High-density package substrate on-hole disk product and preparation method thereof

A packaging substrate, high-density technology, used in the manufacture of printed circuits, the formation of electrical connection of printed components, and the electrical connection of printed components. , Optimize the effect of laser processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present application will be further elaborated below in conjunction with the embodiments and the accompanying drawings.

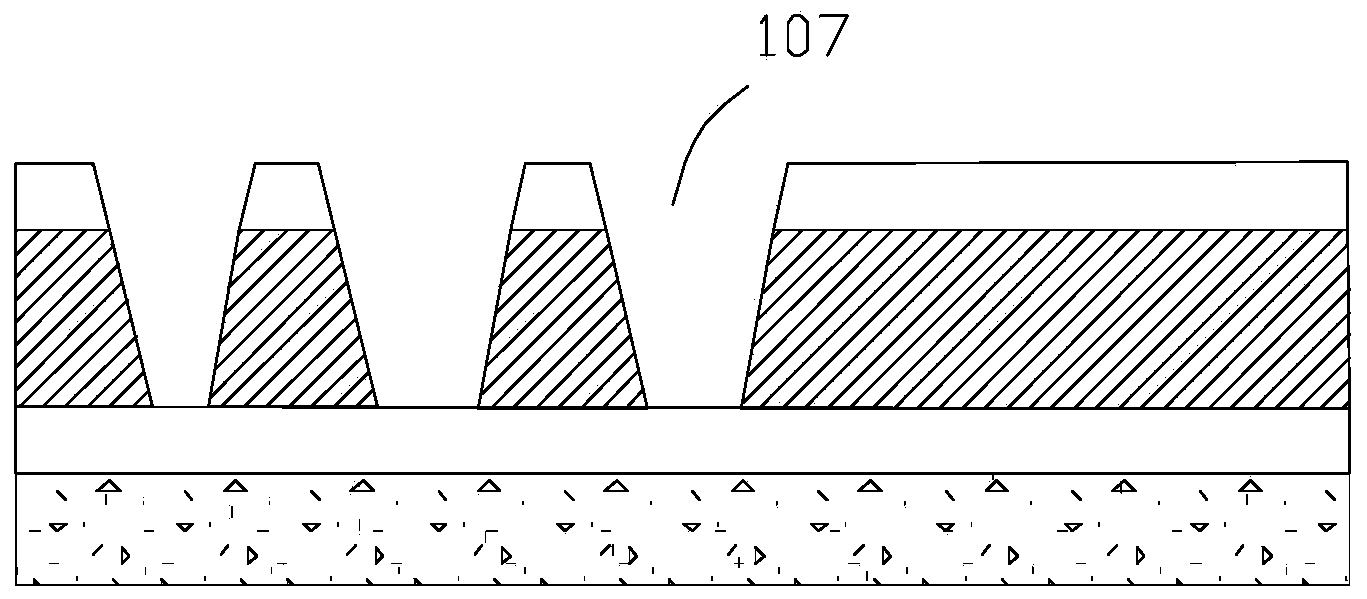

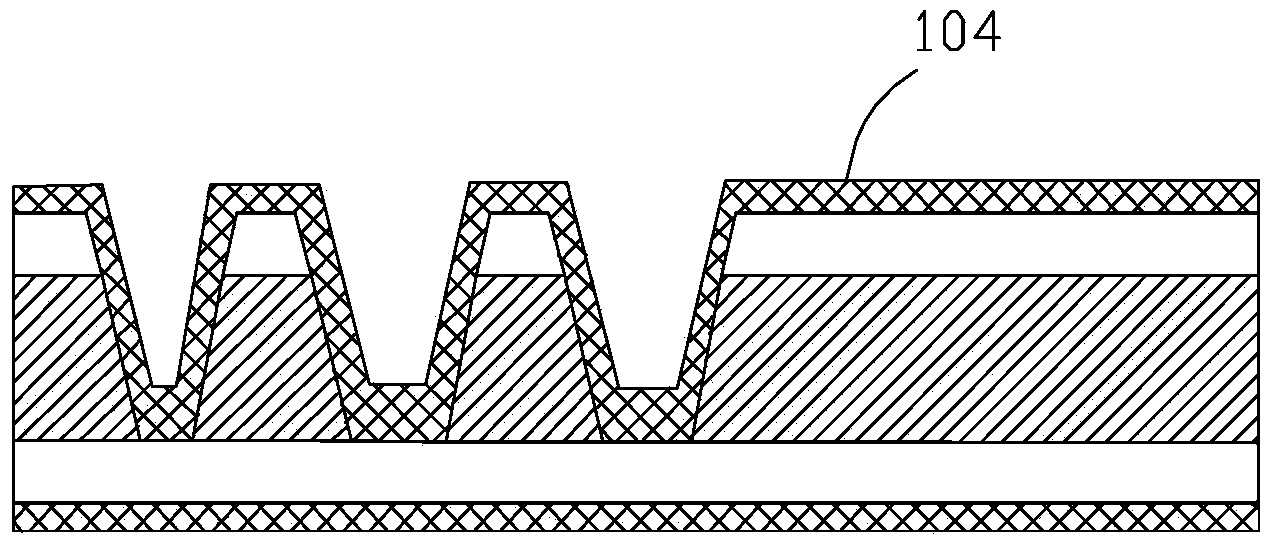

[0042] refer to Figure 1-7 , a method for preparing a high-density packaging substrate hole-mounted product, comprising the following steps:

