Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Settle property damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

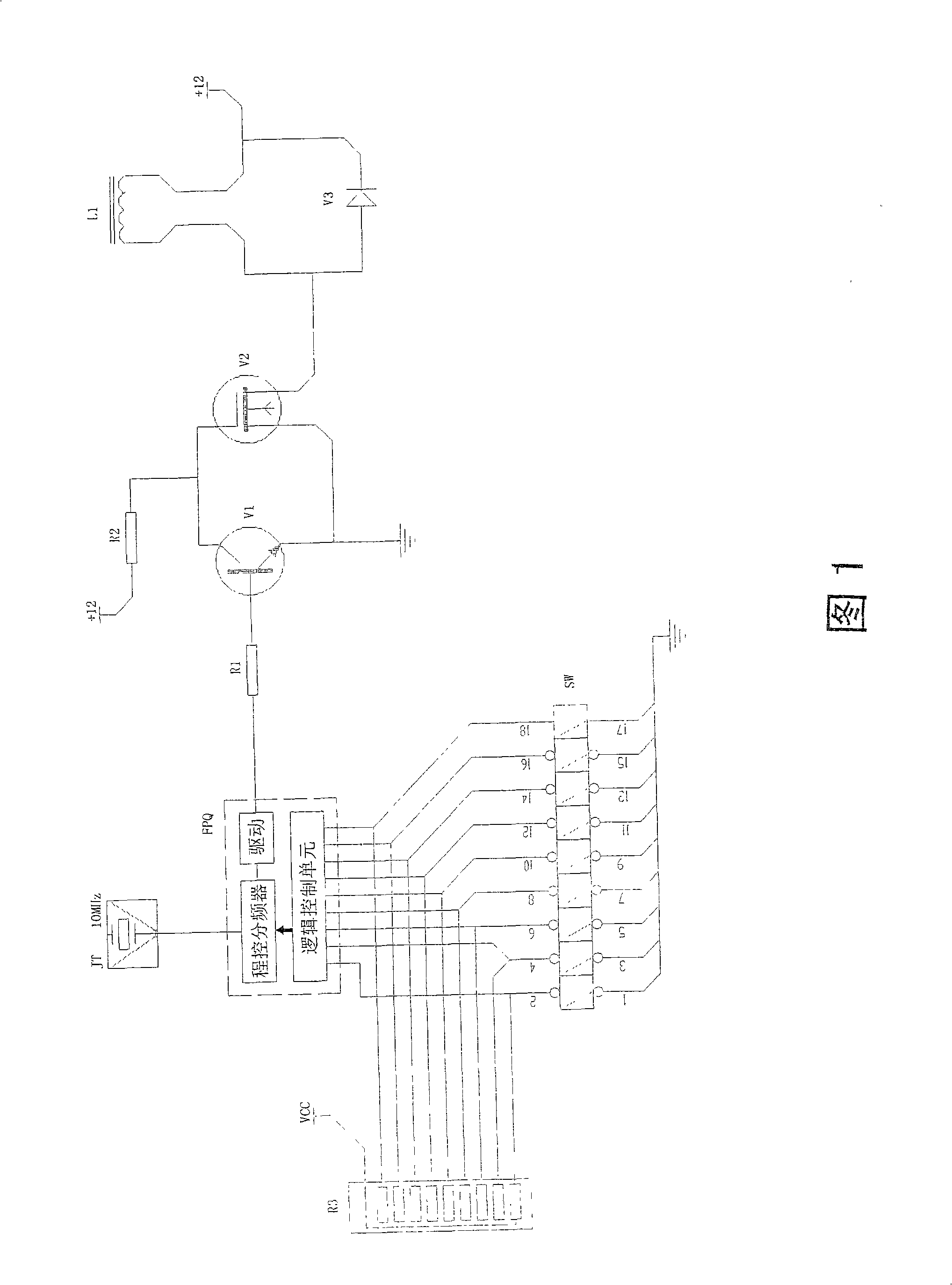

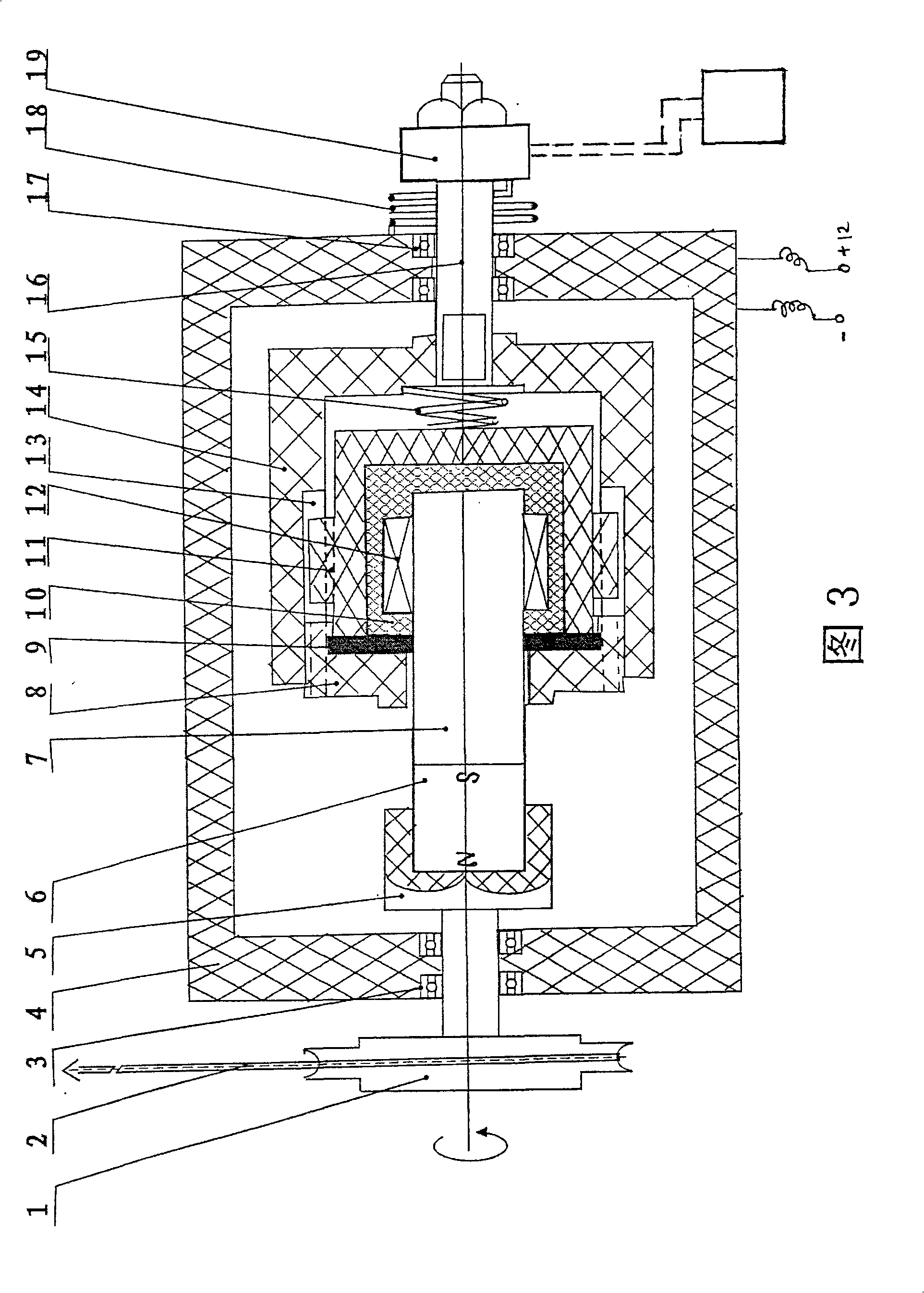

Intervention type active speed limiting control device of motor vehicle

ActiveCN101344990AReduce controversyLess passiveArrangements for variable traffic instructionsControl mannerTraffic accident

The invention provides an active speed limit controlling device of motor-vehicle-involved mode, aiming at solving passiveness and limitation which are introduced by the traditional 'electronic eye' speed detecting method and the novel method of 'interval speed detection' in the detection of an over-speed vehicle on a freeway. The active speed limit controlling device comprises an emission source of a speed-limited value signal, a vehicle-bone signal receiver, a Hall sensor, a speed limit indicator and a circuit thereof, an over-speed alarming circuit, a switch circuit of an electronically-controlled accelerating pedal and components thereof, a single-chip speed controlling software and so on. The emission source is arranged under or on the ground of the entrance of a freeway, with different pulse frequencies representing different vehicle speed limit values. When the vehicle exceeds the speed limit, the system device emits an over-speed alarming signal, and the driver needs to decelerate by self, otherwise, at the end of the alarm, the accelerating pedal does not take effect to the oil-supplied control instantly, and recovers after automatically decelerating the vehicle to a given value in a punishing way. The active speed limit controlling method and the process thereof are carried out repeatedly, which leads the vehicles to be driven in order, reduces the occurrence of traffic jam, and prevents a traffic accident which is easily caused by over-speed.

