Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Sand cleaning is easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shell making process for elongated hole flange investment casting

InactiveCN101670418AShorten drying timeSand cleaning is easyFoundry mouldsFoundry coresInvestment castingSurface layer

The invention discloses a shell making process for elongated hole flange investment casting, which comprises the following steps: firstly forming a shell on the surface of an elongated hole flange waxpattern through spreading a surface layer, spreading a transition layer for the first time and spreading the transition layer for the second time, then blocking one end of a hole with pasty refractory paste after completely drying, then pouring refractory sand with 100-120 meshes into the other end of the hole, blocking the other end also with the pasty refractory paste after compactly pouring, then spreading a backing layer for the first time, spreading the backing layer for the second time after drying, drying again, carrying out slurry sealing, and finishing the shell making process. Compared with the prior art, the shell making process has the biggest characteristic that the refractory paste is adopted for blocking the elongated hole, then the refractory sand is poured, and then the next steps of backing layer spreading, slurry sealing and the like are carried out. The shell made through the process does not drill steel after pouring, sand is easily cleaned, and meanwhile, the drying time is greatly shortened from the original 7 days to 4 days, and the quality is improved from the original lower than 20 percent to more than 95 percent.

Owner:山东燕山精密机械有限公司

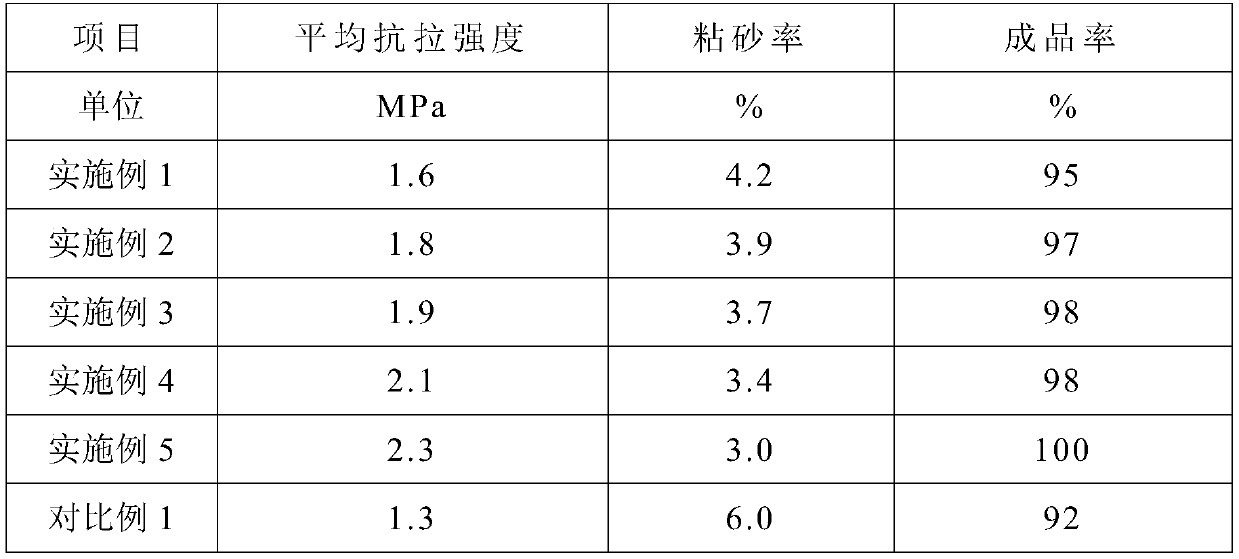

Easily scattered precoated sand and preparation method thereof

InactiveCN103567360AGood collapsibilitySand cleaning is easyFoundry mouldsFoundry coresRiver sandUrea

The invention discloses easily scattered precoated sand and a preparation method thereof. The easily scattered precoated sand is prepared from the following raw materials in parts by weight: 60-80 parts of zircon sand, 15-20 parts of river sand, 10-15 parts of montmorillonoid, 2-4 parts of thermoplastic phenolic resin, 0.5-1 part of anilino-methyl-triethoxysilane, 4-6 parts of triethyl citrate, 2-3 parts of polyvinyl formal, 10-15 parts of urotropine, 3-4 parts of urea, 1.5-2.5 parts of potassium dichromate, 4-6 parts of manganese ore slag, 2-3 parts of salicylic acid, 3-5 parts of butadiene-acrylonitrile rubber powder, 4-8 parts of ethylene bis-stearamide and 3-6 parts of composite powder. The precoated sand has excellent scattering property, the sand is easily cleaned after a casting is cooled and is subjected to sand shakeout, an inner cavity is smooth, the labor intensity of cleaning is obviously reduced, and the precoated sand has the characteristics of high strength, high liquidity, high air release amount, high heat resistance, high air permeability and the like. Moreover, the defects of sand adhesion, air holes, cracks and the like in the casting can be overcome, the surface quality of the casting is improved, and the precoated sand is suitable for production of nonferrous metal castings such as aluminum alloys and copper alloys.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Lost foam steel-casting paint formula and technology method thereof

InactiveCN103357813AImprove breathabilityImprove thixotropyFoundry mouldsFoundry coresLithiumEmulsion

The invention discloses a paint formula, particularly discloses a lost foam steel-casting paint formula and a technology method thereof. The lost foam steel-casting paint formula comprises the following components: 40-60% of bauxite, 30-50% of zirconium sand powder, 1-3% of phenolic resin, 1-5% of white emulsion, 1-5% of silica sol, 1-5% of lithium bentonite, 0.1-0.5% of isopropanol, 0.5-2% of CMC and 0.1-0.5% of JFC. The technology method of the lost foam steel-casting paint formula comprises the following steps: 1, in the ratio of paint powder to water of 1:0.7, putting the paint powder and the water into a stirrer for stirring for 1-1.5 hours, then measuring baume degree, and controlling the baume degree between 65 and 70 through dilution with water; 2, according to production requirements, dip-coating for two times or three times; and 3, the thickness of a coating layer being 1-2 mm. White molds of the paint formula have good wettability, good coating and hanging properties, high strength and good air permeability.

Owner:翼城县福旺铸造实业有限公司

Environment-friendly alcohol-based coating for sand mold casting

ActiveCN104550679AGood dispersionGood suspensionFoundry mouldsFoundry coresSesquioxideSuspending Agents

The invention discloses an environment-friendly alcohol-based coating for sand mold casting. The environment-friendly alcohol-based coating comprises refractory aggregate, a binding agent, a compound suspending agent and an auxiliary agent, wherein the refractory aggregate comprises 60 to 70 parts of quartz powder, 20 to 30 parts of aluminum sesquioxide, 5 to 10 parts of talcum powder, 1 to 5 parts of calcium carbonate, and 10 to 20 parts of magnesium metal crosslinking acrylic acid resin; the particle size range of the refractory aggregate is 150 to 320 meshes; the compound suspending agent comprises the following constituents: 40 to 65 parts of lithium base bentonite, 20 to 35 parts of attapulgite, 0.5 to 2 parts of CMC, and 0.5 to 2 parts of PVB; the binding agent adopts 1 to 2 parts of thermoplastic phenolic resin; a carrier liquid adopts ethyl alcohol or ethylene glycol; the auxiliary agent adopts 0.2 to 0.5 part of defoamer normal butanol. The alcohol-based coating used for sand mold casting, which takes quartz powder as the main refractory aggregate, is not added with graphite, is a low-cost casting coating with an environment-friendly advantage, is high in refractoriness, good in anti-adhesive sand property, is easily peeled from casting after casting, and is easy for sand removal of the casting.

Owner:CHINA THREE GORGES UNIV +1

Furan resin self-hardening sand for casting and preparation method thereof

The invention discloses furan resin self-hardening sand for casting and a preparation method thereof. The furan resin self-hardening sand is prepared from the following raw materials in parts by weight: 20-30 parts of fresh sand, 70-80 parts of old sand, 1-1.5 parts of self-hardening furan resin, 10-15 parts of phosphoric acid, 8-12 parts of p-toluenesulfonic acid, 5-10 parts of ethyl sulfate, 0.5-1.5 parts of N-2-(amino ethyl group)-3-aminopropyl trimethoxy silane, 4-8 parts of tricresyl phosphate, 3-6 parts of waste syrup, 2-4 parts of activated carbon, 3-5 parts of sepiolite, 4-6 parts of zeolite, 5-10 parts of dibutyl phthalate, 2-3 parts of sodium alginate, 3-5 parts of butyl stearate and 4-6 parts of composite powder. The furan resin self-hardening sand has the advantages of being non-toxic, high in strength, small in smell, low in gas evolution and thermal expansivity, good in gas permeability and collapsibility, proper in viscosity, smooth and clean in surface, easy to clean and the like. The prepared casting is high in degree of precision and good in surface quality. The furan resin self-hardening sand is suitable for casting various cast steels, cast iron and non-ferrous castings.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Lost foam casting-use paint formula and technology method thereof

InactiveCN103357814AImprove breathabilityImprove thixotropyFoundry mouldsFoundry coresEmulsionDip-coating

The invention discloses a paint formula, particularly discloses a lost foam casting-use paint formula and a technology method thereof. The lost foam casting-use paint formula comprises the following components: 45-65% of bauxite, 1-5% of silica sol, 20-50% quartz powder, 1-5% of phenolic resin, 1-5% of white emulsion, 1-5% of sodium bentonite, 0.1% of isopropanol, 0.1% of JFC and 0.3-0.5% of CMC. The technology method of the lost foam casting-use paint formula comprises the following steps: 1, in the ratio of paint powder to water of 1:0.7, putting the paint powder and the water into a stirrer for stirring for 1-1.5 hours, then measuring baume degree, and controlling the baume degree between 65 and 70 through dilution with water; 2, according to production requirements, dip-coating for two times or three times; and 3, the thickness of a coating layer being 1-2 mm. White molds of the technology method have good wettability, good coating and hanging property, high strength and good air permeability.

