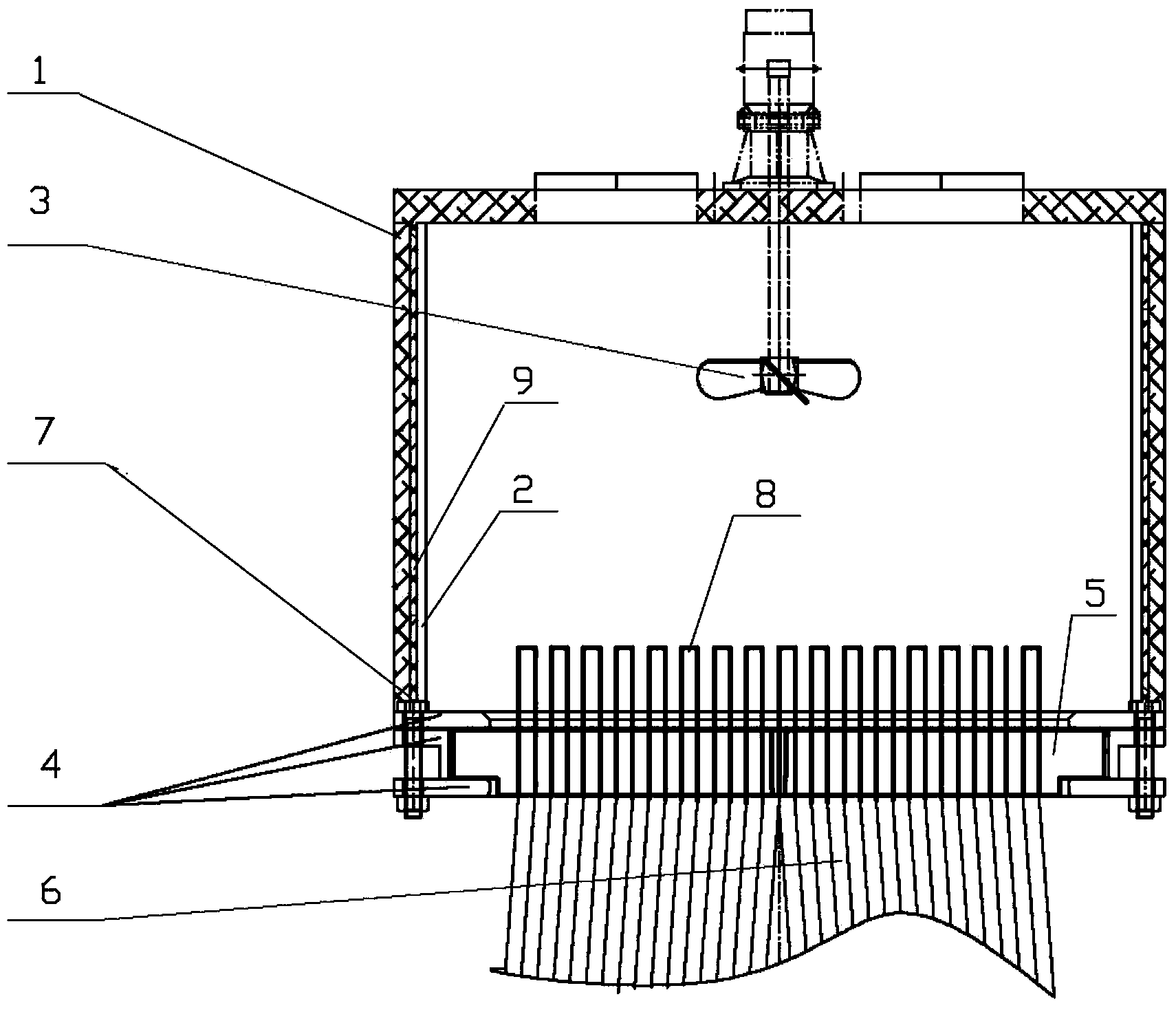

[0022] A fluoroplastic condenser welding equipment, such as figure 1 As shown, it includes a casing 1, and also includes an infrared heater 2 arranged inside the casing 1, a fan 3 arranged on the upper part of the casing 1, a fixed mold 4 arranged at the lower end of the casing 1, and a pipe arranged under the casing 1 through the fixed mold 4. The plate 5, the tube bundle 6 connected to the tube plate 5 through the fixed mold 4 and the temperature sensor 7 connected to the fixed mold 4, the tube bundle 6 is provided with a modified PTFE inner core 8. The tube sheet 5 is fixedly arranged on the fixed mold 4 .

[0023] In this embodiment, the tube sheet 5 is a PFA tube sheet, and the tube bundle 6 is a PFA tube bundle.

[0024] The inner side of the shell 1 is provided with an insulating layer 9 , and the infrared heater 2 is located at the inner end of the insulating layer 9 .

[0025] The blades of the fan 3 extend to the middle of the housing 1 .

[0026] The PFA material...

Embodiment 2

[0030] A process for condenser welding using infrared heating welding equipment, such as figure 2As shown, the steps include: 1) Heating PFA and auxiliary materials, compression molding, pressure-holding molding, then demoulding, 2 heat treatments to finalize the shape, turning processing, numerical control control, cleaning treatment, and inspection to obtain qualified PFA tube sheets; 2 ) PFA and auxiliary materials are extruded and shaped, and the formed tube bundle is obtained through 2 times of tube heat treatment and 2 times of tube shaping; 3) The formed tube bundle and PFA tube sheet are positioned, dust removed, sleeve, flat head, and the welding outer mold is installed. Vinyl fluoride non-metallic inner core, clean twice; 4) Install an infrared heater and use it for fusion welding, inspect after cooling, pull out the inner core, and dismantle the welding equipment; 5) Complete the welding work after passing the pressure inspection. Among them, the melting index of P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com