Owner:李扬荣 +2

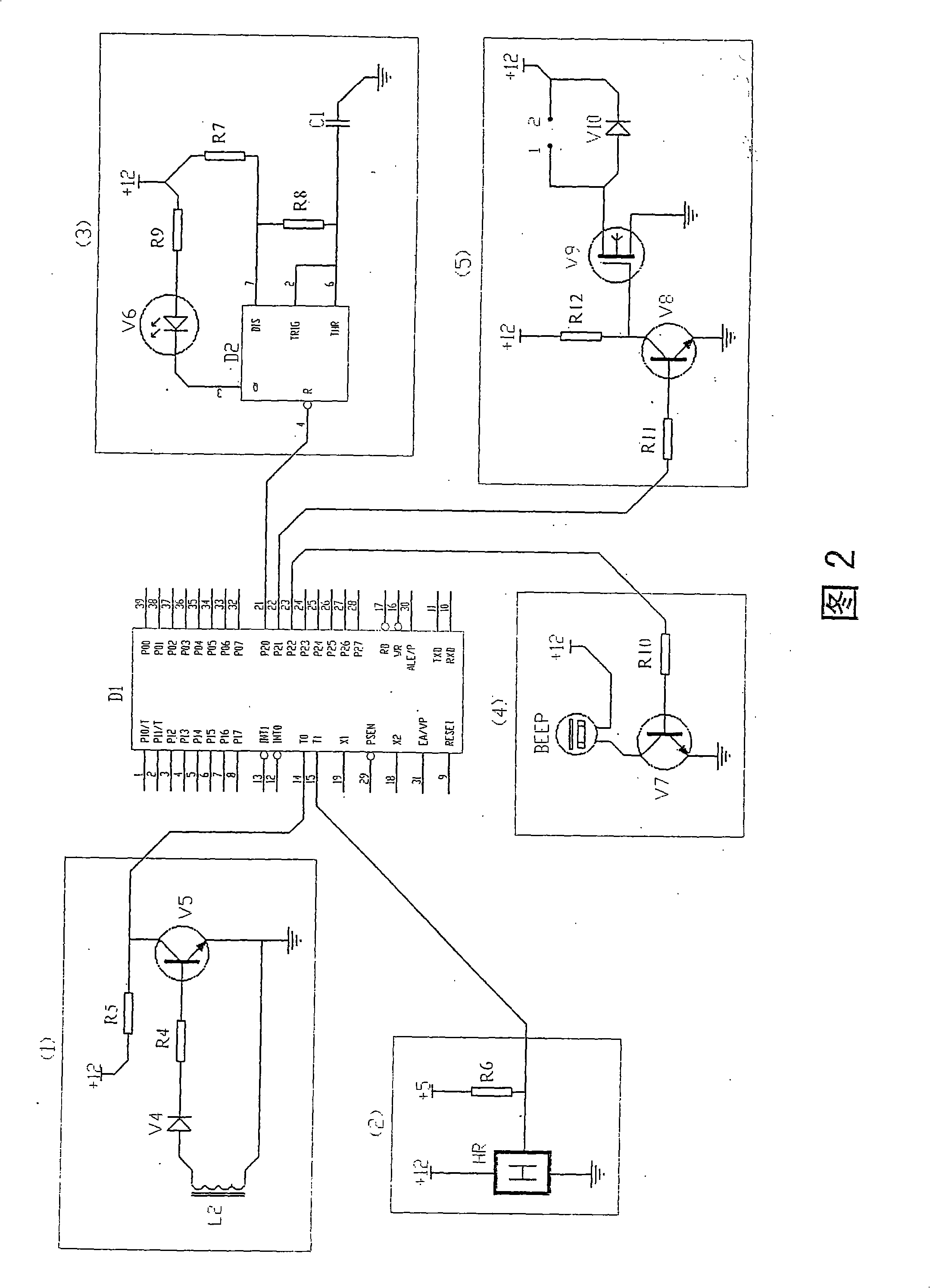

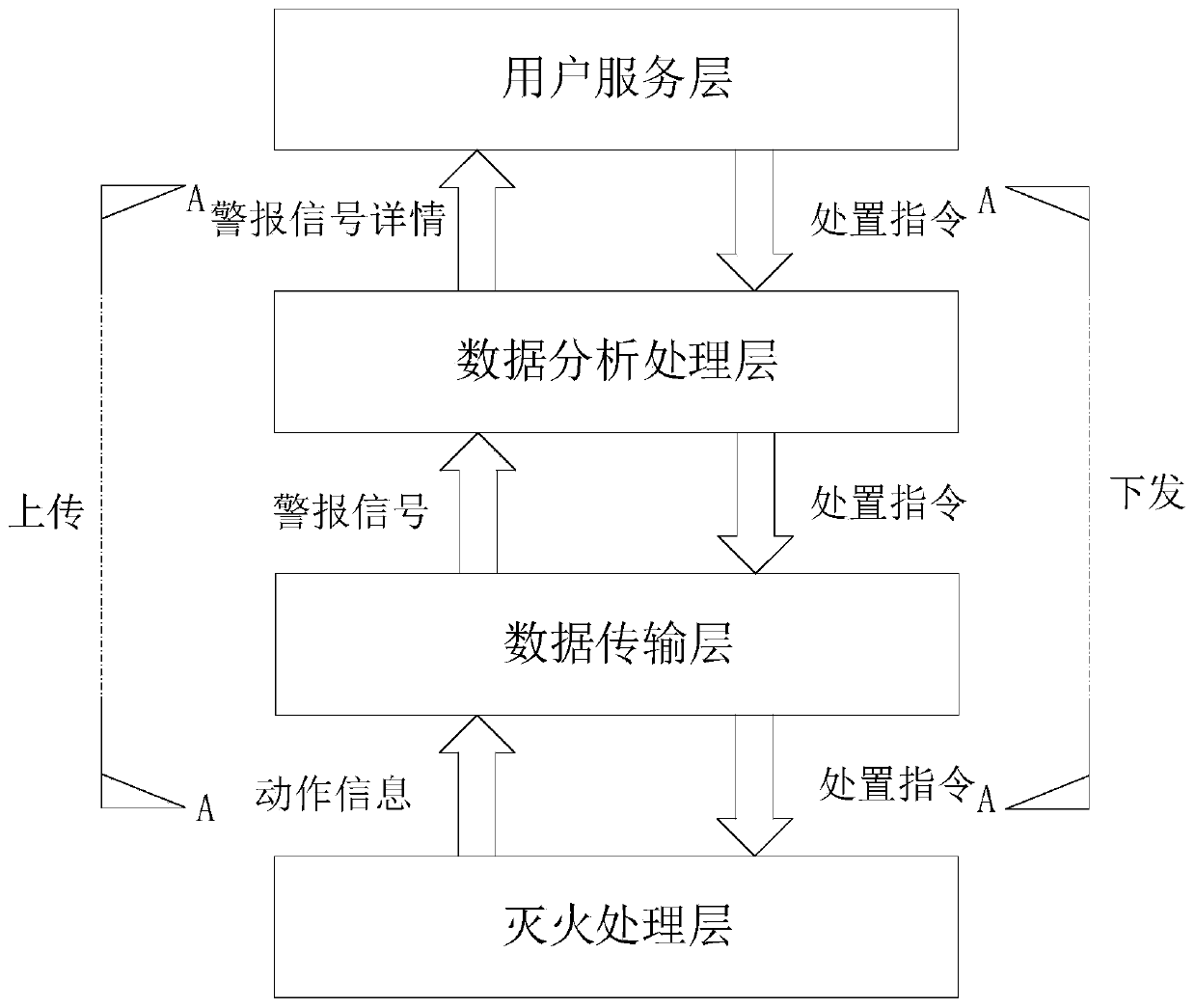

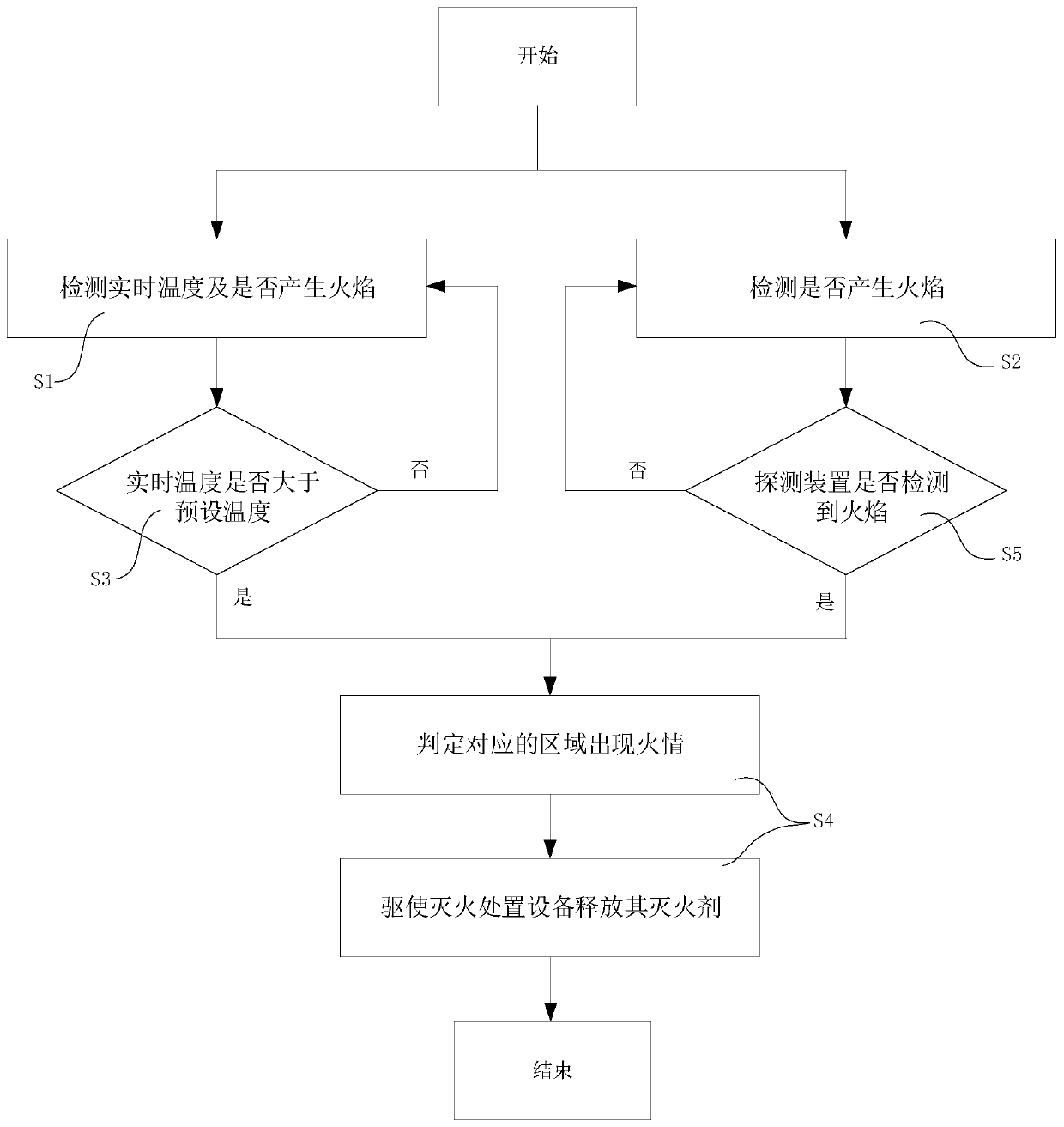

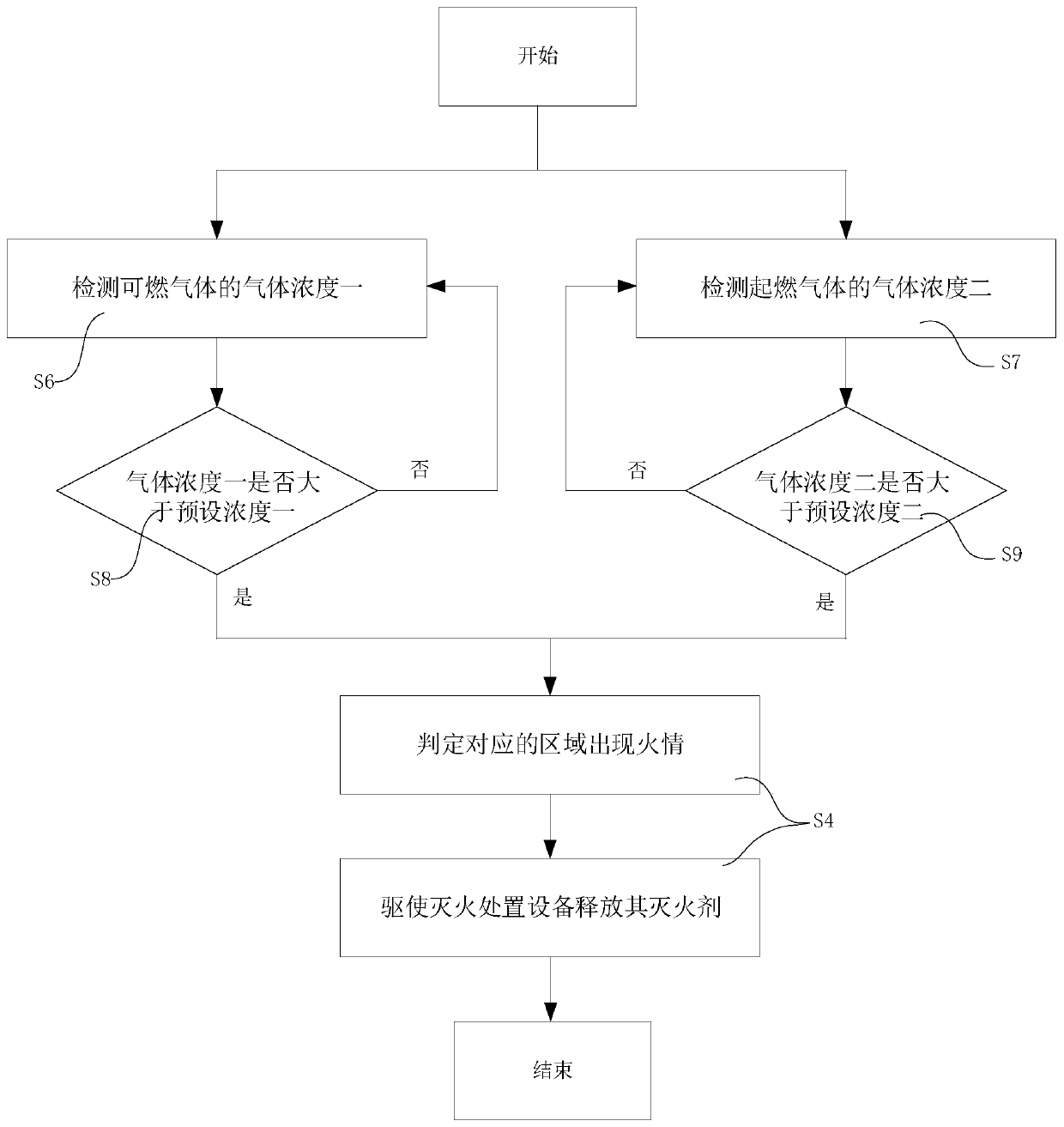

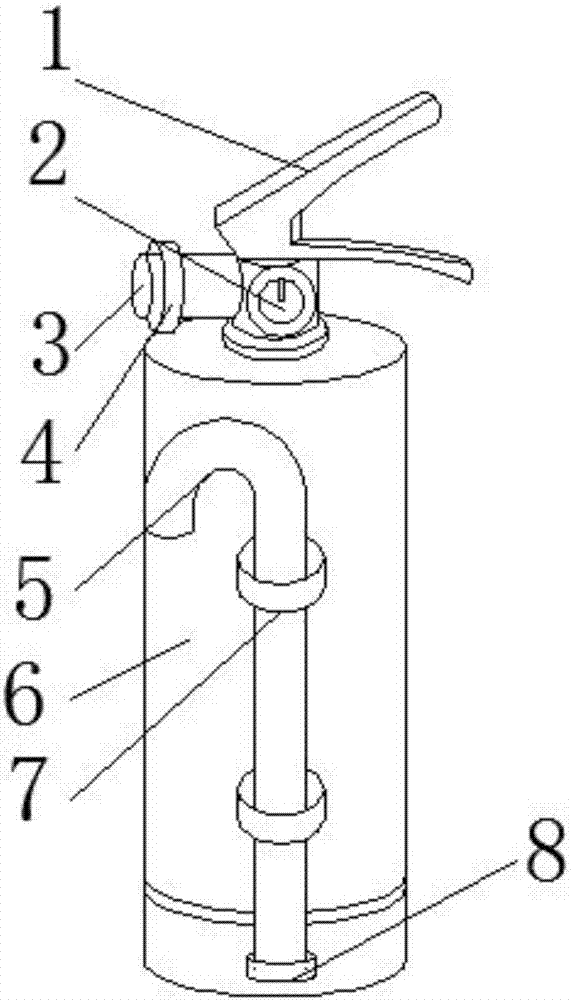

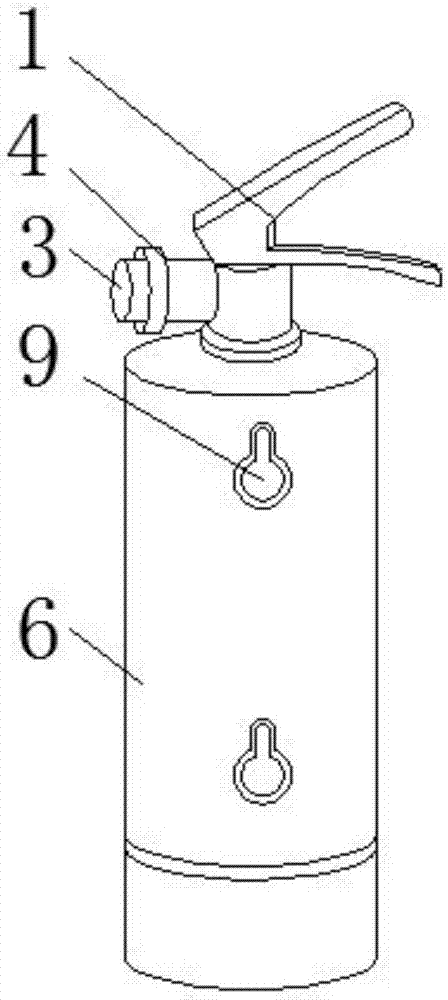

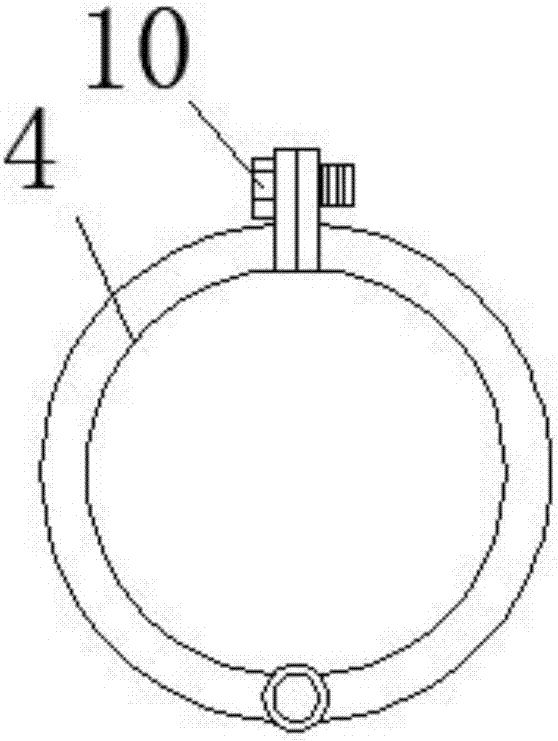

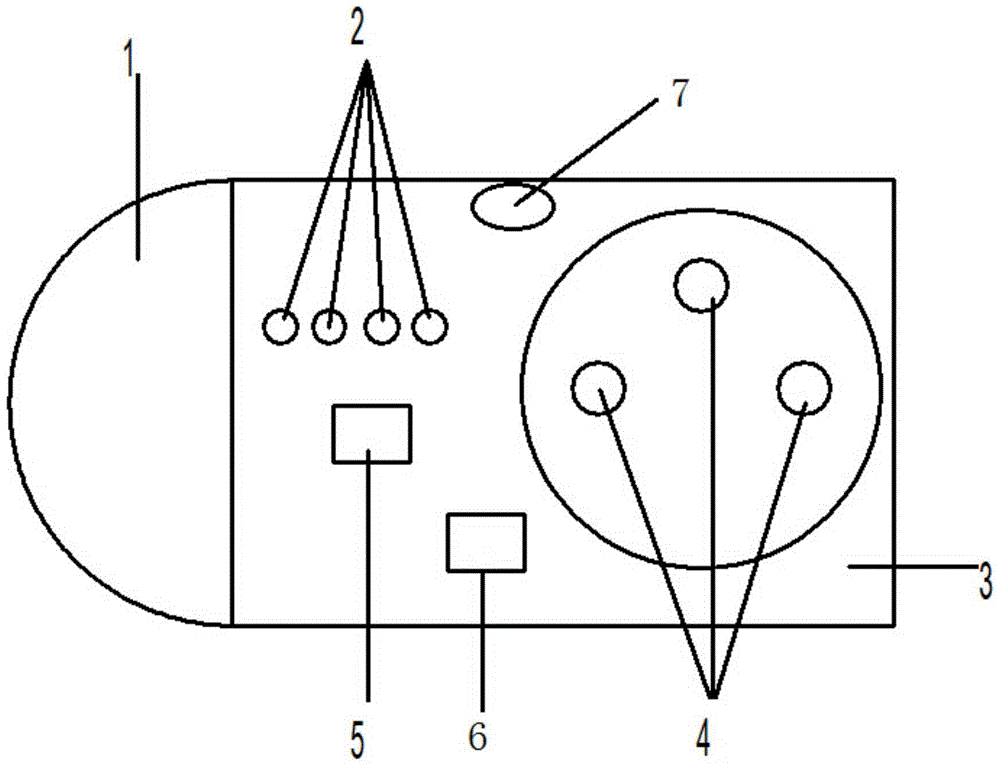

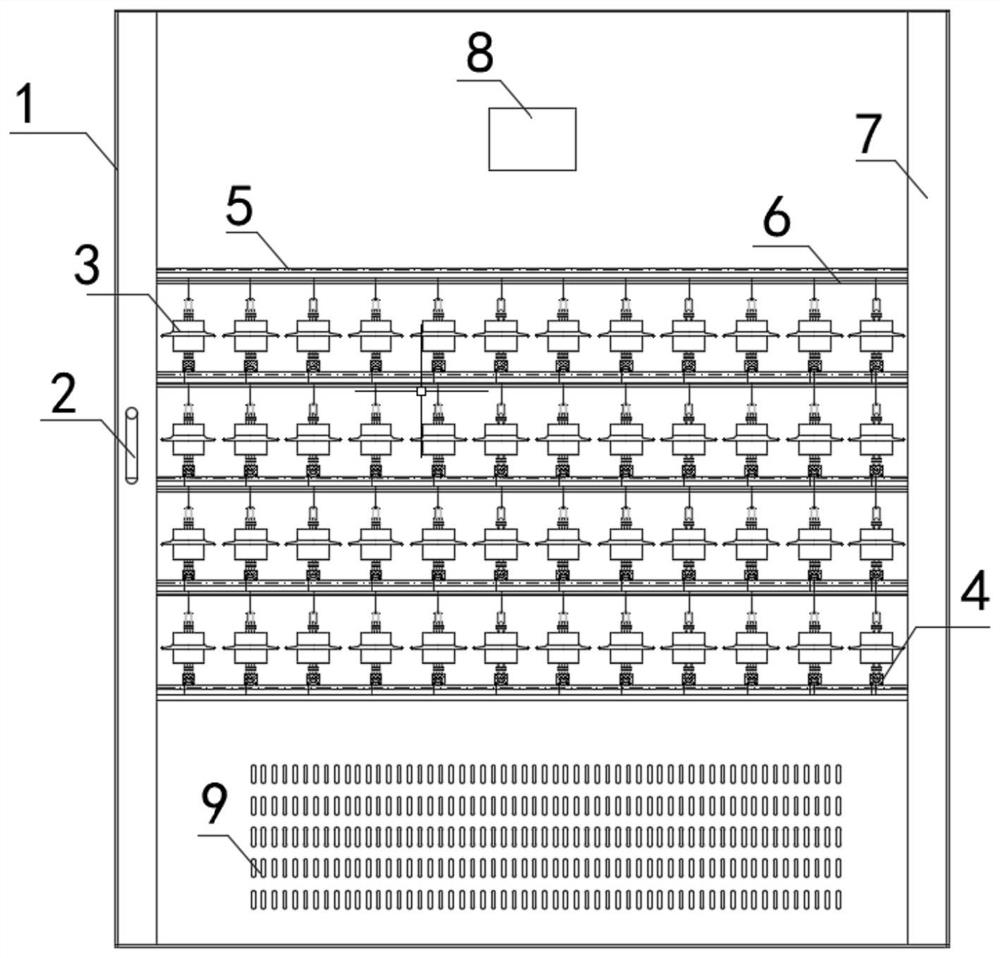

Automatic fire extinguishing system for vehicle and fire extinguishing method thereof

ActiveCN110801588ARealize automatic fire extinguishingSettle property damageFire rescueFire alarm radiation actuationAutomatic fire suppressionData transport

The invention discloses an automatic fire extinguishing system for a vehicle and a fire extinguishing method thereof. The system comprises a fire extinguishing processing layer, a data transmission layer, a data analysis processing layer and a user service layer, wherein the fire extinguishing processing layer comprises a detection device, a fire extinguishing device and a fire extinguishing controller; the detection device is used for detecting the real-time temperature of a compartment; an engine compartment and a battery compartment of the vehicle and is also used for detecting whether flames are generated in the compartment; the engine compartment and the battery compartment; the fire extinguishing device comprises fire extinguishing disposal devices arranged in the compartment; the engine compartment and the battery compartment respectively; each fire extinguishing disposal device is used for releasing a fire extinguishing agent to extinguish a fire in an area where the fire extinguishing disposal device is positioned; and the fire extinguishing controller is used for driving the corresponding fire extinguishing disposal device to release the fire extinguishing agent. The automatic fire extinguishing system for the vehicle and the fire extinguishing method thereof achieve the functions of automatic fire extinguishing and remote manual fire extinguishing of the vehicle, arebeneficial to platform information management of fire fighting data, and can also transmit environmental parameters to a cloud platform so as to monitor operating data of the vehicle before a fire occurs and generate a certain prediction effect.

Owner:安徽育求消防科技有限公司

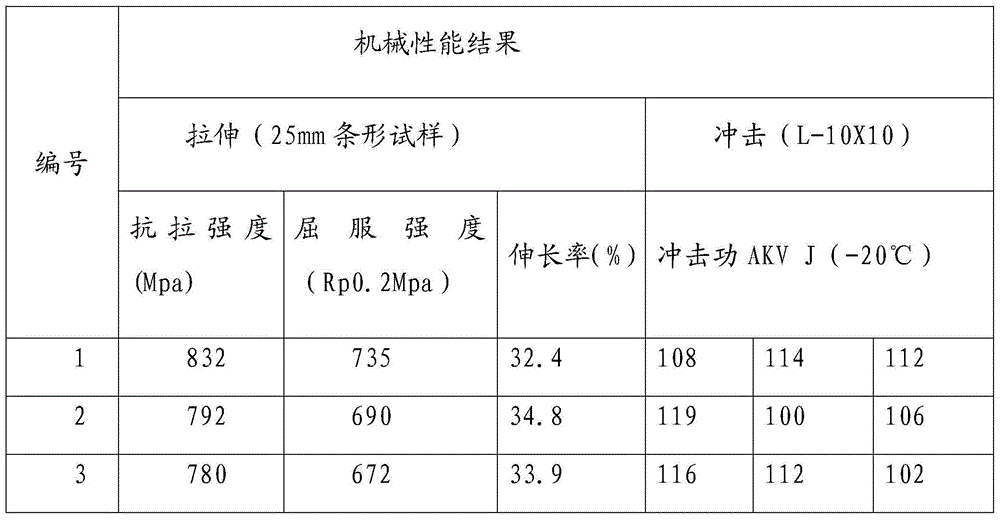

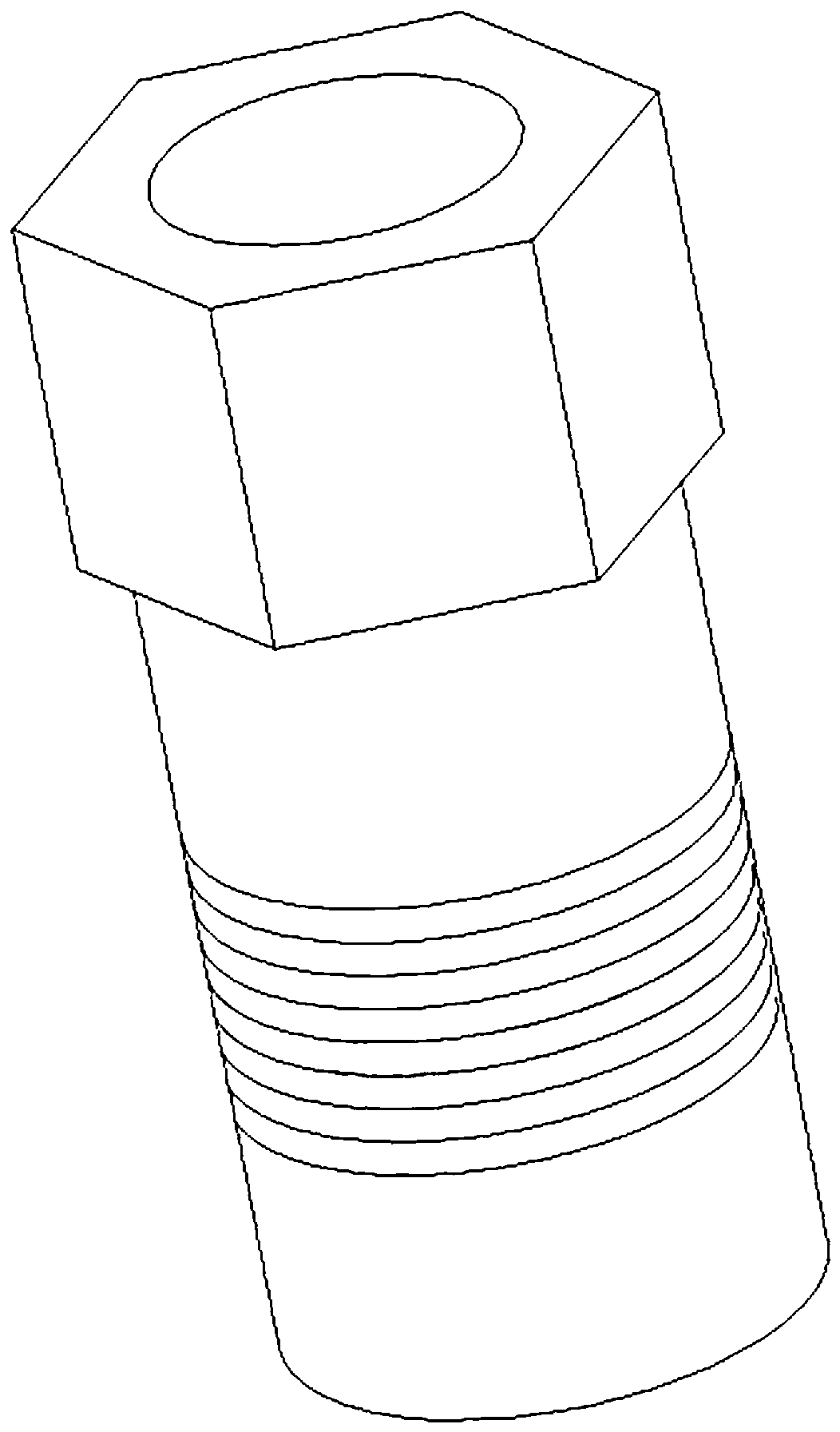

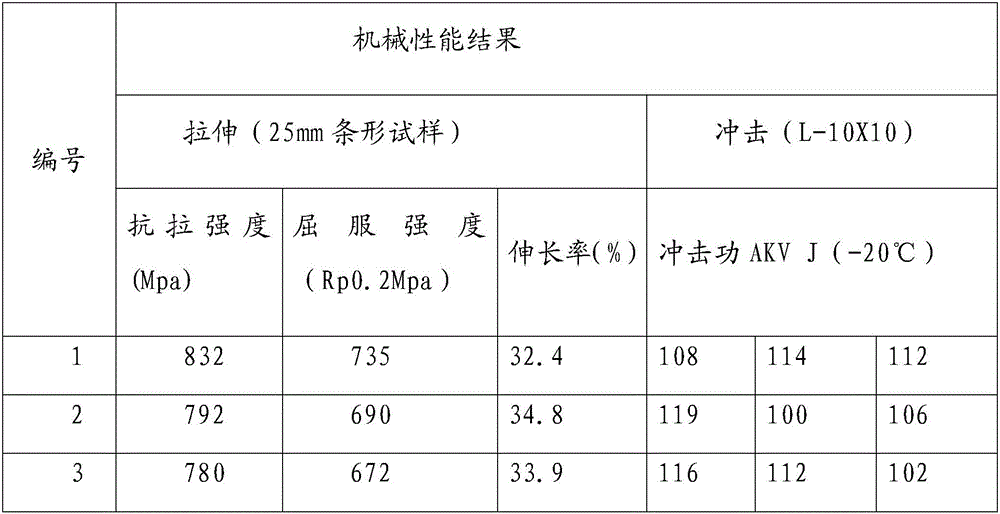

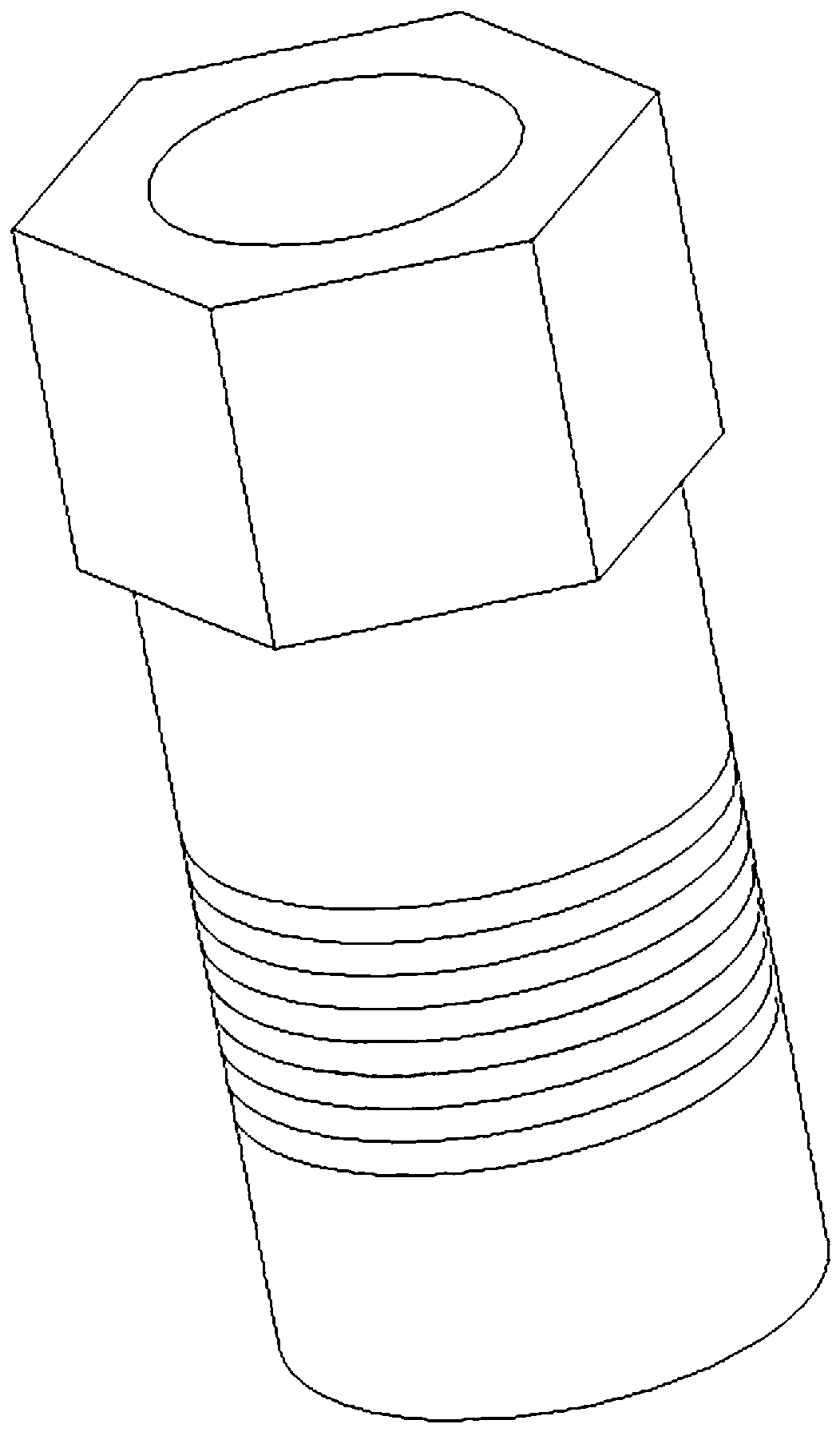

Manufacturing method of seamless steel pipe

The invention discloses a manufacturing method of a seamless steel pipe. The manufacturing method comprises the following steps of making steel: feeding a SiCaBa alloy core wire after slagging molten steel in a steel ladle, and expanding slag to form foamed slag; adjusting the amount, the alkalinity and the fluidity of the slag according to slag conditions, and adding SiC powder, silicon calcium (barium), silicon iron and calcium carbide so as to reduce refined slag to form white slag; adding 0.13-0.20% of carbon, 0.25-0.50% of silicon, 0.9-1.3% of manganese, less than or equal to 0.030% of phosphorus, less than or equal to 0.030% of sulphur, 0.03-0.10% of vanadium, 0.015-0.040% of aluminium, less than or equal to 0.20% of chromium, less than or equal to 0.10% of nickel, less than or equal to 0.10% of molybdenum, less than or equal to 0.10% of titanium, and less than or equal to 0.20% of copper; pouring out a part of the refined slag, and retaining a slag layer, the molten steel surface layer of which is less than or equal to 100 mm; stirring in vacuum; feeding an aluminium wire with the diameter of 12 mm after breaking vacuum; feeding a pure calcium wire for modifying inclusions; blowing by using argon so that the molten steel is uniform; continuously casting; rolling; thermally treating; straightening; and detecting flaws. The seamless steel pipe prepared by the invention has high strength, high toughness, low carbon equivalent and good welding property, and therefore, the use reliability and the safety are increased.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

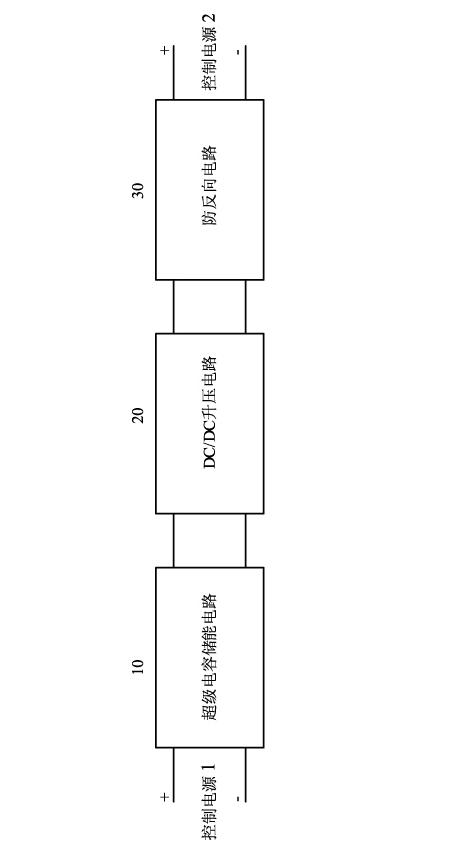

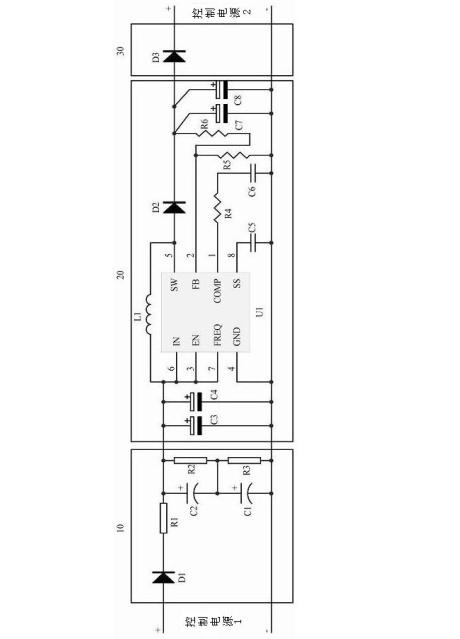

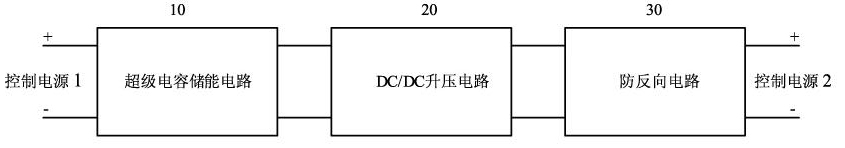

Voltage shock avoiding circuit

InactiveCN102074996ASolve enterprise safety production accidents and property lossesImprove practicalityElectrical storage systemEmission reduction for energy storageElectricityVoltage

The invention discloses a voltage shock avoiding circuit, which comprises a first control power supply, a supercapacitor energy storage circuit, a DC / DC boosting circuit, a reverse-preventing circuit and a second control power supply which are sequentially connected in series. In the invention, after the voltage shock avoiding circuit is additionally arranged on a first control power supply circuit, the supercapacitor energy storage circuit outputs stable voltage through the DC / DC boosting circuit and is connected to the second control power supply through the reverse-preventing circuit, thus the problems that the safety production accidents and the property loss of enterprises due to tripping and halting of a protecting device caused by voltage shock can be solved. The voltage shock avoiding circuit has high practicability in the electrical engineering field, in particular to a protecting device of electrical equipment.