Owner:翼城县福旺铸造实业有限公司

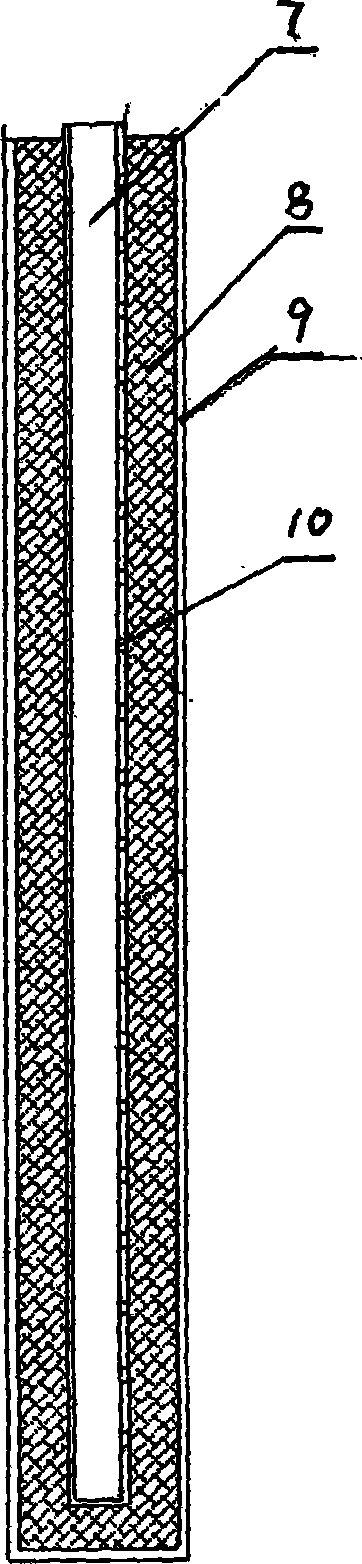

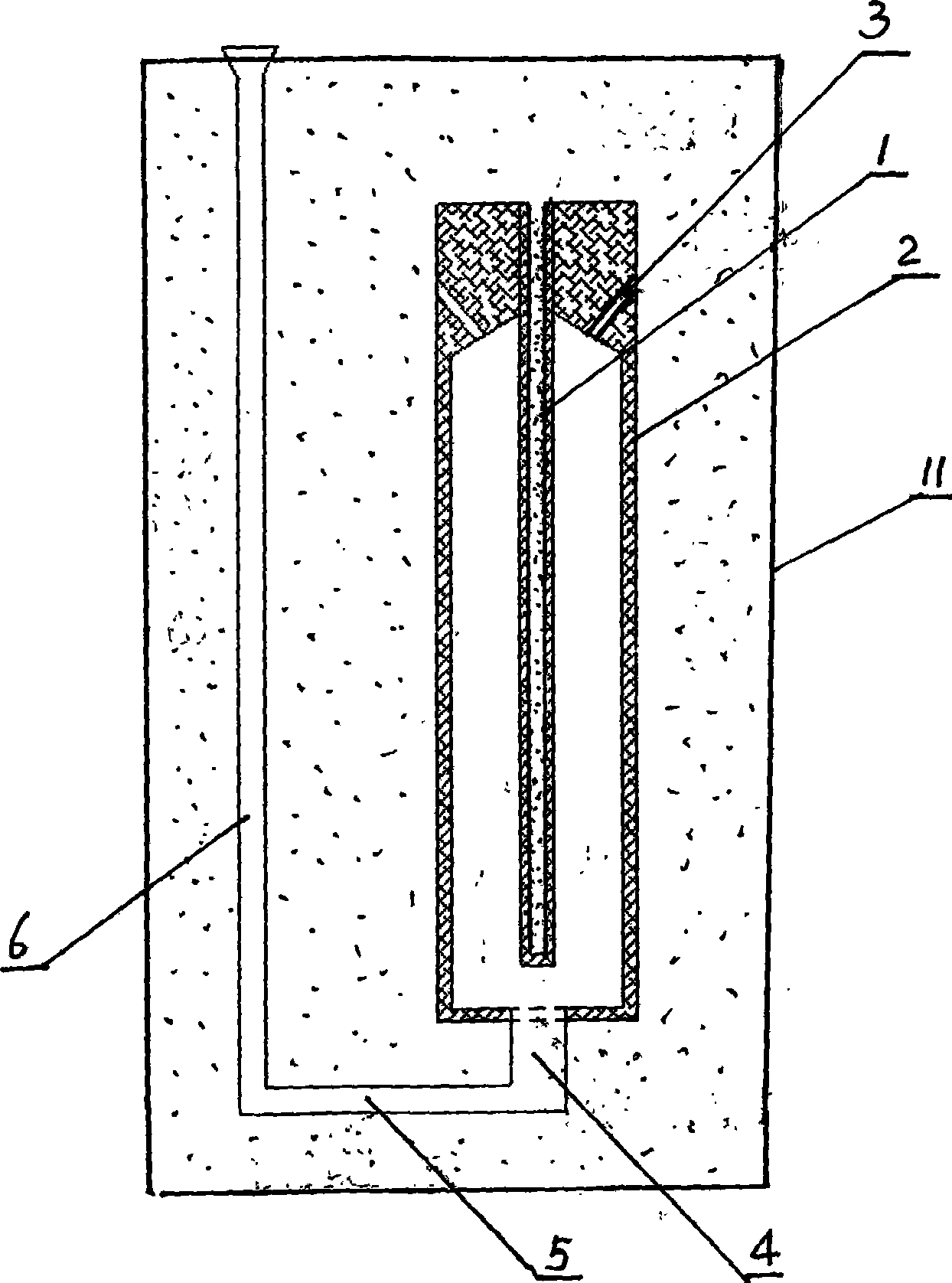

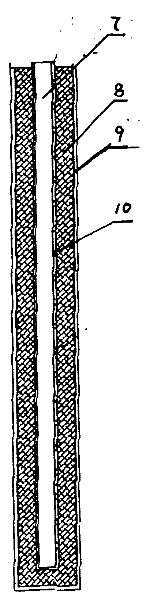

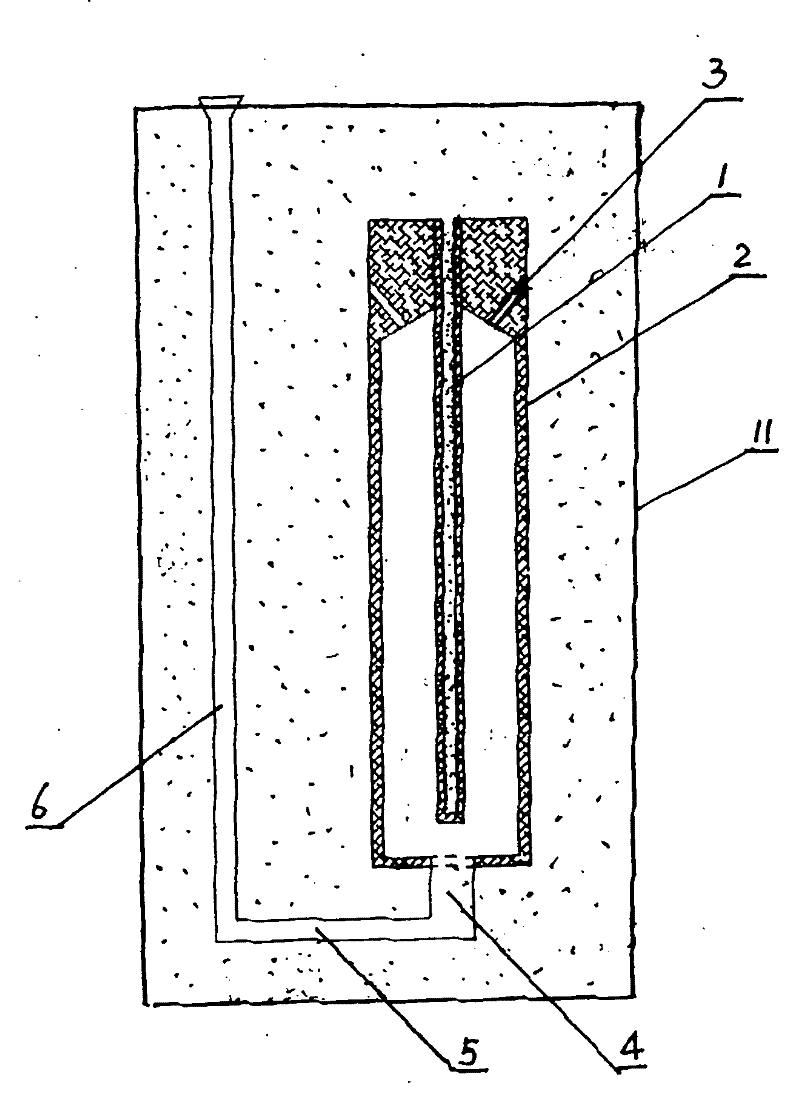

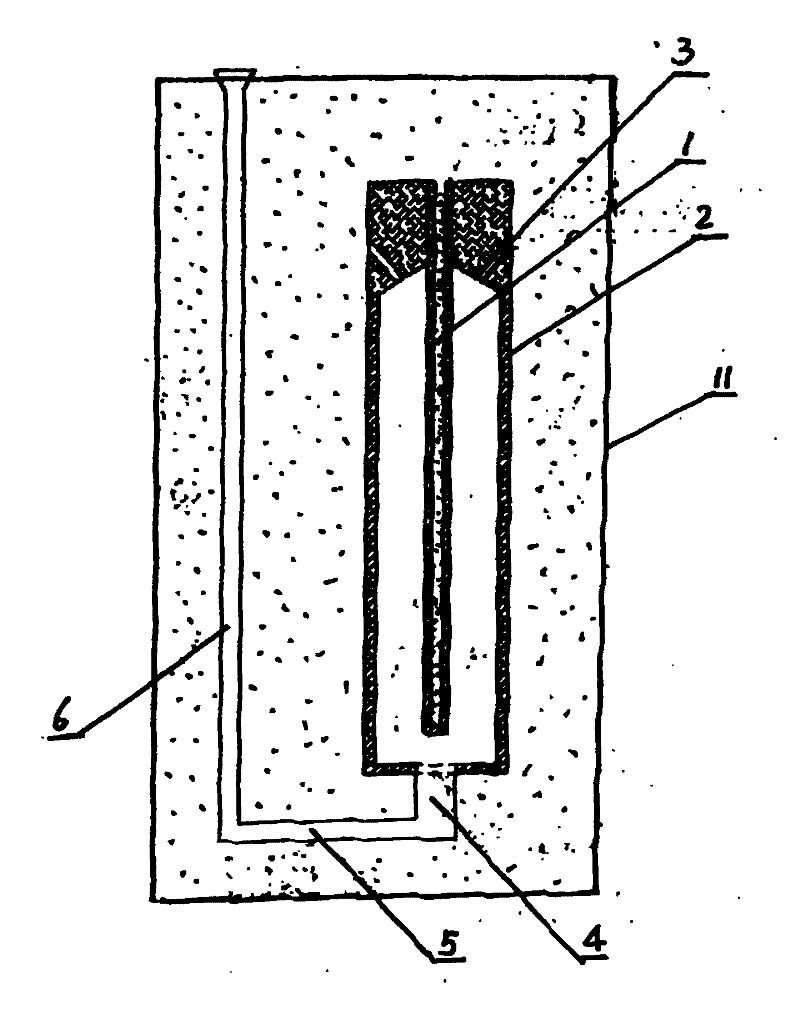

Casting method of heat-resistant steel slime blind-tube and mold thereof

InactiveCN101391283ASolve the problem of one-shot molding technologyAvoid Welding Weld ProblemsFoundry mouldsFoundry coresCastingHeat resistant

The invention discloses a refractory steel vimineous blind tube casting method and a mould thereof. The main point is that a compound core bone is arranged in a resin sand mould shell whose top is provided with an air exhaust hole, the bottom of the resin sand mould shell is provided with a bottom-injected pouring basin, the pouring cup height of the pouring basin is higher than the height of the resin sand mould shell. The invention adopts compound core bone to make sand core, the producing technique is simple, the mould does not deform during roasting and the bottom-injected pouring basin ensure the sand core not to be eccentric.

Owner:山东省耐磨耐蚀材料工程技术研究中心 +1

Method for preparing wear-resistant cast steel bucket tooth

The invention relates to a method for preparing a wear-resistant cast steel bucket tooth, which belongs to the technical field of metal wear-resistant materials. The prior bucket tooth and the processing technique thereof have the problems of high cost, complex technique and the like. In the method, tinplate leftover material, high carbon ferro-chrome, mid-carbon ferromanganese, silicoferrite, ferroboron, ferrozirconium and ferrotitanium are mixed up respectively according to the following mass percent: 96.3 to 97.0 percent, 1.5 to 1.8 percent, 0.8 to 1.2 percent, 0.4 to 0.6 percent, 0.025 to 0.035 percent, 0.045 to 0.055 percent and 0.18 to 0.25 percent; the mixture is compacted by a forcing press to form a quadrel which is then put in an induction furnace for heating and melting down and is cast to form the bucket tooth in a cere shuttering; the bucket tooth is put in water directly for cooling after being congealed, and is tempered under the low temperature at last to obtain the wear-resistant cast steel bucket tooth. The method for preparing the wear-resistant cast steel bucket tooth has the advantages of low manufacture cost, high productivity effect, long service life of the bucket tooth, etc.

Owner:BEIJING UNIV OF TECH

Pouring technology for marine propeller

InactiveCN105817587AGood sand resistanceReduce the amount addedMelt-holding vesselsFoundry mouldsStart timePropeller

