Casting box made of novel material

A new type of material and box technology, applied in casting molding equipment, casting molds, cores, etc., can solve the problems of not fully meeting the production requirements of casting 350km axle boxes, not meeting the theme requirements, environmental pollution, etc., and achieving air hole defects Less, product quality improvement, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

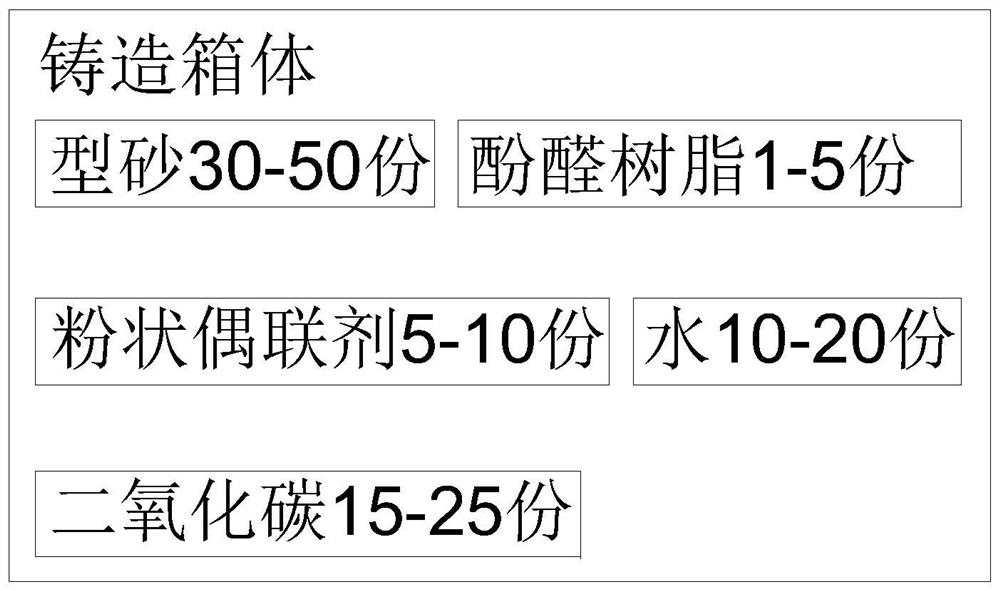

[0016] Embodiment 1: A kind of cast box body that uses new material, comprises the following components by weight ratio:

[0017] 30-50 parts of molding sand, 1-5 parts of phenolic resin, 5-10 parts of powdered coupling agent, 10-20 parts of water, 15-25 parts of carbon dioxide.

[0018] The proportion by weight includes the following components: 35 parts of molding sand, 2 parts of phenolic resin, 5.5 parts of powdery coupling agent, 11 parts of water and 16 parts of carbon dioxide.

[0019] The proportion by weight includes the following components: 38 parts of molding sand, 2.8 parts of phenolic resin, 6.8 parts of powdery coupling agent, 15 parts of water and 20 parts of carbon dioxide.

[0020] The proportion by weight includes the following components: 50 parts of molding sand, 5 parts of phenolic resin, 10 parts of powdery coupling agent, 18 parts of water and 25 parts of carbon dioxide.

[0021] The casting box is formed by mixing molding sand, phenolic resin, powdery...

Embodiment 2

[0024] Embodiment 2: the technical index of phenolic resin is as table 1, and the technical index of coupling agent is as table 2;

[0025] Table 1 Phenolic resin technical indicators

[0026] Grade Exterior density viscosity free phenol free aldehyde JL-168 reddish brown liquid 1.30-1.40g / cm 3

200-300mps.s ≤1% ≤0.2%

[0027] Table 2 coupling agent technical indicators

[0028] Grade Exterior density Amount added Function LG-1 off-white powder 2.1-2.7g / cm 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com