Owner:JIANGSU SFERE ELECTRIC

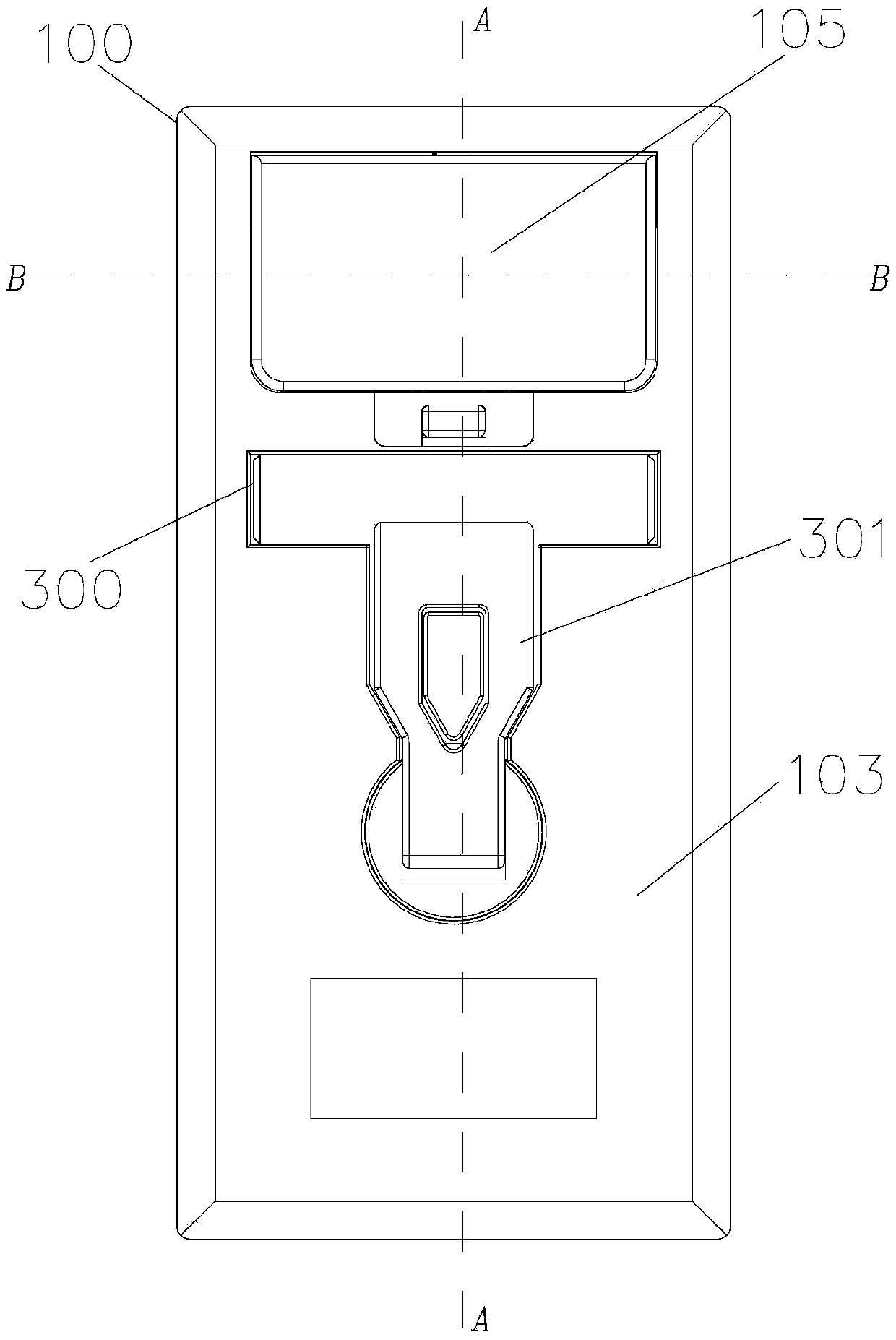

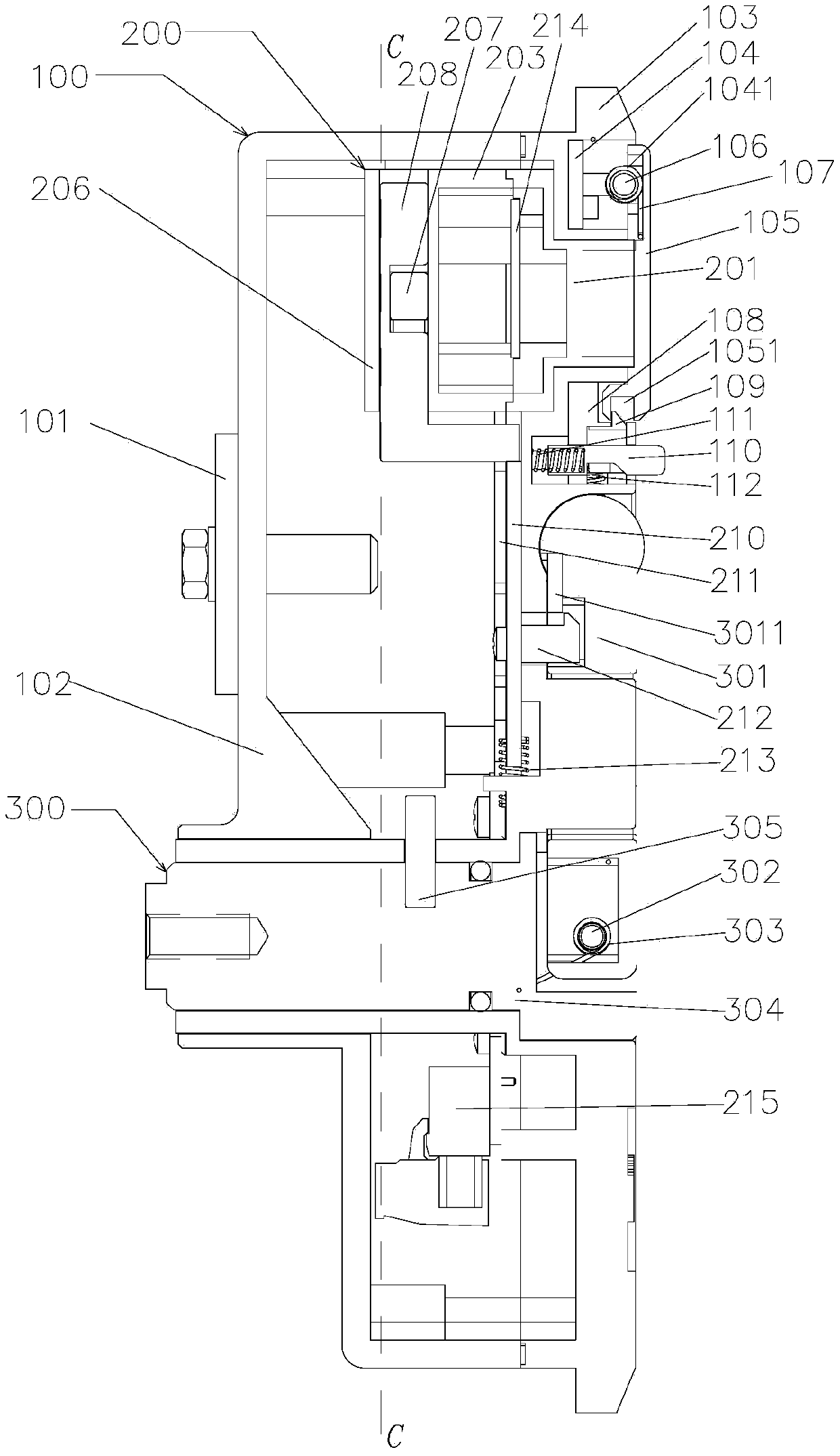

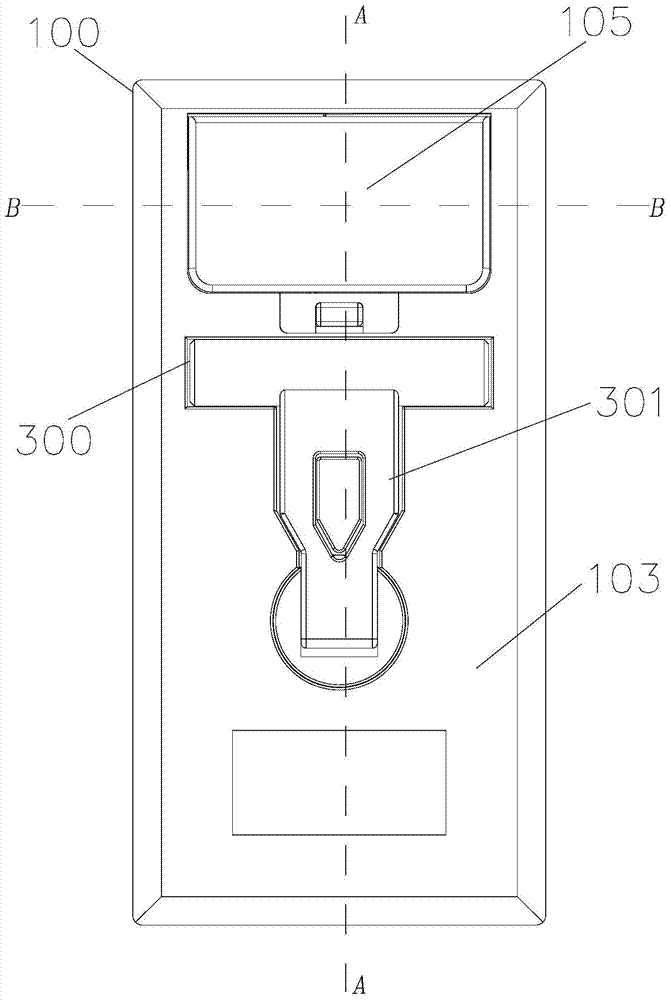

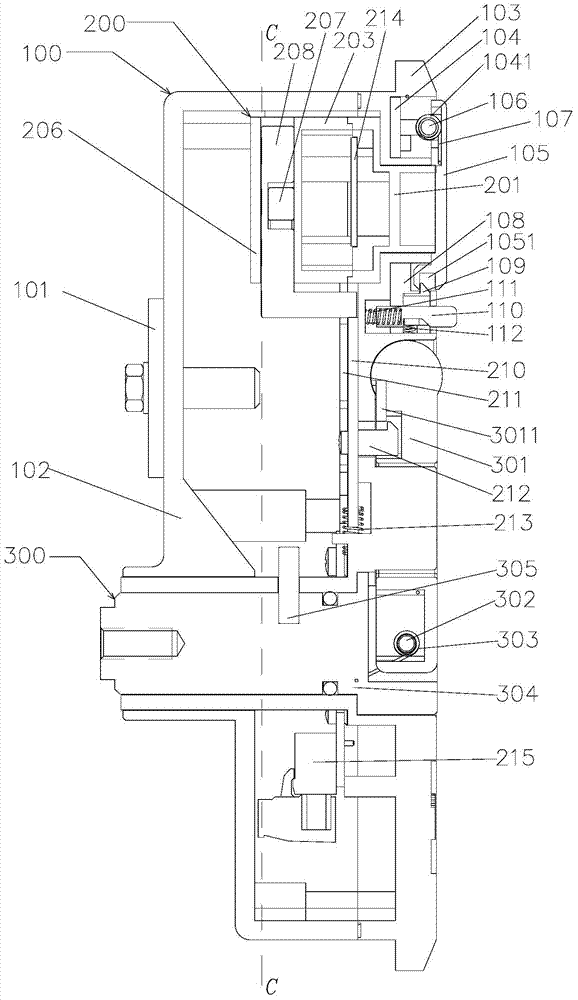

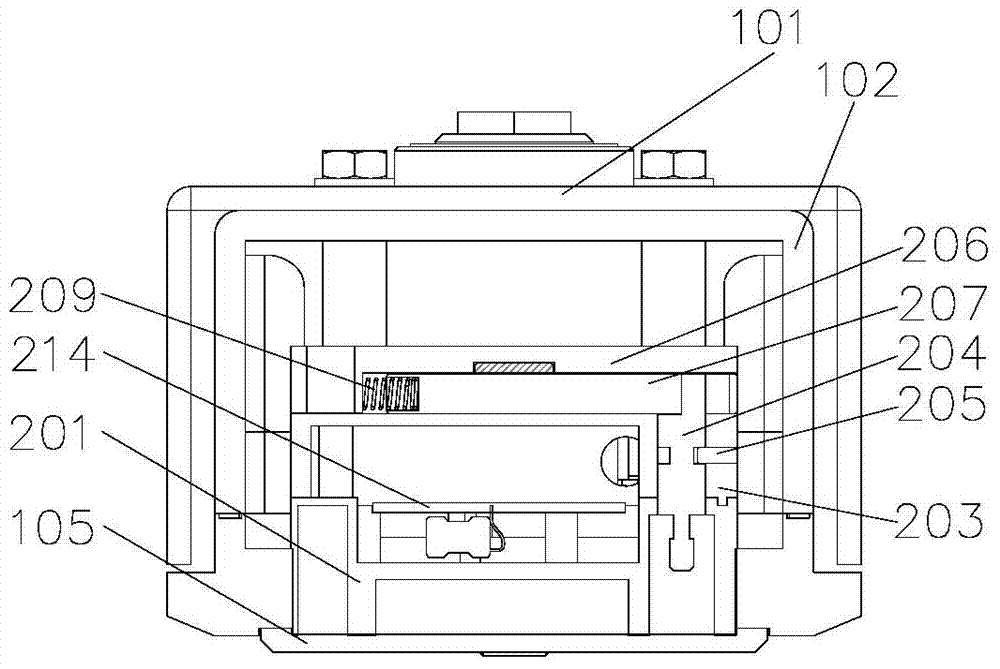

Intelligent door lock

ActiveCN105370108AAddressing personal injury and property damageAddressing Personal InjuryElectric permutation locksElectrical and Electronics engineeringState control

The invention discloses an intelligent door lock which comprises a shell assembly, an unlocking assembly and a handle assembly. The handle assembly comprises a handle, a rotary shaft and a handle limiting mechanism. The rotary shaft is arranged on the shell assembly and rotates between an opening position and a closing position. The tail end of the handle is connected with the rotary shaft. The handle limiting mechanism is controlled to fix and limit the control end of the handle on the shell assembly or release the control end of the handle. The unlocking assembly comprises a lock knob, a transmission mechanism, a handle limiting buckle, a chip circuit board and a state control circuit board. The lock knob is provided with a key matching portion and an unlocking matching portion. The unlocking matching portion is in driving fit with the transmission mechanism. The transmission mechanism drives the handle limiting buckle to act, so that the handle limiting buckle matches the handle limiting mechanism of the handle assembly or is separated from the handle limiting mechanism of the handle assembly. The chip circuit board is connected with the state control circuit board. The chip circuit board generates ID codes of different states. The state control circuit board detects the opening and closing state of the rotary shaft of the handle assembly. The intelligent door lock can be intelligently and uniformly managed.

Owner:CYG CONTRON

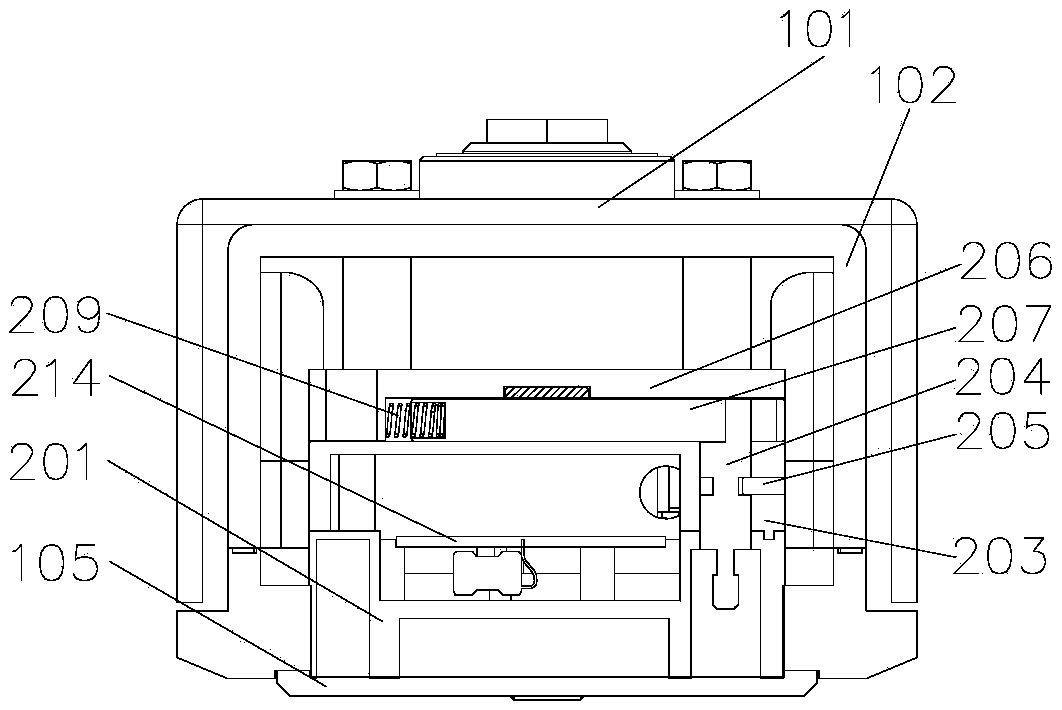

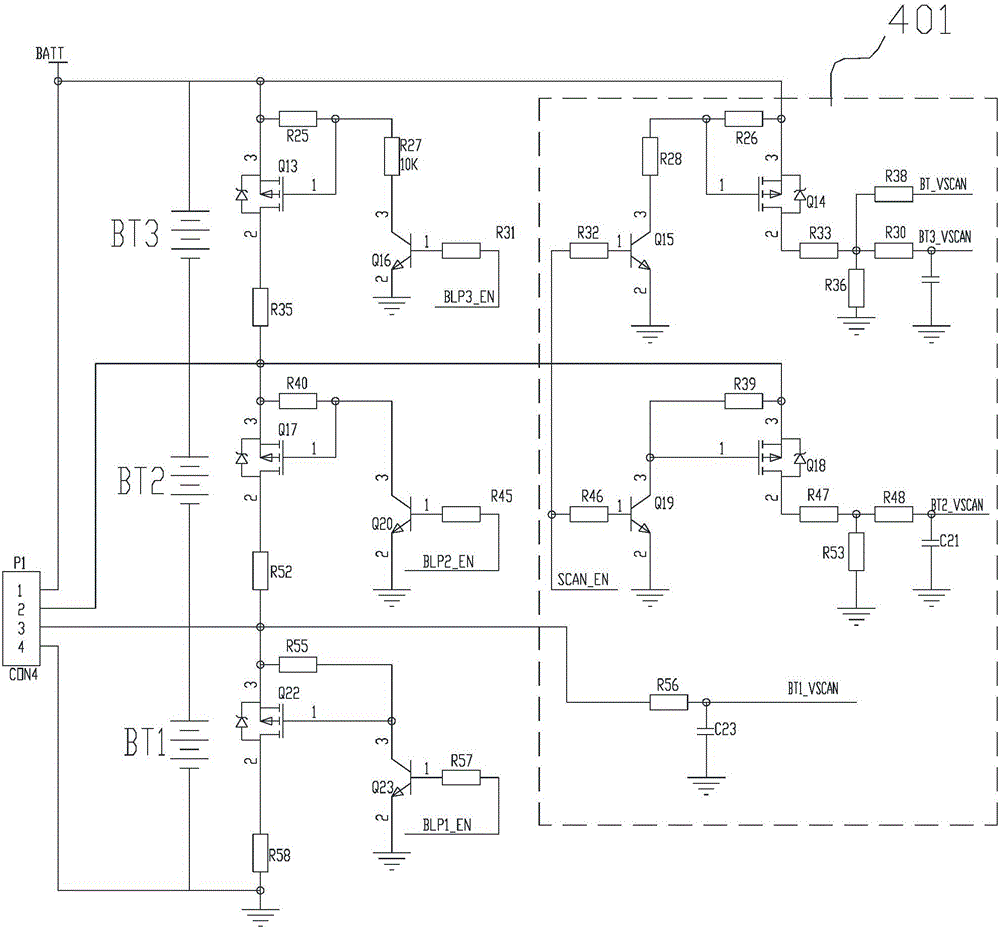

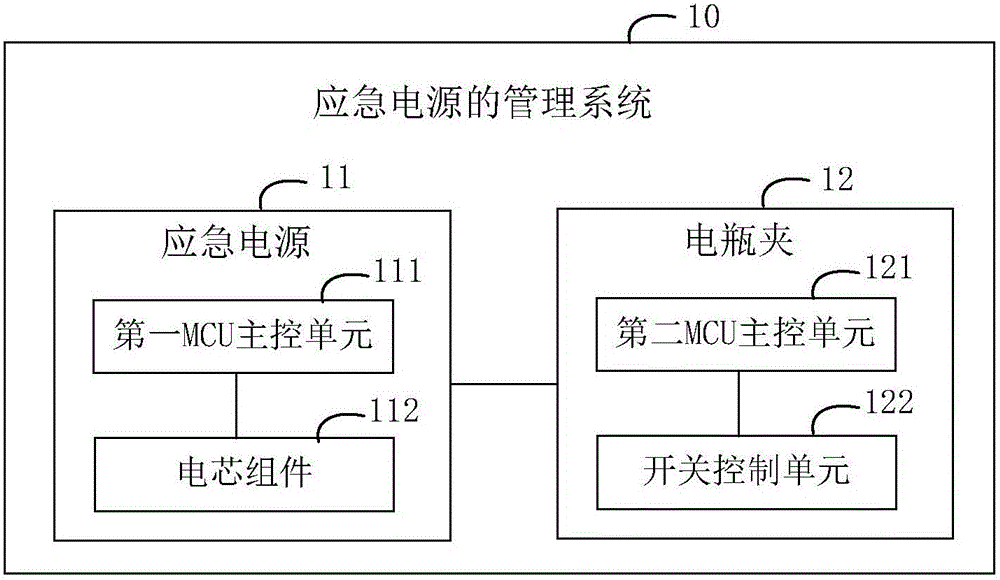

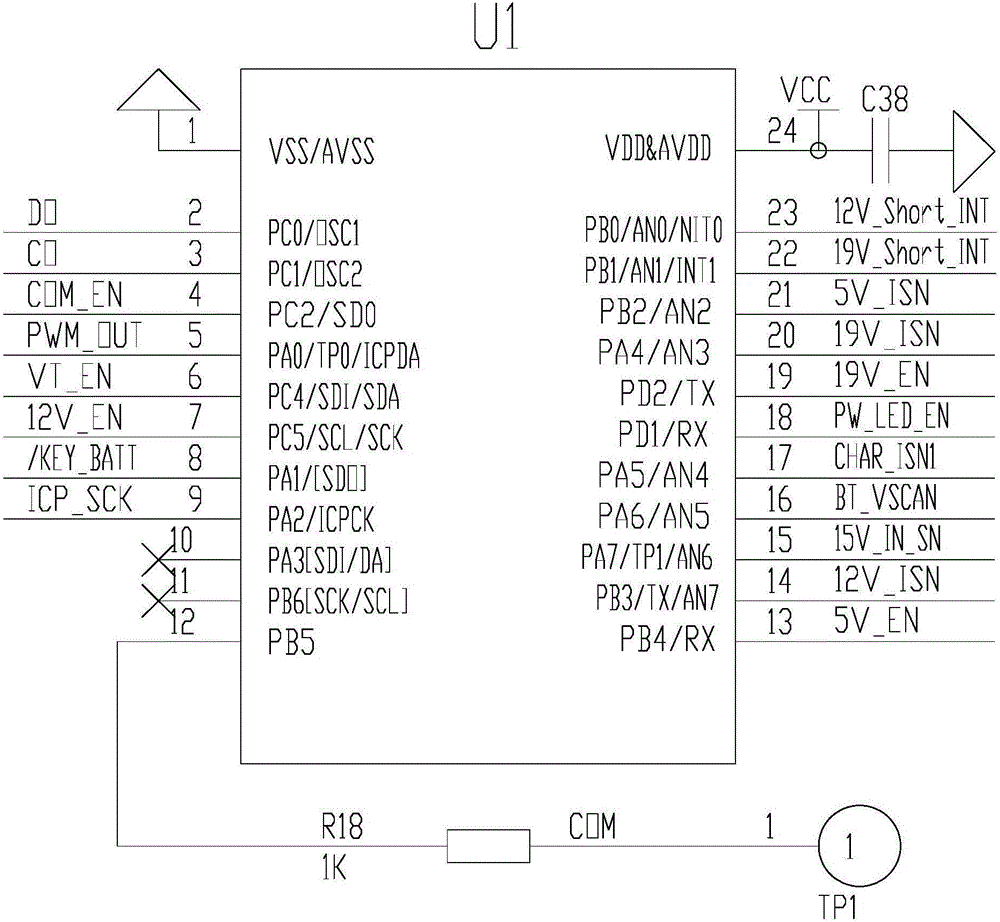

Management system and method for emergency power supply

PendingCN105958139AAddressing Personal InjurySettle property damageSecondary cells servicing/maintenanceEngineeringManagement system

The invention discloses a management system for an emergency power supply. The management system comprises the emergency power supply and a battery clip, wherein the battery clip is connected with the emergency power supply and used for supplying voltage to external equipment; the battery clip and the emergency power supply are also in communication connection, and the battery clip acquires a parameter value of the emergency power supply and executes a corresponding action according to the parameter value. On the other hand, the embodiments of the invention provide a management method for the emergency power supply. The method comprises the steps of acquiring the parameter value of the emergency power supply; and executing a corresponding action according to the parameter value. The management system and method can effectively solve the problems of personal injury and property loss caused by the reason that a lithium battery emergency power supply is bulged and even explodes due to over-high start current, high temperature, overcharge / overdischarge and the like. Meanwhile, the management system can use different types of batteries.

Owner:SHENZHEN CARKU TECH

Fire extinguisher for security and protection

The invention discloses a fire extinguisher for security and protection. The fire extinguisher comprises a fire extinguisher barrel body, wherein a fire extinguisher pressing handle is arranged on one end of the fire extinguisher barrel body, a tray is arranged at the bottom of one side of the fire extinguisher barrel body, a fixed buckle is arranged above the tray, a nozzle is arranged in the fixed buckle, a pressure gage is arranged on one side, which is close to the nozzle, below the fire extinguisher pressing handle, a spray head is arranged on one side of the pressure gage, a fixed retaining ring is arranged on one end, which is far from one end of the pressure gage, of the nozzle, and a fixed groove is formed in one side, which is far from the nozzle, of the fire extinguisher barrel body. The detachable nozzle is designed, so that fires can be conveniently extinguished according to the sizes and distances of the fires, and the problem of property loss or casualties caused by fires because a traditional fire extinguisher cannot be preferably switched between the fires of different sizes and distances is solved; the fixed groove is designed, so that the fire extinguisher can be conveniently fixed or hung, and the problem that the traditional fire extinguisher cannot be independently fixed or hung is solved.