The invention discloses a pouring process for a marine propeller, which solves the problem that air bubbles are easily formed on the surface of the propeller due to the simple pouring process. The key points of the technical scheme are the following steps: determining the opening time of the blast furnace; preparing the sprue cup; and preparing the pouring ladle; Pouring operation; the inspector records the pouring temperature, pouring time, pouring sequence and the pouring status of each product during the entire pouring process, so that the propeller cast by this process has a firm texture, a smooth surface, and no air bubbles inside. Effect.

Owner:TAIZHOU JIAOJIANG YONGGU SHIP PROPELLER FACTORY

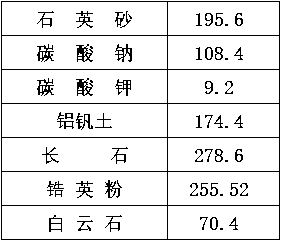

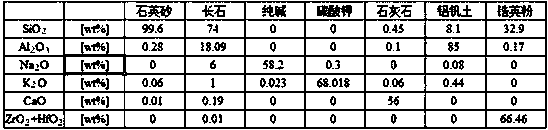

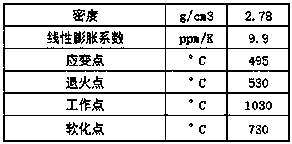

Molding sands for glass matrix casting

ActiveCN107661960AHigh strengthEvenly distributedFoundry mouldsFoundry coresAdhesiveChemical stability

The invention discloses molding sands for glass matrix casting. The molding sands for glass matrix casting are prepared by performing mixing treatment on base sands and an adhesive. The base sands areprepared by the following components in percentage by weight: 50-65 percent of SiO2, 1-6 percent of Al2O3, 1-4 percent of ZrO2, 4-8 percent of K2O, 5-10 percent of Na2O, 1-5 percent of Ca2O, 6-10 percent of SrO and 6-10 percent of BaO, wherein the average particle size of the base sands is from 0.03mm to 2mm. By adopting the molding sands for casting provided by the invention, the base sands areobtained by CRT screen glass treatment, and the environmental protection problem of CRT screen glass recovery is solved; in addition, during crushing, a cleavage plane does not exist, the mechanical strength is high, and the thermal chemical stability is good, so that the production cost during casting production can be lowered, and the casting performance of the molding sands for casting is improved.

Owner:河南博威热能科技有限公司

Sand core of pipe mould

ActiveCN104550756AHigh yieldImprove tissue performanceFoundry mouldsFoundry coresBarrel ShapedMaterials science

The invention relates to a sand core of a pipe mould, and belongs to the technical field of casting. The sand core comprises an inner sand core and an outer sand mould, wherein a cavity is formed between the sand core and the sand mould; the sand core comprises a barrel-shaped water glass sand core outer wall as well as sand blocks and saw dust in a cavity defined by the water glass sand core outer wall; the water glass sand core outer wall adopts an integral structure; the sand mould comprises a plurality of stacked individual sand moulds.