[0043] Cutting—baking plate—making positioning holes—removing the upper surface protective layer—laser drilling—microetching—removing the lower surface protective layer—removing glue—depositing chemical copper—MSAP process—— Electroplating and hole filling - MSAP film removal - MSAP etching - post process.

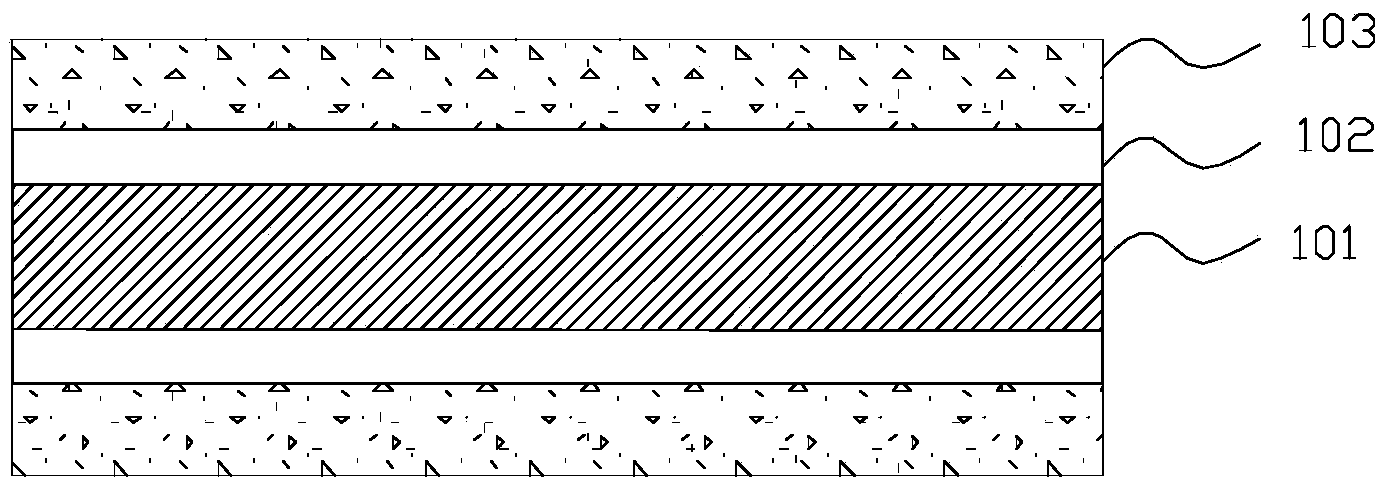

[0044] Among them, the substrate materials used for cutting are such as figure 1 As shown (the thin copper substrate includes a dielectric layer 101, a copper foil 102 and a protective film layer 103). Different from the traditional copper-clad substrate material, the thickness of the substrate is 0.1mm, and the outer side of the copper foil (thickness is 2-4μm) has a layer of protective copper foi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Copper thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com