Owner:安徽初慕科技有限公司

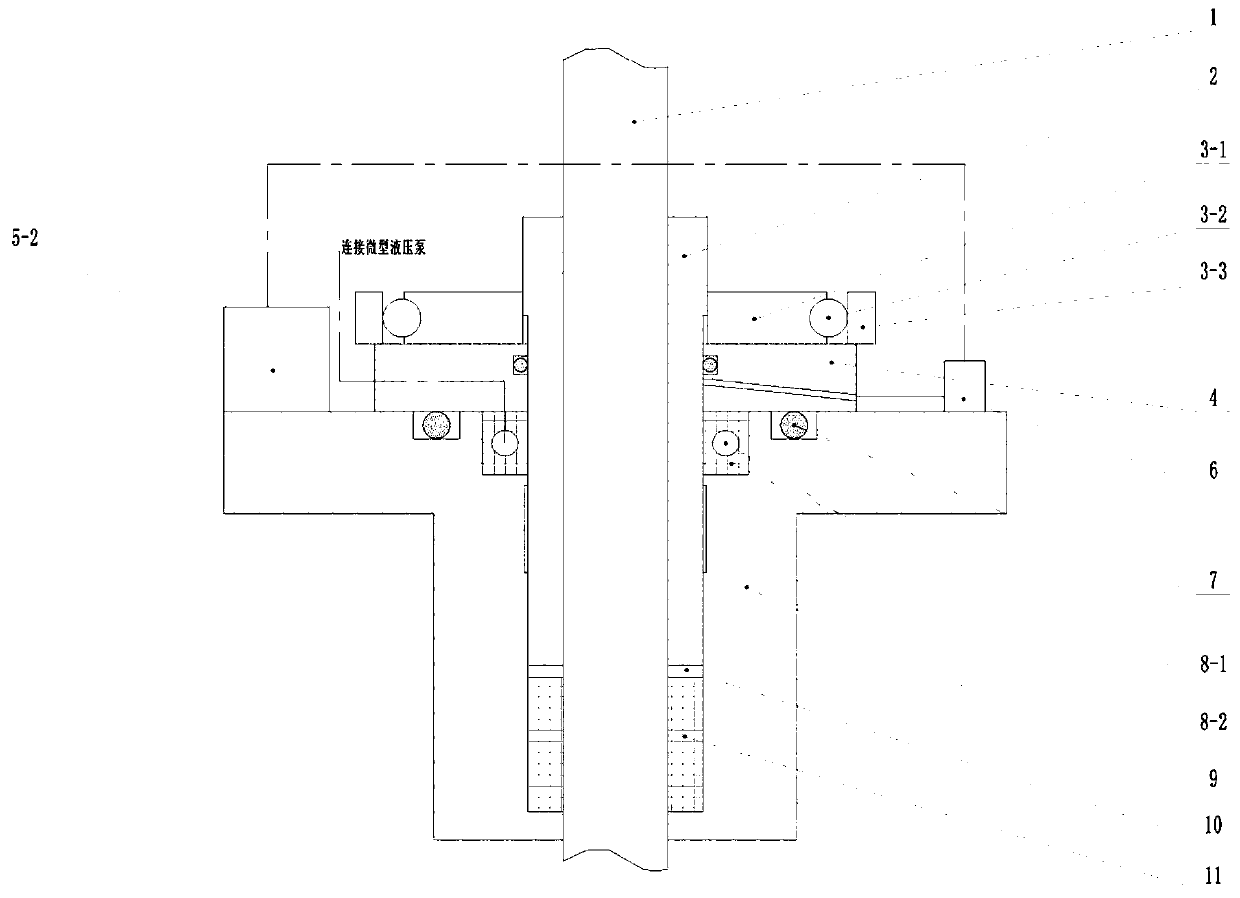

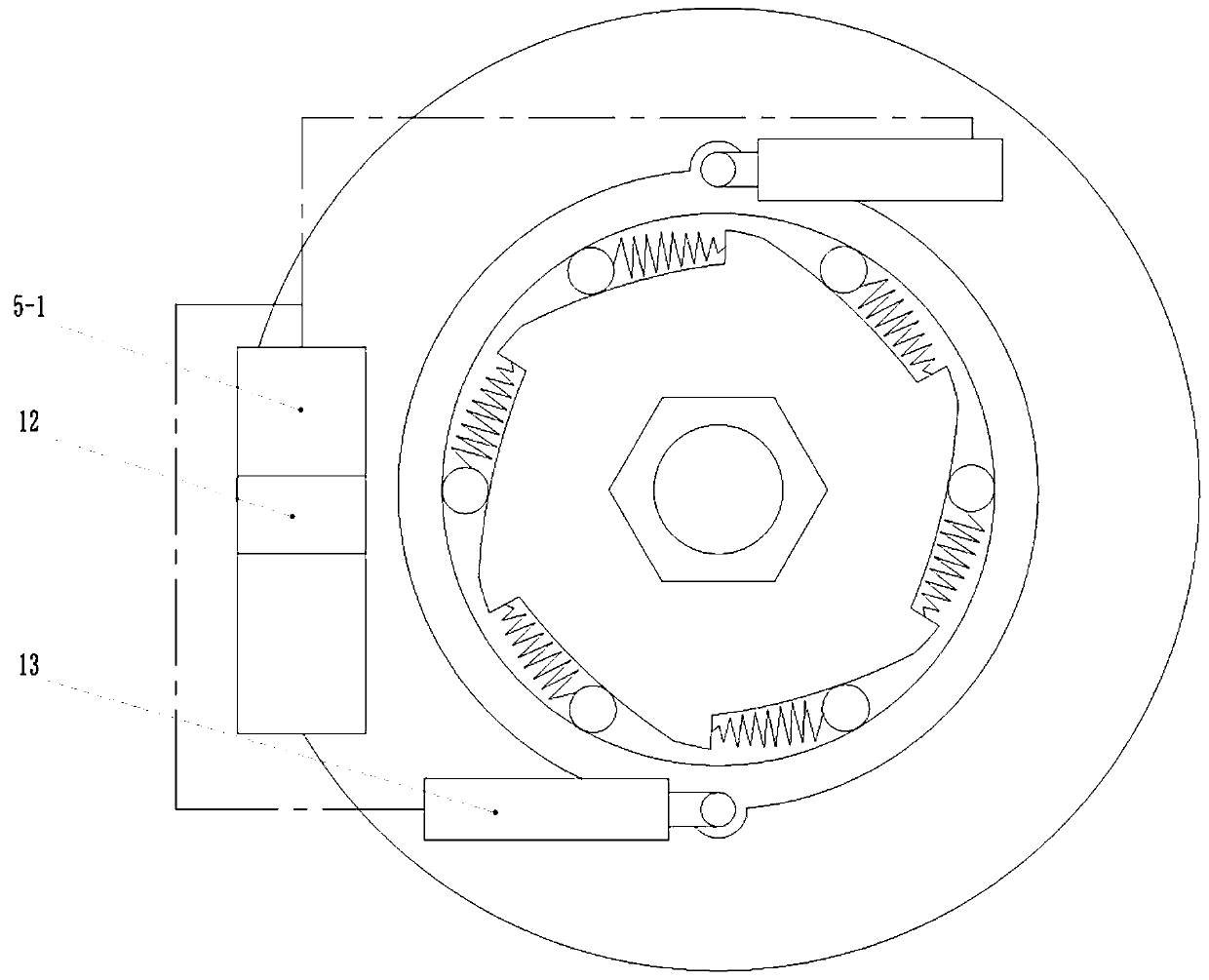

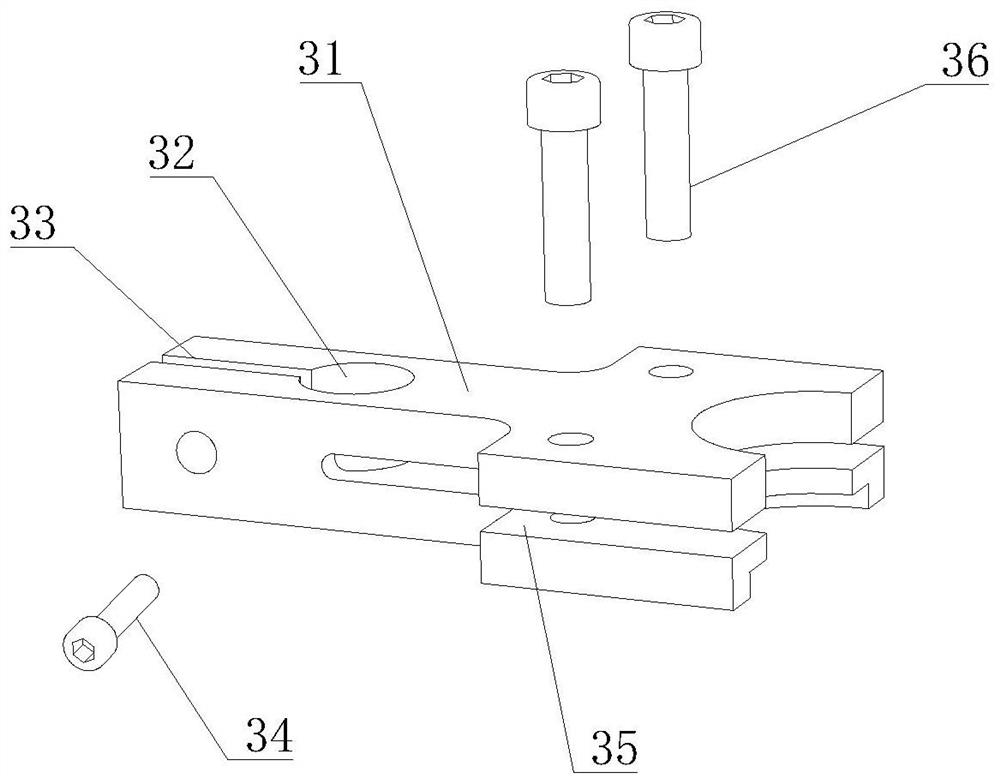

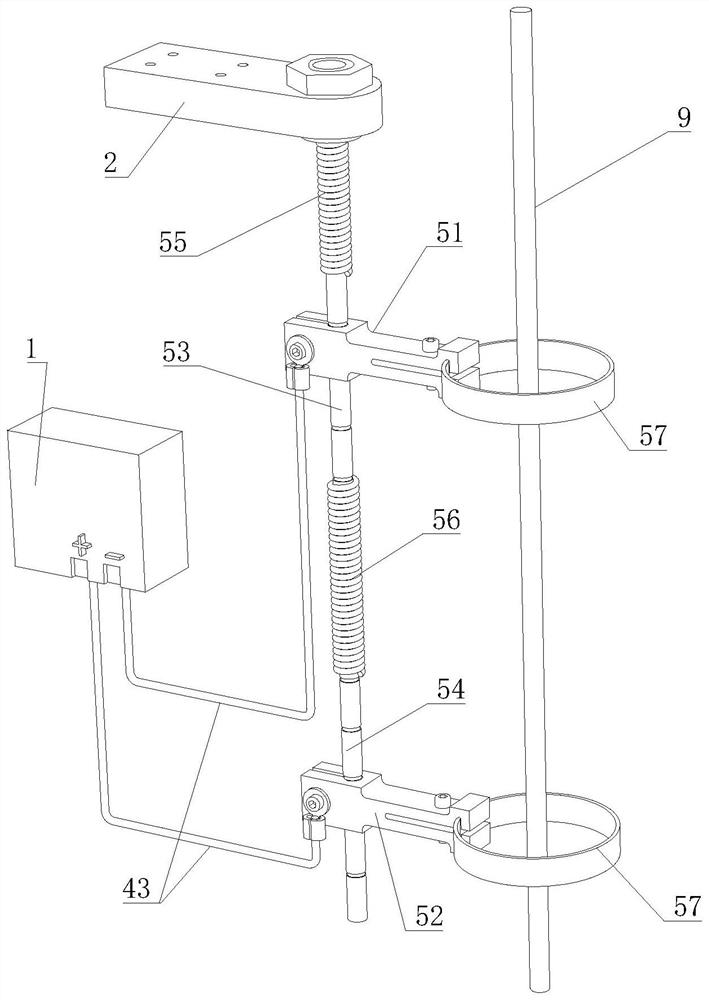

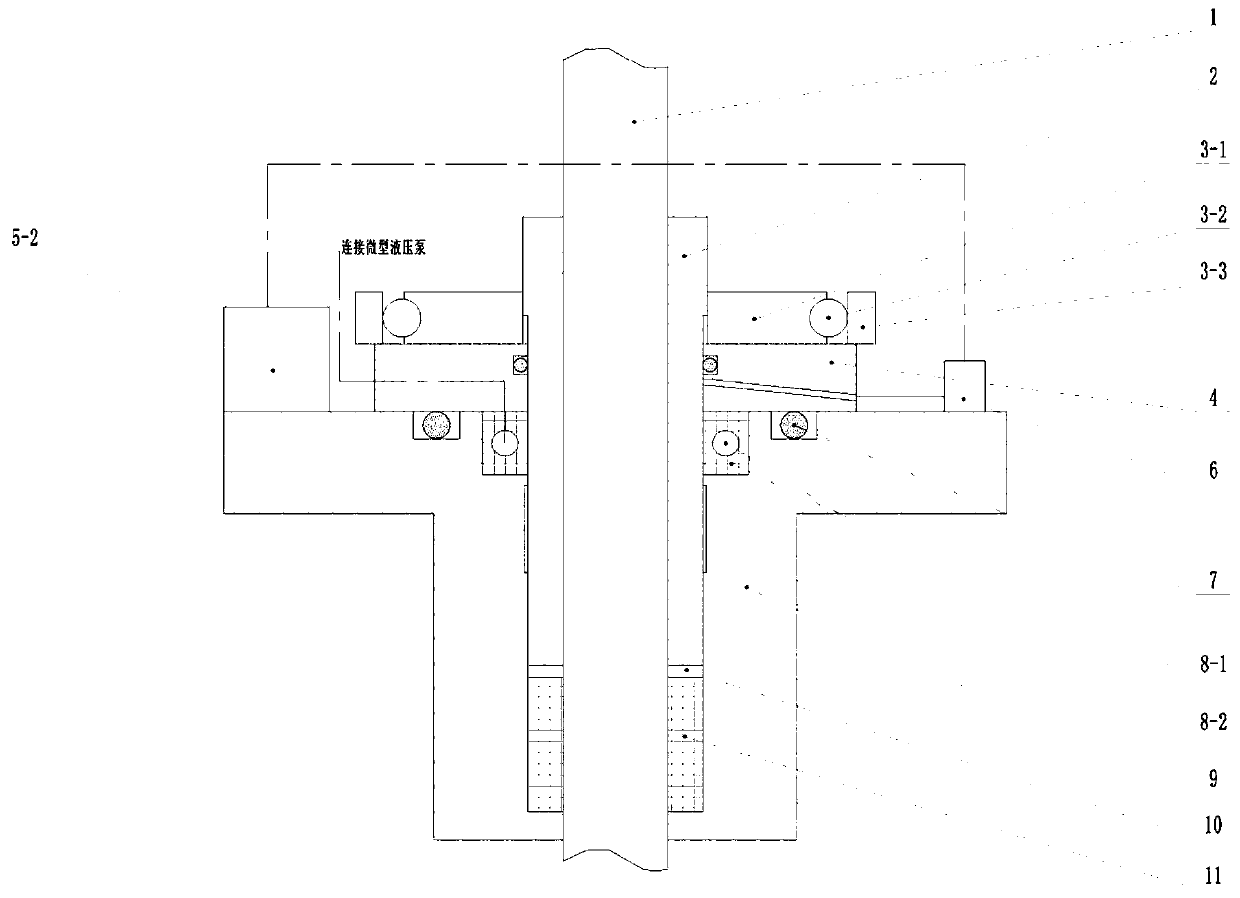

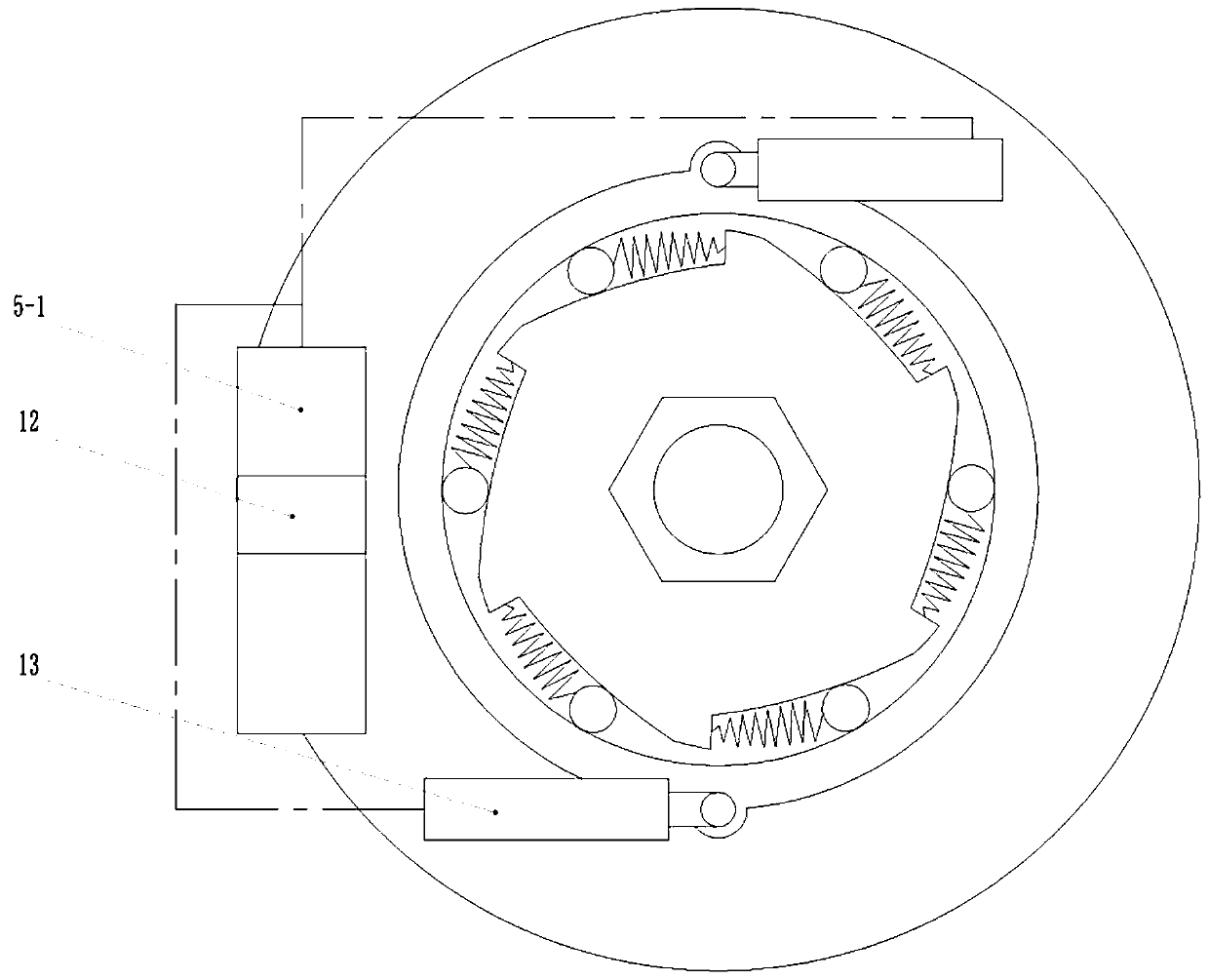

Automatic monitoring compensation and emergency device for valve rod seal

ActiveCN110195799AReal-time feedback of monitoring dataReduce wearSpindle sealingsDetection of fluid at leakage pointHydraulic cylinderDrive wheel

The invention discloses an automatic monitoring compensation and emergency device for valve rod seal, and relates to the field of valve rod seal. The automatic monitoring compensation and emergency device for valve rod seal sequentially comprises a valve body upper end, a soft filler, a metal ring and a valve rod from bottom to top, wherein a threaded filler compression piece is arranged at the upper end of the metal ring; the valve rod penetrates through the soft filler, the metal ring and the threaded filler compression piece; a mould pressing filler and a sealed O-shaped ring slot are arranged at the top end of the valve body upper end; a medium leakage monitoring ring is arranged at the upper ends of the mould pressing filler and the sealed O-shaped ring; a medium leakage monitoring sensor is arranged on a monitoring port of the medium leakage monitoring ring; the medium leakage monitoring ring is connected with a programmable logic controller; a drive wheel, a rolling steel ball and a driven ratchet wheel are arranged at the upper end of the medium leakage monitoring ring; the drive wheel is connected with a micro hydraulic cylinder; the driven ratchet wheel and the threaded filler compression piece are in clearance fit; and the micro hydraulic cylinder is connected with a micro hydraulic pump and the programmable logic controller. The automatic monitoring compensation andemergency device for valve rod seal can realize the real-time monitoring on the valve rod seal leakage, and has the functions on automatically compensating a soft filler and emergently sealing in case of complete failure.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

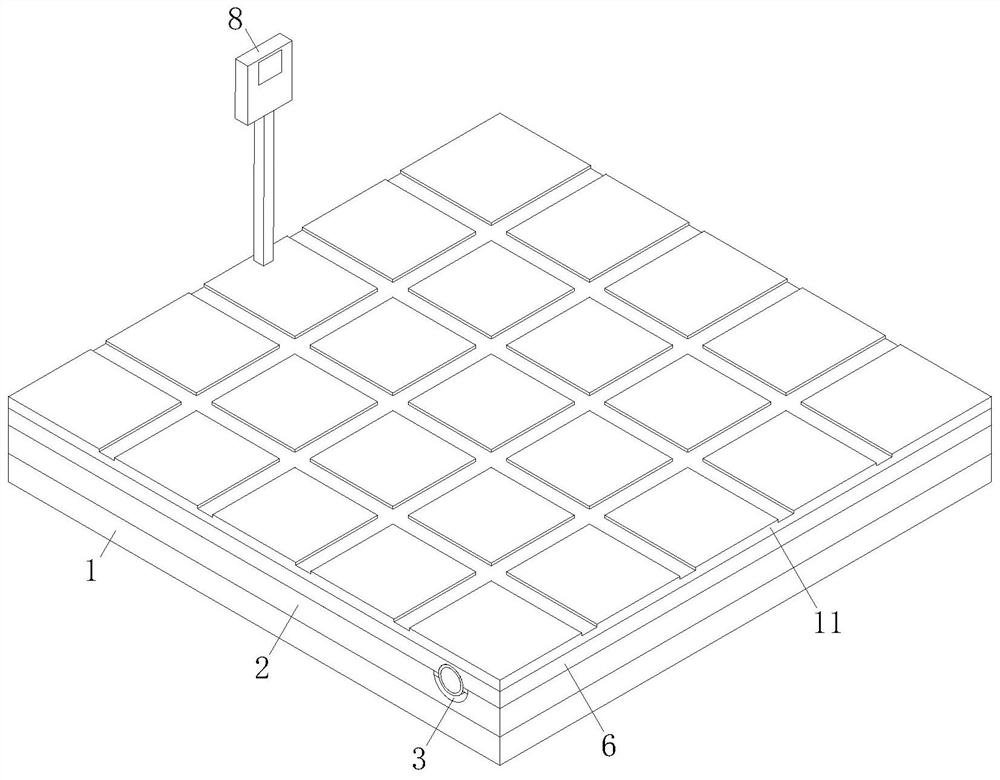

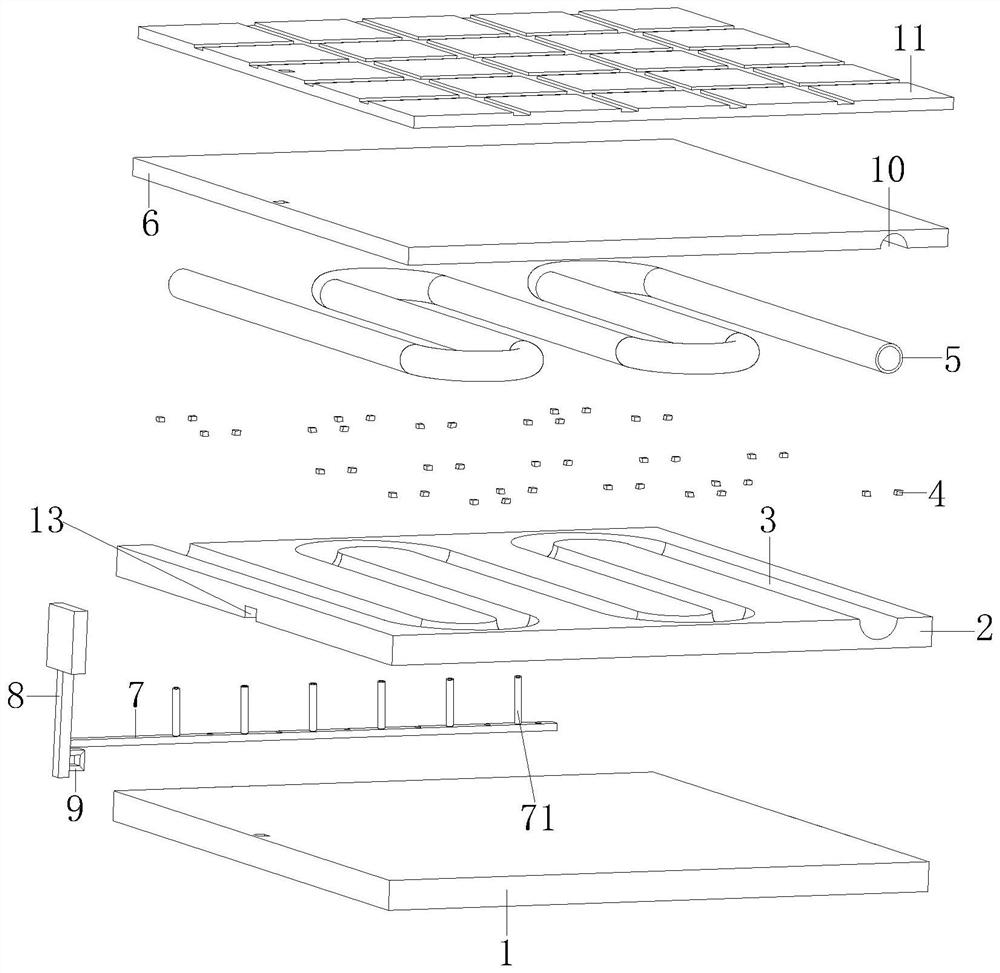

Solid paving floor heating structure

ActiveCN112942727AAvoid spreadingSettle property damageCovering/liningsLighting and heating apparatusLeaking waterThermodynamics

The invention relates to the technical field of decoration, and discloses a solid paving floor heating structure. The floor heating structure comprises a floor, wherein a first mounting layer is fixedly connected to the upper surface of the floor, a first mounting groove is formed in the upper surface of the first mounting layer, mounting blocks are fixedly connected to the inner wall of the first mounting groove, a heating pipe is fixedly connected to the sides, away from the first mounting groove, of the mounting blocks, and a second mounting layer is fixedly connected to the upper surface of the first mounting layer. According to the solid paving floor heating structure, leaked water is collected through the first mounting groove, flows into a flow guide pipe through a water inlet hole and then flows to a warning pipe through the flow guide pipe, when the leakage amount is normal, the water flow is discharged through an outflow hole, and when the heating pipe leaks water due to damage, the hole diameter of the outflow hole is too small, and water cannot be completely drained, so that the solid paving floor heating structure solves the problems that the damage of the heating pipe cannot be known in time for maintenance, and property loss or danger is caused.