Owner:SUFA HENGDIAN MACHINERY CNNC

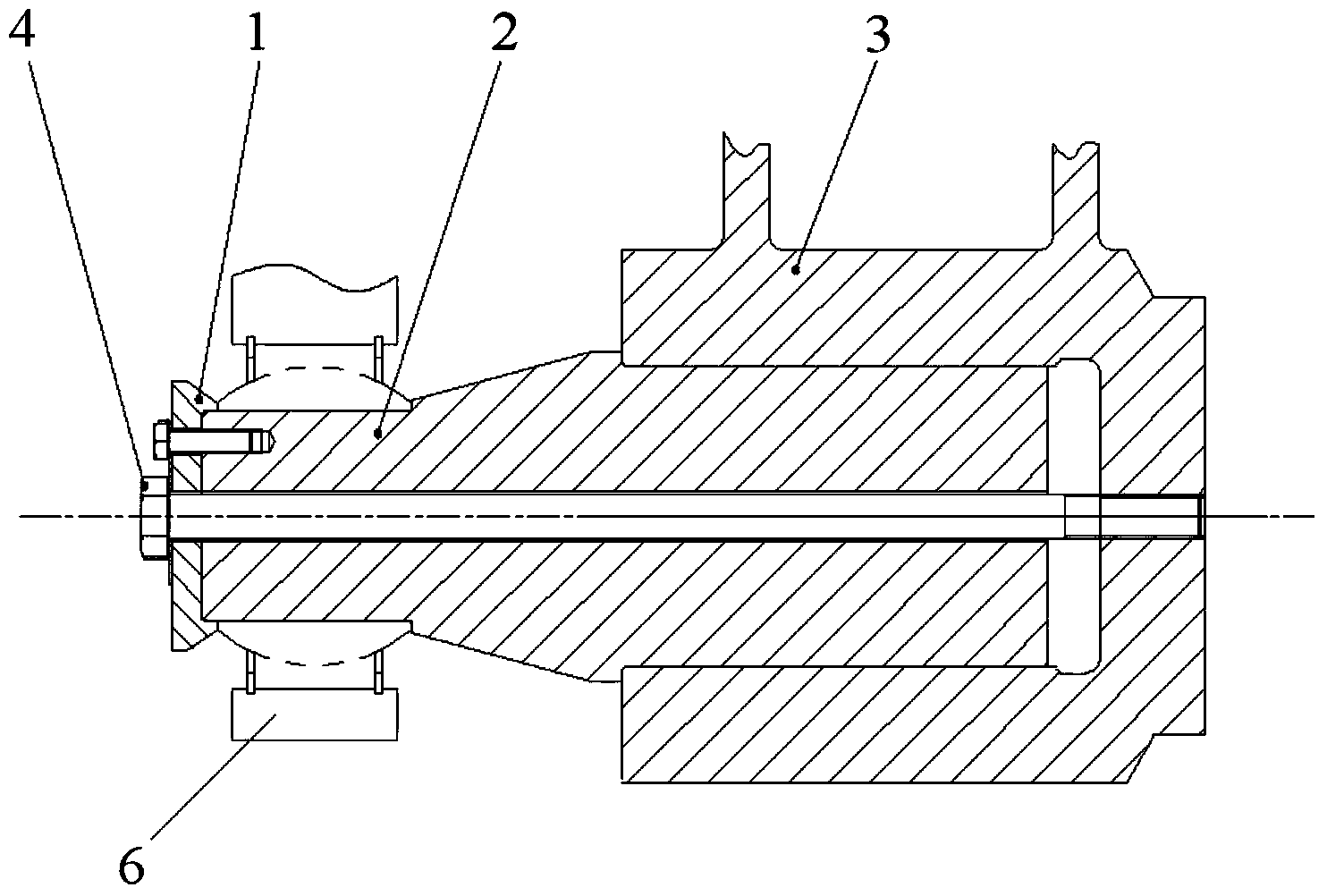

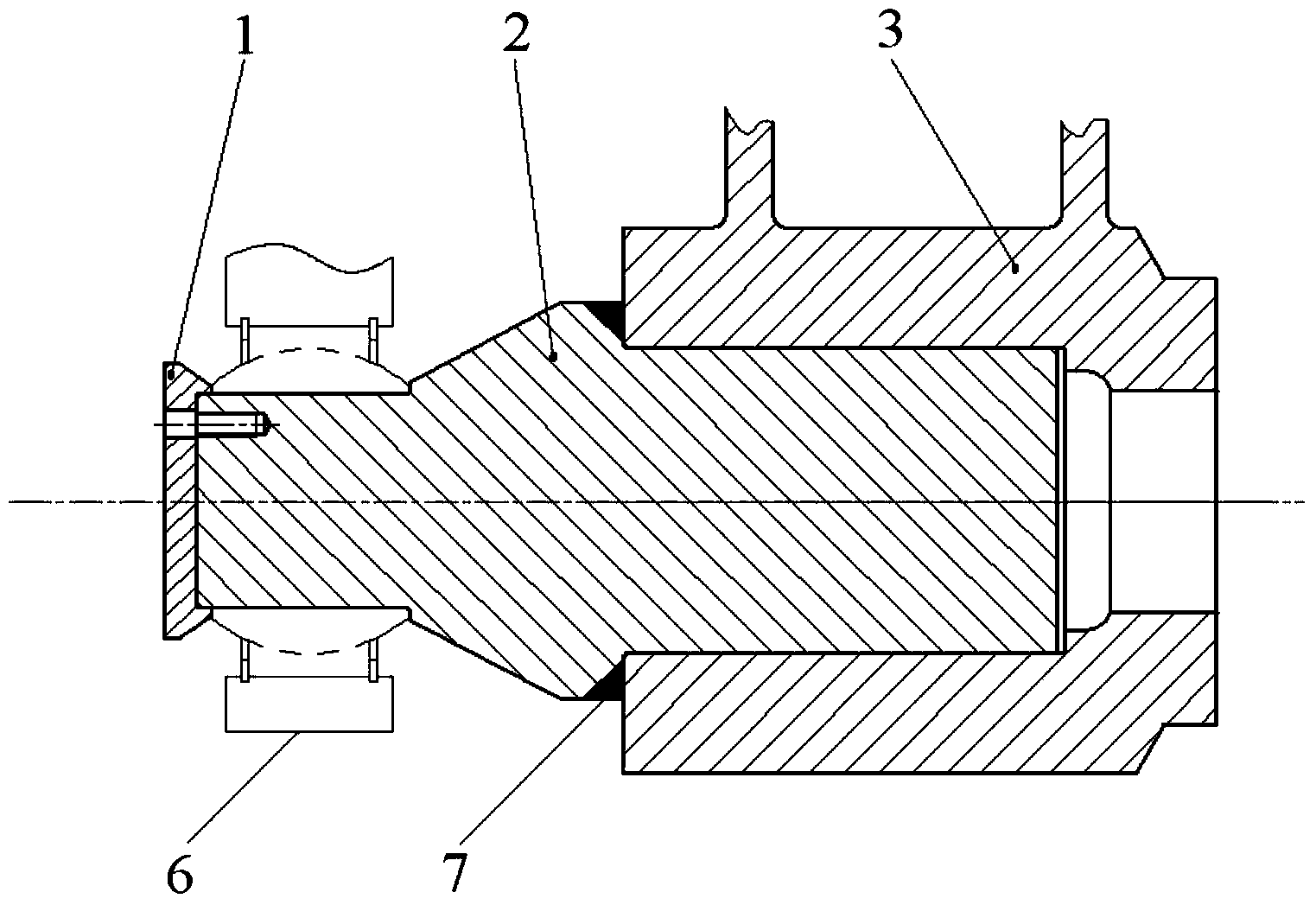

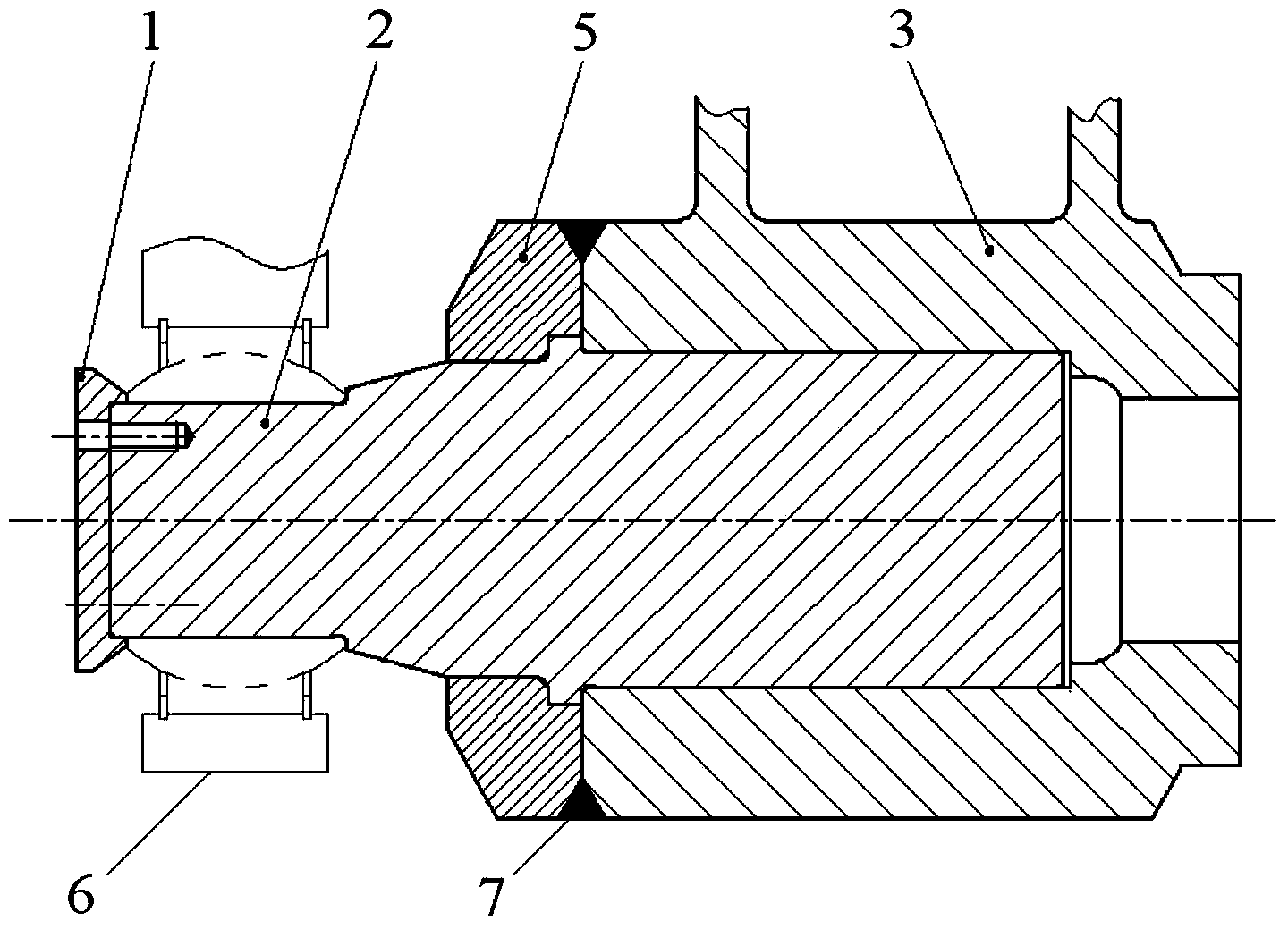

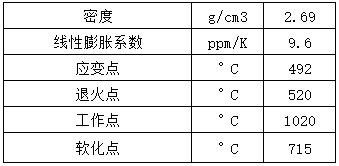

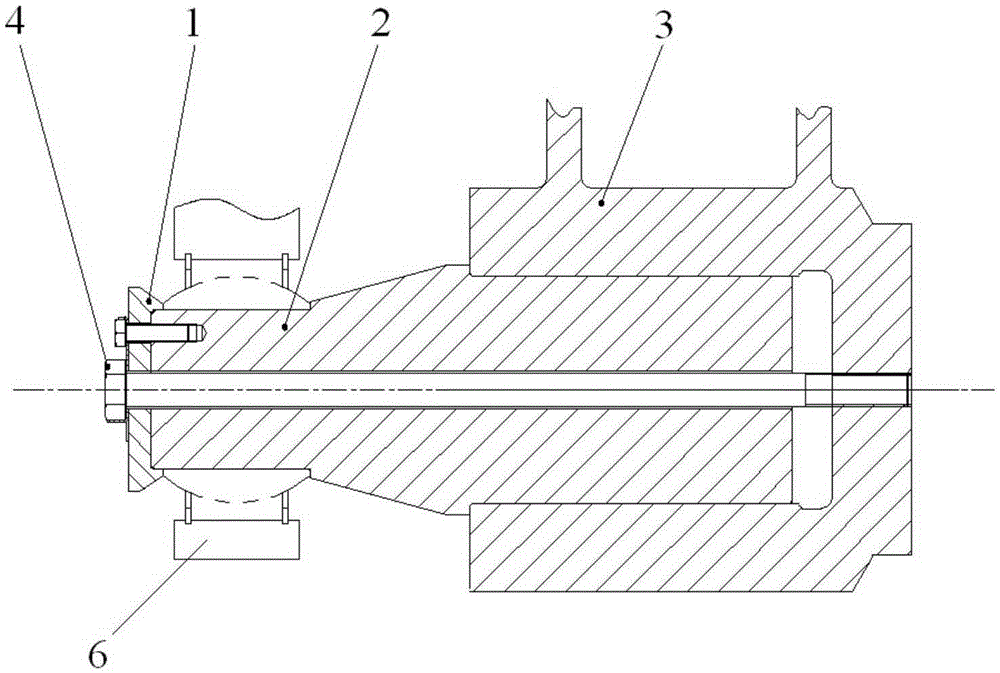

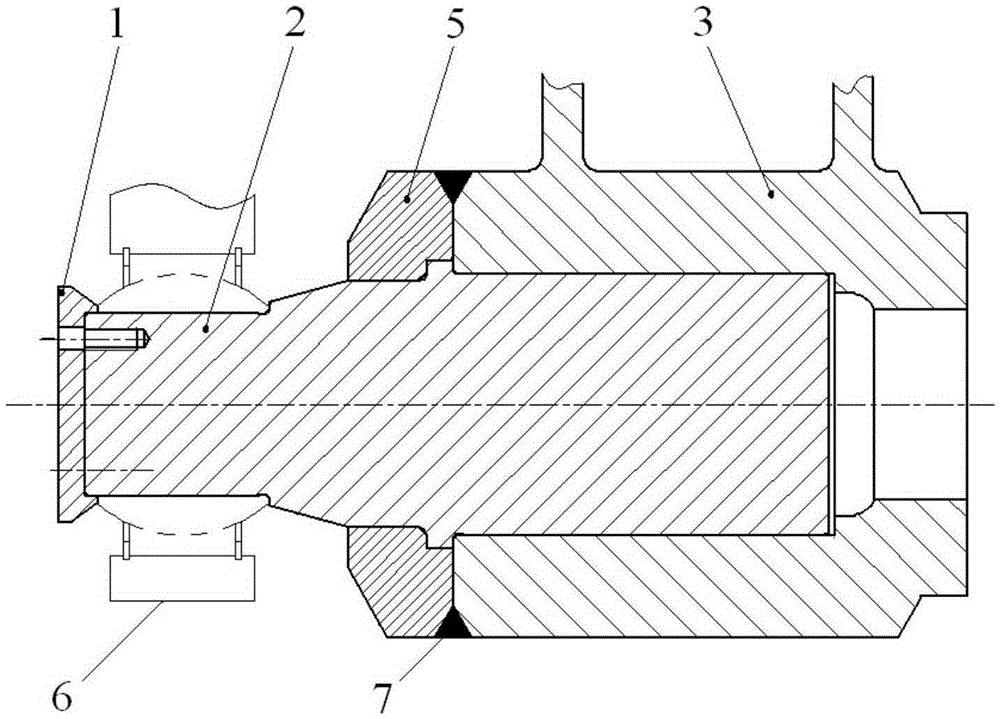

Lifting cylinder shaft assembly of mining dump truck

ActiveCN103661063ASand cleaning is easyEasy dischargeVehicle with tipping movementTruckMechanical engineering

The invention provides a lifting cylinder shaft assembly of a mining dump truck. The lifting cylinder shaft assembly of the mining dump truck comprises a lifting cylinder support, a lifting cylinder shaft, an end cover and a gland, wherein the lifting cylinder support is provided with a shaft hole, the lifting cylinder shaft is provided with a shaft shoulder, a shaft section, at one side of the shaft shoulder, of the lifting cylinder shaft is installed in the shaft hole of the lifting cylinder support, the end cover is arranged at the end of the shaft section, at the other side of the shaft shoulder, of the lifting cylinder shaft, and the gland is axially arranged on the shaft shoulder in a pressing mode and fixed to the lifting cylinder support. The lifting cylinder shaft assembly of the mining dump truck is simple in structure and easy to machine, and the lifting cylinder shaft is high in strength, not damaged easily, stable and reliable in axial fixation, high in size accuracy and installation accuracy, and easy to detach and replace.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Furan resin loaded nano ceramic modified molding sand

The invention discloses furan resin loaded nano ceramic modified molding sand. The furan resin loaded nano ceramic modified molding sand is characterized by comprising the components, by weight, 50-70parts of silica sand, 40-50 parts of quartz sand, 2-5 parts of manganese sand, 3-6 parts of white marble sand, 3-5 parts of glass sand, 3-6 parts of emery, 1-3 parts of borax, 2-4 parts of rare earthporcelain sand, 4-8 parts of coal ash, 5-10 parts of triethoxy-2-furan silane modified nano ceramic powder, 6-9 parts of furan resin, 4-7 parts of epoxidized polyurethane / 2,5-di(aminomethyl) furan polycondensate, 2-4 parts of hyperbranched epoxy resin and 25-35 parts of water. The invention also discloses a preparation method of the furan resin loaded nano ceramic modified molding sand. The furanresin loaded nano ceramic modified molding sand has the advantages of being good in air permeability, flowability, and dispersibility, high in strength, good in heat resistance, excellent in comprehensive performance, smooth in casting surface, not prone to falling out, and capable of being recycled and reused.

Owner:ANHUI SOLID FOUNDRY CO LTD

Clay additive for sand mold casting and bonding

InactiveCN105665616AImprove performanceWith strengthFoundry mouldsFoundry coresPolyethylene glycolLiquid metal

The invention discloses a clay additive for sand casting bonding, which relates to the technical field of sand casting and is prepared from the following raw materials in parts by weight: 30-40 parts of attapulgite, 10-15 parts of waste engine oil, and 10-15 parts of chitin 10-15 parts of polyethylene wax, 7-12 parts of paraffin oil, 6-10 parts of nano talcum powder, 6-10 parts of linseed gum, 6-10 parts of epoxy soybean oil, 5-8 parts of polyethylene glycol , 5-8 parts of polyoxyethylene rosin acid, 3-6 parts of polyacrylamide, 2-4 parts of hydroxypropyl starch ether, 2-4 parts of sodium dodecylbenzenesulfonate, 1-2 parts of sulfur, concentrated 1-2 parts of nitric acid. The addition of the additive of the present invention can effectively improve the performance of the clay, so that the sand mold and the mold core made have a certain strength, and will not be deformed or damaged when the liquid metal is transported, fitted and poured; and the hardening speed is fast and the collapsibility is good. It can be hardened by heating, and the casting is easy to remove sand; the amount of gas generation is small, and no toxic gas will be generated during pouring.