Owner:山东叁旬建筑装饰工程有限公司

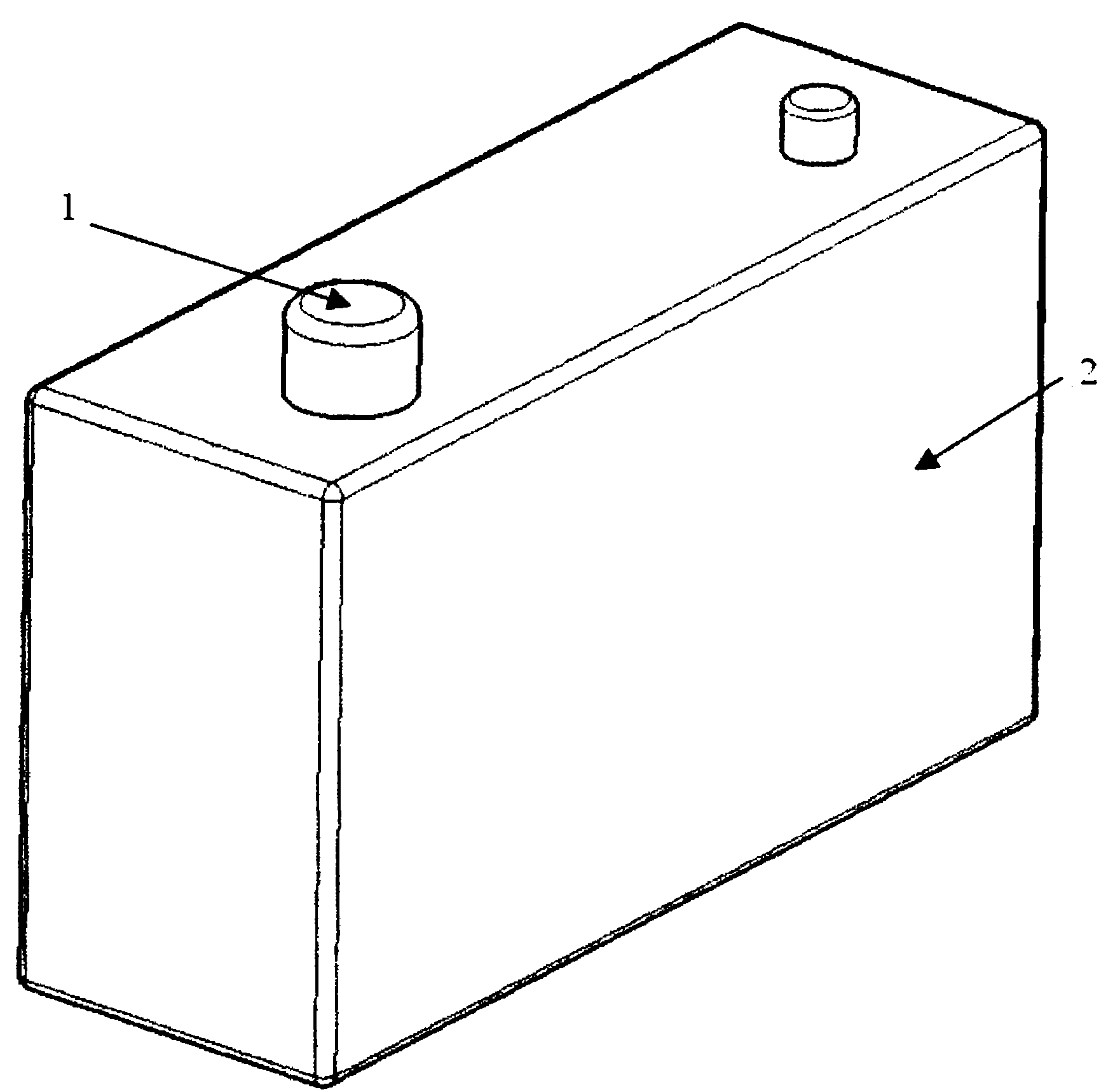

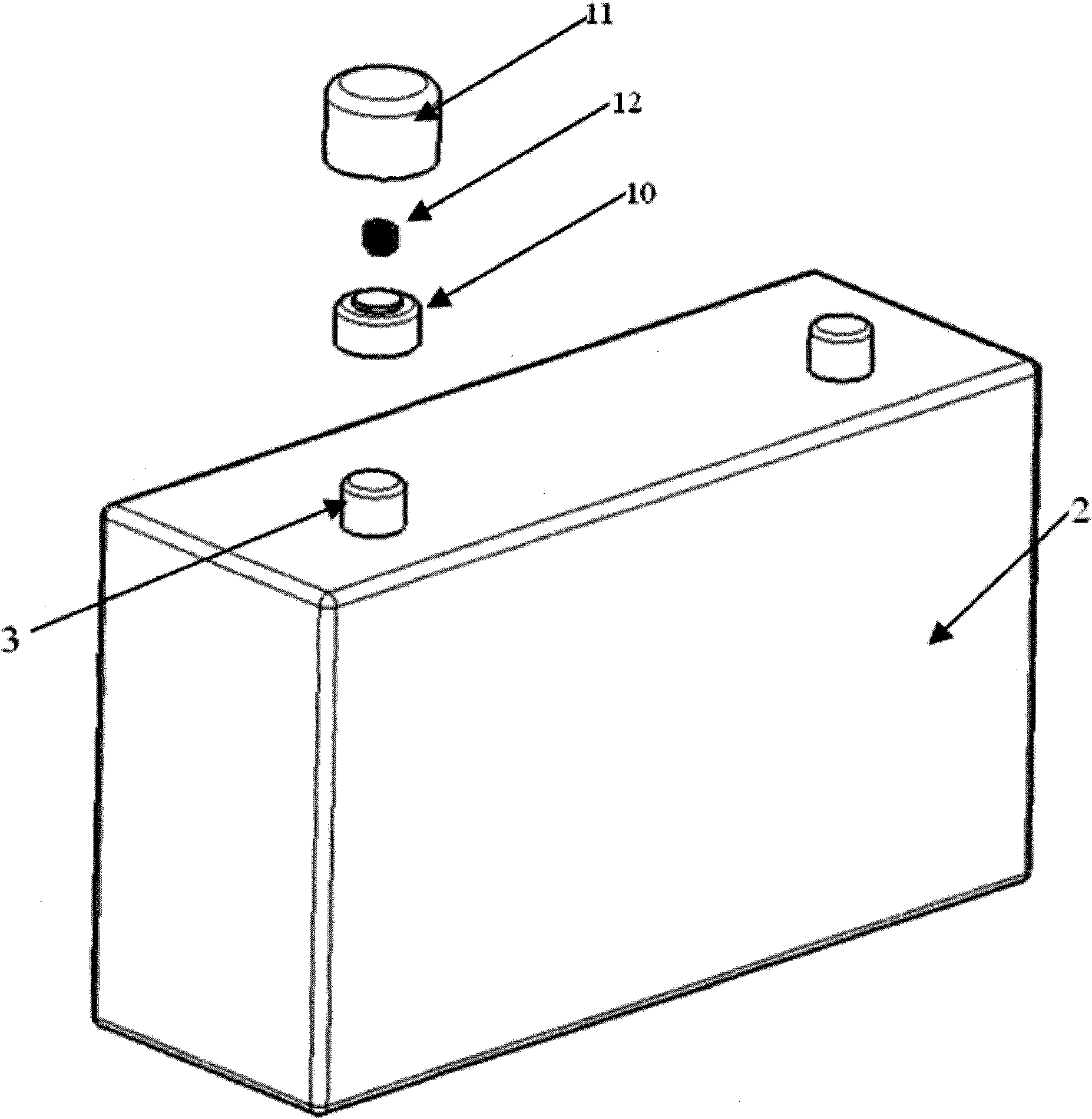

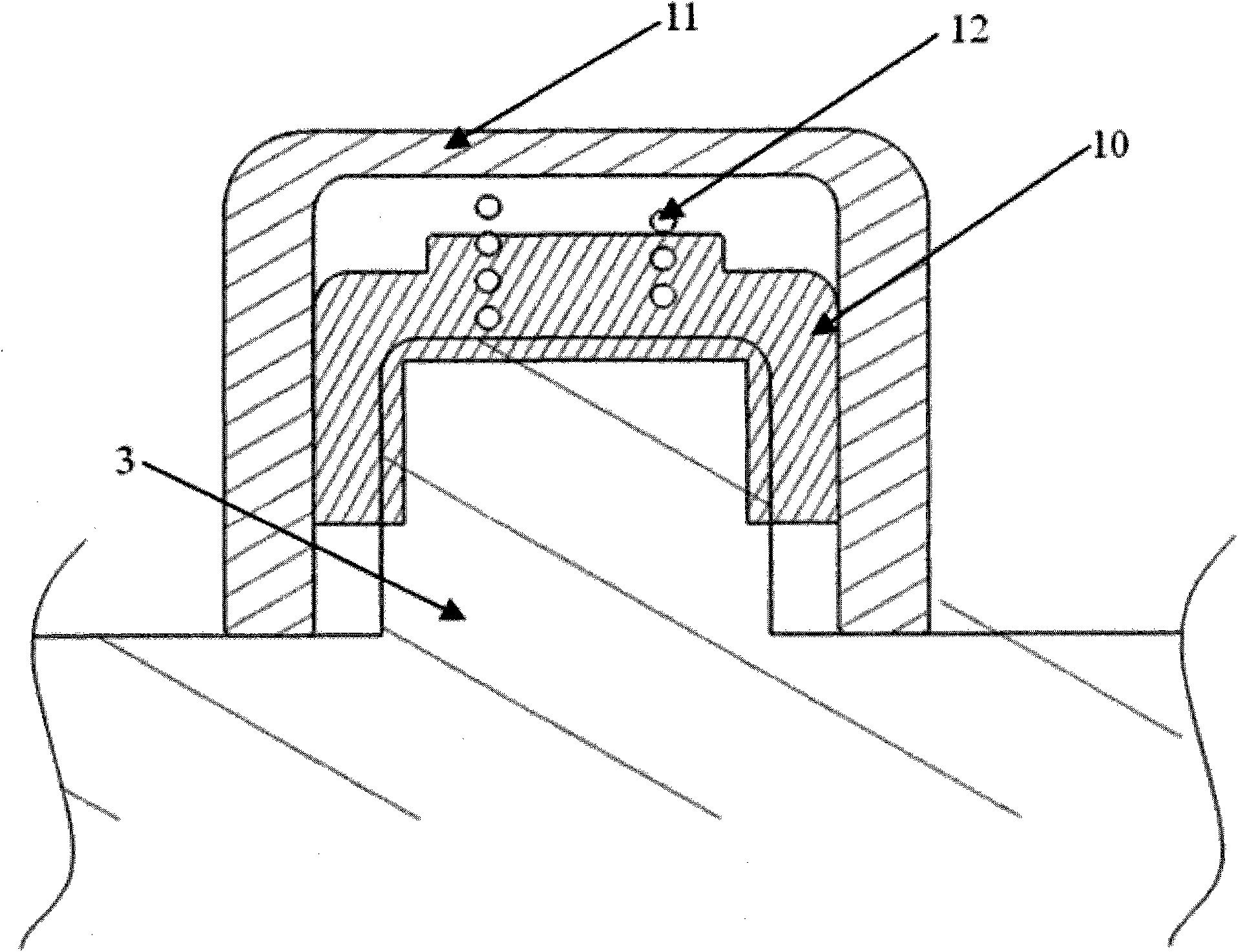

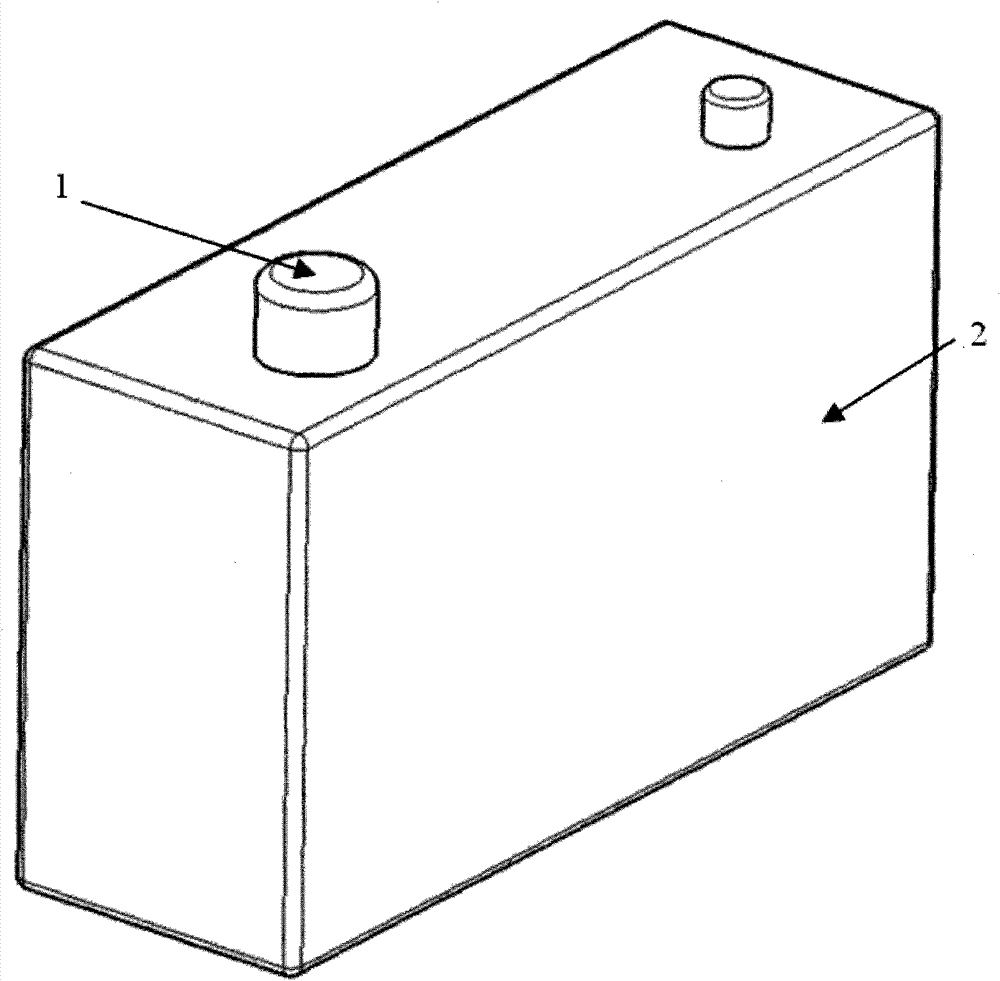

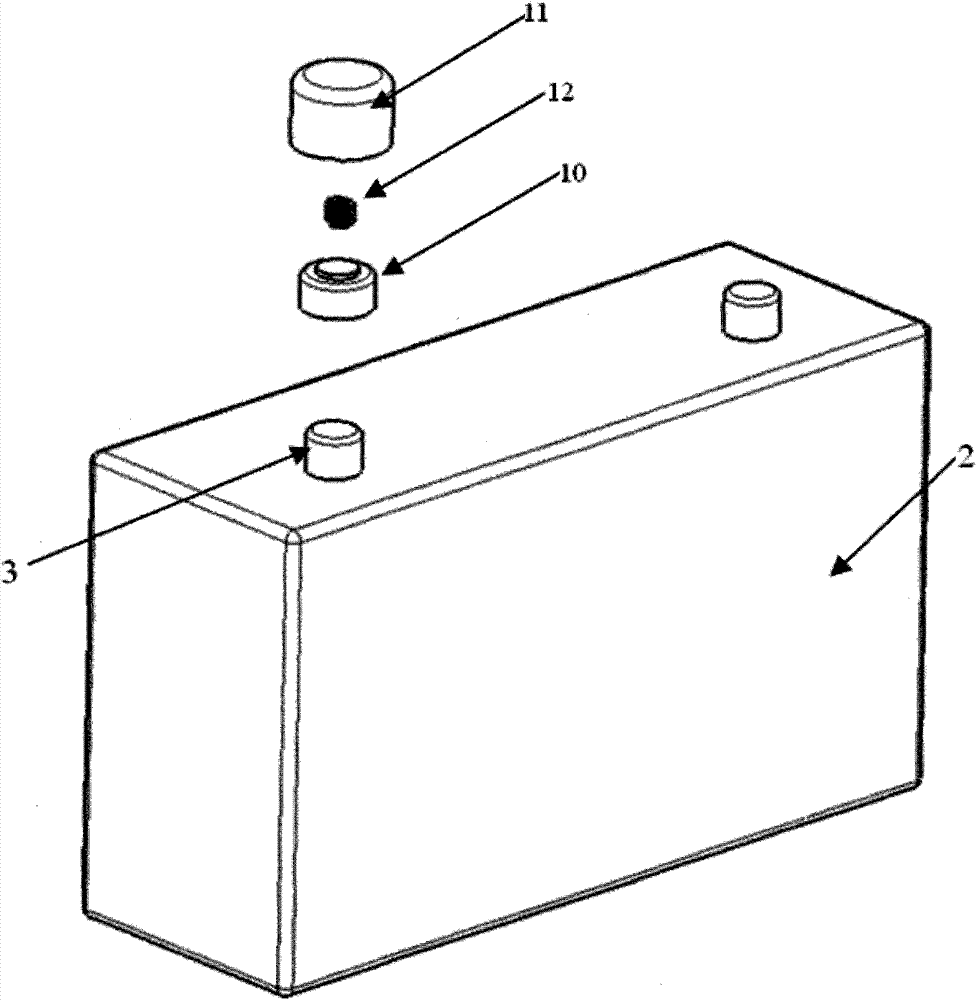

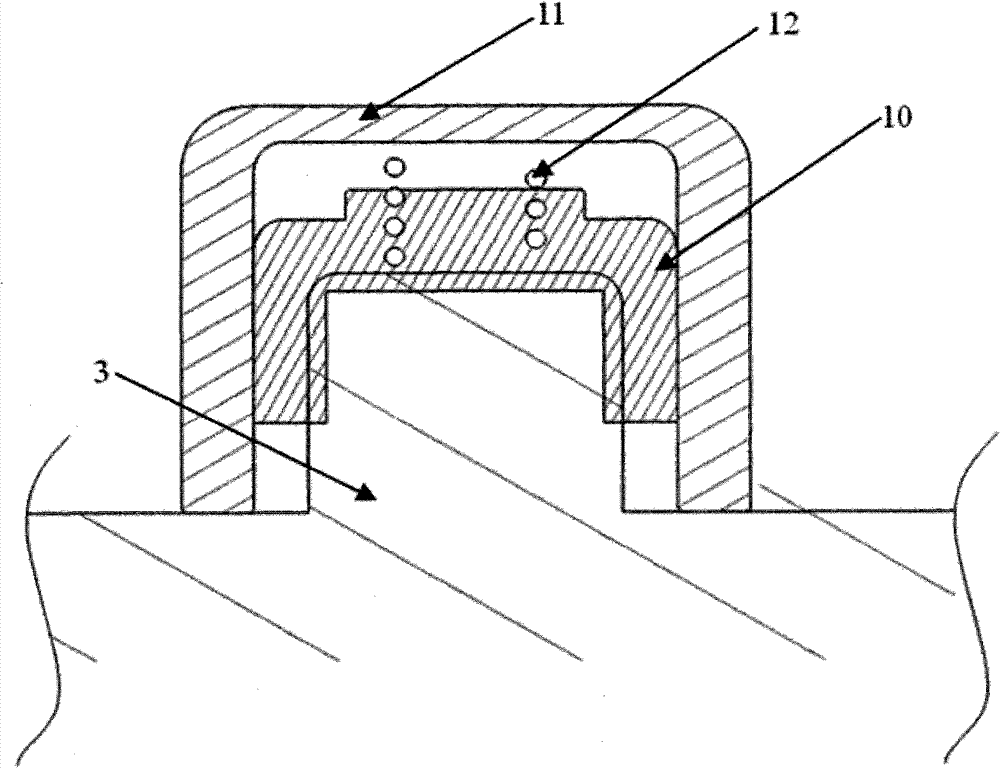

Electrode protection device of battery

InactiveCN101867033ASolve casualtiesSettle property damageActive material electrodesCell component detailsEngineeringCathode

The invention discloses an electrode protection device of a battery, comprising an insulator sheathed on an electrode of the battery, and the insulator is used for completely packing the electrode of the battery to carry out insulation protection on the electrode of the battery. By applying the technical scheme, the insulator is sheathed on one electrode of the battery and completely packs the electrode of the battery to carry out insulation protection on the electrode of the battery. Because one electrode of the battery is insulated from outside, the short circuits of the anode and the cathode of the battery can not be caused so that casualties and property losses can not be caused, thereby solving the problems of casualties and property losses caused by the short circuits of the anode and the cathode of the battery.

Owner:上海奕代汽车技术有限公司

Electric vehicle charging protector

InactiveCN105576728ASettle the lossSolve the problem of power consumptionBatteries circuit arrangementsElectric powerEngineeringElectric vehicle

The invention discloses an electric vehicle charging protector. The protector comprises a shell. The shell is provided with a timing button and a switch. And the shell is also provided with a jack. The shell is connected to a controller. An electric quantity display apparatus and an alarm device used for prompting that a cell is full. By using the electric vehicle charging protector, problems that the cell is damaged, a property is damaged too and electric energy is wasted because people forgets to turn off a power supply during electric vehicle charging are effectively solved. The design is simple and practical, and safe and energy-saving. When cell charging of a battery car is finished, the power supply can be automatically cut off and cell overcharging is prevented so that the service life of the cell is prolonged.

Owner:南京冉科信息技术有限公司

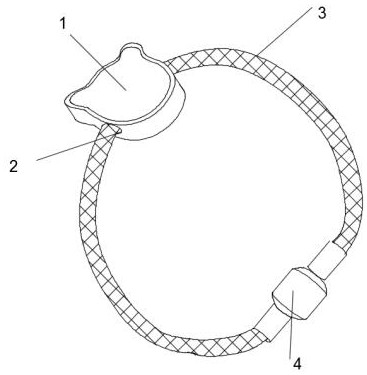

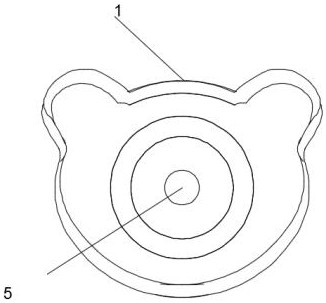

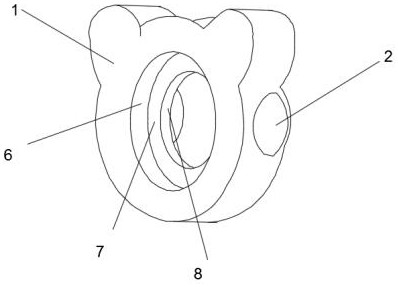

Anti-interference precious metal jewelry with built-in chip

InactiveCN112315146ASolve out of powerSolve the problem of not working without the mobile phoneWatch chainsOrnamental chainsInterference resistanceEngineering

The invention relates to the technical field of gold and silver jewelries, and discloses an anti-interference precious metal jewelry with a built-in chip. The jewelry comprises a metal jewelry body, athrough hole is arranged in the metal jewelry body in a penetrating manner, a wearing bracelet is inserted in the through hole, a snap ring is arranged on the wearing bracelet, and a rear cover is arranged on the back surface of the metal jewelry body; a rear cover groove is formed in the metal jewelry body, a mounting groove is formed in one side of the rear cover groove, a sealing groove is formed in one side of the mounting groove, a metal plate is arranged in the mounting groove, and a groove is formed in the metal plate. According to the precious metal jewelry with the anti-interferencebuilt-in chip, through the built-in chip, a product is not only separated from a power supply, but also can be separated from a mobile phone to be directly used for payment, entrance guard, membershipand other functions; meanwhile, GPS positioning can be recognized by a terminal, and later tracking can be conducted under the condition that the jewelry is lost and stolen; the hidden chip is not exposed on the surface, and can resist high temperature, water and corrosion.

Owner:上海驰零文化发展有限公司

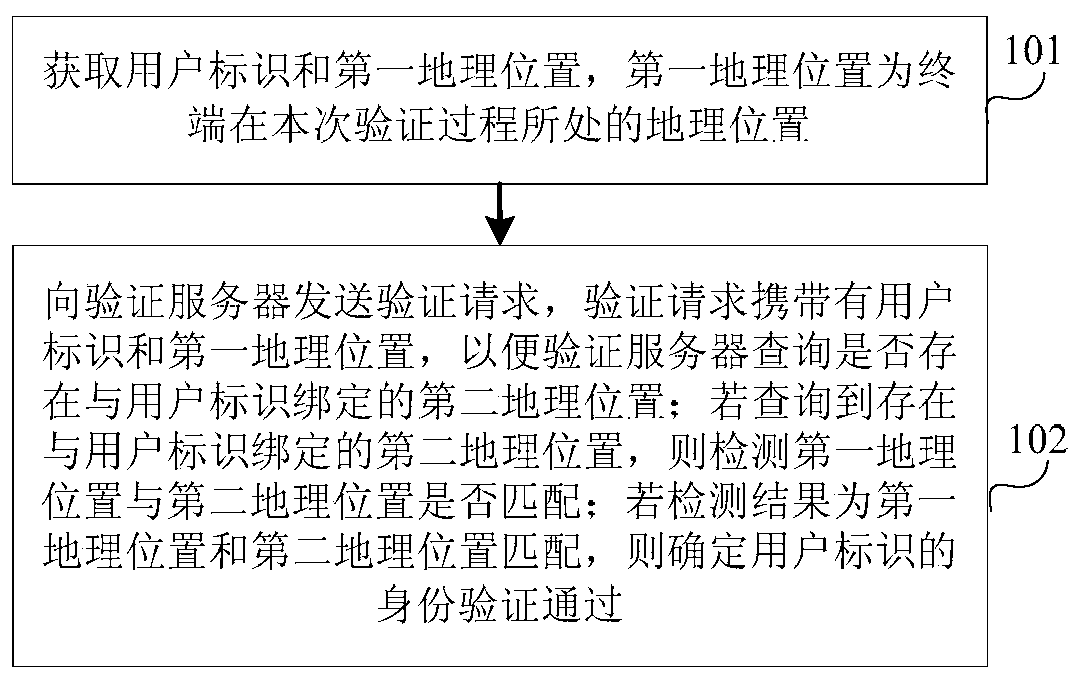

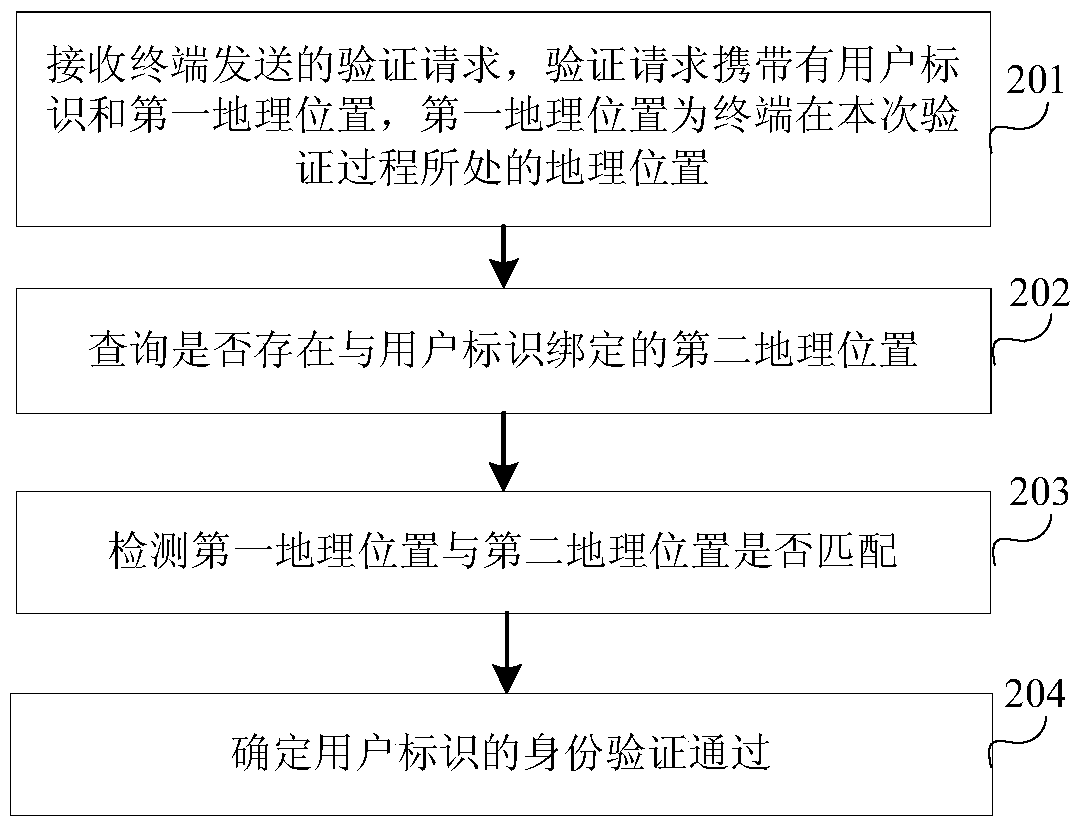

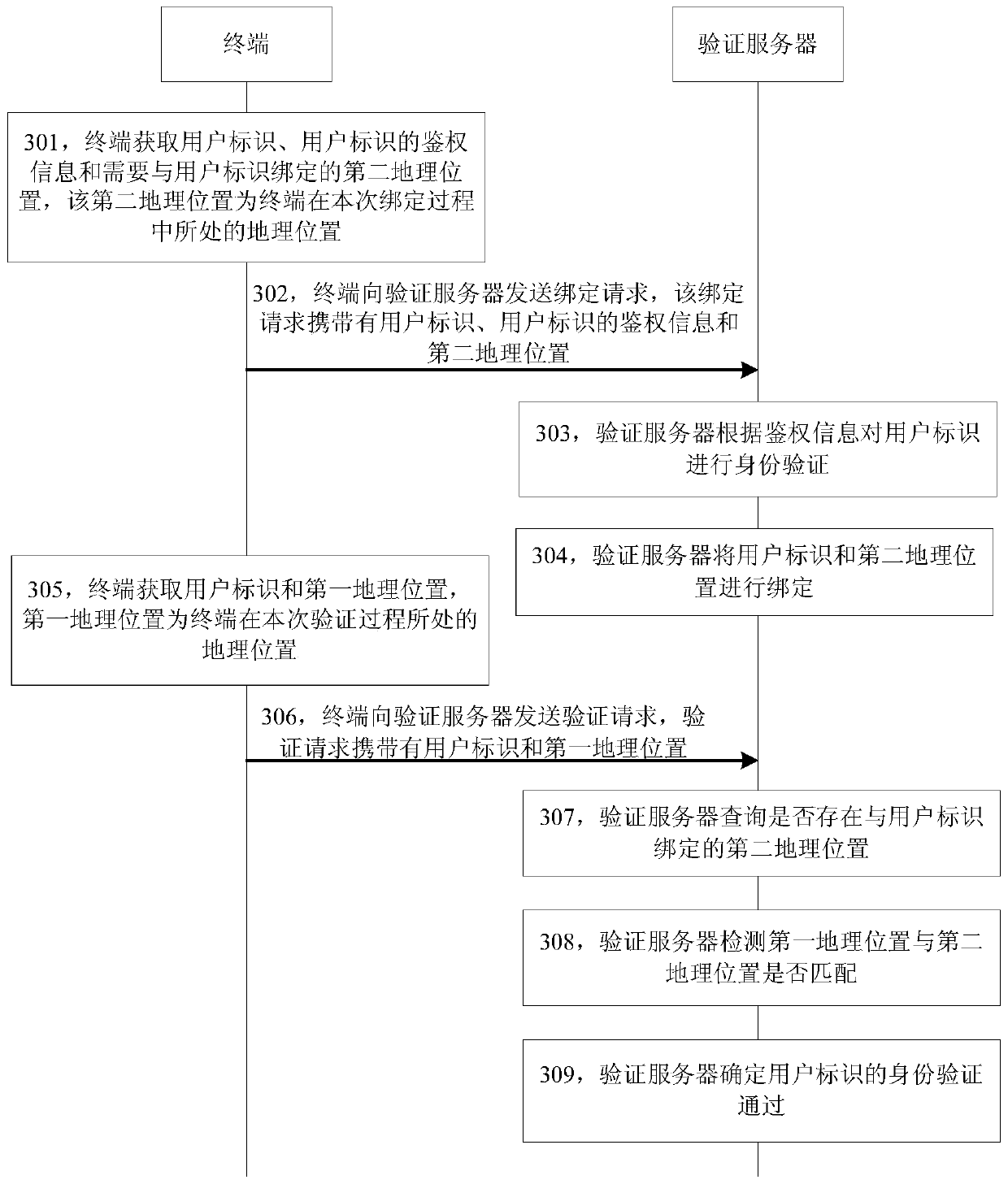

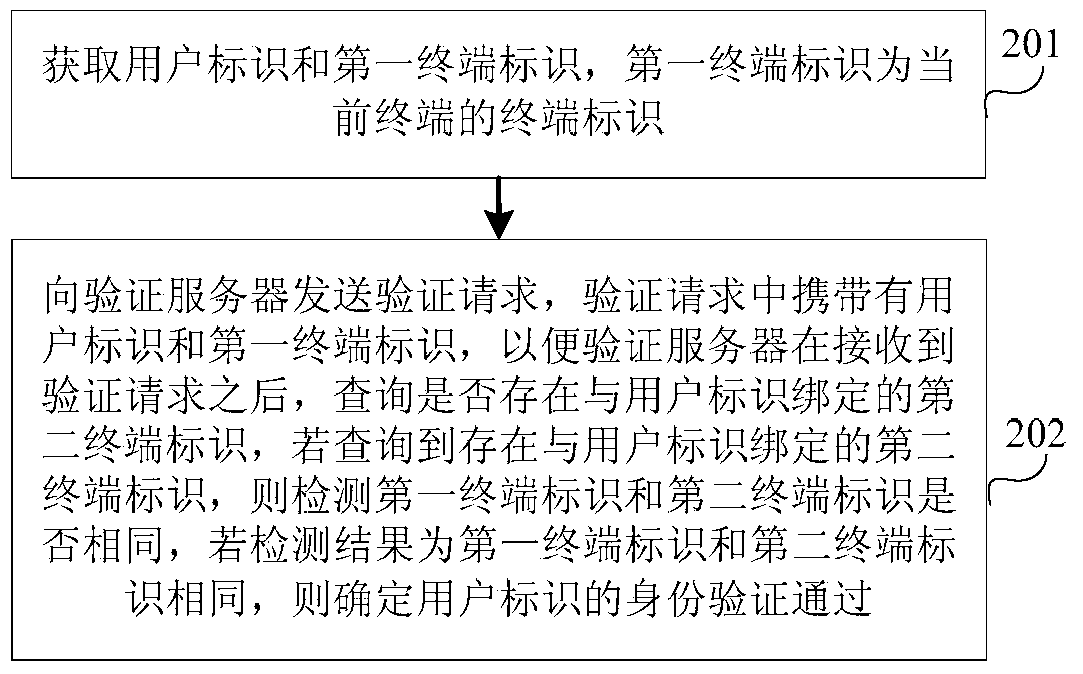

Verification method, device and system

ActiveCN104468463BFix the leakSettle property damageUser identity/authority verificationLocation information based serviceValidation methodsComputer science

The invention discloses a verification method, device and system, belonging to the field of network technology. The method includes: acquiring a user ID and a first geographic location, where the first geographic location is the geographic location of the terminal during the current verification process; sending a verification request to a verification server, so that the verification server can inquire whether there is an ID bound to the user ID; a second geographic location; if the second geographic location exists, then detecting whether the first geographic location matches the second geographic location; if the first geographic location matches the second geographic location, then determining that the identity verification of the user ID is passed. The invention verifies the user ID by checking whether the geographic location of the terminal in the verification process matches the geographic location bound to the user ID by the verification server; it solves the information that may be brought once the user information is illegally obtained by hackers The problem of leakage or property loss; it has achieved the effect of further protecting the security of user information and property.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

Unmanned aerial vehicle flight safety control method based on geofence

PendingCN114428513AFix damageSolve the situationPosition/course control in three dimensionsSafety controlUncrewed vehicle

The invention discloses an unmanned aerial vehicle flight safety control method based on geo-fences, and the method comprises the following two control methods: mode A: a task point is set before an unmanned aerial vehicle takes off to carry out a flight task, and the unmanned aerial vehicle automatically takes off to complete the flight task and then returns to a take-off position; and B, controlling the flight of the unmanned aerial vehicle in real time through the visual control terminal. Compared with the prior art, the method has the advantages that the situation that the unmanned aerial vehicle is damaged or out of control and the like due to various over-limit flight tasks in the process of using the unmanned aerial vehicle by a user is effectively solved; and various potential safety hazards and property loss are avoided. And meanwhile, the striking visual geofence design is more convenient for the user to operate, and better experience is brought to the user.