Owner:ANHUI SOLID FOUNDRY CO LTD

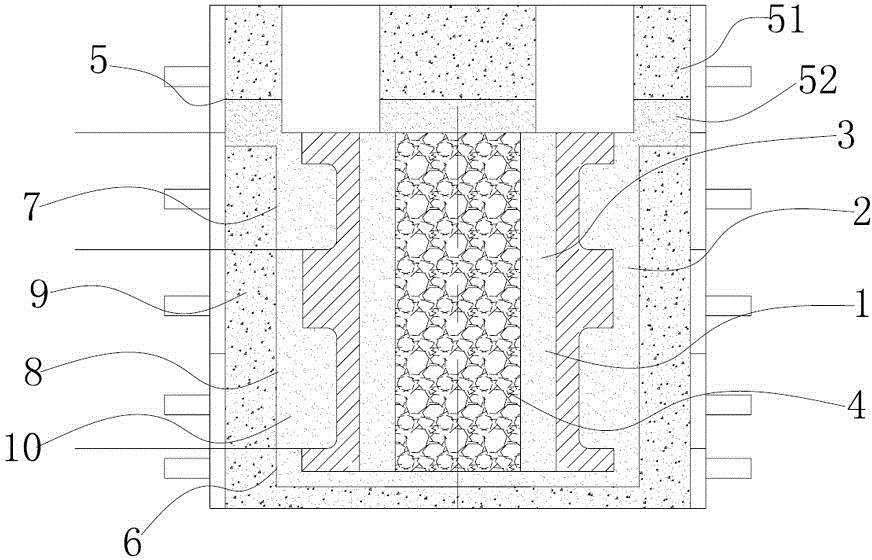

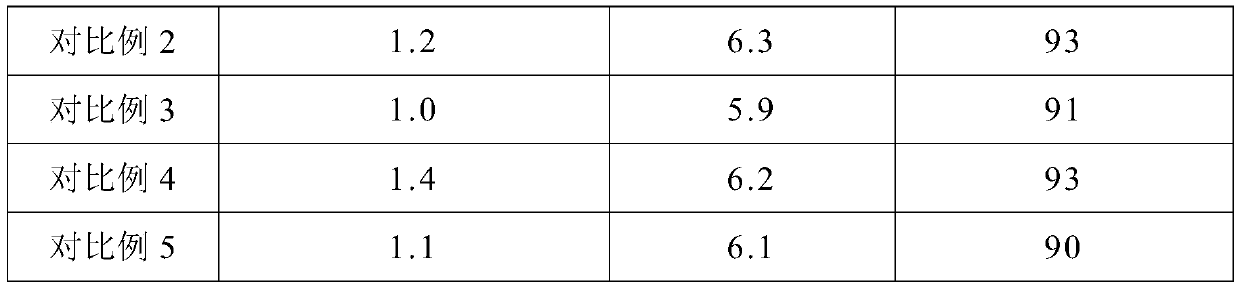

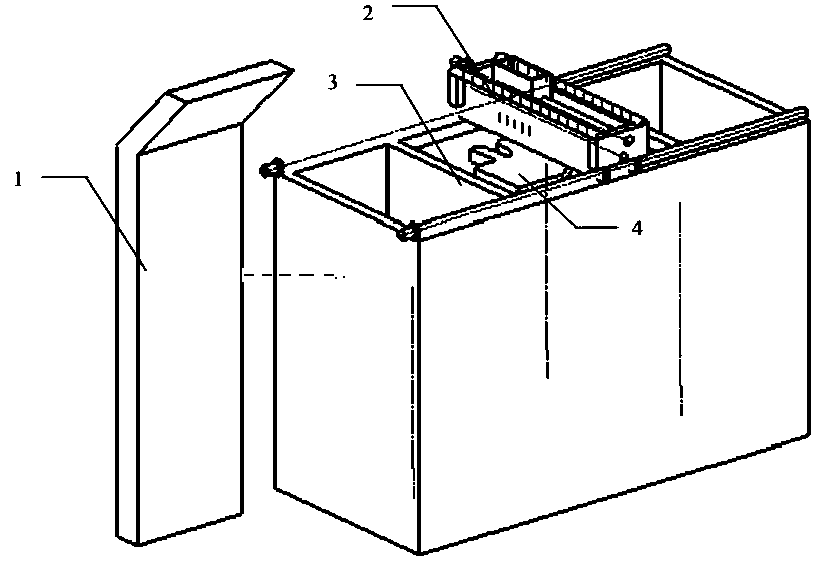

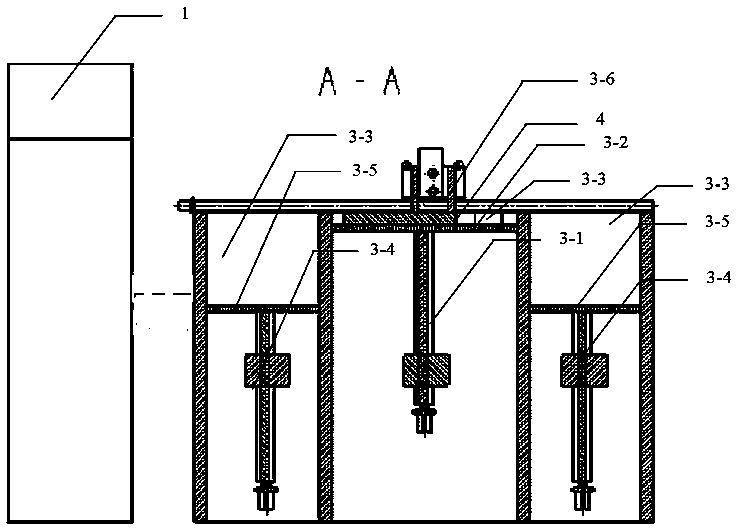

3D printing clay molding sand mold device and method

PendingCN110756731AAvoid Possibility of StomataImprove yieldAdditive manufacturing apparatusFoundry mouldsClay soilMolding sand

The invention discloses a 3D printing clay molding sand mold device and method. The device comprises a computer and control system, a forming system, a powder spreading system and a clay molding sandmold; the computer and control system is connected with the forming system and the powder spreading system, the forming system is arranged on the upper part of the powder spreading system, and the clay molding sand mold is arranged in the middle part of the powder spreading system, a solution spraying system is arranged in the forming system, the solution spraying system is connected with a solution spraying system moving device, the solution spraying system, the solution spraying system moving device and a drying system are connected with a forming system moving device; and powder in the powder spreading system is located above a forming area bottom plate and a powder supplementing area bottom plate, a forming area bottom plate lifting device is connected with the forming area bottom plate, a powder supplementing area bottom plate lifting device is connected with the powder supplementing area bottom plate, and the powder spreading device is arranged between the solution spraying system and the drying system and is connected with the forming system moving device. According to the method adopted by a mold, the characteristics of low air permeability and low gas evolution can be kept, and the possibility of air holes in a casting is reduced.

Owner:FIRST TRACTOR

High-strength and environment-friendly water-based lost foam coating for foundry

InactiveCN102962396BIncrease productivitySimple processFoundry mouldsFoundry coresWater basedSuspending Agents

The invention discloses a casting-purposed high-strength environmental-friendly water-based evanescent mode coating and a preparation method thereof. The casting-purposed high-strength environmental-friendly water-based evanescent mode coating is characterized by comprising the following raw materials in percent by weight: 40-30 percent of quartz powder, 30-40 percent of high alumina, 10 percent of limestone, 12 percent of adhering agent, 5 percent of suspending agent and 3 percent of dispersing agent. The preparation method comprises the steps of: firstly, fully stirring and uniformly mixing the 5 percent of suspending agent and the 3 percent of dispersing agent, and then adding the adhering agent and uniformly mixing for later use; then reacting with main aggregates mixed for 30mins for 1h and then discharging; and during use, regulating a ratio of powder to water between 1:1-1:0.8 to meet demands of different casts. The preparation method has the advantages of wide application range, high production efficiency, simple process and energy saving; raw materials are purely-natural nontoxic materials; the casting-purposed high-strength environmental-friendly water-based evanescent mode coating has the characteristics of easiness in cleaning, small thickness and good air permeability; and the cast-purposed high-strength environmental-friendly water-based evanescent mode coating only needs to be coated 2-3 times, so that labor intensity of workers can be reduced and production cost can be lowered.