Owner:宁波派丽肯智能渔具有限公司

smart door lock

ActiveCN105370108BAddressing Personal InjurySettle property damageElectric permutation locksControl switchActuator

Owner:CYG CONTRON

A method of manufacturing a seamless steel pipe

The invention discloses a manufacturing method of a seamless steel pipe. The manufacturing method comprises the following steps of making steel: feeding a SiCaBa alloy core wire after slagging molten steel in a steel ladle, and expanding slag to form foamed slag; adjusting the amount, the alkalinity and the fluidity of the slag according to slag conditions, and adding SiC powder, silicon calcium (barium), silicon iron and calcium carbide so as to reduce refined slag to form white slag; adding 0.13-0.20% of carbon, 0.25-0.50% of silicon, 0.9-1.3% of manganese, less than or equal to 0.030% of phosphorus, less than or equal to 0.030% of sulphur, 0.03-0.10% of vanadium, 0.015-0.040% of aluminium, less than or equal to 0.20% of chromium, less than or equal to 0.10% of nickel, less than or equal to 0.10% of molybdenum, less than or equal to 0.10% of titanium, and less than or equal to 0.20% of copper; pouring out a part of the refined slag, and retaining a slag layer, the molten steel surface layer of which is less than or equal to 100 mm; stirring in vacuum; feeding an aluminium wire with the diameter of 12 mm after breaking vacuum; feeding a pure calcium wire for modifying inclusions; blowing by using argon so that the molten steel is uniform; continuously casting; rolling; thermally treating; straightening; and detecting flaws. The seamless steel pipe prepared by the invention has high strength, high toughness, low carbon equivalent and good welding property, and therefore, the use reliability and the safety are increased.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

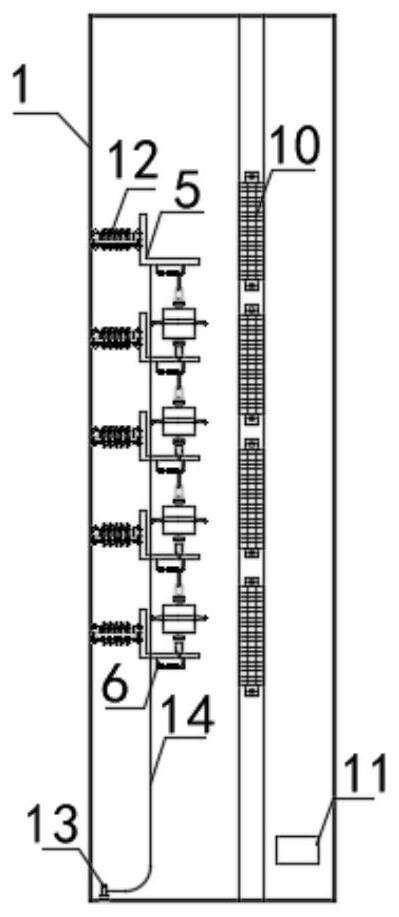

Centralized high-voltage cable sheath protection box

PendingCN113189390ASettle property damageImprove securityCurrent/voltage measurementElectrical testingOvervoltageCurrent sensor

The invention discloses a centralized high-voltage cable sheath protection box, which comprises a box body, a sheath protector, a current sensor, a state display device, a temperature and humidity controller, a heater, a data acquisition and processing unit, a clock module, a power supply module and a monitoring host. The sheath protector is used for overvoltage protection of a metal shielding layer and an armor layer of the high-voltage cable; the total current of the sheath protector under continuous operation voltage is composed of capacitive current and resistive current, and the sheath protector is used for judging the state of equipment by monitoring whether the resistive current is increased or not under normal operation voltage. The problem of property loss or personal safety caused by the fact that the fault of the sheath protector is not found in time through manual inspection in the prior art is solved, and the safety and stability of the railway traction power supply system are improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

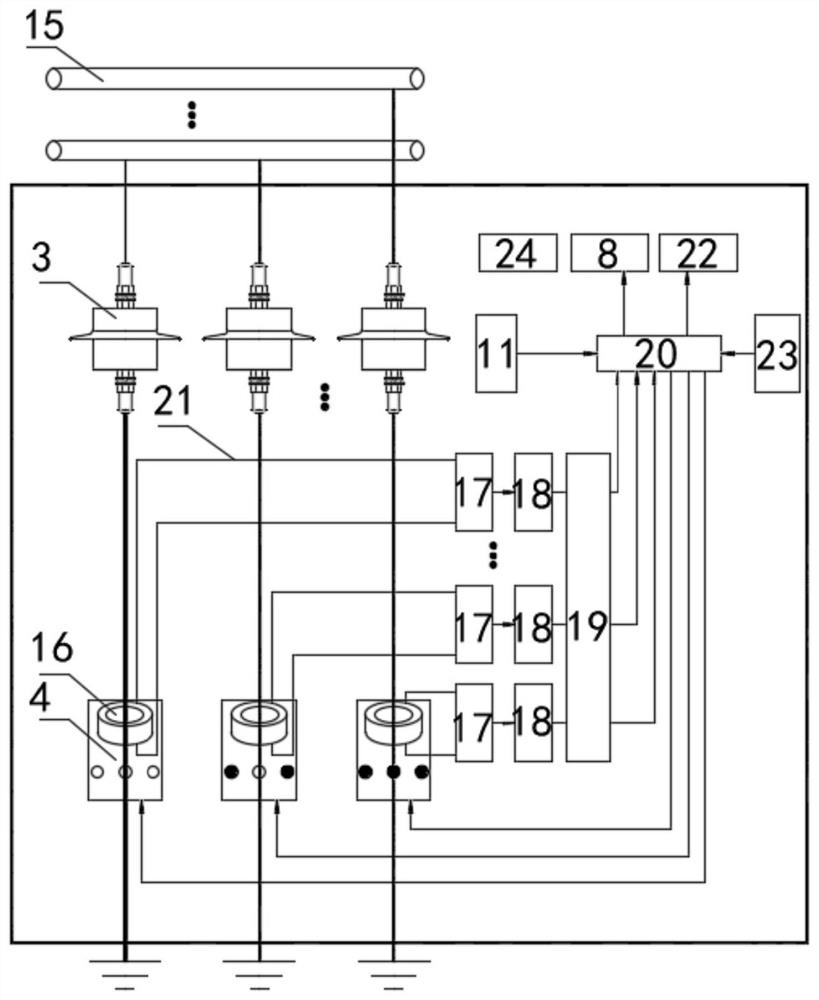

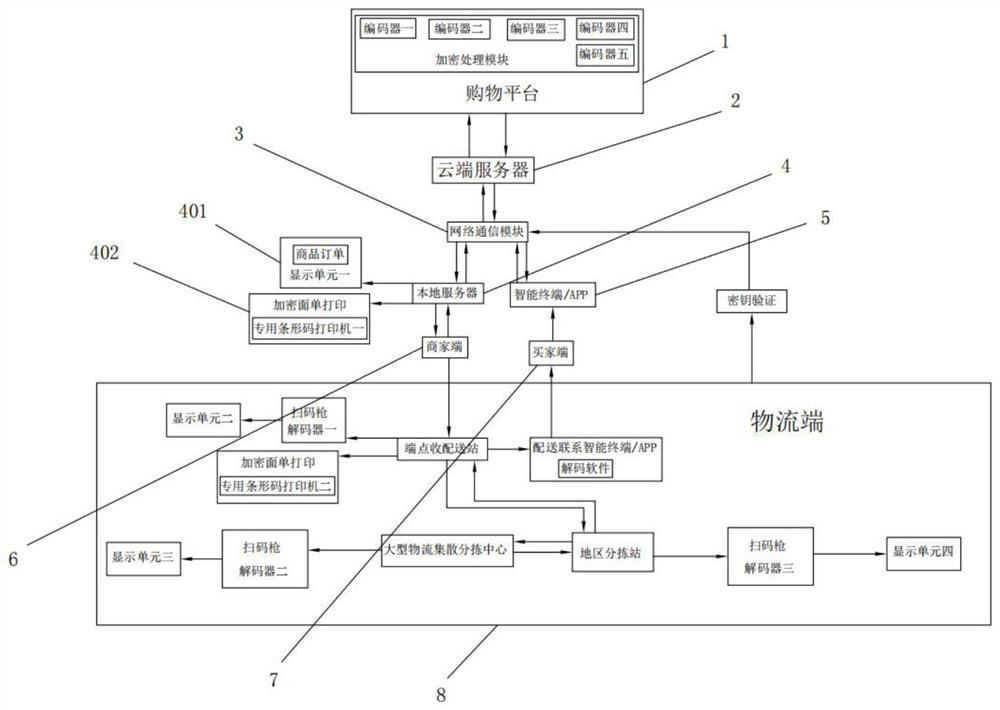

System for ensuring electronic information safety

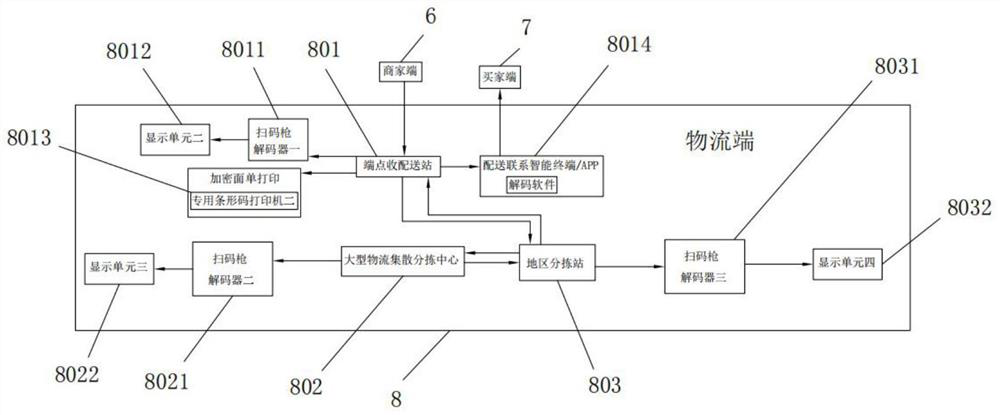

PendingCN114091098ASettle property damageDigital data protectionLogisticsElectronic informationEngineering

The invention belongs to the technical field of information safety, and particularly relates to a system for ensuring electronic information safety, which comprises a shopping platform, the shopping platform is electrically connected with a cloud server, the cloud server is electrically connected with a network communication module, and the network communication module is electrically connected with a local server and an intelligent terminal / APP. According to the system for ensuring the safety of the electronic information, the encryption processing module is arranged, during use, commodity information and buyer information are encrypted, in the logistics distribution process, in a single process, only next distribution point information can be read, and the buyer complete information cannot be obtained; therefore, the problems that in all links of express logistics circulation and distribution in the prior art, the phone number, the receiving address, the recipient name and the purchased commodity information of the shopper are leaked, so that the shopper information is accurately mastered by fraud personnel to carry out telecommunication fraud, and the property loss of the shopper is caused are solved.

Owner:NEUSOFT INST GUANGDONG

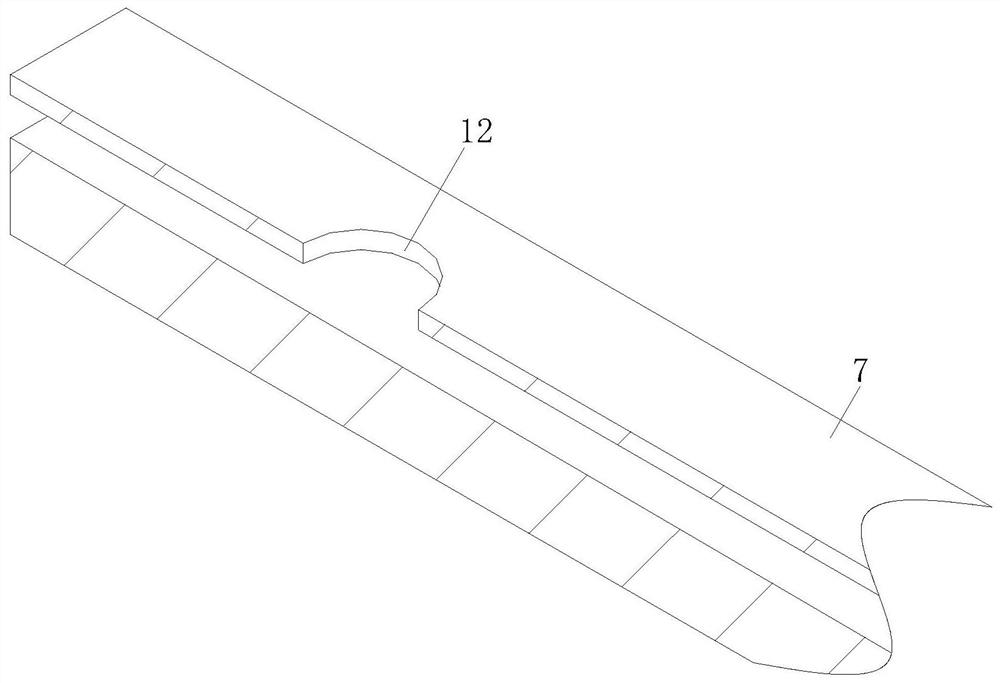

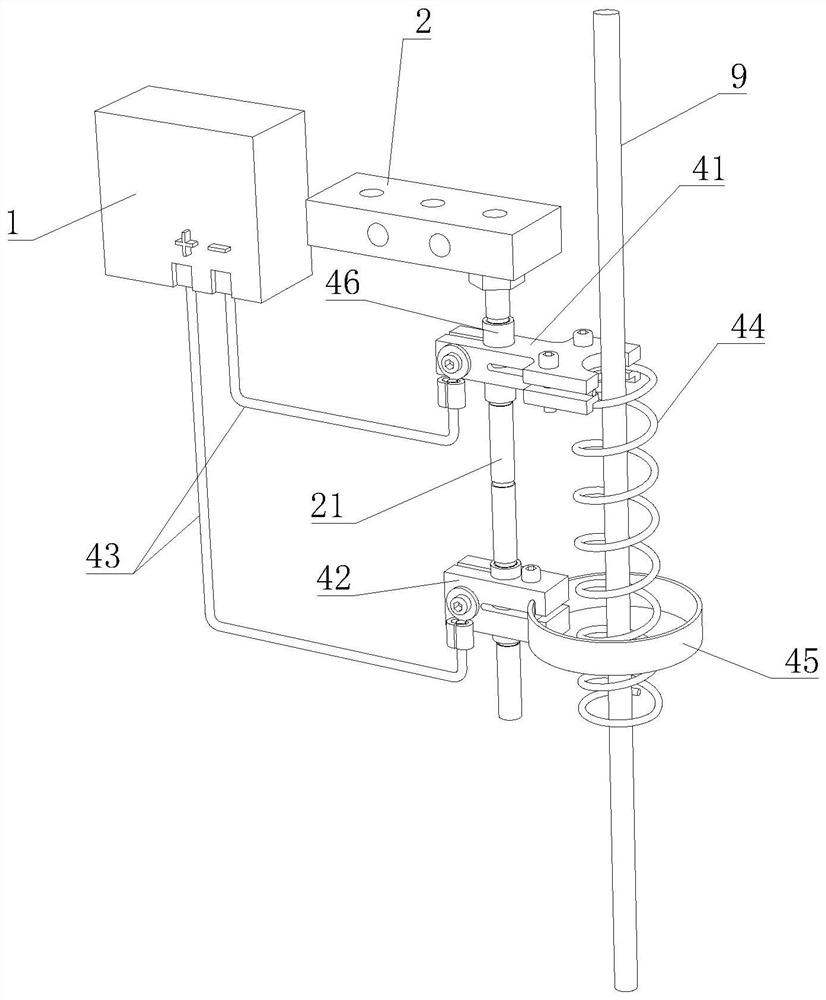

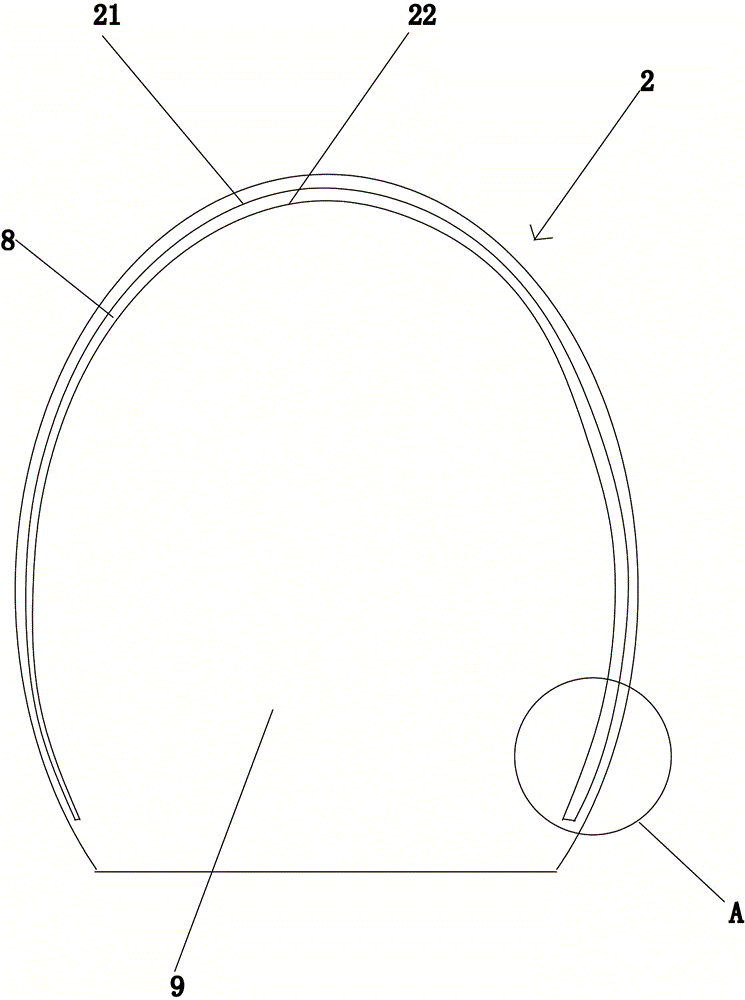

Hoisting steel wire rope inclined pull alarm device

PendingCN113415730AReal-time monitoring statusGuaranteed safe operationSafety gearAlarm deviceTransmitter

The invention discloses a hoisting steel wire rope inclined pull alarm device. The hoisting steel wire rope inclined pull alarm device comprises a signal transmitter (1) and a fixed seat (2); a connecting rod (21) for installing an adjuster (22) is arranged on the fixed seat (2); one end of the adjuster (22) is provided with a conductor surrounding the outside of a steel wire rope (9); and when the steel wire rope (9) inclines to be in contact with the conductor, a circuit of the signal transmitter (1) is connected to give an alarm. The hoisting steel wire rope inclined pull alarm device has the advantages of being simple in structure, low in manufacturing cost and wide in application range.

Owner:德兰华创(杭州)智慧科技有限公司

Stem seal automatic monitoring compensation and emergency device

ActiveCN110195799BReal-time feedback of monitoring dataReduce wearSpindle sealingsDetection of fluid at leakage pointHydraulic cylinderRatchet

The invention discloses an automatic monitoring compensation and emergency device for valve rod seal, and relates to the field of valve rod seal. The automatic monitoring compensation and emergency device for valve rod seal sequentially comprises a valve body upper end, a soft filler, a metal ring and a valve rod from bottom to top, wherein a threaded filler compression piece is arranged at the upper end of the metal ring; the valve rod penetrates through the soft filler, the metal ring and the threaded filler compression piece; a mould pressing filler and a sealed O-shaped ring slot are arranged at the top end of the valve body upper end; a medium leakage monitoring ring is arranged at the upper ends of the mould pressing filler and the sealed O-shaped ring; a medium leakage monitoring sensor is arranged on a monitoring port of the medium leakage monitoring ring; the medium leakage monitoring ring is connected with a programmable logic controller; a drive wheel, a rolling steel ball and a driven ratchet wheel are arranged at the upper end of the medium leakage monitoring ring; the drive wheel is connected with a micro hydraulic cylinder; the driven ratchet wheel and the threaded filler compression piece are in clearance fit; and the micro hydraulic cylinder is connected with a micro hydraulic pump and the programmable logic controller. The automatic monitoring compensation andemergency device for valve rod seal can realize the real-time monitoring on the valve rod seal leakage, and has the functions on automatically compensating a soft filler and emergently sealing in case of complete failure.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

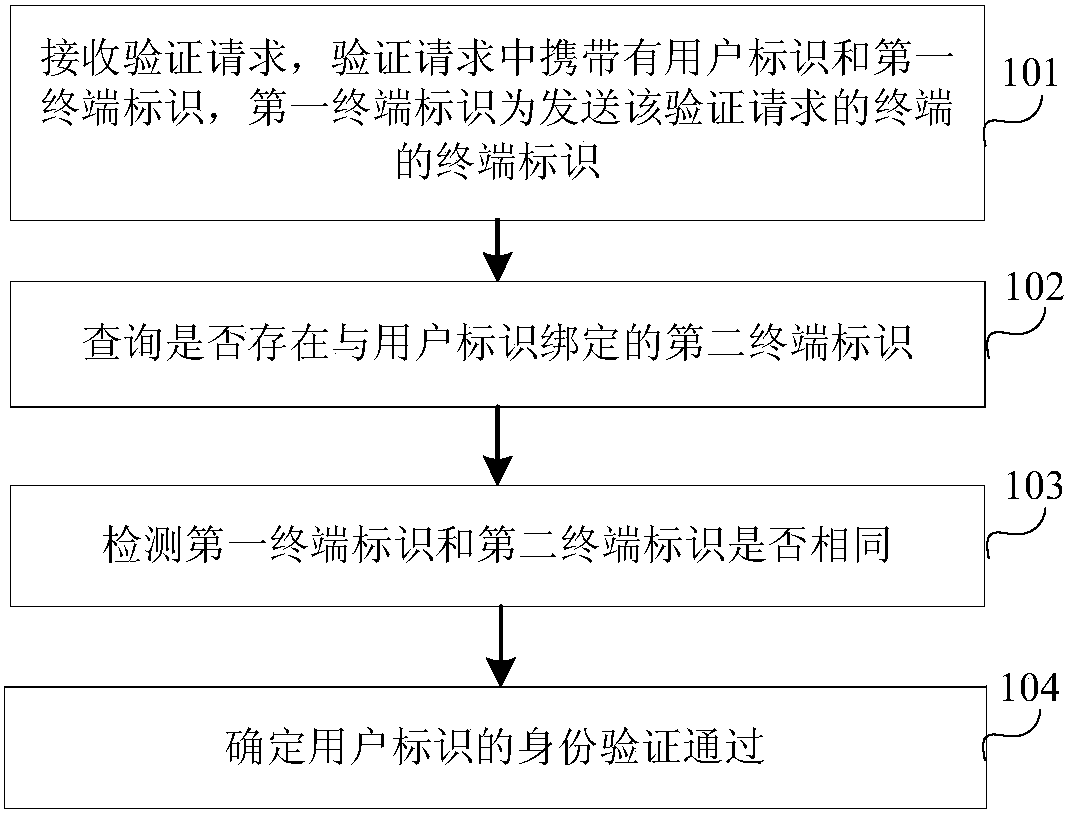

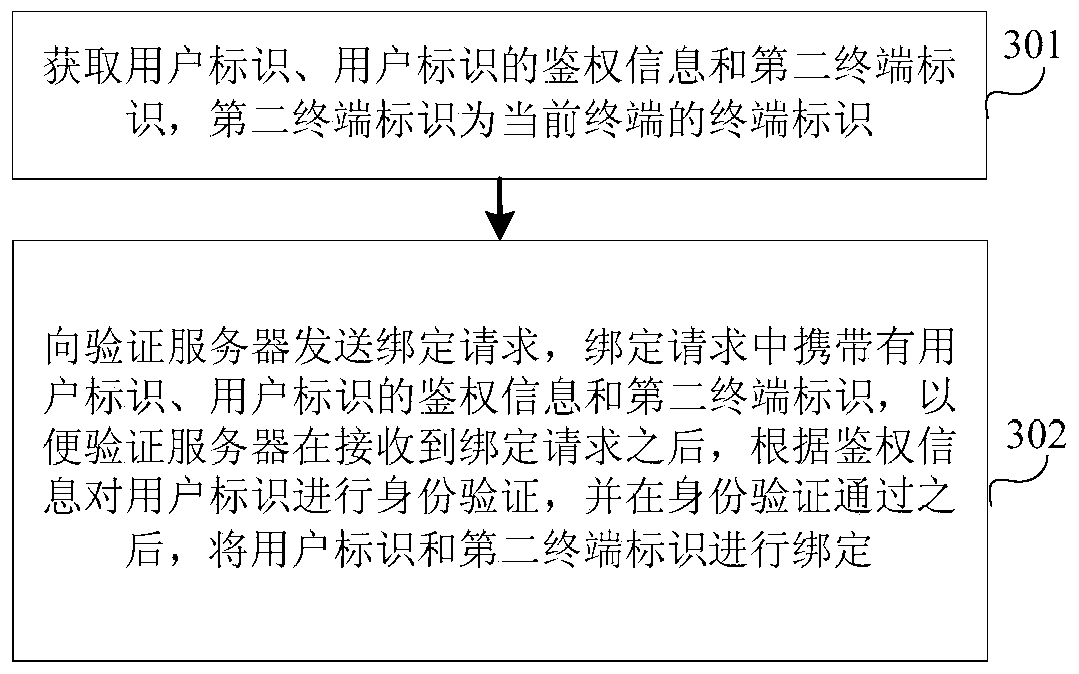

Verification method, device and system

ActiveCN104468464BFix the leakSettle property damageUser identity/authority verificationValidation methodsAuthentication server