Owner:湖北福策来科技有限公司

Method of silica sol narrow-channel closed impeller easy to clear shell

InactiveCN110711848ASand cleaning is easyFlat surfaceFoundry mouldsFoundry coresProcess engineeringMechanical engineering

The invention discloses a method of a silica sol narrow-channel closed impeller easy to clear a shell, and aims to provide a method with the advantages that sand on the surface of the large-diameter closed impeller of a casting piece can be conveniently cleared, the surface is bright and clean, and the casting piece similar to a high-temperature high-pressure silica sol mold shell product is ensured. The invention provides the technical scheme points that the method comprises the steps of S01, dewaxing; S02, roasting; S03, casting; S04, clearing the sand; and adopting a silica sol mold shell for dewaxing, wherein the dewaxing is carried out on the mold shell according to the parameters that the vapor pressure is 98kPa, the temperature is 100 DEG C, and the time is 15 to 25min. The roastingtemperature of the mold shell remains unchanged, and other casting processes remain unchanged. The sand of the large-diameter closed impeller of the casting piece is easy to clear, the surface is bright and clean, and the casting piece similar to the high-temperature high-pressure silica sol mold shell product is ensured. The problem that the large-diameter narrow-channel closed impeller adopts an alkali-explosion sand-clearing process is thoroughly solved. Meanwhile, the safety production of employees is further guaranteed.

Owner:无锡市东明冠特种金属制造有限公司

An environmentally friendly alcohol-based coating for sand casting

ActiveCN104550679BGood dispersionGood suspensionFoundry mouldsFoundry coresSodium BentoniteSesquioxide

The invention discloses an environment-friendly alcohol-based coating for sand mold casting. The environment-friendly alcohol-based coating comprises refractory aggregate, a binding agent, a compound suspending agent and an auxiliary agent, wherein the refractory aggregate comprises 60 to 70 parts of quartz powder, 20 to 30 parts of aluminum sesquioxide, 5 to 10 parts of talcum powder, 1 to 5 parts of calcium carbonate, and 10 to 20 parts of magnesium metal crosslinking acrylic acid resin; the particle size range of the refractory aggregate is 150 to 320 meshes; the compound suspending agent comprises the following constituents: 40 to 65 parts of lithium base bentonite, 20 to 35 parts of attapulgite, 0.5 to 2 parts of CMC, and 0.5 to 2 parts of PVB; the binding agent adopts 1 to 2 parts of thermoplastic phenolic resin; a carrier liquid adopts ethyl alcohol or ethylene glycol; the auxiliary agent adopts 0.2 to 0.5 part of defoamer normal butanol. The alcohol-based coating used for sand mold casting, which takes quartz powder as the main refractory aggregate, is not added with graphite, is a low-cost casting coating with an environment-friendly advantage, is high in refractoriness, good in anti-adhesive sand property, is easily peeled from casting after casting, and is easy for sand removal of the casting.

Owner:CHINA THREE GORGES UNIV +1

A kind of inorganic binder for non-ferrous metal 3D sand mold printing and preparation method thereof

ActiveCN104923717BExcellent resistance to moisture absorptionHigh bonding strengthFoundry mouldsFoundry coresMoisture absorptionMaterials science

The invention relates to an inorganic binder for nonferrous metal 3D sand mould printing and a preparation method thereof. The inorganic binder for nonferrous metal 3D sand mould printing comprises, by weight, 22%-34% of sodium silicate, 2%-11% of sodium hydrogen phosphate, 1.5%-5.5% of D-sorbitol, 0.2%-0.8% of water soluble silicone oil, 0,7%-2.3% of tetraethyl silicate, 0.3%-0.7% of aluminum sulfate, 0.3%-0.7% of naphthalene sulfonic acid, 0.4%-2.6% of phenolic resin, 0.7%-2.3% of sodium hydroxide and 46%-66% of deionized water. The inorganic binder for nonferrous metal 3D sand mould printing has the advantages that when the temperature of the prepared inorganic binder is 25 DEG C, the viscosity is smaller than 15 mpa.s, so that the using demand of sand mould ink jetting and printing is met; the bonding strength is high; the scattering performance of the binder is excellent, and casting sand removal is easy when the inorganic binder is applied to the casting field; and the moisture absorption resistance performance of the binder is excellent, the applicable time is short, and the binder can be quickly hardened.

Owner:NINGXIA KOCEL MOLD

Manufacturing method of core filler for investment casting

InactiveCN101879576ASand cleaning is easyFoundry mouldsFoundry coresInvestment castingSodium silicate

The invention discloses a manufacturing method of core filler for investment casting, comprising the folloing steps: selecting chrome ore and sodium silicate as the ingredient at the ratio of 10:1, and fully stirring the ingredient. Because the invention adopts the technical scheme, after the chrome ore filler is hardened in the hole or groove of the core, the strength and the high-temperature strength of the core exceed those of the quartz sand and sagger sand. The surfaces of the ostiole, longhole and narrow groove are gloss and easy to remove the sand during finishing, and the ostiole has small possibility of deforming.

Owner:浙江红马铸造有限公司

Molding sand for amorphous casting and its manufacturing method

ActiveCN107824742BEvenly distributedHigh purityFoundry mouldsFoundry coresMaterials scienceMolding sand

The invention discloses molding sand for amorphous-state casting. The molding sand is formed by mixing crude sand with a binding agent; the crude sand comprises the following components in percentageby weight: 30-52% of SiO2, 15-20% of Al2O3, 15-30% of ZrO2, 0-3% of K2O, 2-10% of Na2O, K2O+Na2O less than 12%, and 1-5% of Ca2O; and the average particle size of the crude sand is within 0.03-2 mm. In the molding sand for casting, the crude sand thereof is an amorphous-state solid, is free of cleavage planes during crushing, and is low in expansion coefficient and excellent in thermochemical stability.

Owner:河南博威热能科技有限公司

A kind of molding sand for glass matrix casting

ActiveCN107661960BHigh strengthEvenly distributedFoundry mouldsFoundry coresAdhesiveUltimate tensile strength

The invention discloses molding sands for glass matrix casting. The molding sands for glass matrix casting are prepared by performing mixing treatment on base sands and an adhesive. The base sands areprepared by the following components in percentage by weight: 50-65 percent of SiO2, 1-6 percent of Al2O3, 1-4 percent of ZrO2, 4-8 percent of K2O, 5-10 percent of Na2O, 1-5 percent of Ca2O, 6-10 percent of SrO and 6-10 percent of BaO, wherein the average particle size of the base sands is from 0.03mm to 2mm. By adopting the molding sands for casting provided by the invention, the base sands areobtained by CRT screen glass treatment, and the environmental protection problem of CRT screen glass recovery is solved; in addition, during crushing, a cleavage plane does not exist, the mechanical strength is high, and the thermal chemical stability is good, so that the production cost during casting production can be lowered, and the casting performance of the molding sands for casting is improved.

Owner:河南博威热能科技有限公司

A mining dump truck lift cylinder shaft assembly

The invention provides a lifting cylinder shaft assembly of a mining dump truck. The lifting cylinder shaft assembly of the mining dump truck comprises a lifting cylinder support, a lifting cylinder shaft, an end cover and a gland, wherein the lifting cylinder support is provided with a shaft hole, the lifting cylinder shaft is provided with a shaft shoulder, a shaft section, at one side of the shaft shoulder, of the lifting cylinder shaft is installed in the shaft hole of the lifting cylinder support, the end cover is arranged at the end of the shaft section, at the other side of the shaft shoulder, of the lifting cylinder shaft, and the gland is axially arranged on the shaft shoulder in a pressing mode and fixed to the lifting cylinder support. The lifting cylinder shaft assembly of the mining dump truck is simple in structure and easy to machine, and the lifting cylinder shaft is high in strength, not damaged easily, stable and reliable in axial fixation, high in size accuracy and installation accuracy, and easy to detach and replace.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

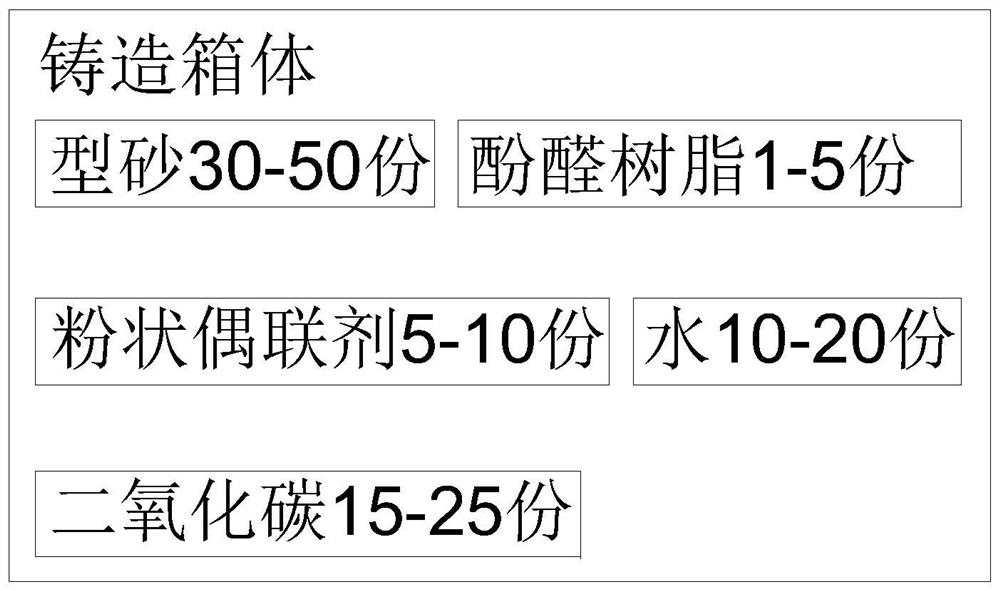

Casting box made of novel material

PendingCN114130944AReduce usageReduce the use effectFoundry mouldsFoundry coresCarbon dioxidePhenol formaldehyde resin

The invention discloses a casting box using a novel material, the casting box comprises the following components in parts by weight: 30-50 parts of molding sand, 1-5 parts of phenolic resin, 5-10 parts of a powdery coupling agent, 10-20 parts of water and 15-25 parts of carbon dioxide, the casting box is formed by mixing the molding sand, the phenolic resin, the powdery coupling agent and the water, molding, blowing carbon dioxide gas in a vacuum environment, and curing. And a forming cavity is formed in the box body, and the box body is used for casting metal products. According to the invention, the problems that the traditional material seriously pollutes the environment, does not meet the theme requirement of current national green casting and cannot fully meet the production requirement of casting the 350km axle box body are solved.

Owner:QINGDAO LIANSHAN CASTING

Casting method of heat-resistant steel slime blind-tube and mold thereof

InactiveCN101391283BSolve the problem of one-shot molding technologyAvoid Welding Weld ProblemsFoundry mouldsFoundry coresCastingHeat resistant

Owner:山东省耐磨耐蚀材料工程技术研究中心 +1

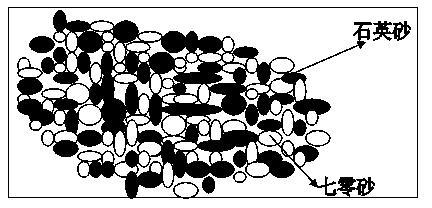

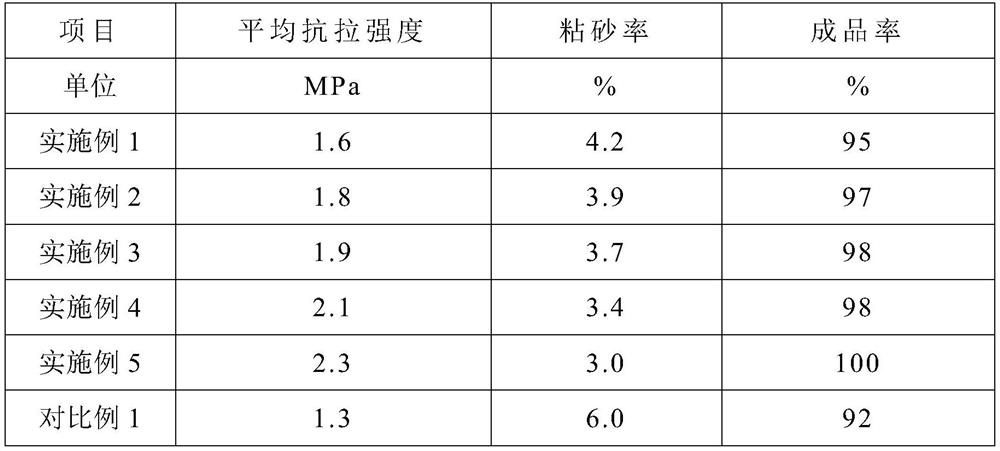

Composite foundry sand material for preventing foundry sand sintering in steel cast casting and preparation method thereof

The invention relates to a composite foundry sand material for preventing foundry sand sintering in steel cast casting and a preparation method thereof. After the material is casted and calcined at high temperature, the foundry sand of the material is of a scrobiculate loose structure, instead of a hard agglomerated cake, and the composite foundry sand material comprises the following components in percentage by weight: 40-65% of quartz sand, 35-60% of 70 sand and 1-1.2% of furane resin, and a curing agent accounts for 30-50% of furane resin. The composite foundry sand material has the advantages that after being casted and calcined, the composite foundry sand forms the scrobiculate loose structure, thereby damaging a quartz sand foundry sand sintered structure, generating no large agglomerated block, being easy for cleaning, greatly improving labor productivity and reducing production cost; in addition, the production materials (quartz sand and 70 sand) have low cost and wide sources; moreover, by using the composite foundry sand material, cracks, misrun and other secondary flaws caused by cleaning can be reduced, therefore, the quality of casts is improved.

Owner:HANGZHOU STEAM TURBINE CASTING & FORGING

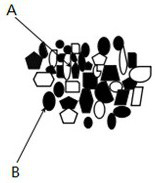

A kind of anti-sintering, non-sticky furan resin molding sand material and its manufacturing method

ActiveCN106311961BSand cleaning is easyImprove labor productivityFoundry mouldsFoundry coresFuranFirming agent

The invention discloses a molding material for casting with anti-sintering and no sand-sticking functions, which comprises 80% of chrome ore sand, 5% of inert sand, 1-1.2% of furan resin and a curing agent accounting for 20-60% of the mass ratio of furan resin , the curing agent is benzenesulfonic acid; the inert sand is surface-treated alkaline ore, and the surface treatment method is to add a layer of neutral organic or inorganic film on the surface of the alkaline ore to form inertness. After calcination, it is cooled to room temperature to become a powder. The material is easy to solidify when using furan resin as a binder. After the molding sand is calcined at high temperature, there is no sintering or chemical sand sticking phenomenon. A substantial improvement over previous materials. In the same way to manufacture a complex metal part with a high melting point, compared with 3D printing, using this product to manufacture has a greater production cost advantage.

Owner:杭州微砂科技有限公司

A kind of furan resin loaded nano-ceramic modified molding sand

The invention discloses furan resin loaded nano ceramic modified molding sand. The furan resin loaded nano ceramic modified molding sand is characterized by comprising the components, by weight, 50-70parts of silica sand, 40-50 parts of quartz sand, 2-5 parts of manganese sand, 3-6 parts of white marble sand, 3-5 parts of glass sand, 3-6 parts of emery, 1-3 parts of borax, 2-4 parts of rare earthporcelain sand, 4-8 parts of coal ash, 5-10 parts of triethoxy-2-furan silane modified nano ceramic powder, 6-9 parts of furan resin, 4-7 parts of epoxidized polyurethane / 2,5-di(aminomethyl) furan polycondensate, 2-4 parts of hyperbranched epoxy resin and 25-35 parts of water. The invention also discloses a preparation method of the furan resin loaded nano ceramic modified molding sand. The furanresin loaded nano ceramic modified molding sand has the advantages of being good in air permeability, flowability, and dispersibility, high in strength, good in heat resistance, excellent in comprehensive performance, smooth in casting surface, not prone to falling out, and capable of being recycled and reused.

Owner:ANHUI SOLID FOUNDRY CO LTD

A kind of composite phosphate inorganic binder for 3D sand printing and preparation method thereof

ActiveCN105127361BGood collapsibilityExcellent resistance to moisture absorptionAdditive manufacturing apparatusFoundry mouldsO-Phosphoric AcidAdhesive

The invention belongs to the field of casting auxiliary materials, and relates to a composite phosphate inorganic binder for 3D sand mold printing and a preparation method thereof. A composite phosphate inorganic binder for 3D sand mold printing comprises the following components: aluminum hydroxide, Magnesium carbonate, boric acid, 85% industrial phosphoric acid, urea, xylitol, D-sorbitol, citric acid, aluminum tripolyphosphate, aluminum dihydrogen tripolyphosphate, deionized water, wherein the mass percentage ratio of each component is: Aluminum hydroxide 4.5%-9.5%, magnesium carbonate 1%-4%, boric acid 2.5%-6.5%, 85% industrial phosphoric acid 30%-70%, urea 0.5%-1.5%, xylitol 1%-3%, D‑sorbitol 1%‑3%, citric acid 0.5%‑1.5%, aluminum tripolyphosphate 1.5%‑6.5%, aluminum dihydrogen tripolyphosphate 1.5%‑6.5%, deionized water 7%‑37%. The beneficial effects of the technical solution of the present invention are: the prepared composite phosphate inorganic binder has low viscosity; high bonding strength; after being baked at a high temperature above 600°C, its residual strength is low, indicating that the binder has Excellent collapsibility; the adhesive has excellent resistance to moisture absorption.

Owner:NINGXIA KOCEL MOLD

A kind of modified phosphate inorganic binder for aluminum alloy casting and preparation method thereof

ActiveCN104815943BExcellent resistance to moisture absorptionGood collapsibilityFoundry mouldsFoundry coresEnvironmental resistancePhosphate

The present invention relates to a novel modified phosphate inorganic binder for aluminum alloy casting, and a preparation method thereof, wherein the novel modified phosphate inorganic binder comprises industrial phosphoric acid with a mass concentration of 85%, aluminum hydroxide, magnesium carbonate, boric acid, citric acid, zinc oxide, polyacrylamide, and deionized water. The novel modified phosphate inorganic binder has characteristics of high compressive strength, excellent adhesion property, excellent collapsing performance, and green environmental protection, and can not produce any toxic gases and condensates during processes such as sand mixing, modeling (core), hardening and casting. The preparation method has characteristics of simple process, flexible operation, and low cost.

Owner:共享新材料(山东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com