The invention discloses a verification method, device and system, belonging to the field of network technology. The method includes: receiving a verification request, the verification request carrying a user ID and a first terminal ID, the first terminal ID being the terminal ID of the terminal sending the verification request; querying whether there is a second terminal ID bound to the user ID; Detecting whether the first terminal ID is the same as the second terminal ID; if the first terminal ID is the same as the second terminal ID, it is determined that the authentication of the user ID is passed. The present invention verifies the user ID by detecting whether the terminal ID of the terminal sending the verification request is the same as the terminal ID bound with the user ID by the verification server; it solves the information leakage or property that may be caused once the user information is obtained illegally by hackers. The problem of loss; it has achieved the effect of further protecting the safety of user information and property.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

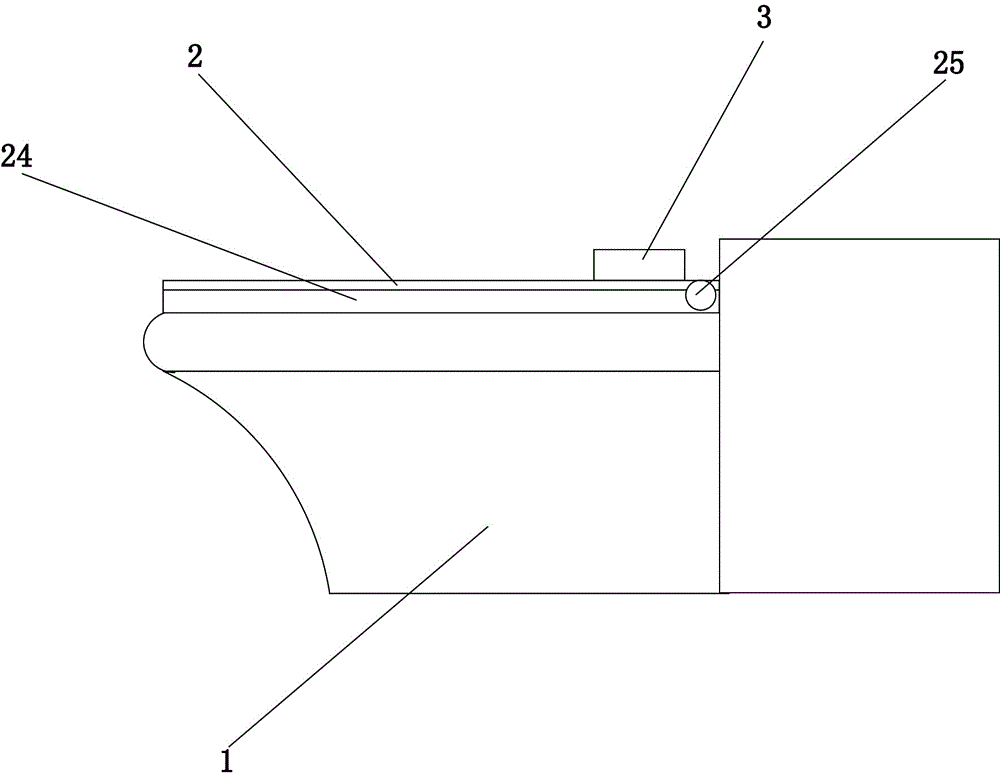

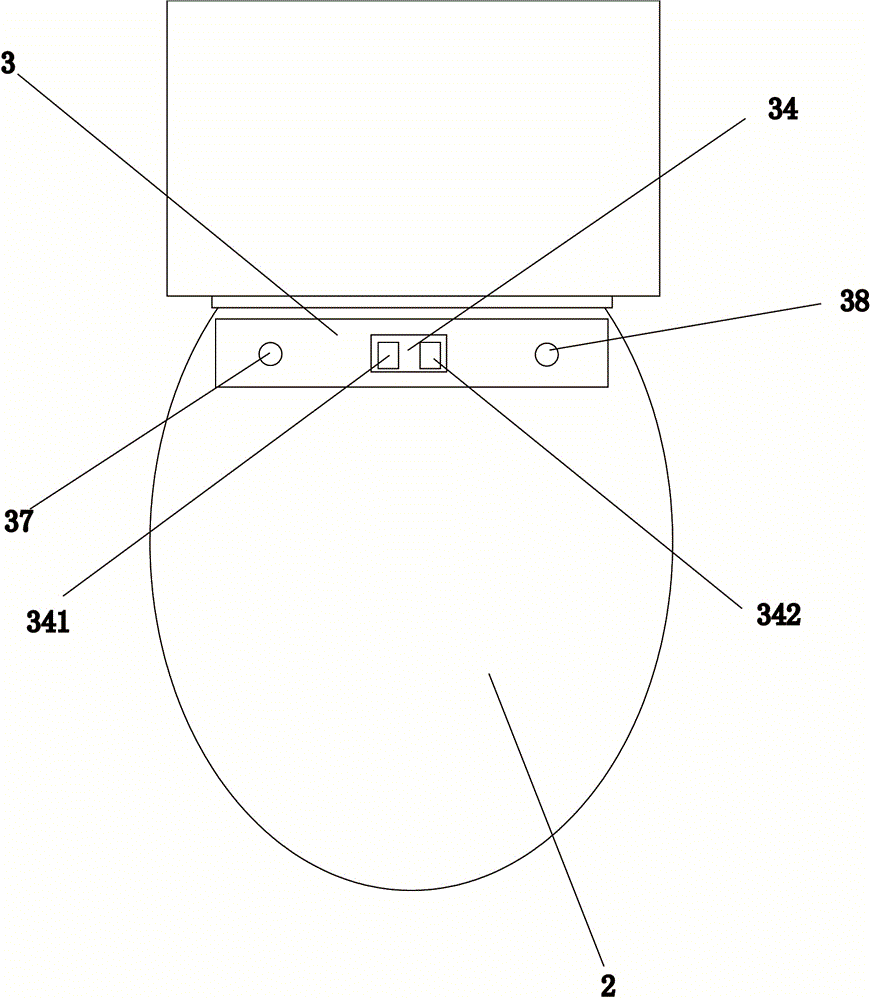

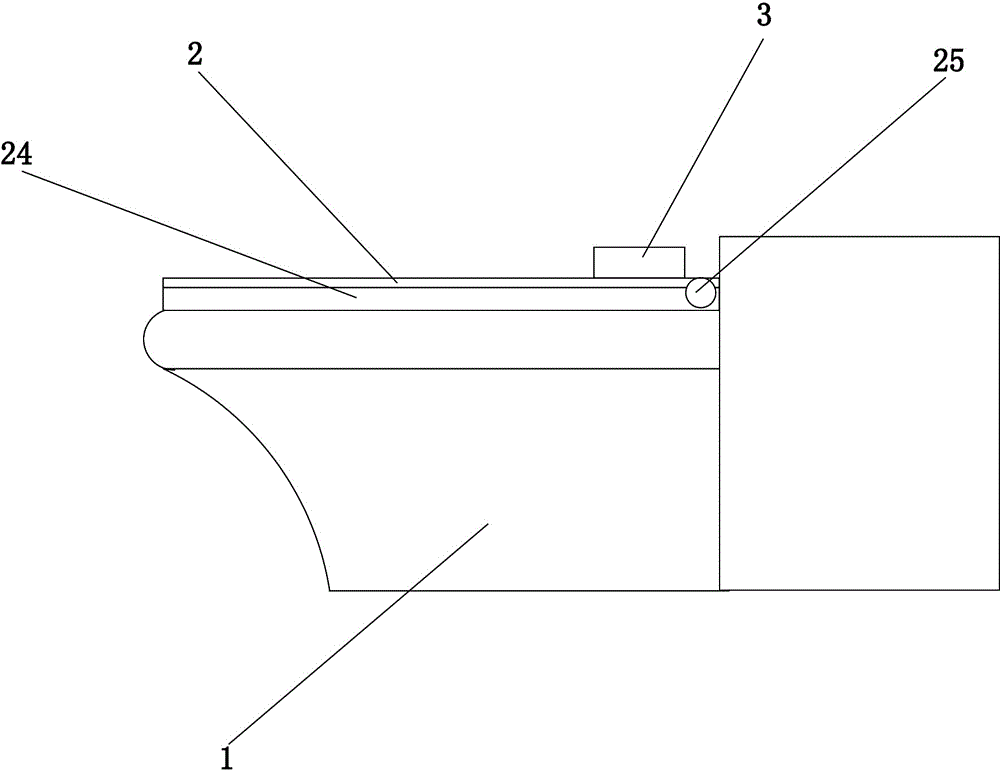

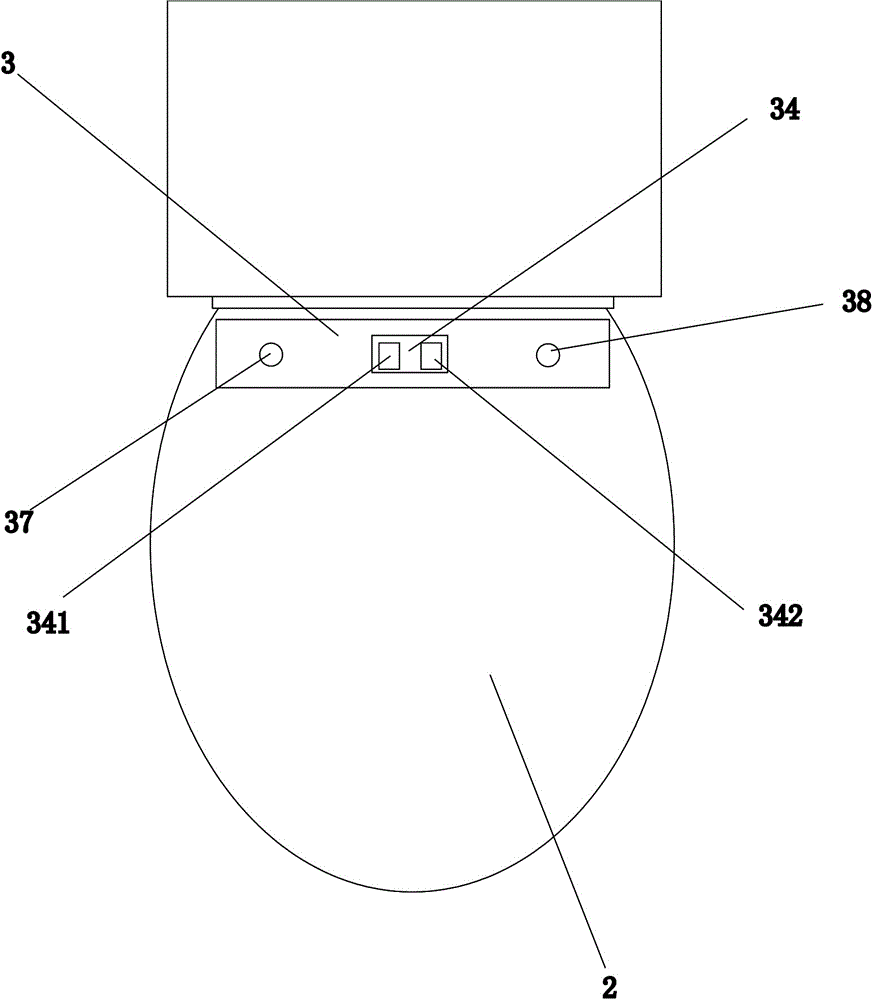

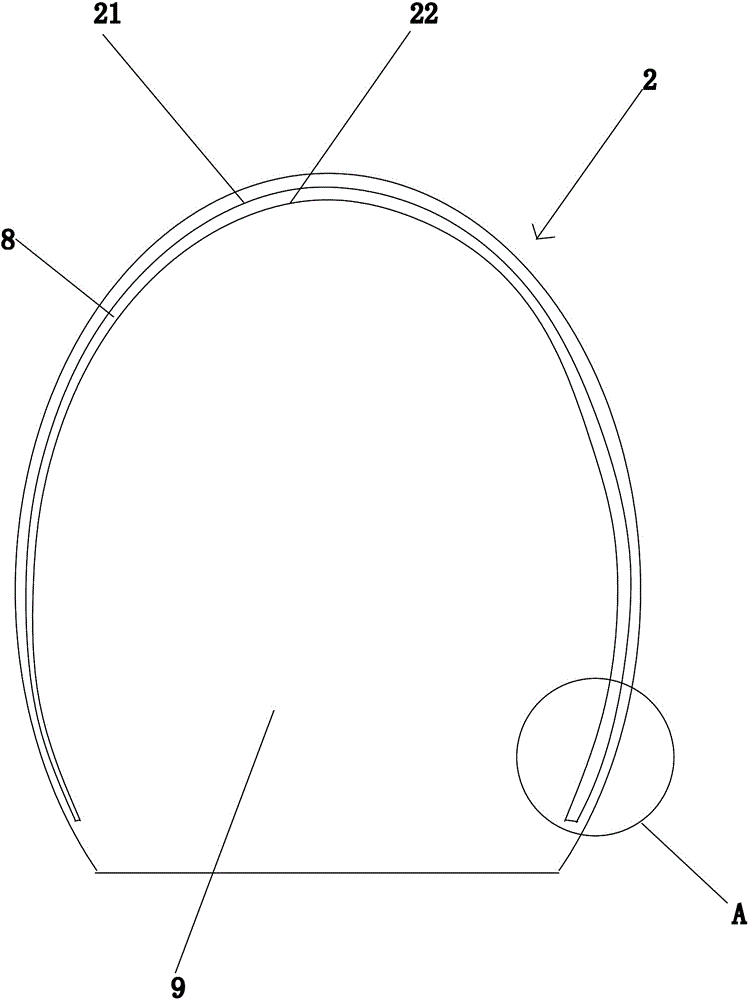

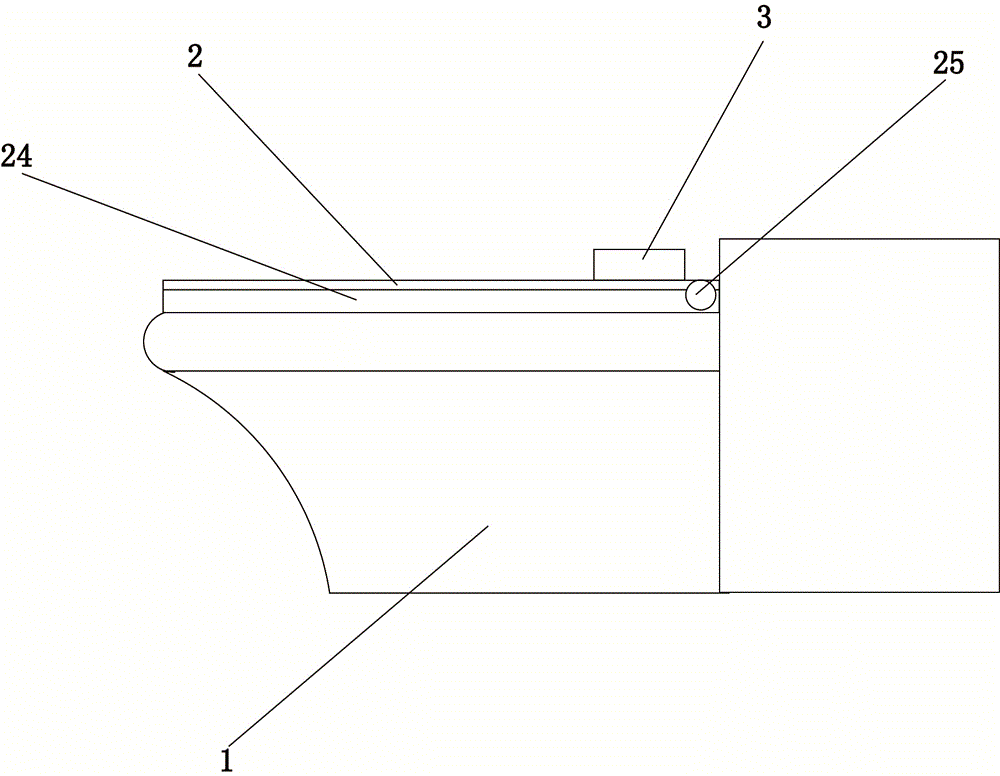

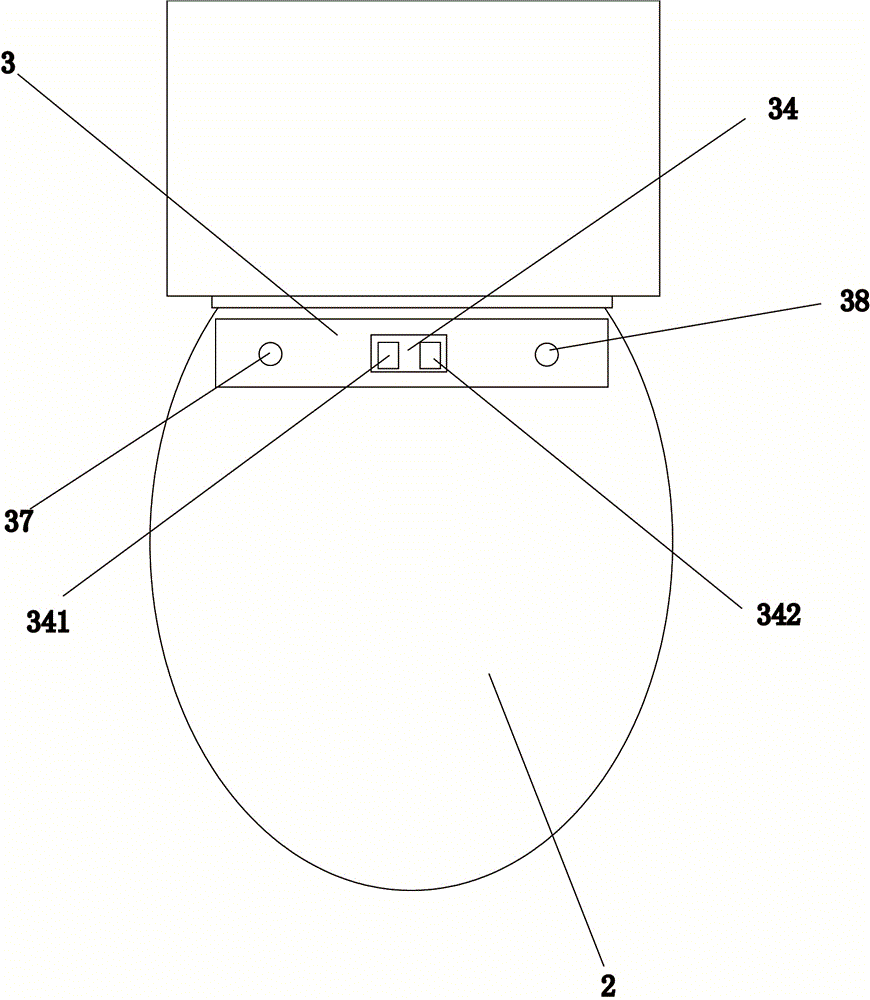

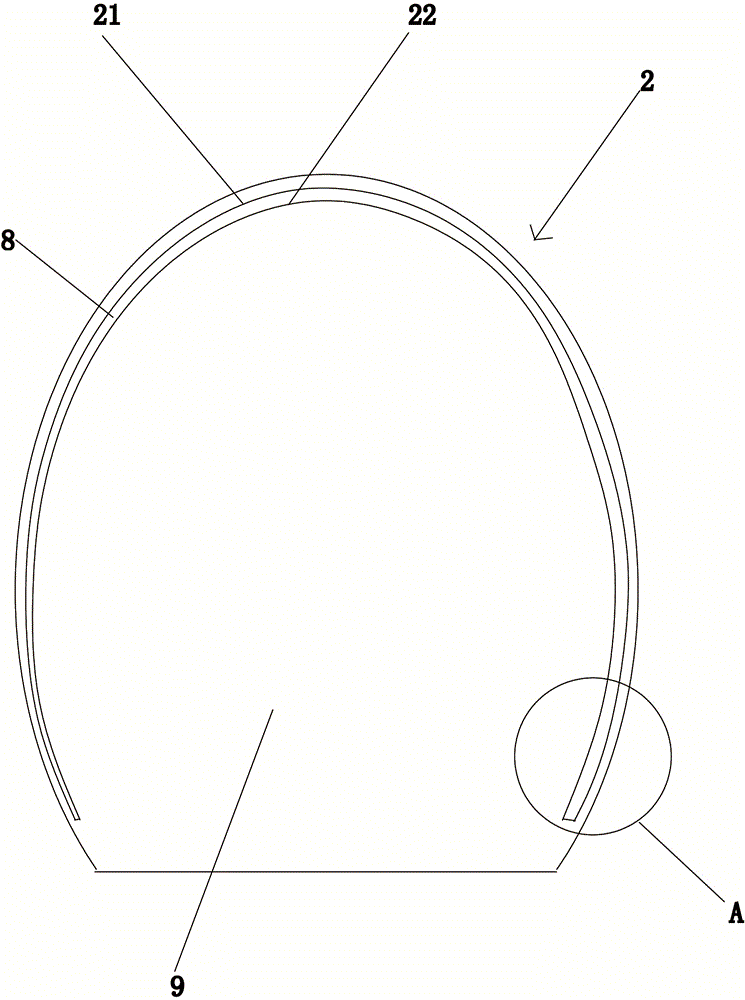

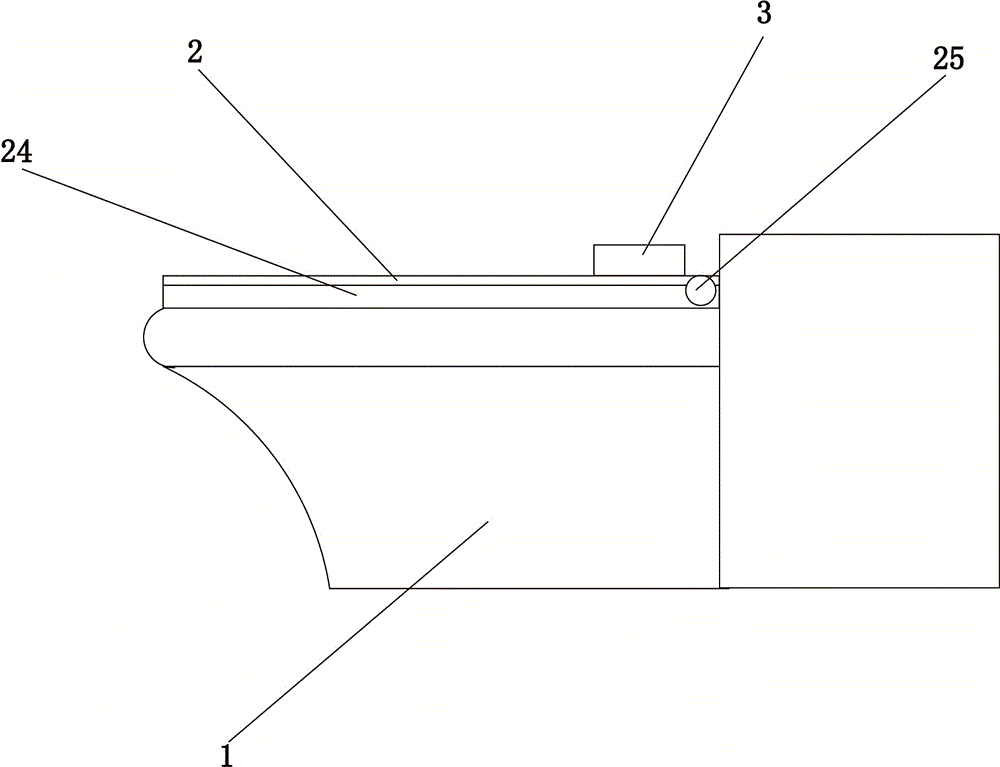

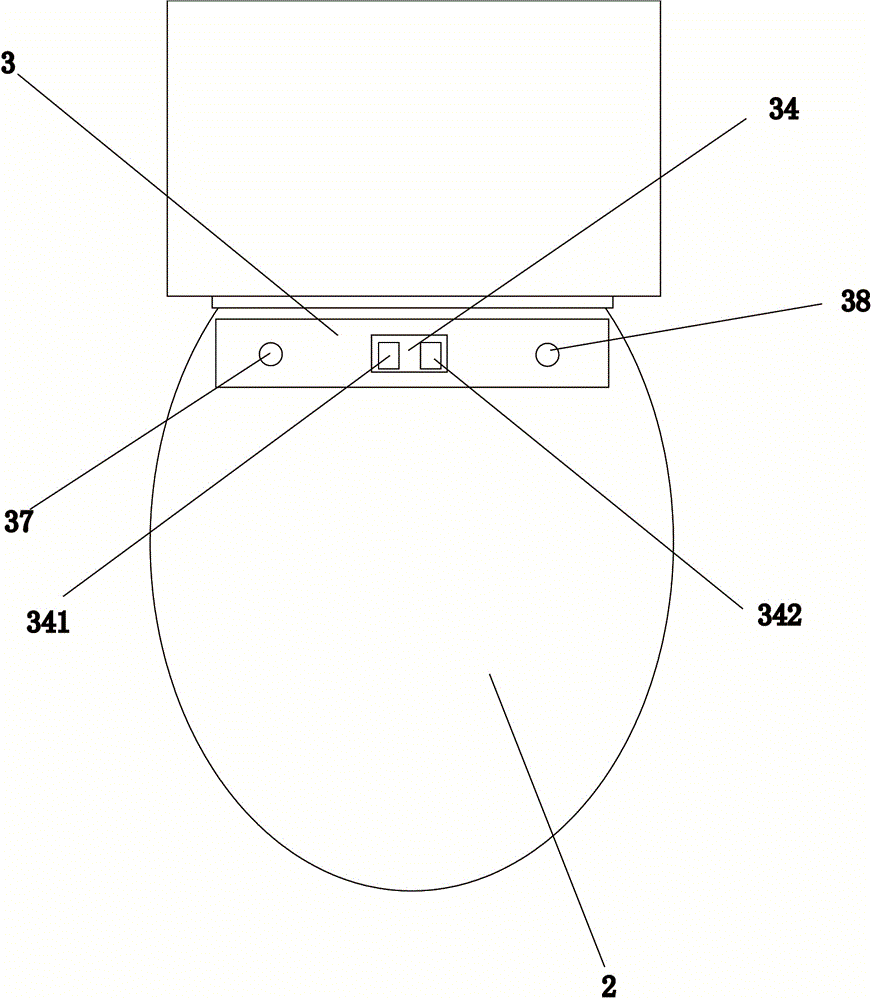

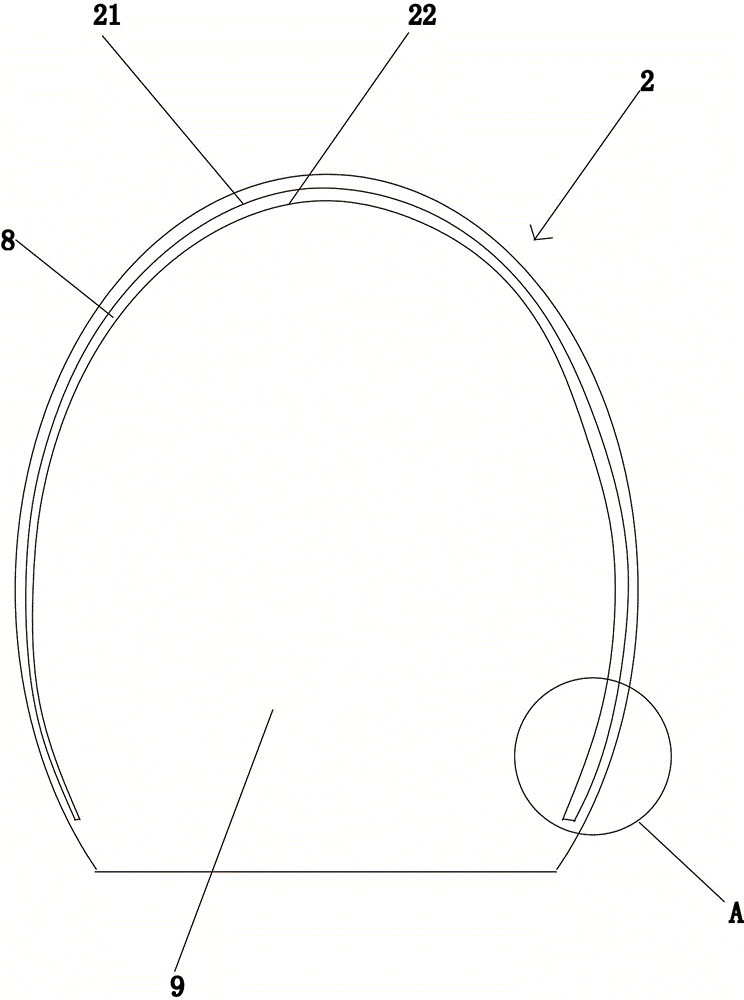

An automatic child-resistant opening device on a toilet

The invention discloses an automatic child-resistant device for a closestool, and belongs to the field of sanitary appliances. The device comprises a closestool seat and a closestool cover, wherein a rubber blocking bar A and a rubber blocking bar B which can be contacted with the closestool seat are arranged on the closestool cover; the rubber blocking bar A and the rubber blocking bar B are connected with each other around the edge of the closestool cover; a holding space A is formed between the rubber blocking bar A and the rubber blocking bar B; an air pumping box is arranged on the closestool cover; an air pumping piston, an electric air cylinder and a battery box are arranged in the air pumping box; the air pumping piston comprises a piston rod; the electric air cylinder is connected with the piston rod; a connecting pipe is arranged on the air pumping piston, and is connected with the holding space; a switch and an angular velocity sensor are further arranged on the air pumping box; the switch is used for controlling the electric air cylinder; the angular velocity sensor is connected with the battery box and the switch. Compared with the prior art, the closestool cover can be firmly adsorbed onto the closestool seat after being put down, thereby preventing young children from opening the closestool cover and climbing into the closestool or throwing sundries into the closestool.

Owner:张朝霞

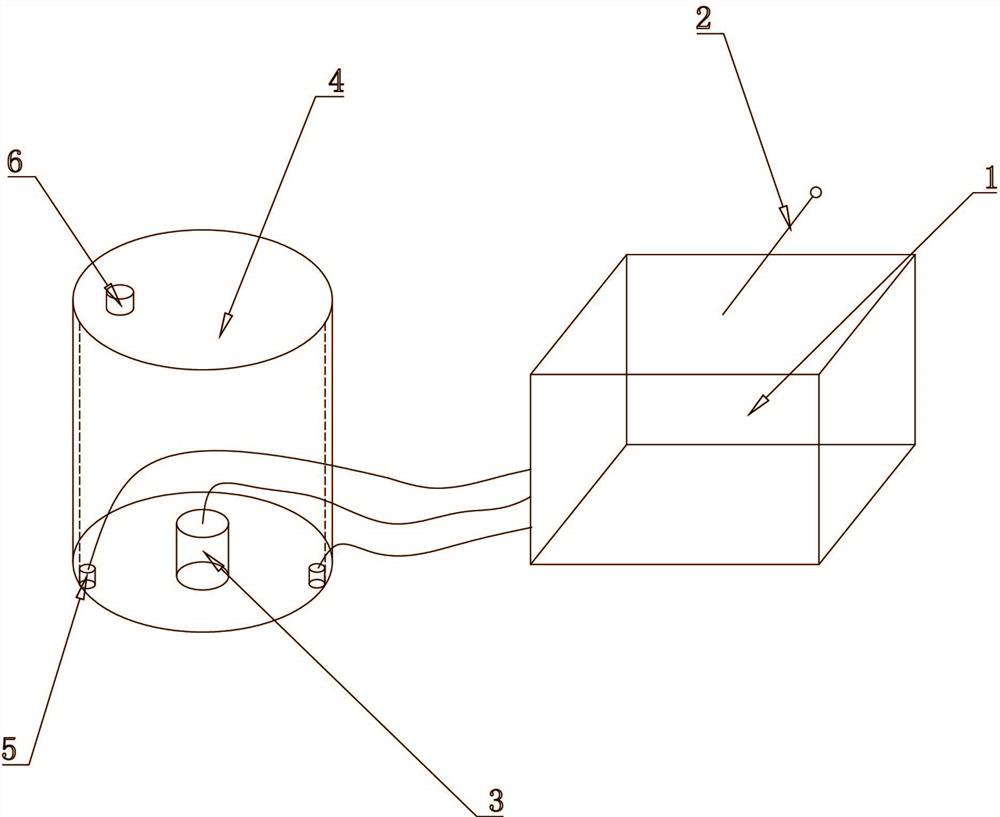

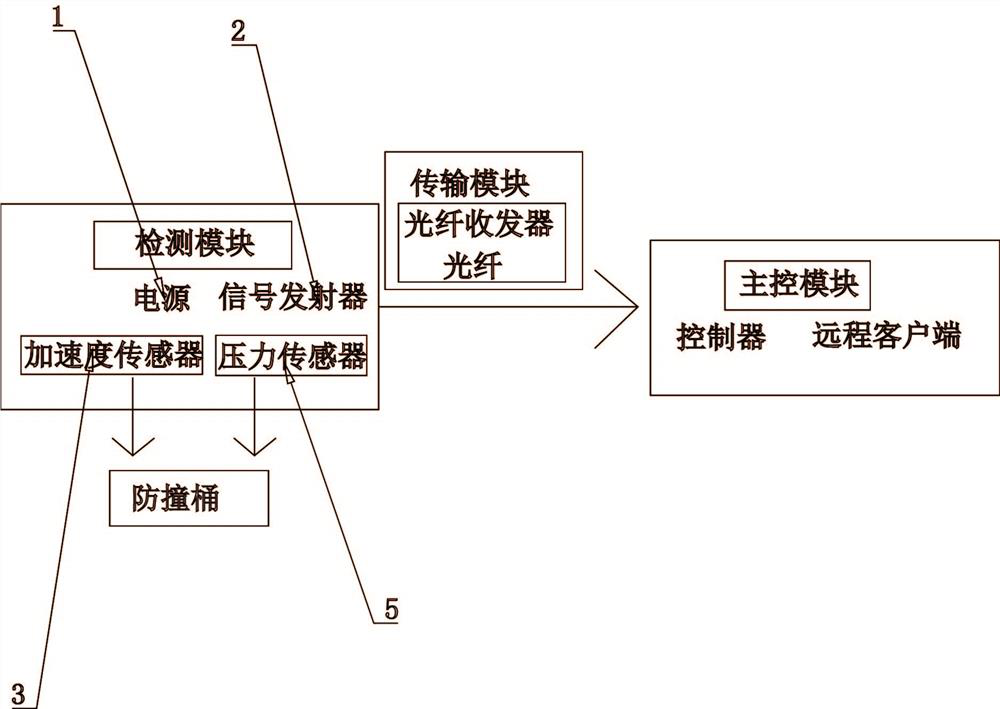

Anti-escape system applied to anti-collision barrel

InactiveCN112211139ASettle property damageTelevision system detailsMeasurement devicesAccidents vehicleControl system

The invention discloses an anti-escape system applied to an anti-collision barrel, and relates to the technical field of road traffic safety, the anti-escape system comprises an anti-collision barrelbody and a control system, a detection module is arranged in the anti-collision barrel body, an internal and external pressure difference exists between the inner wall and the outer wall of the anti-collision barrel body, and the detection module comprises two power supplies; one power supply is electrically connected with an acceleration signal emitter and an acceleration sensor, and the other power supply is electrically connected with a pressure signal emitter and a pressure sensor; the control system comprises a remote client and an executing mechanism. The remote client is used for receiving signals sent by the pressure signal transmitter and the acceleration signal transmitter. An acceleration sensor is arranged in the anti-collision barrel, whether a vehicle collides with the anti-collision barrel or not is detected through the acceleration sensor, the acceleration sensor sends a signal to a remote client side, and an executing mechanism immediately collects cameras near an accident to capture the accident vehicle, so that the problems that in the prior art, a driver collides with traffic safety facilities and escapes, and accidents happen are solved, and road property lossis caused.

Owner:徐大年

Electrode protection device of battery

InactiveCN101867033BSolve casualtiesSettle property damageActive material electrodesCell component detailsEngineeringCathode

The invention discloses an electrode protection device of a battery, comprising an insulator sheathed on an electrode of the battery, and the insulator is used for completely packing the electrode of the battery to carry out insulation protection on the electrode of the battery. By applying the technical scheme, the insulator is sheathed on one electrode of the battery and completely packs the electrode of the battery to carry out insulation protection on the electrode of the battery. Because one electrode of the battery is insulated from outside, the short circuits of the anode and the cathode of the battery can not be caused so that casualties and property losses can not be caused, thereby solving the problems of casualties and property losses caused by the short circuits of the anode and the cathode of the battery.

Owner:上海奕代汽车技术有限公司

A child-resistant opening device on a toilet

InactiveCN103976683BAvoid crawlingAddressing VulnerabilityBathroom coversMechanical engineeringPiston

A child-resistant opening device on a toilet, which belongs to the field of sanitary appliances, includes a toilet seat and a toilet cover. The toilet cover is provided with a rubber bar and a rubber bar that can contact the toilet seat, and the rubber bar and the rubber bar are surrounded The edges of the toilet cover are connected to each other, and the first accommodating space is formed between the first rubber retaining strip and the second rubber retaining strip. The toilet cover is provided with an air extraction box, and an air extraction piston, an electric cylinder and a battery box are arranged in the air extraction box to extract air. The piston includes a piston rod, and the electric cylinder is connected to the piston rod. A connecting pipe is arranged on the suction piston to connect to the first storage space. A switch is also arranged on the suction box, and the switch controls the electric cylinder. Compared with the prior art, the invention can make the toilet cover firmly absorb the toilet seat after the toilet cover is put down, so that young children cannot open the toilet cover, preventing young children from climbing into the toilet or throwing away sundries in the toilet.

Owner:刘思琴

Automatic child-resistant device for closestool

InactiveCN103976687AAvoid crawlingAddressing VulnerabilityBathroom coversAngular velocityEngineering

The invention discloses an automatic child-resistant device for a closestool, and belongs to the field of sanitary appliances. The device comprises a closestool seat and a closestool cover, wherein a rubber blocking bar A and a rubber blocking bar B which can be contacted with the closestool seat are arranged on the closestool cover; the rubber blocking bar A and the rubber blocking bar B are connected with each other around the edge of the closestool cover; a holding space A is formed between the rubber blocking bar A and the rubber blocking bar B; an air pumping box is arranged on the closestool cover; an air pumping piston, an electric air cylinder and a battery box are arranged in the air pumping box; the air pumping piston comprises a piston rod; the electric air cylinder is connected with the piston rod; a connecting pipe is arranged on the air pumping piston, and is connected with the holding space; a switch and an angular velocity sensor are further arranged on the air pumping box; the switch is used for controlling the electric air cylinder; the angular velocity sensor is connected with the battery box and the switch. Compared with the prior art, the closestool cover can be firmly adsorbed onto the closestool seat after being put down, thereby preventing young children from opening the closestool cover and climbing into the closestool or throwing sundries into the closestool.

Owner:张朝霞

Child-resistant device on closestool

InactiveCN103976683AAddressing VulnerabilityAvoid crawlingBathroom coversElectrical and Electronics engineeringToilet

The invention discloses a child-resistant device on a closestool, and belongs to field of utensil appliances. The child-resistant device comprises a closestool seat and a closestool cover, wherein a rubber blocking bar A and a rubber blocking bar B which can be contacted with the closestool seat are arranged on the closestool cover; the rubber blocking bar A and the rubber blocking bar B are connected with each other around the edge of the closestool cover; a holding space A is formed between the rubber blocking bar A and the rubber blocking bar B; an air pumping box is arranged on the closestool cover; an air pumping piston, an electric air cylinder and a battery box are arranged in the air pumping box; the air pumping piston comprises a piston rod; the electric cylinder is connected with the piston rod; a connecting pipe is arranged on the air pumping piston and is connected with the holding space A; a switch is further arranged on the air pumping box, and is used for controlling the electric air cylinder. Compared with the prior art, the child-resistant device has the advantages that the closestool cover can be firmly adsorbed onto the closestool seat after being put down, thereby preventing young children from opening the closestool cover and climbing into the closestool or throwing sundries into the closestool.

Owner:刘思琴

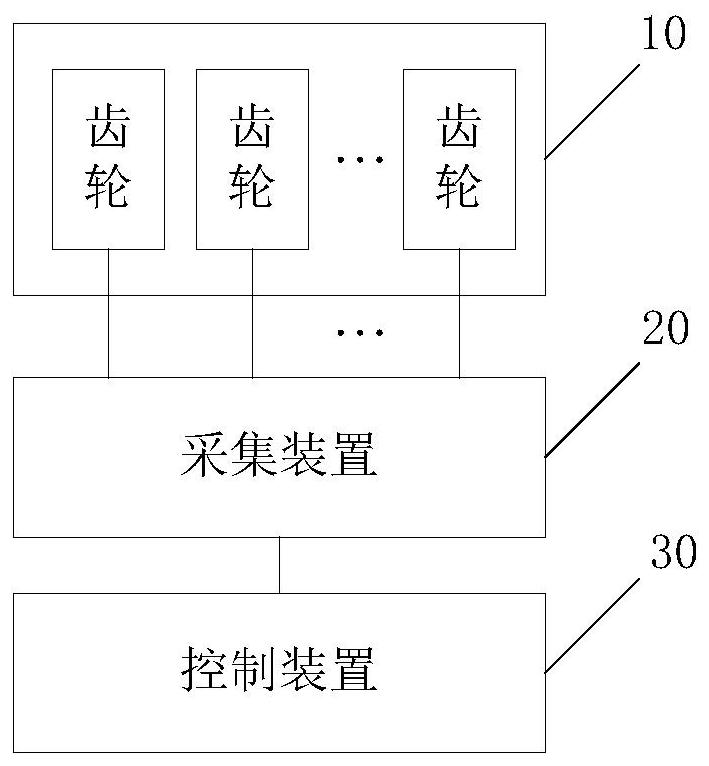

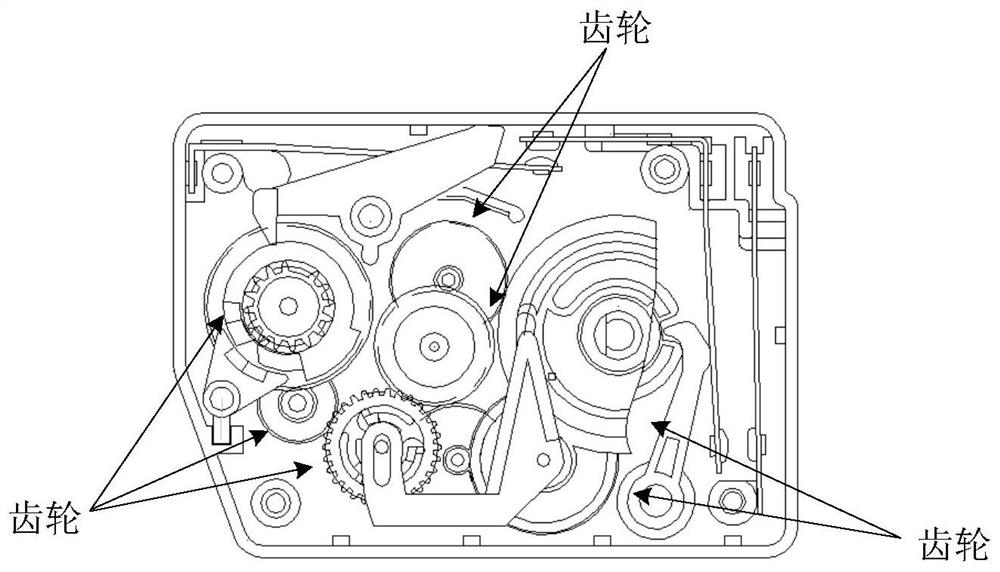

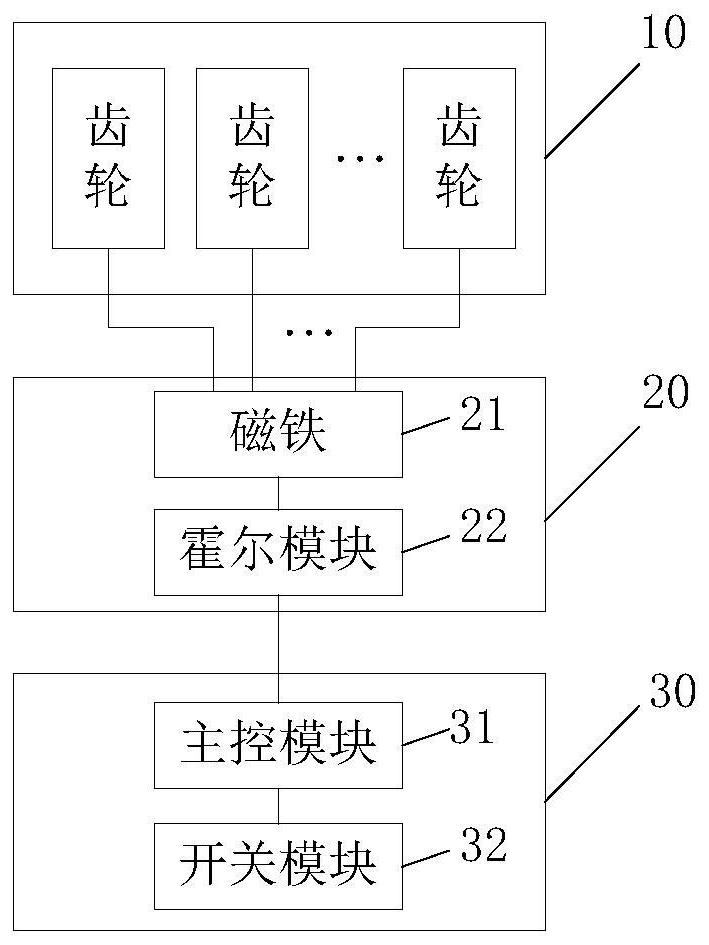

Electrical equipment and method for detecting stuck mechanical timer

ActiveCN109275218BAddress personal safetySettle property damageMicrowave heatingGear wheelControl engineering

The invention discloses an electrical device and a method for detecting that a mechanical timer is stuck, wherein the electrical device includes: a mechanical timer, the mechanical timer includes a plurality of gears; The feedback signal of any gear; the control device is used to judge whether the mechanical timer is stuck according to the feedback signal, and to control the load of the electrical equipment to stop working when the mechanical timer is stuck. The electrical equipment of the present invention can effectively solve the problem that the whole machine catches fire caused by the continuous operation of the mechanical electrical equipment when the timer is stuck, thereby causing the user's personal safety or property loss.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

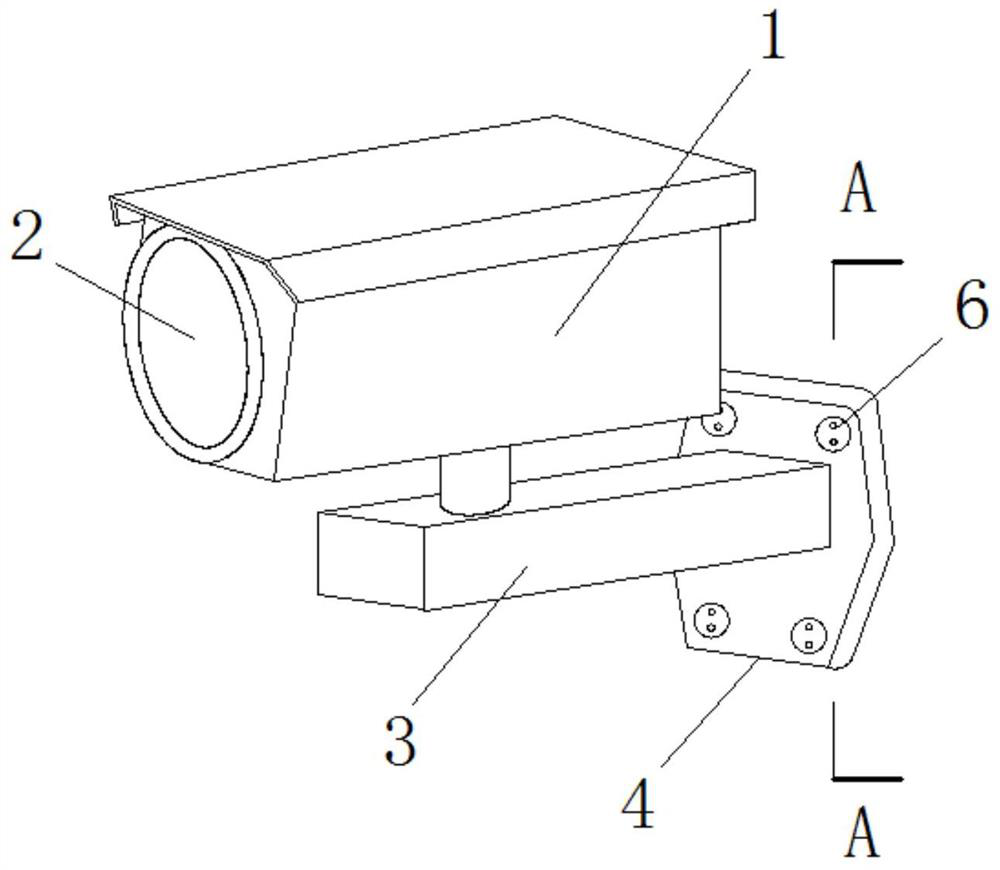

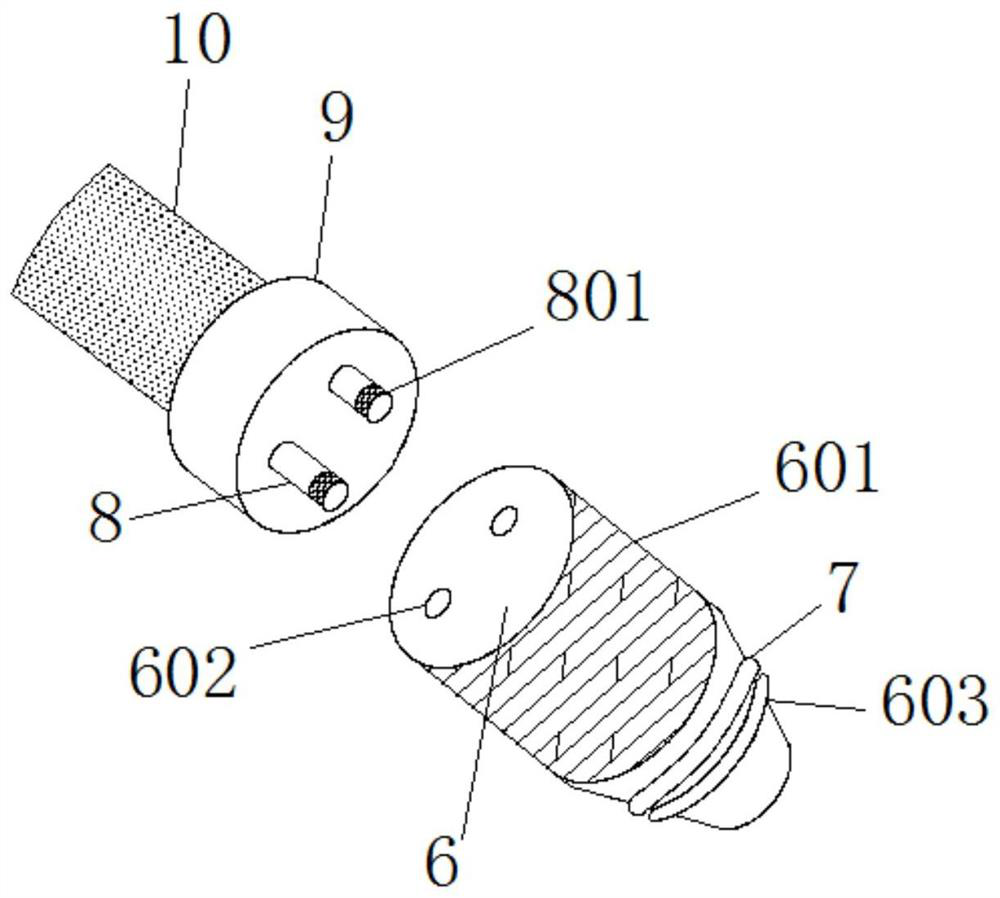

An Internet monitoring anti-theft device for e-commerce

ActiveCN111637345BSolve the general stabilityFirmly connectedTelevision system detailsPinsEngineering

The invention relates to the technical field of e-commerce data encryption, and discloses an Internet monitoring and anti-theft device for e-commerce, which includes a monitor, a mounting nail connected between the mounting base and the base, and a clamping screw on the outside of the rear end of the mounting nail. The outside of the rear end of the mounting nail is connected with a snap ring, the rear end of the post is provided with a column magnet, the inside of the base is connected with a magnetic ball, a rope is connected between the slide plate and the magnetic ball, and the front end of the clip bar is provided with a convex ball. Pull the rope through the magnetic ball absorbed by the cylindrical magnet, the rope drives the slide plate to move to the left in the guide groove, the slide plate drives the left end of the clip to move to the left end of the snap ring, and pull out half of the cylindrical magnet, under the action of the spring, The slide plate drives the clip bar to move to the right and exit directly through the snap ring, and then turn the toggle piece to take out the mounting nail. This structure solves the problem that the existing Internet monitoring device for e-commerce is easy to disassemble and cause property loss.

Owner:湖南印象仙阳旅游开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com